Catalog

Material Insight: Custom Leather Furniture

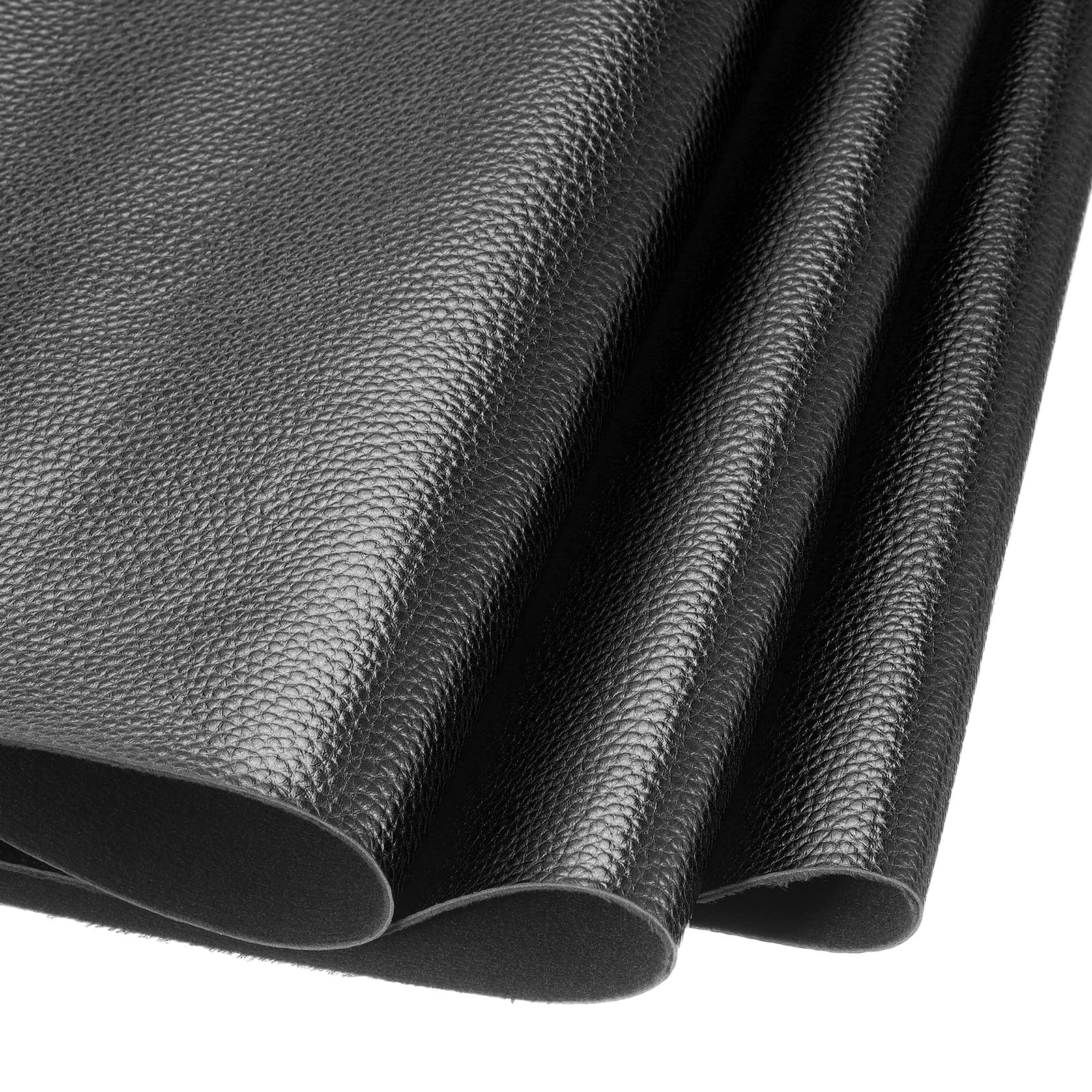

B2B Product Guide: Elevating Custom Leather Furniture with Premium Upholstery Solutions

The custom leather furniture market demands materials that merge exceptional aesthetics with uncompromising performance. As designers and manufacturers seek to deliver unique, high-value pieces for discerning residential and commercial clients, the choice of upholstery material becomes foundational. Substandard materials risk premature wear, inconsistent appearance, and unsustainable production – directly impacting brand reputation and client satisfaction.

Upholstery leather stands as the unequivocal best choice for custom furniture applications for several critical reasons:

- Unmatched Durability & Longevity: Engineered to withstand rigorous daily use, genuine upholstery leather develops a rich patina over time rather than deteriorating, ensuring furniture retains value and appeal for decades.

- Superior Aesthetic Versatility: Offers unparalleled depth of color, natural grain variation, and a tactile luxury that synthetic alternatives often fail to replicate authentically, enabling truly bespoke design statements.

- Enhanced Performance Properties: Provides inherent breathability for user comfort, excellent tensile strength to resist tearing during complex upholstery processes, and superior resistance to abrasion and fading compared to many alternatives.

- Timeless Value Perception: Clients associate premium leather with quality, craftsmanship, and investment, directly supporting higher price points and brand positioning in the luxury and contract furniture segments.

For over 20 years, WINIW has been a trusted global leader in advanced synthetic leather innovation, specifically engineered for demanding upholstery applications like custom furniture. We understand the unique pressures facing B2B partners: the need for consistent quality across large projects, stringent sustainability requirements, complex customization demands, and reliable supply chain performance. WINIW leverages decades of material science expertise to deliver microfiber leather solutions that not only meet but exceed the performance and aesthetic expectations set by top-tier custom furniture makers. Our commitment is to provide you with durable, eco-conscious materials that empower your craftsmanship and elevate your final product, backed by technical support and partnership built on two decades of industry experience. Choose WINIW as your material partner to transform custom furniture visions into enduring realities.

Technical Performance & Standards

WINIW Custom Leather Furniture: Technical Product Guide

WINIW specializes in high-performance synthetic leather solutions engineered for commercial and residential furniture applications. Our custom leather furniture materials are designed to meet stringent international standards while delivering superior aesthetics, durability, and sustainability. Ideal for B2B partners in contract furniture, hospitality, healthcare, and residential sectors, WINIW’s offerings combine advanced material science with eco-conscious production.

Key Technical Advantages

-

Fire Retardant Performance (UK & US Standards Compliant)

WINIW’s custom leather is treated with advanced fire-retardant additives that ensure compliance with both UK and US regulatory requirements. Materials pass BS 5852 (UK) and CAL 117 (US) flammability tests, making them suitable for public and commercial interiors where fire safety is critical. -

Easy Clean & Stain Resistant Surface

The tightly bonded polyurethane (PU) surface resists stains, spills, and everyday wear. Most spills can be wiped away with a damp cloth; no specialized cleaners are required. This low-maintenance feature enhances longevity and reduces lifecycle costs—ideal for high-traffic environments. -

Soft Touch & Premium Aesthetic

Engineered with micro-foamed PU technology, WINIW leather delivers a natural leather-like hand feel with enhanced suppleness. The soft-touch finish improves user comfort while maintaining excellent tensile and tear strength—balancing luxury with performance. -

REACH Compliant & Eco-Safe Chemistry

All formulations are fully compliant with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted hazardous substances. Our production process prioritizes human and environmental safety without compromising performance. -

ISO 9001-Certified Manufacturing

WINIW operates under an ISO 9001-certified quality management system, ensuring consistent product quality, traceability, and process control across all batches. This certification underscores our commitment to reliability and continuous improvement in manufacturing excellence.

Technical Specifications Table

| Spezifikation | Performance Detail |

|---|---|

| Base Material | High-tenacity polyester knit + micro-foamed PU surface |

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Weight | 280 – 380 g/m² (depending on thickness and finish) |

| Fire Resistance (UK) | BS 5852: Source 0 & 1 compliant (ignitability & flame spread) |

| Fire Resistance (US) | CAL 117 compliant (smolder and open flame resistance) |

| Color Fastness to Rubbing | Dry: Class 4–5 / Wet: Class 4 (ISO 105-X12) |

| Light Fastness | ≥ 4–5 (ISO 105-B02, 20-hour exposure) |

| Tensile Strength | ≥ 90 N/30mm (warp), ≥ 80 N/30mm (weft) (ISO 1421) |

| Tear Strength | ≥ 18 N (warp & weft) (ISO 1423) |

| Cold Crack Resistance | Pass at -20°C (ASTM D1790) |

| Reinigung | Water-based wipe clean; resistant to alcohol, oils, and common household stains |

| REACH Compliance | Fully compliant, no SVHCs or restricted phthalates |

| ISO Certification | ISO 9001:2015 – Quality Management Systems |

| Sustainability Features | Solvent-free production, low VOC emissions, recyclable packaging |

WINIW’s custom leather furniture materials offer a balanced solution for global B2B clients seeking certified, durable, and sustainable upholstery alternatives. With fire safety, ease of maintenance, and regulatory compliance built into every meter, WINIW supports long-term product performance and brand integrity.

Why Choose Synthetic over Real Leather

B2B Product Guide: Material Selection for Custom Furniture Manufacturing

Selecting the right upholstery material is critical for furniture manufacturers balancing performance, cost, and sustainability. WINIW, a leader in advanced synthetic leather solutions, provides this comparative analysis to support informed decision-making for specifiers and production teams.

Key Material Considerations

- Real Leather: A natural byproduct of the meat industry, prized for its unique texture and aging characteristics. Requires intensive resource inputs and chemical processing during tanning.

- WINIW Synthetic Leather: Engineered using proprietary PU/PVC-free formulations, often incorporating recycled content (e.g., plant-based oils, post-consumer polyester). Designed for consistency, performance, and reduced environmental impact.

Comparative Analysis: Custom Leather Furniture Applications

| Kriterien | Real Leather | WINIW Synthetic Leather |

|---|---|---|

| Cost | High material cost (30-50% premium); labor-intensive cutting due to hide inconsistencies; significant waste (15-25%); price volatility from hide market fluctuations. | Lower material cost (20-35% savings vs. premium leather); minimal waste (<5%) via precise roll cutting; stable pricing; reduced labor costs through uniform grain and dye consistency. |

| Dauerhaftigkeit | Develops patina but susceptible to scratches, UV fading, and liquid damage; requires regular conditioning; inconsistent thickness affects long-term structural integrity in high-use settings. | Superior resistance to stains, UV degradation, and abrasion; uniform thickness ensures consistent performance; no conditioning needed; ideal for high-traffic commercial environments (e.g., hospitality, healthcare). |

| Eco-Friendliness | Relies on resource-intensive livestock farming; conventional tanning uses heavy metals (e.g., chromium); biodegradability offset by chemical residues; carbon footprint amplified by global hide transport. | Zero animal sourcing; water-based, solvent-free production; 30-60% lower carbon footprint; certified recycled content (up to 40%); OEKO-TEX® Standard 100 compliance; end-of-life recyclability via specialized programs. |

Strategic Recommendations for Manufacturers

- Prioritize real leather only for ultra-luxury, low-volume segments where natural aging is a core value proposition, and clients accept premium pricing.

- Specify WINIW synthetic leather for:

- Commercial contracts requiring durability, stain resistance, and color consistency (e.g., offices, hotels).

- Sustainable product lines targeting LEED® or B Corp-certified projects.

- Cost-sensitive projects needing design flexibility without compromising on performance metrics.

- Leverage WINIW’s customization capabilities (thickness, texture, color matching) to eliminate material waste and accelerate time-to-market versus hide-dependent workflows.

WINIW’s closed-loop production systems and traceable supply chain empower manufacturers to meet evolving ESG mandates while delivering premium, fit-for-purpose furniture. Partner with us to future-proof your material strategy with science-backed sustainability.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, operating from a state-of-the-art production facility that spans over 100,000 square meters. Strategically located in China, our factory integrates advanced manufacturing capabilities with sustainable practices to deliver premium materials for global markets.

Our large-scale facility enables high-volume production without compromising quality or lead times. This extensive footprint supports end-to-end control—from raw material processing to finished product—ensuring consistency and responsiveness to client demands across industries such as automotive, furniture, footwear, and fashion.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 engineers and material scientists focused on innovation, durability, and eco-friendly solutions. The team continuously develops new formulations to meet evolving industry standards, including low-VOC, recyclable, and bio-based materials.

- Strict quality control protocols implemented at every stage of production. Our QC system complies with international standards, including ISO 9001 and OEKO-TEX® certification, ensuring every batch meets rigorous performance and safety requirements.

- Advanced production lines equipped with automated monitoring systems to maintain precision in thickness, color fastness, abrasion resistance, and other critical metrics.

- In-house testing laboratory capable of simulating real-world conditions to validate product performance under extreme heat, UV exposure, wear, and chemical contact.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by leading brands that demand sustainable, high-quality alternatives to genuine leather. With a logistics network designed for efficiency and reliability, we ensure timely delivery to international partners while maintaining full compliance with regional environmental and safety regulations.

Through scale, innovation, and uncompromising quality, WINIW stands as a strategic manufacturing partner for global businesses seeking responsible and high-performance synthetic leather solutions.

Contact Us for Samples

WINIW Premium Synthetic Leather: Sustainable Solutions for Furniture Manufacturing

WINIW delivers high-performance, eco-conscious synthetic leather engineered specifically for the demands of modern furniture production. As a leader in sustainable material innovation, we partner with B2B clients to reduce environmental impact without compromising on durability, aesthetics, or cost-efficiency. Our closed-loop manufacturing process and rigorous eco-certifications ensure compliance with global sustainability standards while meeting the exacting requirements of luxury and contract furniture markets.

Core Sustainability Advantages

- Recycelter Inhalt: Up to 40% certified post-consumer recycled polyester in base fabrics, reducing landfill waste and fossil resource dependence.

- Eco-Certified Production: OEKO-TEX® STANDARD 100 Class I (skin-safe), ISO 14001, and GRS (Global Recycled Standard) compliant facilities.

- PFAS & Heavy-Metal Free: Non-toxic formulations eliminate hazardous chemicals, ensuring safer worker conditions and end-product safety.

- Low Carbon Footprint: 60% lower CO₂ emissions vs. conventional PU leather through renewable energy-powered manufacturing.

Performance Specifications for Furniture Applications

WINIW’s furniture-grade synthetics exceed industry benchmarks for longevity and usability in high-traffic environments. Key technical attributes:

| Property | Test Standard | WINIW Performance | Industry Avg. |

|---|---|---|---|

| Abrasion Resistance | Martindale (ISO 12947) | 100,000+ cycles | 50,000 cycles |

| Color Fastness to Light | ISO 105-B02 | Grade 7-8 | Grade 5-6 |

| Tensile Strength | ISO 1767 | 35-45 N/mm² | 25-30 N/mm² |

| Martindale Pilling | ISO 12945-1 | Grade 4-5 | Grade 3 |

| Recycled Content (Base) | GRS Verification | 30-40% | 0-15% |

Optimized for Furniture Manufacturing

Our materials solve critical production challenges while elevating end-product value:

– Seamless Integration: Consistent thickness (0.6–1.2mm) and backing compatibility with standard cutting, stitching, and laminating equipment.

– Design Flexibility: 200+ stock colors and textures (including leather-grain, nubuck, and smooth finishes); custom color matching within 7 days.

– Durability in Use: Stain-resistant, easy-clean surfaces ideal for hospitality, healthcare, and residential furniture. Resists cracking after 50,000 flex cycles (ISO 7814).

– Waste Reduction: Precision-width rolls (1.37m, 1.50m) minimize cutting waste by up to 18% vs. standard widths.

Custom Leather Furniture Solutions

WINIW specializes in end-to-end collaboration for made-to-order furniture projects. Whether scaling luxury residential collections or developing contract-grade seating, our engineering team tailors:

– Material composition for specific weight, drape, and breathability requirements

– Custom embossing, colorways, and performance additives (e.g., antimicrobial, flame retardancy)

– Low-MOQ flexibility (500m minimum) for boutique designers and large-scale manufacturers

Request Free Samples for Your Next Project

Evaluate WINIW’s quality and sustainability firsthand. Our technical team provides:

– Physical swatch books with 10+ furniture-grade options

– Detailed compliance documentation and test reports

– Design consultation for material integration

→ Contact WINIW’s B2B Solutions Team: MKT88@MicrofiberLeather.com

Specify “Furniture Sample Request” in your subject line. Free samples shipped within 48 hours.

WINIW: Where uncompromising quality meets planetary responsibility. Partner with us to future-proof your furniture line with materials that perform today and protect tomorrow.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.