Introduction: Navigating the Global Market for motorcycle seat vinyl

In the competitive landscape of motorcycle seat vinyl sourcing, international B2B buyers face the significant challenge of finding materials that are not only durable but also comfortable and visually appealing. As motorcycle enthusiasts across Africa, South America, the Middle East, and Europe seek to enhance their riding experience, the demand for high-quality motorcycle seat vinyl has surged. This comprehensive guide serves as a vital resource for businesses aiming to make informed decisions in selecting the right vinyl for their motorcycle upholstery needs.

Throughout this guide, we will explore various types of motorcycle seat vinyl, including marine-grade and stretchable options, and delve into their specific applications in both custom and mass production. Buyers will gain insights into effective supplier vetting processes, essential quality standards, and cost considerations that can impact their purchasing decisions. Additionally, we will address the latest trends in design and functionality, ensuring that businesses are equipped to meet the evolving demands of their customers.

By empowering B2B buyers with actionable knowledge, this guide aims to simplify the often complex process of sourcing motorcycle seat vinyl. Whether you are based in Germany, Nigeria, or any other global market, the insights provided here will help you navigate the intricacies of the motorcycle upholstery industry, ultimately leading to successful procurement strategies and enhanced product offerings.

Table Of Contents

- Top 6 Motorcycle Seat Vinyl Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for motorcycle seat vinyl

- Understanding motorcycle seat vinyl Types and Variations

- Key Industrial Applications of motorcycle seat vinyl

- 3 Common User Pain Points for ‘motorcycle seat vinyl’ & Their Solutions

- Strategic Material Selection Guide for motorcycle seat vinyl

- In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat vinyl

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat vinyl’

- Comprehensive Cost and Pricing Analysis for motorcycle seat vinyl Sourcing

- Alternatives Analysis: Comparing motorcycle seat vinyl With Other Solutions

- Essential Technical Properties and Trade Terminology for motorcycle seat vinyl

- Navigating Market Dynamics and Sourcing Trends in the motorcycle seat vinyl Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat vinyl

- Strategic Sourcing Conclusion and Outlook for motorcycle seat vinyl

- Important Disclaimer & Terms of Use

Understanding motorcycle seat vinyl Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Marine Grade Vinyl | UV resistant, waterproof, and durable against saltwater | Marine applications, motorcycles, ATVs | Pros: Excellent durability; Cons: Higher cost than standard vinyl. |

| Stretch Vinyl | High elasticity, flexible, and easy to mold | Custom seat covers, performance motorcycles | Pros: Provides a smooth finish; Cons: May require specialized tools for installation. |

| Faux Leather Vinyl | Aesthetic appeal, available in various textures | Luxury motorcycle seats, custom designs | Pros: Cost-effective alternative to real leather; Cons: Less durable than other types. |

| Flame Retardant Vinyl | Resistant to ignition, self-extinguishing properties | Racing motorcycles, safety gear | Pros: Enhances safety; Cons: Limited color options. |

| Heavy-Duty Vinyl | Thick, robust material designed for high wear | Heavy-use motorcycles, off-road vehicles | Pros: Exceptional resistance to wear and tear; Cons: Heavier, may affect seat comfort. |

What Are the Characteristics of Marine Grade Vinyl for Motorcycle Seats?

Marine grade vinyl is a top choice for motorcycle upholstery, especially in regions with high humidity or exposure to saltwater. Its UV resistance ensures longevity, making it ideal for outdoor applications. B2B buyers should consider its waterproof properties, which protect against moisture and spills. While the initial cost may be higher compared to standard vinyl, the investment pays off in durability and performance, especially for businesses catering to marine or adventure motorcycle markets.

Why Choose Stretch Vinyl for Custom Motorcycle Seats?

Stretch vinyl is highly regarded for its elasticity and adaptability, making it perfect for custom motorcycle seat covers. This type of vinyl can easily conform to various shapes and contours, providing a professional finish. B2B buyers should note its suitability for performance motorcycles, where aesthetics and comfort are paramount. While stretch vinyl enhances the visual appeal, it may necessitate specialized installation tools, which could influence procurement decisions.

How Does Faux Leather Vinyl Compare for Luxury Applications?

Faux leather vinyl offers a compelling combination of aesthetics and affordability, making it a popular choice for luxury motorcycle seats. Its diverse texture options allow for unique custom designs that can attract high-end clientele. However, B2B buyers should weigh its lesser durability against the cost savings compared to genuine leather. This material is best suited for businesses targeting style-conscious consumers while maintaining budget constraints.

What Are the Safety Benefits of Using Flame Retardant Vinyl?

Flame retardant vinyl is essential for applications where safety is a priority, such as racing motorcycles or protective gear. Its self-extinguishing properties significantly reduce fire risk, making it a vital material for safety-conscious buyers. While this type of vinyl enhances safety features, B2B buyers should be aware of its limited color options, which may restrict design flexibility. Companies in high-risk environments should prioritize this material for compliance and safety standards.

Why is Heavy-Duty Vinyl Ideal for High-Use Motorcycles?

Heavy-duty vinyl is engineered for exceptional resistance to wear, making it suitable for off-road motorcycles and other high-use applications. Its robust nature ensures longevity, which is critical for businesses that rely on durability in their offerings. B2B buyers should consider the trade-off between weight and comfort, as heavier materials may affect overall seating comfort. This type of vinyl is a wise investment for companies that prioritize performance and longevity in their motorcycle seat solutions.

Key Industrial Applications of motorcycle seat vinyl

| Industry/Sector | Specific Application of motorcycle seat vinyl | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Upholstery for OEM motorcycle seats | Enhanced comfort and durability for end-users | Quality of vinyl, color options, and weather resistance |

| Custom Motorcycle Shops | Custom seat covers for personalized motorcycle designs | Unique offerings that attract niche markets | Customization capabilities, lead times, and pricing |

| Recreational Vehicle | Seat coverings for ATVs and snowmobiles | Versatile material that withstands outdoor elements | UV resistance, stretchability, and ease of maintenance |

| Marine Industry | Upholstery for personal watercraft seats | Water-resistant and easy-to-clean options | Marine-grade specifications, colorfastness, and durability |

| Furniture Restoration | Reupholstering vintage motorcycle seats | Revitalizes heritage products for resale | Authenticity of materials, historical accuracy, and pricing |

How is Motorcycle Seat Vinyl Used in Motorcycle Manufacturing?

In the motorcycle manufacturing sector, motorcycle seat vinyl serves as the primary upholstery material for OEM (Original Equipment Manufacturer) motorcycle seats. This vinyl is designed to provide a comfortable seating experience while ensuring durability and resistance to wear and tear. For international buyers, particularly in regions like Africa and South America, sourcing high-quality vinyl that meets specific performance standards is crucial. Factors such as color options, weather resistance, and compliance with local regulations will significantly influence purchasing decisions.

What Role Does Motorcycle Seat Vinyl Play in Custom Motorcycle Shops?

Custom motorcycle shops utilize motorcycle seat vinyl to create bespoke seat covers tailored to individual customer preferences. This application allows shops to differentiate themselves in a competitive market by offering unique designs and colors. Buyers in this sector should consider the vinyl’s stretchability and ease of application, as these factors can streamline the customization process. Additionally, understanding lead times for custom orders can enhance customer satisfaction and retention.

How is Motorcycle Seat Vinyl Applied in Recreational Vehicle Production?

In the recreational vehicle industry, motorcycle seat vinyl is commonly used for seat coverings on ATVs and snowmobiles. The material’s ability to withstand harsh outdoor conditions, including UV exposure and moisture, makes it an ideal choice. For businesses in the Middle East and Europe, sourcing vinyl that meets stringent quality standards while offering a range of color and texture options is essential. Buyers must also assess the vinyl’s stretchability and ease of maintenance to ensure long-lasting performance.

Why is Motorcycle Seat Vinyl Important for the Marine Industry?

The marine industry leverages motorcycle seat vinyl for upholstery in personal watercraft seats due to its water-resistant properties and ease of cleaning. This application ensures that seats remain functional and aesthetically pleasing despite exposure to harsh marine environments. International buyers should prioritize sourcing marine-grade vinyl that meets industry standards for durability and colorfastness. Understanding the specific requirements for marine applications can help businesses maintain compliance and enhance product longevity.

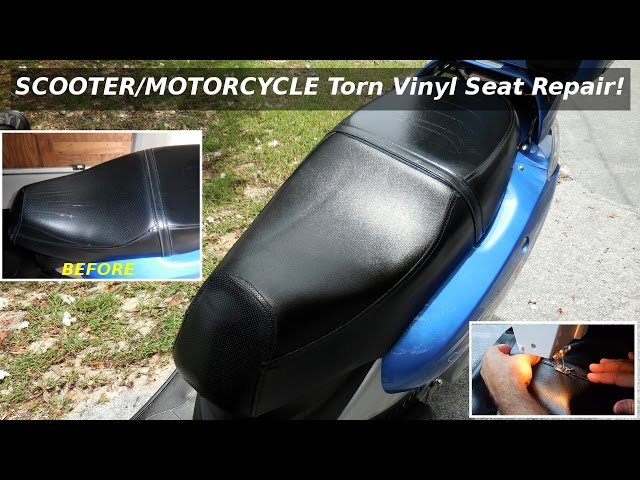

How is Motorcycle Seat Vinyl Used in Furniture Restoration?

In furniture restoration, motorcycle seat vinyl is increasingly used to reupholster vintage motorcycle seats, revitalizing them for resale or personal use. This application not only preserves the aesthetic appeal of heritage products but also ensures that they meet modern durability standards. Buyers in this sector must consider the authenticity of the materials used, as well as pricing and historical accuracy. Sourcing high-quality vinyl that can replicate original textures and colors will significantly enhance the value of restored pieces.

3 Common User Pain Points for ‘motorcycle seat vinyl’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Motorcycle Seat Vinyl

The Problem: B2B buyers often struggle to find high-quality motorcycle seat vinyl that can withstand various environmental conditions, especially in regions with extreme temperatures, such as parts of Africa and the Middle East. Many suppliers offer products that may look appealing but fail to provide the necessary durability, leading to issues like cracking, fading, or tearing after a short period of use. This not only affects the comfort and aesthetics of the motorcycle seat but also results in increased costs due to frequent replacements.

The Solution: To address this issue, buyers should prioritize sourcing vinyl that meets specific performance criteria, such as UV resistance, cold crack resistance, and tear strength. Look for suppliers who provide detailed technical specifications and certifications for their products. For instance, vinyl materials like Morbern™ Allsport, known for its 360° stretch and durability, are ideal for motorcycle seats. Additionally, buyers can request samples to test the vinyl’s performance before making a bulk purchase. Establishing strong relationships with reputable manufacturers who specialize in motorcycle upholstery can also lead to better product knowledge and access to high-quality materials.

Scenario 2: Challenges in Customizing Motorcycle Seat Designs

The Problem: Customization is a key demand among motorcycle enthusiasts, and B2B buyers often find it challenging to procure motorcycle seat vinyl that allows for easy customization. Many vinyl options available in the market may not be stretchable or pliable enough to create intricate designs or patterns. This limitation can hinder a business’s ability to offer unique and appealing products, ultimately affecting customer satisfaction and sales.

The Solution: To overcome this challenge, buyers should focus on sourcing high-stretch vinyl fabrics that facilitate customization. For example, motorcycle vinyls designed for easy sewing and manipulation, such as those that feature a higher degree of elasticity, can be beneficial. It is also advisable to invest in training and resources for staff on how to use these materials effectively for custom jobs. Providing samples and swatches to clients can also help in finalizing designs that meet their expectations. Moreover, partnering with experienced upholstery professionals or consultants can offer valuable insights into effective techniques for working with vinyl, ensuring that businesses can deliver high-quality, customized seats.

Scenario 3: Difficulty in Maintaining the Quality of Motorcycle Seat Vinyl Over Time

The Problem: Over time, motorcycle seat vinyl can deteriorate due to exposure to elements such as sunlight, moisture, and dirt. For B2B buyers, this presents a significant challenge as it can lead to customer complaints and product returns. Businesses often find it hard to educate their customers on the proper maintenance of their motorcycle seats, which can further exacerbate the issue of vinyl degradation.

The Solution: To mitigate this problem, B2B buyers should not only source high-quality, weather-resistant vinyl but also provide comprehensive care instructions to their customers. Consider developing a maintenance guide that includes tips on cleaning and protecting the vinyl, such as using UV protectants or specialized cleaning agents designed for marine-grade vinyl. Additionally, offering warranties or guarantees on the vinyl can enhance customer trust and satisfaction. Educating sales teams about these maintenance practices will empower them to inform customers effectively, ensuring that the vinyl maintains its integrity and appearance over time. This approach not only improves customer satisfaction but also fosters long-term relationships with clients who appreciate the added value.

Strategic Material Selection Guide for motorcycle seat vinyl

When selecting materials for motorcycle seat vinyl, it’s essential to consider various factors that can significantly impact product performance, durability, and suitability for specific applications. Here, we analyze four common materials used in motorcycle seat vinyl, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

What Are the Key Properties of PVC Vinyl for Motorcycle Seats?

Polyvinyl Chloride (PVC) vinyl is one of the most widely used materials for motorcycle seat covers due to its versatility and cost-effectiveness. It offers excellent resistance to moisture, UV rays, and abrasion, making it suitable for outdoor use. PVC vinyl can withstand a temperature range of -20°C to 60°C, which is beneficial for regions with varying climates.

Pros: PVC is durable, easy to clean, and available in a wide range of colors and textures. It is also relatively inexpensive, making it an attractive option for manufacturers aiming to keep costs low.

Illustrative image related to motorcycle seat vinyl

Cons: On the downside, PVC can become brittle over time, especially when exposed to extreme temperatures or prolonged sunlight. It may not be as environmentally friendly as other materials, which could be a concern for companies looking to enhance their sustainability credentials.

International Considerations: Buyers from regions like Europe may need to ensure compliance with REACH regulations regarding chemical safety, while those in Africa and South America should consider local climate conditions that can affect the longevity of PVC products.

How Does Polyurethane (PU) Vinyl Compare for Motorcycle Seats?

Polyurethane (PU) vinyl is another popular choice, known for its superior flexibility and softness compared to PVC. It has excellent abrasion resistance and can tolerate a wider temperature range, making it suitable for high-performance applications.

Pros: PU vinyl provides a more premium feel and appearance, enhancing the aesthetic value of motorcycle seats. It is also more resistant to cracking and fading, ensuring a longer lifespan.

Cons: The primary drawback is its higher cost compared to PVC. Additionally, PU vinyl may require more complex manufacturing processes, which can increase production times and costs.

Illustrative image related to motorcycle seat vinyl

International Considerations: Buyers in regions with stringent environmental regulations, such as Germany, may prefer PU for its lower environmental impact. However, they should also verify compliance with specific standards such as DIN EN ISO 14001.

What Are the Benefits of Using Marine-Grade Vinyl for Motorcycle Seats?

Marine-grade vinyl is specifically designed to withstand harsh outdoor conditions, making it an excellent choice for motorcycle seats, especially in humid or coastal environments. This material is treated to resist mold, mildew, and UV damage, ensuring longevity.

Pros: Its durability and resistance to water make marine-grade vinyl ideal for riders who often face wet conditions. It is also easy to clean and maintain.

Cons: The cost of marine-grade vinyl can be significantly higher than standard options, which may deter budget-conscious manufacturers. Additionally, its heavier weight can impact the overall weight of the motorcycle.

International Considerations: Buyers in the Middle East, where humidity can be high, will find marine-grade vinyl particularly beneficial. Compliance with ASTM standards for marine applications may also be necessary.

How Does Stretch Vinyl Enhance Motorcycle Seat Comfort?

Stretch vinyl is engineered to provide flexibility and comfort, making it an excellent choice for motorcycle seats that require a snug fit. This material can accommodate the contours of the seat while maintaining a smooth appearance.

Pros: The key advantage of stretch vinyl is its ability to conform to various shapes, enhancing the overall comfort of the seat. It also offers good durability and resistance to wear and tear.

Cons: Stretch vinyl can be more challenging to work with during manufacturing, requiring skilled labor for proper installation. Its cost may also be higher than traditional vinyl options.

Illustrative image related to motorcycle seat vinyl

International Considerations: For buyers in Africa and South America, where craftsmanship can vary, it’s essential to ensure that manufacturers are equipped to handle stretch vinyl effectively. Compliance with local quality standards will also be critical.

Summary Table of Motorcycle Seat Vinyl Materials

| Material | Typical Use Case for motorcycle seat vinyl | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC Vinyl | General motorcycle seat covers | Cost-effective and durable | Can become brittle over time | Low |

| PU Vinyl | High-end motorcycle seats | Superior flexibility and aesthetics | Higher cost and manufacturing complexity | High |

| Marine-Grade Vinyl | Seats for wet or humid conditions | Excellent moisture and UV resistance | Higher cost and heavier weight | Medium |

| Stretch Vinyl | Custom-fit motorcycle seats | Enhanced comfort and fit | More challenging to manufacture | Medium |

This analysis provides a comprehensive overview of the key materials used in motorcycle seat vinyl, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat vinyl

What Are the Main Stages of Manufacturing Motorcycle Seat Vinyl?

The manufacturing process of motorcycle seat vinyl is intricate, involving several key stages that ensure the final product meets both aesthetic and functional requirements. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Motorcycle Seat Vinyl?

The journey begins with the selection of high-quality raw materials, primarily polyvinyl chloride (PVC) or polyurethane (PU). The choice between PVC and PU often depends on the desired characteristics of the vinyl, such as flexibility, durability, and resistance to wear. Manufacturers typically source these materials from reputable suppliers, ensuring they adhere to international quality standards.

Once the raw materials are sourced, they undergo a compounding process where additives are blended into the base resin. These additives can include plasticizers for flexibility, stabilizers for UV resistance, and flame retardants for safety. After compounding, the material is extruded into sheets of varying thicknesses, which are then cooled and cut into manageable sizes.

What Techniques Are Used in Forming Motorcycle Seat Vinyl?

Forming is a critical stage where the prepared vinyl is shaped to meet specific design requirements. Common techniques used in this stage include calendaring and lamination.

-

Calendaring involves passing the vinyl through a series of rollers to achieve the desired thickness and texture. This method is particularly effective for producing a smooth, uniform surface that is essential for aesthetic appeal.

-

Lamination is another technique where layers of vinyl are bonded together to enhance durability and provide additional features such as waterproofing or UV resistance. This process can involve heat and pressure to ensure a strong bond between layers.

How Is the Assembly Process Conducted?

After forming, the vinyl sheets are ready for assembly. This stage typically involves cutting the vinyl into specific patterns that correspond to motorcycle seat designs. Skilled workers or automated cutting machines are used to ensure precision and minimize waste.

Once cut, the pieces are sewn together, often using heavy-duty thread that can withstand stress and wear. This sewing process is critical, as it not only affects the appearance of the seat but also its durability and longevity. Manufacturers may also incorporate additional materials, such as foam padding, to enhance comfort.

Illustrative image related to motorcycle seat vinyl

What Quality Assurance Practices Are Essential in Motorcycle Seat Vinyl Production?

Quality assurance (QA) is paramount in the manufacturing of motorcycle seat vinyl, ensuring that products meet both safety and performance standards. International standards such as ISO 9001 are often adopted to guide quality management systems.

Which International Standards Should B2B Buyers Consider?

International standards like ISO 9001 focus on quality management principles, including customer satisfaction, process approach, and continual improvement. Additionally, specific industry standards such as CE marking for safety and compliance with the API (American Petroleum Institute) standards may be relevant, especially for products intended for high-performance environments.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and rectify issues early. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to monitor parameters such as thickness, tensile strength, and color consistency.

-

Final Quality Control (FQC): This is the last checkpoint before products are shipped, where finished goods undergo rigorous testing to verify their compliance with quality standards.

What Common Testing Methods Are Used for Motorcycle Seat Vinyl?

Testing methods for motorcycle seat vinyl may include:

- Tensile Strength Tests: Assessing the material’s ability to withstand stretching forces.

- UV Resistance Tests: Evaluating how well the vinyl can resist degradation from ultraviolet light.

- Flame Retardancy Tests: Ensuring that the material meets fire safety standards.

These tests help in verifying that the product will perform effectively in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control measures of their suppliers. Here are some effective strategies:

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is an essential step for verifying quality assurance practices. This involves visiting the manufacturing facility to assess processes, equipment, and adherence to quality standards. Buyers should prepare a checklist that includes inquiries about materials used, production techniques, and quality certifications.

How Can Buyers Request QC Reports?

Buyers should request regular QC reports from suppliers, which provide insights into production quality and any corrective actions taken. These reports can help in understanding the supplier’s commitment to quality and areas for improvement.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These inspectors can conduct thorough assessments of the manufacturing process and provide certifications that can enhance buyer confidence.

What Are the QC Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control. Different countries may have varying regulatory requirements and standards, making it essential to understand local compliance issues.

Illustrative image related to motorcycle seat vinyl

For instance, buyers from Germany may prioritize compliance with stringent EU regulations, while Nigerian buyers might focus on local standards and certifications. Understanding these differences can facilitate smoother transactions and foster long-term partnerships.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for motorcycle seat vinyl is crucial for B2B buyers. By focusing on quality at every stage—from material preparation to final inspections—buyers can ensure that they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat vinyl’

In the competitive landscape of motorcycle accessories, sourcing high-quality motorcycle seat vinyl is essential for ensuring durability, comfort, and aesthetic appeal. This guide provides a systematic checklist for B2B buyers to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, outline the specific requirements for the motorcycle seat vinyl. Consider factors such as thickness, stretchability, UV resistance, and flame retardant properties.

– Thickness: Ensure the vinyl can withstand wear and tear while maintaining comfort.

– Stretchability: Look for materials that offer flexibility for easier installation and better fit on various seat shapes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in motorcycle seat vinyl. Utilize online platforms, industry forums, and trade shows to gather a list of potential vendors.

– Online Reviews: Check for customer feedback and ratings to assess reliability.

– Industry Connections: Leverage your network to gain insights about trusted suppliers.

Step 3: Evaluate Supplier Certifications

Verify that the suppliers hold relevant certifications that validate their quality standards and compliance with industry regulations. Certifications can include ISO, CE, or specific material safety standards.

– Quality Assurance: Certifications indicate a commitment to maintaining high production standards.

– Regional Compliance: Ensure that the vinyl meets local regulations, especially if exporting to regions with stringent import laws.

Step 4: Request Samples

Always request samples before finalizing any orders. This allows you to evaluate the material’s quality, texture, and color accuracy.

– Durability Testing: Assess how the sample holds up against abrasion and environmental conditions.

– Aesthetic Appeal: Ensure the colors align with your branding and customer preferences.

Step 5: Negotiate Pricing and Terms

Once you’ve identified potential suppliers and evaluated samples, engage in negotiations. Discuss pricing, minimum order quantities, lead times, and payment terms.

– Bulk Discounts: Inquire about volume pricing to maximize cost savings.

– Flexible Payment Options: Ensure terms align with your cash flow management strategies.

Step 6: Confirm Logistics and Shipping Arrangements

Discuss logistics with your supplier to ensure timely delivery and safe transportation of your vinyl materials. Understand the shipping methods, potential customs duties, and delivery timelines.

– Shipping Options: Evaluate different shipping methods for cost-effectiveness and speed.

– Tracking and Insurance: Ensure that shipments are traceable and insured against damage during transit.

Step 7: Establish a Quality Control Process

After receiving the materials, implement a quality control process to inspect the vinyl before use. This step ensures that the materials meet the agreed specifications.

– Visual Inspection: Check for color consistency and defects.

– Performance Testing: Conduct tests to confirm the vinyl’s performance under expected conditions.

By following these steps, B2B buyers can effectively source high-quality motorcycle seat vinyl that meets their technical requirements while ensuring compliance with industry standards. This thorough approach not only enhances product offerings but also strengthens supplier relationships, ultimately leading to greater customer satisfaction.

Comprehensive Cost and Pricing Analysis for motorcycle seat vinyl Sourcing

When sourcing motorcycle seat vinyl, it is essential to understand the intricate cost structure and pricing dynamics that influence procurement decisions. A comprehensive analysis of these factors can help international B2B buyers make informed purchasing choices, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Germany and Nigeria.

What Are the Key Cost Components of Motorcycle Seat Vinyl?

Materials: The primary cost component is the vinyl material itself, which can vary significantly in price based on quality and specifications. For instance, high-performance vinyl, such as Morbern™ Allsport, priced around $23.99 to $39.95 per linear yard, offers enhanced durability and stretchability, making it suitable for motorcycle applications.

Illustrative image related to motorcycle seat vinyl

Labor: Labor costs are incurred during the manufacturing process, including cutting, sewing, and finishing the vinyl. These costs can fluctuate based on the location of the manufacturer and local wage standards.

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment depreciation, and facility maintenance. Manufacturers often distribute these costs across production runs, affecting per-unit pricing.

Tooling: Custom tooling may be necessary for specific designs or specifications, which can add to the initial investment. This cost is generally amortized over larger orders, making it crucial for buyers to consider minimum order quantities (MOQs).

Illustrative image related to motorcycle seat vinyl

Quality Control (QC): Implementing stringent QC processes ensures that the vinyl meets industry standards and customer expectations. While this adds to the cost, it can prevent costly returns and rework, thus enhancing overall value.

Logistics: Shipping and handling costs can vary widely depending on the distance, shipping method, and Incoterms agreed upon. For international buyers, understanding these logistics is crucial to avoid unexpected expenses.

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and the perceived value of their product.

How Do Price Influencers Affect Motorcycle Seat Vinyl Sourcing?

Volume/MOQ: Larger orders often lead to lower per-unit costs. Suppliers may offer significant discounts for bulk purchases, making it advantageous for buyers to negotiate favorable terms.

Specifications and Customization: Custom designs or specific color requirements can increase costs. Buyers should clearly communicate their needs to suppliers to obtain accurate quotes and avoid unexpected price hikes.

Illustrative image related to motorcycle seat vinyl

Materials and Quality Certifications: The presence of certifications (e.g., UV resistance, flame retardant) can enhance the perceived value of the vinyl. Buyers should assess whether these certifications align with their product requirements, as they may influence overall pricing.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more but offer better quality assurance and customer service.

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is vital, as it determines who bears the cost and risk during transit. Buyers should negotiate these terms to optimize their total cost of ownership.

Illustrative image related to motorcycle seat vinyl

What Are the Best Practices for Negotiating Motorcycle Seat Vinyl Prices?

Effective Negotiation: B2B buyers should approach negotiations with a clear understanding of market prices and supplier capabilities. Gathering multiple quotes can provide leverage when discussing terms.

Focus on Cost-Efficiency: Buyers should consider not only the purchase price but also the total cost of ownership, which includes logistics, labor for installation, and potential waste during application.

Pricing Nuances for International Buyers: Different regions may experience price fluctuations due to local demand, tariffs, and currency exchange rates. Buyers should stay informed about market trends and economic conditions that could affect pricing.

Disclaimer on Indicative Prices: Prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Buyers are encouraged to conduct thorough market research and engage with suppliers directly to obtain the most accurate pricing.

By understanding these cost components and pricing influencers, B2B buyers can make strategic sourcing decisions that align with their business objectives and market dynamics.

Illustrative image related to motorcycle seat vinyl

Alternatives Analysis: Comparing motorcycle seat vinyl With Other Solutions

In the competitive landscape of motorcycle upholstery, businesses often seek alternatives to traditional motorcycle seat vinyl. Understanding the options available can help B2B buyers make informed decisions that align with their operational needs and budget constraints. This section explores various solutions, comparing motorcycle seat vinyl with other viable materials and methods.

| Comparison Aspect | Motorcycle Seat Vinyl | Alternative 1: Leather | Alternative 2: Neoprene |

|---|---|---|---|

| Performance | Durable, resistant to wear and UV rays; easy to clean. | Highly durable, excellent comfort, and aesthetics; prone to wear in harsh conditions. | Good flexibility and water resistance; less durable than vinyl and leather. |

| Cost | Generally affordable, around $23-$40 per linear yard. | Higher cost, typically $50-$150 per yard depending on quality. | Moderate cost, typically $30-$60 per yard. |

| Ease of Implementation | Easy to cut and sew, forgiving for DIY projects. | Requires more skill for sewing and handling, can be challenging for beginners. | Moderate skill required; can be tricky to work with due to elasticity. |

| Maintenance | Low maintenance; easily wiped clean and resistant to stains. | Requires regular conditioning to maintain appearance and prevent cracking. | Easy to clean but may require special cleaning agents to avoid degradation. |

| Best Use Case | Ideal for high-volume production and budget-conscious projects. | Best for premium models where aesthetics and comfort are a priority. | Suitable for applications requiring water resistance, such as off-road or adventure bikes. |

What Are the Pros and Cons of Using Leather as an Alternative to Motorcycle Seat Vinyl?

Leather offers a luxurious appearance and exceptional comfort, making it a preferred choice for high-end motorcycles. Its durability is unmatched, providing a long lifespan when properly maintained. However, leather requires regular care to prevent cracking and deterioration, particularly in extreme weather conditions. This upkeep can be a drawback for businesses that prefer low-maintenance solutions. Additionally, the higher cost of leather can impact overall budget considerations, making it less suitable for cost-sensitive projects.

How Does Neoprene Compare as an Alternative Material for Motorcycle Seats?

Neoprene is another alternative that provides good flexibility and water resistance, making it particularly appealing for off-road or adventure motorcycles. Its ability to withstand moisture and provide a decent grip can enhance rider comfort. However, neoprene is generally less durable than vinyl and leather, which may lead to more frequent replacements. Furthermore, working with neoprene can be challenging for those without specialized sewing skills, potentially increasing labor costs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate upholstery material for motorcycle seats, B2B buyers should evaluate their specific needs, including performance requirements, budget constraints, and the intended use case. For businesses focused on high-volume production with budget limitations, motorcycle seat vinyl emerges as a practical and cost-effective choice. In contrast, those targeting premium segments may lean towards leather for its aesthetic appeal and comfort. Finally, neoprene serves as a viable option for specialized applications requiring water resistance, albeit with considerations regarding durability and ease of use. By carefully weighing these factors, buyers can make informed decisions that enhance their product offerings while meeting customer expectations.

Essential Technical Properties and Trade Terminology for motorcycle seat vinyl

What Are the Key Technical Properties of Motorcycle Seat Vinyl?

When sourcing motorcycle seat vinyl, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that buyers should consider:

-

Material Grade

Motorcycle seat vinyl typically falls under marine-grade or automotive-grade materials. Marine-grade vinyl is designed to withstand extreme weather conditions, making it suitable for outdoor motorcycles. Automotive-grade vinyl, while durable, may not offer the same level of water resistance. Choosing the right grade ensures longevity and suitability for specific applications. -

Tensile Strength

This specification measures how much force a material can withstand when being stretched before breaking. High tensile strength is essential for motorcycle seat vinyl, as it needs to endure the stress of regular use without tearing. A tensile strength of at least 2000 psi is often considered adequate for this application, ensuring that the vinyl can maintain its integrity under weight and movement. -

Cold Crack Resistance

Cold crack resistance indicates how well the vinyl performs in low-temperature environments. For regions with varying climates, particularly in Africa and South America, selecting vinyl with good cold crack resistance (typically rated at -60°F) is critical to prevent brittleness and cracking during colder months. -

UV Resistance

UV resistance is the ability of the vinyl to withstand degradation from sunlight exposure. Given that motorcycles are often used outdoors, UV-resistant vinyl prolongs the life of the seat by preventing fading and material breakdown. Look for vinyl that has been treated with UV stabilizers to ensure durability. -

Flame Retardancy

This property indicates whether the vinyl can resist ignition and slow down the spread of flames. Flame-retardant vinyl is particularly important for safety in case of accidents. Many manufacturers label their products with fire ratings, which can be essential for B2B buyers focusing on compliance and safety regulations. -

Weight and Thickness

The weight and thickness of the vinyl affect both its durability and comfort. Thicker vinyl can offer better durability but may add weight to the motorcycle. Typically, a thickness of 1.0 to 1.5 mm is preferred for optimal balance between durability and comfort.

What Are Common Trade Terms Used in the Motorcycle Seat Vinyl Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms related to motorcycle seat vinyl:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or materials that are used in the manufacturing of the final product. When sourcing vinyl, knowing whether a supplier is an OEM can assure you of the quality and compatibility of the materials. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding the MOQ helps buyers plan their inventory and manage costs effectively, particularly when dealing with international suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific quantities of products. Crafting a detailed RFQ can streamline the procurement process and ensure that you receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers avoid misunderstandings and ensures that logistics are handled efficiently. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for supply chain management and can impact production schedules significantly. -

Customs Duties

Customs duties are taxes imposed on imported goods. For B2B buyers, knowing the customs duties applicable to motorcycle seat vinyl can affect the overall cost and profitability of importing materials from international suppliers.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing motorcycle seat vinyl, ultimately enhancing your business’s operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the motorcycle seat vinyl Sector

What Are the Key Trends Shaping the Motorcycle Seat Vinyl Market?

The motorcycle seat vinyl market is witnessing significant growth, driven by several global factors. One primary driver is the increasing demand for customized motorcycle accessories, particularly in regions like Africa, South America, the Middle East, and Europe. Buyers are seeking high-quality, durable materials that not only enhance the aesthetics of their motorcycles but also improve comfort and safety. Additionally, the rising popularity of motorcycle tourism and recreational biking is contributing to the demand for premium upholstery materials.

Illustrative image related to motorcycle seat vinyl

Emerging technologies in manufacturing and sourcing are reshaping how businesses approach the procurement of motorcycle seat vinyl. Digital platforms and e-commerce solutions are making it easier for international buyers to access a wider range of products and suppliers. Innovations in material science have also led to the development of vinyls that are more resilient, weather-resistant, and easier to clean, catering to diverse climates and riding conditions. Furthermore, buyers are increasingly leveraging data analytics to identify trends in consumer preferences, allowing them to make informed sourcing decisions.

B2B buyers must be mindful of market dynamics, including fluctuating prices due to raw material availability and changing trade regulations. As manufacturers adapt to these challenges, international buyers can benefit from strategic partnerships that prioritize transparency and agility in the supply chain.

How Does Sustainability and Ethical Sourcing Impact the Motorcycle Seat Vinyl Industry?

Sustainability is becoming a pivotal consideration for B2B buyers in the motorcycle seat vinyl sector. Environmental concerns regarding the production and disposal of synthetic materials have led to a growing demand for eco-friendly alternatives. Buyers are increasingly interested in sourcing vinyl that is free from harmful chemicals and produced using sustainable practices. This shift not only aligns with global sustainability goals but also enhances brand reputation among environmentally conscious consumers.

Ethical sourcing is equally important, as buyers are looking for suppliers who adhere to fair labor practices and responsible manufacturing processes. Certifications such as OEKO-TEX and Global Recycled Standard can serve as benchmarks for identifying sustainable and ethically produced materials. By choosing vendors with these certifications, international buyers can ensure that their sourcing practices contribute positively to the environment and society.

Illustrative image related to motorcycle seat vinyl

Moreover, the focus on sustainability is prompting innovation in the types of materials used. Recycled and biodegradable vinyl options are emerging, providing buyers with more choices that meet both performance and environmental standards. This trend allows businesses to not only comply with regulatory requirements but also appeal to a growing segment of eco-conscious consumers.

How Has the Motorcycle Seat Vinyl Market Evolved Over Time?

The evolution of motorcycle seat vinyl can be traced back to the early days of motorcycle manufacturing, where leather was the predominant material used for seats. However, the limitations of leather in terms of durability and maintenance led to the adoption of synthetic materials in the latter half of the 20th century. Innovations in vinyl technology have since transformed the market, with modern vinyl options offering enhanced flexibility, weather resistance, and ease of cleaning.

In recent years, the industry has seen a significant shift towards customization and personalization, with consumers increasingly looking for unique designs that reflect their individual style. This trend has propelled the development of a wide range of colors, textures, and finishes in motorcycle seat vinyl, allowing manufacturers to cater to diverse consumer preferences.

As the market continues to evolve, international B2B buyers must stay informed about these historical trends to better understand current sourcing dynamics and make strategic decisions that align with future market directions.

Illustrative image related to motorcycle seat vinyl

Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat vinyl

1. How do I choose the right motorcycle seat vinyl for my needs?

Selecting the right motorcycle seat vinyl involves considering factors such as durability, stretchability, and weather resistance. Look for materials specifically labeled as marine-grade or upholstery vinyl, as these are designed to withstand harsh conditions. Additionally, evaluate the thickness and texture of the vinyl to ensure it meets both aesthetic and functional requirements. Request samples from suppliers to assess quality before making a bulk purchase, and consult with your manufacturer to understand which options align best with your product specifications.

2. What is the best vinyl for motorcycle seat upholstery?

The best vinyl for motorcycle seat upholstery is typically one that offers high durability and flexibility. Products like Morbern™ Allsport vinyl are renowned for their 360-degree stretch and resistance to cracking, making them ideal for motorcycle applications. Additionally, consider options that are UV resistant and easy to clean, as these features enhance the longevity and appearance of the seat. Always check for supplier certifications and customer reviews to ensure the quality of the vinyl.

3. What customization options are available for motorcycle seat vinyl?

Customization options for motorcycle seat vinyl often include various colors, textures, and patterns. Many suppliers allow you to request specific color matches or even print logos and designs directly onto the vinyl. When sourcing, inquire about minimum order quantities (MOQs) for customized products, as these may vary by supplier. It’s also beneficial to discuss lead times for custom orders to ensure alignment with your production schedule.

Illustrative image related to motorcycle seat vinyl

4. How can I vet suppliers of motorcycle seat vinyl?

To vet suppliers effectively, research their reputation within the industry by checking reviews and testimonials from other B2B buyers. Request references and case studies showcasing their work with similar products. Ensure the supplier has the necessary certifications for quality standards and environmental compliance. Additionally, consider visiting their manufacturing facilities, if possible, to evaluate their production capabilities and quality control processes firsthand.

5. What are the typical payment terms for purchasing motorcycle seat vinyl internationally?

Payment terms for international purchases can vary significantly by supplier. Common terms include upfront payment, 30% deposit with the balance due upon shipment, or net 30/60 days payment after delivery. Always clarify payment options before placing an order and be aware of potential currency exchange fees. Additionally, consider using secure payment methods like letters of credit or escrow services to protect your transaction.

6. What quality assurance measures should I expect from suppliers?

Quality assurance measures should include comprehensive testing of the vinyl for durability, UV resistance, and colorfastness. Suppliers should provide certifications or test results to validate these claims. Additionally, inquire about their return policy and warranty terms, as these can be indicators of the supplier’s confidence in their product quality. Regular quality checks during production and pre-shipment inspections are also essential to ensure you receive consistent, high-quality materials.

7. How do logistics and shipping impact my purchase of motorcycle seat vinyl?

Logistics and shipping are crucial factors when sourcing motorcycle seat vinyl internationally. Consider the supplier’s shipping options and costs, as these can significantly affect your overall budget. Discuss lead times for production and shipping to ensure timely delivery aligned with your business needs. Additionally, be aware of customs regulations and import duties in your country, as these can impact delivery timelines and final costs.

8. What are the minimum order quantities (MOQs) for motorcycle seat vinyl?

Minimum order quantities (MOQs) for motorcycle seat vinyl can vary widely depending on the supplier and the type of vinyl. Typically, MOQs can range from as low as 10 yards to several hundred yards for custom orders. Always clarify MOQs before initiating an order, as lower quantities may incur higher per-unit costs. This information will help you plan your inventory and manage your budget effectively.

Top 6 Motorcycle Seat Vinyl Manufacturers & Suppliers List

1. Seattle Fabrics – 54 Moto-X Grabber Upholstery Vinyl

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “54” Moto-X Grabber Upholstery Vinyl”, “Price”: “$39.95/linear yard”, “Part Number”: “FUPHG”, “Width”: “54 inches”, “Material Type”: “NON-Slip Upholstery Vinyl”, “Features”: [“Mildew resistant”, “UV stabilized”, “Perfect for motorcycle seat applications”], “Availability”: “Sold by the yard in .25, .5, .75 yard increments, .5 yard minimum”, “Color”: “Black”, “Weight Per Linear Yard…

2. All Sport – Motorcycle Vinyl

Domain: diyupholsterysupply.com

Registered: 2004 (21 years)

Introduction: Product Name: Motorcycle Vinyl

Brand: All Sport

Description: Stretchable, pliable upholstery vinyl suitable for gaming rails, marine applications, ATVs, snow machines, and motorcycles.

Specifications: -60° cold crack, 360° stretch, flame retardant.

Price: $23.99 per yard

Available Colors:

1. Black

2. High-Tac Black

3. Chalk

4. Nu Bright Yellow

5. Bright Red

6. Silver Met

7. Royal Blue

8. Electric…

3. Sailrite – Morbern™ Allsport Vinyl Fabric

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Materials List: Morbern™ Allsport 360º Stretch Electric Blue 54″ Vinyl Fabric (#104175), Morbern™ Allsport 360º Stretch Black 54″ Vinyl Fabric (#104182), PremoBond® Tex 90 (V-92) White UV Bonded Polyester Thread 4 oz. (1,350 yds.) (#123337), Cushion Wrap Silk Film 54″ (#103933), 5-Ply Waxed Polyester Twine Bobbin (81 ft.) (#29206), 21 Gauge 3/8″ (10mm) Staples 10,000/Box (Stainless Steel) (#8010SS…

4. Triumph Bobber Forum – Automotive Vinyl Paint

Domain: triumphbobberforum.com

Registered: 2016 (9 years)

Introduction: SEMA automotive vinyl paint, Duplicolor spray paint, vinyl/leather dye

5. Corbin – Saddle Material Options

Domain: corbin.com

Registered: 1995 (30 years)

Introduction: Saddle Material Options:

1. Leather Options:

– Black Leather: Supple, durable, colorfast, natural texture.

– Carbon-Fiber Leather: Black genuine leather with nylon weave, excellent friction for sport riding.

– ‘Baby Alligator’ Leather: Pressed cowhide resembling alligator hide, best for trim and accent panels.

– ‘Alligator’ Leather: Shiny black leather, best for trim and accent pa…

6. Advrider – Sunbrella Outdoor Fabric

Domain: advrider.com

Registered: 2001 (24 years)

Introduction: 1. Sunbrella outdoor fabric: Fade and stain resistant, waterproof, wear resistant, available in various colors, textures, and weights. Recommended for traction due to rough texture. 2. High-grade leather-look grain black vinyl: Durable but may not be breathable. 3. 4-way stretch vinyl: Easier to work with, reduces creases and folds, durable. 4. Hospital/industrial grade vinyl: Recommended with a r…

Strategic Sourcing Conclusion and Outlook for motorcycle seat vinyl

What Are the Key Insights for Sourcing Motorcycle Seat Vinyl?

In conclusion, strategic sourcing of motorcycle seat vinyl is essential for international B2B buyers looking to enhance product quality while optimizing costs. The growing demand for durable, versatile, and visually appealing vinyl options underscores the importance of selecting suppliers who can provide high-quality materials that cater to diverse market needs. Buyers should prioritize suppliers who offer customizable solutions and extensive color options, ensuring that their products stand out in competitive markets.

The value of strategic sourcing extends beyond mere cost savings; it fosters strong supplier relationships and enables businesses to stay ahead of trends in the motorcycle industry. By investing time in understanding material specifications and production capabilities, buyers can make informed decisions that align with their brand values and customer expectations.

Looking ahead, the motorcycle market is poised for growth, particularly in regions like Africa, South America, the Middle East, and Europe. Now is the time for B2B buyers to leverage strategic sourcing initiatives, explore innovative materials, and establish partnerships that will drive future success. Engage with suppliers, inquire about new product lines, and stay informed about industry developments to position your business for long-term growth in the motorcycle seat vinyl market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.