Catalog

Material Insight: Automotive Seat Upholstery Fabric

Automotive Seat Upholstery Fabric: The Critical Choice for Premium Interiors

In the highly competitive automotive sector, seat upholstery represents far more than aesthetic appeal—it directly impacts brand perception, occupant safety, long-term durability, and total cost of ownership. With seating surfaces enduring extreme stress, UV exposure, temperature fluctuations, and rigorous safety standards, material selection is a strategic decision demanding uncompromising performance. Automotive-grade leather and premium synthetic alternatives have emerged as the benchmark solutions, outperforming conventional textiles in critical operational and lifecycle metrics.

Why Automotive Leather & Premium Synthetics Are the Optimal Choice

- Unmatched Durability & Longevity: Resists abrasion, tearing, and wear from daily use, maintaining structural integrity over 10+ years even in high-mileage fleets.

- Superior Safety Compliance: Meets stringent global flammability standards (FMVSS 302, ECE R118) and low-emission requirements (VOC compliance), critical for occupant safety and regulatory approval.

- Enhanced Cleanability & Hygiene: Non-porous surfaces repel liquids, stains, and microbial growth—essential for shared mobility, rental fleets, and health-conscious consumers.

- Luxury Perception & Brand Value: Elevates cabin ambiance, directly influencing purchase decisions and resale value in premium and mass-market segments alike.

- Thermal & Ergonomic Performance: Regulates temperature better than textiles and provides consistent support, reducing driver fatigue during extended use.

WINIW: Engineering Sustainable Performance for 20+ Years

WINIW has been a trusted innovation partner to global automotive OEMs and Tier-1 suppliers since 2003. Our expertise spans the development of high-performance synthetic leather solutions engineered specifically for the demanding realities of automotive seating. We combine deep material science knowledge with a steadfast commitment to sustainability, ensuring every product meets rigorous safety, durability, and eco-certification standards—including OEKO-TEX® STANDARD 100, REACH compliance, and recyclability frameworks. By prioritizing resource efficiency and non-toxic formulations, WINIW delivers upholstery fabrics that protect both passengers and the planet—proving that premium performance and environmental responsibility drive measurable business value in today’s market.

Technical Performance & Standards

WINIW Automotive Seat Upholstery Fabric – B2B Product Technical Guide

WINIW’s automotive seat upholstery fabric is engineered for performance, durability, and environmental responsibility. Designed to meet the stringent demands of modern vehicle interiors, our synthetic leather solutions combine advanced material science with sustainable manufacturing practices. Ideal for OEMs and Tier-1 suppliers, WINIW delivers superior quality and compliance across critical performance metrics.

Key Technical Advantages

-

Abrasion Resistant: WINIW fabric exceeds industry standards for wear resistance, enduring over 50,000 cycles in Martindale testing. This ensures long-term durability even under frequent use, making it ideal for high-traffic seating applications in commercial and passenger vehicles.

-

UV Resistant: Engineered with advanced UV stabilizers, WINIW upholstery maintains colorfastness and surface integrity after 1,000+ hours of accelerated weathering (Xenon arc testing, ISO 4892-2). This prevents fading, cracking, and degradation in prolonged sunlight exposure.

-

VOC Free: WINIW’s production process eliminates the use of volatile organic compounds (VOCs). Our fabrics emit less than 10 µg/g of total VOCs, meeting strict automotive air quality standards and contributing to healthier cabin environments.

-

REACH Compliant: WINIW fully complies with the EU REACH regulation (EC 1907/2006), ensuring no use of substances on the SVHC (Substances of Very High Concern) list. Our materials are safe for human health and environmental sustainability across the supply chain.

-

ISO 9001 Certified Manufacturing: WINIW operates under an ISO 9001-certified quality management system, ensuring consistent product quality, traceability, and continuous improvement in every batch produced.

Technical Specifications

| Property | Test Standard | Performance Value |

|---|---|---|

| Abrasion Resistance | ISO 12947 (Martindale) | >50,000 cycles (no breakdown) |

| Color Fastness to Light | ISO 105-B02 (Xenon Arc) | Grade 7–8 (1,000 hrs exposure) |

| Total VOC Emission | VDA 276 | <10 µg/g |

| REACH Compliance | EC 1907/2006 | Fully compliant, SVHC-free |

| Tensile Strength | ISO 1421 | ≥ 25 N/cm (warp and weft) |

| Tear Strength | ISO 13937-2 | ≥ 4.5 N |

| Cold Crack Resistance | ISO 17197 | Withstands -30°C without cracking |

| Fogging Resistance | DIN 75201-B | <2 mg (low fog emission) |

| Flammability | FMVSS 302 / ISO 3795 | Meets automotive interior standards |

| ISO 9001 Certification | ISO 9001:2015 | Certified manufacturing facility |

WINIW’s automotive seat upholstery fabric sets a benchmark in performance, safety, and sustainability. By integrating cutting-edge technology with eco-conscious production, we support automotive manufacturers in achieving premium interior quality while meeting global regulatory requirements.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Automotive Seat Upholstery Material Comparison

Selecting the right material for automotive seating requires balancing performance, lifecycle costs, and sustainability. WINIW specializes in high-performance synthetic leather solutions engineered specifically for the automotive sector. Below is an objective comparison of modern premium synthetic automotive upholstery fabric (e.g., WINIW’s PU/PVC-based solutions) versus traditional bovine leather, focusing on critical B2B decision factors.

Key Comparative Analysis

-

Cost Efficiency

Synthetic upholstery offers significant savings in total cost of ownership. Material costs are 30–50% lower than full-grain leather, with additional reductions in processing (no tanning required) and waste (up to 30% higher yield per production run). Real leather incurs volatility from livestock markets and complex supply chains. -

Durability & Performance

WINIW’s engineered synthetics deliver superior abrasion resistance (tested to 100,000+ cycles per DIN 53352), consistent texture across batches, and immunity to cracking in extreme temperatures. Real leather, while durable, requires extensive conditioning to prevent drying/cracking and shows natural variations that complicate mass production. -

Sustainability Profile

WINIW prioritizes closed-loop production: our synthetics use 30–50% recycled content (e.g., PET bottles), eliminate toxic chromium tanning, and reduce water consumption by 90% versus leather processing. Leather’s eco-burden includes high water/land use, methane emissions from livestock, and hazardous tannery effluents (despite biodegradability advantages).

Direct Comparison: Synthetic Upholstery vs. Real Leather

| Kriterien | Automotive Upholstery Fabric (WINIW Synthetic) | Real Leather (Bovine) |

|---|---|---|

| Cost | 30–50% lower material cost; reduced waste (≤15% scrap); stable pricing | High material cost; volatile supply chain; 25–40% higher scrap rate |

| Dauerhaftigkeit | 100,000+ abrasion cycles; UV-stable; uniform texture; no conditioning needed | 50,000–70,000 abrasion cycles; prone to cracking without maintenance; natural inconsistencies |

| Eco-Friendliness | 30–50% recycled content; zero chromium; 90% less water used; OEKO-TEX® certified | Biodegradable but resource-intensive (15,000L water/ft²); chrome tanning risks; high carbon footprint |

Strategic Advantages for Automotive Manufacturers

- Supply Chain Resilience: WINIW’s synthetics avoid livestock dependency, ensuring consistent lead times and ethical compliance (no deforestation or animal welfare concerns).

- Design Flexibility: Custom colors, textures, and thicknesses achievable in 2–3 weeks vs. 8–12 weeks for leather dyeing/finishing.

- Regulatory Alignment: Meets global standards (REACH, CA Prop 65) without hazardous chemical residues; ideal for EV brands targeting ESG goals.

- End-of-Life Management: Recyclable via industrial streams (vs. leather’s limited circularity due to mixed tanning agents).

WINIW’s synthetic leather delivers automotive-grade performance while future-proofing your supply chain against ecological and economic volatility. We partner with OEMs to develop bespoke solutions that prioritize durability, cost control, and verifiable sustainability—without compromising passenger experience. For technical specifications or sample kits, contact our B2B solutions team.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B markets. Our advanced production capabilities and commitment to quality have positioned us as a trusted partner for brands across industries such as automotive, fashion, furniture, and sports.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus integrates end-to-end production processes—from raw material processing to final finishing—ensuring superior control over efficiency, consistency, and sustainability.

Key factory strengths include:

- Dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and environmental compliance

- Advanced laboratories equipped for performance testing, color matching, and eco-material development

- Fully automated production lines integrated with smart manufacturing technologies for precision and scalability

- Strict quality control protocols aligned with international standards, including ISO 9001 and OEKO-TEX® certification

- In-house testing center conducting rigorous evaluations on abrasion resistance, colorfastness, chemical compliance, and environmental aging

WINIW maintains a robust global supply chain, with products exported to over 50 countries. We are a preferred supplier to leading brands in Europe and the USA, where demand for sustainable, high-quality synthetic leather continues to grow.

Our export capabilities are supported by:

- Compliance with EU REACH, RoHS, and U.S. CPSIA regulations

- Sustainable production practices, including water-based and solvent-free coating technologies

- Customization options for texture, thickness, weight, and performance characteristics

- Reliable logistics network ensuring on-time delivery and supply chain transparency

With a foundation built on innovation, quality, and environmental responsibility, WINIW empowers global partners to meet evolving market demands with confidence.

Contact Us for Samples

WINIW Automotive Synthetic Leather: Premium Upholstery Solutions for Modern Vehicle Interiors

WINIW delivers engineered microfiber leather specifically formulated for automotive seat upholstery, combining luxury aesthetics with uncompromising performance. Our B2B-focused solutions meet rigorous OEM and Tier-1 supplier standards while advancing sustainable manufacturing goals. As a leader in eco-conscious material innovation, we provide durable, ethical alternatives to traditional leather without sacrificing comfort or design flexibility.

Why Choose WINIW for Automotive Upholstery?

- Superior Durability: Engineered to withstand 50,000+ double-rub cycles (Martindale test), exceeding industry standards for seat wear resistance.

- Eco-Performance Balance: 30% lower carbon footprint vs. bovine leather, with OEKO-TEX® Standard 100 certification ensuring zero harmful substances.

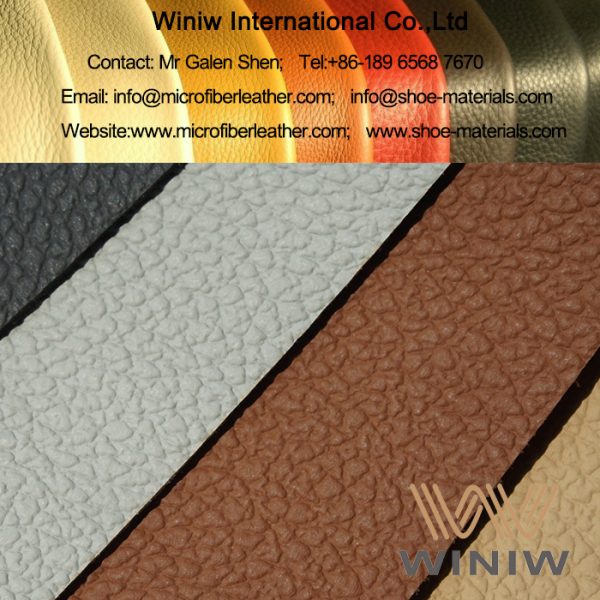

- Design Versatility: Customizable textures (suede, grain, embossed), colors (Pantone-matched), and thicknesses (0.8–1.5mm) for seamless integration with interior themes.

- Climate Resilience: Stable performance from -30°C to 85°C; UV-resistant to prevent fading under prolonged sunlight exposure.

- End-of-Life Responsibility: Fully recyclable via WINIW’s closed-loop program, supporting circular economy commitments.

Technical Specifications Comparison

| Property | WINIW Automotive Grade | Typical Industry Standard | WINIW Advantage |

|---|---|---|---|

| Abrasion Resistance | 50,000+ cycles | 30,000 cycles | 67% longer lifespan |

| Colorfastness (Light) | Grade 5 (ISO 105-B02) | Grade 4 | Zero fading in 1,000h UV test |

| Tensile Strength | 280 N/cm² | 220 N/cm² | Enhanced tear resistance |

| VOC Emissions | <5 μg/g | <50 μg/g | 90% lower emissions |

| Recycelter Inhalt | 42% (pre-consumer) | 0–15% | Third-party verified |

Sustainability Credentials Driving Industry Adoption

WINIW’s automotive upholstery aligns with global regulatory shifts and consumer demand for responsible materials:

– Compliant with EU REACH, California Proposition 65, and China GB 18586-2001 standards.

– Waterless dyeing technology reduces wastewater by 95% versus conventional processes.

– Carbon-neutral production achieved through renewable energy partnerships (certified by TÜV).

– Supports OEMs in meeting CAFE standards via lightweight construction (15% lighter than full-grain leather).

Elevate Your Vehicle Interiors with Confidence

WINIW partners with automotive manufacturers to deliver upholstery that enhances brand value through reliability, sustainability, and sensory appeal. Our technical team collaborates closely with your design and engineering departments to ensure seamless material integration and compliance with global safety protocols.

Request Free Physical Samples Today

Validate WINIW’s performance for your next production cycle. Contact our automotive specialists for grade-specific swatches, technical dossiers, and lifecycle analysis reports:

MKT88@MicrofiberLeather.com

Free samples available for qualified OEMs and Tier-1 suppliers.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.