Introduction: Navigating the Global Market for san diego leather jacket factory

In an increasingly competitive global market, sourcing high-quality leather jackets from a reputable San Diego leather jacket factory poses a significant challenge for international B2B buyers. With diverse consumer preferences and varying standards across regions like Africa, South America, the Middle East, and Europe, buyers must navigate a complex landscape of options. This guide aims to simplify that process, offering a comprehensive overview of types of leather jackets, their applications, supplier vetting criteria, and cost considerations.

By delving into the nuances of leather sourcing, this guide empowers buyers to make informed purchasing decisions tailored to their specific market needs. You’ll discover insights into the different styles available—ranging from aviation jackets to motorcycle gear—as well as the importance of quality craftsmanship and material selection. Understanding these factors will not only enhance your product offerings but also bolster your brand’s reputation in your respective markets.

Furthermore, we will explore the logistical aspects of international procurement, ensuring that you are well-equipped to establish fruitful partnerships with San Diego leather jacket manufacturers. Whether you’re looking to expand your inventory or seeking custom-made options, this guide serves as your essential resource for navigating the global leather jacket market with confidence and precision.

Table Of Contents

- Top 4 San Diego Leather Jacket Factory Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for san diego leather jacket factory

- Understanding san diego leather jacket factory Types and Variations

- Key Industrial Applications of san diego leather jacket factory

- 3 Common User Pain Points for ‘san diego leather jacket factory’ & Their Solutions

- Strategic Material Selection Guide for san diego leather jacket factory

- In-depth Look: Manufacturing Processes and Quality Assurance for san diego leather jacket factory

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘san diego leather jacket factory’

- Comprehensive Cost and Pricing Analysis for san diego leather jacket factory Sourcing

- Alternatives Analysis: Comparing san diego leather jacket factory With Other Solutions

- Essential Technical Properties and Trade Terminology for san diego leather jacket factory

- Navigating Market Dynamics and Sourcing Trends in the san diego leather jacket factory Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of san diego leather jacket factory

- Strategic Sourcing Conclusion and Outlook for san diego leather jacket factory

- Important Disclaimer & Terms of Use

Understanding san diego leather jacket factory Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Motorcycle Jackets | Durable, protective, often with padding and vents | Retailers, motorcycle clubs, and events | Pros: High durability, safety features. Cons: Heavier than fashion jackets. |

| Aviation Jackets | Classic designs, often with historical military ties | Aviation industry, costume shops | Pros: Timeless appeal, brand recognition. Cons: May require specific sizing. |

| Fashion Leather Jackets | Trendy styles, various cuts and finishes | Fashion retailers, boutiques | Pros: Diverse styles for various demographics. Cons: Less durability compared to functional jackets. |

| Police and Tactical Jackets | Reinforced stitching, functional pockets | Law enforcement, security firms | Pros: High functionality, professional appearance. Cons: Can be more expensive due to specialized features. |

| Custom Made Jackets | Tailored to specifications, various materials used | Corporate gifts, promotional items | Pros: Unique offerings, brand customization. Cons: Longer lead times for production. |

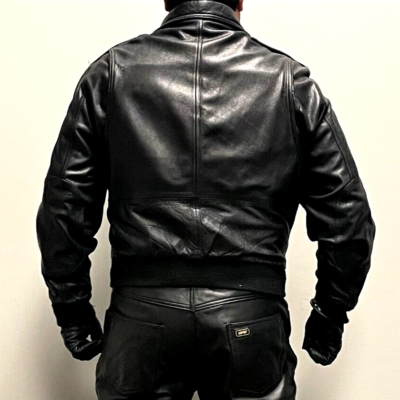

What Are the Key Features of Motorcycle Jackets for B2B Buyers?

Motorcycle jackets are engineered for durability and safety, featuring reinforced stitching and protective padding. These jackets often include ventilation systems to enhance comfort during rides. B2B buyers, such as motorcycle retailers and clubs, find value in these jackets due to their high demand among enthusiasts. It’s essential to consider the weight and bulkiness, as these factors may affect customer preferences, especially in warmer climates.

Illustrative image related to san diego leather jacket factory

Why Choose Aviation Jackets for Your Business Needs?

Aviation jackets, often inspired by military designs, combine style with functionality. They are suitable for businesses in the aviation sector or costume retail, providing a classic look that appeals to various age groups. B2B buyers should be aware of sizing specifics and the historical context that may influence customer interest. Their timeless appeal can drive sales, especially in niche markets.

How Do Fashion Leather Jackets Stand Out in the Market?

Fashion leather jackets are characterized by their trendy designs and diverse styles, catering to various consumer preferences. These jackets are ideal for fashion retailers and boutiques looking to attract a younger demographic. While they offer a wide range of styles, B2B buyers should note that these jackets may not provide the same level of durability as functional options. Understanding seasonal trends is crucial for inventory management.

What Benefits Do Police and Tactical Jackets Offer B2B Buyers?

Police and tactical jackets are designed with functionality in mind, featuring multiple pockets and reinforced areas for durability. They cater primarily to law enforcement and security sectors, making them a vital offering for B2B buyers in these industries. While they provide a professional appearance and essential features, the higher price point can be a consideration for budget-conscious buyers.

Illustrative image related to san diego leather jacket factory

Why Consider Custom Made Jackets for Your B2B Purchases?

Custom-made jackets allow businesses to offer unique products tailored to specific customer needs. This option is particularly appealing for corporate gifts or promotional items, as they can be branded to enhance visibility. However, B2B buyers must consider longer production times and potential costs associated with customization. The uniqueness of these jackets can significantly enhance brand loyalty and customer satisfaction.

Key Industrial Applications of san diego leather jacket factory

| Industry/Sector | Specific Application of san diego leather jacket factory | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aviation | Custom leather aviation jackets for pilots | Enhances brand identity and provides durability | Quality of leather, customization options, lead times |

| Motorcycle Apparel | Biker jackets and vests for motorcycle clubs | Builds community and brand loyalty among riders | Design options, safety features, bulk order discounts |

| Fashion Retail | Leather fashion jackets for men, women, and children | Access to unique styles that appeal to diverse markets | Fashion trends, sizing availability, import/export regulations |

| Promotional Products | Customized leather jackets for corporate branding | Strengthens brand visibility and employee morale | Minimum order quantities, customization capabilities, pricing |

| Costume and Event Apparel | Themed leather jackets for events like Comic-Con | Attracts niche markets and increases sales potential | Licensing agreements, design creativity, production timelines |

How Can Aviation Companies Leverage Custom Leather Jackets?

Aviation companies can source custom leather jackets from the San Diego Leather Jacket Factory to provide their pilots with high-quality, durable outerwear. These jackets not only serve a functional purpose but also enhance brand identity through unique designs that can feature company logos. Buyers should consider the quality of leather, customization options, and lead times, especially for international orders, to ensure timely delivery and compliance with local regulations.

What Benefits Do Motorcycle Clubs Gain from Biker Jackets?

Motorcycle clubs can utilize the San Diego Leather Jacket Factory’s offerings to procure biker jackets and vests that foster a sense of community among members. These jackets can be customized with club insignias, promoting brand loyalty and camaraderie. Key considerations for buyers include design options that adhere to club aesthetics, safety features for rider protection, and potential bulk order discounts that can lower overall costs.

Illustrative image related to san diego leather jacket factory

Why Should Fashion Retailers Partner with San Diego Leather Jacket Factory?

Fashion retailers looking to diversify their inventory can benefit from the unique leather fashion jackets produced by the San Diego Leather Jacket Factory. These jackets cater to various demographics, including men, women, and children, allowing retailers to tap into multiple market segments. Buyers should pay attention to current fashion trends, sizing availability, and import/export regulations that may affect sourcing from the U.S.

How Can Businesses Enhance Branding with Promotional Leather Jackets?

Companies seeking to boost their brand visibility can source customized leather jackets as promotional products from the San Diego Leather Jacket Factory. These jackets serve as both functional apparel and marketing tools, improving employee morale and brand recognition. Buyers should evaluate minimum order quantities, customization capabilities, and pricing structures to ensure they meet their promotional objectives effectively.

What Role Do Themed Leather Jackets Play in Event Marketing?

Themed leather jackets are essential for event marketing, particularly for conventions like Comic-Con. The San Diego Leather Jacket Factory can produce unique designs that cater to specific themes, attracting niche markets and increasing sales potential. Buyers must consider licensing agreements for themed designs, the creativity of the product, and production timelines to ensure that jackets are available for events.

Illustrative image related to san diego leather jacket factory

3 Common User Pain Points for ‘san diego leather jacket factory’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather at Competitive Prices

The Problem: One of the primary challenges faced by B2B buyers from international markets—especially those in Africa and South America—is sourcing high-quality leather jackets at competitive prices. Many buyers are concerned about the balance between quality and cost, particularly when importing products. Subpar materials can lead to returns, damaged reputations, and lost sales, while premium products may exceed budget constraints.

The Solution: To effectively source high-quality leather jackets from the San Diego Leather Jacket Factory, buyers should engage directly with the factory representatives to discuss their specific needs. Establishing a clear understanding of the materials used, production techniques, and quality assurance processes is vital. Buyers should request samples of various leather types to assess quality firsthand. Additionally, considering bulk purchase agreements can lead to better pricing while ensuring the buyer has access to high-quality products. By negotiating terms that include quality guarantees, buyers can mitigate risks associated with inferior products and enhance their market offerings.

Scenario 2: Navigating Custom Orders and Lead Times

The Problem: International buyers often face significant challenges when it comes to custom orders. Whether it’s a specific design, color, or size, many manufacturers may have long lead times or complicated ordering processes. This can be particularly frustrating for B2B buyers who need to meet tight deadlines or seasonal demands, leading to lost sales opportunities if products do not arrive on time.

The Solution: To navigate the complexities of custom orders with the San Diego Leather Jacket Factory, buyers should initiate conversations about their specific requirements early in the procurement process. It is advisable to clearly outline design specifications and deadlines during initial discussions. Establishing a timeline that includes production, quality checks, and shipping can help ensure that orders are fulfilled on time. Additionally, leveraging the factory’s expertise by asking for their recommendations on popular styles or colors can enhance the final product while streamlining the ordering process. Setting up a communication channel for real-time updates can further mitigate delays and foster a collaborative relationship.

Illustrative image related to san diego leather jacket factory

Scenario 3: Understanding Sizing and Fit for Diverse Markets

The Problem: Sizing discrepancies can pose a significant problem for B2B buyers, particularly when dealing with international markets where body types and sizing standards may differ greatly. This can result in high return rates, customer dissatisfaction, and increased shipping costs, which can undermine profitability and complicate inventory management.

The Solution: To address sizing and fit challenges, buyers should utilize the comprehensive sizing charts and fit guides provided by the San Diego Leather Jacket Factory. It is essential to communicate with the factory to clarify any sizing questions and ensure that the products are tailored to the target market’s specific measurements. Additionally, considering a small trial order can help gauge how well the sizing aligns with customer expectations before committing to larger orders. Gathering feedback from end consumers regarding fit and comfort can also inform future purchases, allowing buyers to make more accurate orders that cater to their clientele. By prioritizing fit and actively seeking input, buyers can reduce return rates and enhance customer satisfaction.

Strategic Material Selection Guide for san diego leather jacket factory

What Are the Key Materials Used in Leather Jacket Manufacturing?

When selecting materials for leather jackets, the San Diego Leather Jacket Factory commonly utilizes a variety of leather types and synthetic alternatives. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers looking to make informed purchasing decisions.

Illustrative image related to san diego leather jacket factory

What Are the Key Properties of Cowhide Leather?

Cowhide leather is one of the most popular materials for leather jackets due to its durability and versatility. It is known for its strength and resistance to wear and tear, making it suitable for motorcycle jackets and outdoor apparel. Cowhide can withstand various temperatures and is resistant to moisture, although prolonged exposure can lead to degradation.

Pros: Cowhide leather offers excellent durability and abrasion resistance, making it ideal for high-wear applications. Its natural grain also provides a classic aesthetic that appeals to consumers.

Cons: The cost of cowhide is relatively high compared to synthetic alternatives. Additionally, its weight can make jackets bulkier, which may not suit all fashion preferences.

Illustrative image related to san diego leather jacket factory

Impact on Application: Cowhide is compatible with various climates, particularly in regions with cooler temperatures, making it a preferred choice for buyers from Europe and the Middle East.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding leather sourcing and animal welfare. Standards such as ASTM D7255 for leather testing may be applicable.

How Does Lambskin Leather Compare in Performance?

Lambskin leather is another common choice, particularly for fashion jackets. Known for its softness and lightweight properties, lambskin provides a luxurious feel and drape, making it ideal for stylish outerwear.

Pros: The primary advantage of lambskin is its comfort and aesthetic appeal. It is softer and lighter than cowhide, making it suitable for fashion-oriented products.

Illustrative image related to san diego leather jacket factory

Cons: While lambskin is visually appealing, it is less durable than cowhide and can be more susceptible to scratches and wear. This limits its suitability for rugged applications.

Impact on Application: Lambskin is best suited for urban environments and moderate climates, appealing to buyers in South America and Europe who prioritize style over ruggedness.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for lambskin across regions. Compliance with JIS (Japanese Industrial Standards) may be necessary for certain markets.

What Role Does Goatskin Leather Play in Jacket Manufacturing?

Goatskin leather is increasingly popular for its unique texture and durability. It combines the softness of lambskin with the toughness of cowhide, making it versatile for various jacket styles.

Pros: Goatskin is lightweight yet strong, offering good resistance to abrasion and weather conditions. Its unique grain also adds a distinct aesthetic appeal.

Cons: The cost of goatskin can be higher than cowhide, and its sourcing may raise ethical concerns for some buyers. Additionally, its availability may vary by region.

Impact on Application: Goatskin is suitable for both fashion and functional jackets, appealing to a wide range of consumers, particularly in Africa and the Middle East.

Illustrative image related to san diego leather jacket factory

Considerations for International Buyers: Buyers should consider the ethical sourcing of goatskin and ensure compliance with local regulations. Familiarity with DIN (Deutsches Institut für Normung) standards can be beneficial.

How Do Synthetic Materials Compare to Traditional Leathers?

Synthetic materials, such as polyurethane (PU) and polyvinyl chloride (PVC), are increasingly used in leather jacket production. These materials offer a cost-effective alternative to natural leather while providing similar aesthetics.

Pros: Synthetic leathers are often less expensive and easier to maintain than traditional leathers. They can also be produced in various colors and textures, appealing to diverse consumer preferences.

Cons: Synthetic materials may lack the durability and breathability of natural leathers. They can also be less environmentally friendly, raising concerns among eco-conscious consumers.

Illustrative image related to san diego leather jacket factory

Impact on Application: Synthetic leathers are suitable for fashion-forward designs and are often preferred in warmer climates, particularly in regions like Brazil and Vietnam.

Considerations for International Buyers: Buyers should evaluate the environmental impact of synthetic materials and consider compliance with international sustainability standards.

Summary Table of Material Selection for San Diego Leather Jacket Factory

| Material | Typical Use Case for san diego leather jacket factory | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Motorcycle jackets, outdoor apparel | Excellent durability and abrasion resistance | Higher cost, bulkier weight | Hoch |

| Lambskin Leather | Fashion jackets | Soft and luxurious feel | Less durable, susceptible to scratches | Med |

| Goatskin Leather | Versatile jackets | Lightweight with unique texture | Higher cost, ethical sourcing concerns | Hoch |

| Synthetic Leather | Fashion-forward designs | Cost-effective and easy to maintain | Less durable, environmental concerns | Low |

This guide provides B2B buyers with essential insights into material selection, helping them make informed decisions that align with their market needs and compliance requirements.

Illustrative image related to san diego leather jacket factory

In-depth Look: Manufacturing Processes and Quality Assurance for san diego leather jacket factory

What Are the Key Stages in the Manufacturing Process of Leather Jackets?

The manufacturing process for leather jackets at the San Diego Leather Jacket Factory involves several critical stages, each essential for producing high-quality garments that meet international standards.

1. Material Preparation

The first step in the manufacturing process is sourcing high-quality leather. The factory primarily uses cowhide, lambskin, and goatskin, which are selected based on their durability and aesthetic appeal. The leather is then treated and dyed to achieve the desired color and finish. This preparation phase may also include cutting the leather into specific patterns that will be used in the later stages of production.

2. Forming

Once the leather is prepared, the next stage is forming. This involves shaping the leather into the desired jacket style. Techniques such as die-cutting and hand-cutting are employed to ensure precision. For specialized designs, such as those required for aviation or motorcycle jackets, additional features like pockets, zippers, and ventilation are integrated into the design during this phase.

3. Assembly

Assembly is where the individual pieces of leather are sewn together. The factory utilizes advanced sewing machines capable of handling thick leather, ensuring durability in the final product. Skilled artisans perform this task, often employing techniques such as double stitching and reinforced seams to enhance the jacket’s strength and longevity. Quality craftsmanship is paramount in this stage to meet the expectations of both local and international buyers.

4. Finishing

The finishing stage includes several processes that enhance the jacket’s appearance and functionality. This may involve adding linings, applying protective coatings, and conducting final inspections to ensure the product meets quality standards. Additionally, the jackets undergo processes like conditioning and polishing, which not only improve their look but also increase their resistance to wear and tear.

How Is Quality Assurance Managed in Leather Jacket Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process at the San Diego Leather Jacket Factory. The factory adheres to international quality standards to ensure that all products meet or exceed customer expectations.

What International Standards Are Followed for Quality Assurance?

The factory complies with ISO 9001 standards, which provide a framework for effective quality management systems. This involves documentation of processes, regular audits, and continuous improvement practices. Additionally, industry-specific certifications such as CE (Conformité Européenne) are pursued to ensure that products meet European safety and quality standards.

Illustrative image related to san diego leather jacket factory

What Are the Key Quality Control Checkpoints in the Production Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality standards before they enter the production line.

-

In-Process Quality Control (IPQC): During the assembly phase, random samples of jackets are inspected for stitching quality, material integrity, and adherence to design specifications. This helps identify any issues early in the production process.

-

Final Quality Control (FQC): Once the jackets are finished, a final inspection is conducted to assess overall quality, including functionality (zippers, buttons) and aesthetic appeal (color consistency, stitching).

What Testing Methods Are Commonly Employed?

To maintain high-quality standards, various testing methods are employed, including:

-

Physical Testing: This involves checking the durability of seams, leather flexibility, and resistance to tearing.

-

Chemical Testing: Leather is tested for color fastness and resistance to various environmental factors (e.g., water, UV light).

-

Wear Testing: Sample jackets are subjected to wear tests to simulate real-world usage conditions, ensuring longevity and comfort.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, ensuring quality is crucial. Here are effective strategies to verify supplier QC:

Conducting Supplier Audits

Regular audits of the manufacturing facility can provide insights into the factory’s adherence to quality standards. Buyers can request pre-shipment inspections to ensure that the products meet their specifications before shipping.

Requesting Quality Control Reports

Buyers should request detailed QC reports that outline inspection results, testing outcomes, and any corrective actions taken for defects. This transparency fosters trust and ensures that products are consistently meeting quality standards.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These services can conduct on-site inspections and provide comprehensive reports, offering added assurance for buyers.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of specific nuances related to QC and certification:

-

Import Regulations: Different countries have varying import regulations concerning leather goods. Buyers should ensure that their suppliers are compliant with these regulations, which may include specific labeling and documentation.

-

Cultural Expectations: Understanding the cultural expectations regarding leather quality and craftsmanship in different regions can help buyers set appropriate quality benchmarks.

-

Communication: Open lines of communication with suppliers regarding quality expectations and standards can mitigate misunderstandings and ensure that both parties are aligned on product specifications.

In conclusion, the San Diego Leather Jacket Factory employs a comprehensive manufacturing process combined with stringent quality assurance protocols to deliver high-quality leather jackets. For international B2B buyers, understanding these processes and maintaining active engagement with suppliers can lead to successful partnerships and high customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘san diego leather jacket factory’

Einführung

Navigating the procurement process for leather jackets from the San Diego Leather Jacket Factory requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This guide provides a clear, actionable checklist for international B2B buyers seeking to source leather jackets from this region. By following these steps, you can streamline your sourcing process and build a successful partnership with the factory.

Step 1: Identify Your Product Requirements

Before initiating contact with suppliers, clearly define the types of leather jackets you wish to procure. Consider aspects such as styles (e.g., biker, aviation, fashion), materials (cowhide, lambskin), and any specific features (zippers, pockets). This clarity will enable you to communicate effectively with suppliers and ensure that you receive products that meet your needs.

Step 2: Research the Supplier’s Reputation

Investigate the San Diego Leather Jacket Factory’s reputation within the industry. Look for reviews, testimonials, and case studies from previous international buyers. Reliable suppliers will have a track record of delivering quality products and excellent customer service. Utilize platforms like LinkedIn or trade forums to gather insights and feedback.

Step 3: Request Samples

Before placing a large order, request samples of the leather jackets. This step is critical for assessing the quality, craftsmanship, and suitability of the products. Pay attention to the stitching, finishing, and overall durability of the leather. Ensure that the samples align with your specified requirements and market expectations.

Step 4: Verify Compliance and Certifications

Ensure that the San Diego Leather Jacket Factory complies with international manufacturing standards and certifications. This includes checking for environmental sustainability practices and labor regulations. Certifications such as ISO can indicate a commitment to quality and ethical production, which is increasingly important for global buyers.

Illustrative image related to san diego leather jacket factory

Step 5: Negotiate Terms and Pricing

Once you are satisfied with the product samples and supplier credentials, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget constraints and explore options for bulk discounts. Establishing favorable terms upfront can lead to a more beneficial long-term partnership.

Step 6: Establish Clear Communication Channels

Effective communication is vital for successful sourcing. Set up regular check-ins with the supplier to discuss order progress, potential issues, and updates on inventory. Utilize tools such as email, video calls, and project management software to maintain transparency and address any concerns promptly.

Step 7: Plan for Logistics and Shipping

Finally, coordinate logistics for shipping and delivery. Discuss shipping methods, costs, and timelines with the supplier. Ensure you are aware of customs regulations and import duties that may apply when bringing products into your region. A well-planned logistics strategy will help avoid delays and additional costs.

By following this comprehensive checklist, international B2B buyers can confidently source leather jackets from the San Diego Leather Jacket Factory, ensuring a smooth and efficient procurement process.

Comprehensive Cost and Pricing Analysis for san diego leather jacket factory Sourcing

What Are the Key Cost Components for Sourcing from a San Diego Leather Jacket Factory?

When sourcing leather jackets from a San Diego factory, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of leather significantly influences costs. Options range from cowhide to lambskin, with prices varying accordingly. Specialty materials, such as treated leather for motorcycle jackets, may incur additional costs due to their durability and weather resistance.

-

Labor: Labor costs in the U.S. can be higher compared to other manufacturing countries. Skilled artisans involved in leather crafting will command premium wages, especially for custom or high-quality products.

-

Manufacturing Overhead: This includes the costs associated with running the facility, such as utilities, rent, and administrative expenses. Given the location in San Diego, which has a higher cost of living, overheads may be slightly elevated compared to factories in other regions.

-

Tooling: Initial tooling costs for custom designs can be significant. For bespoke orders, factories might require specialized equipment, which can raise upfront costs but may be amortized over larger production runs.

-

Quality Control (QC): Ensuring that products meet quality standards is vital, especially for international buyers who may face stringent import regulations. Investing in QC processes can add to the overall cost but enhances product reliability.

-

Logistics: Shipping costs must be considered, particularly for international orders. Factors such as weight, dimensions, and destination will impact logistics expenses. Utilizing efficient shipping methods can help reduce costs.

-

Margin: The markup applied by the manufacturer to cover costs and generate profit will vary. This margin can also reflect the perceived value of the brand and product quality.

What Influences Pricing for Leather Jackets in San Diego?

Several factors can influence the pricing of leather jackets sourced from San Diego:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from reduced per-unit costs. Establishing a relationship with the factory may also lead to more favorable pricing terms.

-

Specifications and Customization: Custom designs or unique specifications will incur additional costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (like eco-friendly or sustainable practices) can raise costs but may be attractive selling points in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established factories with a track record of quality may charge more but offer peace of mind regarding product consistency.

-

Incoterms: Understanding the terms of shipping and responsibility for costs is crucial. Incoterms dictate who bears the cost and risk during transportation, impacting the overall pricing structure.

How Can Buyers Optimize Their Sourcing Strategy?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, here are some actionable tips to enhance cost-efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for larger orders. Factories may be willing to offer discounts for bulk purchases or long-term contracts.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but the total cost, including shipping, tariffs, and potential returns. This holistic view can lead to better decision-making.

-

Understand Pricing Nuances: Be aware of how exchange rates and local economic conditions may affect pricing. Some regions may experience inflation or currency fluctuations that can impact costs.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and service. Regular communication can also facilitate smoother transactions and quicker resolution of issues.

-

Research Market Trends: Stay informed about trends in leather fashion and consumer preferences, which can affect demand and pricing. Being ahead of the curve can provide a competitive advantage in your offerings.

Disclaimer on Indicative Prices

The prices mentioned in this analysis are indicative and can vary based on numerous factors, including market conditions, material availability, and supplier negotiations. It is advisable for buyers to conduct thorough research and obtain quotes directly from manufacturers to ensure accurate cost assessments.

Alternatives Analysis: Comparing san diego leather jacket factory With Other Solutions

When considering leather apparel manufacturing, buyers often seek alternatives to ensure they find the best fit for their needs. The San Diego Leather Jacket Factory is a reputable option, but understanding how it stacks up against other alternatives is crucial for informed decision-making. This section will compare the San Diego Leather Jacket Factory with two notable alternatives: an overseas leather manufacturer and a custom leather tailoring service.

Comparison Table

| Comparison Aspect | San Diego Leather Jacket Factory | Overseas Leather Manufacturer | Custom Leather Tailoring Service |

|---|---|---|---|

| Performance | High-quality craftsmanship; USA-made | Variable quality; often lower standards | Premium quality; bespoke designs |

| Cost | Moderate to high price range | Generally lower costs | Higher price due to customization |

| Ease of Implementation | Quick turnaround for in-stock items; 2-3 weeks for custom | Longer shipping times; customs delays | Longer lead times due to custom work |

| Wartung | Local repairs and alterations available | Limited local support | Ongoing support for maintenance and repairs |

| Best Use Case | Retail and personal use; quick purchases | Bulk orders for resale | Unique, custom pieces for branding or events |

What Are the Pros and Cons of an Overseas Leather Manufacturer?

Overseas leather manufacturers often provide significant cost advantages due to lower labor costs. They can produce large quantities of leather goods at competitive prices, making them an attractive option for businesses looking to maximize profit margins. However, quality can be inconsistent, and longer shipping times may delay inventory replenishment. Additionally, there may be challenges related to communication and logistics, which could impact overall customer satisfaction.

How Does a Custom Leather Tailoring Service Compare?

Custom leather tailoring services offer the distinct advantage of personalized designs, ensuring that each piece meets specific client requirements. This level of customization often results in exceptional quality and unique products that stand out in the market. However, the cost can be significantly higher than standard options, and lead times may be extended due to the bespoke nature of the work. This option is ideal for businesses focused on niche markets or those wanting to create a signature look.

Conclusion: How Can B2B Buyers Choose the Right Leather Solution?

Selecting the right leather jacket supplier requires careful consideration of various factors, including performance, cost, and the specific needs of your business. For companies prioritizing quality and local support, the San Diego Leather Jacket Factory is an excellent choice, particularly for retail and personal use. If cost is a primary concern and bulk purchasing is necessary, an overseas manufacturer may offer the best value. Conversely, for businesses looking to differentiate themselves with unique, high-end products, a custom leather tailoring service could be the optimal solution. Ultimately, understanding these alternatives will empower B2B buyers to make decisions that align with their strategic goals and customer expectations.

Essential Technical Properties and Trade Terminology for san diego leather jacket factory

What Are the Essential Technical Properties of Leather Jackets from a San Diego Factory?

When sourcing leather jackets from a San Diego factory, understanding the technical properties of the products is crucial for B2B buyers. Here are some key specifications to consider:

-

Material Grade

The grade of leather used is paramount. Common types include full-grain, top-grain, and corrected-grain leather. Full-grain leather is the highest quality, retaining the hide’s natural texture and durability. Top-grain leather is slightly more processed but still offers a good balance of quality and cost. Understanding material grades helps buyers assess product longevity and suitability for their target market. -

Thickness

Leather thickness is typically measured in ounces or millimeters. A thicker leather (around 1.2 to 1.4 mm) is ideal for motorcycle jackets as it offers enhanced protection and durability. Conversely, thinner leather (0.8 to 1.0 mm) is often used for fashion jackets, providing a lighter, more flexible fit. Buyers should align thickness with their intended use to ensure customer satisfaction. -

Tanning Process

The tanning method affects the leather’s look, feel, and durability. Vegetable tanning is eco-friendly but may take longer, resulting in a softer, more supple leather. Chrome tanning is faster and produces a more consistent finish, making it suitable for mass production. Understanding tanning processes can help buyers evaluate product quality and sustainability. -

Water Resistance

Depending on the intended use, the water resistance of leather jackets can be critical. Some jackets are treated with water-repellent finishes, enhancing their usability in wet conditions. Buyers should inquire about water resistance if they target markets in regions with high rainfall or adverse weather conditions. -

Stitching and Construction Quality

The stitching technique and thread used are indicators of overall quality. Double stitching is often preferred for durability, especially in high-stress areas like seams and zippers. Understanding construction quality helps buyers ensure they are investing in products that will withstand wear and tear. -

Fit and Size Specifications

Accurate sizing is essential for customer satisfaction. Factories often provide sizing charts and customization options to accommodate different body types. Buyers should ensure that the factory adheres to standard sizing or offers bespoke solutions to meet their market’s needs.

What Trade Terms Should B2B Buyers Know When Working with a Leather Jacket Factory?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms relevant to B2B transactions in the leather jacket industry:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or products that may be marketed by another company under its brand. Buyers should know whether the factory operates as an OEM to understand product sourcing and branding options. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest order size that a supplier is willing to accept. Understanding MOQs helps buyers plan inventory and budget effectively, especially when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price bids from suppliers. It typically includes specifications, quantities, and delivery timelines. Buyers should prepare detailed RFQs to receive accurate quotes and compare offers. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Knowing these terms helps buyers understand shipping costs, insurance, and liability during transit. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. It is crucial for inventory management and planning, especially in seasonal markets. Buyers should clarify lead times to ensure timely delivery. -

Quality Assurance (QA)

QA refers to the systematic processes put in place to ensure that products meet specified quality standards. Understanding QA practices helps buyers ensure product consistency and reliability.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing leather jackets from San Diego factories. This knowledge not only enhances negotiation power but also ensures alignment with market expectations and customer needs.

Navigating Market Dynamics and Sourcing Trends in the san diego leather jacket factory Sector

What Are the Key Market Dynamics and Trends Affecting the San Diego Leather Jacket Factory Sector?

The San Diego leather jacket factory sector is influenced by several global drivers that shape the market landscape for international B2B buyers. One of the primary factors is the increasing demand for high-quality, durable leather products, particularly in emerging markets across Africa and South America. As disposable incomes rise, consumers are willing to invest in premium leather apparel, thereby expanding the market for manufacturers. Additionally, the motorcycle culture, especially prevalent in regions like the Middle East and parts of Europe, is contributing to a surge in demand for specialized leather jackets.

Technological advancements in production processes, such as automated cutting and sewing, are streamlining manufacturing, reducing costs, and improving efficiency. This shift towards automation allows factories to respond more swiftly to market trends, such as the growing preference for custom and made-to-order jackets. Digital platforms are also becoming crucial for B2B transactions, facilitating easier sourcing and enabling buyers to access a wider range of products and suppliers.

Moreover, sustainability is becoming a significant concern, with buyers increasingly seeking products that are ethically sourced and environmentally friendly. This trend is particularly relevant for international buyers from Europe, where regulations around sustainable practices are stringent. The ability to offer transparency in sourcing and production processes will be a key differentiator for suppliers in the San Diego leather jacket sector.

How Is Sustainability and Ethical Sourcing Impacting the San Diego Leather Jacket Factory Sector?

Sustainability and ethical sourcing are no longer optional considerations but essential elements of the supply chain for the San Diego leather jacket factory sector. The environmental impact of leather production, including water usage and chemical treatment processes, has led to increased scrutiny from consumers and regulatory bodies alike. As a result, many manufacturers are adopting sustainable practices, such as using vegetable-tanned leather, which is less harmful to the environment than traditional chrome-tanned leather.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for suppliers who can provide certifications that attest to responsible sourcing, such as the Leather Working Group (LWG) certification. This not only assures buyers of the quality and sustainability of the leather but also enhances their brand reputation among environmentally conscious consumers.

Furthermore, the trend towards circular economy practices is gaining traction, with many manufacturers offering repair services and take-back programs for old leather goods. This not only reduces waste but also creates an opportunity for suppliers to build long-term relationships with their clients by promoting sustainability in their business practices.

Illustrative image related to san diego leather jacket factory

What Is the Historical Context of the San Diego Leather Jacket Sector for B2B Buyers?

The San Diego leather jacket factory sector has a rich history that dates back several decades, evolving alongside changes in fashion and consumer preferences. Initially focused on basic leather goods, the sector has diversified significantly, now encompassing a wide range of products from motorcycle jackets to high-fashion apparel. This evolution has been driven by a combination of local craftsmanship and the incorporation of global trends, making San Diego a notable hub for leather manufacturing.

As the demand for leather products grew, so did the emphasis on quality and customization. The San Diego leather industry has capitalized on its proximity to major markets and its ability to deliver both standard and bespoke items, making it an attractive sourcing destination for international B2B buyers. The legacy of skilled artisans in the region continues to influence product offerings, ensuring that the San Diego leather jacket factory sector remains competitive in a global market increasingly focused on quality, sustainability, and ethical sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of san diego leather jacket factory

-

How can I ensure the quality of leather jackets from San Diego Leather Jacket Factory?

To ensure quality, request samples of the leather and finished products before placing a bulk order. Inquire about their quality assurance processes, including material sourcing and manufacturing standards. Additionally, consider visiting the factory if possible, or ask for references from other B2B clients. Reading reviews and ratings can also provide insight into their reliability and product quality. -

What are the customization options available for leather jackets?

San Diego Leather Jacket Factory offers a variety of customization options, including size, color, design, and specific features such as pockets or linings. You can also request custom logos or branding on jackets, which is ideal for corporate gifts or promotional products. Discuss your specific needs with their sales team to understand the full range of customization capabilities and associated costs. -

What is the minimum order quantity (MOQ) for wholesale purchases?

The minimum order quantity at San Diego Leather Jacket Factory typically varies based on the type of product and customization requested. Generally, MOQs can range from 10 to 50 pieces per style. It is advisable to directly contact their sales department to confirm specific MOQs for your desired products, as they may offer flexibility for larger orders or recurring customers. -

What payment terms can I expect when sourcing from San Diego Leather Jacket Factory?

Payment terms for B2B transactions typically include options such as a deposit upfront (often 30-50%) with the balance due upon delivery or prior to shipment. Some buyers may also negotiate net payment terms (like 30 or 60 days post-delivery). It’s crucial to discuss and finalize these terms before placing your order to avoid any misunderstandings. -

How does San Diego Leather Jacket Factory handle international shipping?

San Diego Leather Jacket Factory is experienced in international shipping and can provide various shipping options based on your location and urgency. They typically work with reliable logistics partners to ensure timely delivery. Be sure to discuss shipping costs, delivery timelines, and customs handling during your negotiations to avoid unexpected delays or charges. -

What should I look for when vetting a leather jacket supplier?

When vetting a supplier, assess their manufacturing capabilities, product quality, and customer service reputation. Request references or case studies from previous international buyers. Evaluate their responsiveness during communication and willingness to provide samples. Additionally, check for certifications or compliance with international trade standards, which can indicate reliability and professionalism. -

What quality assurance measures are in place at San Diego Leather Jacket Factory?

San Diego Leather Jacket Factory implements several quality assurance measures, including thorough inspections at various stages of production. They utilize high-grade materials and conduct tests on finished products to ensure durability and craftsmanship. Request detailed information about their QA processes and any certifications they hold, which can further assure you of their commitment to quality. -

Can I return or exchange items if they don’t meet my expectations?

Return and exchange policies at San Diego Leather Jacket Factory may vary based on the type of product and customization. Generally, standard items may be returnable within a specific timeframe if they are unused and in original condition. Customized items may have stricter return policies. It is advisable to clarify these terms before placing your order to understand your options in case the products do not meet your expectations.

Top 4 San Diego Leather Jacket Factory Manufacturers & Suppliers List

1. Leather.com – Key Product Categories

Domain: leather.com

Registered: 1994 (31 years)

Introduction: Key product categories include:

– Men’s Aviation Jackets (Basic, Classic, Racing, USA Made)

– Ladies Aviation Jackets (Basic, Classic, Racing, USA Made)

– Kids Aviation Jackets

– Motorcycle Jackets (Biker, Club Apparel, Classic, Racing, Padded, Vests)

– Leather Shirts (Men’s, Ladies, Airvents)

– Fabric Apparel (Men’s, Ladies, Kids)

– Leather Boots (Men’s, Ladies, Kids)

– Accessories (Saddle Bags,…

2. San Diego Leather – USA Made Jackets

Domain: sandiegoleather.com

Registered: 1998 (27 years)

Introduction: Men’s Fashion: USA Made Bomber Jackets, Airline Jackets, Police Jackets, Motorcycle Jackets, MC Vests, Club Vests, Western Vests, MC Jackets, Classic Jackets, Scooter Jackets; Imported Bomber Jackets. Ladies Fashion: USA Made Bomber Jackets, Airline Jackets, Police Jackets, Motorcycle Jackets, MC Vests, Club Vests, Western Vests, MC Jackets, Classic Jackets, Scooter Jackets; Imported Bomber Jacket…

3. &Jacket – San Diego Leather Jacket

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: San Diego Leather Jacket available in various styles including Bomber, Varsity, Motorcycle, and Biker. Sizes range from XS to 5XL, including Big & Tall options. Colors include Black, Blue, Brown, Gold, Multicolor, Orange, Red, White, and Yellow. Brands featured include &Jacket, Flight, Golden Bear, Hard Rock, Infinity, NFL, Pro-player, and Unbranded. Lining materials vary with options like Leather…

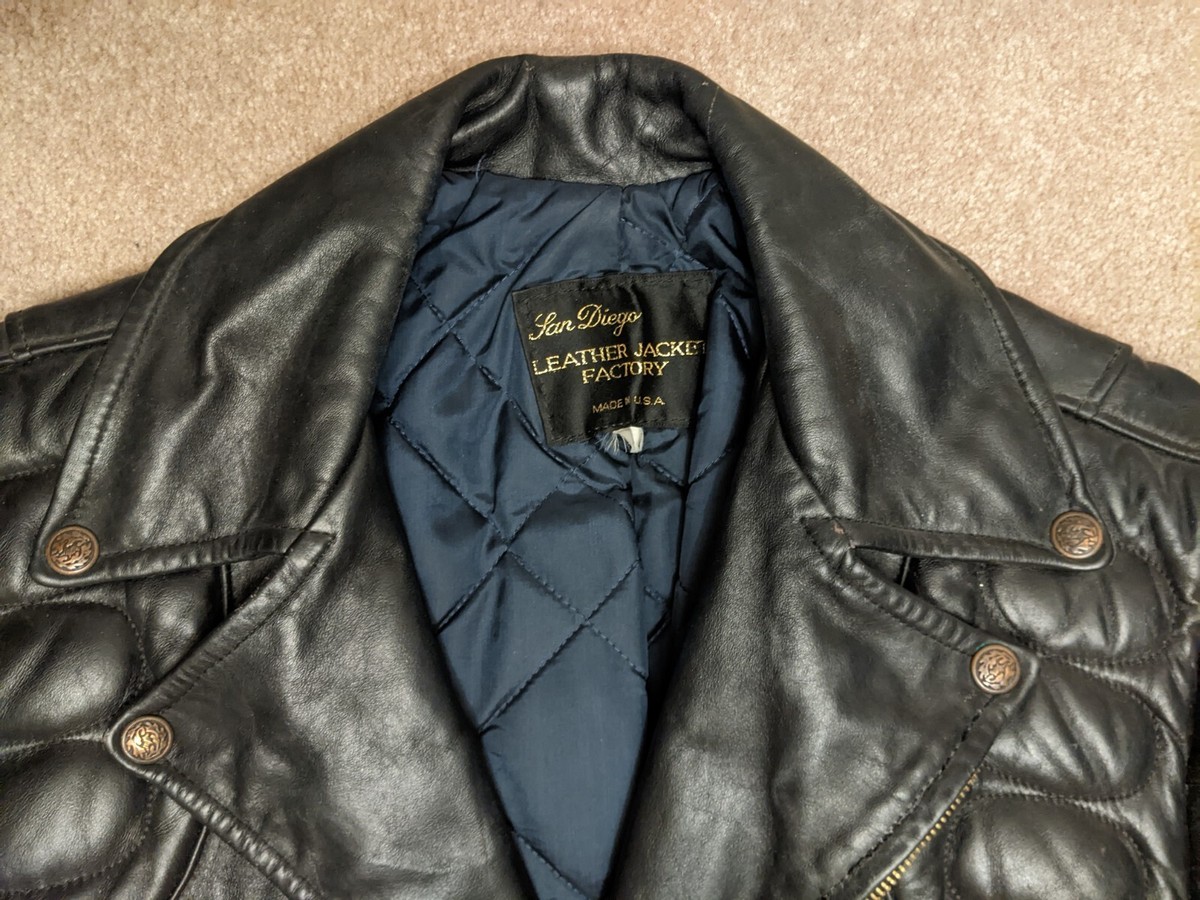

4. Vintage San Diego – Heavy Leather Jacket

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Vintage San Diego Leather Factory Leather Jacket, Made in USA, YKK Zippers, Heavy Duty Snaps, Weighs 5lb, Very Heavy Leather, No Belt Style, Conditioned with Doc Baileys Black Conditioner.

Strategic Sourcing Conclusion and Outlook for san diego leather jacket factory

In the evolving landscape of leather apparel, the San Diego Leather Jacket Factory stands out as a premier source for high-quality products tailored to diverse market needs. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage the factory’s extensive catalog, which includes custom-made jackets, motorcycle gear, and fashion apparel. The facility’s commitment to quality craftsmanship and responsiveness to market demands offers a strategic advantage for businesses seeking to enhance their product offerings.

Illustrative image related to san diego leather jacket factory

Strategic sourcing from San Diego Leather Jacket Factory not only ensures access to premium leather goods but also enables partnerships that foster innovation and sustainability. The factory’s focus on USA-made products aligns with global trends favoring ethical sourcing, appealing to conscious consumers across various markets.

As you consider your sourcing options, now is the opportune moment to engage with the San Diego Leather Jacket Factory. By tapping into their expertise and expansive inventory, you can position your business at the forefront of the leather apparel market. Explore the potential for collaboration and elevate your brand with quality leather products that resonate with your target audience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to san diego leather jacket factory