Catalog

Material Insight: Leather Fabric Material

B2B Product Guide: Leather Fabric Material

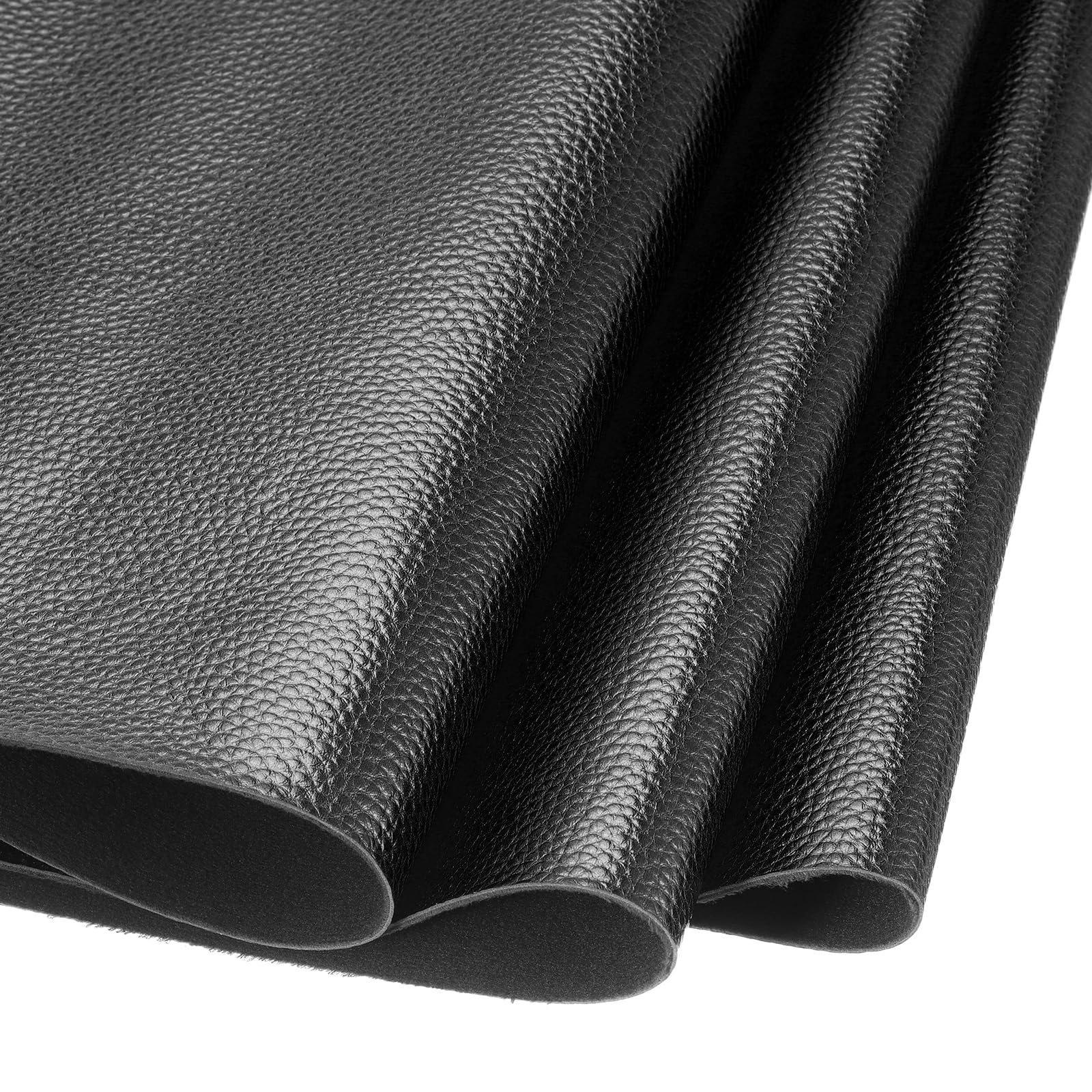

Leather fabric material has become a cornerstone in a wide range of industries, including furniture, automotive interiors, fashion accessories, and upholstery. As demand for sustainable, durable, and cost-effective alternatives to genuine leather grows, faux leather—also known as synthetic leather—has emerged as a leading solution. Engineered to deliver the aesthetic appeal and tactile qualities of natural leather without the associated environmental and ethical concerns, modern faux leather offers consistent quality, enhanced performance, and greater design flexibility.

Why Faux Leather is the Best Choice for This Application

Faux leather stands out as the optimal material choice for commercial and industrial applications due to its numerous advantages:

- Sustainability: Faux leather reduces reliance on animal hides, supporting cruelty-free and eco-conscious production practices.

- Dauerhaftigkeit: Resistant to cracking, fading, and abrasion, synthetic leather maintains its appearance and integrity over extended use.

- Consistency: Unlike natural leather, which can vary in grain and texture, faux leather offers uniform quality across large production runs.

- Customization: Available in a wide range of colors, finishes, and textures, it allows for tailored solutions to meet specific design and functional requirements.

- Cost-Efficiency: Lower production and maintenance costs make faux leather a financially viable option for high-volume manufacturing.

- Low Maintenance: Easy to clean and resistant to stains and moisture, it is ideal for high-traffic environments.

Introducing WINIW

WINIW is a globally recognized leader in the development and production of high-performance synthetic leather solutions. With over 20 years of industry expertise, WINIW has built a reputation for innovation, quality, and sustainability. Our advanced manufacturing processes utilize premium polyurethane (PU) and microfiber materials to create leather fabrics that mimic the look and feel of genuine leather while exceeding it in performance and environmental responsibility.

We serve a diverse portfolio of B2B clients across furniture, transportation, electronics, and lifestyle sectors, delivering customized materials that align with both technical specifications and sustainability goals. Backed by rigorous quality control and a commitment to R&D, WINIW continues to set benchmarks in the synthetic leather industry—empowering brands to create responsibly without compromising on quality or design.

Technical Performance & Standards

WINIW Engineered Leather Fabric Material: Technical Product Guide for B2B Applications

WINIW’s engineered leather fabric material represents a strategic advancement in sustainable, high-performance synthetic surfaces for demanding commercial applications. Designed specifically for B2B partners in furniture, automotive interiors, luggage, and technical textiles, our material delivers exceptional value through optimized performance, rigorous compliance, and supply chain efficiency. Moving beyond traditional leather and basic synthetics, WINIW provides a scientifically formulated solution that addresses core operational and sustainability challenges faced by manufacturers.

Core Technical Advantages for Your Business:

- Cost-Effective Performance: Engineered with precision thickness control (0.6mm to 1.2mm standard) and high yield rates, WINIW material minimizes cutting waste by up to 30% compared to inconsistent natural hides. Its inherent stability reduces production downtime and rework, lowering total cost of ownership. The absence of solvent-based processing in our standard lines further decreases VOC abatement costs and regulatory burdens.

- Superior Durability & Longevity: Our proprietary polymer matrix and advanced coating technologies deliver exceptional resistance to abrasion (tested to 50,000+ cycles Wyzenbeek), tearing, and seam slippage. WINIW material maintains structural integrity and aesthetic appeal under rigorous use, significantly extending product lifespan and reducing warranty claims. Enhanced UV resistance (ISO 105-B02) prevents fading and degradation in both interior and semi-exterior applications.

- Extensive & Consistent Color Customization: Access our comprehensive digital color library featuring over 1,200 standard options, all rigorously batch-controlled for absolute consistency. WINIW offers rapid, low-MOQ custom color matching (Pantone®/RAL) without sacrificing performance, enabling responsive design cycles and unique brand differentiation. Colorfastness ratings consistently exceed Grade 4 (ISO 105-C06) for washing and light exposure.

- Guaranteed REACH Compliance: WINIW material is proactively manufactured to fully comply with the stringent EU REACH Regulation (EC) No 1907/2006, including Annex XVII restrictions on SVHCs (Substances of Very High Concern). Comprehensive, up-to-date test reports are readily available for every production batch, ensuring seamless market access and mitigating supply chain risk for global partners.

- ISO 9001 Certified Quality Management: Every meter of WINIW material is produced under our rigorously audited ISO 9001:2015 certified quality management system. This guarantees consistent dimensional stability, physical properties, and surface finish across all production runs, providing the reliability your manufacturing processes demand.

Technical Specifications Overview:

| Property | WINIW Standard Range/Value | Key Standard/Method | Advantage for B2B Production |

|---|---|---|---|

| Thickness | 0.6 mm – 1.2 mm | ISO 2417 | Optimized for cutting yield, consistent lamination |

| Tensile Strength (MD) | ≥ 25 N/mm² | ISO 1766 | Resists tearing during fabrication & use |

| Tear Strength (MD) | ≥ 45 N | ISO 13937-1 (Elmendorf) | Enhances product longevity, reduces failure |

| Abrasion Resistance | ≥ 50,000 cycles | ISO 5470-1 (Martindale) | Superior wear life, meets heavy-duty specs |

| Color Fastness (Wash) | ≥ Grade 4 | ISO 105-C06 | Maintains appearance after cleaning |

| Color Fastness (Light) | ≥ Grade 6 (Blue Scale) | ISO 105-B02 | Excellent UV resistance, minimal fade |

| REACH Compliance | Full Annex XVII Adherence | EC 1907/2006 | Guaranteed market access, reduced risk |

| Production Standard | ISO 9001:2015 Certified | Quality Management System | Batch-to-batch consistency, reliability |

WINIW’s commitment to eco-conscious engineering is fundamental. Our standard material lines utilize water-based and solvent-free production processes, significantly reducing environmental impact without compromising performance metrics. Partnering with WINIW means gaining a reliable source of technically superior, compliant, and customizable synthetic leather that directly enhances your product quality, operational efficiency, and sustainability profile. Request our detailed technical datasheets and compliance documentation to integrate WINIW material into your next high-value project.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather Fabric vs. Real Leather

In the evolving landscape of material sourcing for industries such as furniture, automotive, fashion, and accessories, businesses are increasingly evaluating the benefits and trade-offs between synthetic leather fabric materials and real leather. This guide provides a professional comparison to support informed procurement and product development decisions.

Synthetic leather—often referred to as leatherette, faux leather, or engineered leather—is typically made from polyurethane (PU) or polyvinyl chloride (PVC) laminated onto a fabric backing. In contrast, real leather is derived from animal hides, primarily bovine, through a tanning process that preserves and stabilizes the natural material.

Each material presents distinct advantages and limitations across key performance and sustainability metrics:

- Cost Efficiency: Synthetic leather offers a more predictable and generally lower production cost. It eliminates the variability and premium pricing associated with high-grade animal hides.

- Dauerhaftigkeit: Real leather typically outperforms in long-term wear, developing a desirable patina over time. However, modern synthetic leathers—especially high-performance PU variants—offer excellent resistance to abrasion, UV light, and staining, with consistent thickness and fewer natural imperfections.

- Eco-Friendliness: Real leather utilizes a byproduct of the meat industry, reducing waste. However, its tanning process—especially chrome tanning—can involve toxic chemicals and high water consumption. In contrast, premium synthetic leathers, such as those made from bio-based or recycled content, offer lower environmental impact, especially when manufactured using closed-loop systems.

WINIW specializes in advanced synthetic leather solutions that prioritize durability, aesthetic versatility, and environmental responsibility. Our materials are engineered for B2B applications requiring consistent quality, scalability, and compliance with eco-standards such as REACH, RoHS, and OEKO-TEX.

Below is a comparative overview:

| Metric | Synthetic Leather Fabric | Real Leather |

|---|---|---|

| Cost | Lower to moderate | High (especially full-grain) |

| Dauerhaftigkeit | High (resists fading, cracking; uniform quality) | Very high (ages well, develops patina; may show natural flaws) |

| Eco-Friendliness | Moderate to high (depends on base polymer and manufacturing; PU > PVC; recyclable options available) | Moderate (uses animal byproducts but tanning has high environmental cost) |

Key considerations for B2B buyers:

- Synthetic leather enables design consistency, faster production cycles, and compliance with vegan and animal welfare standards.

- Real leather remains preferred in luxury markets for its tactile authenticity and heritage appeal.

- Innovations in bio-based polymers and water-based coatings are narrowing the performance and sustainability gap, making synthetic leather a competitive, future-forward choice.

For partners seeking scalable, eco-conscious, and high-performance materials, synthetic leather from trusted manufacturers like WINIW delivers a responsible alternative without compromising on quality or aesthetics.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global Brands

WINIW operates one of Asia’s most advanced synthetic leather manufacturing facilities, engineered to deliver consistent quality, scalability, and innovation for B2B partners worldwide. Our vertically integrated 100,000 sqm campus in China serves as the cornerstone of reliable supply chain solutions, combining industrial capacity with rigorous environmental stewardship.

Core Manufacturing Capabilities

- Scale & Infrastructure: 100,000 sqm production ecosystem housing automated coating lines, precision embossing units, and dedicated R&D laboratories, enabling 50,000+ meters of daily output.

- Innovation Engine: 150+ member R&D team specializing in eco-material science, holding 47 patents for water-based PU/PVC formulations, recyclable backings, and low-carbon processes.

- Qualitätssicherung: Triple-tier QC protocol (incoming materials → inline production → final shipment) with AQL 1.0 standards, 100% roll inspection, and ISO 9001/14001-certified traceability.

Global Compliance & Export Readiness

All WINIW facilities adhere to stringent international regulatory frameworks, ensuring seamless market access:

| Certification | Scope | Key Markets Validated |

|---|---|---|

| REACH/ROHS | Heavy metal & phthalate limits | EU, UK, Switzerland |

| CPSIA | Lead/chemical safety | USA, Canada |

| OEKO-TEX® STANDARD 100 | Harmful substance screening | Global retail networks |

| ISO 14064 | Carbon footprint management | Eco-conscious brands |

Why Global Brands Partner with WINIW

- Supply Chain Resilience: 15+ years exporting to Tier-1 European/US fashion, automotive, and furniture brands with 99.6% on-time delivery rate.

- Sustainable Scale: LEED-certified facility using 30% recycled energy and closed-loop water systems, reducing ecological impact per meter by 40% vs. industry average.

- Technical Collaboration: Co-development programs for custom textures, bio-based content (up to 35%), and circularity-focused materials meeting GRS/SCS standards.

WINIW transforms manufacturing scale into strategic advantage for B2B clients—delivering not just materials, but certified, scalable pathways to sustainable performance. Partner with us to integrate rigorously controlled innovation into your next collection.

Contact Us for Samples

WINIW Microfiber Leather – Premium Synthetic Leather Fabric for B2B Applications

WINIW is a leading innovator in high-performance synthetic leather solutions, delivering eco-friendly, durable, and luxurious microfiber leather fabric tailored for commercial and industrial applications. Our advanced manufacturing processes ensure consistent quality, superior texture, and exceptional performance across diverse industries—from automotive and furniture to fashion and footwear.

Engineered to meet rigorous industry standards, WINIW microfiber leather offers a sustainable alternative to genuine leather without compromising on aesthetics or functionality. With a strong commitment to environmental responsibility, our materials are free from harmful substances and produced using low-impact processes.

Key Advantages of WINIW Microfiber Leather Fabric:

- High durability and abrasion resistance for long-term use

- Excellent tensile and tear strength suitable for heavy-duty applications

- Superior breathability and soft hand feel for enhanced comfort

- UV and colorfast resistance ensuring lasting appearance

- Water-resistant and easy to clean, ideal for high-traffic environments

- Eco-conscious production with reduced carbon footprint and recyclable components

- Customizable thickness, texture, color, and finish to meet specific client requirements

Industry Applications:

- Automotive interiors (seats, dashboards, door panels)

- Upholstered furniture and residential/commercial seating

- Sports and protective gear

- Luggage, handbags, and accessories

- Footwear and apparel

Technical Specifications (Standard Grade):

| Property | Value |

|---|---|

| Thickness | 0.6 mm – 1.8 mm (customizable) |

| Weight | 200 – 400 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Color Fastness | ≥ Grade 4 (Xenon arc test) |

| Cold Crack Resistance | ≤ -30°C |

| Compliance | REACH, RoHS, OEKO-TEX® STANDARD 100 |

WINIW supports global B2B partners with scalable production capacity, fast lead times, and comprehensive technical support. Our R&D team collaborates closely with clients to develop bespoke solutions that align with brand values and performance needs.

Request Free Samples Today

Experience the quality and versatility of WINIW microfiber leather firsthand. Free samples are available for qualified business partners.

For inquiries about our leather fabric material, contact:

MKT88@MicrofiberLeather.com

Elevate your product line with sustainable innovation—choose WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.