Introduction: Navigating the Global Market for custom leather die

In today’s competitive landscape, sourcing custom leather die can present significant challenges for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. With the increasing demand for precision and efficiency in leather production, companies face the pressure of finding reliable suppliers who can deliver high-quality cutting dies tailored to their specific needs. This guide serves as a comprehensive resource, addressing key concerns such as the various types of custom leather dies available, their applications across different industries, and the critical factors to consider when vetting suppliers.

The scope of this guide extends beyond mere product descriptions; it offers actionable insights into cost considerations, manufacturing processes, and the importance of timely delivery in maintaining production schedules. By equipping international buyers with the knowledge to make informed purchasing decisions, this resource aims to streamline the sourcing process and enhance operational efficiency. Whether you’re based in Brazil, Nigeria, or any other region, understanding the global market dynamics for custom leather die is essential for optimizing your supply chain and ensuring the success of your leather projects. Engage with this guide to empower your sourcing strategy, mitigate risks, and ultimately drive growth in your business.

Table Of Contents

- Top 4 Custom Leather Die Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather die

- Understanding custom leather die Types and Variations

- Key Industrial Applications of custom leather die

- 3 Common User Pain Points for ‘custom leather die’ & Their Solutions

- Strategic Material Selection Guide for custom leather die

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather die

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather die’

- Comprehensive Cost and Pricing Analysis for custom leather die Sourcing

- Alternatives Analysis: Comparing custom leather die With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather die

- Navigating Market Dynamics and Sourcing Trends in the custom leather die Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather die

- Strategic Sourcing Conclusion and Outlook for custom leather die

- Important Disclaimer & Terms of Use

Understanding custom leather die Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Rule Dies | Made from steel with a cutting edge; precise cuts; durable. | High-volume production; custom shapes. | Pros: High precision, long-lasting. Cons: Higher initial cost. |

| Polycarbonate Clicker Dies | Lightweight, impact-resistant; suitable for complex shapes. | Mass production; intricate designs. | Pros: Cost-effective, versatile. Cons: Less durable than steel. |

| Laser Engraved Dies | Custom engraved patterns; high precision; suitable for branding. | Custom branding; unique product designs. | Pros: High detail, customizable. Cons: Longer lead time for production. |

| Acrylic Mount Dies | Acrylic base for easy material alignment; reduces waste. | Craft projects; small batch production. | Pros: Easy alignment, lightweight. Cons: Limited cutting depth. |

| Custom Hand-Crafted Dies | Tailored to specific designs; handmade; unique shapes. | Specialty items; artisan crafts. | Pros: Unique designs, artisanal quality. Cons: Longer production time, higher cost. |

What Are Steel Rule Dies and Their B2B Benefits?

Steel rule dies are a staple in the leather cutting industry, known for their durability and precision. Made from a steel cutting edge, these dies can cut through various materials, including leather, paper, and felt, making them ideal for high-volume production. B2B buyers should consider the initial investment, as the cost may be higher than other types. However, their long lifespan and accuracy can lead to significant savings in the long run, especially for businesses focusing on consistent quality.

How Do Polycarbonate Clicker Dies Enhance Production?

Polycarbonate clicker dies are designed for efficiency, particularly in mass production settings. They are lightweight yet durable, allowing for quick and precise cuts of intricate shapes. This type of die is particularly beneficial for businesses looking to streamline their production processes while maintaining quality. B2B buyers should weigh the cost-effectiveness of these dies against their durability, as they may not last as long as steel options, but their versatility often justifies the investment.

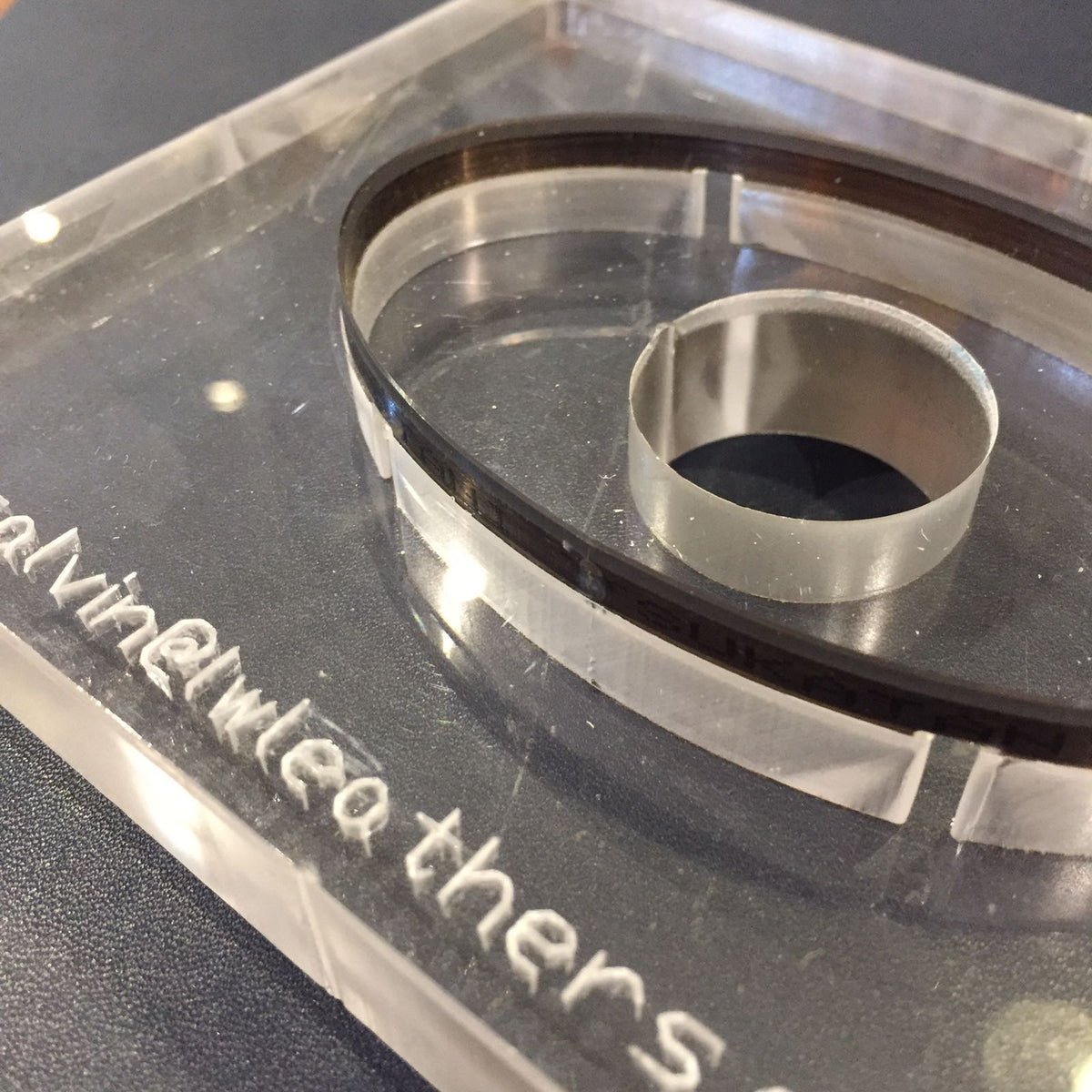

What Advantages Do Laser Engraved Dies Offer for Branding?

Laser engraved dies provide an opportunity for high precision and customization, making them ideal for branding and unique product designs. These dies can incorporate intricate patterns and logos, allowing businesses to create distinctive leather products. However, the production lead time may be longer due to the detailed nature of the engraving. B2B buyers looking for ways to enhance their brand identity through custom designs will find laser engraved dies to be a valuable asset.

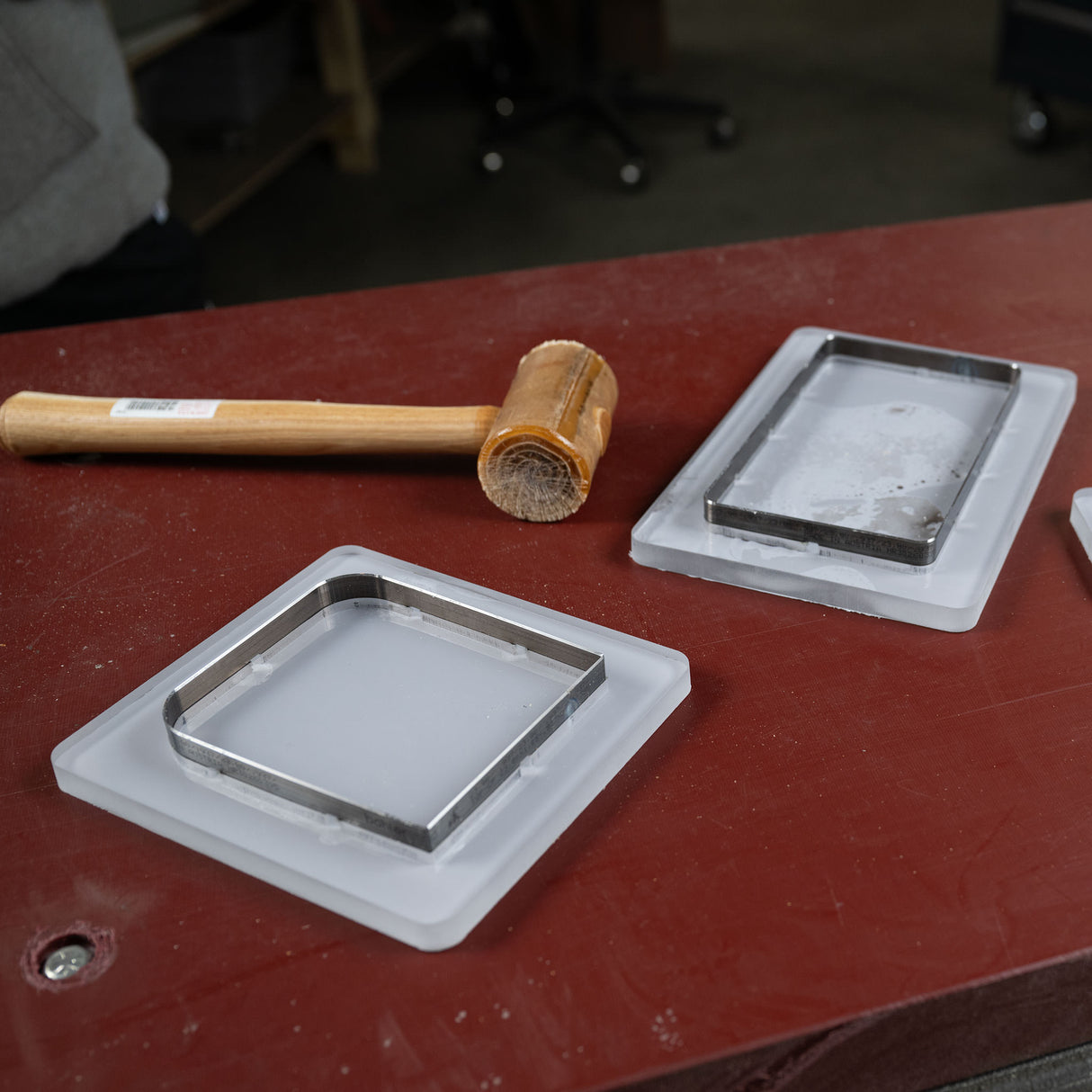

Why Choose Acrylic Mount Dies for Small Batch Production?

Acrylic mount dies are particularly useful for small batch production or craft projects. The acrylic base allows for easy alignment of materials, which can significantly reduce waste during the cutting process. While these dies may have limitations in cutting depth, they offer a lightweight and user-friendly option for artisans and small businesses. B2B buyers should consider their specific production needs and whether the advantages of reduced waste and ease of use align with their operational goals.

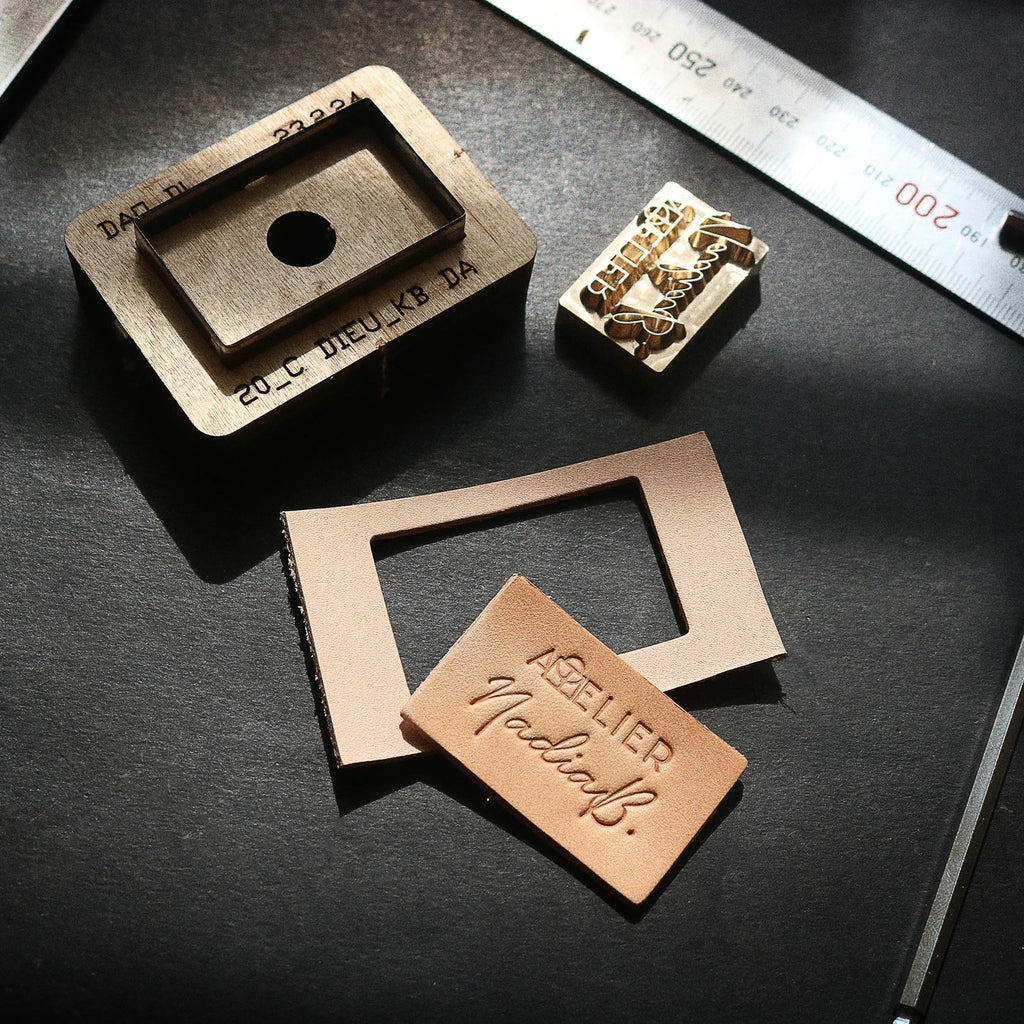

Illustrative image related to custom leather die

What Are the Benefits of Custom Hand-Crafted Dies?

Custom hand-crafted dies are tailored to meet specific design requirements, making them ideal for specialty items and artisan crafts. These dies provide unique shapes and designs that can set a business apart in a competitive market. While they typically come with a higher price tag and longer production times, the artisanal quality and distinctiveness can attract niche markets. B2B buyers should evaluate their target audience and product offerings to determine if investing in custom hand-crafted dies aligns with their branding and market strategy.

Key Industrial Applications of custom leather die

| Industry/Sector | Specific Application of custom leather die | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Accessories | Custom shapes for bags, wallets, and belts | Enhances design versatility and production efficiency | Ensure precision in die cutting for intricate designs |

| Automobilindustrie | Upholstery and interior components | Streamlines production and reduces material waste | Look for dies that can handle various leather thicknesses |

| Footwear | Cutting shoe components | Increases speed and consistency in mass production | Verify compatibility with different cutting machines |

| Craft and Hobby | DIY projects and artisan products | Expands creative possibilities and custom offerings | Consider ease of use for small-scale production |

| Industrial Packaging | Custom leather packaging solutions | Provides unique branding opportunities and durability | Assess the durability and sharpness of the die for repeated use |

How Is Custom Leather Die Used in Fashion Accessories?

In the fashion accessories sector, custom leather dies are essential for creating unique shapes for products like bags, wallets, and belts. They allow manufacturers to cut multiple pieces quickly and consistently, which is vital for meeting market demand. Buyers in this industry should prioritize precision in die cutting, as intricate designs can significantly enhance the product’s appeal. Additionally, sourcing from suppliers who offer rapid production and shipping can help businesses keep up with fashion trends.

What Role Does Custom Leather Die Play in the Automotive Industry?

The automotive industry utilizes custom leather dies for upholstery and interior components, ensuring that parts fit seamlessly within vehicle designs. These dies facilitate efficient mass production, ultimately reducing labor costs and material waste. For international buyers, it is crucial to choose dies that can accommodate various leather thicknesses to match different vehicle specifications. Ensuring that the supplier can meet stringent quality standards and timelines is also vital for maintaining production schedules.

How Are Custom Leather Dies Beneficial for Footwear Manufacturers?

Footwear manufacturers rely on custom leather dies to cut shoe components, which significantly speeds up the production process while maintaining design integrity. This technology allows for consistent cuts that ensure all parts fit together perfectly, reducing the risk of defects. Buyers should verify that the dies are compatible with their cutting machines and can handle different leather types, including synthetic options. Sourcing dies from reputable manufacturers with a history of durability can enhance long-term production efficiency.

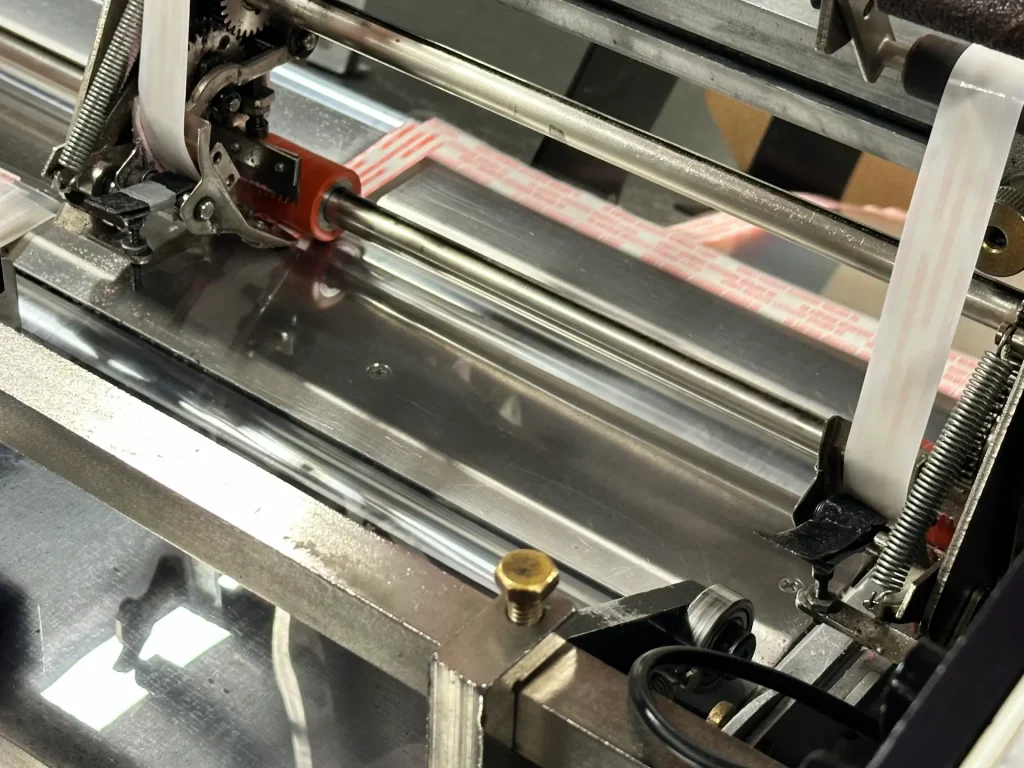

Illustrative image related to custom leather die

In What Ways Do Craft and Hobby Industries Utilize Custom Leather Dies?

In the craft and hobby sector, custom leather dies open up a world of creative possibilities for DIY projects and artisan products. They enable crafters to create unique shapes and designs that can elevate their offerings in a competitive market. Buyers should consider the ease of use of the dies, especially for small-scale production, and whether they can be employed with manual or automated cutting tools. Collaborating with suppliers who provide design assistance can also enhance product innovation.

What Are the Applications of Custom Leather Dies in Industrial Packaging?

Custom leather dies are increasingly used in industrial packaging solutions, providing businesses with unique branding opportunities through tailored packaging designs. These dies ensure that the packaging is not only aesthetically appealing but also durable enough to protect the contents. Buyers should assess the durability and sharpness of the die to ensure it can withstand repeated use without losing effectiveness. Additionally, understanding the supplier’s production capabilities can help businesses align packaging solutions with their operational needs.

3 Common User Pain Points for ‘custom leather die’ & Their Solutions

Scenario 1: Precision Matters in Custom Leather Die Orders

The Problem: B2B buyers often face issues with the precision of custom leather dies. When dealing with intricate designs, even a slight deviation can lead to wasted materials and increased production costs. For instance, a buyer in Nigeria ordering a die for a bespoke leather product might receive a die that does not match the specified dimensions, resulting in flawed cuts and the need for reorders. This not only frustrates the buyer but also affects their production timeline and profitability.

The Solution: To mitigate precision issues, it is crucial to work closely with manufacturers who utilize CAD (Computer-Aided Design) technology in their die-making processes. Buyers should provide detailed design files in formats like .ai or .pdf, ensuring that all dimensions and specifications are clearly outlined. It’s beneficial to request a digital proof before production begins, allowing for any necessary adjustments. Additionally, establishing a solid line of communication with the supplier can lead to greater accuracy, as they can confirm details and provide insights based on their experience in the industry.

Scenario 2: Reducing Material Waste During Leather Cutting

The Problem: Many B2B buyers encounter significant material waste when cutting leather, particularly when using traditional methods. This is especially pertinent for businesses in South America that aim for sustainable practices but struggle with the inefficiencies of hand-cutting. Each flawed cut not only leads to wasted materials but also increases overall production costs, hampering the company’s sustainability goals.

Illustrative image related to custom leather die

The Solution: Investing in custom leather dies designed specifically for the intended shapes can drastically reduce material waste. Suppliers that offer acrylic-mounted steel rule dies provide easy alignment, ensuring that every cut is accurate and efficient. Buyers should also inquire about the die’s effective cutting depth and material compatibility to optimize usage. To further minimize waste, implementing a clicker press can enhance the cutting process, allowing for consistent and precise cuts across multiple pieces. Regular training on die usage and maintenance can also help reduce errors and improve overall efficiency.

Scenario 3: Navigating Long Lead Times for Custom Orders

The Problem: Long lead times for custom leather dies can be a major pain point for B2B buyers, particularly those in the Middle East who are under pressure to deliver quality products quickly. When suppliers take weeks to fulfill orders, it can disrupt production schedules and lead to missed deadlines, ultimately affecting customer satisfaction and business reputation.

The Solution: To address lead time issues, buyers should prioritize working with suppliers who offer expedited services for custom die orders. It’s advisable to ask about the average turnaround time and whether rush orders are available, even if they come at an additional cost. Suppliers that maintain a robust inventory of standard dies can often fulfill requests faster, so consider exploring their in-stock options first. Furthermore, establishing a long-term partnership with a reliable manufacturer can lead to improved lead times as they become more familiar with your specific needs and can prioritize your orders accordingly. Regularly reviewing and forecasting your production needs can also help in placing orders well in advance, thus mitigating the pressure of tight timelines.

Illustrative image related to custom leather die

Strategic Material Selection Guide for custom leather die

What Are the Key Materials Used in Custom Leather Dies?

When selecting materials for custom leather dies, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the die. Below, we analyze four common materials used in the production of custom leather dies, focusing on their suitability for various applications and the specific considerations for international B2B buyers.

How Does Steel Perform as a Material for Custom Leather Dies?

Steel is a popular choice for custom leather dies due to its strength and durability. It can withstand high pressure and temperature, making it suitable for various cutting applications. Steel dies are resistant to wear and can maintain their sharpness over extended use, which is critical for mass production scenarios.

Pros: Steel offers excellent durability and precision, making it ideal for intricate designs. It is also relatively cost-effective for larger production runs.

Cons: The primary drawback of steel is its susceptibility to rust if not properly maintained. Additionally, the manufacturing process can be complex, requiring specialized equipment and expertise.

Illustrative image related to custom leather die

Impact on Application: Steel dies are compatible with a wide range of materials, including leather, paper, and synthetic materials. This versatility makes them suitable for diverse applications across different industries.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM or DIN for quality assurance. In regions like Africa and South America, where humidity can be high, proper rust-proofing measures should be considered during the manufacturing process.

What Advantages Do Polycarbonate Dies Offer for Leather Cutting?

Polycarbonate is another material commonly used for custom leather dies, particularly in applications requiring lightweight and high-impact resistance. Polycarbonate dies are known for their ability to produce clean cuts and intricate shapes with high precision.

Pros: The primary advantage of polycarbonate is its lightweight nature, which makes it easier to handle and reduces the strain on cutting machines. They are also less prone to chipping compared to steel dies.

Cons: While polycarbonate is durable, it may not withstand as high a pressure as steel, limiting its use for thicker materials. Additionally, the cost of polycarbonate dies can be higher than steel, which may affect budget-sensitive projects.

Illustrative image related to custom leather die

Impact on Application: Polycarbonate dies are particularly effective for cutting thinner materials, making them suitable for detailed work in leather goods, fashion, and accessories.

Considerations for International Buyers: Buyers should verify the quality of polycarbonate used, as variations can affect performance. Compliance with international safety standards is also essential, especially in regions with strict regulations.

Why Choose Acrylic for Custom Leather Dies?

Acrylic is often used for the mounting of steel rule dies due to its transparency and ease of use. It allows for precise alignment of materials, which helps reduce waste during the cutting process.

Illustrative image related to custom leather die

Pros: The transparency of acrylic makes it easy to position materials accurately. It is also lightweight and can be produced quickly, making it ideal for rapid prototyping.

Cons: Acrylic is less durable than steel and can crack under extreme pressure. It may not be suitable for heavy-duty applications where longevity is a concern.

Impact on Application: Acrylic mounts are best used in conjunction with steel rule dies for applications that require high precision and minimal waste.

Considerations for International Buyers: Buyers should ensure that the acrylic meets relevant safety and quality standards. In regions like the Middle East, where temperatures can soar, it is essential to consider the thermal stability of acrylic.

Illustrative image related to custom leather die

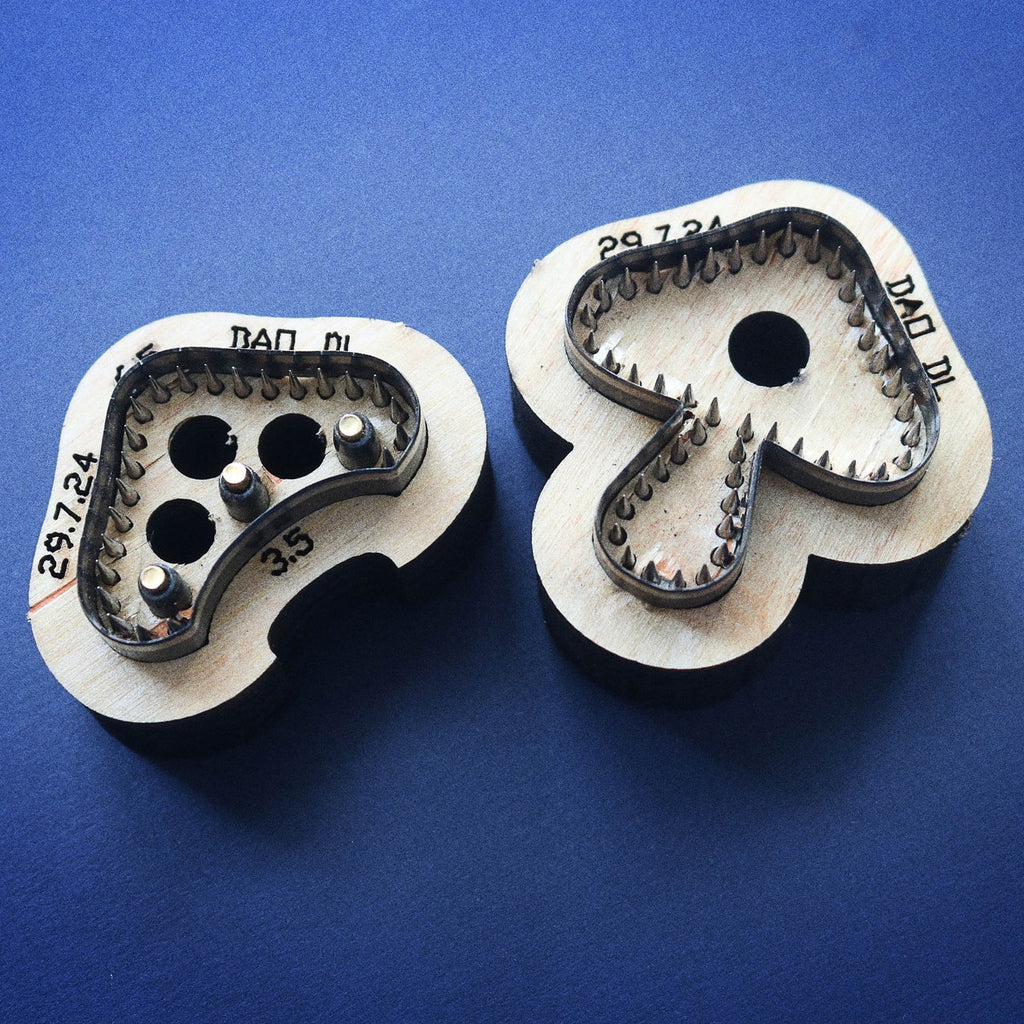

What Role Does Wood Play in Custom Leather Die Production?

Wood is sometimes used in the production of custom leather dies, particularly for prototypes or lower-volume runs. It is easy to work with and can be shaped quickly to meet design specifications.

Pros: Wood is cost-effective and readily available, making it an attractive option for small businesses or startups. It can be easily customized and modified.

Cons: The primary limitation of wood is its durability; it is not suitable for high-volume production as it wears out quickly. Additionally, wood can absorb moisture, which may affect its performance over time.

Illustrative image related to custom leather die

Impact on Application: Wooden dies are typically used for lighter materials and less intricate designs, making them suitable for craft projects or small-scale production.

Considerations for International Buyers: Buyers should be aware of the sourcing and treatment of wood to comply with international regulations concerning sustainability and environmental impact.

Summary Table of Material Selection for Custom Leather Dies

| Material | Typical Use Case for custom leather die | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-volume production of intricate designs | Excellent durability and precision | Susceptible to rust, complex mfg | Medium |

| Polycarbonate | Cutting thinner materials, detailed work | Lightweight, clean cuts | Limited pressure resistance | Hoch |

| Acrylic | Mounting for steel rule dies | Easy alignment, quick production | Less durable, cracks under pressure | Medium |

| Wood | Prototyping, low-volume runs | Cost-effective, easy to customize | Wears out quickly, moisture absorption | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing custom leather dies.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather die

What Are the Main Stages in the Manufacturing Process of Custom Leather Dies?

The manufacturing of custom leather dies involves several critical stages that ensure precision, durability, and functionality. Understanding these stages is vital for B2B buyers looking to invest in high-quality leather cutting tools.

1. Material Preparation: Selecting the Right Components

The first step in the manufacturing process is the selection of appropriate materials. Custom leather dies are typically made from high-quality steel or polycarbonate, chosen for their durability and cutting efficiency. The steel used often undergoes a heat treatment process to enhance hardness, ensuring that the dies can withstand repeated use without dulling. Additionally, acrylic mounts may be employed to provide stability and ease of alignment during the cutting process, which reduces material waste.

2. Forming: Precision Shaping of Dies

Once the materials are prepared, the forming process begins. This involves using Computer-Aided Design (CAD) software to create precise die patterns. The design is then transferred to cutting machines, where the materials are shaped into the desired die form. Techniques such as laser cutting or CNC machining may be utilized to achieve high precision, ensuring that tolerances of ±0.2mm are maintained. This level of accuracy is crucial for B2B buyers, as it directly impacts the quality of the final leather products.

3. Assembly: Combining Components for Functionality

In the assembly stage, various components of the die are brought together. For steel rule dies, the blade is typically mounted on a sturdy base, often made of wood or acrylic. This assembly must ensure that the die can cut through leather or other materials effectively. During this phase, manufacturers may also add optional features such as engraving or custom hole punches, enhancing the versatility of the die for specific applications.

4. Finishing: Ensuring Quality and Readiness for Use

The finishing stage involves several processes aimed at preparing the dies for shipment. This includes cleaning, polishing, and applying protective coatings to prevent rust or wear during transport. Manufacturers often conduct final inspections to ensure that the die meets the specified dimensions and quality standards before it is packaged. Proper packaging, such as using foam inserts to protect sharp edges, is also essential to prevent damage during shipping.

How Is Quality Assurance Integrated into the Custom Leather Die Manufacturing Process?

Quality assurance is a cornerstone of the manufacturing process for custom leather dies. Implementing robust QA practices helps ensure that the products meet international standards and customer expectations.

Relevant International Standards for Quality Assurance

B2B buyers should be aware of various international standards that govern manufacturing quality. ISO 9001 is a widely recognized standard for quality management systems that applies to manufacturers across industries, including those producing leather dies. Compliance with ISO 9001 demonstrates a commitment to quality and continuous improvement.

Illustrative image related to custom leather die

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant depending on the intended use of the leather die. These certifications indicate that the products comply with specific safety and performance requirements.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are essential throughout the manufacturing process to catch defects early and ensure that each die meets the required specifications. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. For instance, steel must be free from defects and meet hardness specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the accuracy of cutting and assembly. This may involve measuring dimensions at various stages to ensure they remain within tolerances.

-

Final Quality Control (FQC): After finishing, the dies undergo a comprehensive inspection to confirm that they meet all specifications. This includes checking dimensions, alignment, and functionality.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is crucial to avoid costly mistakes and ensure the reliability of products.

Audits and Factory Visits

One effective way to verify a supplier’s QA practices is through audits and factory visits. Conducting an on-site inspection allows buyers to assess the manufacturing environment, observe the production processes, and review quality control documentation. This firsthand experience can provide valuable insights into the supplier’s capabilities.

Requesting Quality Reports and Certifications

B2B buyers should request quality reports and certifications from suppliers. These documents can include results from internal quality checks, third-party inspection reports, and compliance certifications. Reviewing these materials can help buyers gauge the supplier’s commitment to quality and adherence to industry standards.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections at various stages of production, providing unbiased reports on quality and compliance. This approach is particularly valuable for buyers unfamiliar with local suppliers or those operating in international markets.

What Are the QC and Certification Nuances for International Buyers?

When sourcing custom leather dies internationally, buyers should be aware of specific nuances in quality control and certification that can vary by region. For example:

-

Local Regulations and Standards: Different countries may have unique regulations regarding materials and manufacturing processes. It is essential for buyers to understand these requirements to ensure compliance.

-

Cultural Differences in Quality Expectations: Cultural perceptions of quality may differ, influencing how products are manufactured and marketed. Buyers should communicate their quality expectations clearly to avoid misunderstandings.

-

Logistics and Shipping Considerations: Quality assurance does not end at manufacturing. Buyers should consider how products will be shipped and stored. Ensuring that packaging is robust enough to protect the dies during transport is critical to maintaining quality.

By understanding the manufacturing processes and quality assurance practices involved in custom leather dies, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather die’

In today’s competitive market, sourcing custom leather dies effectively is crucial for businesses aiming to optimize their production processes. This guide provides a practical checklist to help B2B buyers navigate the procurement of custom leather dies, ensuring quality, cost-effectiveness, and timely delivery.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your custom leather die. This includes the design dimensions, materials to be cut, and any particular features like engraving or hole punches. Clear specifications help potential suppliers understand your needs and provide accurate quotes.

- Consider factors such as the thickness of the materials and the complexity of the design.

- Specify tolerances and dimensions to ensure precision in the final product.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in custom leather dies. Look for companies with a strong track record and positive customer reviews.

- Utilize industry directories, trade shows, and online platforms to gather information.

- Pay attention to suppliers’ experience and their ability to handle international shipping, especially if you are sourcing from regions like Africa or South America.

Step 3: Evaluate Supplier Certifications

Verify that the suppliers have the necessary certifications and compliance with industry standards. This step is essential for ensuring product quality and reliability.

- Check for certifications such as ISO or other relevant industry-specific standards.

- Request documentation to confirm their manufacturing processes and quality assurance measures.

Step 4: Request Samples and Prototypes

Before making a bulk order, ask for samples or prototypes of the custom dies. This allows you to evaluate the craftsmanship and ensure that the product meets your specifications.

- Analyze the sample for accuracy, durability, and cutting performance.

- Use this opportunity to assess the supplier’s responsiveness and willingness to make adjustments based on your feedback.

Step 5: Discuss Lead Times and Shipping Options

Clarify the lead times for production and shipping as part of your sourcing strategy. Understanding the timeline is critical for planning your inventory and production schedules.

Illustrative image related to custom leather die

- Inquire about standard lead times and the possibility of expedited options for urgent orders.

- Check shipping methods and costs, especially for international shipments, to avoid unexpected delays.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing and payment terms. This step is vital to ensure that you secure a fair deal while maintaining quality.

- Discuss bulk order discounts and payment options that align with your budget.

- Ensure that all terms, including warranties and return policies, are clearly defined in the contract.

Step 7: Establish a Communication Plan

Develop a clear communication plan with your chosen supplier. Effective communication is key to a successful partnership and helps prevent misunderstandings.

- Set regular check-ins to monitor progress and address any issues that arise during production.

- Utilize email, phone calls, or video conferencing for ongoing updates and feedback.

By following this checklist, B2B buyers can streamline their sourcing process for custom leather dies, leading to improved efficiency and product quality in their operations.

Comprehensive Cost and Pricing Analysis for custom leather die Sourcing

What Are the Key Cost Components in Custom Leather Die Pricing?

When sourcing custom leather dies, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for leather dies include steel and polycarbonate, each with varying price points. Steel dies tend to be more durable but costlier, while polycarbonate offers a balance between performance and price.

-

Labor: Skilled labor is required for the design and manufacturing of custom dies. Labor costs may vary based on the complexity of the design and the expertise of the craftsmen involved.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Manufacturers often factor these expenses into the overall pricing structure.

-

Tooling: Tooling costs cover the creation of molds and other specialized tools needed to produce custom dies. These costs can vary significantly based on the design complexity and the number of different dies required.

-

Quality Control (QC): Ensuring the precision and quality of the dies involves QC processes, which add to the overall cost. This includes testing for tolerances and ensuring that the dies meet the specified requirements.

-

Logistics: Shipping and handling costs can vary widely depending on the destination and the chosen shipping method. International buyers should be aware of potential customs fees and import duties.

-

Margin: Suppliers will apply a profit margin to cover their costs and ensure sustainability. This margin can vary based on the supplier’s market position and the competitiveness of their pricing.

What Influences the Pricing of Custom Leather Dies?

Several factors influence the pricing of custom leather dies, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Highly customized dies with intricate designs or specific dimensions may incur additional costs. Buyers should clearly define their needs to avoid unexpected charges.

-

Material Selection: The choice between different materials can impact both the performance and the price of the dies. For instance, opting for high-quality steel may increase upfront costs but offer better durability.

-

Quality Certifications: Dies that come with quality certifications may carry a premium price. Buyers should weigh the benefits of guaranteed quality against potential cost savings from uncertified options.

-

Supplier Factors: The reputation, location, and experience of the supplier can affect pricing. Established suppliers may charge more due to their reliability and service quality.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Buyer Tips Can Help Optimize Costs When Sourcing Custom Leather Dies?

International B2B buyers should consider several strategies to optimize costs and ensure efficient sourcing of custom leather dies:

-

Negotiate Pricing: Engaging in negotiations can lead to better pricing. Buyers should prepare to discuss volumes and potential long-term partnerships to leverage favorable terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial cost but also the long-term implications, including durability, maintenance, and performance. A higher upfront investment in a quality die may lead to lower costs over time due to reduced waste and longer lifespan.

-

Understand Pricing Nuances: Pricing may vary based on the supplier’s geographical location and market conditions. For example, sourcing from suppliers in regions with lower labor costs may yield significant savings.

-

Request Samples: Before committing to a large order, request samples to assess quality and compatibility with your production process. This can prevent costly mistakes down the line.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and fluctuations in material costs can help buyers make informed decisions and avoid price shocks.

By understanding the intricate cost structure and factors influencing pricing, B2B buyers can navigate the complexities of sourcing custom leather dies more effectively, ensuring that they achieve the best value for their investment.

Alternatives Analysis: Comparing custom leather die With Other Solutions

Exploring Alternatives to Custom Leather Dies for Leather Cutting

In the dynamic landscape of leather crafting, businesses often seek efficient solutions that meet their specific production needs. While custom leather dies are a popular choice for precision cutting, it’s essential to evaluate other viable alternatives that can also deliver quality results. This section compares custom leather dies with alternative methods, enabling B2B buyers to make informed decisions based on performance, cost, and ease of use.

Illustrative image related to custom leather die

| Comparison Aspect | Custom Leather Die | Laser Cutting System | Manual Cutting Tools |

|---|---|---|---|

| Performance | High precision with complex designs | Extremely precise; intricate patterns can be cut | Moderate precision; limited to simpler shapes |

| Cost | Moderate initial investment; variable based on design complexity | High upfront cost; ongoing operational costs (maintenance, electricity) | Low initial cost; limited only by labor |

| Ease of Implementation | Requires design submission; setup time varies | Requires skilled operation; software proficiency needed | Simple to use; minimal training required |

| Wartung | Low; occasional blade replacement needed | High; regular maintenance and software updates necessary | Low; mainly manual upkeep needed |

| Best Use Case | Ideal for mass production of unique shapes | Best for intricate, detailed designs | Suitable for small-scale projects or prototypes |

In-Depth Analysis of Alternatives

Laser Cutting System

Laser cutting systems provide unmatched precision and versatility, allowing for intricate designs that would be challenging with traditional dies. They operate through computer-controlled lasers, which can cut various materials, including leather, with high accuracy. However, the initial investment is significant, as is the ongoing cost for maintenance and energy consumption. Additionally, operating these systems requires trained personnel familiar with both the machinery and design software. For businesses focused on high-volume production of complex designs, laser cutting is a powerful alternative.

Manual Cutting Tools

Manual cutting tools, such as rotary cutters and knives, represent the most accessible option for leather crafting. They are cost-effective and require minimal investment, making them ideal for small businesses or hobbyists. However, the performance is limited to simpler shapes and requires skilled labor for consistent results. While these tools are advantageous for low-volume production, they may not meet the efficiency demands of larger operations. Their simplicity and ease of use make them suitable for prototyping or crafting unique one-off items.

Choosing the Right Solution for Your Business Needs

When selecting the appropriate cutting method for leather, B2B buyers must consider their production scale, budget constraints, and the complexity of designs they intend to create. Custom leather dies excel in delivering high precision for mass production, making them ideal for businesses with established designs and consistent output needs. In contrast, laser cutting systems are better suited for businesses requiring flexibility and intricate designs, albeit at a higher cost. Manual cutting tools serve well for smaller operations or those just entering the leather crafting market.

Ultimately, the right choice will depend on aligning the selected method with the specific requirements of the business, ensuring both efficiency and quality in production.

Essential Technical Properties and Trade Terminology for custom leather die

What Are the Key Technical Properties of Custom Leather Dies?

Understanding the critical specifications of custom leather dies is essential for B2B buyers aiming to enhance their production efficiency and product quality. Here are some key properties to consider:

-

Material Grade

– Custom leather dies are primarily made from steel or polycarbonate. Steel dies offer durability and sharpness, making them ideal for high-volume production. Polycarbonate dies are lighter and less expensive but may not offer the same longevity. Selecting the right material can significantly impact production costs and die performance. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension. For custom leather dies, a tolerance of ±0.2mm is common. This precision is crucial in maintaining consistency in cuts, which directly affects the quality of the final product. Inaccurate tolerances can lead to increased material waste and production delays. -

Cutting Depth

– The effective cutting depth indicates the thickness of material that the die can cut through. Many custom dies can effectively cut materials up to 8.8mm thick. Understanding the cutting depth is vital for selecting a die that meets specific project requirements, especially when working with various leather thicknesses. -

Die Height

– The total height of the die, including the mount, is usually around 23.8mm. This measurement affects the compatibility with cutting machines and can influence the ease of use. Buyers should ensure that the die height fits their existing equipment to avoid operational issues. -

Customizability

– The ability to customize dies is a significant advantage for B2B buyers. Custom features such as engraving or additional hole punches can be added to meet specific project needs. This flexibility allows businesses to create unique products and streamline their production processes. -

Lead Time

– Lead time refers to the duration from order placement to delivery. Many suppliers offer expedited services, with some custom dies ready for shipment in as little as 2-3 business days. Understanding lead times is essential for inventory management and project planning.

What Are Common Trade Terms Related to Custom Leather Dies?

Familiarity with industry terminology can facilitate smoother negotiations and transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of custom leather dies, buyers might work with OEMs to create specialized dies tailored for their unique applications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they can meet production needs without overcommitting resources or incurring unnecessary costs. -

RFQ (Request for Quotation)

– An RFQ is a document that businesses send to suppliers to solicit pricing information for specific products or services. Crafting a clear RFQ can help buyers obtain accurate quotes for custom leather dies, ensuring they understand the costs involved. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is essential for B2B transactions, especially when importing custom leather dies from different countries. -

CAD (Computer-Aided Design)

– CAD refers to the use of computer software to create precise drawings and specifications. Many die makers use CAD technology to ensure accuracy in custom die production, making it a critical aspect of the design and manufacturing process. -

Lead Time

– As mentioned earlier, lead time is the period between placing an order and receiving the goods. It is a crucial factor in supply chain management, impacting production schedules and inventory levels.

Understanding these technical properties and industry terms can empower B2B buyers to make informed decisions when sourcing custom leather dies, ultimately enhancing their operational efficiency and product offerings.

Illustrative image related to custom leather die

Navigating Market Dynamics and Sourcing Trends in the custom leather die Sector

What Are the Key Market Trends Influencing the Custom Leather Die Sector?

The global market for custom leather dies is witnessing significant transformation driven by technological advancements, increasing demand for personalized products, and evolving consumer preferences. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking high-precision, custom solutions that enhance their production efficiency and product differentiation. A notable trend is the rise of digital technologies in the design and manufacturing processes. Companies are leveraging CAD software for precise die designs, which not only improves accuracy but also reduces lead times.

Moreover, the demand for eco-friendly materials is shaping sourcing strategies. Buyers are now looking for suppliers who can provide sustainable options, such as dies made from recycled or biodegradable materials. The move towards automation and the adoption of advanced cutting technologies, such as laser cutting, are also notable trends, allowing manufacturers to achieve higher output with consistent quality. This shift is particularly appealing to businesses looking to scale operations without compromising on craftsmanship.

How Is Sustainability Impacting the Sourcing of Custom Leather Dies?

Sustainability is becoming a crucial factor in sourcing decisions within the custom leather die sector. The environmental impact of leather production, including water usage and chemical waste, has prompted B2B buyers to prioritize suppliers who adhere to ethical practices. Companies that offer ‘green’ certifications or utilize environmentally friendly materials are gaining a competitive edge in the market. Buyers are increasingly aware that sourcing from ethical suppliers not only enhances their brand image but also aligns with the growing consumer demand for transparency in supply chains.

Furthermore, the importance of ethical sourcing extends beyond just materials; it encompasses fair labor practices and community engagement. Suppliers who can demonstrate a commitment to social responsibility are more likely to attract international buyers, particularly from regions with strong ethical consumerism movements. As the market evolves, B2B buyers will benefit from integrating sustainability into their procurement strategies, ensuring they meet both regulatory requirements and customer expectations.

What Is the Historical Context of Custom Leather Die Manufacturing?

The custom leather die manufacturing industry has evolved significantly over the decades. Initially, the production of leather dies was a labor-intensive process, relying heavily on manual labor and basic tools. As demand for leather products grew, so did the need for more efficient cutting solutions. The introduction of steel rule dies in the mid-20th century marked a pivotal moment, allowing manufacturers to produce complex shapes with greater precision and speed.

Illustrative image related to custom leather die

In recent years, advancements in technology have further transformed the sector. The advent of computer-aided design (CAD) and CNC (Computer Numerical Control) machines has enabled manufacturers to create highly intricate die designs with minimal waste. This evolution not only improved production efficiency but also allowed for the customization that modern consumers desire. Today, the custom leather die market continues to adapt to technological innovations and sustainability trends, positioning itself as a dynamic sector in the global manufacturing landscape.

Conclusion: How Can B2B Buyers Navigate This Evolving Market?

For international B2B buyers, understanding these market dynamics is essential for making informed sourcing decisions. Emphasizing sustainability, leveraging technological advancements, and prioritizing ethical suppliers will not only enhance their product offerings but also align them with global market trends. As the custom leather die sector continues to evolve, those who adapt swiftly to these changes will thrive in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather die

-

How do I choose the right custom leather die supplier?

When selecting a supplier for custom leather dies, prioritize those with a strong track record in the industry. Look for manufacturers who provide transparent communication, detailed customization options, and robust quality assurance processes. Check client reviews and case studies to gauge their reliability. It’s beneficial to ask about their production capabilities and lead times, especially for international shipping, to ensure they can meet your needs efficiently. -

What customization options are available for custom leather dies?

Most suppliers offer a variety of customization options, including size adjustments, design alterations, and additional features like engraving or multiple cutting depths. You can typically submit your own design files in formats such as AI, PDF, or JPG. Discussing your specific requirements with the supplier can help them tailor the die to your exact specifications, ensuring optimal performance for your projects. -

What is the minimum order quantity (MOQ) for custom leather dies?

Minimum order quantities can vary significantly among suppliers. Some may accept small orders, while others might require a higher MOQ to justify production costs. It’s essential to confirm the MOQ upfront to align with your production needs. If you are a smaller business, look for suppliers that cater to smaller orders or offer flexible solutions for startups. -

What payment terms should I expect when ordering custom leather dies?

Payment terms vary by supplier, but common practices include upfront payment or a deposit with the balance due upon completion. International buyers should inquire about any additional costs related to currency conversion, taxes, or tariffs that may apply. Always clarify payment methods accepted, such as credit cards, PayPal, or bank transfers, to streamline the transaction process. -

How can I ensure the quality of my custom leather dies?

To ensure quality, request samples or prototypes before placing a large order. Many reputable suppliers will offer this option. Additionally, inquire about their quality assurance processes, such as testing for precision and durability. Establishing clear specifications and maintaining open communication throughout the production phase can also help mitigate quality issues. -

What are the logistics considerations for shipping custom leather dies internationally?

When ordering from international suppliers, consider shipping methods, costs, and estimated delivery times. Different carriers offer various options, including express and standard shipping. Ensure that your supplier provides tracking information and consider customs regulations that may affect delivery times and costs. Discuss potential delays and how they handle logistics to avoid surprises. -

How do I handle issues with my order of custom leather dies?

In the event of issues with your order, such as defects or incorrect specifications, contact your supplier immediately. Most reputable companies will have a customer service protocol in place for handling complaints. Document the issue with photos and clear descriptions to facilitate a swift resolution. Understanding the supplier’s return and warranty policies will also guide you in managing such situations. -

What materials can custom leather dies cut effectively?

Custom leather dies are versatile and can cut through various materials, including leather, paper, felt, and some types of synthetic materials. When discussing your project with a supplier, specify the types of materials you plan to use to ensure the die is designed for optimal performance. Some manufacturers also offer dies tailored for specific materials, enhancing their effectiveness in production.

Top 4 Custom Leather Die Manufacturers & Suppliers List

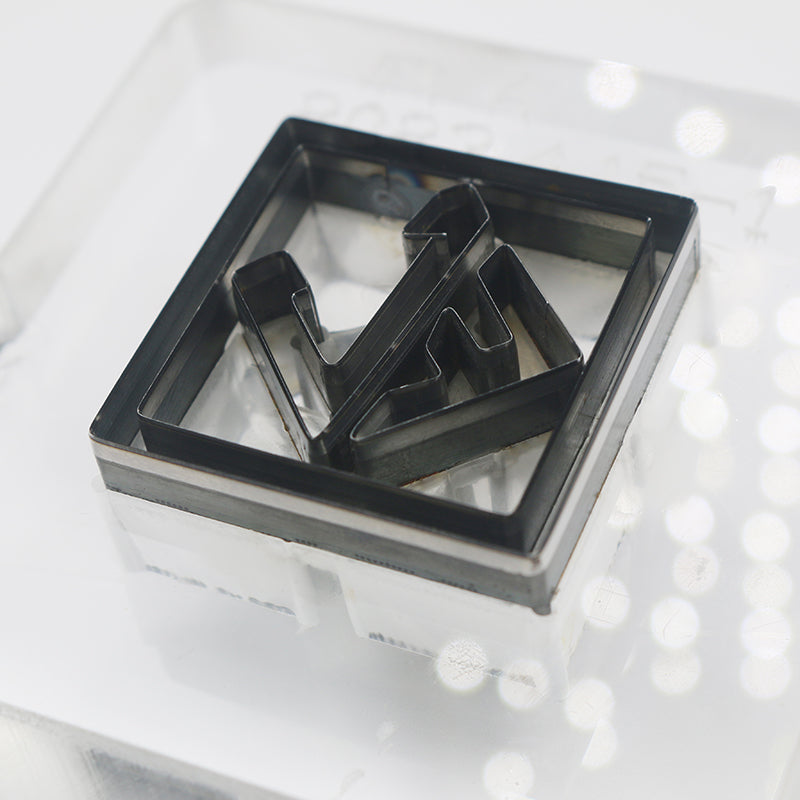

1. LW Leathers – Custom Die Cuts for Leather and Paper

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: Leather Die Cut with Acrylic mount for leather cutting and paper cutting. Regular price: US$138.00. Available sizes: Up to 3×3 inch, Up to 4×4 inch, Up to 5×5 inch, Up to 6×6 inch. Custom made laser engraved leather die cut / steel rule die cut for cutting leather, paper, card stock, silicone, thin magnet, etc. Acrylic mount steel rule die cut for easy alignment of material to reduce waste. Specif…

2. Weaver Leather Supply – Clicker Dies & Sets

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Clicker Dies & Sets from Weaver Leather Supply are designed for efficient leather cutting. They are made from high impact polycarbonate and steel, providing durability and precision for cutting complex shapes. The dies are suitable for mass production, saving time and ensuring consistency in projects. The collection includes various sizes and types, such as dies for belts, wallets, and themed shap…

3. DM Leather Studio – Custom Leather Cutting Dies

Domain: dmleatherstudio.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Custom Leather Cutting Dies, Steel Die for Cutting Leather”, “product_code”: “X09-LCD”, “price”: “$2.00”, “availability”: “Many in stock”, “materials”: [“wood”, “steel”], “default_height”: “24mm (0.95in)”, “usage”: “Can cut leather, paper, felt cloth, etc. Perfect for crafts.”, “custom_order”: “Accepted for size adjustments, card slots, and construction rearrangements.”, “how_to_…

4. USA Cutting Die – Custom Die Cutting Services

Domain: usacuttingdie.com

Registered: 2009 (16 years)

Introduction: Die cutting services for customers without a press, custom saddle dies, small key fobs, coaster dies.

Strategic Sourcing Conclusion and Outlook for custom leather die

In the evolving landscape of custom leather die sourcing, the importance of strategic partnerships cannot be overstated. By selecting reliable suppliers who understand the nuances of your specific requirements—whether for intricate designs or bulk production—businesses can significantly enhance their operational efficiency. The precision offered by advanced die technologies, such as steel rule and polycarbonate options, ensures consistency in production while minimizing material waste.

For B2B buyers in Africa, South America, the Middle East, and Europe, leveraging these innovations can lead to not only cost savings but also faster time-to-market for your leather products. As you consider your sourcing strategies, prioritize suppliers that offer customization and rapid turnaround times, as these factors are critical in meeting market demands and staying ahead of competitors.

Looking ahead, the global demand for custom leather products is set to grow, driven by evolving consumer preferences. Engaging with forward-thinking suppliers will empower your business to capitalize on this trend. Take action now to explore your options in custom leather dies, and position your company for sustained growth in this dynamic industry.

Illustrative image related to custom leather die

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.