Introduction: Navigating the Global Market for custom leather branding stamp

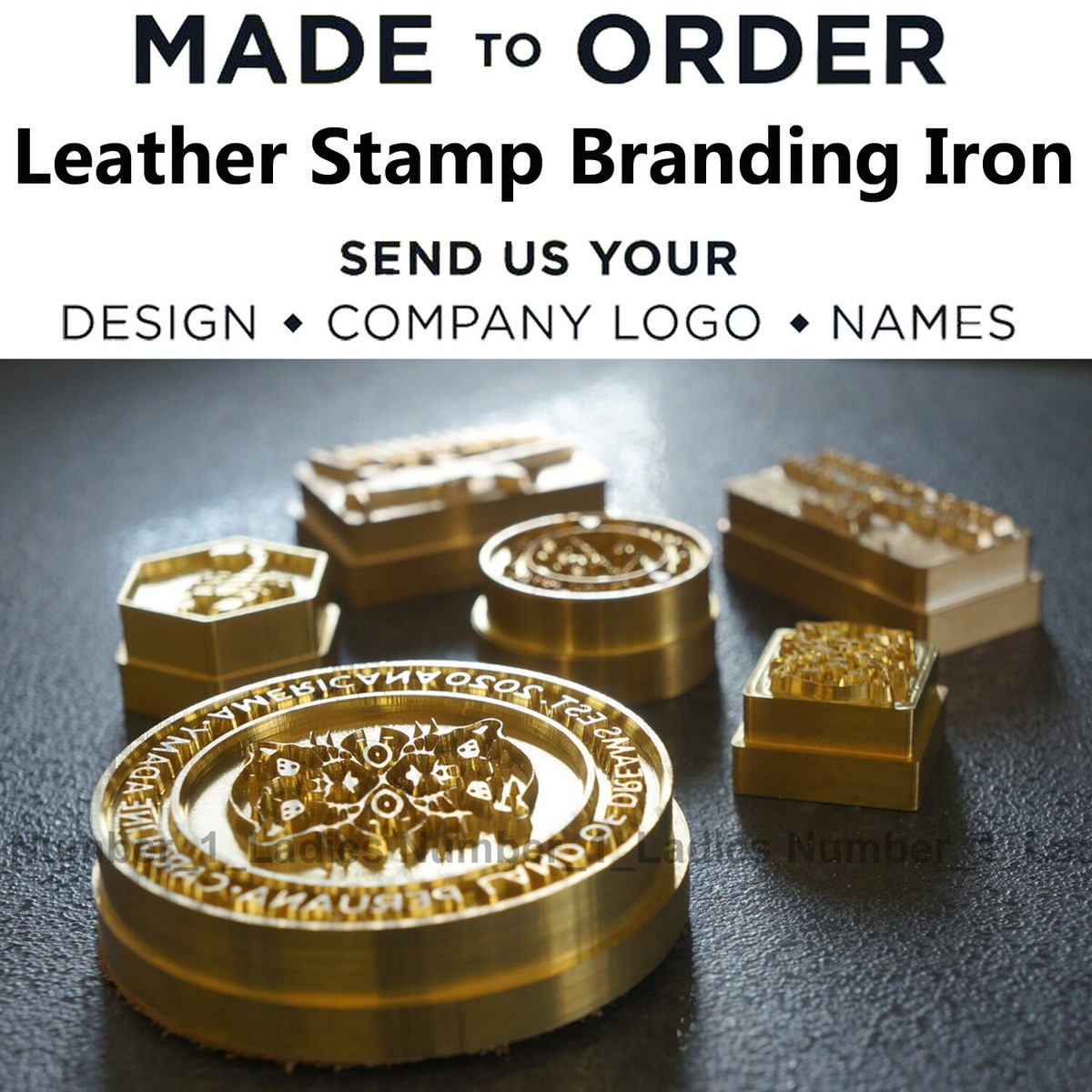

Navigating the intricacies of sourcing custom leather branding stamps can pose significant challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe—regions with diverse leather industries—understanding the nuances of design, material selection, and supplier reliability is crucial. This comprehensive guide delves into the various types of custom leather branding stamps available, including their applications in leather embossing, stamping, and branding across different leather types.

Buyers will find valuable insights into the specifications and costs associated with high-quality stamps, enabling them to make informed purchasing decisions. We will also cover essential aspects such as supplier vetting processes, ensuring that businesses can partner with reputable manufacturers who meet stringent quality standards. By equipping B2B buyers with actionable knowledge on factors like material durability—brass vs. aluminum, for instance—and the capabilities of different stamping methods, this guide empowers stakeholders to enhance their product branding effectively.

In a competitive global market, leveraging this information will not only streamline your sourcing process but also elevate your brand’s presence and recognition in the leather industry.

Table Of Contents

- Top 8 Custom Leather Branding Stamp Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather branding stamp

- Understanding custom leather branding stamp Types and Variations

- Key Industrial Applications of custom leather branding stamp

- 3 Common User Pain Points for ‘custom leather branding stamp’ & Their Solutions

- Strategic Material Selection Guide for custom leather branding stamp

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather branding stamp

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather branding stamp’

- Comprehensive Cost and Pricing Analysis for custom leather branding stamp Sourcing

- Alternatives Analysis: Comparing custom leather branding stamp With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather branding stamp

- Navigating Market Dynamics and Sourcing Trends in the custom leather branding stamp Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather branding stamp

- Strategic Sourcing Conclusion and Outlook for custom leather branding stamp

- Important Disclaimer & Terms of Use

Understanding custom leather branding stamp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hand Stamps | Made from brass, aluminum, or steel; manual operation. | Small-scale leather goods, artisan crafts. | Pros: Cost-effective, customizable. Cons: Labor-intensive, less uniform results. |

| Electric Branding Irons | Heated metal branding with adjustable temperature control. | Large-scale production, consistent branding. | Pros: High efficiency, consistent results. Cons: Higher initial investment, requires power source. |

| Custom Dies | Precision-cut stamps for unique designs; often used in presses. | Mass production, detailed embossing. | Pros: High detail, suitable for various presses. Cons: Longer lead time, higher cost. |

| Heat Embossing Stamps | Uses heat to imprint designs; often made from durable materials. | Decorative leather items, promotional goods. | Pros: High-quality finish, versatile. Cons: Requires specific equipment, potential for overheating. |

| Resin Stamps | Made from high-density resin; limited durability. | Short-term projects, low-volume marking. | Pros: Lower cost, quick turnaround. Cons: Less durable, not suitable for heavy use. |

What Are Hand Stamps and Their B2B Relevance?

Hand stamps are versatile tools crafted from materials such as brass, aluminum, or steel. They are manually operated and are ideal for small-scale leather goods and artisan crafts. B2B buyers often appreciate their cost-effectiveness and customization options. However, the labor-intensive nature of hand stamping may lead to inconsistencies in results, making them less suitable for high-volume production.

How Do Electric Branding Irons Enhance Production Efficiency?

Electric branding irons utilize heated metal to imprint designs onto leather, often featuring adjustable temperature controls. This makes them ideal for large-scale production, where consistency and efficiency are paramount. B2B buyers benefit from the high output and uniform results they provide. However, the initial investment can be higher, and they require access to a power source, which may not be feasible for all businesses.

Why Choose Custom Dies for Precision Branding?

Custom dies are precision-cut stamps designed for unique branding needs, often used in conjunction with presses. They are particularly beneficial for mass production and detailed embossing, allowing for intricate designs that can enhance product appeal. While they offer high detail and adaptability to various press types, they typically come with a longer lead time and higher costs, making them a significant investment for B2B buyers.

What Advantages Do Heat Embossing Stamps Offer?

Heat embossing stamps use heat to create impressions, often resulting in a high-quality finish. They are suitable for decorative leather items and promotional goods, appealing to businesses looking for a premium branding solution. Their versatility is a significant advantage; however, they require specific equipment and the risk of overheating can be a concern for less experienced users.

When Are Resin Stamps a Suitable Choice?

Resin stamps are made from high-density resin and are often seen as a budget-friendly option for short-term projects or low-volume marking. They provide quick turnaround times and are easy to produce, making them attractive for businesses that need rapid solutions. However, their lower durability compared to metal stamps limits their use in high-demand environments, which is an essential consideration for B2B buyers.

Key Industrial Applications of custom leather branding stamp

| Industry/Sector | Specific Application of custom leather branding stamp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Accessories | Branding leather goods such as handbags and belts | Enhances brand identity and creates a premium feel | Material durability, design complexity, and precision in engraving |

| Furniture and Home Decor | Embossing leather upholstery for furniture | Adds unique customization and elevates product value | Compatibility with various leather types and heat resistance |

| Automotive | Stamping leather interiors in vehicles | Strengthens brand recognition and provides a luxury touch | Customization options for logos and designs, heat resistance |

| Craft and Hobby | Personalizing leather craft products like wallets and journals | Increases customer engagement and satisfaction | Flexibility in design submission and turnaround time |

| Sports Equipment | Marking leather sports gear such as gloves and balls | Enhances product authenticity and brand loyalty | Material suitability for different sports and weather conditions |

How is Custom Leather Branding Stamp Used in the Fashion and Accessories Industry?

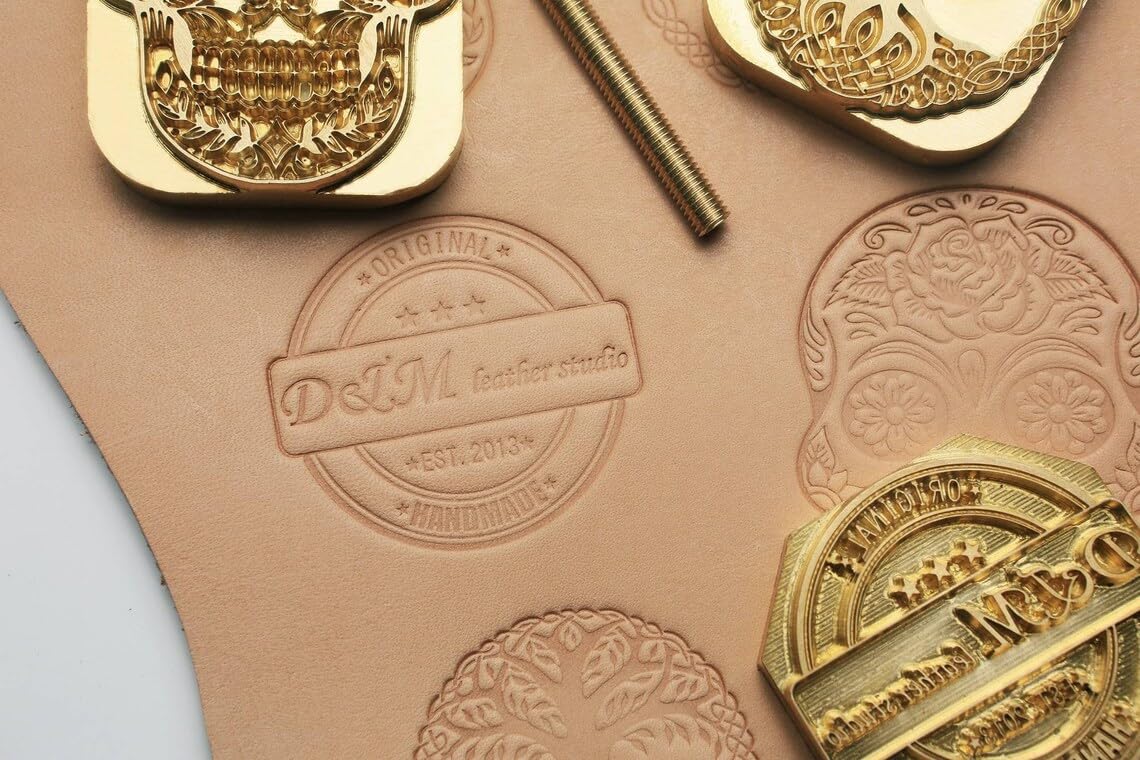

In the fashion and accessories sector, custom leather branding stamps are extensively used to imprint logos on products like handbags, belts, and wallets. This not only enhances brand identity but also provides a premium feel that appeals to consumers. For international buyers, especially those from regions like Europe and the Middle East, it’s crucial to consider the durability of the stamp material and the precision of the engraving to ensure a high-quality finish that withstands wear over time.

What Role Does Custom Leather Branding Stamp Play in Furniture and Home Decor?

In the furniture and home decor industry, custom leather branding stamps are employed to emboss leather upholstery, adding a layer of uniqueness to each piece. This customization elevates the perceived value of the furniture, making it more attractive to consumers. Buyers should focus on sourcing stamps that are compatible with various leather types and can withstand the rigors of heat and pressure during the stamping process, ensuring a lasting impression.

How is Custom Leather Branding Stamp Utilized in the Automotive Sector?

The automotive industry uses custom leather branding stamps to mark leather interiors in vehicles, reinforcing brand recognition and offering a luxurious touch to the customer experience. For B2B buyers, especially in regions like Saudi Arabia, it’s vital to ensure that the stamps can accommodate complex designs and logos while being durable enough to endure varying temperatures and conditions within the vehicle environment.

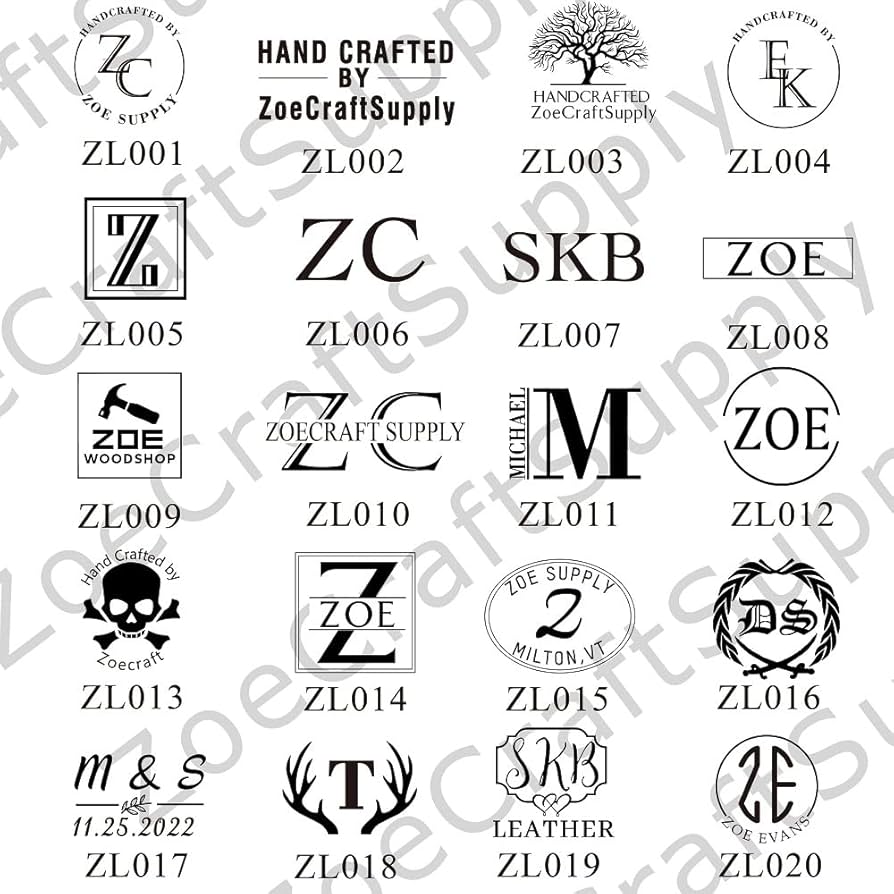

Illustrative image related to custom leather branding stamp

What Benefits Does Custom Leather Branding Stamp Provide for Craft and Hobby?

In the craft and hobby sector, custom leather branding stamps are essential for personalizing items like journals, wallets, and other handmade leather goods. This personalization fosters customer engagement and satisfaction, as buyers appreciate unique, customized products. When sourcing these stamps, international buyers should look for suppliers that offer flexibility in design submission and have a quick turnaround time, allowing for efficient production cycles.

How is Custom Leather Branding Stamp Important in Sports Equipment Manufacturing?

Custom leather branding stamps play a significant role in marking leather sports gear, such as gloves and balls, enhancing product authenticity and brand loyalty. For businesses, especially in regions with a strong sports culture, the ability to customize and brand their equipment can be a differentiator in a competitive market. Buyers should prioritize sourcing stamps that are suitable for various sports conditions and materials to ensure that the branding remains intact under stress and wear.

3 Common User Pain Points for ‘custom leather branding stamp’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality Across Batches

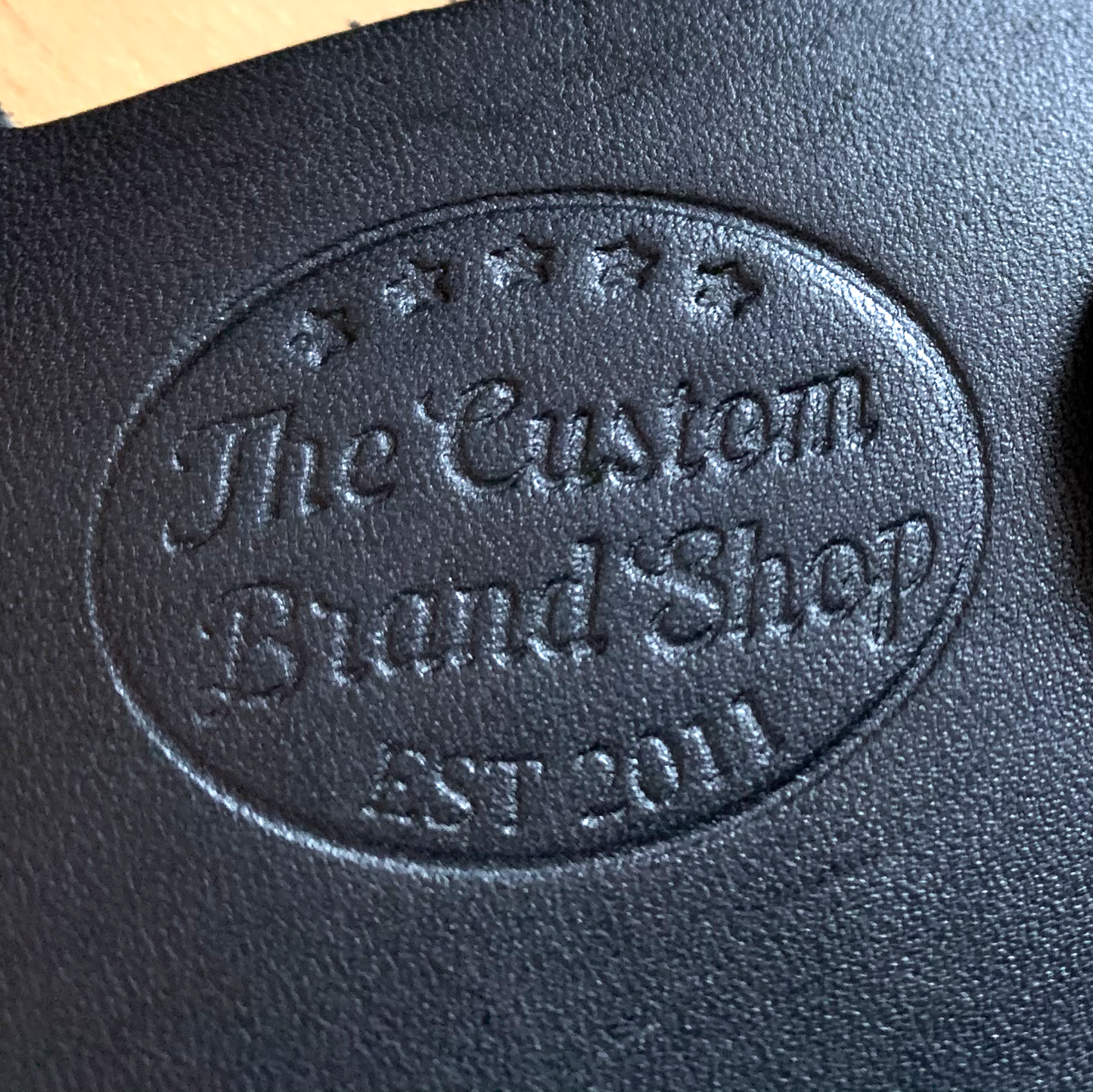

The Problem: Many B2B buyers struggle with the inconsistency of branding quality when using custom leather branding stamps. Variations can arise from differences in pressure applied during stamping, the type of leather used, or even the conditions under which the stamping is performed. This inconsistency can lead to customer dissatisfaction, increased returns, and a tarnished brand reputation, especially when large orders are involved.

The Solution: To achieve consistent quality, buyers should invest in high-quality custom leather branding stamps made from durable materials like brass or steel, which provide better results over time compared to aluminum. When placing an order, it’s crucial to provide detailed specifications regarding the design, including size and depth of engraving. Additionally, standardizing the stamping process—such as using a dedicated leather press with uniform pressure settings—can significantly enhance consistency. Training staff on proper stamping techniques and conducting quality checks on sample pieces can also help maintain the desired quality across all products.

Illustrative image related to custom leather branding stamp

Scenario 2: Miscommunication and Design Approval Delays

The Problem: Miscommunication regarding design specifications can lead to delays in production and increased costs. Buyers often experience frustration when the final product does not match their initial vision, which can result in time-consuming revisions and additional costs for re-manufacturing stamps. This is particularly problematic in fast-paced industries where timely delivery is critical.

The Solution: To mitigate these issues, buyers should engage in thorough communication with their suppliers from the outset. Providing clear and comprehensive design files, preferably in vector formats like AI or PDF, can help ensure that the supplier accurately understands the intended design. Additionally, requesting a mock-up or prototype before final production can save time and money. Suppliers that offer unlimited revisions to the mock-up can help buyers refine their designs until they are completely satisfied. Establishing a clear timeline for design approval can also streamline the process and keep projects on track.

Scenario 3: Limited Knowledge of Material Compatibility

The Problem: Many buyers are uncertain about which materials are best suited for their specific leather types and branding methods. This lack of knowledge can lead to choosing the wrong stamp, resulting in poor impressions or damage to the leather. For example, using a branding iron on delicate chrome-tanned leather can scorch the material, while inadequate pressure during stamping can result in incomplete designs.

The Solution: Buyers should educate themselves on the various materials and techniques available for leather stamping. Engaging with suppliers who provide comprehensive guidance on material compatibility can be invaluable. When selecting a custom leather branding stamp, consider the type of leather being used (e.g., vegetable-tanned vs. chrome-tanned) and the intended stamping method (e.g., heat embossing vs. cold stamping). Suppliers often have experience working with a range of leather types and can recommend the best options based on the specific project. Additionally, conducting small test runs on sample pieces before full production can help identify the most effective methods and prevent costly mistakes.

Strategic Material Selection Guide for custom leather branding stamp

What Are the Key Materials for Custom Leather Branding Stamps?

When selecting materials for custom leather branding stamps, it is crucial to consider properties that directly affect performance, durability, and application compatibility. The most common materials used in the production of these stamps include brass, steel, aluminum, and high-density resin. Each material has unique characteristics that can influence the choice based on specific project requirements.

Illustrative image related to custom leather branding stamp

How Does Brass Perform as a Material for Leather Branding Stamps?

Brass is a popular choice for custom leather branding stamps due to its excellent thermal conductivity and resistance to corrosion. It can withstand high temperatures and pressures, making it suitable for both wet and dry stamping applications. The durability of brass ensures that it can produce high-quality impressions over extended use, which is essential for businesses that require consistent branding.

Pros: Brass stamps are robust and can last for years with proper care. They provide clear, detailed impressions and are particularly effective for heat stamping.

Cons: The initial cost of brass can be higher than aluminum, and it may require more maintenance to prevent tarnishing.

For international buyers, especially in regions like Europe and the Middle East, brass is compliant with various standards, including ASTM and DIN, making it a reliable choice for quality assurance.

What Advantages Does Steel Offer for Leather Branding Stamps?

Steel is another durable option for leather branding stamps, known for its strength and longevity. It can withstand high pressure and is less prone to deformation compared to softer metals. Steel stamps are often used in industrial applications where high-volume production is necessary.

Pros: Steel stamps can handle rigorous use and provide sharp, clear impressions, making them ideal for detailed designs.

Cons: They are typically heavier and more expensive than aluminum options and may require specialized equipment for use.

International buyers should consider that steel stamps may need to meet specific compliance standards, especially in regions with stringent manufacturing regulations.

How Does Aluminum Compare for Custom Leather Branding Stamps?

Aluminum is often chosen for its lightweight nature and cost-effectiveness. While it is less durable than brass or steel, it is suitable for lower-volume applications or projects requiring less intricate designs.

Pros: The lower cost of aluminum makes it an attractive option for startups or smaller businesses. It is also easier to machine, allowing for quick turnaround times.

Cons: Aluminum stamps may wear out faster than their brass or steel counterparts and are less effective for heat stamping applications.

For buyers in Africa and South America, aluminum can be a practical choice, especially for businesses looking to minimize initial investment while still achieving quality branding.

Illustrative image related to custom leather branding stamp

What Role Does High-Density Resin Play in Leather Branding Stamps?

High-density resin is a newer material option for custom leather branding stamps, primarily used for specific applications where cost is a significant factor. It is less durable than metal options but can be effective for short-term projects.

Pros: Resin stamps are lightweight and cost-effective, making them suitable for one-off projects or low-volume applications.

Cons: They have a limited lifespan and cannot withstand high temperatures, making them unsuitable for heat stamping.

International buyers should be cautious with resin stamps, as they may not meet the durability expectations for high-quality branding, particularly in competitive markets like Europe.

Illustrative image related to custom leather branding stamp

Summary Table of Material Options for Custom Leather Branding Stamps

| Material | Typical Use Case for custom leather branding stamp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-volume, detailed leather branding | Excellent thermal conductivity and durability | Higher initial cost and maintenance | High |

| Steel | Industrial applications requiring strength | Strong and long-lasting | Heavier and more expensive | High |

| Aluminum | Lower-volume or budget-conscious projects | Cost-effective and lightweight | Less durable and wears out faster | Low |

| High-Density Resin | Short-term or low-volume branding | Lightweight and inexpensive | Limited lifespan and temperature sensitivity | Low |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their branding needs and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather branding stamp

What Are the Main Stages in the Manufacturing Process of Custom Leather Branding Stamps?

The production of custom leather branding stamps involves several critical stages, each essential to ensuring the final product meets the specifications of B2B buyers. Understanding these stages can help you evaluate potential suppliers more effectively.

Material Preparation: What Materials Are Used for Leather Stamps?

The choice of material significantly influences the durability and performance of leather branding stamps. Common materials include:

- Brass: Highly favored for its strength, thermal conductivity, and resistance to rust, making it ideal for both wet and heat stamping applications. Brass stamps can endure extensive use and maintain their precision over time.

- Steel: Often used for its durability, steel stamps are suitable for heavy-duty applications. However, they may rust if not properly maintained.

- Aluminum: Typically used for lower-cost options, aluminum stamps are lightweight and suitable for less demanding applications. However, they may not last as long as brass or steel.

Before manufacturing begins, the selected material is cut into appropriate sizes and shapes according to the design specifications provided by the client.

How Is the Forming Process Executed for Custom Leather Branding Stamps?

The forming process is pivotal in creating the unique designs required for leather branding. This process often involves:

- CNC Machining: Computer Numerical Control (CNC) machining is a key technique used to achieve high precision in engraving designs onto the stamp material. This method allows for intricate designs to be replicated consistently.

- Hand Finishing: After the CNC process, skilled artisans often perform hand finishing to ensure that every detail is refined and free of imperfections. This attention to detail is crucial for maintaining quality standards.

The forming stage culminates with a thorough inspection of the stamped design to ensure it matches the client’s specifications.

What Assembly Techniques Are Used in Creating Leather Branding Stamps?

In many cases, the assembly of leather branding stamps is straightforward. For instance, stamps may require handles for ease of use. There are various handle options available, including:

- Removable Steel Handles: These provide the necessary leverage for manual stamping and can be easily attached or removed.

- Electric Branding Irons: For higher volume applications, electric branding irons with temperature control offer an efficient means of applying heat and pressure.

During assembly, quality checks are performed to ensure that all components fit correctly and function as intended.

How Is the Finishing Process Conducted for Leather Branding Stamps?

The finishing process encompasses several steps designed to enhance the durability and aesthetic appeal of the stamp:

- Polishing: This step is critical for removing any rough edges and ensuring a smooth surface, which is essential for achieving clean impressions on leather.

- Surface Treatment: Some manufacturers apply coatings to enhance resistance to corrosion and wear, particularly for steel stamps.

After finishing, each stamp undergoes a final inspection to confirm that it meets quality and design standards.

What Are the Key Quality Assurance Practices in Leather Stamp Manufacturing?

Quality assurance (QA) is vital in the manufacturing of custom leather branding stamps, particularly for international B2B transactions where standards may vary. Key practices include:

What International Standards Should B2B Buyers Look For?

- ISO 9001: This is a globally recognized standard for quality management systems. Manufacturers adhering to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

- CE Marking: This indicates compliance with European safety standards, which can be particularly important for buyers in Europe and the Middle East.

Buyers should ensure that their suppliers can provide documentation demonstrating compliance with these standards.

What Are the Main Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical in ensuring that each stage of production meets established standards:

Illustrative image related to custom leather branding stamp

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects before they enter the manufacturing process.

- In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to identify any deviations from quality standards. This may include checking engraving depth, alignment, and design accuracy.

- Final Quality Control (FQC): After production, each stamp undergoes a comprehensive inspection. This includes testing for durability, precision of the imprint, and overall aesthetic quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of potential suppliers is essential for B2B buyers, especially when sourcing internationally. Here are actionable strategies:

What Should Buyers Request from Suppliers?

- Quality Assurance Documentation: Request copies of quality certifications, including ISO 9001 and any other relevant compliance documents.

- Quality Control Reports: Ask for reports detailing the quality control measures implemented during the manufacturing process.

- Third-Party Inspections: Consider engaging third-party inspection services to conduct an independent review of the manufacturing process and final products.

How Can Buyers Conduct Supplier Audits?

Conducting a supplier audit can provide deep insights into the manufacturing and quality assurance processes. Buyers should:

- Schedule On-Site Visits: If feasible, visiting the manufacturing facility can help assess the production environment and quality measures firsthand.

- Evaluate Production Capabilities: During the visit, inquire about machinery, workforce training, and the overall production workflow.

What Quality Control Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

- Cultural Differences: Understanding local business practices and communication styles can enhance negotiations and foster better supplier relationships.

- Logistics and Shipping: Ensure clarity on shipping terms and international regulations, as these can impact delivery timelines and costs.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices associated with custom leather branding stamps is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and rigorous quality control measures, buyers can ensure they partner with reliable suppliers who meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather branding stamp’

Introduction

Navigating the procurement of custom leather branding stamps can be a complex process, particularly for B2B buyers seeking high-quality products that meet specific needs. This guide provides a practical, step-by-step checklist to streamline your sourcing process, ensuring you find the right supplier and product tailored to your requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical to ensuring the final product meets your branding needs. Consider factors such as the size of the stamp, the material (e.g., brass, aluminum, or resin), and the engraving depth.

– Size Considerations: Determine the maximum dimensions you require for your design.

– Material Choice: Brass is typically favored for its durability and thermal conductivity, making it suitable for both wet and heat stamping.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather branding stamps. Look for vendors with a strong track record and positive reviews from past customers.

– Supplier Profiles: Check their websites for testimonials, case studies, and examples of previous work.

– Industry Experience: Consider suppliers that have experience working with businesses in your sector or region.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the capabilities of potential suppliers to ensure they can meet your specific needs. Inquire about their manufacturing processes and the technology they use.

– Customization Options: Ensure they can accommodate unique designs and provide mock-ups prior to production.

– Lead Times: Ask about production and shipping times, especially if you have urgent requirements.

Step 4: Verify Quality Assurance Processes

Quality assurance is vital in ensuring you receive a product that meets your expectations. Ask suppliers about their quality control measures and certifications.

– Material Testing: Confirm that they conduct tests on the materials used for durability and performance.

– Engraving Precision: Inquire about the precision of their engraving techniques to ensure high-quality results.

Illustrative image related to custom leather branding stamp

Step 5: Request Samples

Before placing a bulk order, request samples of the custom leather branding stamps. This step allows you to evaluate the quality and effectiveness of the stamp firsthand.

– Testing for Compatibility: Use the samples on the type of leather you intend to brand to assess the results.

– Feedback Loop: Provide feedback to the supplier based on your testing, ensuring they can make any necessary adjustments.

Step 6: Discuss Pricing and Terms

Engage in a detailed discussion about pricing, including any additional costs associated with custom designs, shipping, and rush orders.

– Transparent Quotations: Ensure that the supplier provides a clear breakdown of costs to avoid hidden fees.

– Payment Terms: Clarify payment methods and terms, including any deposits required before production.

Step 7: Establish Communication Protocols

Effective communication is essential throughout the sourcing process. Set clear expectations regarding how you will communicate with the supplier.

– Point of Contact: Designate a specific contact person for all inquiries and updates.

– Regular Updates: Agree on a schedule for progress updates to ensure you remain informed about your order status.

By following this checklist, B2B buyers can ensure a smooth sourcing process for custom leather branding stamps, ultimately leading to successful branding outcomes.

Comprehensive Cost and Pricing Analysis for custom leather branding stamp Sourcing

What Are the Key Cost Components in Custom Leather Branding Stamps?

When sourcing custom leather branding stamps, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

Illustrative image related to custom leather branding stamp

-

Materials: The choice of material significantly influences cost. Common materials include solid brass, aluminum, and high-density resin. Brass is favored for its durability and resistance to rust, making it suitable for long-term use, while aluminum offers a more budget-friendly option.

-

Labor: Skilled labor is required to engrave the designs accurately, which can vary in cost depending on the complexity of the design and the expertise of the engraver. Custom designs require more labor-intensive processes, impacting overall costs.

-

Manufacturing Overhead: This includes costs associated with equipment maintenance, utilities, and other operational expenses. Companies with advanced CNC machinery may have lower overhead costs due to efficiency.

-

Tooling: Initial tooling costs for creating custom stamps can be substantial. This includes the expenses related to designing and producing the molds or dies necessary for the stamping process.

-

Quality Control (QC): Ensuring that each stamp meets quality standards involves additional costs, including testing and inspection. A rigorous QC process can enhance product reliability, which is crucial for maintaining customer satisfaction.

-

Logistics: Shipping costs can vary based on the destination and shipping method. International shipping, particularly to regions like Africa or South America, may incur additional customs duties and tariffs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on the supplier’s position in the market and their operational efficiencies.

What Factors Influence Pricing for Custom Leather Branding Stamps?

Several factors can influence the pricing of custom leather branding stamps:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often have tiered pricing structures. Larger orders can reduce the per-unit cost, making it essential for buyers to assess their long-term needs versus immediate requirements.

-

Specifications and Customization: Custom designs, especially intricate logos or unique shapes, can lead to higher costs. The more detailed the design, the more time and resources are required to produce the stamp.

-

Material Quality and Certifications: The choice of high-quality materials and certifications for environmental standards can affect the overall price. Buyers in Europe, for example, may prioritize suppliers who adhere to specific quality certifications.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. Established suppliers with a track record of quality may charge more but can offer reliability and faster turnaround times.

-

Incoterms: Understanding the shipping terms (Incoterms) is crucial for international buyers. Costs can vary significantly based on who is responsible for shipping, insurance, and customs clearance.

What Tips Can Help Buyers Negotiate Better Prices?

-

Negotiate Based on Volume: If planning for larger orders, leverage this to negotiate better pricing. Suppliers may be willing to provide discounts for bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the longevity, maintenance, and potential resale value of the branding stamps. A higher upfront cost may lead to lower long-term expenses.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide insight into market pricing and help identify competitive offers.

-

Clarify Customization Costs Upfront: Ensure clarity on any additional costs associated with custom designs or specific material requests to avoid surprises during the ordering process.

-

Be Aware of International Pricing Nuances: Understand the economic conditions and currency fluctuations in your region. Price sensitivity may vary significantly between markets like Europe and Africa.

Conclusion

Navigating the cost and pricing landscape for custom leather branding stamps requires a comprehensive understanding of various components and influencing factors. By considering these elements, B2B buyers can make informed decisions that align with their branding needs while maximizing cost-efficiency. It is advisable to approach the market with a clear strategy, ensuring that all aspects from material choice to supplier negotiation are thoroughly evaluated. Always keep in mind that indicative prices may vary, and it’s essential to confirm current pricing with suppliers before finalizing any orders.

Alternatives Analysis: Comparing custom leather branding stamp With Other Solutions

Introduction to Alternative Solutions for Leather Branding

When it comes to branding leather goods, businesses often seek various methods to achieve their desired aesthetic and durability. The custom leather branding stamp is a popular choice, but there are alternative solutions that may better suit specific needs. In this analysis, we will compare the custom leather branding stamp with two viable alternatives: heat branding and laser engraving. Each method has its unique advantages and considerations, making it essential for B2B buyers to understand their options.

Comparison Table

| Comparison Aspect | Custom Leather Branding Stamp | Heat Branding | Laser Engraving |

|---|---|---|---|

| Performance | High detail and durability | Excellent for deep branding | Precision and versatility |

| Cost | Moderate ($68-$79) | Moderate to high (varies) | High (equipment and service) |

| Ease of Implementation | Simple setup, manual effort | Requires equipment setup | Needs specialized machinery |

| Maintenance | Low, minimal care required | Moderate, depends on usage | High, regular maintenance needed |

| Best Use Case | Small to medium projects | Thicker leather, high volume | Intricate designs, varied materials |

Detailed Breakdown of Alternatives

Heat Branding

Heat branding utilizes a heated metal stamp to imprint designs onto leather. This method is particularly effective for creating deep, long-lasting marks that can withstand wear. The heat penetrates the leather, resulting in a durable finish. However, the initial setup can be more complex than using a traditional stamp. The cost may vary depending on the equipment required, but it typically falls within a moderate to high range. Heat branding is best suited for businesses that frequently work with thicker leather and require high-volume production.

Pros:

– Produces highly durable impressions

– Ideal for thicker leather types

– Can be used for high-volume production

Illustrative image related to custom leather branding stamp

Cons:

– Requires more setup time and equipment

– Potentially higher initial costs

– Limited to leather types that can withstand high heat

Laser Engraving

Laser engraving is a cutting-edge method that uses a focused beam of light to etch designs onto leather surfaces. This technique offers unparalleled precision and allows for intricate designs that would be challenging with traditional methods. However, the cost of laser engraving equipment can be significant, making it a more considerable investment for businesses. Additionally, ongoing maintenance of the machinery can add to operational costs. Laser engraving is ideal for companies looking to produce highly detailed designs or work with various materials beyond leather.

Pros:

– Allows for intricate, detailed designs

– Versatile for different materials

– Consistent results with minimal manual effort

Cons:

– High initial investment for equipment

– Requires technical expertise to operate

– Regular maintenance can be costly

Conclusion: Choosing the Right Solution for Your Leather Branding Needs

Selecting the right branding method for leather goods depends on various factors, including the type of leather, desired detail level, production volume, and budget. The custom leather branding stamp offers a balance of affordability and ease of use, making it suitable for small to medium projects. In contrast, heat branding excels in durability and is well-suited for thicker leathers, while laser engraving provides the highest precision for intricate designs but at a higher cost. B2B buyers should carefully evaluate their specific requirements and long-term goals to choose the most effective solution for their leather branding needs.

Illustrative image related to custom leather branding stamp

Essential Technical Properties and Trade Terminology for custom leather branding stamp

What Are the Key Technical Properties of Custom Leather Branding Stamps?

When selecting a custom leather branding stamp, understanding the technical properties is crucial for ensuring optimal performance and durability in various applications. Here are several key specifications to consider:

-

Material Grade

The material used for the stamp significantly impacts its longevity and effectiveness. Common materials include brass, aluminum, and steel. Brass is favored for its resistance to rust and excellent thermal conductivity, making it ideal for heat stamping and wet applications. In contrast, aluminum is more cost-effective but less durable, while steel offers strength but may rust if not properly cared for. -

Engraving Depth

The depth of the engraving affects the clarity and permanence of the imprint. Typically, a depth of 3mm is standard for quality stamps, allowing for clear impressions that can withstand wear over time. This specification is essential for businesses focused on branding consistency and product quality. -

Stamp Thickness

The thickness of the stamp, often around 8mm, determines the stability and durability during use. Thicker stamps provide better resistance to bending and breaking, ensuring that the branding process remains consistent even under high pressure. -

Size Tolerance

Precision in size is critical. Stamps are often available in various sizes, typically measured in square centimeters. A common offering might be up to 10 cm². Understanding size tolerance ensures that the branding fits perfectly on the intended leather goods, preventing any misalignment or errors in the branding process. -

Customization Options

The ability to customize stamps, including design complexity and shape, is vital for businesses looking to create unique branding elements. Many manufacturers offer mock-ups and design assistance, ensuring that the final product meets the specific branding vision of the buyer.

What Are Common Trade Terms in the Custom Leather Branding Stamp Industry?

Familiarizing oneself with industry jargon can enhance communication and negotiation with suppliers. Here are several common terms used in the custom leather branding stamp market:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leather branding, it might refer to businesses that create custom stamps for other brands, often under private labels. -

MOQ (Minimum Order Quantity)

This is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management. Suppliers often set MOQs to ensure that production costs are covered and profitability is maintained. -

RFQ (Request for Quotation)

A formal request sent to suppliers to obtain pricing information for specific products or services. An RFQ is crucial for B2B buyers to compare costs and services among different manufacturers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, insurance, and risk management in cross-border transactions. -

Debossing vs. Embossing

These terms describe the two primary methods of imprinting designs onto leather. Debossing creates a recessed design, while embossing raises the design above the leather surface. Knowing the difference helps buyers choose the right method for their branding needs. -

Heat Stamping

This refers to the process of applying a heated stamp to leather, creating a permanent mark. This technique is particularly useful for achieving high-quality results on various leather types, making it a preferred choice for many businesses.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when procuring custom leather branding stamps, ultimately enhancing their branding strategies and product offerings.

Illustrative image related to custom leather branding stamp

Navigating Market Dynamics and Sourcing Trends in the custom leather branding stamp Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Branding Stamp Sector?

The global market for custom leather branding stamps is experiencing significant growth, driven by a surge in demand from various sectors including fashion, furniture, and accessories. As businesses increasingly seek unique branding solutions to differentiate their products, the customization of leather goods has become a pivotal strategy. Notably, markets in Africa, South America, the Middle East, and Europe are displaying robust growth potential. For instance, regions like Saudi Arabia and Germany are witnessing a rise in artisanal leather production, which necessitates high-quality branding tools.

Emerging technologies such as CNC engraving and 3D printing are transforming the manufacturing landscape, allowing for precision and speed in producing custom designs. This technological advancement not only enhances product quality but also reduces lead times, with some suppliers offering turnaround times as short as two to three days. International B2B buyers are increasingly leveraging online platforms to source these tools, allowing for greater accessibility to global suppliers and competitive pricing.

Another key trend is the integration of digital solutions in the procurement process. Buyers are utilizing online quote systems and mock-up approvals to streamline their ordering experience. This shift towards digital procurement is particularly beneficial for businesses looking to scale operations efficiently while ensuring that their branding needs are met with high precision.

How Is Sustainability and Ethical Sourcing Addressed in the Custom Leather Branding Stamp Sector?

Sustainability and ethical sourcing are becoming paramount considerations for international B2B buyers in the custom leather branding stamp sector. The environmental impact of leather production, including deforestation and water pollution, has led to a growing demand for sustainable practices. Buyers are increasingly prioritizing suppliers that utilize vegetable-tanned leather and other eco-friendly materials, which have a lower environmental footprint compared to traditional chrome-tanned leather.

Furthermore, the importance of ethical supply chains cannot be overstated. Businesses are seeking suppliers who can demonstrate transparency in their sourcing practices, ensuring that materials are obtained from responsible sources. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential credentials for suppliers aiming to build trust with environmentally conscious buyers.

Illustrative image related to custom leather branding stamp

Incorporating ‘green’ certifications into the sourcing process not only helps brands align with consumer expectations but also positions them favorably in a competitive market. By choosing ethically produced materials and sustainable manufacturing processes, businesses can enhance their brand image while contributing positively to the environment.

What Is the Brief Evolution and History of Custom Leather Branding Stamps?

The history of custom leather branding stamps dates back centuries, with early forms used by artisans to signify ownership and craftsmanship. Originally crafted from rudimentary materials, these stamps have evolved significantly over time. The introduction of metalworking techniques allowed for more durable and intricate designs, enhancing the quality of branding on leather goods.

In the late 20th century, advancements in technology revolutionized the manufacturing of branding stamps. The shift from manual engraving to CNC machining enabled greater precision and customization, catering to the increasing demand for personalized branding solutions. Today, custom leather branding stamps are not only a tool for marking but also a vital component of brand identity for businesses worldwide, reflecting the craftsmanship and uniqueness of leather goods.

This evolution highlights the importance of innovation in the custom leather branding stamp sector, making it essential for international B2B buyers to stay informed about the latest trends and technologies to remain competitive in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather branding stamp

-

How do I ensure the quality of a custom leather branding stamp?

To guarantee quality, work with reputable suppliers that provide detailed specifications and examples of their previous work. Request samples or mock-ups before production, ensuring that they meet your design requirements. Inquire about materials used—brass is preferred for durability and thermal conductivity. Additionally, verify their quality assurance processes, including how they handle defects or issues post-production. Engaging with suppliers who have a strong track record in the leather industry can also help ensure that you receive a high-quality product. -

What factors should I consider when choosing a custom leather branding stamp?

When selecting a custom leather branding stamp, consider the material (brass, aluminum, or steel), the size of the design, and the type of leather you will be working with. Ensure the stamp’s engraving depth and thickness meet your specific needs for clarity and longevity. Also, evaluate the customization options available, such as the ability to upload your design or request modifications. Finally, consider the supplier’s production time and shipping capabilities, particularly for international orders, to align with your project timelines. -

What are the typical lead times for custom leather branding stamps?

Lead times can vary significantly based on the supplier, complexity of the design, and order volume. Generally, expect a turnaround time of 2-6 business days for standard orders after design approval. For rush orders, some suppliers offer expedited services at an additional cost. Always confirm production and shipping timelines with the supplier to ensure they align with your project deadlines, particularly if you’re sourcing internationally. -

What is the minimum order quantity (MOQ) for custom leather branding stamps?

Minimum order quantities can differ between suppliers. Some may offer single stamp orders, while others may require a minimum of 5-10 pieces to ensure cost-effectiveness. Always clarify the MOQ upfront to avoid potential issues during the ordering process. If your needs are lower than the MOQ, discuss the possibility of ordering a sample or inquire about potential bulk discounts for future orders. -

How can I customize my design for a leather branding stamp?

Most suppliers allow you to customize your design by providing a logo, image, or sketch. It’s best to submit high-resolution vector files (AI or PDF) for optimal results. If you have a complex design, suppliers typically offer assistance in refining your artwork. Always request a mock-up before production to ensure that the design meets your expectations. Communication is key; don’t hesitate to ask for adjustments until you are satisfied with the final design. -

What payment terms are typically offered for international orders?

Payment terms for international orders can vary widely among suppliers. Common options include upfront payment, partial deposits, or net terms (e.g., net 30 days). Always confirm accepted payment methods—credit cards, bank transfers, or online payment platforms like PayPal. Additionally, check if there are any currency conversion fees or international transaction charges that may apply. Establishing clear payment terms can help avoid misunderstandings and ensure smooth transactions. -

What should I know about shipping and logistics for international orders?

When sourcing internationally, inquire about the shipping options available, including express and standard delivery. Confirm the estimated shipping times, costs, and whether the supplier provides tracking services. Understand customs duties and taxes applicable in your country, as these can impact the total cost and delivery timeline. It’s beneficial to work with suppliers who have experience with international shipping to navigate potential logistical challenges effectively. -

How can I assess the reliability of a supplier for custom leather branding stamps?

To evaluate a supplier’s reliability, research their reputation through reviews, testimonials, and case studies. Look for suppliers with a strong history in the leather industry and a portfolio showcasing their work. Request references from past clients, especially those in your region, to gain insights into their experiences. Additionally, assess their communication responsiveness and willingness to address your concerns, as these factors can indicate their commitment to customer satisfaction and product quality.

Top 8 Custom Leather Branding Stamp Manufacturers & Suppliers List

1. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Custom Leather Stamp”, “description”: “Custom Leather Stamp for leather embossing & leather stamping.”, “regular_price”: “US$68.00”, “size_options”: [“Up to 1.25 x 1.25 inch / 3 x 3 cm”, “Up to 1.5 x 1.5 inch / 4 x 4 cm”, “Up to 2 x 2 inch / 5 x 5 cm”, “Up to 3 x 3 inch / 7.5 x 7.5 cm”, “Up to 4 x 4 inch / 10 x 10 cm”], “lead_time”: “2-5 working days”, “material”: “Solid Brass”, …

2. Custom Leather Stamps – Premium Quality Brands

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Custom leather stamps, dies, and brands for leather stamping and embossing needs. Made from aluminum, steel, or brass. Aluminum offers a lower price point; brass is popular for durability and rust resistance. Customization options include original designs from artwork, signatures, or sketches. High detail engraving with deep background clearance. Leather hand stamps come with a heavy-duty removabl…

3. Custom Brand – Leather Embossing Stamp

4. Tandy Leather – Custom Stamp

5. Infinity Stamps – Leather Crafting Tools

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Leather Stamps – Handheld and Plate Stamps for leather crafting. Includes Pin Marking Device, Roll Dies, Maker Stamps, Hot Stamps, Steel Type Stamps & Holders.

6. Steel Stamps Inc – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Introduction: Custom leather stamps for personalized branding and designs. Available in various sizes and styles to suit different leather projects. Ideal for artisans, crafters, and businesses looking to create unique leather goods. High-quality materials ensure durability and precision in stamping. Easy to use with a variety of leather types.

7. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets available. Custom stamps are CNC milled from solid brass, thickness up to 1″. Compatible with branding irons and standard presses. Custom leather cutting dies made from solid steel, usable with mechanical, hydraulic, or clicker presses. Offe…

8. Custom Leather Stamps – Quality Options at Great Prices

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather stamps, good price point, quality stamp, options include: Leatherstampstools on Etsy, Springfield Leather (custom stamps from PDF designs), leatherstampmaker (free quotes and proof, quick delivery), TyraCraftTools on Etsy (custom design communication, $55 for a 2.5 cm x 5 cm stamp).

Strategic Sourcing Conclusion and Outlook for custom leather branding stamp

In the competitive landscape of custom leather branding stamps, strategic sourcing emerges as a crucial factor for international B2B buyers. Selecting suppliers who offer high-quality materials, such as brass or steel, ensures durability and optimal performance across various leather types. Additionally, understanding the production timelines, with many suppliers providing rapid turnaround times of 2-6 business days, can significantly enhance your operational efficiency.

Moreover, leveraging the expertise of manufacturers who assist in design and customization enables buyers to create unique branding solutions that resonate with their target markets. Whether you are in Africa, South America, the Middle East, or Europe, forging partnerships with reliable suppliers can elevate your brand’s visibility and authenticity in the leather goods sector.

As you explore sourcing options, consider the long-term implications of your investments in custom leather branding stamps. By prioritizing quality, efficiency, and supplier collaboration, you position your business for sustained growth and success. Take the next step in enhancing your brand identity and reach out to potential partners today to discuss your specific needs and embark on a journey toward impactful branding solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.