Introduction: Navigating the Global Market for first manufacturing leather jacket

In the dynamic landscape of the global market, sourcing high-quality leather jackets from reputable manufacturers can pose significant challenges for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The quest for durable, stylish, and competitively priced leather jackets requires not only an understanding of product specifications but also a keen insight into supplier reliability and market trends. This guide on first manufacturing leather jackets is designed to address these complexities by providing a thorough exploration of various types, applications, and key considerations for selecting the right supplier.

Within this comprehensive resource, international B2B buyers will find valuable insights into the nuances of leather jacket manufacturing, including material quality, design options, and the importance of compliance with regional regulations. Additionally, the guide will delve into effective supplier vetting processes, cost analysis, and best practices for negotiating favorable terms. By equipping buyers with the knowledge needed to make informed decisions, this guide empowers businesses to streamline their purchasing processes, ultimately leading to successful partnerships and enhanced market competitiveness. As you navigate the intricate world of leather apparel procurement, let this guide serve as your roadmap to making strategic choices that align with your business goals.

Table Of Contents

- Top 3 First Manufacturing Leather Jacket Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for first manufacturing leather jacket

- Understanding first manufacturing leather jacket Types and Variations

- Key Industrial Applications of first manufacturing leather jacket

- 3 Common User Pain Points for ‘first manufacturing leather jacket’ & Their Solutions

- Strategic Material Selection Guide for first manufacturing leather jacket

- In-depth Look: Manufacturing Processes and Quality Assurance for first manufacturing leather jacket

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘first manufacturing leather jacket’

- Comprehensive Cost and Pricing Analysis for first manufacturing leather jacket Sourcing

- Alternatives Analysis: Comparing first manufacturing leather jacket With Other Solutions

- Essential Technical Properties and Trade Terminology for first manufacturing leather jacket

- Navigating Market Dynamics and Sourcing Trends in the first manufacturing leather jacket Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of first manufacturing leather jacket

- Strategic Sourcing Conclusion and Outlook for first manufacturing leather jacket

- Important Disclaimer & Terms of Use

Understanding first manufacturing leather jacket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Motorcycle Jacket | Traditional cut, durable leather, protective features | Motorcycle retailers, rental services | Pros: Timeless style, robust protection. Cons: Heavier, may not suit all riding styles. |

| Perforated Leather Jacket | Ventilated design for summer riding | Adventure and touring motorcycle businesses | Pros: Breathable, comfortable in hot weather. Cons: Less insulation for colder climates. |

| Cafe Racer Jacket | Slim fit, retro aesthetic, minimalistic design | Custom bike builders, fashion retailers | Pros: Stylish, lightweight. Cons: Limited protection, may not appeal to all riders. |

| Leather Vests | Open front design, often with patches | Custom motorcycle clubs, promotional events | Pros: Customizable, versatile layering piece. Cons: Less protection than full jackets. |

| Women’s Motorcycle Jacket | Tailored fit, often includes additional style elements | Women’s motorcycle gear shops, lifestyle brands | Pros: Designed for comfort and style. Cons: Limited selection compared to men’s options. |

What Are the Key Features of Classic Motorcycle Jackets?

Classic motorcycle jackets are characterized by their traditional cut and robust leather construction, designed primarily for durability and protection. These jackets are ideal for motorcycle retailers and rental services that prioritize safety and timeless style. When considering a purchase, B2B buyers should evaluate the jacket’s weight and fit, as its heavier construction may not suit all riding styles or climates. However, its enduring appeal and protective features make it a staple in many riders’ wardrobes.

How Do Perforated Leather Jackets Enhance Comfort?

Perforated leather jackets offer a ventilated design that caters specifically to summer riding conditions. Their breathability makes them a popular choice among adventure and touring motorcycle businesses, allowing riders to stay cool on long trips. When purchasing, B2B buyers should consider the jacket’s insulation properties, as these jackets may not provide adequate warmth in cooler climates. Despite this limitation, their comfort in hot weather is a significant selling point.

What Makes Cafe Racer Jackets a Trendy Option?

Cafe racer jackets are known for their slim fit and retro aesthetic, appealing to custom bike builders and fashion retailers. Their minimalistic design allows for easy pairing with various outfits, making them a stylish choice for urban riders. However, B2B buyers should be aware that while these jackets are lightweight and fashionable, they offer limited protection compared to more robust options. This can be a consideration for businesses targeting safety-conscious riders.

Why Choose Leather Vests for Customization?

Leather vests are a versatile option, often featuring open front designs that allow for personalization with patches or club logos. They are particularly popular among custom motorcycle clubs and for promotional events where branding is essential. While vests provide excellent customization opportunities, they offer less protection than full jackets, which may be a drawback for businesses that prioritize rider safety. Buyers should weigh the benefits of customization against the need for protective gear.

Illustrative image related to first manufacturing leather jacket

How Do Women’s Motorcycle Jackets Differ from Men’s?

Women’s motorcycle jackets are tailored specifically for a female fit, often incorporating additional style elements that appeal to female riders. They are increasingly found in women’s motorcycle gear shops and lifestyle brands, catering to a growing market segment. However, B2B buyers should note that the selection may be more limited compared to men’s options, which could affect inventory decisions. The focus on comfort and style in these jackets makes them a valuable addition to any retailer’s offerings.

Key Industrial Applications of first manufacturing leather jacket

| Industry/Sector | Specific Application of first manufacturing leather jacket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Apparel | Retail of motorcycle jackets and gear | High-quality leather jackets enhance brand reputation and customer loyalty. | Durability, style, and compliance with safety standards. |

| Event Management | Merchandise for motorcycle rallies and events | Unique branded apparel can drive sales and enhance event visibility. | Customization options and bulk purchasing capabilities. |

| Tourism and Recreation | Rental services for motorcycle tours | Providing quality gear increases customer satisfaction and safety. | Availability of various sizes and styles to cater to diverse clientele. |

| Fashion Retail | High-end fashion boutiques focusing on leather apparel | Leather jackets can appeal to fashion-forward consumers, increasing sales margins. | Trend alignment and quality assurance for high-end markets. |

| Military and Security | Tactical and protective gear for military personnel | Enhanced protection and durability in challenging environments. | Compliance with military specifications and bulk order capabilities. |

How is the First Manufacturing Leather Jacket Utilized in the Motorcycle Apparel Industry?

In the motorcycle apparel sector, first manufacturing leather jackets serve as essential gear for riders, combining style with safety. Retailers benefit from offering durable, high-quality jackets that resonate with motorcycle enthusiasts, enhancing brand loyalty. Buyers must consider factors such as the jacket’s durability, style, and compliance with safety regulations to ensure they meet customer expectations and industry standards.

What Role Do First Manufacturing Leather Jackets Play in Event Management?

For event management, particularly in motorcycle rallies, first manufacturing leather jackets can be leveraged as merchandise. These jackets not only serve as practical gear for participants but also as promotional items that elevate brand visibility. The opportunity for customization allows event organizers to create unique apparel that resonates with attendees, driving sales and strengthening community ties. Key sourcing considerations include the ability to order in bulk and provide customization options that align with event branding.

Illustrative image related to first manufacturing leather jacket

How Do First Manufacturing Leather Jackets Enhance Tourism and Recreation?

In the tourism and recreation industry, particularly for motorcycle rental services, first manufacturing leather jackets are crucial. They provide tourists with the necessary safety gear while enhancing their overall experience. Tour operators benefit from offering high-quality jackets that ensure customer safety and satisfaction, which can lead to positive reviews and repeat business. Buyers should focus on sourcing a variety of sizes and styles to accommodate diverse customer needs and preferences.

Why are First Manufacturing Leather Jackets Important for Fashion Retail?

In high-end fashion retail, first manufacturing leather jackets appeal to consumers looking for stylish yet functional outerwear. Fashion boutiques can leverage the timeless appeal of leather jackets to attract trend-conscious customers, enhancing their sales margins. Buyers in this sector must ensure that the products align with current fashion trends and maintain high-quality standards to meet the expectations of discerning consumers.

How Do First Manufacturing Leather Jackets Serve the Military and Security Sector?

First manufacturing leather jackets also find applications in the military and security sectors, where durability and protection are paramount. These jackets provide personnel with reliable outerwear that withstands challenging environments while offering a professional appearance. Buyers in this industry need to ensure that the jackets comply with specific military specifications and can handle bulk orders to equip their teams effectively.

3 Common User Pain Points for ‘first manufacturing leather jacket’ & Their Solutions

Scenario 1: Sizing and Fit Challenges in Bulk Orders

The Problem: One of the most significant challenges faced by B2B buyers, particularly in the leather apparel industry, is ensuring that the sizing of leather jackets fits a diverse customer base. Sizing inconsistencies can lead to high return rates, dissatisfied customers, and ultimately, loss of revenue. International buyers from regions like Africa and the Middle East may encounter even more complexity, as sizing standards can vary significantly across different markets. This often results in a mismatch between the manufacturer’s sizing chart and the actual fit when the jackets are received.

Illustrative image related to first manufacturing leather jacket

The Solution: To mitigate sizing issues, B2B buyers should invest time in understanding the target market’s specific sizing needs. It’s advisable to request detailed size charts from manufacturers, including measurements for key dimensions such as chest, waist, and sleeve length. Additionally, consider implementing a sample order of various sizes before placing a bulk order. This allows you to assess the fit and make adjustments based on customer feedback. Collaborating closely with manufacturers, like First Manufacturing, to create a tailored size guide that aligns with local market standards can enhance customer satisfaction and reduce returns.

Scenario 2: Quality Assurance and Material Concerns

The Problem: Quality assurance in leather products is paramount, especially when sourcing from international manufacturers. B2B buyers often worry about the durability and overall quality of leather jackets, which can impact brand reputation. Concerns may arise regarding the leather’s authenticity, treatment processes, and whether it meets safety standards, particularly for motorcycle gear. This is especially critical in regions where the climate and riding conditions can be harsh, such as in South America and the Middle East.

The Solution: To ensure quality, buyers should conduct thorough research on the manufacturer’s production processes and material sourcing. Requesting certifications that validate the quality of the leather, such as ISO standards, can provide peace of mind. It’s also beneficial to establish a quality control protocol that includes regular inspections during production and after shipment. Engaging with manufacturers like First Manufacturing, known for their commitment to quality, can facilitate access to high-grade materials and craftsmanship. Moreover, consider creating a feedback loop with end-users to continuously monitor product performance and make necessary adjustments.

Scenario 3: Lead Time and Supply Chain Reliability

The Problem: B2B buyers often face challenges related to lead times and the reliability of supply chains when ordering leather jackets. Delays in production or shipping can disrupt retail plans, especially when preparing for seasonal sales or launching new collections. Buyers from regions with varying import regulations, such as Nigeria or Saudi Arabia, may experience further complications, leading to uncertainty about delivery timelines and potential additional costs.

Illustrative image related to first manufacturing leather jacket

The Solution: To navigate lead time issues, it is crucial to establish clear communication with the manufacturer. Buyers should discuss expected timelines and any potential risks that could affect delivery. Implementing an inventory management system that accounts for variable lead times can help maintain stock levels and mitigate the impact of delays. Additionally, diversifying suppliers can provide alternatives in case of unexpected disruptions in the supply chain. Building a strong partnership with a reliable manufacturer like First Manufacturing, which has a proven track record of fulfilling orders on time, can significantly enhance supply chain efficiency. Regular updates on production status and proactive problem-solving can further strengthen this relationship, ensuring that your business remains agile and responsive to market demands.

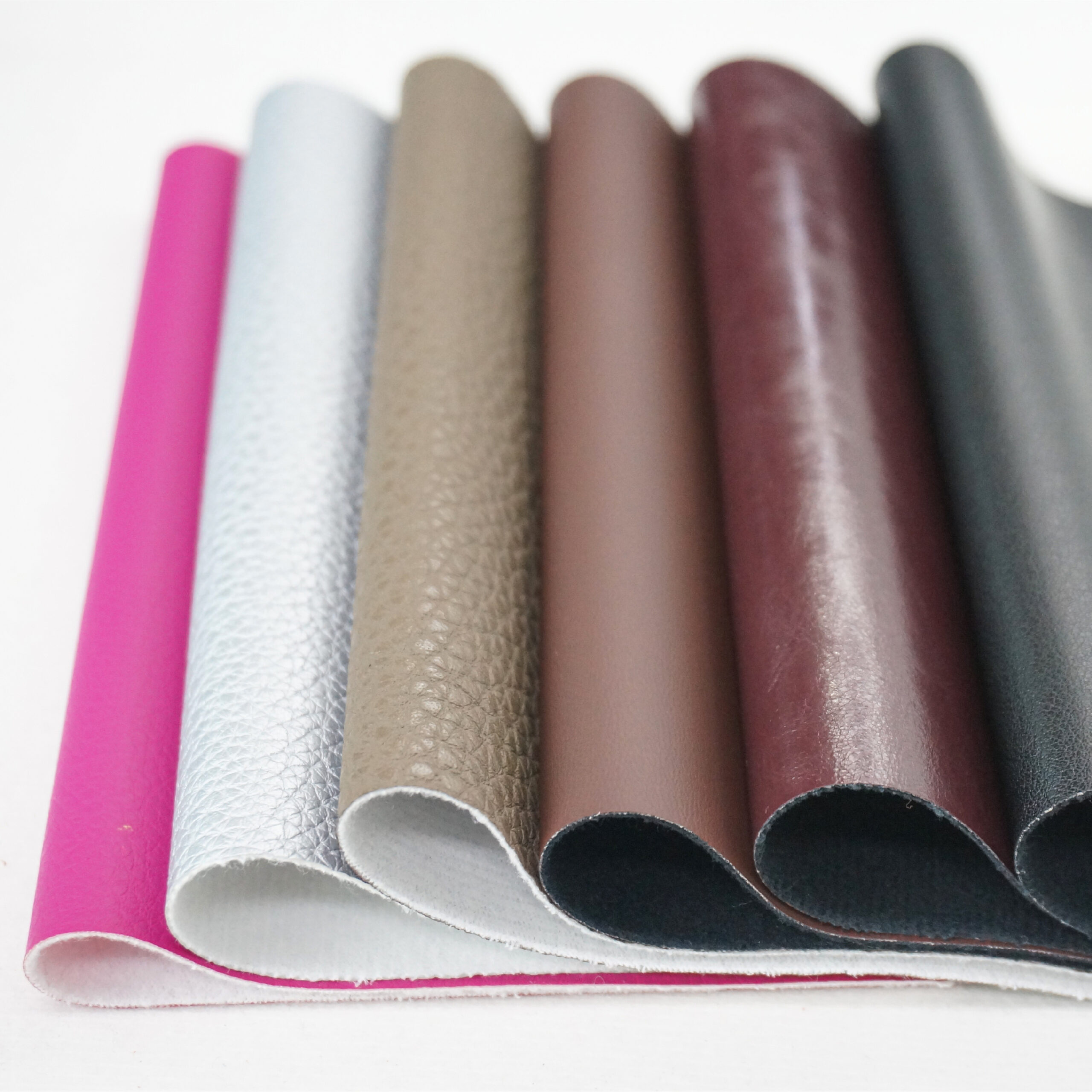

Strategic Material Selection Guide for first manufacturing leather jacket

What Are the Key Materials Used in Manufacturing Leather Jackets?

When considering the manufacturing of leather jackets, selecting the right material is crucial for ensuring product quality, performance, and market appeal. Below is an analysis of four common materials used in leather jacket production, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Cowhide Leather Perform in Leather Jacket Manufacturing?

Cowhide leather is one of the most commonly used materials for leather jackets due to its durability and resistance to wear. It typically has a temperature rating that withstands varying climates, making it suitable for both warm and cool environments.

Pros: Cowhide leather is highly durable, offers excellent abrasion resistance, and provides a classic aesthetic that appeals to consumers. It can withstand significant stress, making it ideal for motorcycle jackets where safety is paramount.

Cons: The main drawback is the cost, as high-quality cowhide can be expensive. Additionally, the manufacturing process can be complex due to the need for careful tanning and finishing.

Impact on Application: Cowhide leather is compatible with various protective gear, making it a popular choice for motorcycle apparel.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the leather complies with local environmental regulations regarding tanning processes.

Illustrative image related to first manufacturing leather jacket

What Are the Benefits of Sheepskin Leather for Jackets?

Sheepskin leather is another popular option, particularly for fashion-oriented jackets. It is lighter and softer than cowhide, offering a luxurious feel.

Pros: Sheepskin is known for its comfort and flexibility, making it ideal for casual wear. It provides good insulation, which is beneficial for colder climates.

Cons: While it is softer, sheepskin is less durable than cowhide and may not offer the same level of abrasion resistance. It can also be more susceptible to damage from water and stains.

Impact on Application: Sheepskin is often used in fashion jackets rather than protective gear, limiting its application in high-risk environments.

Illustrative image related to first manufacturing leather jacket

Considerations for International Buyers: Buyers should be aware of the care and maintenance required for sheepskin jackets, particularly in humid climates where mold may be a concern.

Why Is Goat Leather a Viable Option for Leather Jackets?

Goat leather is gaining popularity in the leather jacket market due to its unique properties. It is lightweight yet strong, making it suitable for a variety of applications.

Pros: Goat leather is known for its excellent breathability and flexibility, which enhances comfort. It is also naturally water-resistant, providing an additional layer of protection.

Cons: The primary downside is that goat leather can be less durable than cowhide, particularly in high-abrasion situations. Additionally, it may have a higher cost due to the sourcing and processing involved.

Impact on Application: Goat leather is often used in fashion and casual jackets, appealing to a younger demographic looking for stylish yet functional options.

Illustrative image related to first manufacturing leather jacket

Considerations for International Buyers: Compliance with local leather sourcing regulations is important, especially in regions like Europe where sustainability is a key focus.

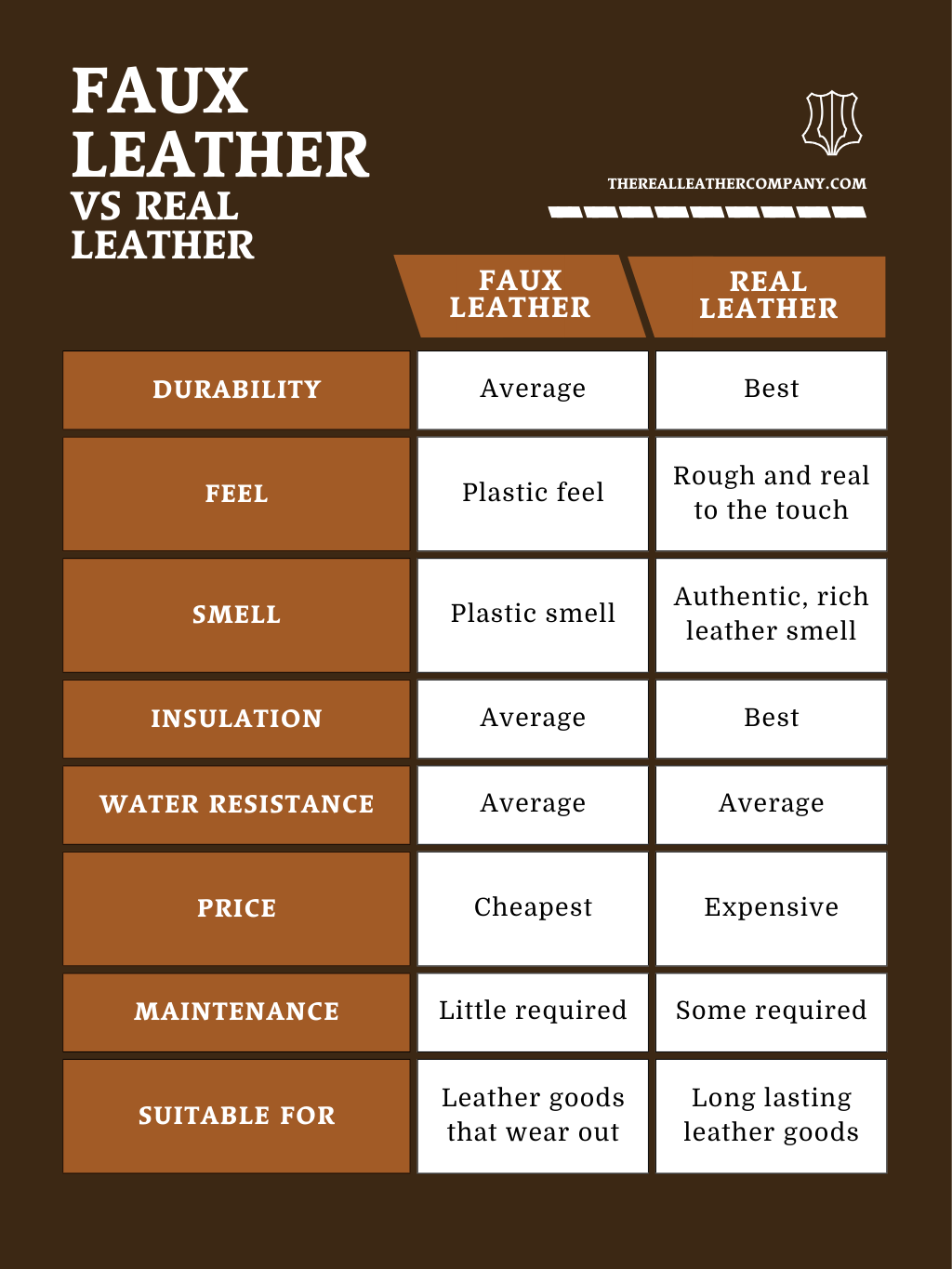

How Does Synthetic Leather Compare to Traditional Options?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is an alternative to traditional leather. It offers a vegan-friendly option that is increasingly popular in the fashion industry.

Pros: Synthetic leather is generally more affordable and easier to maintain than genuine leather. It can also be produced in a variety of colors and textures.

Cons: While it is resistant to stains and water, synthetic leather lacks the breathability and durability of natural leather. It may also not provide the same level of warmth in colder climates.

Illustrative image related to first manufacturing leather jacket

Impact on Application: Synthetic leather is often used in fashion jackets, appealing to consumers looking for trendy, affordable options.

Considerations for International Buyers: Buyers should consider the environmental impact of synthetic materials and ensure compliance with local regulations regarding plastic use.

Summary Table of Material Selection for Leather Jackets

| Material | Typical Use Case for first manufacturing leather jacket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Motorcycle jackets | High durability and abrasion resistance | Higher cost and complex manufacturing | High |

| Sheepskin Leather | Fashion-oriented jackets | Soft, comfortable, and luxurious feel | Less durable and water-sensitive | Medium |

| Goat Leather | Casual and fashion jackets | Lightweight and breathable | Less durable in high-abrasion areas | Medium |

| Synthetic Leather | Trendy, affordable fashion jackets | Cost-effective and easy to maintain | Lacks durability and breathability | Low |

This strategic material selection guide provides valuable insights for B2B buyers in diverse international markets, helping them make informed decisions when sourcing leather jackets.

Illustrative image related to first manufacturing leather jacket

In-depth Look: Manufacturing Processes and Quality Assurance for first manufacturing leather jacket

What Are the Key Stages in the Manufacturing Process of Leather Jackets?

The manufacturing of leather jackets involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

-

Material Preparation

The journey of a leather jacket begins with the selection and preparation of the leather. High-quality full-grain or top-grain leather is typically chosen for its durability and aesthetic appeal. During this phase, hides are inspected for imperfections and sorted according to their grade. The leather is then treated to enhance its properties, such as water resistance and flexibility. This preparation often includes processes like tanning, which can be done using vegetable or chrome tanning methods, each affecting the final texture and durability of the leather. -

Forming

After preparation, the leather is cut into patterns based on the design specifications. This requires precision to minimize waste and ensure consistency across batches. Advanced cutting techniques, including laser cutting and die-cutting, are often employed to achieve intricate designs. Once cut, the leather pieces are subjected to forming processes such as shaping and molding, which help to create the desired fit and structure of the jacket. -

Assembly

The assembly stage is where individual leather pieces come together to form the jacket. Skilled artisans typically sew the components using industrial sewing machines. This step may involve various stitching techniques, such as double stitching for added strength and decorative stitching for aesthetic appeal. Hardware such as zippers, buttons, and snaps are also attached during this phase. Quality control is crucial at this stage to ensure that seams are strong and that all components are correctly aligned. -

Finishing

The final touches are applied during the finishing stage, which enhances the jacket’s appearance and functionality. This can include processes such as dyeing, polishing, and applying protective coatings. Finishing techniques not only add to the visual appeal but also contribute to the jacket’s resistance to wear and environmental factors. The finished jackets undergo a thorough inspection to ensure they meet the brand’s quality standards before packaging and shipping.

How is Quality Assurance Implemented in Leather Jacket Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that every leather jacket meets international and industry-specific standards. For B2B buyers, understanding these QA processes can help in selecting reliable suppliers.

-

International Standards and Certifications

Adhering to international standards such as ISO 9001 is crucial for manufacturers. This certification ensures that companies maintain consistent quality management systems, which include processes for continual improvement and customer satisfaction. Other relevant certifications may include CE marking, which indicates compliance with health, safety, and environmental protection standards within the European market. -

Quality Control Checkpoints

Quality control is typically divided into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials, including leather and hardware, upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, continuous checks are performed to monitor the production process, identifying any deviations from quality standards in real-time.

– Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is conducted to ensure the final product meets all quality criteria. This includes checking for defects, ensuring proper stitching, and verifying that all components function correctly. -

Common Testing Methods for Leather Jackets

To ensure durability and performance, various testing methods are employed, such as:

– Tensile Strength Testing: Assessing the strength of seams and leather to withstand stress.

– Water Resistance Testing: Evaluating the jacket’s ability to repel water, which is crucial for motorcycle gear.

– Colorfastness Testing: Ensuring that colors do not bleed or fade under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential for ensuring product reliability.

Illustrative image related to first manufacturing leather jacket

-

Supplier Audits

Conducting on-site audits is one of the most effective ways to assess a supplier’s manufacturing and quality control processes. This allows buyers to observe firsthand the production environment, equipment used, and adherence to quality standards. Audits can also verify compliance with international certifications, providing peace of mind regarding the supplier’s capabilities. -

Quality Control Reports

Requesting regular quality control reports from suppliers can provide valuable insights into their QA processes. These reports should detail findings from IQC, IPQC, and FQC stages, highlighting any issues identified and corrective actions taken. Consistent reporting indicates a commitment to quality and transparency. -

Third-Party Inspections

Engaging third-party inspection services can enhance the verification process. These independent entities can conduct inspections at various stages of production, offering unbiased assessments of quality control practices. This is particularly beneficial for international buyers who may not be able to conduct on-site visits.

What Are the Nuances of Quality Control for International B2B Buyers?

When sourcing leather jackets globally, B2B buyers must navigate several nuances in quality control specific to their regions.

-

Understanding Regional Standards

Different regions may have unique quality standards and regulations that manufacturers must adhere to. For instance, European markets often require CE marking, while buyers in the Middle East may prioritize compliance with local safety standards. Buyers should familiarize themselves with these requirements to ensure that products meet local regulations. -

Cultural and Communication Considerations

Cultural differences can impact quality assurance processes. Clear communication about quality expectations is essential, and buyers should be aware of potential language barriers. Establishing strong relationships with suppliers can facilitate better understanding and adherence to quality standards. -

Logistics and Supply Chain Considerations

The logistics of shipping leather jackets internationally can pose challenges. Buyers should ensure that suppliers have robust quality control measures in place for packaging and transportation to minimize damage during transit. This includes using appropriate packaging materials and methods to protect the jackets from environmental factors.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures involved in leather jacket production is vital for B2B buyers. By evaluating suppliers based on their manufacturing capabilities and quality control practices, buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘first manufacturing leather jacket’

In the competitive landscape of leather jacket manufacturing, sourcing effectively is paramount for B2B buyers seeking quality products. This guide offers a concise checklist to streamline your procurement process for first manufacturing leather jackets, ensuring you make informed decisions that align with your business needs.

Illustrative image related to first manufacturing leather jacket

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the leather jackets you intend to procure. This includes material type, design elements, color options, and size ranges. Specificity helps suppliers understand your requirements and reduces the likelihood of miscommunication.

- Material Quality: Specify whether you need genuine leather, faux leather, or a blend.

- Design Features: Consider additional elements such as zippers, pockets, or armor integration for motorcycle jackets.

Step 2: Conduct Market Research

Investigate the market to identify trends, competitive pricing, and potential suppliers. Understanding the landscape will equip you with the insights necessary to negotiate effectively and choose the right partners.

- Regional Preferences: Pay attention to regional differences in style and preferences, especially in diverse markets like Africa and South America.

- Competitor Offerings: Analyze what similar businesses are offering and at what price points.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, production capabilities, and references from other clients, particularly those in your industry or geographic area.

Illustrative image related to first manufacturing leather jacket

- Reputation: Look for reviews and testimonials to gauge the reliability of the supplier.

- Experience: Consider suppliers with a proven track record in leather goods, particularly motorcycle apparel.

Step 4: Verify Compliance and Certifications

Ensure that your chosen supplier complies with industry standards and holds relevant certifications. This is crucial for maintaining quality and safety standards, particularly for motorcycle jackets that may require specific protective features.

- Quality Certifications: Check for ISO or similar certifications that indicate adherence to quality management standards.

- Environmental Compliance: Consider suppliers that follow sustainable practices, which can be an appealing factor for many consumers.

Step 5: Request Samples

Before finalizing your order, request samples of the leather jackets. This step allows you to assess the quality of materials, craftsmanship, and overall fit.

- Physical Inspection: Examine the jacket for stitching quality, leather texture, and finish.

- Fit Testing: If applicable, ensure that the sizing aligns with your target market’s expectations.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Clear agreements can prevent misunderstandings later in the process.

- Volume Discounts: Discuss potential discounts for larger orders to optimize your procurement costs.

- Delivery Schedules: Establish clear timelines for production and delivery to align with your inventory needs.

Step 7: Establish a Quality Control Process

Implement a quality control procedure to monitor the production and delivery of leather jackets. This can help mitigate risks associated with defects or non-compliance with your specifications.

Illustrative image related to first manufacturing leather jacket

- On-Site Inspections: If possible, conduct inspections during the production phase to ensure adherence to your specifications.

- Post-Delivery Checks: Set up a process for inspecting the jackets upon arrival to confirm they meet your expectations.

By following this checklist, B2B buyers can streamline their sourcing process for first manufacturing leather jackets, ensuring they partner with reliable suppliers and obtain high-quality products that meet market demands.

Comprehensive Cost and Pricing Analysis for first manufacturing leather jacket Sourcing

When sourcing leather jackets, understanding the cost structure is vital for international B2B buyers. The price of leather jackets is influenced by various cost components and external factors. Here’s an in-depth analysis to help you navigate this complex landscape effectively.

What Are the Key Cost Components for Leather Jackets?

-

Materials: The primary cost driver in leather jackets is the quality of leather used. Full-grain and top-grain leathers command higher prices due to their durability and aesthetic appeal. Additionally, the choice of linings, zippers, and other accessories can significantly affect the overall material cost.

-

Labor: Labor costs vary by region, reflecting local wage standards. Countries with lower labor costs can offer competitive pricing, but this may come at the expense of quality. Skilled craftsmanship is essential for leather jackets, so sourcing from regions with a strong reputation for leatherwork can ensure better quality.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Understanding the supplier’s operational efficiency can provide insights into their pricing structure.

-

Tooling: Initial investment in tooling for custom designs can be substantial. If you are ordering customized jackets, these costs must be factored into the overall pricing.

-

Quality Control (QC): Rigorous QC processes add to the cost but are essential for maintaining high standards. Products that undergo thorough inspection can justify a higher price due to reduced defects and returns.

-

Logistics: Shipping costs can vary significantly depending on the mode of transport and distance. Buyers should consider the implications of Incoterms, as these define the responsibilities of buyers and sellers in terms of shipping and handling.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary based on market demand, competition, and brand positioning.

How Do Pricing Influencers Impact Leather Jacket Costs?

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their inventory needs to optimize costs.

-

Specifications and Customization: Custom designs or specialized features can significantly increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Quality Certifications: Jackets that meet specific safety or environmental standards may cost more. Certifications can enhance a brand’s reputation, making it worth the investment.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate the responsibilities for shipping costs, insurance, and risk transfer, which can greatly affect the total landed cost of the product.

What Are Some Buyer Tips for Cost-Efficiency?

-

Negotiate Wisely: Building a strong relationship with suppliers can lead to better pricing. Don’t hesitate to negotiate terms and explore options for discounts on bulk orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with the product, including maintenance, repairs, and potential resale value.

-

Pricing Nuances for International Buyers: Different markets have varying price expectations. Buyers from Africa, South America, the Middle East, and Europe should research local market conditions and competitor pricing to make informed decisions.

-

Stay Informed on Trends: Market trends can influence leather prices. For instance, fluctuations in leather supply due to environmental regulations or economic factors can affect sourcing costs.

By understanding these components and influencers, B2B buyers can make informed sourcing decisions for leather jackets that align with their business goals while ensuring quality and cost-effectiveness.

Alternatives Analysis: Comparing first manufacturing leather jacket With Other Solutions

When considering the procurement of leather jackets for motorcycle use, it’s essential to explore various alternatives that meet the same performance standards while potentially offering different benefits. The goal is to ensure that B2B buyers can make informed decisions based on specific needs, such as budget constraints, use cases, and maintenance requirements. Below is a comparison of the First Manufacturing Leather Jacket against two viable alternatives: textile motorcycle jackets and custom leather jackets.

| Comparison Aspect | First Manufacturing Leather Jacket | Textile Motorcycle Jacket | Custom Leather Jacket |

|---|---|---|---|

| Performance | High durability and protection | Moderate durability, varies widely | High durability, tailored fit |

| Cost | $249.99 – $559.99 | $100 – $300 | $400 – $800 |

| Ease of Implementation | Readily available online | Widely available | Longer lead time for custom |

| Maintenance | Requires regular conditioning | Easy to clean, machine washable | Requires care, but long-lasting |

| Best Use Case | Long rides and rugged conditions | Casual riding and short trips | Personalized fit for specific needs |

What Are the Benefits and Drawbacks of Textile Motorcycle Jackets?

Textile motorcycle jackets are often made from synthetic materials that provide a lightweight alternative to leather. They typically feature waterproofing and breathability, making them ideal for various weather conditions. However, while they offer moderate durability, they may not withstand the same level of abrasion as leather jackets. For businesses looking for a cost-effective solution for short rides or casual use, textile jackets can be a practical choice, but they might not provide the same level of protection for long-distance riders.

Illustrative image related to first manufacturing leather jacket

Why Consider Custom Leather Jackets as an Alternative?

Custom leather jackets provide a personalized fit and style, allowing businesses to brand their jackets uniquely. They often use high-quality leather that offers excellent durability and protection. However, the cost is significantly higher compared to standard options, and the lead time for production can be longer. For companies that prioritize brand identity and customer experience, investing in custom leather jackets can yield a strong return on investment, but they require careful planning and budget allocation.

How Can B2B Buyers Decide on the Right Solution for Their Needs?

When selecting a leather jacket solution, B2B buyers should consider factors such as the intended use, budget, and maintenance capabilities. For long-distance riders or those in rugged conditions, the First Manufacturing Leather Jacket stands out for its performance and durability. Conversely, for businesses focused on budget and casual riding, textile jackets may suffice. Custom leather jackets are an excellent option for those seeking a personalized touch but require a higher investment. By weighing these factors, buyers can align their choice with their operational needs and customer expectations.

Essential Technical Properties and Trade Terminology for first manufacturing leather jacket

What Are the Essential Technical Properties of First Manufacturing Leather Jackets?

When considering the purchase of leather jackets for manufacturing, understanding key technical properties is crucial for making informed decisions. Here are some critical specifications to keep in mind:

-

Material Grade

Leather quality is often classified by its grade, which can range from full-grain to corrected grain. Full-grain leather, made from the top layer of the hide, is known for its durability and natural aesthetics. In contrast, corrected grain leather is more affordable but may lack some natural characteristics. B2B buyers should prioritize material grade based on the intended use of the jackets, as this directly affects durability, comfort, and overall customer satisfaction. -

Thickness

The thickness of leather, typically measured in ounces, can significantly influence the jacket’s strength and weight. For instance, a jacket with a thickness of 1.2 to 1.4 mm is suitable for motorcycle use, providing adequate protection without being overly heavy. Buyers must consider the balance between protection and comfort, especially for markets with varying climates. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. It is essential for ensuring that each jacket fits consistently and meets design specifications. Tight tolerances are critical in the B2B space, as they can impact customer returns and satisfaction. A well-defined tolerance can lead to better quality control and reduce manufacturing waste. -

Water Resistance

Many leather jackets come with treatments that enhance water resistance. This property is particularly important for motorcycle riders who may encounter varying weather conditions. B2B buyers should evaluate whether their target market values water-resistant features, as this can be a selling point in regions with unpredictable climates. -

Lining Material

The lining of the jacket plays a significant role in comfort and insulation. Common materials include polyester, cotton, and thermal linings. Depending on the intended use, selecting the appropriate lining can enhance the jacket’s wearability in different environments. Buyers should assess the importance of thermal insulation versus breathability based on their target demographic.

What Are Common Trade Terms Used in the Leather Jacket Industry?

Familiarizing yourself with industry jargon can facilitate smoother negotiations and improve communication with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the leather jacket industry, B2B buyers might engage with OEMs to create custom designs or specifications tailored to their brand. Understanding OEM relationships can help buyers navigate sourcing and production more effectively. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it directly impacts inventory management and cash flow. Knowing the MOQ helps buyers plan their purchasing strategy, especially when entering new markets or testing product demand. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. In the context of leather jackets, buyers use RFQs to obtain pricing and terms from multiple manufacturers. This process can help secure the best deals and ensure competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms is crucial for B2B buyers, as they dictate shipping costs, risk, and responsibility for goods during transit. Familiarity with these terms can prevent costly misunderstandings in cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. In the leather jacket industry, lead times can vary significantly based on the complexity of the order and the supplier’s capacity. B2B buyers should consider lead times when planning inventory and marketing strategies to align with customer demand.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing leather jackets, ensuring quality, profitability, and customer satisfaction.

Illustrative image related to first manufacturing leather jacket

Navigating Market Dynamics and Sourcing Trends in the first manufacturing leather jacket Sector

What Are the Current Market Dynamics and Key Trends Affecting the First Manufacturing Leather Jacket Sector?

The global leather jacket market is experiencing a resurgence, driven by several factors including the rising popularity of motorcycle culture, fashion trends favoring leather apparel, and a growing consumer interest in premium, durable products. Emerging markets in Africa, South America, the Middle East, and Europe are particularly pivotal as they showcase increasing disposable incomes and a burgeoning middle class eager to invest in quality leather goods.

Technological advancements are reshaping sourcing practices in the leather industry. B2B buyers are increasingly utilizing digital platforms for sourcing, enabling them to access a broader range of suppliers and products. This shift towards e-commerce is complemented by data analytics tools that enhance inventory management and forecasting, allowing for more agile responses to market demands. Moreover, buyers are keen on understanding the supply chain’s transparency, emphasizing the importance of supplier certifications and ethical practices.

How Is Sustainability and Ethical Sourcing Impacting the First Manufacturing Leather Jacket Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the leather jacket sector. The environmental impact of leather production, particularly concerning water usage, chemical treatments, and waste management, has prompted companies to adopt more sustainable practices. Buyers are increasingly looking for suppliers who prioritize eco-friendly materials, such as vegetable-tanned leather, and those who implement waste reduction strategies in their production processes.

Additionally, the demand for ‘green’ certifications is rising. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) not only help buyers ensure environmental compliance but also enhance brand credibility in a competitive market. As consumers become more environmentally conscious, B2B buyers who align with sustainable sourcing practices are likely to gain a competitive advantage.

What Is the Historical Context of the First Manufacturing Leather Jacket Sector?

The first manufacturing leather jacket sector has evolved significantly since its inception. Initially, leather jackets were primarily associated with functionality and protection, particularly in the motorcycle and aviation industries. Over the decades, they have transcended their utilitarian roots to become fashion statements, popularized by cultural icons and the rise of subcultures.

The shift towards more stylish designs and tailored fits occurred in the late 20th century, with brands like First Manufacturing Co. leading the way. Today, the sector is characterized by a blend of traditional craftsmanship and modern design, appealing to a diverse clientele. This evolution has not only expanded market opportunities but also set the stage for the integration of sustainability and technology in sourcing practices, further shaping the future of leather apparel.

Frequently Asked Questions (FAQs) for B2B Buyers of first manufacturing leather jacket

-

How do I ensure the quality of first manufacturing leather jackets?

To ensure quality, request samples from potential suppliers. Assess the material, stitching, and overall craftsmanship. Inquire about their quality assurance processes, including any certifications they possess (e.g., ISO 9001). Consider visiting the manufacturing facility if possible, or utilize third-party inspection services to verify product quality before bulk orders. Reviews and testimonials from other B2B clients can also provide insights into the supplier’s reliability. -

What customization options are available for first manufacturing leather jackets?

First Manufacturing typically offers various customization options, including color, size, and design features. Buyers can often select specific styles, add logos, or modify details such as zippers and pockets. Discuss your specific requirements with the supplier to understand the extent of customization available, including minimum order quantities (MOQs) and any associated costs. -

What are the typical minimum order quantities (MOQs) for leather jackets?

MOQs for leather jackets can vary significantly based on the supplier and product line. Generally, you might expect MOQs to range from 50 to 200 units. Confirm the MOQ with your chosen supplier, as some may offer lower MOQs for specific items or during promotional periods. Understanding the MOQ is crucial for planning your inventory and ensuring you meet market demand. -

What payment terms should I expect when sourcing leather jackets internationally?

Payment terms can vary widely among suppliers. Common arrangements include a deposit (often 30% upfront) with the balance due before shipment. Some suppliers may offer net payment terms (e.g., Net 30 or Net 60) for established buyers. Discuss and negotiate terms early in the process to ensure they align with your cash flow and financial capabilities, and consider using secure payment methods to mitigate risk. -

How can I vet suppliers of first manufacturing leather jackets effectively?

Vetting suppliers involves researching their reputation, production capacity, and compliance with international trade regulations. Look for reviews, testimonials, and case studies from other B2B clients. Request references and check their history in exporting to your region. Additionally, consider using platforms that provide supplier verification services to ensure legitimacy and reliability before entering into any agreements. -

What logistics considerations should I keep in mind when importing leather jackets?

Logistics considerations include shipping methods, freight costs, and customs regulations in your country. Determine the most cost-effective shipping options, whether by air or sea, and factor in transit times. Understand the import duties and taxes that will apply to your shipment. Engaging with a freight forwarder can help navigate these complexities and ensure timely delivery of your products. -

How can I address potential trade barriers when importing leather jackets?

To address trade barriers, familiarize yourself with the import regulations of your country, including tariffs, quotas, and compliance standards for leather goods. Engage with local trade associations or government export promotion agencies for guidance. Building strong relationships with suppliers who have experience in your market can also help mitigate risks associated with trade barriers and ensure smoother transactions. -

What are the best practices for handling quality assurance during production?

Implementing quality assurance during production involves regular communication with your supplier and setting clear quality standards. Conduct pre-production meetings to establish expectations, and consider arranging in-line inspections during manufacturing. Final inspections before shipment can catch defects or issues early. Document all quality assurance processes and keep records for accountability and future reference.

Top 3 First Manufacturing Leather Jacket Manufacturers & Suppliers List

1. First MFG Co. – Raider Men’s Motorcycle Leather Jacket

Domain: firstmfg.com

Registered: 2000 (25 years)

Introduction: Men’s Leather Motorcycle Jackets available at First MFG Co. include various styles and features. Key products include: 1. Raider Men’s Motorcycle Leather Jacket – Price: $499.99, Colors: Black, Copper. 2. Vendetta Men’s Motorcycle Leather Jacket – Price: $499.99, Colors: Black, Olive. 3. Superstar Men’s Motorcycle Leather Jacket – Price: $259.99, Colors: Black. 4. Mastermind Men’s Motorcycle Leath…

2. First MFG Co – Leather Jackets and Vests

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: First MFG Co produces leather jackets, vests, and chaps. Some models are available at Harley Davidson stores. Customers report mixed experiences: some praise the quality and customer service, while others complain about long shipping times and poor customer service. The company has been criticized for not replenishing inventory and for taking orders without having products in stock. Specific produ…

3. RevZilla – First Manufacturing Chaos Leather Jacket

Domain: revzilla.com

Registered: 2006 (19 years)

Introduction: This company, RevZilla – First Manufacturing Chaos Leather Jacket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for first manufacturing leather jacket

In the dynamic landscape of leather apparel, strategic sourcing is paramount for international B2B buyers looking to capitalize on high-quality products like the First Manufacturing leather jackets. By focusing on reputable suppliers, buyers can ensure they receive durable, stylish, and competitively priced products that resonate with their target markets. The diverse range of options available, including vests and jackets tailored for various riding styles, enables businesses to cater to a wide spectrum of consumer preferences.

As the global market continues to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, there is a burgeoning demand for reliable, fashionable motorcycle gear. Buyers should prioritize partnerships that not only offer quality products but also demonstrate a commitment to ethical sourcing and sustainability. This approach not only enhances brand reputation but also fosters long-term customer loyalty.

Illustrative image related to first manufacturing leather jacket

Looking ahead, the potential for growth in the leather jacket segment is significant. B2B buyers are encouraged to engage with suppliers who are innovative and responsive to market trends, ensuring their offerings remain relevant. Embrace the opportunity to enhance your product line with First Manufacturing leather jackets and position your business for success in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.