Introduction: Navigating the Global Market for belt backing

In today’s competitive landscape, sourcing high-quality belt backing can be a daunting challenge for international B2B buyers. Whether you’re in the textile, manufacturing, or fashion industry, understanding the nuances of belt backing—from material types to specific applications—can significantly influence your product quality and market success. This guide serves as a comprehensive resource, offering insights into various types of belt backing, their applications, and essential tips for vetting suppliers effectively.

With a focus on cost considerations, material characteristics, and sourcing strategies, we aim to equip you with the knowledge needed to make informed purchasing decisions. This is especially crucial for buyers from diverse regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—where local preferences and regulations may vary significantly.

By delving into the intricacies of belt backing, this guide empowers you to navigate the global market confidently, ensuring that you select the right materials that align with your production needs and business goals. The insights provided herein will help you mitigate risks, optimize your supply chain, and ultimately enhance the value of your offerings in an increasingly interconnected marketplace.

Table Of Contents

- Top 5 Belt Backing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for belt backing

- Understanding belt backing Types and Variations

- Key Industrial Applications of belt backing

- 3 Common User Pain Points for ‘belt backing’ & Their Solutions

- Strategic Material Selection Guide for belt backing

- In-depth Look: Manufacturing Processes and Quality Assurance for belt backing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt backing’

- Comprehensive Cost and Pricing Analysis for belt backing Sourcing

- Alternatives Analysis: Comparing belt backing With Other Solutions

- Essential Technical Properties and Trade Terminology for belt backing

- Navigating Market Dynamics and Sourcing Trends in the belt backing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of belt backing

- Strategic Sourcing Conclusion and Outlook for belt backing

- Important Disclaimer & Terms of Use

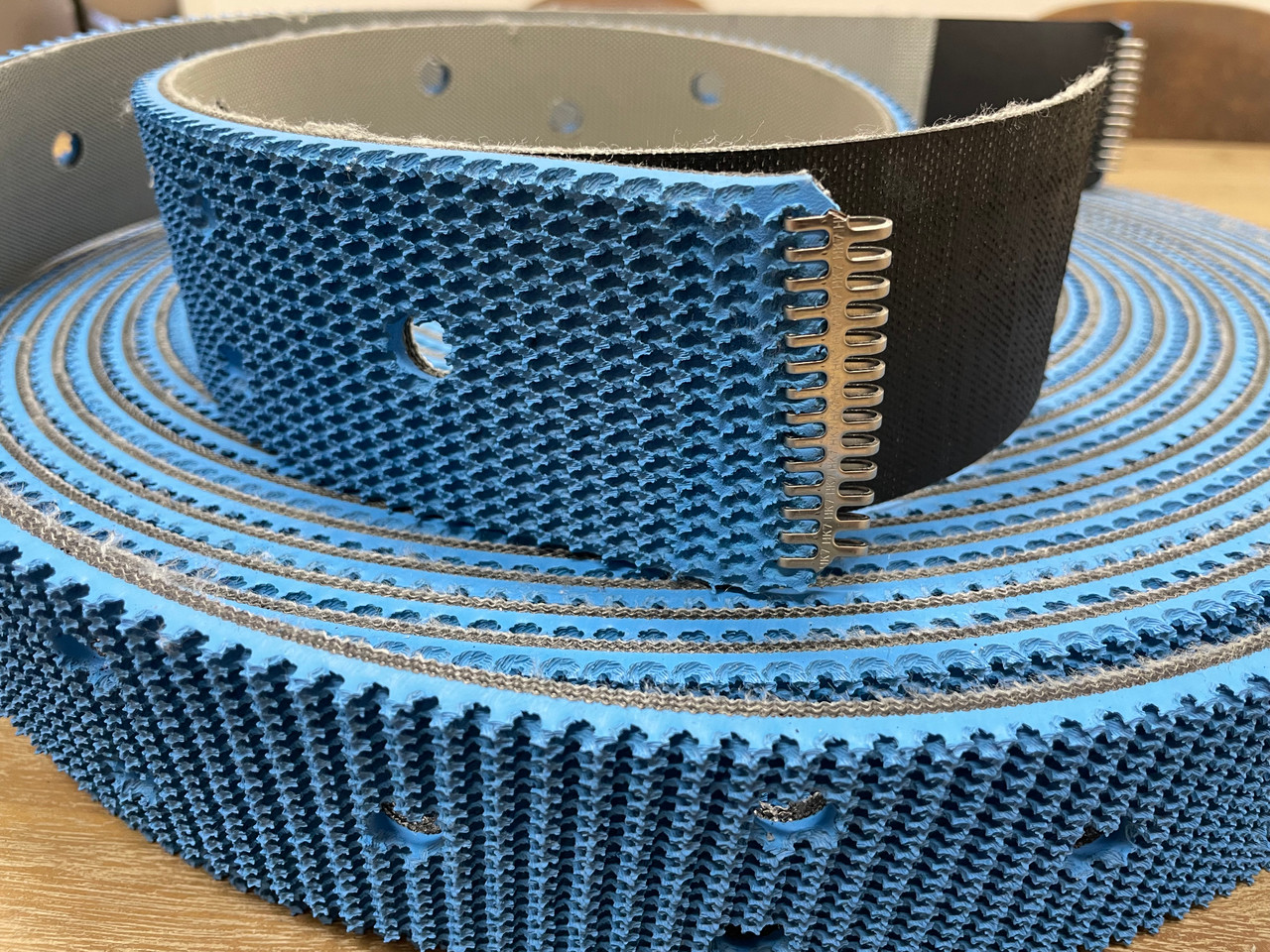

Understanding belt backing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cotton Fabric Backing | Flexible, lightweight, and breathable | Apparel manufacturing, fashion accessories | Pros: Cost-effective, easy to sew; Cons: Less durable in wet conditions. |

| Polyester Backing | Durable, waterproof, and resistant to wear | Industrial belts, outdoor gear | Pros: Long-lasting, suitable for heavy-duty use; Cons: Higher initial cost. |

| Cardboard-like Backing | Rigid structure, typically used in lightweight belts | Custom fashion belts, DIY projects | Pros: Inexpensive, customizable; Cons: Limited durability under stress. |

| Cloth Covered Plastic | Aesthetic finish with a plastic core | Fashion belts, accessories | Pros: Attractive appearance, versatile; Cons: Can be less sturdy than solid materials. |

| Abrasive Backing | Made from various materials like fabric or paper | Sanding and grinding applications | Pros: Wide range of grit options; Cons: Specific to certain applications, may require specialized equipment. |

What Are the Characteristics of Cotton Fabric Backing?

Cotton fabric backing is recognized for its flexibility and lightweight nature, making it ideal for a variety of applications in apparel manufacturing and fashion accessories. This type of backing is breathable, which enhances comfort for the end-user. When considering cotton backing for procurement, B2B buyers should evaluate its cost-effectiveness and ease of sewing against its limitations in durability, especially in wet conditions.

Why Choose Polyester Backing for Industrial Applications?

Polyester backing offers superior durability and is often waterproof, making it suitable for industrial belts and outdoor gear. Its resistance to wear and tear is a significant advantage for businesses requiring long-lasting materials. When purchasing polyester backing, buyers should consider the higher initial costs but recognize the potential for long-term savings due to reduced replacement frequency.

Illustrative image related to belt backing

How Does Cardboard-like Backing Fit into Custom Fashion?

Cardboard-like backing is characterized by its rigid structure, commonly used for lightweight belts in custom fashion and DIY projects. This type of backing allows for easy customization, making it appealing for businesses looking to create unique products. However, buyers should weigh the advantages of low cost and ease of customization against the limited durability under stress, which may not meet all application needs.

What Benefits Does Cloth Covered Plastic Offer?

Cloth-covered plastic backing combines aesthetic appeal with a plastic core, making it popular in fashion belts and accessories. This backing type provides a visually pleasing finish while maintaining some level of flexibility. B2B buyers should consider its versatility and attractive appearance, but also be aware that it may not offer the same sturdiness as more solid backing materials.

What Are the Applications of Abrasive Backing?

Abrasive backing can be made from various materials, including fabric and paper, and is specifically designed for sanding and grinding applications. This type of backing is essential for businesses in manufacturing and construction that require precise material removal. Buyers should assess the range of grit options available and ensure compatibility with their equipment, while also considering that abrasive backings are specialized and may not be suitable for all applications.

Key Industrial Applications of belt backing

| Industry/Sector | Specific Application of belt backing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile Manufacturing | Custom Fabric Belt Production | Enhances product aesthetics and functionality, allowing for tailored designs. | Sourcing high-quality, durable materials that meet design specifications. |

| Abrasive Manufacturing | Abrasive Belt Production | Improves efficiency in grinding and sanding processes, leading to better surface finishes. | Selecting the appropriate backing material for specific abrasive grains and applications. |

| Automotive Industry | Seatbelt and Accessories Production | Ensures safety and compliance with industry standards while providing comfort. | Compliance with safety regulations and the ability to customize for different vehicle models. |

| Fashion and Apparel | Fashion Belt Making | Provides a versatile solution for creating stylish and functional accessories. | Availability of various sizes and styles to cater to diverse fashion trends. |

| Packaging Industry | Conveyor Belt Systems | Increases operational efficiency in packaging lines, enhancing productivity. | Durability and resistance to wear and tear under varying load conditions. |

How is Belt Backing Used in Textile Manufacturing, and What Are the Benefits?

In textile manufacturing, belt backing is crucial for producing custom fabric belts. This application allows businesses to create unique designs that align with their branding while ensuring durability and functionality. The primary benefit is the enhancement of product aesthetics, as customized belts can complement various garments, improving overall sales potential. International buyers must consider sourcing high-quality materials that meet specific design requirements, including width and texture, to cater to diverse fashion markets across regions like Africa and Europe.

What Role Does Belt Backing Play in Abrasive Manufacturing?

In the abrasive manufacturing sector, belt backing is essential for creating high-performance abrasive belts used in grinding and sanding applications. These belts are designed to improve efficiency and ensure superior surface finishes, which are critical in industries such as metalworking and woodworking. The value lies in the ability to select the right backing material that can withstand heavy use while maintaining flexibility. Buyers must pay attention to the compatibility of backing materials with different abrasive grains and the specific requirements of their machinery to optimize performance.

Illustrative image related to belt backing

How is Belt Backing Integral to the Automotive Industry?

Within the automotive industry, belt backing is utilized in the production of seatbelts and related accessories. This application is vital for ensuring safety and compliance with stringent industry standards. The benefits include enhanced safety features and increased comfort for passengers, which are paramount in vehicle design. International buyers should focus on sourcing materials that not only meet safety regulations but also offer customization options to fit various vehicle models, particularly in diverse markets such as the Middle East and Europe.

What Benefits Does Belt Backing Provide in Fashion and Apparel?

In the fashion and apparel sector, belt backing is employed to manufacture stylish and functional belts that cater to current fashion trends. This application allows brands to offer versatile accessories that enhance their product lines and attract a broader customer base. The primary value is the ability to create fashionable items that meet consumer demand for personalization and style. Buyers should ensure the availability of various sizes and styles in their sourcing strategies to adapt to changing fashion dynamics, especially in competitive markets like South America.

How Does Belt Backing Enhance Efficiency in the Packaging Industry?

In the packaging industry, belt backing is integral to the operation of conveyor belt systems used in packaging lines. This application significantly boosts operational efficiency by facilitating the smooth movement of products, thereby enhancing productivity. The benefits include reduced downtime and improved workflow, which are critical for meeting production targets. Buyers should prioritize sourcing durable backing materials that can withstand varying load conditions and provide long-lasting performance, ensuring reliability in high-demand environments.

Illustrative image related to belt backing

3 Common User Pain Points for ‘belt backing’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Belt Backing Materials

The Problem:

International B2B buyers often face challenges when sourcing high-quality belt backing materials. This is particularly true for businesses in emerging markets such as Africa and South America, where access to reliable suppliers may be limited. Buyers may encounter low-quality materials that do not meet their performance standards, leading to product failures and customer dissatisfaction. Additionally, language barriers and varying shipping regulations can complicate the procurement process, making it hard to establish trustworthy supplier relationships.

The Solution:

To effectively source quality belt backing materials, buyers should start by identifying reputable suppliers with a proven track record in their region or globally. Utilizing platforms like Alibaba or ThomasNet can help in finding suppliers with verified reviews and certifications. It is crucial to request samples before committing to larger orders to evaluate the material’s durability and performance. Engaging in direct communication with suppliers can also help clarify specifications, such as weight and material composition, ensuring that the product meets specific manufacturing requirements. Furthermore, establishing long-term partnerships with suppliers can lead to better pricing and priority service, reducing lead times and enhancing reliability.

Scenario 2: Inconsistent Quality Control in Manufacturing

The Problem:

Another common pain point for B2B buyers of belt backing is inconsistent quality during manufacturing. Variations in thickness, width, and material properties can lead to significant production issues, impacting the final product’s quality. For companies that rely on belt backing for high-stakes applications, such as automotive or aerospace manufacturing, these inconsistencies can result in costly rework or even safety hazards, creating a ripple effect throughout the supply chain.

The Solution:

Implementing rigorous quality control processes is essential for buyers to mitigate these risks. This includes developing a clear set of quality standards that suppliers must adhere to, such as material certifications and performance benchmarks. Conducting regular audits and inspections at the supplier’s facility can help ensure compliance with these standards. Additionally, utilizing a third-party quality assurance service can provide an unbiased assessment of the materials before they reach the manufacturing floor. Establishing a robust feedback loop with suppliers allows for continuous improvement and helps build a culture of quality that benefits both parties.

Scenario 3: Lack of Customization Options for Specific Applications

The Problem:

B2B buyers often struggle with the lack of customization options for belt backing materials to suit their unique applications. This is especially relevant in industries like fashion, where specific aesthetic and functional requirements are crucial. Many suppliers offer only standard sizes and materials, which may not align with the buyer’s needs, leading to suboptimal performance and wasted resources. The inability to obtain customized solutions can hinder innovation and competitiveness.

The Solution:

To address this pain point, buyers should proactively communicate their specific requirements to potential suppliers. This includes discussing dimensions, materials, and any desired features, such as water resistance or enhanced durability. Many manufacturers are willing to develop custom solutions if they understand the buyer’s needs clearly. Engaging in collaborative design sessions can also help facilitate the customization process. Additionally, exploring local manufacturers or niche suppliers that specialize in custom belt backing can provide more tailored solutions and support quicker turnaround times. Building a partnership with these suppliers can also foster innovation, allowing for the development of new materials that can meet emerging market trends.

Strategic Material Selection Guide for belt backing

What Are the Key Properties of Common Belt Backing Materials?

When selecting materials for belt backing, it is essential to consider various properties that directly influence the performance and longevity of the belts. The most common materials include cotton, polyester, vinyl, and cloth-covered plastic. Each material has distinct characteristics that can affect its suitability for specific applications.

How Does Cotton Belt Backing Perform in Various Applications?

Cotton belt backing is known for its flexibility and adaptability. It typically has a moderate temperature resistance, making it suitable for applications that do not involve extreme heat. Cotton is also relatively inexpensive and easy to manufacture, which can lower production costs. However, its durability may be limited in high-stress environments, and it is not waterproof, which can lead to degradation in wet conditions. For international buyers, especially in regions with varying climates like Africa and the Middle East, it is crucial to consider the environmental conditions when opting for cotton backing.

Illustrative image related to belt backing

What Advantages Does Polyester Offer for Belt Backing?

Polyester is a popular choice for belt backing due to its high strength and durability. It can withstand higher temperatures and is resistant to moisture, making it suitable for a wide range of applications, including those in humid environments. Polyester belts are less prone to stretching and deformation, ensuring consistent performance over time. However, the manufacturing process can be more complex and costly compared to cotton. Buyers from Europe, particularly Germany, may prefer polyester for its compliance with stringent quality standards such as DIN.

Why Choose Vinyl for Belt Backing?

Vinyl-backed belts are known for their exceptional resistance to chemicals and moisture. This makes them ideal for applications in industries like food processing and pharmaceuticals, where hygiene and contamination prevention are critical. Vinyl is also easy to clean and maintain, enhancing its appeal for various sectors. However, vinyl can be less flexible than cotton or polyester, which may limit its use in applications requiring a high degree of adaptability. Buyers in South America should consider the specific regulatory requirements for materials in food-related applications when selecting vinyl.

How Does Cloth-Covered Plastic Compare to Other Materials?

Cloth-covered plastic combines the durability of plastic with the aesthetic appeal of fabric. This material is often used in applications where visual appearance is essential, such as fashion belts. It offers good resistance to wear and tear, making it suitable for everyday use. However, it may not perform as well under extreme temperatures or heavy loads compared to other options. International buyers should be aware of varying standards for fabric and plastic composites, particularly in regions like Europe, where compliance with EU regulations is mandatory.

Illustrative image related to belt backing

Summary Table of Belt Backing Materials

| Material | Typical Use Case for belt backing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Fashion belts, light-duty applications | Flexible and cost-effective | Limited durability and moisture resistance | Low |

| Polyester | Heavy-duty applications, industrial use | High strength and moisture resistance | Higher manufacturing complexity | Medium |

| Vinyl | Food processing, pharmaceuticals | Chemical and moisture resistance | Less flexibility | Medium |

| Cloth-Covered Plastic | Fashion belts, aesthetic applications | Durable and visually appealing | Poor performance under extreme conditions | Hoch |

This guide should assist B2B buyers in making informed decisions regarding belt backing materials, considering their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for belt backing

What Are the Key Stages in the Manufacturing Process of Belt Backing?

The manufacturing process of belt backing involves several critical stages that ensure the final product meets the required specifications for durability, flexibility, and usability. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Belt Backing Production?

The process begins with material selection, where manufacturers typically choose from a range of substrates including cardboard, plastic, or fabric. These materials are often sourced based on their intended application, such as for fashion belts or industrial uses. Once selected, materials undergo a thorough cleaning and conditioning process to remove any impurities that could affect adhesion or performance.

After preparation, materials are cut to precise dimensions, which is crucial for ensuring uniformity across batches. Manufacturers may utilize automated cutting machines that enhance precision and reduce waste, which is particularly important in B2B settings where volume and consistency are vital.

Illustrative image related to belt backing

What Forming Techniques Are Used in Belt Backing Manufacturing?

Forming involves shaping the prepared materials into the desired configuration. Techniques may vary based on the type of backing being produced. For example, plastic belt backings might undergo extrusion processes, where heated plastic is forced through a die to create a specific shape. Alternatively, fabric backings may be laminated or coated with adhesive to enhance durability and flexibility.

During this stage, manufacturers also ensure that the belt backing can accommodate additional features such as eyelets or reinforcements, which are essential for functionality. The choice of forming technique can significantly impact the quality and performance of the final product.

How Does Assembly Occur in Belt Backing Production?

Once the individual components are formed, assembly takes place. This stage often involves attaching any additional elements, such as metal fittings or decorative components, that enhance both functionality and aesthetic appeal.

Quality control is crucial during assembly, as any defects can compromise the entire belt’s integrity. Manufacturers may employ automated systems to assist with assembly, ensuring that the components fit together seamlessly and adhere to strict design specifications.

What Finishing Processes Are Essential for High-Quality Belt Backing?

Finishing processes are the final steps in belt backing production and are essential for ensuring product durability and aesthetic quality. This stage may include processes such as coating, painting, or applying protective finishes that enhance resistance to wear and environmental factors.

Manufacturers often perform additional quality checks during this phase to ensure that the finish is uniform and free from defects. This attention to detail is crucial for maintaining a strong market reputation, especially among international buyers who prioritize quality.

What Quality Assurance Practices Are Implemented in Belt Backing Manufacturing?

Quality assurance (QA) is a vital aspect of the belt backing manufacturing process, ensuring that products meet international standards and buyer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates a commitment to continuous improvement and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the intended use of the belt backing. These certifications ensure that products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Belt Backing Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and address defects early. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify issues as they arise, allowing for immediate corrective actions.

- Final Quality Control (FQC): This final inspection phase assesses the completed products for compliance with specifications before they are shipped.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify a supplier’s quality control practices. Conducting supplier audits is one of the most effective methods. These audits involve reviewing the supplier’s processes, documentation, and certifications to ensure compliance with international standards.

Buyers should also request detailed QC reports that outline inspection results, defect rates, and corrective actions taken. Third-party inspections can provide an unbiased assessment of the supplier’s quality practices, adding an additional layer of assurance for international buyers.

What Are the Nuances of Quality Certification for International Buyers?

For international buyers, understanding the nuances of quality certification is critical. Different regions may have varying requirements and standards. For instance, buyers in Europe may prioritize CE certification, while those in the Middle East may look for compliance with local standards.

It is also essential for buyers to understand the implications of non-compliance, such as potential delays in customs clearance or product recalls. By being informed about these nuances, B2B buyers can make more educated decisions and ensure that they are partnering with reputable suppliers.

Illustrative image related to belt backing

Conclusion

In conclusion, the manufacturing processes and quality assurance practices for belt backing are complex and multifaceted. By understanding the key stages of production, the importance of quality control, and the relevant international standards, B2B buyers can make informed decisions that enhance their supply chain reliability and product quality. This knowledge is particularly valuable for international buyers from diverse markets, including Africa, South America, the Middle East, and Europe, as they navigate the global landscape of belt backing manufacturing.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt backing’

The purpose of this sourcing guide is to provide B2B buyers with a clear and actionable checklist for procuring belt backing, ensuring that they make informed decisions that align with their business needs. Belt backing is a critical component in various applications, from garment making to industrial uses, and understanding how to source it effectively can enhance product quality and operational efficiency.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for belt backing. Consider factors such as width, material type (e.g., cloth-covered, plastic, or cardboard), and any specific features needed, such as eyelets for fastening. By defining these specifications upfront, you can streamline your search and ensure that potential suppliers can meet your precise needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in belt backing. Look for companies with a solid reputation in the industry and a track record of servicing clients in your geographic region. Utilize platforms like trade directories, industry associations, and online marketplaces to compile a list of potential vendors.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that suppliers adhere to relevant industry standards and certifications. This is especially important if you are sourcing from international markets, as different regions may have varying regulations. Check for certifications such as ISO, and inquire about their compliance with safety and environmental regulations, which can impact product quality and your brand reputation.

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, always request samples of the belt backing. This allows you to assess the quality, durability, and overall suitability of the product for your intended application. Pay attention to aspects like texture, flexibility, and any manufacturing defects. Testing samples can prevent costly mistakes down the line.

Step 5: Negotiate Pricing and Terms

Once you have narrowed down your supplier options, engage in discussions to negotiate pricing, payment terms, and delivery schedules. Consider factors such as minimum order quantities and shipping costs, which can significantly affect your overall budget. Establishing favorable terms can enhance your profit margins and contribute to long-term supplier relationships.

Step 6: Check References and Client Feedback

Before finalizing a supplier, request references and seek feedback from other clients who have worked with them. This step is crucial to understanding the supplier’s reliability, quality of service, and ability to meet deadlines. Look for testimonials from businesses in similar sectors or regions to gauge their performance accurately.

Illustrative image related to belt backing

Step 7: Finalize the Purchase Agreement

After selecting a supplier, ensure that you finalize a comprehensive purchase agreement that outlines all agreed-upon terms. Include details such as pricing, delivery timelines, quality expectations, and return policies. A well-documented agreement protects both parties and minimizes misunderstandings during the transaction.

By following this practical checklist, B2B buyers can enhance their sourcing strategy for belt backing, ensuring they choose suppliers that align with their operational goals and product standards.

Comprehensive Cost and Pricing Analysis for belt backing Sourcing

What Are the Key Cost Components in Belt Backing Sourcing?

When sourcing belt backing, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common options include cardboard-like materials, cloth-covered plastics, and various fabric blends. Prices can range from $1.45 to over $7.95 per yard depending on the material quality and specifications.

-

Labor: Labor costs encompass the expenses associated with manufacturing and processing the belt backing. This can vary based on the location of production, labor rates in that region, and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and other indirect costs associated with production facilities. Efficient production processes can help reduce these costs, benefiting both manufacturers and buyers.

-

Tooling: Tooling costs arise from the need for specific machinery and molds for producing customized belt backing. These costs can be amortized over larger production runs, making it more cost-effective for high-volume orders.

-

Quality Control (QC): Ensuring that the belt backing meets industry standards and buyer specifications requires investment in QC processes. This can add to the overall cost but is crucial for maintaining product integrity.

-

Logistics: Transporting materials and finished products adds another layer of costs. Factors such as distance, shipping method, and customs duties play a significant role in logistics expenses.

-

Margin: The profit margin that suppliers build into their pricing can vary widely. Understanding the typical margins in the industry can help buyers gauge the fairness of pricing.

How Do Price Influencers Affect Belt Backing Costs?

Several factors influence the pricing of belt backing, including:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders typically reduce the cost per unit due to economies of scale, making it crucial for buyers to align their purchasing strategies with anticipated needs.

-

Specifications and Customization: Custom dimensions, finishes, or specific material requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials: The choice of material not only affects the initial cost but also the durability and performance of the belt backing, which can influence long-term value.

-

Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can justify higher prices. Buyers should consider whether these certifications are necessary for their specific applications.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Strong relationships with reputable suppliers can lead to better pricing and service.

-

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) is vital for cost management. These terms dictate who bears the shipping costs and risks, impacting the overall pricing strategy.

What Are the Best Buyer Tips for Cost-Efficient Belt Backing Sourcing?

To optimize sourcing strategies for belt backing, consider the following tips:

-

Negotiate Wisely: Build relationships with suppliers and leverage volume commitments to negotiate better prices. Understanding the supplier’s cost structure can provide leverage during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and potential waste to determine the true cost over the product’s lifecycle.

-

Understand Pricing Nuances for International Sourcing: For buyers in regions like Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import duties, and regional market conditions that may affect pricing.

-

Request Samples: Before placing large orders, request samples to evaluate quality and suitability. This can prevent costly mistakes and ensure you receive the desired product specifications.

-

Stay Informed on Market Trends: Regularly monitor market trends and pricing fluctuations to make informed purchasing decisions. Engaging in industry networks or forums can provide insights into best practices and pricing strategies.

Disclaimer on Pricing

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific requirements. Always obtain current quotes from suppliers to ensure accurate budgeting and planning.

Alternatives Analysis: Comparing belt backing With Other Solutions

Understanding Alternative Solutions to Belt Backing

In the realm of industrial applications, selecting the right backing for belts is crucial for achieving optimal performance and durability. While belt backing is a popular choice, several alternative solutions exist that may cater to specific needs or preferences. This analysis compares belt backing with other viable alternatives, highlighting their respective benefits and drawbacks to aid B2B buyers in making informed decisions.

| Comparison Aspect | Belt Backing | Cloth Backing | Film Backing |

|---|---|---|---|

| Performance | Good strength and flexibility; suitable for a variety of applications | Moderate durability; less resistant to wear | High durability and moisture resistance; ideal for specific applications |

| Cost | Moderate (typically $4.95 – $7.95 per yard) | Generally lower cost (around $2 – $5 per yard) | Higher cost (ranging from $6 to $10 per yard) |

| Ease of Implementation | Easy to cut and customize; requires basic tools | Simple to work with; minimal tools needed | Requires specific tools for cutting; may need heat sealing |

| Wartung | Low maintenance; regular checks advised | Low maintenance; may require replacement sooner | Low maintenance; resistant to moisture and chemicals |

| Best Use Case | General use in various garment and accessory applications | Casual belts and fashion items | High-performance belts in demanding environments, such as industrial applications |

Exploring the Alternatives: Cloth and Film Backing

What are the Advantages and Disadvantages of Cloth Backing?

Cloth backing is a common alternative to traditional belt backing, often chosen for its lower cost and ease of use. It is typically made from woven materials that provide moderate strength and flexibility. However, while cloth backing can be a suitable choice for casual belts and fashion items, it may not withstand heavy wear and tear as effectively as belt backing. Buyers seeking a budget-friendly option for less demanding applications may find cloth backing advantageous, but should consider its limited lifespan in high-stress environments.

How Does Film Backing Compare to Belt Backing?

Film backing is another alternative that boasts superior durability and moisture resistance, making it ideal for specific industrial applications. It is often used in environments where exposure to chemicals or moisture is a concern. However, the higher cost of film backing may deter some buyers, especially for applications that do not require its advanced properties. Additionally, the implementation of film backing may necessitate specialized tools for cutting and sealing, which could complicate the production process. Businesses focused on long-term performance and reliability may find film backing to be a worthy investment.

How Can B2B Buyers Choose the Right Solution?

When evaluating belt backing against alternatives like cloth and film backing, B2B buyers should consider several key factors: the specific application requirements, budget constraints, and the expected lifespan of the product. Understanding the performance attributes and maintenance needs of each option will help businesses align their choice with operational goals. For instance, companies operating in high-stress environments may prioritize the durability of film backing, while those in fashion-focused sectors might opt for the cost-effectiveness and flexibility of cloth backing. Ultimately, the right solution will depend on balancing performance needs with financial considerations to achieve the best outcomes for their specific applications.

Illustrative image related to belt backing

Essential Technical Properties and Trade Terminology for belt backing

What Are the Key Technical Properties of Belt Backing?

When sourcing belt backing for manufacturing or crafting, understanding the essential technical properties is crucial for ensuring compatibility with production requirements and end-use performance. Here are several critical specifications:

-

Material Grade

The material grade of belt backing can vary widely, typically including options like cotton, polyester, or composite materials. Higher-grade materials offer increased durability, flexibility, and resistance to wear and tear, which is vital in industrial applications where belts undergo heavy stress. For B2B buyers, selecting the appropriate material grade ensures that the belts meet the operational demands of their specific applications, thereby reducing downtime and maintenance costs. -

Width and Thickness

Belt backing is available in various widths (commonly from ¾” to 3”) and thicknesses. The width influences compatibility with specific belt buckles and applications, while thickness impacts strength and flexibility. For instance, thicker belts are often used in heavy-duty applications requiring robust support. Buyers should consider the specific width and thickness needed for their machinery or projects to ensure optimal performance. -

Tensile Strength

This property refers to the maximum amount of tensile (pulling) stress that a belt backing can withstand before breaking. High tensile strength is essential for applications involving heavy loads or high-speed operations. Understanding tensile strength helps B2B buyers ensure that the belt backing will perform reliably under expected operational stresses, minimizing the risk of failure. -

Flexibility and Bend Radius

Flexibility indicates how easily the belt backing can bend without cracking or losing its structural integrity. The bend radius is the minimum radius the belt can form without damage. Both properties are critical in applications where belts need to navigate tight spaces or curves. Buyers should assess these properties to ensure the belt backing can adapt to the intended machinery layout without compromising performance. -

Moisture and Chemical Resistance

Depending on the operating environment, resistance to moisture and chemicals can significantly affect the longevity of belt backing. Materials that resist degradation from water or various chemicals are essential in industries such as food processing or chemicals manufacturing. B2B buyers need to evaluate their specific environmental conditions to select belt backing that will withstand potential exposure.

What Are Common Trade Terms Related to Belt Backing?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several terms commonly encountered in the belt backing industry:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for buyers looking to source belt backing that fits seamlessly with existing machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects purchasing decisions and inventory management. Buyers should negotiate MOQs that align with their production needs to avoid excess inventory or supply shortages. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. This process is crucial for comparing pricing and terms before making purchasing decisions. B2B buyers should provide detailed specifications in their RFQs to receive accurate quotes that facilitate informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers engaging in global trade to ensure clarity and mitigate risks associated with shipping and logistics. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for planning production schedules and ensuring timely delivery of components, particularly in industries where timing is critical.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing belt backing, ultimately leading to enhanced operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the belt backing Sector

What Are the Global Drivers and Current Trends Influencing the Belt Backing Market?

The belt backing market is experiencing significant transformation driven by various global factors. First, the increasing demand for customized and high-quality textile products is reshaping sourcing strategies. B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are seeking suppliers that offer versatile belt backing options, including various widths and materials. This trend is partly fueled by the rise of e-commerce platforms, enabling buyers to access a broader range of products and suppliers worldwide.

Additionally, the integration of advanced manufacturing technologies, such as automation and digital textile printing, is revolutionizing production processes. These technologies allow for rapid prototyping and shorter lead times, providing B2B buyers with the flexibility to meet changing consumer preferences. In regions like Saudi Arabia and Germany, where quality and innovation are paramount, suppliers are increasingly adopting these technologies to enhance product offerings.

Emerging trends also highlight a shift towards sustainable materials, prompting buyers to prioritize eco-friendly options. The market is witnessing a growing preference for belt backings made from recycled or organic materials, aligning with the global sustainability movement. As such, international B2B buyers are encouraged to stay informed about these trends to make strategic sourcing decisions that enhance their competitive edge.

How Are Sustainability and Ethical Sourcing Shaping the Belt Backing Sector?

Sustainability and ethical sourcing are no longer optional in the belt backing sector; they are essential components that influence buyer decisions and supplier practices. The environmental impact of production processes in textile manufacturing has led to increased scrutiny from consumers and regulators alike. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing sustainable materials.

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® serve as benchmarks for ethical practices in textile production, including belt backings. These certifications assure buyers that the materials used are environmentally friendly and produced under fair labor conditions. As a result, suppliers who obtain these certifications gain a competitive advantage in the marketplace, attracting buyers who prioritize sustainability in their sourcing decisions.

Illustrative image related to belt backing

Moreover, the shift towards circular economy principles is driving innovation in the belt backing sector. Suppliers are increasingly developing products designed for longevity and recyclability, helping to minimize waste. For buyers in regions like Europe, where sustainability regulations are stringent, sourcing from certified suppliers can mitigate risks and enhance brand reputation.

What Is the Historical Context of Belt Backing Development in the B2B Landscape?

The evolution of belt backing can be traced back to the early days of textile manufacturing, where simple fabrics were used for functionality. Over the decades, advancements in materials science and production techniques have dramatically transformed belt backings into specialized products that cater to diverse applications. Initially, cotton and leather were the primary materials; however, the introduction of synthetic options has expanded design possibilities and enhanced durability.

In the 20th century, the rise of mass production techniques further influenced the belt backing market, allowing for greater consistency and scalability. Today, the landscape is defined by innovation, with suppliers offering a range of materials—from traditional textiles to high-performance composites—tailored to meet the specific needs of B2B buyers across various industries.

This historical context underscores the importance of understanding market dynamics and sourcing trends, enabling buyers to make informed decisions that align with current demands and future opportunities.

Illustrative image related to belt backing

Frequently Asked Questions (FAQs) for B2B Buyers of belt backing

-

How do I choose the right belt backing for my manufacturing needs?

Selecting the appropriate belt backing involves understanding the specific requirements of your application. Consider factors such as the weight and flexibility of the material needed, the environment in which the belts will be used (e.g., wet or dry conditions), and the type of products being manufactured. Additionally, evaluate the compatibility of the backing with your existing machinery and processes. Consult with suppliers for samples to test performance before making a bulk purchase. -

What types of materials are available for belt backing?

Belt backing materials vary widely, including fabric, plastic, cardboard, and foam. Each type offers unique benefits; for example, fabric backings provide flexibility, while plastic options are often more durable and moisture-resistant. Consider your application’s needs, such as whether the belts will face heavy abrasion or require a specific level of support. Discuss your requirements with suppliers to find the best match for your production processes. -

What is the minimum order quantity (MOQ) for belt backing, and how does it affect pricing?

MOQs for belt backing can vary significantly between suppliers, ranging from as low as 10 yards to several hundred yards. Generally, larger orders can lead to reduced pricing per yard due to economies of scale. It’s essential to communicate your projected needs to suppliers to negotiate favorable terms, especially if you are looking to minimize costs while ensuring you have enough material for your production cycle. -

How do I ensure the quality of belt backing products before purchase?

To ensure quality, request samples from potential suppliers to assess the material’s durability and suitability for your application. Additionally, inquire about certifications, such as ISO or other industry standards, that indicate adherence to quality control processes. Conducting a factory visit or third-party inspection can also provide insights into the manufacturing practices and materials used by the supplier. -

What are the typical payment terms for purchasing belt backing internationally?

Payment terms can vary widely depending on the supplier and the buyer’s relationship. Common terms include advance payment, letters of credit, or net payment terms (e.g., Net 30 or Net 60). It is advisable to establish clear payment agreements upfront to avoid misunderstandings. Ensure that the chosen payment method is secure and provides adequate protection for both parties in case of disputes. -

What logistics considerations should I be aware of when importing belt backing?

When importing belt backing, consider shipping costs, customs duties, and delivery timelines. It’s crucial to work with reliable logistics partners who understand the complexities of international shipping. Ensure all documentation is in order to facilitate smooth customs clearance. Additionally, factor in potential delays due to regulatory compliance in your destination country, especially in regions with stringent import regulations. -

Can I customize the belt backing to meet specific design requirements?

Many suppliers offer customization options for belt backing, including size, thickness, and color. If you have specific design requirements, communicate these clearly to potential suppliers. Customization may affect pricing and lead times, so it’s vital to discuss these aspects early in the sourcing process. Be prepared to provide detailed specifications and, if necessary, prototypes to ensure the final product meets your expectations. -

What are common issues faced when sourcing belt backing internationally, and how can I mitigate them?

Common issues include supply chain disruptions, quality inconsistencies, and communication barriers. To mitigate these risks, establish strong relationships with multiple suppliers and maintain open lines of communication. Regularly review product quality and delivery performance, and consider diversifying your supplier base to avoid reliance on a single source. Additionally, stay informed about geopolitical factors that may impact trade routes or tariffs in your target markets.

Top 5 Belt Backing Manufacturers & Suppliers List

1. WeSewRetro – Belt Buckle Kits

Domain: shop.wesewretro.com

Registered: 2011 (14 years)

Introduction: Belt Making Supplies available at WeSewRetro include various belt buckle kits and belt backing kits. Key products include:

– Belt Buckle Kit – 1″ Buckle to Cover – $6.45

– Belt Buckle Kit – 3/4″ (0.75″) Buckle to Cover – $6.45

– Belt Buckle Kit – 1 1/2″ (1.5″) Buckle to Cover – $6.45

– Belt Buckle Kit – 2″ Buckle to Cover – $6.45

– Belt Buckle Kit – 3″ Buckle to Cover – $7.75 (Sold Out)

– Be…

2. GAN – Belt Backing

Domain: gotanotion.shop

Introduction: {“product_name”: “Belt Backing”, “brand”: “GAN – Got A Notion”, “prices”: [{“size”: “3/4″ YD.”, “price”: “$4.95”}, {“size”: “3/4″ ROLL”, “price”: “$86.50”}, {“size”: “1” YD.”, “price”: “$5.95”}, {“size”: “1” ROLL”, “price”: “$96.50”}, {“size”: “1 1/4″ YD.”, “price”: “$5.95”}, {“size”: “1 1/4″ ROLL”, “price”: “$105.50”}, {“size”: “2” YD.”, “price”: “$5.95”}, {“size”: “2” ROLL”, “price”: “$133.50”},…

3. Country Store Fabrics – Cloth Covered Plastic Belt Backing

Domain: countrystorefabrics.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Cloth Covered Plastic Belt Backing”, “product_code”: “100323”, “price”: “$1.45”, “availability”: “In Stock”, “size”: “3 inch black”, “minimum_order”: “1 yard”, “fraction_conversion”: {“1/4 Yard”: “.25”, “1/3 Yard”: “.33”, “1/2 Yard”: “.5”, “2/3 Yard”: “.67”, “3/4 Yard”: “.75”}}

4. Maxant – BB-075: 3/4 Belt Backing

Domain: maxant.com

Registered: 1996 (29 years)

Introduction: [{‘product_name’: ‘BB-075: 3/4″ Belt Backing’, ‘price’: ‘$5.95’, ‘length’: ’44 inches / 1.1 meters’, ‘roll_length’: ’25 yards / 22.86 meters’}, {‘product_name’: ‘BB-100: 1″ Belt Backing’, ‘price’: ‘$5.95’, ‘length’: ’44 inches / 1.1 meters’, ‘roll_length’: ’25 yards / 22.86 meters’}, {‘product_name’: ‘BB-125: 1-1/4″ Belt Backing’, ‘price’: ‘$5.95’, ‘length’: ’44 inches / 1.1 meters’, ‘roll_length’…

5. Dritz – Belting/Belt Backing

Domain: sewing.patternreview.com

Registered: 2001 (24 years)

Introduction: Dritz belting/belt backing: hard, compact, curved, plastic laminate; used for substantial self-fabric belts. Disappeared from stores and online suppliers. Alternatives mentioned: BanRol (stiff, good for waistbands and belts), available in various widths. Sources for purchase include The Sewing Place and Wawak. Maxant single-belt packs noted as available but limited. Some users report difficulty fi…

Strategic Sourcing Conclusion and Outlook for belt backing

In the evolving landscape of belt backing procurement, strategic sourcing emerges as a critical component for international B2B buyers. By understanding the diverse material options, sizes, and applications of belt backing, businesses can tailor their sourcing strategies to meet specific operational needs. Whether selecting cloth-covered plastic for versatility or abrasive belt backings for heavy-duty applications, making informed decisions enhances product quality and performance.

Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers that offer not only competitive pricing but also reliable delivery schedules and customization options. This approach ensures that companies can maintain production efficiency and meet market demands without interruption.

Looking ahead, the trend toward sustainability and innovation in manufacturing processes is expected to shape the belt backing market significantly. As global supply chains adapt, B2B buyers are encouraged to stay ahead of these trends by engaging in proactive sourcing strategies that align with their long-term goals. Embrace the opportunity to enhance your supply chain resilience—connect with suppliers who share your vision for quality and sustainability in belt backing solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to belt backing

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.