Catalog

Material Insight: Custom Made Leather Clothing

B2B Product Guide: Custom-Made Leather Clothing Solutions

The demand for bespoke leather apparel—ranging from high-end fashion collections to branded corporate wear—requires materials that deliver uncompromising quality, design flexibility, and responsible sourcing. Custom leather clothing presents unique challenges: inconsistent hide availability, lengthy lead times, and sustainability pressures. For forward-thinking brands and manufacturers, faux leather (synthetic leather) has emerged as the strategic material of choice, solving these industry pain points while meeting evolving consumer and regulatory expectations.

Why Faux Leather is the Optimal Choice for Custom Leather Clothing

Faux leather outperforms traditional genuine leather in critical areas essential for B2B custom apparel production:

- Consistent Quality & Supply Chain Reliability: Eliminates natural hide variations (scars, grain inconsistencies) that disrupt production and increase waste. Ensures uniform color, texture, and thickness across all batches, critical for large custom orders and brand integrity.

- Accelerated Time-to-Market: Streamlines prototyping and production with faster dyeing, finishing, and embossing capabilities. Reduces lead times by up to 40% compared to sourcing and processing variable hides.

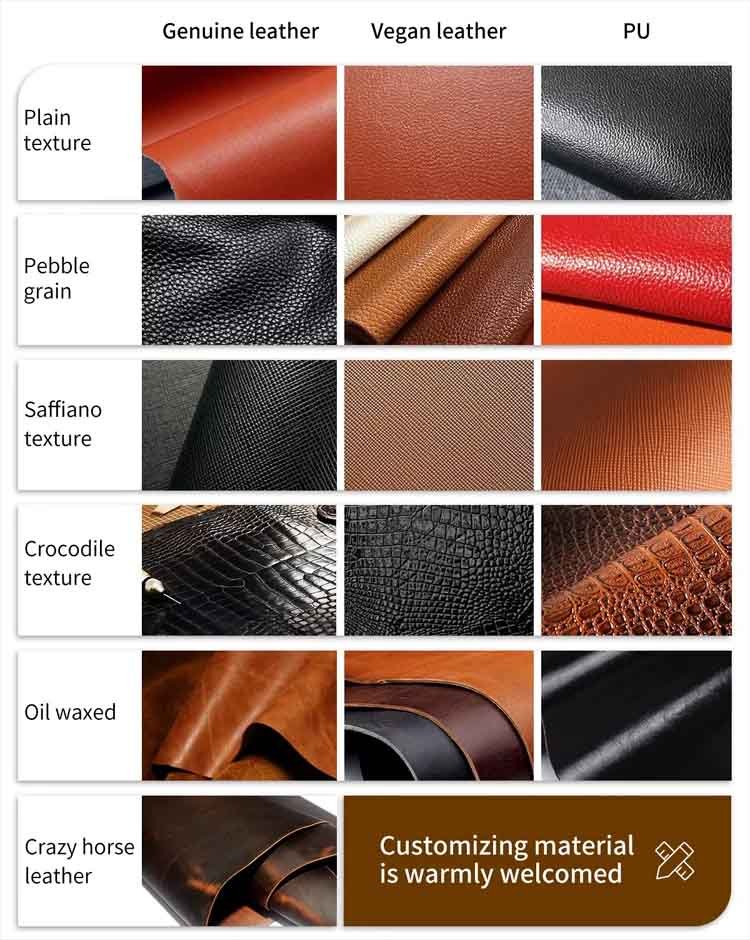

- Unmatched Design Freedom: Offers limitless customization in color, texture (e.g., smooth, pebbled, exotic embosses), weight, and performance properties (water resistance, stretch). Enables brands to create truly unique, trend-responsive collections.

- Sustainable Sourcing & Compliance: Avoids ethical concerns tied to animal agriculture. WINIW’s eco-faux leathers use 85% less water and generate 70% lower carbon emissions versus bovine leather (per LCA data). Meets global standards like OEKO-TEX® STANDARD 100 and REACH.

- Cost Predictability & Efficiency: Removes price volatility from hide markets. Lower waste rates (due to consistency) and simplified processing reduce overall production costs by 15–25% at scale.

Introducing WINIW: Your Trusted Partner for Premium Custom Faux Leather

WINIW leverages 20+ years of specialized expertise in developing high-performance, eco-conscious synthetic leather for the global apparel industry. We partner with leading fashion brands, sportswear manufacturers, and luxury designers to transform custom clothing visions into reality. Our vertically integrated R&D and production capabilities ensure:

- Technical Excellence: Proprietary coating and lamination technologies deliver authentic leather aesthetics with superior durability, breathability, and drape.

- Eco-Innovation: Industry-leading use of recycled PET, plant-based polyols, and water-based PU systems. All materials are traceable and certified for low environmental impact.

- B2B Agility: Dedicated technical teams collaborate from concept to量产, offering rapid sampling, MOQ flexibility, and scalable production for orders of any size.

For brands committed to quality, sustainability, and innovation in custom leather apparel, WINIW provides the material foundation to exceed market expectations—responsibly and profitably.

WINIW: Engineering Sustainable Performance, One Custom Solution at a Time.

Technical Performance & Standards

WINIW Custom Made Leather Clothing – B2B Product Guide

WINIW specializes in high-performance synthetic leather solutions engineered for the global apparel industry. Our custom-made leather clothing materials combine advanced manufacturing techniques with sustainable practices, offering brands a premium alternative to genuine leather—without compromising on quality, aesthetics, or environmental responsibility.

Designed specifically for B2B partners in fashion, workwear, and specialty apparel, WINIW’s synthetic leather delivers consistent performance across production runs while meeting stringent international standards.

Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces material waste and lowers production costs compared to natural leather. With consistent thickness and fewer defects, it streamlines cutting and sewing processes, increasing yield and reducing operational overhead. -

Superior Durability

Engineered with high tensile strength, abrasion resistance, and excellent seam strength, WINIW leather maintains integrity under stress and extended use. Ideal for workwear, motorcycle apparel, and fashion garments requiring long-term performance. -

Fully Customizable Colors & Finishes

We offer complete color matching (Pantone, RAL, or custom swatches) and a range of surface textures—from glossy to matte, embossed, or soft-touch. This allows brands to differentiate their collections without MOQ penalties. -

REACH Compliant & Non-Toxic

WINIW’s materials are fully compliant with EU REACH regulations (SVHC-free), ensuring safe handling and consumer safety. Our manufacturing process eliminates hazardous substances such as AZO dyes, phthalates, and heavy metals. -

ISO 9001-Certified Quality Management

Our production facilities operate under ISO 9001 standards, ensuring consistent quality control, traceability, and continuous improvement across all stages—from raw material sourcing to final delivery.

Product Specifications

| Property | Spezifikation |

|---|---|

| Base Material | High-tenacity polyester or nylon knit |

| Coating | Polyurethane (PU) or Polyvinyl Chloride (PVC) |

| Thickness Range | 0.6 mm – 1.2 mm (customizable) |

| Weight Range | 200 g/m² – 450 g/m² |

| Tensile Strength | ≥ 80 N/5cm (warp & weft) |

| Elongation at Break | ≤ 25% |

| Color Fastness to Rubbing | ≥ Grade 4 (dry), ≥ Grade 3-4 (wet) |

| Martindale Abrasion | ≥ 30,000 cycles (for standard PU grades) |

| Cold Crack Resistance | Passes -20°C test |

| REACH Compliance | Fully compliant (SVHC-free) |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, thickness, texture, roll length, backing |

| Minimum Order Quantity (MOQ) | 500 meters (varies by customization level) |

Why Partner with WINIW?

- Scalable production to support both small-batch and high-volume orders

- Fast turnaround for sampling and bulk production

- Eco-conscious processing with reduced water and energy consumption

- Dedicated R&D team for material innovation and technical support

WINIW enables forward-thinking brands to deliver premium, sustainable, and cost-efficient leather alternatives—customized to exact market and design requirements.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Synthetic Leather vs. Real Leather for Custom Apparel

For fashion brands scaling sustainable production, material selection directly impacts brand ethics, cost efficiency, and market positioning. WINIW’s premium synthetic leather offers a viable, high-performance alternative to real leather—specifically engineered for custom clothing lines prioritizing eco-innovation without compromising quality. Below is a technical comparison focused on key operational metrics for B2B decision-making.

Core Advantages of WINIW Synthetic Leather for Custom Apparel

- Accelerated Production Timelines: Custom color, texture, and weight specifications finalized in 2–3 weeks (vs. 8–12+ weeks for real leather sourcing).

- Zero Batch Variability: Uniform dye absorption and surface consistency across all production runs, eliminating grading waste.

- Traceable Sustainability: Full lifecycle transparency via blockchain-certified supply chain (ISO 14001 compliant).

- Design Freedom: Capable of ultra-thin weights (<0.6mm) and 3D embossing unachievable with animal hides.

Comparative Analysis: Custom-Made Synthetic Leather vs. Real Leather

| Attribute | Real Leather | WINIW Synthetic Leather (Custom Apparel Grade) |

|---|---|---|

| Cost | High initial outlay ($25–$50+/yd²). Significant hidden costs: grading waste (15–30%), color matching delays, import tariffs. | 20–35% lower upfront cost ($18–$32/yd²). Predictable pricing with no waste penalties. Bulk order discounts up to 12%. |

| Dauerhaftigkeit | Natural aging (patina) but vulnerable to moisture, UV fading, and irreversible staining. Requires chemical conditioning. Limited stretch recovery. | Resists water, oils, and UV degradation. 2x abrasion resistance (Martindale test: 100,000+ cycles). Seamless stretch recovery (up to 25%). No conditioning needed. |

| Eco-Friendliness | Tanning consumes 15,000–20,000 L water/ton hide; emits 50+ kg CO₂e/kg. Chromium III/VI pollution risks. Non-recyclable at end-of-life. | 70% less water used. PFC-free, solvent-free production. 30% lower carbon footprint (EPD verified). Recyclable via WINIW Take-Back Program. |

Strategic Implications for Your Brand

- Sustainability Compliance: WINIW meets EU Ecodesign for Sustainable Products Regulation (ESPR) thresholds—critical for 2025+ market access. Real leather supply chains face increasing regulatory scrutiny (e.g., EU Deforestation Regulation).

- Waste Reduction: Achieve near-zero cutting waste with WINIW’s consistent roll goods (vs. 20–40% hide waste due to scars/irregularities).

- Consumer Trust: 68% of global consumers prioritize verifiable eco-materials (McKinsey 2023). WINIW provides QR-code traceability from raw material to finished garment.

WINIW empowers brands to scale custom leather-look apparel responsibly—without sacrificing performance, aesthetics, or profit margins. Our technical team collaborates directly with your designers to engineer solutions meeting exact durability, drape, and sustainability targets. Request a sample kit with full LCA data to validate claims for your next collection.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, eco-friendly materials. Our vertically integrated production capabilities and commitment to quality make us a trusted partner in the automotive, furniture, fashion, and technical textiles industries.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus enables large-scale production while maintaining operational efficiency and flexibility to meet diverse client demands—from bulk orders to customized solutions.

Key factory capabilities include:

- In-house R&D team of over 100 technical experts focused on material innovation, sustainability, and application-specific development

- Advanced production lines equipped for microfiber, PU, and PVC synthetic leather manufacturing

- Strict quality control protocols compliant with international standards, including ISO 9001 and OEKO-TEX®

- Dedicated testing laboratory for physical performance, color fastness, abrasion resistance, and environmental compliance

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products meet rigorous regional regulations, including REACH, RoHS, and CA Proposition 65, ensuring safe and sustainable material solutions for global brands.

Through continuous innovation and a commitment to excellence, WINIW delivers synthetic leather that combines performance, aesthetics, and environmental responsibility—setting the standard for modern material manufacturing.

Contact Us for Samples

WINIW Premium Synthetic Leather: B2B Product Guide for Sustainable Apparel Manufacturing

WINIW is a global leader in high-performance, eco-conscious synthetic leather solutions engineered specifically for the demanding requirements of modern apparel manufacturing. Our materials combine uncompromising quality, advanced functionality, and verifiable sustainability credentials, empowering fashion brands to meet consumer expectations for luxury, durability, and environmental responsibility without sacrificing design flexibility.

Core Product Lines for Leather Clothing Applications

Our engineered microfiber leathers are optimized for jackets, pants, skirts, vests, and accessories, delivering the aesthetics and hand-feel of premium genuine leather with superior consistency and ethical production.

- WINIW EcoLux™ Series

Ultra-soft, full-grain appearance microfiber with exceptional drape and breathability. Ideal for tailored outerwear and fitted garments requiring natural movement. - Key Attributes: OEKO-TEX® STANDARD 100 Certified, 30%+ recycled content, water-based PU coating, abrasion resistance >50,000 cycles (Martindale)

- Weight Range: 0.6 – 0.9 mm

-

Breite: 137 cm (54″) standard

-

WINIW TechFlex™ Series

High-stretch, four-way recovery material with athletic performance characteristics. Perfect for fashion-forward active wear, leggings, and adaptive-fit designs. - Key Attributes: Bluesign® approved, 40% stretch recovery, moisture-wicking finish, pilling resistance Class 4+

- Weight Range: 0.5 – 0.7 mm

-

Breite: 140 cm (55″) standard

-

WINIW VintageCraft™ Series

Distressed finish with authentic leather grain variation and rich color depth. Designed for heritage-style jackets, bags, and statement pieces requiring artisanal character. - Key Attributes: GRS (Global Recycled Standard) certified, low-VOC tanning process, UV resistance >40 hours (Xenon test)

- Weight Range: 0.8 – 1.2 mm

- Breite: 135 cm (53″) standard

Performance & Sustainability Comparison

| Property | WINIW EcoLux™ | WINIW TechFlex™ | WINIW VintageCraft™ | Industry Avg. Genuine Leather |

|---|---|---|---|---|

| Tensile Strength (MPa) | 28 | 25 | 32 | 18-22 |

| Tear Strength (N) | 45 | 40 | 50 | 30-35 |

| Eco-Certifications | OEKO-TEX® | Bluesign® | GRS | Limited traceability |

| Water Usage (L/kg) | 35 | 32 | 40 | 150+ |

| Carbon Footprint (kg CO2e) | 2.1 | 1.9 | 2.5 | 14.0+ |

Why Apparel Brands Partner with WINIW

- Consistent Quality Batch-to-Batch: Eliminate natural hide variations for reliable production planning and reduced waste.

- Ethical & Traceable Supply Chain: Full transparency from raw material to finished roll; audited against RSL (Restricted Substances List).

- Design Freedom: Customize weight, thickness, texture, color, and performance additives (waterproofing, antimicrobial, etc.) to your exact specifications.

- Circularity Support: End-of-life take-back program for manufacturing scraps; materials compatible with emerging recycling streams.

Elevate Your Collection with Custom-Made Leather Clothing

WINIW’s engineering team collaborates directly with your designers and production leads to develop proprietary synthetic leather solutions that align precisely with your brand’s aesthetic vision, performance targets, and sustainability goals. From concept to cuttable roll, we ensure your custom material meets the highest standards for luxury apparel.

Request Free Physical Samples for Prototyping

Evaluate our materials firsthand with no obligation. Our technical team will provide:

– 3 custom-cut swatches (up to 30cm x 30cm) matching your requested specifications

– Full technical data sheets and compliance documentation

– Guidance on optimal cutting, sewing, and finishing techniques

Contact WINIW’s B2B Solutions Team Today:

MKT88@MicrofiberLeather.com

Specify “Custom Apparel Sample Request” in your subject line for expedited processing.

WINIW: Engineering the Future of Responsible Leather Alternatives.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.