Introduction: Navigating the Global Market for custom patches for leather vest

In today’s competitive landscape, sourcing custom patches for leather vests presents a unique challenge for international B2B buyers. As the demand for personalized and branded apparel grows across Africa, South America, the Middle East, and Europe—particularly in markets like Germany and Nigeria—businesses must navigate a complex web of supplier options, quality standards, and pricing structures. This guide aims to simplify that journey, offering a comprehensive overview of the types of custom patches available, their various applications, and essential supplier vetting processes.

From embroidered designs that capture a brand’s identity to heat-sealed options that ensure durability, buyers will discover the nuances of each type of patch. We will also delve into critical considerations such as production costs, lead times, and logistical challenges that can arise when sourcing internationally. By providing actionable insights and best practices, this guide empowers B2B buyers to make informed purchasing decisions that align with their business objectives.

Whether you’re a retailer looking to enhance your product offerings or a manufacturer seeking reliable suppliers, understanding the global market for custom patches is vital. This resource will equip you with the knowledge needed to choose the right partners and products, ultimately driving your business’s success in this dynamic and evolving market.

Table Of Contents

- Top 3 Custom Patches For Leather Vest Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom patches for leather vest

- Understanding custom patches for leather vest Types and Variations

- Key Industrial Applications of custom patches for leather vest

- 3 Common User Pain Points for ‘custom patches for leather vest’ & Their Solutions

- Strategic Material Selection Guide for custom patches for leather vest

- In-depth Look: Manufacturing Processes and Quality Assurance for custom patches for leather vest

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom patches for leather vest’

- Comprehensive Cost and Pricing Analysis for custom patches for leather vest Sourcing

- Alternatives Analysis: Comparing custom patches for leather vest With Other Solutions

- Essential Technical Properties and Trade Terminology for custom patches for leather vest

- Navigating Market Dynamics and Sourcing Trends in the custom patches for leather vest Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom patches for leather vest

- Strategic Sourcing Conclusion and Outlook for custom patches for leather vest

- Important Disclaimer & Terms of Use

Understanding custom patches for leather vest Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Embroidered Patches | High durability with intricate designs; customizable thread colors | Motorcycle clubs, promotional events, branding | Pros: Long-lasting, visually appealing. Cons: Higher production time and cost. |

| PVC Patches | Made from flexible, waterproof material; vibrant colors | Outdoor events, military applications, casual wear | Pros: Weather-resistant, easy to clean. Cons: Limited design complexity compared to embroidery. |

| Woven Patches | Lightweight with a flat design; suitable for detailed logos | Fashion brands, corporate uniforms, merchandise | Pros: Cost-effective for bulk orders. Cons: Less tactile appeal than embroidered patches. |

| Leather Patches | Authentic leather feel; often used for rugged aesthetics | Custom motorcycle gear, artisan crafts, luxury brands | Pros: Unique texture, premium look. Cons: Higher cost, less flexibility in design. |

| Heat Transfer Patches | Applied using heat; allows for full-color designs | Sports teams, fashion labels, event promotions | Pros: Quick application, vibrant colors. Cons: May not be as durable as sewn options. |

What Are Embroidered Patches and Their B2B Suitability?

Embroidered patches are a popular choice for their durability and visual appeal. These patches feature intricate designs that are stitched onto a fabric base, allowing for a wide range of customization in terms of thread colors and patterns. B2B buyers often favor embroidered patches for motorcycle clubs and promotional events due to their robust nature and ability to withstand wear and tear. However, the production process can be time-consuming and may incur higher costs, making it essential for buyers to plan their orders in advance.

Illustrative image related to custom patches for leather vest

How Do PVC Patches Stand Out for Outdoor Applications?

PVC patches are known for their flexibility and waterproof qualities, making them ideal for outdoor events and military applications. These patches are vibrant and easy to clean, which appeals to businesses looking for low-maintenance branding solutions. B2B buyers in sectors like outdoor gear and casual wear often choose PVC patches for their practicality. However, it’s important to note that while PVC patches are weather-resistant, they may not offer the same level of design intricacy as embroidered options.

What Advantages Do Woven Patches Offer for Bulk Orders?

Woven patches are lightweight and feature a flat design, making them suitable for detailed logos and intricate graphics. They are particularly appealing to fashion brands and corporate uniforms, where a polished look is essential. B2B buyers appreciate woven patches for their cost-effectiveness, especially when ordering in bulk. However, the tactile appeal may be less pronounced compared to embroidered patches, which could influence brand perception.

Why Choose Leather Patches for a Premium Aesthetic?

Leather patches provide an authentic and rugged aesthetic, making them a preferred choice for custom motorcycle gear and artisan crafts. Their unique texture and premium appearance can enhance the perceived value of products, appealing to luxury brands. B2B buyers should consider the higher cost associated with leather patches and the limitations on design flexibility. However, the distinctive look can justify the investment for brands aiming to create a strong identity.

What Are the Benefits and Limitations of Heat Transfer Patches?

Heat transfer patches allow for full-color designs and can be applied quickly, making them an excellent option for sports teams and fashion labels. These patches are ideal for event promotions where rapid production is necessary. B2B buyers benefit from the vibrant colors and ease of application, but they should be aware that heat transfer patches may not be as durable as sewn options. This consideration is crucial for brands that require long-lasting solutions.

Illustrative image related to custom patches for leather vest

Key Industrial Applications of custom patches for leather vest

| Industry/Sector | Specific Application of custom patches for leather vest | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

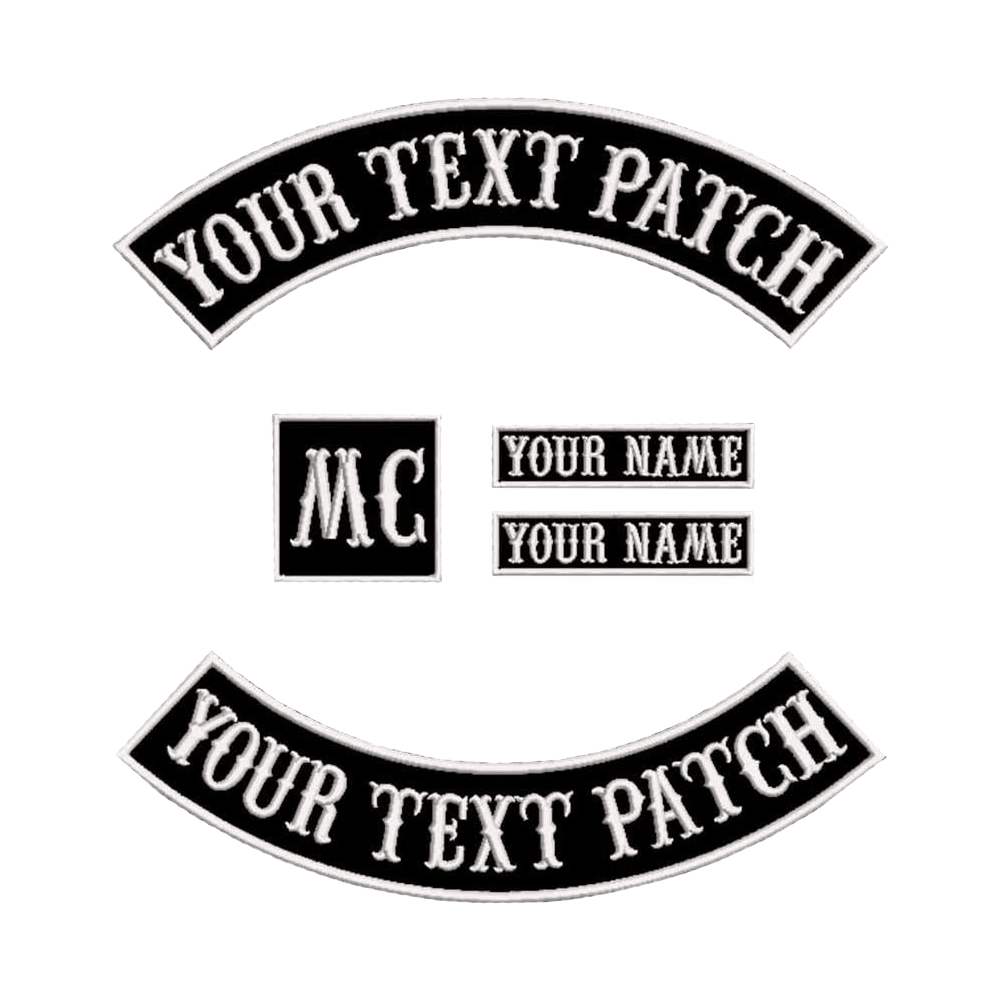

| Motorcycle Clubs | Identification and branding of club members and affiliations | Enhances community sense and visibility | Quality of embroidery, customization options, and durability |

| Fashion and Apparel Retailers | Unique fashion statements and brand representation | Differentiates product lines and attracts customers | Design flexibility, material quality, and production timelines |

| Military and Tactical Gear | Customization for uniforms and personal identification | Boosts morale and fosters unit cohesion | Compliance with military standards, customization capabilities |

| Promotional Events and Marketing | Promotional giveaways or merchandise for events | Increases brand awareness and customer loyalty | Cost-effectiveness, design options, and delivery speed |

| Automotive Customization | Personalization of leather vests for car clubs or enthusiasts | Appeals to niche markets and enhances customer engagement | Material compatibility, design intricacy, and durability under outdoor conditions |

How Are Custom Patches for Leather Vests Used in Motorcycle Clubs?

In the motorcycle club sector, custom patches serve as vital identifiers, showcasing club membership and affiliation. These patches often feature unique designs, logos, and colors that signify the club’s identity and values. For international buyers, particularly from regions like Africa and Europe, sourcing high-quality patches that withstand outdoor conditions while maintaining vibrant colors is crucial. Buyers should consider embroidery quality and the ability to customize designs to ensure they resonate with club members and enhance community pride.

What Role Do Custom Patches Play in Fashion and Apparel Retail?

Fashion retailers leverage custom patches for leather vests to create distinctive fashion statements. These patches can be used to brand products, introduce limited edition collections, or enhance existing apparel lines. For B2B buyers in South America and the Middle East, it is essential to source patches that align with current fashion trends and consumer preferences. Key considerations include the flexibility of design options, material quality, and the speed of production to meet market demands.

How Are Custom Patches Utilized in Military and Tactical Gear?

In the military and tactical sectors, custom patches are crucial for identifying units and enhancing the personalization of uniforms. These patches can include rank insignias, unit logos, and morale patches that foster unit pride and cohesion. Buyers from regions with active military engagements, such as the Middle East, must ensure that patches comply with military standards and are durable enough for rugged use. Sourcing partners should provide options for customization while maintaining high-quality production standards.

What Benefits Do Custom Patches Offer for Promotional Events?

Custom patches are often utilized as promotional items during events, serving as merchandise that boosts brand visibility and customer engagement. They can be given away or sold, helping to create a lasting impression on attendees. B2B buyers in Europe and Africa should focus on cost-effectiveness and design options to maximize return on investment. Timely delivery and the ability to produce patches in bulk are also vital considerations to ensure promotional efforts align with event schedules.

How Do Automotive Enthusiasts Use Custom Patches?

Automotive customization enthusiasts often use custom patches to personalize leather vests that showcase their passion for specific car brands or clubs. These patches help build a sense of belonging within niche markets, appealing to car enthusiasts who value individuality. Buyers from regions like South America should prioritize material compatibility with leather and the durability of the patches, especially for outdoor use. Sourcing partners should offer intricate design capabilities to cater to the unique aesthetics of automotive culture.

3 Common User Pain Points for ‘custom patches for leather vest’ & Their Solutions

Scenario 1: Quality Assurance in Custom Patch Production

The Problem: B2B buyers often struggle with ensuring the quality of custom patches for leather vests, particularly when sourcing from international suppliers. The risk of receiving low-quality patches that fray easily, lose color, or do not adhere properly to leather can result in significant financial losses and damage to their brand reputation. This challenge is compounded by the lack of standardized quality checks across different suppliers, leading to inconsistency in product quality.

The Solution: To mitigate quality concerns, buyers should establish a comprehensive sourcing strategy that includes rigorous supplier vetting. Start by requesting samples from potential manufacturers to evaluate the quality of the embroidery, material, and adhesion methods used. Collaborate closely with suppliers to communicate specific quality standards, including thread count, fabric types, and adherence techniques. Additionally, consider implementing a quality assurance process that involves periodic audits of supplier facilities to ensure compliance with the agreed standards. This proactive approach will help secure high-quality patches that align with the buyer’s expectations.

Scenario 2: Customization and Design Complexity

The Problem: Many B2B buyers face difficulties when trying to convey their design ideas for custom patches, particularly when dealing with intricate logos or multi-color designs. Miscommunication during the design phase can lead to delays, increased costs, and ultimately unsatisfactory products that do not meet the buyer’s vision. This issue is particularly pressing for businesses that require patches with specific branding elements that must reflect their identity accurately.

The Solution: To streamline the customization process, buyers should provide detailed design specifications, including color codes, size dimensions, and examples of desired styles. Utilizing design software can facilitate clearer communication by allowing buyers to create mock-ups that visually represent their ideas. Furthermore, establishing a collaborative design phase with the supplier can significantly enhance the outcome. Engage in open discussions where both parties can share feedback and make adjustments before finalizing the design. By ensuring that all design elements are clearly outlined and agreed upon, buyers can reduce the risk of errors and achieve a product that resonates with their brand identity.

Illustrative image related to custom patches for leather vest

Scenario 3: Cost Management and Budget Constraints

The Problem: Budget constraints are a common concern for B2B buyers when ordering custom patches for leather vests. The costs can quickly escalate due to factors like minimum order quantities, design complexity, and shipping fees, particularly when sourcing internationally. This financial pressure can lead to compromises on quality or design, negatively impacting the overall product and brand image.

The Solution: To effectively manage costs, buyers should adopt a strategic approach to budgeting for custom patches. First, conduct thorough market research to understand the pricing structures of different suppliers and identify competitive options. Next, consider consolidating orders to meet minimum quantities while maximizing cost efficiency. Additionally, explore the possibility of negotiating pricing based on long-term partnerships or bulk orders. When discussing pricing with suppliers, be transparent about budget constraints and seek their advice on cost-saving measures, such as simplified designs or alternative materials that still meet quality standards. By taking these steps, buyers can maintain their budget without sacrificing the quality and impact of their custom patches.

Strategic Material Selection Guide for custom patches for leather vest

What Are the Key Materials for Custom Patches for Leather Vests?

When selecting materials for custom patches for leather vests, it’s essential to consider various factors such as durability, cost, and compatibility with the leather. Below, we analyze four common materials used in the production of these patches, focusing on their properties, advantages and disadvantages, and specific considerations for international buyers.

Illustrative image related to custom patches for leather vest

How Does Embroidered Thread Perform in Custom Patches?

Embroidered thread, typically made from polyester or rayon, is a popular choice for custom patches due to its vibrant colors and durability. Polyester threads are known for their resistance to fading and moisture, making them suitable for outdoor use. However, rayon threads offer a softer finish and a luxurious sheen, which might appeal to certain aesthetic preferences.

Pros: Embroidered patches exhibit excellent durability and can withstand washing and wear. They also provide a high-quality appearance that enhances branding.

Cons: The manufacturing process can be complex, requiring specialized machinery. Additionally, while polyester is generally cost-effective, rayon can be more expensive.

Impact on Application: Embroidered threads are compatible with various media, including leather, cotton, and synthetic fabrics, making them versatile for different vest styles.

Considerations for International Buyers: Compliance with international standards such as ASTM for textile materials is crucial. Buyers from regions like Europe may prefer eco-friendly materials, while buyers in Africa and South America might prioritize cost-effectiveness.

Illustrative image related to custom patches for leather vest

What Role Does PVC Play in Custom Patches?

Polyvinyl chloride (PVC) is often used for patches that require a waterproof and weather-resistant option. PVC patches can be molded into various shapes, offering flexibility in design.

Pros: PVC patches are highly durable, resistant to UV light, and easy to clean. They are ideal for outdoor activities and can withstand harsh weather conditions.

Cons: While PVC is generally cost-effective, it may not offer the same aesthetic appeal as embroidered options. Additionally, the manufacturing process can involve more steps, potentially increasing lead times.

Impact on Application: PVC patches are suitable for leather vests used in rugged environments, as they are less likely to degrade compared to fabric options.

Considerations for International Buyers: Buyers should be aware of environmental regulations regarding PVC usage, especially in Europe, where there are strict guidelines on plastic materials.

Why Choose Leather for Custom Patches?

Leather patches provide a classic and rugged look, making them a favorite for biker vests. They can be made from genuine leather or synthetic alternatives, each offering unique benefits.

Illustrative image related to custom patches for leather vest

Pros: Leather patches are durable and can withstand significant wear and tear. They also provide a premium appearance that resonates well with the biker community.

Cons: Genuine leather can be more expensive and may require special care to maintain its appearance. Synthetic leather, while cheaper, might not have the same durability.

Impact on Application: Leather patches are particularly compatible with leather vests, providing a cohesive look and feel.

Illustrative image related to custom patches for leather vest

Considerations for International Buyers: Buyers in Europe may need to consider compliance with animal welfare standards when sourcing genuine leather, while buyers in Africa may find synthetic options more accessible and cost-effective.

How Do Woven Patches Compare?

Woven patches are created by weaving threads together, resulting in a flat, detailed design. They are often used for logos and intricate designs.

Pros: Woven patches can capture fine details and are generally more cost-effective than embroidered patches. They are also durable and can withstand washing.

Cons: While they are suitable for detailed designs, woven patches may lack the three-dimensional quality of embroidered patches.

Impact on Application: These patches are versatile and can be applied to various fabrics, including leather, making them suitable for custom vests.

Illustrative image related to custom patches for leather vest

Considerations for International Buyers: It is essential to ensure that the manufacturing processes adhere to local labor laws and environmental regulations, particularly in regions with stringent compliance standards.

Summary Table of Material Selection for Custom Patches

| Material | Typical Use Case for custom patches for leather vest | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Embroidered Thread | General patches for branding and aesthetics | High durability and vibrant colors | Complex manufacturing process | Medium |

| PVC | Outdoor and rugged use patches | Waterproof and UV resistant | Less aesthetic appeal | Low |

| Leather | Premium patches for a classic look | Durable and premium appearance | Higher cost and care requirements | Hoch |

| Gewebt | Detailed logos and designs | Cost-effective and detailed | Lacks three-dimensional quality | Medium |

This strategic material selection guide aims to provide B2B buyers with actionable insights into the various materials available for custom patches, ensuring informed purchasing decisions that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom patches for leather vest

What Are the Main Stages in the Manufacturing Process of Custom Patches for Leather Vests?

The manufacturing process for custom patches tailored for leather vests involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the final product meets quality standards and customer specifications.

Material Preparation: The first step involves selecting high-quality materials suitable for patches, such as durable fabrics, threads, and backing materials. Common choices include twill, felt, and embroidered threads. The selection process should consider factors like durability, colorfastness, and texture to ensure the patches can withstand wear and tear, particularly in rugged environments. Pre-shrinking fabrics is also essential to prevent distortion during the manufacturing process.

Forming: During the forming stage, the design is digitized and transformed into a format suitable for embroidery machines. This process involves creating a digital file that dictates how the patch will be stitched. Key techniques include embroidery, screen printing, and heat transfer, depending on the complexity and desired finish of the patch. Advanced embroidery techniques, like 3D puff embroidery, can add depth and texture, enhancing the visual appeal of the patches.

Illustrative image related to custom patches for leather vest

Assembly: In the assembly stage, patches are cut, sewn, or otherwise constructed according to the design specifications. This may involve layering different materials, applying heat seal backing for easy application, and ensuring all components are securely attached. Hand finishing is often employed for intricate designs, where attention to detail is paramount. Quality control checkpoints are crucial during assembly to catch any discrepancies early in the process.

Finishing: The final stage involves trimming excess material, applying additional treatments (like water resistance), and packaging the patches for shipment. This stage not only ensures the patches look polished but also prepares them for transport. Proper packaging is essential for preventing damage during shipping, especially for international orders.

How Is Quality Assurance Implemented in Custom Patch Manufacturing?

Quality assurance (QA) is vital to maintaining high standards in custom patch production. Implementing a robust QA process involves adhering to international standards and conducting thorough checks throughout the manufacturing stages.

Relevant International Standards: Many manufacturers adhere to ISO 9001, which outlines requirements for a quality management system. This standard emphasizes continuous improvement and customer satisfaction, making it essential for suppliers targeting international markets. Additionally, other industry-specific certifications, such as CE marking for products sold in Europe or API standards for quality assurance in textiles, may apply.

Quality Control Checkpoints: Effective QA involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Suppliers should verify the specifications of fabrics, threads, and other materials against industry standards to ensure they meet required quality levels.

-

In-Process Quality Control (IPQC): During production, regular inspections are necessary to monitor the stitching, color accuracy, and adherence to design specifications. This step helps identify and rectify issues before the patches reach the finishing stage.

-

Final Quality Control (FQC): Once production is complete, a final inspection is conducted to check for defects, ensure the patches meet design specifications, and confirm that packaging is appropriate for shipping. This step is crucial for maintaining customer satisfaction and minimizing returns.

What Common Testing Methods Are Used in Quality Assurance for Custom Patches?

Several testing methods are commonly employed to evaluate the quality of custom patches. These methods help ensure that the patches will perform well under various conditions.

-

Durability Testing: This involves subjecting patches to stress tests that simulate wear and tear. Common tests include abrasion resistance, tensile strength, and colorfastness under various environmental conditions (e.g., UV light exposure, washing).

-

Adhesion Testing: For patches with heat seal backing, adhesion testing is crucial to ensure that the patches will stay securely attached to leather vests. This test checks the bond strength between the patch and the leather after exposure to heat and pressure.

-

Visual Inspection: A thorough visual inspection is performed to check for defects such as loose threads, uneven stitching, or color discrepancies. This step is often the last line of defense before patches are shipped.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability and compliance with standards.

Illustrative image related to custom patches for leather vest

Conducting Audits: One of the most effective ways to verify a supplier’s quality control practices is through on-site audits. Buyers can assess the manufacturing environment, review quality control documentation, and observe production processes firsthand. This direct engagement can provide valuable insights into the supplier’s commitment to quality.

Requesting Quality Reports: Buyers should request quality assurance reports that detail the testing methods used, results obtained, and any corrective actions taken. These documents can offer transparency into the supplier’s processes and help buyers make informed decisions.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can conduct random inspections of production batches, ensuring that the products meet specified standards before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control and certification when sourcing custom patches.

Understanding Regional Standards: Different regions may have varying standards and regulations. For example, European buyers may prioritize CE marking, while buyers in other regions might focus on different certifications. Familiarizing oneself with the relevant standards in the target market is crucial for ensuring compliance.

Cultural Considerations in Quality Expectations: Buyers from different cultural backgrounds may have unique expectations regarding quality and customer service. Understanding these nuances can aid in establishing effective communication and fostering strong relationships with suppliers.

Illustrative image related to custom patches for leather vest

Logistical Challenges: International shipping can introduce additional complexities in quality assurance. Buyers should consider how transportation methods and environmental conditions may affect the integrity of the patches during transit. Engaging suppliers who offer robust packaging solutions and shipping insurance can help mitigate these risks.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols is essential for B2B buyers in the custom patch market. By focusing on quality at every stage, from material selection to final inspection, suppliers can meet the diverse needs of international clients while ensuring product reliability and satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom patches for leather vest’

In the competitive landscape of custom patches for leather vests, B2B buyers must navigate various considerations to ensure they procure high-quality products that meet their specific needs. This guide provides a clear, step-by-step checklist to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as patch size, design complexity, embroidery techniques, and the type of backing (e.g., heat seal or sew-on). This clarity will help suppliers understand your requirements and deliver products that align with your brand’s vision.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom patches. Look for manufacturers with a strong reputation in the industry and a portfolio showcasing their work. Utilize B2B platforms, trade shows, and industry forums to gather insights about potential partners.

Illustrative image related to custom patches for leather vest

- Key Considerations:

- Check online reviews and testimonials.

- Verify the supplier’s experience with similar projects.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; instead, engage in direct communication to gauge their responsiveness and willingness to collaborate.

- Questions to Ask:

- What is your production lead time?

- Can you provide samples of previous work?

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, minimum order quantities, and delivery timelines. A comprehensive quote should include any additional costs such as shipping, taxes, or customization fees.

- Checklist for Quotes:

- Compare pricing against your budget.

- Ensure all components of the order are included.

Step 5: Assess Quality Control Measures

Quality assurance is paramount when sourcing custom patches. Inquire about the supplier’s quality control processes, including material sourcing, production techniques, and final inspections. Understanding these measures can help ensure that the patches meet your quality standards.

Illustrative image related to custom patches for leather vest

- Important Factors:

- Are materials sourced sustainably?

- What is the process for handling defects or errors?

Step 6: Review Shipping and Return Policies

Understanding shipping logistics and return policies is critical for a smooth transaction. Confirm the shipping methods, estimated delivery times, and costs associated with shipping. Additionally, clarify the return policy in case the products do not meet your expectations or arrive damaged.

- Key Points to Confirm:

- Is shipping insurance available?

- What are the conditions for returning custom items?

Step 7: Finalize the Order and Maintain Communication

After selecting a supplier, finalize your order while ensuring that all specifications are confirmed in writing. Maintain open communication throughout the production process to address any potential issues promptly. This proactive approach fosters a strong partnership and can lead to better outcomes in future orders.

By following this checklist, B2B buyers can streamline their procurement process for custom patches for leather vests, ensuring they find reliable suppliers who deliver high-quality products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for custom patches for leather vest Sourcing

What Are the Key Cost Components in Custom Patches for Leather Vests?

When sourcing custom patches for leather vests, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of fabric, thread, and backing significantly impacts costs. High-quality embroidery threads and durable fabrics such as twill or felt often lead to higher prices but result in superior patches. For instance, patches with heat seal backing or specialized finishes may incur additional material costs.

-

Labor: Labor costs vary depending on the complexity of the design and the skill level required. Handcrafted patches, which demand more intricate attention, will naturally cost more than machine-produced alternatives.

-

Manufacturing Overhead: This includes expenses related to running the production facility, such as utilities and rent. Efficient manufacturing processes can help minimize these costs, which is beneficial for bulk orders.

-

Tooling: If the design requires custom tools or molds, these costs should be factored in. While one-time tooling fees can be high, they are amortized over larger production runs.

-

Quality Control (QC): Investing in quality control ensures that the final products meet the required standards. This may involve additional labor and inspection processes, which can add to the overall cost.

-

Logistics: Shipping costs are influenced by the weight and volume of the patches, as well as the delivery location. International shipping may incur tariffs and duties, impacting the total cost.

-

Margin: Suppliers will apply a markup to cover their costs and ensure profitability. Understanding the average margin in the industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Custom Patch Costs?

Several factors influence the pricing of custom patches, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on their anticipated order volumes.

-

Specifications/Customization: The complexity of the design—such as multiple colors, sizes, and shapes—can drive up costs. Customization options, like unique backing or finishes, also contribute to the final price.

-

Materials: The choice of high-end materials will increase costs. Buyers should balance quality with their budget, considering that cheaper materials may lead to lower durability.

-

Quality and Certifications: Patches that meet specific industry standards or certifications may come at a premium. Buyers should assess whether these certifications add value to their offerings.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Established suppliers may charge more due to their experience and reliability.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Incoterms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Tips Can Help Buyers Optimize Cost Efficiency?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiation: Engage in discussions with suppliers regarding pricing, especially for bulk orders. Highlighting long-term relationships may yield better terms.

-

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase price, shipping, handling, and potential returns. This holistic view can help in making more informed decisions.

-

Pricing Nuances: Be aware of regional pricing differences and currency fluctuations. Understanding local market conditions can aid in negotiating better deals.

-

Supplier Relationships: Building strong relationships with reliable suppliers can lead to preferential pricing and terms over time.

Disclaimer

Prices for custom patches can vary widely based on the factors outlined above. The figures mentioned are indicative and may change based on market conditions, specific requirements, and supplier negotiations. Always conduct thorough market research and supplier evaluations to ensure competitive pricing and quality standards.

Alternatives Analysis: Comparing custom patches for leather vest With Other Solutions

Exploring Alternative Solutions to Custom Patches for Leather Vests

When considering custom patches for leather vests, it’s essential to evaluate other viable solutions that could meet similar needs. Alternatives can provide unique benefits, from cost savings to different aesthetic options, allowing B2B buyers to make informed decisions tailored to their specific requirements. This analysis will compare custom patches with embroidered logos and screen-printed designs, exploring their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Custom Patches For Leather Vest | Embroidered Logos | Screen-Printed Designs |

|---|---|---|---|

| Performance | High durability; resistant to wear | Excellent quality; can handle washing | Varies; may fade or peel over time |

| Cost | Moderate to high; depends on customization | Generally higher due to complexity | Lower initial cost; bulk discounts available |

| Ease of Implementation | Requires sewing; can be complex | Usually straightforward; machine or hand-stitched | Easy application; can be done quickly |

| Wartung | Low; durable and withstands cleaning | Moderate; may require special care | Low; easy to clean but may wear out |

| Best Use Case | Personalization for clubs and events | Branding for companies; high visibility | Large-scale promotional events; cost-effective |

Understanding the Pros and Cons of Alternatives

Embroidered Logos

Embroidered logos offer a sophisticated appearance, making them ideal for companies seeking to enhance their branding efforts. They are typically made using high-quality materials that ensure longevity, but the complexity of the embroidery process can lead to higher costs. Additionally, while they are durable, embroidered items may require special care when washing, limiting their practicality in some scenarios. They are best suited for businesses looking to make a strong visual impact with their branding, particularly in corporate settings.

Illustrative image related to custom patches for leather vest

Screen-Printed Designs

Screen printing is a cost-effective alternative for those looking to produce items in bulk. This method allows for vibrant colors and complex designs, making it appealing for promotional events or merchandise. However, the longevity of screen-printed items can be a concern, as the designs may fade or peel over time, particularly with frequent washing. Maintenance is minimal, as these items can be easily cleaned, but businesses should be aware that they might need to replace them more often than other options. Screen printing is ideal for events where cost-efficiency is crucial, and the designs do not require high durability.

Making the Right Choice for Your Business Needs

In conclusion, the selection of custom patches for leather vests versus alternatives like embroidered logos and screen-printed designs depends on various factors, including budget, desired durability, and specific use cases. B2B buyers should evaluate their branding objectives, the environments in which the products will be used, and the importance of aesthetics versus cost. Ultimately, the right choice will align with the organization’s goals and ensure that the selected solution delivers value and meets the expectations of their target audience.

Essential Technical Properties and Trade Terminology for custom patches for leather vest

What Are the Key Technical Properties of Custom Patches for Leather Vests?

When sourcing custom patches for leather vests, understanding the technical specifications is crucial for ensuring product quality and suitability for your specific needs. Here are several essential properties that should be considered:

Material Grade

The material used in patches can significantly affect their durability and appearance. Common materials include twill, felt, and embroidered threads. Twill is often chosen for its robustness and resistance to wear, while felt provides a softer texture. Selecting the right material grade ensures that the patch can withstand environmental elements, especially for outdoor activities, and maintains its aesthetic appeal over time.

Thread Count

Thread count refers to the number of threads woven into the fabric of the patch. Higher thread counts generally indicate better quality and more intricate designs. This property is essential for achieving detailed logos or images, making it vital for brands that require high-definition representations of their identity.

Adhesive Backing

The backing of a patch can come in various forms, including heat seal, iron-on, or sew-on options. Heat seal backing is popular for its ease of application, while sew-on patches offer greater durability for high-movement applications. Understanding the adhesive options helps in selecting the right patch for the intended use, ensuring that it remains securely attached to the leather vest.

Size and Tolerance

Custom patches can vary in size, and it is essential to specify exact dimensions when placing an order. Tolerances typically refer to the acceptable range of deviation from the specified size. This property is crucial for ensuring that patches fit perfectly on designated areas of the vest, enhancing the overall appearance and functionality.

Colorfastness

Colorfastness measures how well a patch retains its color when exposed to various conditions such as washing, sunlight, and abrasion. It is vital for ensuring that the patches maintain their visual integrity over time, especially for products that may undergo frequent cleaning or be exposed to harsh environments.

What Are Common Trade Terms in the Custom Patch Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms associated with custom patches:

Illustrative image related to custom patches for leather vest

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold by another company under its brand name. In the context of custom patches, an OEM can provide specialized patches that meet specific design and quality standards, allowing businesses to leverage established manufacturing capabilities.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products that a supplier is willing to produce or sell. Understanding the MOQ is critical for budget planning and inventory management, as it may influence the decision to source patches from a particular supplier.

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. When sourcing custom patches, submitting an RFQ helps buyers obtain competitive pricing and detailed specifications from multiple suppliers, facilitating informed decision-making.

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps businesses understand shipping costs, risks, and responsibilities, ensuring smoother logistics and compliance during international transactions.

Lead Time

Lead time refers to the amount of time taken from placing an order to its delivery. Understanding lead times is crucial for inventory management, especially when timing is essential for events or promotions. Buyers should inquire about lead times during negotiations to ensure timely delivery of custom patches.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom patches for leather vests, ultimately leading to better partnerships and product outcomes.

Navigating Market Dynamics and Sourcing Trends in the custom patches for leather vest Sector

What Are the Current Market Dynamics and Key Trends in Custom Patches for Leather Vests?

The custom patches for leather vests market is experiencing significant growth, driven by a surge in personalized fashion and the rising popularity of motorcycling culture. As consumers seek unique ways to express their identity, the demand for custom patches has escalated. Key trends include the increasing use of high-quality embroidery techniques and innovative designs that resonate with specific cultural and regional aesthetics. B2B buyers are particularly interested in sourcing patches that not only fulfill aesthetic needs but also reflect the values of their target markets, including those from Africa, South America, the Middle East, and Europe.

Illustrative image related to custom patches for leather vest

Emerging technologies such as digital printing and 3D embroidery are reshaping the production landscape. This allows manufacturers to offer quicker turnaround times and greater customization options. Additionally, the rise of e-commerce platforms has enabled international buyers to access a wider range of suppliers and products, facilitating easier price comparisons and supplier evaluations. Importantly, buyers are increasingly prioritizing suppliers who can demonstrate flexibility in order quantities and customization capabilities, catering to both small-scale and bulk orders.

Furthermore, market dynamics are influenced by changing consumer preferences towards vintage and retro styles, which are often incorporated into patch designs. In regions like Germany and Nigeria, where motorcycling is both a lifestyle and a cultural statement, the integration of local symbols and narratives into patch designs is becoming increasingly relevant. As a result, B2B buyers are encouraged to stay attuned to these evolving trends to effectively cater to their clientele’s demands.

How Can Sustainability and Ethical Sourcing Impact the Custom Patches Market?

The growing emphasis on sustainability and ethical sourcing is reshaping the landscape of the custom patches for leather vests market. Environmental concerns, particularly regarding the impact of textile production on ecosystems, are prompting buyers to seek out suppliers who prioritize sustainable practices. This includes the use of eco-friendly materials, such as organic cotton or recycled polyester, which are gaining traction in the production of patches.

Furthermore, ethical supply chains are becoming a critical consideration for B2B buyers. Many consumers are increasingly aware of labor practices and the environmental footprint of the products they purchase. This shift is leading buyers to partner with manufacturers who can provide transparency in their sourcing and production processes. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

By aligning with suppliers that prioritize sustainability, international buyers can enhance their brand reputation and appeal to environmentally conscious consumers. This alignment not only fulfills corporate social responsibility goals but also positions businesses favorably in competitive markets, particularly in regions where sustainability is a key purchasing factor, such as Europe.

What Is the Brief Evolution of Custom Patches for Leather Vests?

The evolution of custom patches for leather vests can be traced back to the early days of motorcycle culture, where patches served as symbols of affiliation, rank, and personal expression among riders. Initially, these patches were simple fabric designs, often hand-stitched, conveying loyalty to motorcycle clubs or commemorating rides and events. Over the decades, advancements in embroidery technology have allowed for intricate designs and a broader range of materials.

Today, custom patches are not only a staple in motorcycle apparel but have also transcended into mainstream fashion, serving as decorative elements on various clothing items. The rise of social media has further popularized the use of custom patches, with individuals showcasing their unique styles, encouraging businesses to innovate and expand their offerings. This historical context underscores the importance of understanding consumer sentiment and cultural significance when sourcing custom patches, ensuring that designs resonate with target audiences across diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of custom patches for leather vest

-

How do I ensure the quality of custom patches for leather vests?

To ensure the quality of custom patches, start by selecting suppliers with a strong reputation for craftsmanship and customer satisfaction. Request samples of previous work to assess the stitching, material quality, and durability. Additionally, inquire about their manufacturing processes, including the type of embroidery used and any quality assurance measures in place. Establish clear specifications for your patches, including size, colors, and materials, to ensure that the final product meets your expectations. -

What are the minimum order quantities (MOQs) for custom patches?

Minimum order quantities for custom patches can vary significantly based on the supplier and the complexity of the design. Some manufacturers may offer MOQs as low as 50 pieces, while others might require orders of 100 or more. It’s essential to discuss your needs with potential suppliers and confirm their MOQs upfront. If you require a smaller quantity, consider negotiating or exploring suppliers that specialize in small-batch production. -

What customization options are available for patches on leather vests?

Customization options for patches include size, shape, color, design, and backing materials. Suppliers may offer various embroidery techniques, such as appliqué or direct embroidery, to achieve different looks. You can also choose between different types of backing, such as heat seal or sew-on, depending on your application needs. Collaborating closely with your supplier during the design phase will help you create patches that align with your brand identity and the specific style of leather vests. -

What payment terms should I expect when sourcing custom patches?

Payment terms for custom patches typically involve an upfront deposit (usually 30-50%) before production begins, with the balance due upon completion or delivery. Some suppliers may offer flexible payment options, including letters of credit or payment upon receipt. It’s crucial to clarify payment terms with suppliers in advance to avoid misunderstandings. Additionally, consider using secure payment methods to protect your financial transactions during international trade. -

How do I vet suppliers for custom patches in international markets?

To vet suppliers, start by researching their background, customer reviews, and industry reputation. Request references and reach out to other clients to gauge their experiences. Look for suppliers with certifications or memberships in relevant industry associations, as this can indicate a commitment to quality. Additionally, consider conducting a factory visit or utilizing third-party inspection services to verify the supplier’s capabilities and production standards. -

What logistics considerations should I be aware of when sourcing custom patches internationally?

When sourcing custom patches internationally, consider shipping costs, delivery times, and customs regulations. Choose a reliable shipping partner experienced in handling international logistics to ensure timely delivery. Be aware of potential import duties and taxes that may apply to your shipment, as these can significantly impact overall costs. Establishing clear communication with your supplier regarding shipping timelines and tracking will help mitigate delays. -

What are the common challenges when sourcing custom patches for leather vests internationally?

Common challenges include language barriers, differing quality standards, and logistics issues. Ensure clear communication by using detailed specifications and visual references to minimize misunderstandings. Additionally, familiarize yourself with international trade regulations that may affect shipping and customs. Building a strong relationship with your supplier can also help address challenges more effectively, as they will be more willing to accommodate your needs. -

What is the process for returning defective custom patches?

Returning defective patches typically involves contacting your supplier within a specified timeframe, often within 30 days of receipt. You will need to provide evidence of the defect, such as photos, and details about your order. Policies vary by supplier, but many will offer replacements or refunds for defective items. Custom patches may have stricter return policies, so it’s essential to clarify these terms before placing your order to avoid complications.

Top 3 Custom Patches For Leather Vest Manufacturers & Suppliers List

1. Ninja Patches – Custom Embroidered Patches

Domain: ninjapatches.com

Registered: 2022 (3 years)

Introduction: Custom Patches for Hats & Apparel, Shipped Fast! Patches ship as fast as 5 business days with free shipping. No setup, art fees, or minimums required. Various types of patches available:

– Embroidered Patches: As low as $1.42 each, premium thread on durable fabric.

– 3D Embroidered Patches: As low as $2.31 each, raised effect for enhanced detail.

– Full Color Printed Patches: As low as $1.09…

2. Reddit – Custom Leather Jacket Patches

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom patches for leather jackets, focusing on quality over price, with potential for bulk orders. Recommendations for small businesses are sought.

3. Make My Patch – Custom Biker Vests

Strategic Sourcing Conclusion and Outlook for custom patches for leather vest

In the evolving landscape of custom patches for leather vests, strategic sourcing emerges as a pivotal factor for international B2B buyers. By aligning with reliable manufacturers who emphasize quality craftsmanship, such as those utilizing high-grade embroidery techniques and durable materials, businesses can ensure product longevity and customer satisfaction. Engaging in thorough supplier evaluations and fostering collaborative relationships can yield significant advantages, including reduced costs and enhanced customization options tailored to diverse markets.

For buyers in Africa, South America, the Middle East, and Europe, the ability to navigate global supply chains effectively is crucial. Leveraging local insights and understanding regional preferences can facilitate the creation of unique designs that resonate with target audiences. As the demand for custom patches continues to rise, particularly among motorcycle enthusiasts and fashion-forward consumers, the opportunity for growth is substantial.

Looking ahead, now is the time to take action. Explore partnerships with trusted suppliers, invest in innovative designs, and stay attuned to market trends. By doing so, businesses can position themselves to capitalize on the burgeoning demand for custom patches, ensuring not only their relevance in the market but also their leadership in the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.