Introduction: Navigating the Global Market for custom made leather holsters

In the dynamic landscape of the global market for custom made leather holsters, B2B buyers face the challenge of sourcing products that not only meet quality standards but also align with specific regional preferences and regulations. As international buyers from Africa, South America, the Middle East, and Europe seek reliable suppliers, understanding the diverse types and applications of leather holsters becomes crucial. This guide provides a comprehensive overview of the various styles—ranging from shoulder holsters to IWB and OWB models—each tailored for different firearms and uses.

Moreover, the guide delves into essential aspects of supplier vetting, ensuring that buyers can identify reputable manufacturers who uphold quality craftsmanship and ethical sourcing practices. It also addresses cost considerations, helping businesses navigate pricing structures that vary across regions and product specifications. By equipping B2B buyers with actionable insights and expert recommendations, this guide empowers informed purchasing decisions that can enhance product offerings and meet customer demands effectively.

Whether you are a distributor looking to expand your portfolio or a retailer aiming to provide your clients with the best in leather holster technology, understanding the intricacies of this market is vital. Join us as we explore the essential elements that will help you successfully navigate the global landscape of custom made leather holsters.

Table Of Contents

- Top 6 Custom Made Leather Holsters Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom made leather holsters

- Understanding custom made leather holsters Types and Variations

- Key Industrial Applications of custom made leather holsters

- 3 Common User Pain Points for ‘custom made leather holsters’ & Their Solutions

- Strategic Material Selection Guide for custom made leather holsters

- In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather holsters

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather holsters’

- Comprehensive Cost and Pricing Analysis for custom made leather holsters Sourcing

- Alternatives Analysis: Comparing custom made leather holsters With Other Solutions

- Essential Technical Properties and Trade Terminology for custom made leather holsters

- Navigating Market Dynamics and Sourcing Trends in the custom made leather holsters Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather holsters

- Strategic Sourcing Conclusion and Outlook for custom made leather holsters

- Important Disclaimer & Terms of Use

Understanding custom made leather holsters Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Inside the Waistband (IWB) | Concealed carry design, fits inside the waistband, minimal bulk | Law enforcement, personal defense | Pros: Discreet, comfortable for daily wear. Cons: May require specific sizing for comfort. |

| Outside the Waistband (OWB) | Mounted on the outside of the waistband, easier access | Tactical operations, outdoor activities | Pros: Quick draw, often more comfortable. Cons: Less concealed, may be bulkier. |

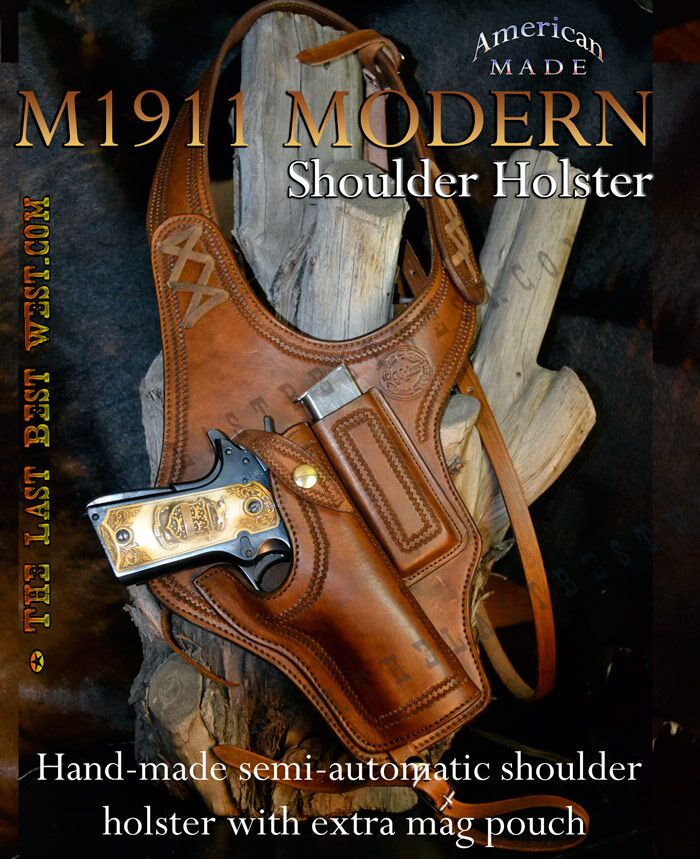

| Shoulder Holsters | Suspended from the shoulders, distributes weight evenly | Professional security, law enforcement | Pros: Comfortable for extended wear, good concealment. Cons: Can be cumbersome to put on. |

| Crossdraw Holsters | Designed for drawing across the body, ideal for seated carry | Driving, tactical situations | Pros: Fast access from seated positions. Cons: May not be suitable for all body types. |

| Ankle Holsters | Secured around the ankle, ideal for deep concealment | Plainclothes law enforcement, civilians | Pros: Extremely discreet, good for backup weapons. Cons: Limited accessibility, may shift during movement. |

What Are the Characteristics of Inside the Waistband (IWB) Holsters?

Inside the Waistband (IWB) holsters are designed for concealed carry by fitting snugly within the waistband of pants. This design minimizes bulk and allows for easy concealment under clothing, making it a preferred choice for law enforcement and personal defense. When purchasing, consider the holster’s material, retention features, and comfort level, as these factors significantly affect usability during extended wear.

How Do Outside the Waistband (OWB) Holsters Differ from IWB Options?

Outside the Waistband (OWB) holsters are mounted externally, providing quicker access to the firearm. These holsters are often favored in tactical operations or outdoor activities where rapid draw is essential. Buyers should consider the holster’s retention mechanism and material durability, as these will influence the holster’s performance in rugged environments. While they offer comfort and accessibility, they may sacrifice some concealment.

What Are the Advantages of Shoulder Holsters?

Shoulder holsters distribute the weight of the firearm across the shoulders, making them ideal for professional security personnel and law enforcement officers who require extended wear. These holsters provide excellent concealment and comfort but can be cumbersome to don and doff. B2B buyers should assess the adjustability and fit of the holster to ensure it meets the specific needs of their personnel.

Illustrative image related to custom made leather holsters

Why Choose Crossdraw Holsters for Tactical Situations?

Crossdraw holsters allow for firearm access by drawing across the body, which is particularly advantageous for individuals seated in vehicles. This design is beneficial in tactical situations where quick access is necessary. When selecting a crossdraw holster, consider the draw angle and how it accommodates various body types to ensure optimal performance and comfort.

What Makes Ankle Holsters Suitable for Deep Concealment?

Ankle holsters are an excellent choice for deep concealment, securing the firearm around the ankle. They are commonly used by plainclothes law enforcement or civilians seeking a backup weapon. However, they can be challenging to access quickly, and buyers should evaluate the holster’s stability and comfort during movement to prevent shifting. This type is best for those who prioritize discretion over immediate accessibility.

Key Industrial Applications of custom made leather holsters

| Industry/Sector | Specific Application of custom made leather holsters | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Duty holsters for firearms and equipment | Enhanced safety and accessibility for officers in the field | Durability, comfort, and fit for specific weapons and gear |

| Military | Tactical holsters for various firearms | Improved operational efficiency and quick access during missions | Customization for specific military needs and environments |

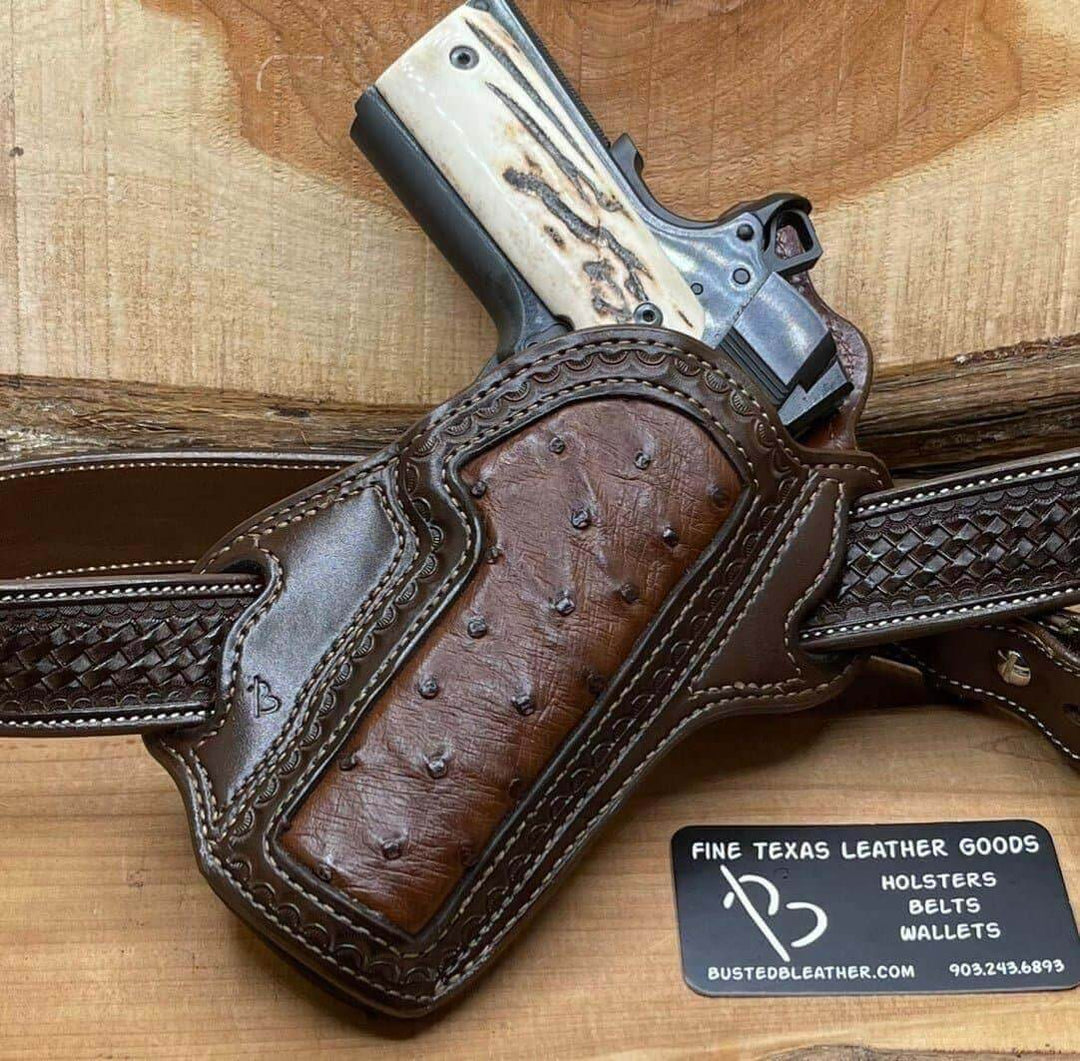

| Outdoor Recreation | Holsters for hunting and shooting sports | Secure and convenient carrying of firearms in rugged conditions | Weather resistance, comfort, and style tailored for outdoor use |

| Security Services | Holsters for security personnel in corporate settings | Professional appearance and reliable access to firearms | Aesthetic appeal, durability, and compliance with corporate policies |

| Retail and E-commerce | Custom holsters for gun shops and online retailers | Differentiation in product offerings and customer satisfaction | Quality assurance, branding opportunities, and stock availability |

How Are Custom Made Leather Holsters Used in Law Enforcement?

In law enforcement, custom made leather holsters are essential for officers to securely carry their firearms while ensuring quick access in critical situations. These holsters are designed with durability and comfort in mind, allowing officers to perform their duties without hindrance. For international buyers, especially in regions like Africa and the Middle East, sourcing holsters that comply with local regulations and provide a perfect fit for specific firearms is crucial. Additionally, considerations for weather conditions and local crime rates may influence the choice of materials and designs.

What Role Do Custom Holsters Play in Military Applications?

Military applications for custom leather holsters focus on tactical efficiency and functionality. These holsters are crafted to accommodate various firearms used by personnel in diverse environments, ensuring that soldiers have reliable access to their weapons during missions. Buyers from Europe and South America should prioritize holsters that offer customization options suited to specific military operations, such as concealment features or compatibility with other tactical gear. The ability to withstand harsh conditions is also a significant factor in the sourcing process.

Illustrative image related to custom made leather holsters

How Are Custom Holsters Beneficial for Outdoor Recreation?

In the outdoor recreation sector, custom made leather holsters serve hunters and shooting sports enthusiasts by providing secure and comfortable firearm storage. These holsters are designed to endure rugged outdoor conditions while allowing for easy access to firearms when needed. For international buyers, particularly in regions with a strong hunting culture, sourcing holsters that reflect local preferences and environmental challenges is vital. Features such as water resistance and ergonomic designs can significantly enhance the user experience in the field.

Why Are Custom Holsters Important for Security Services?

For security services, custom made leather holsters offer a professional appearance while ensuring that personnel have quick access to their firearms. These holsters are tailored to meet the specific needs of corporate environments, where aesthetics and functionality must align. Buyers in the Middle East and Europe should look for holsters that comply with local security regulations while also providing comfort and durability. The choice of materials and design can also influence the perception of professionalism and reliability within the security industry.

How Can Retailers Benefit from Custom Holsters?

Retail and e-commerce businesses can leverage custom made leather holsters to differentiate their product offerings. By providing unique designs that cater to specific customer preferences, retailers can enhance customer satisfaction and loyalty. International buyers should consider sourcing holsters that not only meet quality standards but also offer branding opportunities, such as customization with logos or colors. Additionally, maintaining a steady stock of popular designs is essential for meeting demand and ensuring customer retention.

Illustrative image related to custom made leather holsters

3 Common User Pain Points for ‘custom made leather holsters’ & Their Solutions

Scenario 1: Ensuring Quality and Durability in Custom Leather Holsters

The Problem: B2B buyers often face the challenge of ensuring that the leather holsters they order are made from high-quality materials and can withstand rigorous use. This concern is particularly pronounced when sourcing from suppliers in regions where leather quality may vary. Buyers might receive products that quickly wear out, leading to dissatisfaction among their customers and potential damage to their own business reputation.

The Solution: To mitigate this issue, buyers should prioritize sourcing from manufacturers with a long-standing reputation for craftsmanship and quality assurance. They should inquire about the type of leather used—American leather is often a hallmark of durability—and request information about the production processes, including stitching methods and quality checks. It’s also advisable to request samples before placing large orders to evaluate the feel, strength, and overall quality of the product. Additionally, establishing a clear communication line with the supplier regarding expectations for durability and performance can help ensure that the final products meet the necessary standards.

Scenario 2: Customization and Fit for Diverse Firearm Models

The Problem: A frequent pain point for B2B buyers is the need for customization to accommodate a wide range of firearm models. Buyers may find that standard holsters do not fit specific models, leading to issues with accessibility and safety. This is especially critical in markets where gun models vary significantly, making it essential for holsters to be tailored to specific firearms to ensure proper fit and function.

The Solution: To address this challenge, buyers should partner with manufacturers who specialize in bespoke solutions. When placing orders, they should provide detailed specifications about the firearms that the holsters will accommodate, including make, model, and any unique features. Engaging in a collaborative design process can also be beneficial, allowing buyers to discuss specific needs and receive prototypes for evaluation. Furthermore, manufacturers should be encouraged to invest in adjustable or universal designs that can cater to multiple models, offering flexibility and reducing the risk of inventory mismatch.

Scenario 3: Navigating Import Regulations and Compliance Issues

The Problem: B2B buyers often grapple with navigating complex import regulations and compliance issues related to firearms accessories, including custom leather holsters. Different countries have varying legal frameworks that govern the sale and distribution of such products, and failure to comply can result in costly penalties or shipment delays.

Illustrative image related to custom made leather holsters

The Solution: To overcome these hurdles, buyers should conduct thorough research on the regulatory landscape in their target markets before making any purchases. This includes understanding customs regulations, import duties, and specific legal requirements for firearms accessories. Collaborating with suppliers who have experience in international shipping can also streamline the process, as they can provide insights into compliance measures. Additionally, buyers may benefit from engaging legal counsel or trade experts familiar with firearms regulations to ensure that all aspects of the transaction adhere to local laws, thus avoiding complications down the line.

Strategic Material Selection Guide for custom made leather holsters

What Are the Key Materials Used in Custom Made Leather Holsters?

When selecting materials for custom made leather holsters, it’s essential to consider various types of leather and their properties. Each material has distinct characteristics that can influence the performance, durability, and overall suitability for specific applications. Below, we analyze four common materials used in the production of leather holsters, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Full-Grain Leather Perform in Custom Holster Applications?

Full-grain leather is known for its durability and natural appearance, making it a popular choice for high-quality holsters. This type of leather retains the hide’s original grain, which enhances its strength and breathability. Full-grain leather can withstand significant wear and tear, making it suitable for daily use.

Pros: It offers excellent durability and develops a unique patina over time, adding character to the holster. Additionally, it provides good moisture resistance, which is crucial for maintaining the integrity of the firearm.

Cons: The cost of full-grain leather is relatively high, which may not be suitable for budget-conscious buyers. Its manufacturing process can also be more complex, requiring skilled artisans to ensure quality.

Illustrative image related to custom made leather holsters

Impact on Application: Full-grain leather is compatible with a variety of climates, making it suitable for international markets. However, buyers should consider local humidity and temperature conditions that may affect leather performance.

What Are the Benefits of Top-Grain Leather for Holsters?

Top-grain leather is a step down from full-grain leather but still offers a good balance of quality and cost. It is sanded and treated to remove imperfections, resulting in a smoother finish.

Pros: This material is more affordable than full-grain leather while still providing decent durability and aesthetic appeal. It is easier to work with during the manufacturing process, allowing for more design flexibility.

Illustrative image related to custom made leather holsters

Cons: Top-grain leather is generally less durable than full-grain leather and may not develop the same rich patina over time. It can also be more susceptible to moisture damage if not properly treated.

Impact on Application: Top-grain leather is suitable for various environments, but buyers in regions with high humidity should ensure adequate treatment to prevent mold and mildew.

Why Choose Suede Leather for Custom Holsters?

Suede leather, made from the underside of the hide, offers a unique texture and aesthetic appeal. It is often used for more casual or decorative holsters.

Pros: Suede is lightweight and provides a soft touch, making it comfortable for wear. It can also be dyed in various colors, allowing for customization.

Cons: The durability of suede is lower compared to full-grain and top-grain leather. It is more prone to staining and damage from moisture, which can limit its suitability for everyday carry.

Impact on Application: Suede may not be the best choice for regions with extreme weather conditions, as its performance can be compromised. Buyers should consider protective coatings to enhance its durability.

What Role Does Bonded Leather Play in Holster Manufacturing?

Bonded leather is created by combining leather scraps with adhesives, resulting in a more affordable alternative to traditional leather. It is often used in budget-friendly holsters.

Pros: Bonded leather is cost-effective and can mimic the appearance of genuine leather, making it appealing for entry-level products. Its manufacturing process is less labor-intensive, leading to lower production costs.

Illustrative image related to custom made leather holsters

Cons: This material lacks the durability and longevity of natural leather types. It is more susceptible to wear and tear, which can affect the holster’s performance over time.

Impact on Application: While bonded leather can be suitable for lighter use, buyers should be cautious in regions where durability is paramount, as it may not meet the expectations of demanding environments.

Summary of Material Selection for Custom Made Leather Holsters

| Material | Typical Use Case for custom made leather holsters | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end, daily use holsters | Exceptional durability and breathability | Higher cost and complex manufacturing | High |

| Top-Grain Leather | Versatile, mid-range holsters | Good balance of quality and cost | Less durable than full-grain leather | Medium |

| Suede Leather | Decorative or casual holsters | Soft texture and aesthetic appeal | Lower durability and moisture sensitivity | Medium |

| Bonded Leather | Budget-friendly holsters | Cost-effective and visually appealing | Lacks durability and longevity | Low |

This strategic material selection guide provides insights into the various leather options available for custom holsters, assisting international B2B buyers in making informed decisions based on their specific needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather holsters

What Are the Key Manufacturing Processes for Custom Made Leather Holsters?

The manufacturing of custom leather holsters is an intricate process that combines traditional craftsmanship with modern techniques. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to custom made leather holsters

How Is Material Prepared for Custom Leather Holsters?

The journey begins with selecting high-quality leather. Suppliers typically source full-grain leather, renowned for its durability and aesthetic appeal. The leather undergoes a preparation process that includes:

- Tanning: This crucial step transforms raw hides into leather, enhancing their durability and resistance to moisture. Vegetable tanning is preferred for its eco-friendliness and natural finish.

- Cutting: Skilled artisans cut the leather into specific patterns using precision tools. This ensures that each piece is tailored for the intended design, maximizing efficiency and minimizing waste.

Using top-tier materials not only affects the final product’s durability but also its overall quality, which is vital for B2B buyers seeking long-lasting solutions.

What Techniques Are Used in Forming and Shaping Holsters?

After material preparation, the next stage involves forming and shaping the holsters. This stage often employs various techniques:

- Molding: Leather is soaked and then molded around a specific firearm model, ensuring a precise fit. This process can include the use of molds and forms that replicate the firearm’s dimensions.

- Stitching: Using high-strength nylon thread, artisans sew the pieces together. Double stitching is a common practice in critical areas to enhance strength and durability.

- Reinforcement: Additional leather or synthetic materials may be added to high-stress areas to ensure longevity and structural integrity.

Each technique contributes to the holster’s functionality, ensuring it provides secure firearm retention while allowing for easy access.

How Are Custom Leather Holsters Assembled and Finished?

Once the holsters are formed, they move to the assembly and finishing stage, which includes:

- Assembly: All components, including clips, straps, and retention systems, are assembled. This step requires precision to ensure that all elements work harmoniously together.

- Finishing: The final touches involve sanding, burnishing, and applying protective coatings. This not only enhances the aesthetic appeal but also protects the leather from wear and moisture.

Quality finishes can significantly impact the product’s marketability, making it essential for B2B buyers to consider suppliers that prioritize this stage.

Illustrative image related to custom made leather holsters

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is vital in ensuring that the holsters meet international and industry-specific standards. Buyers should be aware of the following:

Which International Standards Are Relevant?

- ISO 9001: This standard ensures that manufacturers maintain consistent quality in their processes. It covers all aspects of production, from material sourcing to final inspection.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

These certifications provide a framework for quality management, assuring buyers of the manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, periodic checks are conducted to verify that manufacturing processes adhere to quality standards.

- Final Quality Control (FQC): The finished products undergo a comprehensive inspection to ensure they meet design specifications and quality benchmarks.

Implementing these checkpoints helps in catching defects early, reducing waste, and ensuring a high-quality final product.

Illustrative image related to custom made leather holsters

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s QC processes is crucial to ensure product reliability. Here are actionable steps to consider:

What Audits and Reports Should Buyers Request?

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This includes reviewing documentation related to certifications and compliance.

- Quality Reports: Requesting regular quality reports can provide insight into the supplier’s QC performance over time. These reports should include metrics on defect rates, corrective actions taken, and improvements implemented.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These inspections can cover:

- Material Quality Assessments: Ensuring the leather and other materials meet the required standards before production begins.

- Final Product Inspections: Verifying that the finished holsters conform to agreed specifications and quality standards.

This added layer of scrutiny can help mitigate risks associated with international sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can help in establishing effective communication with suppliers.

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Familiarizing oneself with these can prevent compliance issues.

- Logistical Considerations: Shipping and logistics play a crucial role in maintaining quality. Buyers should inquire about how suppliers manage these aspects to ensure products arrive in optimal condition.

By taking these factors into account, international buyers can navigate the complexities of sourcing custom leather holsters more effectively.

Conclusion

In summary, a deep understanding of the manufacturing processes and quality assurance practices is essential for B2B buyers in the custom leather holster market. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure they are partnering with reliable suppliers who deliver products that meet their specific needs. This diligence will ultimately foster long-term relationships and enhance business success in this competitive industry.

Illustrative image related to custom made leather holsters

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather holsters’

In the competitive landscape of custom made leather holsters, sourcing effectively can lead to significant advantages for your business. This guide provides a structured checklist to help B2B buyers navigate the procurement process, ensuring they select quality suppliers that meet their unique needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements before initiating contact with suppliers. This includes details such as the type of leather, holster design (e.g., IWB, OWB, shoulder), and any custom features like engraving or specific hardware. Defining these parameters will help you communicate effectively with potential suppliers and streamline the selection process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable manufacturers. Utilize online platforms, industry directories, and trade shows to compile a list of potential suppliers. Focus on their experience in the leather industry, particularly in producing custom holsters. Look for companies with positive reviews and strong reputations, as this can significantly impact the quality of the products you receive.

Step 3: Evaluate Supplier Certifications

Verify that suppliers meet industry standards and certifications. This may include quality management certifications like ISO 9001 or environmental compliance certifications. Ensuring that your suppliers adhere to these standards can help guarantee product quality and ethical sourcing practices, which are increasingly important to B2B buyers.

Illustrative image related to custom made leather holsters

Step 4: Request Samples and Prototypes

Before placing a large order, request samples or prototypes. This step allows you to assess the craftsmanship, materials, and overall quality of the holsters. Pay attention to details such as stitching, leather finish, and functionality. Assessing samples can also provide insights into the supplier’s ability to meet your specific design requirements.

Step 5: Discuss Lead Times and Production Capacity

Engage in discussions regarding lead times and the supplier’s production capacity. Understanding how long it will take for your order to be fulfilled is crucial for inventory management and customer satisfaction. Ensure that the supplier can handle your volume requirements without compromising quality.

Step 6: Negotiate Terms and Pricing

Negotiate terms that align with your budget and business needs. Discuss pricing structures, payment terms, and potential discounts for bulk orders. Be transparent about your expectations and establish a clear agreement that outlines responsibilities on both sides, including delivery timelines and quality standards.

Step 7: Establish a Communication Plan

Set up a communication strategy for ongoing collaboration. Regular updates on production status, potential challenges, and market trends can foster a strong partnership. Ensure that both parties agree on communication channels and frequency, which can help address issues proactively and maintain alignment throughout the sourcing process.

Illustrative image related to custom made leather holsters

By following this checklist, B2B buyers can make informed decisions when sourcing custom made leather holsters, ensuring they partner with suppliers who align with their quality standards and business objectives.

Comprehensive Cost and Pricing Analysis for custom made leather holsters Sourcing

What Are the Key Cost Components in Custom Made Leather Holsters?

When sourcing custom made leather holsters, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: High-quality leather is the foundation of any leather holster. The type of leather (e.g., full-grain, top-grain) significantly influences the cost. Additionally, hardware such as buckles, snaps, and stitching materials can add to the overall expense.

-

Labor: Skilled artisans are essential for crafting custom holsters. Labor costs can vary based on the complexity of the design and the level of craftsmanship required. Customization often necessitates additional labor hours, impacting the final price.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help control these costs.

-

Tooling: Custom tooling for specific designs can incur significant upfront costs. This is especially relevant for unique holster shapes or features, as specialized molds and tools are required.

-

Quality Control (QC): Ensuring that each holster meets quality standards is vital. QC processes may add costs but are necessary to maintain customer satisfaction and brand reputation.

-

Logistics: Shipping costs can vary based on the destination and shipping method. Import duties and taxes must also be factored in for international buyers.

-

Margin: Suppliers typically mark up prices to cover their costs and ensure profitability. Understanding the margin can help buyers negotiate better deals.

How Do Price Influencers Affect Custom Leather Holster Costs?

Several factors can influence pricing in the custom leather holster market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often come with volume discounts. Establishing a good relationship with suppliers can lead to favorable terms for future orders.

-

Specifications and Customization: The more specialized the holster (e.g., specific firearm models, unique designs), the higher the price. Offering standard designs can often yield lower costs.

-

Materials Quality and Certifications: Higher quality materials or certified eco-friendly options typically increase costs. Buyers should weigh the benefits of premium materials against budget constraints.

-

Supplier Factors: The location and reputation of the supplier can also impact pricing. Established brands with a history of quality may charge a premium.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Costs can vary significantly based on whether the seller or buyer is responsible for shipping and insurance.

What Are Effective Buyer Tips for Sourcing Custom Leather Holsters?

To optimize purchasing decisions, consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing. Understanding their cost structure can provide leverage during negotiations.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the upfront price. Consider durability, maintenance, and potential resale value when evaluating holsters.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import taxes, and shipping costs when sourcing from suppliers in different regions. This is particularly relevant for buyers in Africa, South America, the Middle East, and Europe.

-

Seek Multiple Quotes: Always request quotes from multiple suppliers to compare prices and terms. This practice helps identify the best value for money.

-

Understand Market Trends: Stay informed about market trends and consumer preferences in your region. This knowledge can help you make informed decisions about design specifications and materials.

Disclaimer on Indicative Prices

Prices for custom leather holsters can vary widely based on the factors discussed. The ranges provided by suppliers can serve as a guideline, but buyers should conduct thorough research and communicate directly with suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing custom made leather holsters With Other Solutions

Understanding Alternatives to Custom Made Leather Holsters

In the competitive landscape of firearm accessory solutions, custom made leather holsters stand out due to their craftsmanship and functionality. However, it’s essential for B2B buyers to consider alternative options that may better suit specific operational needs or budget constraints. This analysis compares custom made leather holsters against two viable alternatives: synthetic holsters and universal holsters.

Illustrative image related to custom made leather holsters

Comparison Table

| Comparison Aspect | Custom Made Leather Holsters | Synthetic Holsters | Universal Holsters |

|---|---|---|---|

| Performance | High durability, tailored fit | Moderate durability, adjustable fit | Variable fit, often less secure |

| Cost | Higher price point ($130-$700) | Lower price point ($30-$150) | Moderate price point ($50-$200) |

| Ease of Implementation | Longer lead time due to customization | Ready-to-use, minimal setup | Ready-to-use, minimal setup |

| Maintenance | Requires conditioning and care | Minimal maintenance needed | Minimal maintenance needed |

| Best Use Case | Personal use, collectors, specialized needs | Everyday carry, tactical situations | General use, budget-conscious users |

Detailed Breakdown of Alternatives

Synthetic Holsters

Synthetic holsters, often made from materials like Kydex or nylon, offer a lightweight and flexible alternative to leather. One of the key advantages of synthetic holsters is their affordability, making them accessible for a wider range of buyers. They are typically ready-to-use right off the shelf, minimizing the lead time often associated with custom leather options. However, while they may provide a good fit for many firearms, they do not offer the same level of durability or aesthetic appeal as leather. Additionally, synthetic materials may not conform to the body as comfortably, which can be a drawback for long-term wear.

Universal Holsters

Universal holsters are designed to fit a variety of firearm models, making them a versatile option for buyers with multiple firearms. They are generally more affordable than custom leather holsters, appealing to those on a budget. The implementation is straightforward since these holsters are available off-the-shelf, requiring no waiting time for customization. However, their variable fit means they may not provide the same level of security and retention as custom solutions, potentially impacting performance during high-action scenarios. The lack of a tailored fit may lead to discomfort over extended periods of wear.

Conclusion: How to Choose the Right Holster Solution for Your Needs

For B2B buyers, the decision to invest in custom made leather holsters versus alternatives hinges on specific requirements, including budget, intended use, and desired performance. Custom holsters are ideal for those seeking high durability, aesthetic appeal, and a tailored fit, especially for personal collections or specialized applications. Conversely, synthetic and universal holsters present cost-effective solutions for everyday carry or tactical situations where budget constraints are a priority. Evaluating these factors carefully will empower buyers to select the holster solution that best aligns with their operational demands and financial considerations.

Essential Technical Properties and Trade Terminology for custom made leather holsters

What Are the Key Technical Properties of Custom Made Leather Holsters?

When selecting custom made leather holsters, understanding their technical properties is crucial for ensuring quality, durability, and functionality. Here are some essential specifications to consider:

1. Material Grade

The material grade refers to the quality and type of leather used in the holster’s construction. Full-grain leather is the highest quality, known for its durability and natural look, while top-grain leather is slightly less durable but more affordable. For B2B buyers, choosing the right material grade is vital as it affects the holster’s lifespan, appearance, and overall performance. Premium materials ensure that the holsters can withstand regular use and environmental factors.

Illustrative image related to custom made leather holsters

2. Stitching Type and Thread Quality

The stitching type and thread quality are critical for the structural integrity of the holster. Double stitching with bonded nylon thread is preferred, as it enhances durability and reduces the risk of unraveling over time. For businesses, investing in holsters with superior stitching means fewer returns and higher customer satisfaction, as well-constructed holsters are less likely to fail under stress.

3. Fit and Tolerance

Fit refers to how well the holster accommodates the specific firearm it is designed for, while tolerance indicates the permissible variation in dimensions during the manufacturing process. A well-fitted holster ensures secure retention of the firearm and allows for quick access. For B2B buyers, understanding fit and tolerance is crucial to minimize discrepancies that could lead to product returns or customer dissatisfaction.

4. Finish and Treatment

The finish and treatment of the leather can significantly affect its durability, moisture resistance, and appearance. Common treatments include oiling and dyeing, which enhance the leather’s water resistance and aesthetic appeal. For businesses, selecting holsters with high-quality finishes ensures that products remain visually appealing and functional over time, leading to a better brand reputation.

5. Weight Capacity

Weight capacity refers to the maximum weight that the holster can safely carry, which is particularly important for holsters designed for larger firearms or additional accessories. Understanding weight capacity is essential for B2B buyers to ensure that the holsters can adequately support the intended firearm and provide comfort for the end-user.

What Are Common Trade Terms in the Custom Leather Holster Industry?

Familiarizing yourself with industry jargon can help streamline communication and negotiations. Here are some common terms relevant to custom made leather holsters:

Illustrative image related to custom made leather holsters

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces products that are marketed by another company. In the context of leather holsters, it means that a manufacturer may create holsters for another brand. Understanding OEM agreements is vital for B2B buyers to ensure they are sourcing quality products that meet their standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand pricing structures and inventory management. Knowing the MOQ helps businesses plan their purchases efficiently and avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. For buyers, issuing an RFQ can help compare pricing and terms across multiple suppliers, ensuring they get the best deal for custom leather holsters.

Illustrative image related to custom made leather holsters

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers, as they dictate shipping responsibilities, risk, and costs, ensuring clear agreements when sourcing from international manufacturers.

5. Customization Options

Customization options refer to the various ways a holster can be tailored to meet specific customer needs, such as size, color, and additional features. For businesses, offering customization can enhance product appeal and cater to niche markets, leading to increased sales opportunities.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing custom made leather holsters, ensuring they select high-quality products that meet their business needs.

Navigating Market Dynamics and Sourcing Trends in the custom made leather holsters Sector

What Are the Current Market Dynamics Influencing Custom Made Leather Holsters?

The custom made leather holsters market is witnessing dynamic shifts influenced by global trends and buyer preferences. Key drivers include the growing demand for personalized products, which emphasizes craftsmanship and quality. International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for unique, high-quality leather holsters that reflect both their personal style and functional needs. The rise of e-commerce and digital platforms has also facilitated access to a broader range of suppliers, allowing buyers to source products from various parts of the world.

Illustrative image related to custom made leather holsters

Emerging technologies are reshaping the sourcing landscape, with advancements in materials and manufacturing processes enhancing product quality and customization capabilities. Digital design tools, such as 3D modeling software, enable manufacturers to create tailored solutions that meet specific buyer requirements. Moreover, the integration of data analytics allows businesses to forecast demand trends more accurately and optimize their inventory management.

Market dynamics are further influenced by the increasing popularity of outdoor activities and self-defense training, leading to a surge in demand for custom leather holsters among enthusiasts and professionals alike. Buyers are keen on understanding the heritage and expertise behind the products they purchase, which underscores the importance of transparent communication regarding craftsmanship and sourcing practices.

How Is Sustainability Shaping Sourcing Trends for Custom Made Leather Holsters?

Sustainability has become a critical consideration in the sourcing of custom made leather holsters. The environmental impact of leather production, particularly concerning deforestation and chemical waste, has prompted buyers to prioritize ethical sourcing practices. International buyers are increasingly demanding transparency in supply chains, seeking out manufacturers who utilize eco-friendly materials and processes.

Ethical sourcing is not just about environmental responsibility; it also encompasses social factors, including fair labor practices and community engagement. Buyers are more likely to partner with suppliers who demonstrate a commitment to ethical practices, as this aligns with the growing consumer preference for brands that prioritize corporate social responsibility.

Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential benchmarks for buyers assessing potential suppliers. These certifications ensure that the leather used in custom holsters meets specific environmental and ethical standards. By opting for suppliers with ‘green’ certifications, international buyers can enhance their brand reputation while contributing positively to environmental conservation and ethical labor practices.

What Historical Context Is Relevant to Understanding the Custom Made Leather Holsters Market?

The evolution of custom made leather holsters can be traced back several centuries, originating from the need for practical solutions for carrying firearms safely and securely. Initially crafted by local artisans, these holsters were essential for both protection and convenience, reflecting the cultural significance of firearms in various societies. Over time, the market has shifted from purely functional designs to a focus on aesthetics, craftsmanship, and personalization.

In recent decades, the global demand for high-quality, custom leather products has surged, driven by enthusiasts and professionals who value the artistry and durability of handcrafted items. As a result, the industry has seen a blend of traditional techniques and modern innovations, allowing for unique designs that cater to diverse buyer preferences. Understanding this historical context is crucial for international B2B buyers, as it highlights the importance of craftsmanship and the stories behind the products they source, enhancing their connection to the market.

In summary, the custom made leather holsters sector is evolving rapidly, influenced by market dynamics, sustainability trends, and a rich historical backdrop. International buyers should consider these factors when sourcing products, ensuring they align with both their business values and consumer expectations.

Illustrative image related to custom made leather holsters

Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather holsters

-

How do I choose the right supplier for custom made leather holsters?

Selecting the right supplier involves evaluating their experience, craftsmanship, and reputation in the industry. Look for suppliers with a proven track record of producing high-quality leather goods, as well as positive reviews from previous clients. It’s beneficial to request samples to assess material quality and workmanship. Additionally, inquire about their production capabilities, lead times, and whether they can accommodate custom designs to ensure they align with your specific needs. -

What is the minimum order quantity (MOQ) for custom leather holsters?

The MOQ for custom leather holsters can vary significantly among suppliers, typically ranging from 50 to 100 units. Some manufacturers may offer lower MOQs for initial orders or pilot projects, especially if you are establishing a long-term partnership. It’s important to discuss your requirements upfront and negotiate MOQs that align with your business strategy and market demands. -

How can I ensure the quality of custom leather holsters?

To ensure quality, establish clear specifications regarding materials, dimensions, and design features in your purchase order. Request samples before placing a bulk order to evaluate craftsmanship and durability. Additionally, consider implementing a quality assurance process that includes on-site inspections or third-party audits during production. Regular communication with the supplier during the manufacturing process can also help address any concerns before the final product is delivered. -

What customization options are typically available for leather holsters?

Customization options can include various leather types, colors, stitching patterns, and finishes. Many suppliers also offer personalized features such as embossed logos, custom shapes, and adjustable retention systems. When discussing your needs with suppliers, be specific about the functionality and aesthetic aspects you require, as this will help them create a product that meets your expectations. -

What payment terms should I expect when sourcing custom leather holsters internationally?

Payment terms can vary widely based on the supplier’s policies and the nature of the transaction. Common arrangements include a deposit upfront (usually 30-50%) with the balance due upon completion or delivery. Some suppliers may offer credit terms for repeat customers. It’s advisable to clarify payment methods, currency preferences, and any applicable international transaction fees to avoid misunderstandings later. -

How do shipping and logistics work for international orders of custom leather holsters?

Shipping logistics for international orders typically involve selecting a reliable freight forwarder familiar with customs regulations in both the exporting and importing countries. Suppliers often provide shipping options, including air and sea freight, which differ in cost and delivery time. Ensure that you discuss shipping costs, insurance, and responsibilities for customs clearance in advance to streamline the process. -

What factors should I consider when determining the pricing of custom leather holsters?

Pricing for custom leather holsters is influenced by factors such as material quality, design complexity, and production volume. Consider the cost of raw materials, labor, and any additional features or customizations when evaluating pricing. It’s also essential to assess the market demand and competitor pricing to ensure your offerings are competitively positioned while still allowing for a profitable margin. -

How do I handle potential disputes or issues with my supplier?

Handling disputes requires clear communication and documentation. Start by addressing any concerns directly with the supplier, providing specific details about the issue. If necessary, refer to your contract or purchase agreement to clarify terms and conditions. Establishing a dispute resolution process upfront can help mitigate conflicts. If resolution efforts fail, consider mediation or arbitration as a means to resolve disputes without resorting to litigation.

Top 6 Custom Made Leather Holsters Manufacturers & Suppliers List

1. Lone Star Holsters – The Shadow Holster

Domain: lonestarholsters.com

Registered: 2007 (18 years)

Introduction: {“custom_holsters”: {“description”: “Practical custom leather holsters for practically every handgun.”, “types”: [“Belt Conceal & Accessories”, “Shoulder & Accessories”, “Western & Accessories”, “Leather Slings”]}, “featured_holsters”: [{“name”: “The Shadow Holster”, “price”: “$118.50”, “description”: “Leather-covered metal reinforced holster mouth”}, {“name”: “1911 Hunting Shoulder Holster”, “pri…

2. Tucker Gun Leather – High-Quality Holsters and Gun Belts

Domain: tuckergunleather.com

Registered: 2001 (24 years)

Introduction: Tucker Gun Leather offers a variety of high-quality leather holsters and gun belts designed for concealed carry. Key product details include:

– Types of Holsters: Inside the waistband (IWB), Outside the waistband (OWB), Appendix Holsters, Deep Carry Holsters, Revolver Holsters, Pocket Holsters, Chest Holsters, Shoulder Holsters, Ankle Holsters, and Field Holsters.

– Customization: Customers can p…

3. Diamond D Holsters – Custom Leather Gun Holsters

Domain: diamonddcustomleather.com

Registered: 2010 (15 years)

Introduction: Diamond D Holsters offers a range of custom leather gun holsters, all 100% handcrafted using Hermann Oak Leather, which is vegetable tanned, top grade, full-grain leather. The holsters are designed to protect firearms from rust and damage, featuring hand molding around an exact replica of the firearm for a precise fit. Key products include: Guides Choice® Chest Holster, Alaska Hunter Hip Holster, …

4. High Noon Holsters – Premium Leather Holsters

Domain: highnoonholsters.com

Registered: 2000 (25 years)

Introduction: High Noon Holsters offers a variety of leather holsters designed for comfort and durability. The holsters are crafted from premium leather and are available in different styles, including inside-the-waistband (IWB) and outside-the-waistband (OWB) options. Each holster is tailored to fit specific firearm models, ensuring a secure fit. The products emphasize ease of draw, retention, and concealment,…

5. Hunter Company – Key Products

Domain: huntercompany.com

Registered: 1997 (28 years)

Introduction: Key Products:

1. Everyday Cowboy CCW Holster (3600 Series)

– Price: $79.99

– Rating: 4.97/5.0

– Description: Most comfortable CCW holster on the market, crafted from premium American Steerhide leather.

2. Everyday Cowboy CCW Holster (5300 Series)

– Price: $94.99

– Rating: 4.98/5.0

– Description: Combines tactical precision with leather craftsmanship for comfort and performance.

…

6. Falco – Leather Gun Holsters

Domain: falcoholsters.com

Registered: 2009 (16 years)

Introduction: Leather Gun Holsters (169 products) | Falco includes a variety of holster types such as IWB (Inside the Waistband), OWB (Outside the Waistband), Shoulder Holsters, Thigh Holsters, Ankle Holsters, and more. The materials used include Leather, Kydex, Nylon, and Carbon Fiber. Specific products mentioned include: C113 Bat Pancake Style OWB Leather Holster for Pistol with Laser/Light ($99.95), A634 L W…

Strategic Sourcing Conclusion and Outlook for custom made leather holsters

In conclusion, the strategic sourcing of custom-made leather holsters presents a unique opportunity for international B2B buyers to capitalize on quality craftsmanship, innovative designs, and regional preferences. The emphasis on sourcing from reputable manufacturers ensures that businesses can offer products that meet stringent quality standards while also appealing to the specific needs of their target markets.

By prioritizing partnerships with established leather artisans who understand the nuances of customer requirements, buyers can enhance their product offerings and build a loyal customer base. As the demand for high-quality, durable, and aesthetically pleasing holsters continues to rise, especially in regions like Africa, South America, the Middle East, and Europe, now is the ideal time to invest in strategic sourcing initiatives.

Looking ahead, it is crucial for buyers to stay informed about emerging trends in leather craftsmanship and consumer preferences. Engaging in meaningful collaborations with local artisans not only fosters economic growth but also ensures a diverse and competitive product portfolio. Take action today by exploring potential partnerships and leveraging the unmatched quality of custom-made leather holsters to elevate your business in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom made leather holsters

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.