Catalog

Material Insight: Leather Apparel Fabric

B2B Product Guide: Leather Apparel Fabric Solutions

For apparel manufacturers and designers, selecting the right leather-look fabric is critical for balancing aesthetics, performance, ethics, and market demand. Traditional genuine leather faces growing challenges in consistency, environmental impact, and ethical sourcing—making high-performance faux leather (synthetic leather) the strategic choice for modern apparel production. WINIW, with 20+ years of specialized expertise in advanced synthetic leather innovation, delivers premium, sustainable solutions engineered specifically for the demanding requirements of fashion and performance wear.

Why Faux Leather is the Optimal Choice for Apparel Fabric

Faux leather outperforms traditional leather in key areas essential for scalable, responsible, and profitable apparel manufacturing:

- Sustainability & Compliance: Significantly reduces water consumption, chemical runoff, and land use compared to bovine leather. WINIW’s eco-conscious production aligns with global regulations (REACH, OEKO-TEX®) and brand ESG goals, featuring PFC-free, low-VOC, and recycled-content options.

- Ethical Assurance: Eliminates animal welfare concerns and complex traceability issues, supporting transparent, cruelty-free supply chains demanded by conscious consumers.

- Design Flexibility & Consistency: Offers uniform texture, color, and thickness across large production runs—critical for color-matching collections and reducing waste. Enables innovative finishes (matte, metallic, embossed) unachievable with genuine leather.

- Performance Durability: Engineered for stretch recovery, abrasion resistance, and weather resilience—ideal for jackets, pants, skirts, and accessories requiring frequent wear and washing.

- Cost Efficiency: Predictable pricing and reduced lead times vs. volatile genuine leather markets, with minimal cutting waste due to consistent roll goods.

Introducing WINIW: Your Trusted Synthetic Leather Partner

Since 2003, WINIW has pioneered next-generation synthetic leather for global apparel leaders. Our vertically integrated R&D and manufacturing platform combines deep technical expertise with an unwavering commitment to planet-positive innovation. We partner with brands to transform vision into reality—delivering custom-engineered fabrics that meet exact performance, aesthetic, and sustainability criteria without compromise. From concept to commercialization, WINIW ensures reliability, traceability, and excellence at every stage of your supply chain.

Elevate your apparel line with materials built for the future. WINIW: Where Performance Meets Responsibility.

Technical Performance & Standards

B2B Product Guide: WINIW Leather Apparel Fabric

WINIW specializes in high-performance synthetic leather solutions designed for the global apparel industry. Our leather apparel fabric combines technical innovation with sustainable manufacturing practices, delivering a cost-effective, durable, and customizable material ideal for fashion brands, outerwear manufacturers, and accessory producers. Engineered for scalability and compliance, WINIW’s fabric meets the rigorous demands of modern textile applications while supporting eco-conscious production goals.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces dependency on volatile raw material markets associated with genuine leather. The streamlined manufacturing process lowers production costs, minimizes waste, and supports high-volume output without compromising quality—ideal for OEMs and private-label brands seeking competitive pricing. -

Superior Durability

Our fabric features enhanced tensile strength, excellent abrasion resistance, and dimensional stability. It maintains integrity under repeated flexing and exposure to environmental stressors, ensuring longevity in garments such as jackets, pants, and footwear uppers. -

Customizable Colors & Finishes

WINIW offers full color customization with precise Pantone matching and batch consistency. Clients can also select from a range of surface textures (suede, grain, matte, glossy) and functional treatments (water-repellent, anti-scratch, soft-touch), enabling brand-specific design differentiation. -

REACH Compliant

All WINIW leather apparel fabrics are manufactured in compliance with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). Our products are free from SVHCs (Substances of Very High Concern), ensuring safety for end-users and alignment with global chemical safety standards. -

ISO 9001-Certified Quality Management

WINIW’s production facilities are ISO 9001 certified, guaranteeing a consistent, process-driven approach to quality control. From raw material sourcing to finished roll inspection, every stage adheres to internationally recognized standards for reliability and performance.

Technical Specifications

| Property | Spezifikation |

|---|---|

| Base Material | High-tenacity polyester or nylon knit |

| Coating | Polyurethane (PU) or thermoplastic polyurethane (TPU) |

| Thickness Range | 0.6 mm – 1.2 mm |

| Weight | 280 – 450 g/m² |

| Tensile Strength (MD) | ≥ 80 N/5cm |

| Elongation at Break (MD) | ≤ 25% |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 4 (Grade) |

| Martindale Abrasion | ≥ 30,000 cycles |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, texture, backing, roll width |

| Roll Width | 137 cm, 145 cm, or custom cuts |

| Minimum Order Quantity | 500 meters (color/finish) |

WINIW’s leather apparel fabric is engineered for brands seeking a responsible, high-performance alternative to genuine leather. With scalable production, rigorous quality assurance, and full regulatory compliance, our material supports sustainable innovation across the global fashion supply chain.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Synthetic Leather Apparel Fabric vs. Real Leather

As a strategic partner for forward-thinking fashion brands, WINIW provides high-performance synthetic leather solutions engineered for modern apparel demands. Understanding material selection is critical for balancing aesthetics, cost, sustainability, and brand values. Below, we objectively compare WINIW’s premium synthetic leather apparel fabrics against traditional bovine leather across key commercial criteria.

Key Advantages of WINIW Synthetic Leather for Apparel

- Consistent Supply Chain: Eliminates seasonal/grading variability, ensuring reliable production timelines.

- Enhanced Design Flexibility: Offers uniform texture, color, and thickness across all batches; compatible with laser cutting, ultrasonic welding, and digital printing.

- Reduced Waste: Precision-engineered roll goods minimize cutting waste by up to 15% vs. irregular hides.

- Traceable Sustainability: Fully documented LCA (Life Cycle Assessment) with ISO 14044 verification; 100% PFC-free and REACH-compliant.

- Animal-Free Certification: Meets global vegan textile standards (e.g., PETA-Approved Vegan) without compromising luxury aesthetics.

Comparative Analysis: Synthetic Leather Apparel Fabric vs. Real Leather

| Kriterien | WINIW Synthetic Leather Apparel Fabric | Real Leather (Bovine) |

|---|---|---|

| Cost | – 20-35% lower material cost per linear meter – Predictable pricing (no hide grade fluctuations) – Lower processing costs (no tanning, reduced waste) |

– High volatility due to hide scarcity/grade – Significant waste (25-40% unusable hide area) – Rising tanning/chemical costs (€12-18/m² avg.) |

| Dauerhaftigkeit | – Superior resistance to stains, moisture, and UV fading – Consistent abrasion resistance (50,000+ Martindale cycles) – No cracking or stiffness in cold climates |

– Prone to water damage/staining without treatment – Variable strength (depends on hide origin/grade) – Requires conditioning to prevent drying/cracking |

| Eco-Friendliness | – 60% lower carbon footprint (ISO 14067 verified) – 90% less water used in production – Contains 30-50% recycled content (e.g., PET bottles) – Fully recyclable via WINIW Take-Back Program |

– High land/water use (17,000L water per kg leather) – Toxic tanning chemicals (e.g., chromium) – Non-recyclable waste (trimmings, shavings) – Methane emissions from livestock |

Strategic Value for Your Brand

WINIW’s synthetic leather delivers commercial resilience without ethical compromise. Our closed-loop production uses renewable energy and solvents captured at 99.7% efficiency, directly supporting ESG goals and circular economy commitments. For apparel manufacturers, this translates to:

– Faster time-to-market with zero supply chain disruption risk.

– Compliance with EU Green Deal regulations (e.g., upcoming microplastic filters, chemical restrictions).

– Consumer trust through transparent, audited sustainability metrics.

Partner with WINIW to future-proof your material sourcing—where innovation meets accountability. Request our full LCA report and sample kit to validate performance for your next collection.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, eco-friendly materials. Our manufacturing excellence is built on scale, technological advancement, and uncompromising quality standards.

Our state-of-the-art production facility spans 100,000 square meters, making it one of the largest synthetic leather manufacturing bases in Asia. This extensive infrastructure enables us to support high-volume orders with consistent turnaround times, offering scalability for partners across industries such as automotive, fashion, furniture, and sportswear.

At the core of our operations is a dedicated R&D team comprised of material scientists and product engineers. This team drives continuous innovation in texture, durability, and sustainability, developing solutions that meet evolving market demands—including water-based, solvent-free, and recycled-material formulations. Our R&D capabilities ensure clients receive customized products aligned with technical and environmental requirements.

Quality control is integrated at every stage of production. We enforce strict QC protocols monitored by advanced testing equipment and certified processes. Each batch undergoes rigorous evaluation for color fastness, abrasion resistance, tensile strength, and environmental compliance, ensuring all materials meet international standards.

- 100,000 sqm manufacturing facility with automated production lines

- In-house R&D team focused on material innovation and sustainable development

- Full-cycle quality control system compliant with ISO and OEKO-TEX® standards

- Environmentally responsible production using low-impact processes

- Proven export experience to Europe, the USA, and other key global markets

WINIW’s global logistics network supports reliable delivery to B2B partners worldwide. Our synthetic leather is trusted by leading brands in Europe and North America for its consistency, performance, and compliance with regional safety and sustainability regulations. By combining manufacturing scale with technical expertise, WINIW delivers value-driven, eco-conscious solutions for international clients.

Contact Us for Samples

WINIW® Synthetic Leather: Premium Microfiber Solution for Sustainable Apparel Manufacturing

WINIW revolutionizes leather alternatives with advanced microfiber technology engineered exclusively for B2B apparel partners. Our eco-conscious manufacturing process delivers uncompromising quality, durability, and ethical sourcing—meeting stringent global sustainability standards while reducing environmental impact by up to 60% compared to traditional leather production. Partner with us to future-proof your supply chain with traceable, high-performance materials.

Key Advantages for Apparel Brands

- Superior Eco-Profile: OEKO-TEX® STANDARD 100 certified, PVC-free, and 100% solvent-free production. Reduces water consumption by 80% versus conventional leather tanning.

- Performance Parity: Mimics genuine leather’s drape, breathability, and tear resistance (tested to 45N). Retains flexibility down to -20°C for all-season wear.

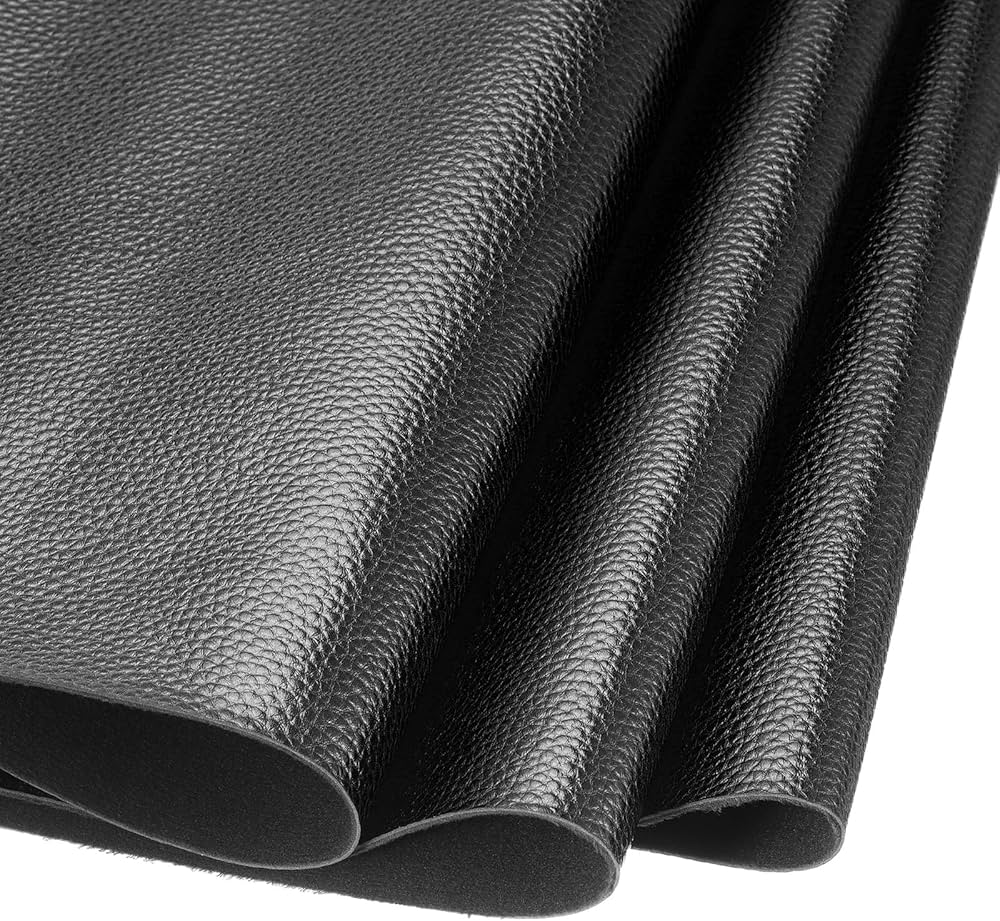

- Design Versatility: Available in 0.6–1.2mm thicknesses with customizable textures (suede, pebble, smooth), 200+ color options, and embossing capabilities.

- Supply Chain Resilience: 30-day lead times, MOQs from 500m, and global logistics support.

Technical Specifications Comparison

| Property | WINIW Microfiber Leather | Standard PU Leather |

|---|---|---|

| Tensile Strength | 45–60 N | 20–35 N |

| Abrasion Resistance | 50,000+ cycles | 15,000 cycles |

| Eco-Certifications | OEKO-TEX®, GRS, ISO 14001 | Limited/None |

| Biodegradability Rate | 40% in 5 years (soil) | <5% |

| Kohlenstoff-Fußabdruck | 3.2 kg CO2e/m² | 12.7 kg CO2e/m² |

Ideal Applications

- Outerwear (jackets, trench coats)

- Footwear uppers and linings

- Luxury handbags and accessories

- Performance sportswear trims

- Vegan-certified fashion collections

Elevate your apparel line with materials that align with conscious consumer values without sacrificing aesthetics or function. WINIW’s microfiber leather reduces waste through precision cutting compatibility and offers consistent batch-to-batch color accuracy—eliminating costly production delays.

Request Free Samples for Your Next Collection

Experience the WINIW difference firsthand. Contact our technical team to receive complimentary 30cm x 30cm swatches of our leather apparel fabric, tailored to your specifications.

→ Email MKT88@MicrofiberLeather.com with your company name, application, and required specifications. Samples dispatched within 48 hours.

WINIW: Where Innovation Meets Responsibility in Every Fiber.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.