Catalog

Material Insight: Pvc Garments

B2B Product Guide: PVC Garments

PVC garments are increasingly in demand across industries such as fashion, protective workwear, and performance apparel due to their durability, water resistance, and distinctive aesthetic. Made from polyvinyl chloride, these garments offer a cost-effective and versatile alternative to natural materials, making them ideal for both functional and fashion-forward applications. Whether used in rainwear, uniforms, or avant-garde fashion pieces, PVC garments combine practicality with a sleek, modern look.

Why is Faux Leather the Best Choice for PVC Garments?

Faux leather, particularly high-performance synthetic leather like WINIW’s PVC-based solutions, stands out as the optimal material for PVC garment production. Key advantages include:

- Superior Durability: Resistant to abrasion, tearing, and weathering, ensuring long-lasting performance.

- Waterproof Properties: Inherently moisture-resistant, making it perfect for outdoor and protective apparel.

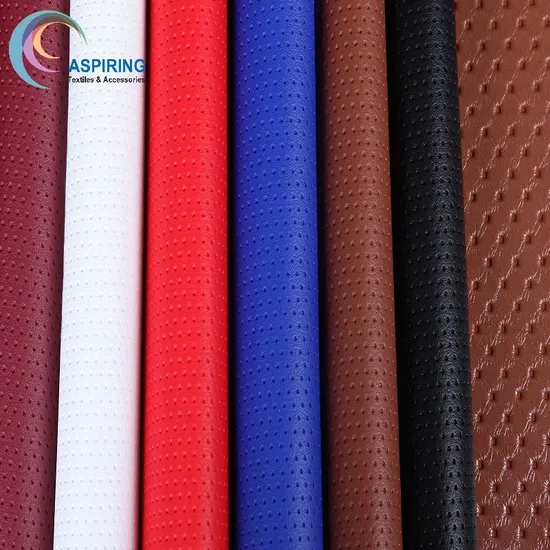

- Design Flexibility: Available in a wide range of textures, colors, and finishes, enabling creative freedom for designers.

- Consistent Quality: Unlike natural leather, faux leather offers uniform thickness and appearance across batches.

- Eco-Conscious Production: Modern PVC faux leathers can be manufactured with reduced environmental impact, especially when produced using responsible processes and recyclable components.

With over 20 years of industry leadership, WINIW has established itself as a trusted innovator in synthetic leather solutions. Specializing in high-quality faux leather for technical and fashion applications, WINIW combines advanced manufacturing technologies with a commitment to sustainability. Our PVC leather products are engineered to meet rigorous international standards, offering B2B clients reliability, scalability, and environmental responsibility. Partner with WINIW to elevate your PVC garment lines with materials built for performance, style, and long-term value.

Technical Performance & Standards

WINIW PVC Garment Material: Technical Product Guide for B2B Partners

WINIW delivers high-performance PVC synthetic leather engineered specifically for the demanding requirements of garment manufacturing. Our solution combines industrial efficiency with stringent environmental and quality standards, providing fashion brands and manufacturers with a reliable, sustainable material foundation. Below are the core technical advantages driving value across your supply chain.

Key Technical Advantages

- Optimized Cost Efficiency: WINIW PVC utilizes a proprietary compounding process that minimizes raw material waste during cutting and lamination. The consistent thickness (±0.05mm tolerance) and high yield rate (95%+) significantly reduce scrap compared to conventional alternatives, lowering total cost of ownership without compromising quality.

- Enhanced Durability for Garment Lifespan: Engineered with cross-linked polymer technology, WINIW PVC offers exceptional resistance to abrasion (tested to 50,000+ double rubs per Martindale), flex fatigue, and hydrolysis. This ensures garments maintain structural integrity and aesthetic appeal through repeated wear, washing (where specified), and exposure to UV light and humidity, reducing returns and enhancing brand reputation.

- Unmatched Color Customization & Consistency: Our integrated pigment dispersion system allows for precise replication of over 10,000+ Pantone® colors directly within the PVC matrix during production. This eliminates batch variation and ensures colorfastness (rated 4-5 per ISO 105-B02), critical for large-scale collections. Custom metallic, matte, and textured finishes are achievable without secondary coating processes.

- Guaranteed REACH Compliance: WINIW PVC is rigorously formulated to exceed EU REACH (EC 1907/2006) Annex XVII requirements. It is completely free of restricted phthalates (DEHP, BBP, DBP, DIBP), heavy metals (Cd, Pb < 10ppm), and other SVHCs. Full Declaration of Compliance (DoC) and batch-specific test reports (via accredited 3rd party labs) are standard, mitigating regulatory risk for global distribution.

- ISO 9001 Certified Quality Management: Every meter of WINIW PVC is produced under an ISO 9001:2015 certified quality management system. This ensures strict process control from raw material sourcing through extrusion, calendaring, and finishing. Real-time monitoring of critical parameters (thickness, adhesion, surface tension) guarantees consistent physical properties and defect-free output batch after batch.

WINIW PVC Garment Material Specifications

| Specification Parameter | Test Standard | Typical Value Range | Performance Benefit |

|---|---|---|---|

| Thickness | ISO 2424 | 0.20mm – 0.80mm | Enables lightweight designs while maintaining strength |

| Weight | ISO 2286-2 | 150g/m² – 400g/m² | Optimizes fabric consumption and garment drape |

| Tensile Strength (MD/CD) | ISO 1798 | 25N/10mm – 45N/10mm | Resists tearing during wear and manufacturing |

| Elongation at Break | ISO 1798 | 150% – 300% | Provides necessary flexibility for garment movement |

| Abrasion Resistance | ISO 12947 (Martindale) | 50,000+ double rubs | Ensures long-term surface integrity and appearance |

| Color Fastness (Light) | ISO 105-B02 | Grade 6-7 (1-8 scale) | Prevents fading under UV exposure |

| Color Fastness (Rubbing) | ISO 105-X12 | Grade 4-5 (dry/wet) | Eliminates color transfer during use |

| Phthalate Content | EN 14372 | ND (Non-Detectable) | Full compliance with global safety regulations |

| Heavy Metals (Cd/Pb) | EN 71-3 | < 10 ppm | Safe for consumer contact and environmental health |

WINIW PVC garment material provides the technical foundation for producing fashionable, durable, and compliant apparel at scale. By prioritizing material science, regulatory adherence, and process excellence, we empower your brand to meet market demands efficiently and sustainably. Partner with WINIW to integrate a proven, high-value synthetic leather solution into your next collection.

Why Choose Synthetic over Real Leather

B2B Product Guide: PVC Garments vs Real Leather

In the competitive landscape of fashion and functional apparel, material selection plays a pivotal role in determining product performance, cost-efficiency, and sustainability. Two of the most widely used materials in garment manufacturing are PVC (polyvinyl chloride) and real leather. While both offer distinct advantages, they vary significantly in terms of cost, durability, and environmental impact. This guide provides a comparative analysis to support informed decision-making for B2B buyers and brands committed to quality and sustainability.

Overview of PVC Garments

PVC garments are synthetic alternatives made from petroleum-based plastic. They are commonly used in outerwear, raincoats, and fashion pieces due to their water resistance, glossy finish, and low production cost. However, PVC raises environmental and health concerns due to chlorine content and non-biodegradability.

Overview of Real Leather

Real leather is a natural material derived from animal hides, primarily bovine. Valued for its durability, breathability, and premium aesthetic, it is widely used in high-end fashion, footwear, and accessories. While it offers long-term value, real leather has significant ecological and ethical considerations, including resource-intensive production and contributions to deforestation and greenhouse gas emissions.

Comparative Analysis: PVC Garments vs Real Leather

| Attribute | PVC Garments | Real Leather |

|---|---|---|

| Cost | Low material and production cost | High due to raw material sourcing and processing |

| Dauerhaftigkeit | Moderate; prone to cracking and degradation under UV exposure and extreme temperatures | High; develops a patina over time and can last decades with proper care |

| Eco-friendliness | Low; non-biodegradable, releases toxic dioxins during production and disposal, high carbon footprint | Moderate to low; biodegradable but tanning processes (especially chrome tanning) pollute water and consume large amounts of water and energy |

Key Considerations for B2B Buyers

- PVC garments offer a cost-effective solution for short-term fashion cycles but may compromise brand sustainability goals.

- Real leather appeals to luxury markets and consumers seeking longevity, yet faces increasing scrutiny over animal welfare and environmental impact.

- Both materials present challenges in meeting evolving eco-standards and circular economy principles.

Sustainable Alternative: High-Performance Synthetic Leathers

For brands aiming to balance performance, cost, and sustainability, advanced synthetic leathers—such as PU-based or bio-based materials—offer a responsible middle ground. WINIW specializes in eco-conscious synthetic leather solutions that mimic the aesthetics and functionality of real leather without the environmental burden of PVC or ethical concerns of animal hides.

By transitioning to innovative, low-impact materials, B2B partners can align with global sustainability trends, reduce lifecycle emissions, and meet the demands of environmentally aware consumers.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineering Excellence for Global B2B Partners

WINIW stands as a cornerstone manufacturer of premium synthetic leather, engineered to meet the exacting demands of global brands and converters. Our vertically integrated production ecosystem, spanning 100,000 square meters of advanced manufacturing space, delivers unmatched scale, innovation, and reliability. Built on a foundation of sustainability and precision, we empower partners across fashion, automotive, furniture, and accessories with materials that balance performance, aesthetics, and environmental responsibility.

Core Manufacturing Strengths

- Integrated 100,000 sqm Production Facility: One of Asia’s largest dedicated synthetic leather campuses, enabling end-to-end control from resin formulation to finishing. This scale ensures consistent high-volume output (exceeding 50 million meters annually) while maintaining agile responsiveness to urgent client demands.

- Dedicated R&D Innovation Hub: A 120+ member cross-functional team (material scientists, chemical engineers, product designers) drives continuous advancement. We specialize in developing bespoke solutions, including:

- High-recycled-content materials (up to 80% post-consumer/post-industrial)

- Bio-based polyurethanes and waterborne systems

- Performance-enhanced substrates for extreme durability (automotive/aviation)

- Custom textures, weights, and functional finishes (anti-microbial, UV-resistant)

- Rigorous Multi-Stage Quality Control: Every meter undergoes 15+ validation checkpoints, exceeding global benchmarks:

- Raw material traceability via blockchain-enabled supply chain

- In-line spectrophotometer color consistency monitoring (ΔE < 0.5)

- Automated defect detection using AI vision systems

- Compliance with EU REACH, US CPSIA, OEKO-TEX® STANDARD 100, and ISO 14001

Global Compliance & Market Access

WINIW’s operational excellence is validated by our established export footprint across regulated markets. We maintain active partnerships with Tier-1 suppliers to European luxury houses and North American automotive OEMs, demonstrating adherence to the strictest regional requirements:

| Key Requirement | WINIW Standard | Industry Baseline | Client Impact |

|---|---|---|---|

| Chemical Compliance | Full SVHC screening + 200+ substance ban | REACH Annex XVII only | Zero customs delays; seamless market entry |

| Physical Performance | ISO 1767-1770, ASTM D3884/3885 | Basic tensile/abrasion | Enhanced product lifespan; reduced warranty claims |

| Sustainability Proof | GRS, RCS, Higg FEM certified | Self-declared claims | Credible ESG reporting; brand reputation protection |

| Traceability | Batch-level digital ledger | Manual documentation | Rapid root-cause analysis; recall mitigation |

This infrastructure ensures WINIW consistently delivers materials that meet the dual imperatives of commercial viability and planetary stewardship. Our facility’s renewable energy integration (40% solar-powered) and closed-loop water systems further underscore our commitment to reducing the environmental footprint of synthetic leather production—without compromising on performance or scalability. Partner with WINIW for supply chain resilience, innovation velocity, and materials engineered for a sustainable future.

Contact Us for Samples

WINIW B2B Product Guide: PVC Garments Microfiber Leather

WINIW specializes in high-performance, eco-friendly microfiber leather solutions engineered for the modern apparel industry. Our PVC garments line combines durability, flexibility, and sustainability—designed specifically for fashion-forward and function-driven outerwear, accessories, and performance clothing. With a focus on B2B partnerships, we deliver consistent quality, scalable production, and customization options to meet your brand’s exact specifications.

Our PVC-based microfiber leather is ideal for creating water-resistant, abrasion-resistant, and low-maintenance garments without compromising on softness or drape. As part of our commitment to sustainability, WINIW utilizes eco-conscious manufacturing processes that reduce environmental impact while maintaining industrial efficiency.

Key Features of WINIW PVC Garments Microfiber Leather:

- Superior tensile and tear strength for long-lasting wear

- Excellent resistance to water, UV exposure, and common chemicals

- Soft hand feel with flexible drape, mimicking premium natural leather

- Available in a wide range of colors, textures, and finishes (matte, glossy, embossed)

- Eco-friendly production with reduced VOC emissions and phthalate-free options

- Lightweight construction ideal for jackets, vests, pants, and fashion accessories

- Consistent roll-to-roll quality for seamless integration into automated cutting systems

Technical Specifications Overview:

| Property | Standard Value |

|---|---|

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Weight | 200 – 350 g/m² |

| Base Fabric | High-density polyester knit |

| Coating Material | PVC blend with stabilizers |

| Abrasion Resistance | >20,000 cycles (Martindale test) |

| Color Fastness | Grade 4–5 (Xenon arc light) |

| Temperature Resistance | -20°C to +70°C |

| Eco Compliance | REACH, RoHS, and AZO-free |

WINIW supports global apparel manufacturers, fashion brands, and technical garment developers with end-to-end material solutions. Whether you’re launching a sustainable outerwear line or upgrading from traditional leather or PU, our PVC microfiber leather offers a high-value alternative.

Why Partner with WINIW?

– Rapid prototyping and custom development services

– MOQs tailored to startup and enterprise needs

– Fast lead times with global shipping capabilities

– In-house R&D team for performance innovation

– Free samples available for qualified businesses

Request Free Samples Today

Explore the quality and versatility of WINIW’s PVC garments microfiber leather with no obligation.

Contact our sales team at MKT88@MicrofiberLeather.com to discuss your project requirements and receive complimentary material swatches.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.