Introduction: Navigating the Global Market for custom leather straps

In today’s competitive landscape, sourcing high-quality custom leather straps poses a significant challenge for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the quest for durable, stylish, and tailored leather solutions can be daunting. This guide aims to demystify the global market for custom leather straps, providing insights into various types, applications, and materials that can elevate your product offerings. From luxury watch bands to specialized straps for bags and equipment, understanding the nuances of custom leather can lead to better purchasing decisions.

As you navigate this intricate market, we will also delve into key considerations such as supplier vetting, pricing structures, and the latest trends that influence buyer behavior. By equipping you with actionable information, this guide empowers you to make informed decisions that align with your business needs and customer expectations. You will learn how to evaluate suppliers based on quality, craftsmanship, and service, ensuring that your investments yield the best returns.

Whether you are looking to enhance your product line or seeking reliable partners for your leather goods, our comprehensive overview will provide the necessary tools to succeed in the global arena. With a focus on quality and customization, you can confidently elevate your brand while meeting the diverse demands of your clientele across continents.

Table Of Contents

- Top 6 Custom Leather Straps Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather straps

- Understanding custom leather straps Types and Variations

- Key Industrial Applications of custom leather straps

- 3 Common User Pain Points for ‘custom leather straps’ & Their Solutions

- Strategic Material Selection Guide for custom leather straps

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather straps

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather straps’

- Comprehensive Cost and Pricing Analysis for custom leather straps Sourcing

- Alternatives Analysis: Comparing custom leather straps With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather straps

- Navigating Market Dynamics and Sourcing Trends in the custom leather straps Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather straps

- Strategic Sourcing Conclusion and Outlook for custom leather straps

- Important Disclaimer & Terms of Use

Understanding custom leather straps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Straps | Made from traditional leather like cowhide or calfskin. | Luxury watch brands, fashion accessories. | Pros: Timeless appeal, durability. Cons: Requires regular maintenance to prevent wear. |

| Exotic Leather Straps | Crafted from unique materials such as alligator or ostrich. | High-end watch markets, luxury fashion. | Pros: Distinctive look, premium quality. Cons: Higher cost, limited availability. |

| Rubber Straps | Made from synthetic rubber, offering flexibility and comfort. | Sports watches, casual wear. | Pros: Water-resistant, easy to clean. Cons: Less formal appearance, may lack durability compared to leather. |

| Velcro Straps | Lightweight and adjustable, often made from durable fabric. | Sports and casual watches, youth markets. | Pros: Easy to use, versatile fit. Cons: Less luxurious feel, may not suit formal occasions. |

| Customizable Straps | Allow for personalized designs, colors, and materials. | Niche luxury markets, promotional items. | Pros: Unique branding opportunities, tailored fit. Cons: Longer lead times, potential for higher costs. |

What Are the Characteristics of Classic Leather Straps?

Classic leather straps are the cornerstone of traditional watch accessories, crafted from high-quality materials such as cowhide or calfskin. Their timeless design and versatility make them suitable for both formal and casual watches, appealing to a wide range of buyers. B2B purchasers should consider the brand reputation and leather sourcing, as these factors significantly influence the strap’s durability and aesthetic appeal. Regular maintenance is necessary to keep these straps looking their best, which can be a consideration for businesses aiming for long-term customer satisfaction.

Why Choose Exotic Leather Straps for Luxury Markets?

Exotic leather straps, made from materials like alligator or ostrich, represent the pinnacle of luxury in the watch strap market. These unique materials not only provide a distinctive look but also enhance the perceived value of the timepiece. B2B buyers targeting high-end markets should focus on the authenticity and sourcing of these exotic leathers, as quality can vary significantly. While the investment is higher, the appeal of exclusivity and premium craftsmanship often justifies the cost, making them an attractive option for luxury retailers.

How Do Rubber Straps Fit Into the B2B Landscape?

Rubber straps have gained popularity in the B2B market due to their practicality and comfort. Ideal for sports watches and casual wear, these straps are water-resistant and easy to clean, making them suitable for active lifestyles. Businesses should consider the quality of the rubber used, as this can affect the strap’s durability and comfort. While they may lack the formality of leather straps, their versatility and ease of use can appeal to a broad customer base, particularly in markets focused on outdoor activities and casual fashion.

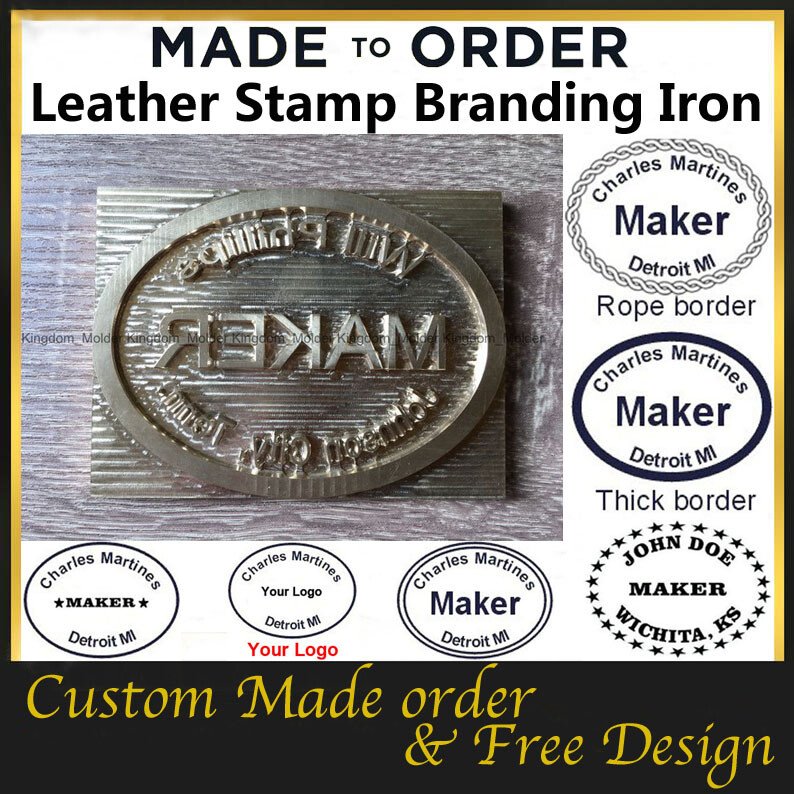

Illustrative image related to custom leather straps

What Makes Velcro Straps a Viable Option?

Velcro straps are characterized by their lightweight, adjustable design, making them a practical choice for sports and casual watches. Their ease of use and ability to fit various wrist sizes make them particularly appealing to younger consumers and active individuals. B2B buyers should evaluate the durability of the fabric used in Velcro straps, as quality can vary. While they may not convey the luxury associated with leather, their versatility and functionality make them a valuable addition to a diverse product lineup.

Why Invest in Customizable Straps for Unique Branding?

Customizable straps offer an exciting opportunity for B2B buyers looking to differentiate their offerings. These straps can be tailored in terms of design, color, and material, allowing brands to create unique products that resonate with their target audience. However, businesses should be prepared for longer lead times and potentially higher costs associated with customization. The ability to provide personalized products can enhance customer loyalty and create memorable brand experiences, making them a worthwhile investment for businesses aiming to stand out in a competitive market.

Key Industrial Applications of custom leather straps

| Industry/Sector | Specific Application of custom leather straps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Watch Manufacturing | Custom watch straps for luxury timepieces | Enhances product differentiation and brand prestige | Quality of leather, customization options, lead times |

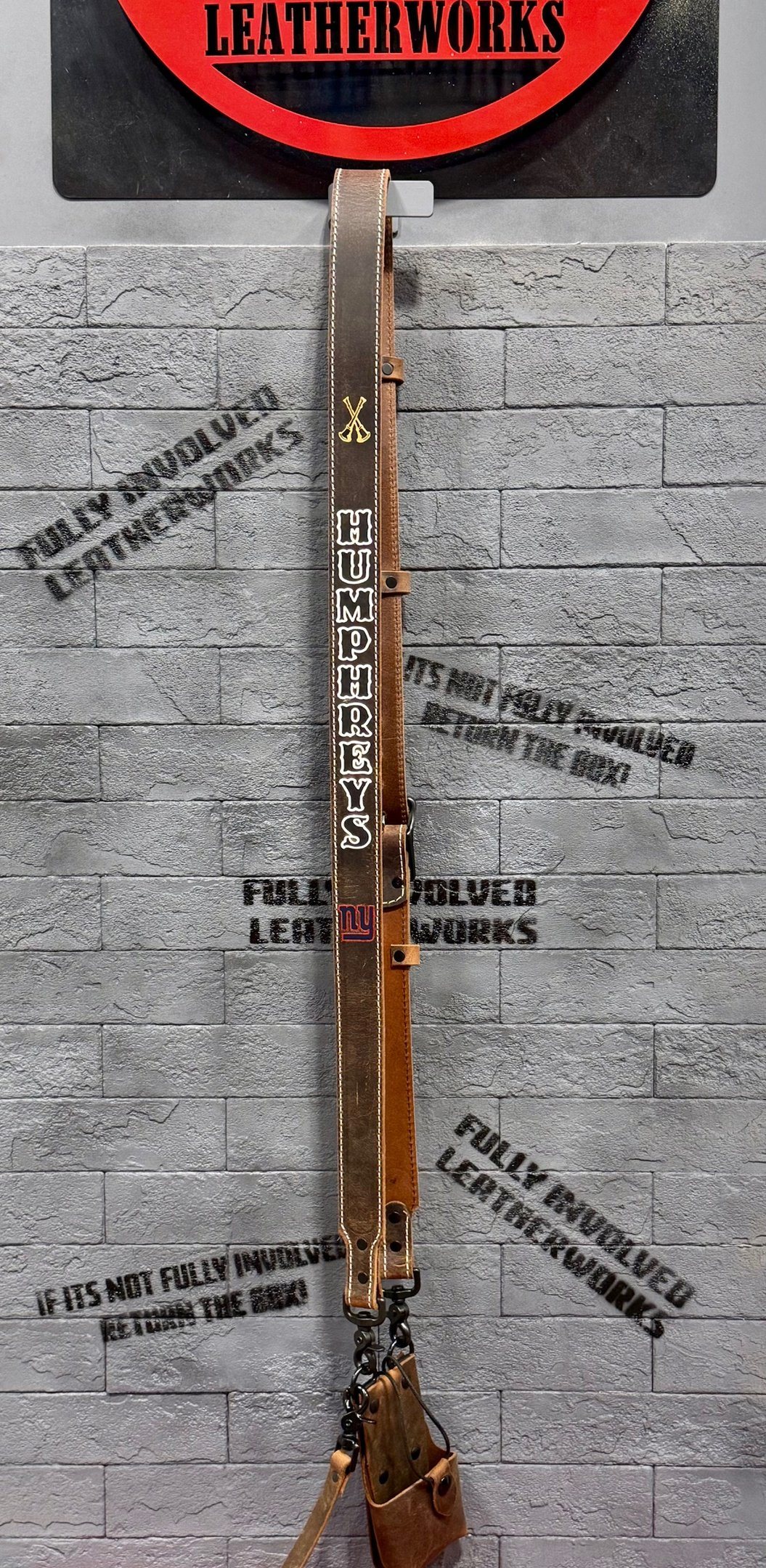

| Fashion and Accessories | Custom belts and bag straps | Aligns with current fashion trends and customer personalization | Material variety, durability, and design flexibility |

| Automotive | Custom leather straps for seat belts and interiors | Adds luxury and comfort, enhancing customer experience | Safety compliance, material certification, and design specs |

| Sports Equipment | Custom straps for sports watches and gear | Increases functionality and user engagement | Waterproof options, breathability, and ergonomic designs |

| Industrial Equipment | Custom straps for tools and machinery | Improves usability and safety in industrial environments | Strength and durability, resistance to wear and tear |

How Are Custom Leather Straps Used in Watch Manufacturing?

In the watch manufacturing sector, custom leather straps are essential for luxury timepieces. These straps not only provide comfort and style but also act as a significant differentiator in a crowded market. Buyers from regions like Europe and the Middle East seek high-quality leather that complements their brand’s aesthetics while ensuring durability. Customization options such as color, texture, and stitching allow for a tailored approach, meeting the unique demands of various watch models.

Illustrative image related to custom leather straps

What Role Do Custom Leather Straps Play in Fashion and Accessories?

The fashion and accessories industry frequently utilizes custom leather straps for belts and bags. These straps are designed to align with current trends, offering personalized solutions that appeal to consumers’ tastes. B2B buyers in South America and Africa often look for materials that not only meet aesthetic criteria but also promise longevity. Sourcing considerations include a wide variety of leather types, ensuring that products can withstand daily use while maintaining their visual appeal.

How Are Custom Leather Straps Integrated into Automotive Designs?

In the automotive sector, custom leather straps are increasingly used in seat belts and interior accents. They add a touch of luxury and enhance the overall driving experience. International buyers, particularly from Europe, emphasize safety compliance and durability, requiring straps that can withstand wear and tear while maintaining a high-end look. Sourcing considerations include certifications for material quality and adherence to safety standards, ensuring that the final product meets regulatory requirements.

Why Are Custom Leather Straps Important in Sports Equipment?

Custom leather straps are vital in the sports equipment industry, particularly for sports watches and gear. They enhance functionality by providing secure fits that improve user engagement during activities. Buyers from regions like Africa and South America are often focused on features such as waterproofing and breathability, which are crucial for active lifestyles. When sourcing, businesses need to consider ergonomic designs that cater to the specific demands of sports enthusiasts.

Illustrative image related to custom leather straps

How Are Custom Leather Straps Used in Industrial Equipment?

In the industrial sector, custom leather straps are used for tools and machinery, improving usability and safety. These straps are designed to withstand harsh conditions, making them invaluable in various industrial applications. B2B buyers must prioritize strength and durability when sourcing, ensuring that the straps can endure significant wear and tear while maintaining functionality. Additionally, resistance to elements such as oil and chemicals is often a critical requirement for industrial applications.

3 Common User Pain Points for ‘custom leather straps’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Materials for Custom Leather Straps

The Problem: B2B buyers often face challenges when it comes to sourcing high-quality materials for custom leather straps. This is particularly true for those in regions where access to premium leather is limited or where local suppliers may not meet international quality standards. Buyers can become frustrated when the materials do not match their specifications, leading to inconsistent product quality that can tarnish their brand reputation.

The Solution: To overcome this challenge, B2B buyers should establish relationships with reputable suppliers who specialize in high-quality leather. Conducting thorough research and due diligence is crucial. Look for suppliers with a proven track record and positive reviews from other businesses. When placing orders, specify the type of leather, grain, and finish you require, and request samples before committing to larger orders. Additionally, consider sourcing from suppliers that offer detailed product descriptions and images, so you can ensure the materials align with your brand’s standards. Establishing a clear communication channel for ongoing support and feedback can also help mitigate issues related to material quality.

Illustrative image related to custom leather straps

Scenario 2: Managing Customization Requests and Timelines

The Problem: Another significant pain point for B2B buyers is managing the customization process and the associated timelines. Buyers often require specific designs, colors, and sizes for their leather straps, which can lead to longer production times. Delays can result in lost sales opportunities, particularly if the straps are intended for a product launch or seasonal campaign.

The Solution: To effectively manage customization requests, buyers should work closely with manufacturers who have a flexible and efficient production process. Set clear expectations regarding timelines at the outset and inquire about the production lead times for custom orders. Use project management tools to track the progress of your order and maintain regular communication with the supplier to address any potential delays promptly. It’s also beneficial to have a buffer in your scheduling—ordering samples well in advance can help mitigate last-minute issues. By creating a detailed specification sheet that outlines every aspect of the strap design, you can reduce the likelihood of miscommunication and ensure a smoother customization process.

Scenario 3: Ensuring Consistency in Product Quality and Design

The Problem: B2B buyers frequently encounter challenges in maintaining consistency in product quality and design across multiple orders. When dealing with custom leather straps, even slight variations in craftsmanship can lead to significant discrepancies in the final product. This inconsistency can undermine brand credibility and lead to customer dissatisfaction.

The Solution: To ensure consistency, buyers should establish a robust quality assurance (QA) process with their suppliers. This involves setting clear quality standards and conducting regular inspections of sample products prior to full-scale production. Implementing a standardized production checklist can help maintain consistency in craftsmanship, color, and design elements. Additionally, consider using a third-party quality control service that specializes in leather goods to assess products before they are shipped. Regularly reviewing and providing feedback on the samples received can help suppliers understand your expectations better and align their production accordingly. Building a strong partnership with your supplier, characterized by transparency and collaboration, can foster an environment that prioritizes quality consistency in every order.

Strategic Material Selection Guide for custom leather straps

What Are the Key Materials Used in Custom Leather Straps?

When selecting materials for custom leather straps, several options stand out due to their unique properties and suitability for various applications. Below, we explore four common materials: calfskin, alligator leather, rubber, and synthetic leather, analyzing their performance, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to custom leather straps

How Does Calfskin Perform as a Material for Custom Leather Straps?

Calfskin is a popular choice for custom leather straps due to its soft texture and durability. It typically offers good temperature resistance and can withstand moderate pressure, making it suitable for everyday wear. Calfskin is also relatively easy to dye and finish, allowing for a variety of aesthetic options.

Pros: Calfskin is known for its luxurious feel and visual appeal, making it a favorite for high-end watch straps. It is also less expensive than exotic leathers, which can be a significant advantage for B2B buyers looking to balance quality and cost.

Cons: While calfskin is durable, it is not as resistant to scratches and moisture as some other materials. Care must be taken to maintain its appearance, which may increase long-term maintenance costs.

Illustrative image related to custom leather straps

Impact on Application: Calfskin is ideal for luxury watches and everyday use, but it may not be suitable for environments with high moisture or extreme temperatures.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that calfskin complies with local regulations regarding leather sourcing and processing. Familiarity with standards such as ASTM or DIN can aid in making informed decisions.

What Advantages Does Alligator Leather Offer for Custom Straps?

Alligator leather is revered for its unique texture and unparalleled durability. It boasts excellent resistance to wear and tear, making it suitable for high-end applications. The material can handle a range of temperatures and pressures, ensuring longevity.

Illustrative image related to custom leather straps

Pros: The aesthetic appeal of alligator leather is unmatched, providing a luxurious touch to any watch strap. Its durability means that it can withstand daily use without significant wear, making it a worthwhile investment.

Cons: Alligator leather is significantly more expensive than calfskin and requires more complex manufacturing processes. This can lead to longer lead times and higher costs for B2B buyers.

Impact on Application: Alligator leather is best suited for luxury watches and formal occasions. It may not be the best choice for rugged or outdoor use due to its sensitivity to moisture.

Illustrative image related to custom leather straps

Considerations for International Buyers: Buyers should be aware of ethical sourcing practices and compliance with CITES regulations, especially in regions like Europe where environmental sustainability is increasingly prioritized.

How Does Rubber Compare as a Material for Custom Leather Straps?

Rubber is a versatile alternative to traditional leather materials, offering excellent resistance to moisture and temperature extremes. It is particularly suited for sports and casual watches, where durability and comfort are paramount.

Pros: Rubber straps are lightweight, easy to clean, and highly durable. They are also less expensive than leather options, making them an attractive choice for budget-conscious buyers.

Cons: While rubber is practical, it lacks the luxury appeal of leather materials, which may be a disadvantage for high-end applications. Additionally, rubber can degrade over time when exposed to UV light.

Impact on Application: Rubber is ideal for outdoor and sports watches, but it may not be suitable for formal occasions or luxury brands.

Illustrative image related to custom leather straps

Considerations for International Buyers: Buyers should check for compliance with international standards for rubber materials, especially in markets like the Middle East where climate conditions can affect product performance.

What Role Does Synthetic Leather Play in Custom Leather Strap Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers an alternative to traditional leather. It is designed to mimic the appearance of leather while providing enhanced durability and moisture resistance.

Pros: Synthetic leather is generally less expensive than genuine leather and offers a wide range of colors and textures. It is also easier to maintain, making it a practical choice for mass production.

Cons: The primary drawback is that synthetic leather may not provide the same luxurious feel or longevity as genuine leather. It can also be less breathable, which may affect comfort.

Illustrative image related to custom leather straps

Impact on Application: Synthetic leather is suitable for fashion-forward designs and casual wear but may not be appropriate for high-end luxury watches.

Considerations for International Buyers: Buyers should ensure that synthetic leather products meet relevant safety and environmental standards, particularly in European markets where regulations are strict.

Summary Table of Material Selection for Custom Leather Straps

| Material | Typical Use Case for custom leather straps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Calfskin | Luxury and everyday watch straps | Soft texture and aesthetic appeal | Less resistant to moisture and scratches | Medium |

| Alligator Leather | High-end luxury watch straps | Exceptional durability and luxury look | High cost and complex manufacturing | High |

| Rubber | Sports and casual watch straps | Lightweight and moisture-resistant | Lacks luxury appeal and UV degradation | Low |

| Synthetic Leather | Fashion and casual watch straps | Cost-effective and easy maintenance | Less luxurious feel and comfort | Low |

This guide provides B2B buyers with a comprehensive overview of material options for custom leather straps, enabling informed decisions based on performance, cost, and market preferences.

Illustrative image related to custom leather straps

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather straps

What Are the Key Stages in the Manufacturing Process of Custom Leather Straps?

The manufacturing of custom leather straps involves several critical stages, each essential for producing a high-quality product. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the right leather type, which could include full-grain, top-grain, or exotic leathers like alligator or ostrich. The leather is then conditioned and dyed to achieve the desired color and texture. This stage is crucial as the quality of the leather directly influences the final product’s durability and aesthetics.

-

Forming: Once the leather is prepared, it is cut into specific shapes according to the strap design. Advanced cutting techniques, such as laser cutting, may be employed to ensure precision. This stage often involves the use of templates or computer-aided design (CAD) software to guarantee that the dimensions match the specifications provided by the client.

-

Assembly: After cutting, the pieces are stitched together. High-quality stitching techniques, such as saddle stitching, are preferred for their durability and aesthetic appeal. The assembly process may also include adding hardware components, like buckles or clasps, which must be compatible with the design and intended use of the strap.

-

Finishing: The final stage involves treating the leather to enhance its appearance and longevity. This may include edge finishing, polishing, and applying protective coatings. Quality finishings ensure that the strap is not only visually appealing but also resistant to wear and environmental factors.

How Is Quality Assurance Integrated into Custom Leather Strap Production?

Quality assurance (QA) is integral to the manufacturing of custom leather straps, ensuring that products meet both international standards and client expectations.

-

International Standards Compliance: Manufacturers often adhere to standards such as ISO 9001, which outlines quality management systems. Compliance with such standards demonstrates a commitment to quality and consistency, which is crucial for B2B buyers seeking reliable suppliers.

-

Industry-Specific Certifications: In addition to ISO, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, especially when materials or processes intersect with regulated industries. These certifications assure buyers that the products meet specific safety and quality benchmarks.

-

Quality Control Checkpoints: Quality control is structured around several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): At this stage, raw materials, including leather and hardware, are inspected for quality and compliance with specifications.

– In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process and identify any defects early.

– Final Quality Control (FQC): Once the straps are completed, a final inspection is performed to assess overall quality, functionality, and aesthetics.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure that custom leather straps meet the required standards. These methods can include:

- Visual Inspections: Checking for surface defects, color consistency, and overall craftsmanship.

- Durability Testing: Assessing the strap’s ability to withstand wear and tear through tensile strength tests and abrasion resistance tests.

- Water Resistance Testing: Evaluating how well the leather holds up against moisture, which is particularly important for straps intended for outdoor or high-humidity environments.

- Colorfastness Testing: Ensuring that the dye used in the leather does not bleed or fade when exposed to light or water.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are several actionable strategies:

Illustrative image related to custom leather straps

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality assurance practices. This direct assessment allows buyers to evaluate the supplier’s capabilities and adherence to standards.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports that outline their quality control measures, testing results, and compliance with relevant standards. This documentation is essential for building trust and ensuring accountability.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices. These services can conduct inspections at various production stages and provide comprehensive reports on quality compliance.

What Are the QC/CERT Nuances for International Buyers from Diverse Regions?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital. Here are key considerations:

-

Regional Standards Variability: Different regions may have varying standards and regulations regarding leather goods. Buyers must familiarize themselves with the specific requirements applicable in their target markets to ensure compliance.

-

Logistical Challenges: Shipping and customs regulations can impact the delivery of quality materials and finished products. Buyers should work with suppliers who have experience navigating these complexities to avoid delays and compliance issues.

-

Cultural Expectations: Quality perceptions can vary significantly across cultures. Understanding the expectations of the target market will help suppliers tailor their products and quality assurance practices accordingly.

Conclusion

The manufacturing processes and quality assurance measures for custom leather straps are critical components that B2B buyers should thoroughly understand. By familiarizing themselves with the manufacturing stages, quality control processes, testing methods, and nuances specific to their regions, buyers can make informed decisions when selecting suppliers. Ultimately, a robust understanding of these elements will help ensure that the custom leather straps they procure meet their quality standards and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather straps’

To facilitate the procurement of custom leather straps, this guide provides a structured checklist that B2B buyers can follow to ensure they make informed and effective sourcing decisions. Whether you’re looking to enhance your product offerings or establish partnerships with reliable suppliers, these steps will guide you through the process.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of a successful procurement process. This includes the dimensions, materials, colors, and design features you need. Specificity helps suppliers understand your expectations and prevents miscommunication later in the process.

Illustrative image related to custom leather straps

- Consider factors like strap width, thickness, and desired leather type (e.g., calfskin, alligator).

- Think about any unique features such as stitching color or buckle style that can differentiate your product.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to find suppliers that specialize in custom leather straps. Look for manufacturers with a strong reputation in the industry, particularly those with international experience relevant to your market.

- Utilize platforms like trade directories, industry forums, and social media to gather a list of potential suppliers.

- Pay attention to reviews and testimonials from other businesses to gauge reliability and quality.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist of suppliers, assess their production capabilities. This involves understanding their manufacturing processes, lead times, and minimum order quantities.

- Request samples of their work to evaluate craftsmanship and material quality.

- Inquire about their ability to handle custom designs and modifications, as flexibility can be a crucial factor in your sourcing decision.

Step 4: Verify Certifications and Compliance

Ensuring that suppliers comply with relevant industry standards and certifications is essential for maintaining product quality and safety. This step can prevent potential legal issues and enhance your brand’s credibility.

Illustrative image related to custom leather straps

- Look for certifications such as ISO 9001 for quality management and any environmental compliance standards.

- Confirm that the supplier adheres to ethical sourcing practices, especially if you are sourcing from regions with strict labor laws.

Step 5: Request Quotes and Compare Pricing

Engage with your shortlisted suppliers to obtain detailed quotes. This should include pricing, shipping costs, and any additional fees associated with custom orders.

- Ensure that quotes are itemized for clarity, highlighting differences in pricing based on material choices or design complexity.

- Compare not just the costs but also the value offered, such as warranty terms or after-sales support.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a preferred supplier, negotiate the terms of your agreement. This includes payment terms, delivery schedules, and any provisions for quality assurance.

- Be clear about your expectations regarding timelines and penalties for delays.

- Establish a mutually beneficial payment structure that aligns with your business cash flow.

Step 7: Establish a Communication Plan

Effective communication is critical throughout the sourcing process. Establish a clear communication plan that details how often and through what channels you will interact with your supplier.

- Set regular updates on production status and shipping timelines to avoid surprises.

- Use collaborative tools or platforms to streamline communication and documentation sharing.

By following these steps, B2B buyers can confidently navigate the sourcing of custom leather straps, ensuring they partner with suppliers who meet their specific needs while also maintaining quality and efficiency.

Comprehensive Cost and Pricing Analysis for custom leather straps Sourcing

What Are the Key Cost Components for Custom Leather Straps?

When sourcing custom leather straps, understanding the cost structure is essential for B2B buyers to make informed decisions. The primary cost components include:

-

Materials: The type of leather significantly influences cost. Premium materials such as alligator or exotic leathers command higher prices than standard cowhide. Additionally, the treatment and finishing processes can add to material costs.

-

Labor: Skilled craftsmanship is vital in the production of custom leather straps. Labor costs vary by region, with countries known for leather craftsmanship, such as Italy and France, typically having higher labor rates.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, rent, and administrative expenses. Higher overhead can lead to increased pricing, especially in regions with elevated operational costs.

-

Tooling: Custom designs may require specialized tools or molds, which can add to the initial setup costs. Buyers should inquire about any tooling fees, particularly for unique or complex designs.

-

Quality Control (QC): Ensuring that each strap meets quality standards incurs additional costs. Rigorous QC processes can prevent defects but may add to the overall price.

-

Logistics: Shipping costs, which can vary widely depending on the destination and shipping method, are a significant factor. International buyers should consider potential tariffs and duties as part of their logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Custom Leather Strap Costs?

Several factors can influence the pricing of custom leather straps:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often come with discounts. Buyers should negotiate MOQ to optimize their costs while ensuring their needs are met.

-

Specifications and Customization: More complex designs or unique specifications generally lead to higher prices. Clearly defining requirements upfront can help avoid unexpected costs.

-

Material Quality and Certifications: Straps made from certified sustainable or ethically sourced materials may carry premium pricing. Buyers should assess the value these certifications provide against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their brand value and perceived quality.

-

Incoterms: Understanding the terms of shipment is crucial. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can affect overall costs and responsibilities in the shipping process.

What Tips Can Help B2B Buyers Negotiate Custom Leather Strap Prices?

To secure the best pricing for custom leather straps, buyers should consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing based on volume commitments and potential long-term partnerships. Emphasizing a willingness to place repeat orders can incentivize better pricing.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price to consider maintenance, durability, and potential resale value. A higher upfront cost may be justified by a longer lifespan or superior quality.

-

Understand Pricing Nuances for International Orders: When sourcing from regions like Africa, South America, or the Middle East, buyers should be aware of exchange rate fluctuations, potential import taxes, and local economic conditions that might affect pricing.

-

Request Sample Products: Before committing to larger orders, request samples to assess quality. This can help in evaluating whether the higher costs are justified by the product’s craftsmanship and materials.

Conclusion

Sourcing custom leather straps involves a nuanced understanding of cost components and pricing influencers. By leveraging negotiation strategies and considering the Total Cost of Ownership, B2B buyers can make informed purchasing decisions that align with their business objectives. Always remain vigilant about potential market changes and supplier dynamics to optimize costs effectively.

Disclaimer: Prices and costs mentioned in this analysis are indicative and may vary based on supplier, region, and market conditions.

Illustrative image related to custom leather straps

Alternatives Analysis: Comparing custom leather straps With Other Solutions

Understanding Alternatives to Custom Leather Straps in the B2B Market

In the competitive landscape of watch accessories, custom leather straps represent a premium solution known for their quality and personalization. However, B2B buyers should consider various alternatives that may better suit their specific requirements, including performance, cost, and maintenance. This analysis compares custom leather straps with synthetic straps and metal bracelets, providing a comprehensive view to inform purchasing decisions.

| Comparison Aspect | Custom Leather Straps | Synthetic Straps | Metal Bracelets |

|---|---|---|---|

| Performance | High durability and comfort; customizable fit enhances user experience | Good durability; less comfortable than leather; limited customization | Extremely durable; often heavier; can be less comfortable |

| Cost | Moderate to high price range; reflects quality and craftsmanship | Generally lower cost; budget-friendly options available | Can vary widely; high-end metal can be expensive |

| Ease of Implementation | Requires specific fitting; longer lead time for customization | Easy to source and install; readily available | Installation can be complex; may require tools for adjustments |

| Maintenance | Requires regular care to maintain appearance; prone to wear over time | Low maintenance; resistant to fading and wear | Minimal maintenance; highly resistant to damage |

| Best Use Case | Ideal for luxury and high-end watches; personalized branding opportunities | Suitable for casual and sporty watches; great for promotional uses | Best for robust and outdoor watches; offers a classic aesthetic |

What Are the Benefits and Drawbacks of Synthetic Straps?

Synthetic straps, often made from materials like nylon or silicone, present a cost-effective alternative to custom leather options. They are lightweight, water-resistant, and often available in vibrant colors and patterns, making them appealing for casual wear. Their affordability and ease of sourcing make them an attractive choice for businesses aiming to meet bulk orders or promotional needs. However, synthetic materials may lack the luxury appeal and comfort associated with leather, making them less suitable for high-end watches.

How Do Metal Bracelets Compare to Custom Leather Straps?

Metal bracelets, crafted from stainless steel or titanium, offer a high level of durability and a timeless aesthetic. They are perfect for buyers seeking a robust option for outdoor activities or environments where wear and tear is a concern. Additionally, metal bracelets can provide a premium feel that complements luxury watches. However, they can be heavier and less comfortable than leather options, especially during extended wear. The complexity of fitting and adjusting metal bracelets may also deter some buyers who prefer the simplicity of leather.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a strap solution, B2B buyers should consider their target market and the intended use of the watches. Custom leather straps are ideal for luxury segments, where personalization and quality are paramount. On the other hand, synthetic straps are perfect for more casual markets or bulk promotional items, while metal bracelets cater to those requiring durability and classic style. Understanding these alternatives allows businesses to align their product offerings with customer expectations, ensuring satisfaction and repeat sales.

Essential Technical Properties and Trade Terminology for custom leather straps

What Are the Key Technical Properties of Custom Leather Straps?

When sourcing custom leather straps, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

Illustrative image related to custom leather straps

-

Material Grade

The quality of leather used is paramount. Common grades include full-grain, top-grain, and genuine leather. Full-grain leather, which retains the original grain and imperfections, is the highest quality and most durable. For B2B buyers, selecting the right material grade affects the product’s longevity and overall aesthetic appeal. -

Thickness

Measured in millimeters, the thickness of the leather strap can influence its comfort and durability. Typically, thicker straps provide greater longevity but may sacrifice flexibility. Buyers should consider their target market’s preferences—whether they prioritize durability or comfort—when assessing thickness. -

Tolerance Levels

Tolerance refers to the acceptable range of variation in dimensions such as width, length, and hole placement. High tolerance levels ensure that straps fit perfectly on various watch models, reducing returns and dissatisfaction. For B2B buyers, understanding tolerance levels is critical for maintaining product quality and customer satisfaction. -

Finish Type

The finish applied to leather can significantly affect its appearance and performance. Common finishes include matte, glossy, and embossed. Each finish offers different aesthetic qualities and durability levels. B2B purchasers should align the finish type with their brand’s identity and the expectations of their end customers. -

Stitching Quality

Stitching not only contributes to the strap’s visual appeal but also to its structural integrity. The type of thread used, stitch density, and pattern can all impact durability and style. Buyers should evaluate stitching quality as it can influence customer perceptions of craftsmanship and value. -

Flexibility and Break-in Period

Custom leather straps often require a break-in period for optimal comfort. Flexibility varies based on leather type and thickness. B2B buyers need to communicate these characteristics to customers, as they can influence purchasing decisions and overall satisfaction.

What Are Common Trade Terminology and Jargon in the Custom Leather Strap Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end product. In the context of custom leather straps, buyers may work with OEMs to ensure their designs are produced to specific standards and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. Understanding MOQs is critical for buyers to assess their purchasing power and plan inventory accordingly. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It allows buyers to compare costs and terms from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and mitigate risks in international transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the final product. Understanding lead times is essential for inventory management and aligning production schedules with market demand. -

Customization Options

This term encompasses the various ways a product can be tailored to meet specific customer needs, including material choice, color, stitching, and branding. Offering extensive customization options can be a significant competitive advantage in attracting and retaining customers.

By grasping these technical properties and trade terms, B2B buyers can navigate the custom leather strap market more effectively, ensuring they make choices that align with their business objectives and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the custom leather straps Sector

What Are the Key Market Dynamics and Trends Influencing the Custom Leather Straps Sector?

The global custom leather straps market is experiencing significant growth, driven by rising consumer demand for personalized accessories and luxury goods. B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, customizable options that reflect personal style and brand identity. This trend is fueled by the expansion of e-commerce platforms and advancements in digital technologies, which allow for tailored shopping experiences and efficient order fulfillment. Notably, buyers are leveraging online configurators and customization tools, enabling them to select materials, colors, and designs that cater to specific market niches and customer preferences.

Illustrative image related to custom leather straps

Emerging trends include a growing inclination towards exotic leather materials and innovative designs, which can enhance product differentiation in a competitive marketplace. The demand for sustainability is also shaping sourcing strategies, with buyers increasingly favoring suppliers who prioritize ethical practices and environmentally friendly materials. Additionally, the integration of advanced manufacturing techniques, such as laser cutting and 3D printing, is revolutionizing production efficiency and enabling faster turnaround times for custom orders. As these market dynamics evolve, B2B buyers must remain agile to capitalize on new opportunities while ensuring their offerings align with consumer expectations.

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Straps Market?

Sustainability and ethical sourcing are becoming paramount in the custom leather straps sector, reflecting a broader shift towards responsible consumerism. The environmental impact of traditional leather production processes has led to heightened scrutiny from both consumers and regulatory bodies. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of vegetable-tanned leather, which reduces harmful chemical usage, and sourcing from farms that adhere to ethical animal husbandry standards.

Moreover, the demand for ‘green’ certifications, such as the Leather Working Group (LWG) certification, is rising among international buyers. These certifications not only validate the sustainability of leather production but also enhance brand reputation in a market that increasingly values transparency. By choosing suppliers who utilize eco-friendly materials and adhere to ethical sourcing guidelines, B2B buyers can strengthen their brand’s sustainability narrative, attract environmentally conscious consumers, and gain a competitive edge in the marketplace.

Illustrative image related to custom leather straps

How Has the Custom Leather Straps Market Evolved Over Time?

The evolution of the custom leather straps market is marked by a transition from traditional craftsmanship to modern, technology-driven customization. Initially, leather straps were predominantly mass-produced, offering limited options for personalization. However, as consumer preferences shifted towards unique and personalized products, manufacturers began to adopt more flexible production methods.

The introduction of digital technologies has further transformed the landscape, enabling buyers to engage with suppliers through online platforms that facilitate customization and direct communication. This shift has opened new avenues for creativity and innovation, allowing businesses to cater to diverse markets and preferences. As the industry continues to evolve, the emphasis on quality, craftsmanship, and sustainability will remain central to meeting the demands of discerning B2B buyers globally.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather straps

-

How do I choose the right supplier for custom leather straps?

When selecting a supplier for custom leather straps, assess their experience and reputation in the industry. Look for suppliers with a proven track record of quality craftsmanship and customer satisfaction. Request samples to evaluate the materials and workmanship. Additionally, ensure they have a transparent supply chain and good communication practices to facilitate smooth transactions. Consider suppliers who offer customization options and are willing to accommodate specific requirements, such as materials and design features. -

What is the minimum order quantity (MOQ) for custom leather straps?

Minimum order quantities (MOQs) for custom leather straps can vary significantly between suppliers. Typically, MOQs range from 50 to 200 pieces, depending on the complexity of the design and materials used. It’s essential to discuss MOQs upfront with potential suppliers to align your purchasing plans with their production capabilities. Some suppliers may offer flexibility for larger orders or repeat customers, so it’s beneficial to negotiate based on your needs. -

What customization options are available for leather straps?

Customization options for leather straps can include material selection (e.g., calfskin, alligator), color choices, stitching styles, and buckle types. Many suppliers also offer personalized engravings or embossing for branding purposes. When approaching suppliers, provide detailed specifications of your desired customization to ensure they can meet your expectations. Some suppliers may offer online configurators to help visualize your design choices before placing an order. -

How can I ensure the quality of custom leather straps?

To ensure the quality of custom leather straps, request samples from potential suppliers before placing a bulk order. Check for craftsmanship, material quality, and durability. Look for suppliers that offer warranties or guarantees on their products, indicating confidence in their craftsmanship. Additionally, consider their quality assurance processes, such as inspections and testing, to ensure that every strap meets your standards before shipment. -

What payment terms should I expect when ordering custom leather straps?

Payment terms for custom leather strap orders can vary based on the supplier and your relationship with them. Common practices include a deposit upon order placement (often 30-50%) with the balance due before shipment. Some suppliers may offer credit terms for established customers. Always clarify payment options, including methods (bank transfer, credit card, etc.) and any potential discounts for early payment. Ensure that all terms are documented to avoid misunderstandings. -

What are the shipping options for international orders of custom leather straps?

Shipping options for international orders of custom leather straps typically include express courier services (like DHL or FedEx) and standard shipping methods. The choice of shipping method will affect delivery time and cost, so consider your urgency and budget when selecting. Verify with the supplier about their shipping capabilities, including tracking options and customs handling. It’s also wise to inquire about any additional fees or taxes that may apply upon arrival in your country. -

How do I handle customs duties and taxes for international shipments?

When importing custom leather straps, customs duties and taxes will vary based on your country’s regulations and the value of the goods. It’s essential to research the import laws in your region to understand potential costs. Many suppliers provide necessary documentation to facilitate customs clearance, but it’s your responsibility to ensure compliance. Consider working with a customs broker if you’re unfamiliar with the process, as they can help navigate complex regulations and ensure timely delivery. -

What are the best practices for maintaining custom leather straps?

To maintain custom leather straps, regular cleaning and conditioning are crucial. Use a soft, damp cloth to wipe away dirt and moisture, and apply a leather conditioner periodically to keep the material supple. Avoid exposing straps to extreme temperatures or direct sunlight, as this can cause fading or cracking. Storing straps in a cool, dry place and using proper storage solutions can also extend their lifespan, ensuring they remain in excellent condition for years to come.

Top 6 Custom Leather Straps Manufacturers & Suppliers List

1. Delugs – Custom Watch Straps

Domain: delugs.com

Registered: 2018 (7 years)

Introduction: Custom Watch Strap by Delugs

– Price: Starting at USD 150.00

– Free Shipping: Available for first order with code FREE-FIRST-SHIPPING (minimum spend of US$100)

– Materials Available: Alcantara, Alligator/Crocodile, Babele, Baranil, Buttero, Chevre, Crazy Horse, Epsom, Lizard, Nubuck, Ostrich (Body and Leg), Pueblo, Rubberised Leather (Smooth and Togo), Saffiano, Sailcloth, Salmon, Shell Cordovan, …

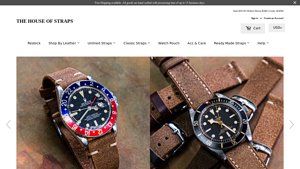

2. The House Of Straps – Hand-Made Leather Watch Straps

Domain: thehouseofstraps.com

Registered: 2018 (7 years)

Introduction: The House Of Straps offers a variety of hand-made leather watch straps made from different types of leather including Horween Shell Cordovan, Horween Leather, Wickett & Craig Bridle Leather, Italian Leather, Chevre Leather, and Suede. Key features include:

– Horween Shell Cordovan: Extremely resilient, non-creasing, rich color, subtle luster.

– Horween Chromexcel Leather: Rich pull-up effect, comf…

3. Jack Foster – Custom Leather Watch Straps

Domain: jack-foster.com

Registered: 2013 (12 years)

Introduction: Custom Leather Watch Straps from Jack Foster in Greenville, SC. Available products include: 73 different watch straps, such as Aviator Bund Straps and Classic Watch Straps, made from premium materials like Horween Dublin Leather, Horween Chromexcel Leather, American Shrunken Bison, and Crazy Horse Leather. Prices range from $58.00 to $155.00. Customization options include standard, short, or long-…

4. Veblenist – Custom Watch Straps

Domain: veblenist.com

Registered: 2013 (12 years)

Introduction: Custom watch straps available in leather and canvas, including luxury bespoke handmade bands. Categories include: two-piece leather, canvas, alligator, cordovan, calfskin, suede, rubber, and NATO straps (leather, cordovan, suede, nylon). Designed for various watch types including Panerai and Apple Watch. Products include new arrivals, bestsellers, and limited runs. Prices range from $15 for nylon …

5. Vintager Straps – Custom Leather Watch Straps

Domain: vintagerstraps.com

Registered: 2006 (19 years)

Introduction: Vintager Straps by Micah offers custom leather watch straps for all brands. Key product details include: 1. Handcrafted in Napa Valley, USA. 2. Turnaround time: 3 to 4 weeks. 3. Free worldwide shipping. 4. Categories include Fine Leather (64 products), Gator (8 products), Horween Straps (15 products), Rolled Canvas (7 products), Leather Backed Canvas (4 products), and Shark (8 products). 5. Exampl…

6. FinWatchStraps – Exotic & Premium Leather Watch Straps

Domain: finwatchstraps.com

Registered: 2017 (8 years)

Introduction: Free shipping on orders over €250 with DHL and UPS (applies on EU, USA and Canada shipping destinations). Product categories include: Alligator watch straps (Artisan, Prestige Collection, Luxe Edition, Exquisite Collection), Premium Bison Leather Watch Straps, Exotic leather watch straps (Camel, Shark, Stingray, Lizard, Ostrich, Python, African kudu, Kangaroo), Ammo Vintage watch straps (1930-1980…

Strategic Sourcing Conclusion and Outlook for custom leather straps

In the ever-evolving landscape of custom leather straps, strategic sourcing remains a critical element for international B2B buyers. By understanding the diverse offerings from manufacturers around the globe, businesses can leverage quality, craftsmanship, and unique materials to differentiate their products in competitive markets. The ability to customize not only enhances brand identity but also caters to the growing consumer demand for personalized luxury goods.

As buyers from Africa, South America, the Middle East, and Europe explore sourcing options, it is essential to prioritize partnerships with reputable suppliers who emphasize quality and customer service. Engaging with manufacturers that offer robust customization options and reliable shipping can significantly enhance the value proposition of your product lineup.

Looking ahead, the demand for custom leather straps is set to increase as brands seek to elevate their offerings and provide consumers with unique, high-quality accessories. Embrace this opportunity to explore innovative designs and sustainable materials that resonate with your target market. By focusing on strategic sourcing, you can ensure your business remains at the forefront of this dynamic industry. Reach out today to start building partnerships that will drive your success in the custom leather strap market.

Illustrative image related to custom leather straps

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather straps