Introduction: Navigating the Global Market for suede lining

The global market for suede lining presents a unique opportunity for B2B buyers, yet navigating its complexities can be challenging. Sourcing high-quality suede lining that meets both aesthetic and functional requirements is crucial for businesses across various sectors, from luxury fashion to automotive interiors. This guide offers a comprehensive overview of suede lining, exploring different types, applications, and the nuances of supplier vetting. With insights into cost considerations and material characteristics, it equips buyers with the knowledge to make informed purchasing decisions.

As international B2B buyers from Africa, South America, the Middle East, and Europe—such as Brazil and Nigeria—seek reliable suppliers, understanding the landscape of suede lining becomes essential. The guide delves into sourcing strategies, highlighting reputable manufacturers and the importance of quality assurance in maintaining brand integrity. Moreover, it addresses the growing trend of sustainable sourcing, catering to a market increasingly concerned with environmental impact.

By providing actionable insights and practical tips, this guide empowers businesses to streamline their procurement processes, ultimately enhancing product quality and customer satisfaction. Whether you’re a seasoned buyer or new to the industry, understanding the dynamics of suede lining will enable you to navigate the global market with confidence and expertise.

Table Of Contents

- Top 3 Suede Lining Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for suede lining

- Understanding suede lining Types and Variations

- Key Industrial Applications of suede lining

- 3 Common User Pain Points for ‘suede lining’ & Their Solutions

- Strategic Material Selection Guide for suede lining

- In-depth Look: Manufacturing Processes and Quality Assurance for suede lining

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘suede lining’

- Comprehensive Cost and Pricing Analysis for suede lining Sourcing

- Alternatives Analysis: Comparing suede lining With Other Solutions

- Essential Technical Properties and Trade Terminology for suede lining

- Navigating Market Dynamics and Sourcing Trends in the suede lining Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of suede lining

- Strategic Sourcing Conclusion and Outlook for suede lining

- Important Disclaimer & Terms of Use

Understanding suede lining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Italian Calf Suede | Luxurious texture, durable, and rich colors; sourced from high-quality hides. | Luxury handbags, footwear, and accessories | Pros: Exceptional quality, long-lasting; Cons: Higher cost, may require minimum order quantities. |

| Micro Suede | Synthetic, lightweight, and economical; resembles real suede but lacks natural properties. | Budget-friendly products, fashion accessories | Pros: Cost-effective, easy to clean; Cons: Less luxurious feel, can be less durable. |

| Sheepskin Suede | Lighter weight, plush texture, and softer feel; ideal for high-end applications. | Custom luxury items, specialty bags | Pros: Unique softness, customizable; Cons: Limited availability, can be more expensive than calf suede. |

| Pig Suede | More affordable, thicker texture, and often less refined; available in various colors. | Casual footwear, budget-friendly bags | Pros: Cost-effective, good for bulk purchases; Cons: Inferior quality, less desirable for luxury markets. |

| Thermo Foam Suede Lining | Insulating properties, combines polyester and cotton; offers sun protection. | Drapery, upholstery, and functional applications | Pros: Functional benefits, versatile; Cons: Less aesthetic appeal for luxury items. |

What Are the Key Characteristics of Italian Calf Suede?

Italian calf suede is known for its luxurious feel and durability, making it a top choice for high-end applications. This type of suede is crafted from young cattle hides, resulting in a finer texture and richer color palette. B2B buyers in the luxury market should consider sourcing this material for handbags, footwear, and other accessories, as it aligns with premium branding and customer expectations. While the initial investment is higher, the long-term value and appeal can justify the cost.

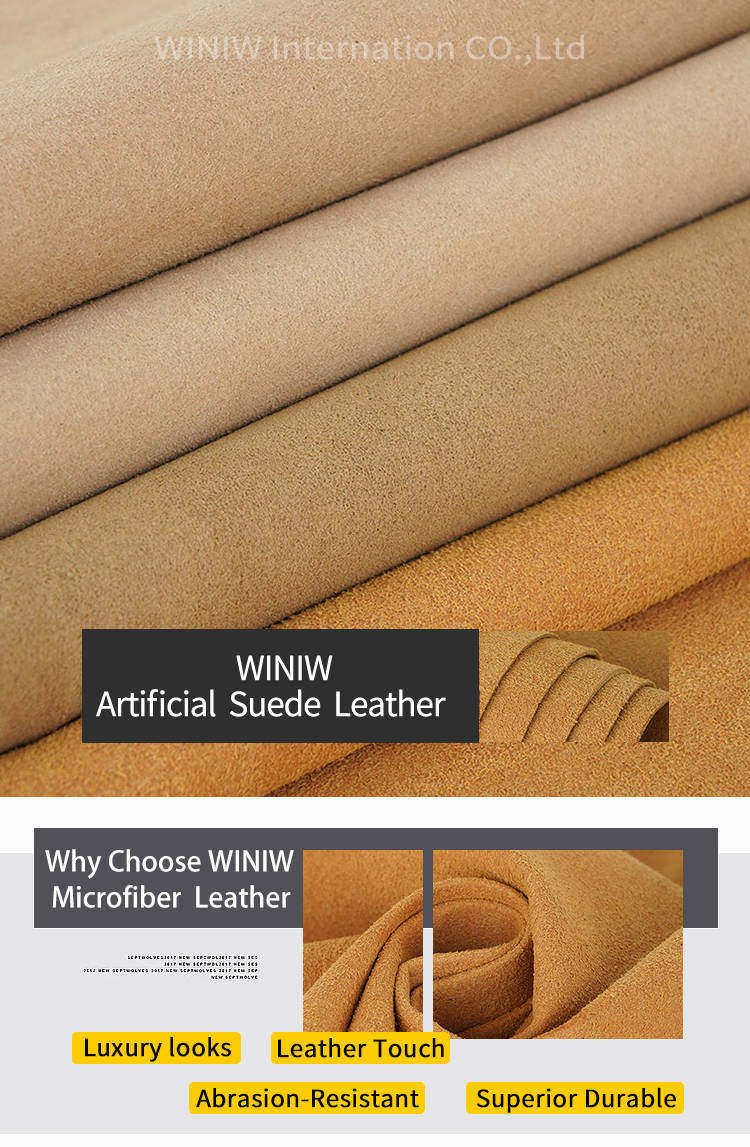

Illustrative image related to suede lining

How Does Micro Suede Compare to Traditional Suede?

Micro suede is a synthetic alternative that mimics the appearance of real suede while being lighter and more economical. This material is commonly used in budget-friendly fashion accessories and products. For B2B buyers, micro suede offers significant cost savings and ease of maintenance, making it ideal for high-volume production. However, it lacks the luxurious feel and longevity of genuine suede, which may be a drawback for brands aiming for a premium image.

What Makes Sheepskin Suede a Unique Option?

Sheepskin suede is characterized by its lightweight and plush texture, making it an excellent choice for bespoke luxury items. This type of suede enhances the tactile experience of products, appealing to discerning consumers. B2B buyers should consider sheepskin for specialty bags and custom orders, as it provides a unique selling proposition. However, availability can be limited, and the cost may be higher than other suede types, necessitating careful planning for inventory.

Why Choose Pig Suede for Budget-Friendly Solutions?

Pig suede is a more affordable option, offering a thicker texture and a variety of color choices. It is often utilized in casual footwear and budget-friendly bags, making it suitable for brands targeting cost-conscious consumers. For B2B buyers, pig suede can be an attractive option for bulk purchases. However, its lower quality may not appeal to luxury markets, which could impact brand perception.

Illustrative image related to suede lining

What Are the Advantages of Using Thermo Foam Suede Lining?

Thermo foam suede lining is unique due to its insulating properties, combining polyester and cotton to provide sun protection. This type of lining is ideal for drapery and upholstery applications, where functionality is key. B2B buyers can leverage this material for versatile uses, although it may not have the aesthetic appeal required for luxury items. Understanding its practical benefits can help brands differentiate their products in a competitive market.

Key Industrial Applications of suede lining

| Industry/Sector | Specific Application of suede lining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Lining for high-end garments and accessories | Enhances luxury appeal, provides comfort and durability | Ensure quality and color consistency; consider sourcing from reputable tanneries. |

| Footwear | Interior lining for shoes and boots | Improves comfort, moisture absorption, and wear resistance | Look for lightweight options; assess for breathability and durability. |

| Automotive | Upholstery lining for luxury vehicles | Adds aesthetic value, enhances comfort, and reduces noise | Verify compliance with safety standards; focus on fire resistance and durability. |

| Furniture & Interior Design | Lining for high-quality upholstery and cushions | Elevates aesthetic appeal and provides a soft touch | Source from environmentally responsible suppliers; consider color matching with fabrics. |

| Leather Goods | Lining for bags, wallets, and belts | Offers a premium finish and enhances product longevity | Ensure availability of custom colors and thickness; assess for compatibility with leather types. |

How is Suede Lining Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, suede lining is predominantly used in high-end garments and accessories such as jackets, handbags, and belts. Its soft texture and luxurious appearance enhance the overall aesthetic, making products more appealing to discerning consumers. Buyers should prioritize sourcing suede that maintains color consistency and quality, as these factors directly influence brand perception in competitive markets.

What Role Does Suede Lining Play in Footwear Manufacturing?

Suede lining is widely utilized in the footwear industry, particularly for upscale shoes and boots. It provides superior comfort and moisture absorption, ensuring that wearers enjoy a pleasant experience throughout the day. When sourcing suede for footwear, businesses should seek lightweight and breathable options that can withstand the rigors of daily use, particularly in regions with diverse climates.

Illustrative image related to suede lining

How is Suede Lining Beneficial in Automotive Upholstery?

In the automotive sector, suede lining is favored for luxury vehicle interiors, where it is used in seats, dashboards, and door panels. This material not only enhances the visual appeal but also improves passenger comfort and reduces noise levels. Buyers in this industry must ensure that the suede meets safety standards, including fire resistance, while also being durable enough to handle frequent use and exposure to varying temperatures.

Why is Suede Lining Important for Furniture & Interior Design?

Suede lining finds significant application in the furniture and interior design sectors, where it is used for upholstery and cushions. Its plush feel and rich texture elevate the aesthetic of furniture pieces, making them more inviting and luxurious. When sourcing suede for this application, businesses should consider environmentally responsible suppliers and ensure that the suede can be color-matched with existing fabrics to create a cohesive design.

What Benefits Does Suede Lining Offer in Leather Goods Production?

In the leather goods industry, suede lining is commonly used for products like bags, wallets, and belts. It provides a premium finish and enhances the durability of these items, making them more appealing to consumers. Buyers should focus on sourcing suede that offers a range of custom colors and thicknesses, ensuring compatibility with various leather types to meet diverse design specifications.

3 Common User Pain Points for ‘suede lining’ & Their Solutions

Scenario 1: Sourcing Quality Suede Lining Materials

The Problem:

For B2B buyers in the leather goods industry, sourcing high-quality suede lining can be a significant challenge. Many suppliers offer various grades of suede, but distinguishing between genuine luxury materials and lower-quality alternatives can be difficult. This confusion often leads to the procurement of products that do not meet the expected standards, resulting in customer dissatisfaction and potential damage to the brand’s reputation. Additionally, buyers may face issues related to inconsistent quality, availability of colors, and varying textures that impact the final product’s aesthetics and performance.

The Solution:

To overcome sourcing challenges, it is essential to establish relationships with reputable suppliers known for their commitment to quality. Look for tanneries and distributors that specialize in premium suede, such as Italian calf suede, which is celebrated for its rich texture and durability. Request samples to evaluate the quality firsthand, paying attention to factors like softness, thickness, and color consistency. Consider working with suppliers who provide transparent information about their materials’ origin and manufacturing processes. This due diligence will ensure that you procure suede linings that enhance your products’ luxury appeal while satisfying customer expectations.

Scenario 2: Managing Color Consistency in Suede Linings

The Problem:

Color inconsistency in suede lining can pose a significant headache for B2B buyers, particularly those producing high-end products where uniformity is crucial. Variations in dye lots can lead to mismatched colors in production, resulting in wasted materials and increased costs. Furthermore, customers purchasing leather goods expect a cohesive look, and deviations can lead to returns or complaints, affecting overall sales and customer loyalty.

The Solution:

To mitigate color inconsistency, establish a clear communication line with your suppliers regarding color specifications and dye lot management. When placing orders, request a color standard or swatch to ensure alignment with your production needs. Additionally, consider implementing a policy of ordering sufficient stock of a single dye lot at once to avoid mixing different batches in production. If you anticipate needing more material in the future, communicate this to your supplier upfront so they can help manage inventory levels. By taking these proactive steps, you can minimize the risk of color discrepancies and maintain the integrity of your brand’s products.

Scenario 3: Overcoming Installation Challenges with Suede Linings

The Problem:

B2B buyers often face installation challenges when integrating suede linings into various leather goods, such as bags and footwear. Proper installation is critical to achieving the desired aesthetic and functional outcome, but inexperienced workers or inadequate tools can result in poorly finished products. This situation not only affects the product’s appearance but can also lead to durability issues, which may impact customer satisfaction and return rates.

The Solution:

Investing in proper training and tools for your production team can significantly enhance the installation process of suede linings. Conduct workshops to educate staff on best practices for cutting, stitching, and adhering suede, emphasizing the importance of precision and care. Additionally, provide high-quality tools specifically designed for working with suede, such as sharp cutting blades and specialized adhesives that ensure a secure bond without damaging the material. Consider collaborating with experienced artisans or consultants to refine your techniques further. By prioritizing training and resource allocation, you can improve the quality of your finished products and reduce the likelihood of costly errors during installation.

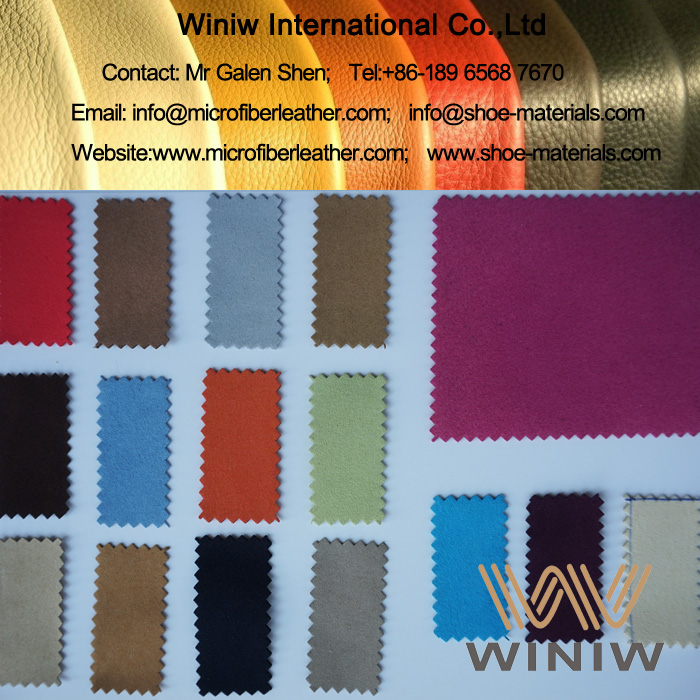

Illustrative image related to suede lining

Strategic Material Selection Guide for suede lining

When selecting materials for suede lining in various applications, it is essential to consider the properties, advantages, and limitations of each option. This guide analyzes four common materials used for suede lining: genuine leather suede, microsuede, synthetic suede, and sheepskin suede. Each material has unique characteristics that can significantly impact product performance and suitability for specific applications.

What Are the Key Properties of Genuine Leather Suede?

Genuine leather suede, typically sourced from calf or lamb hides, is renowned for its luxurious feel and durability. The key properties include excellent breathability, a soft texture, and a natural ability to age gracefully over time. Its temperature resistance is generally high, making it suitable for various environments. However, it requires proper care to maintain its appearance and durability.

Pros & Cons: The primary advantage of genuine leather suede is its premium quality and aesthetic appeal, making it a preferred choice for luxury items. However, it comes with a higher cost and may require more complex manufacturing processes, such as specialized stitching techniques to prevent fraying.

Impact on Application: Genuine leather suede is compatible with high-end fashion and luxury goods, appealing to markets that prioritize craftsmanship and quality. International buyers should be aware of compliance with leather sourcing regulations and standards, especially in regions like Europe, where animal welfare laws are stringent.

Illustrative image related to suede lining

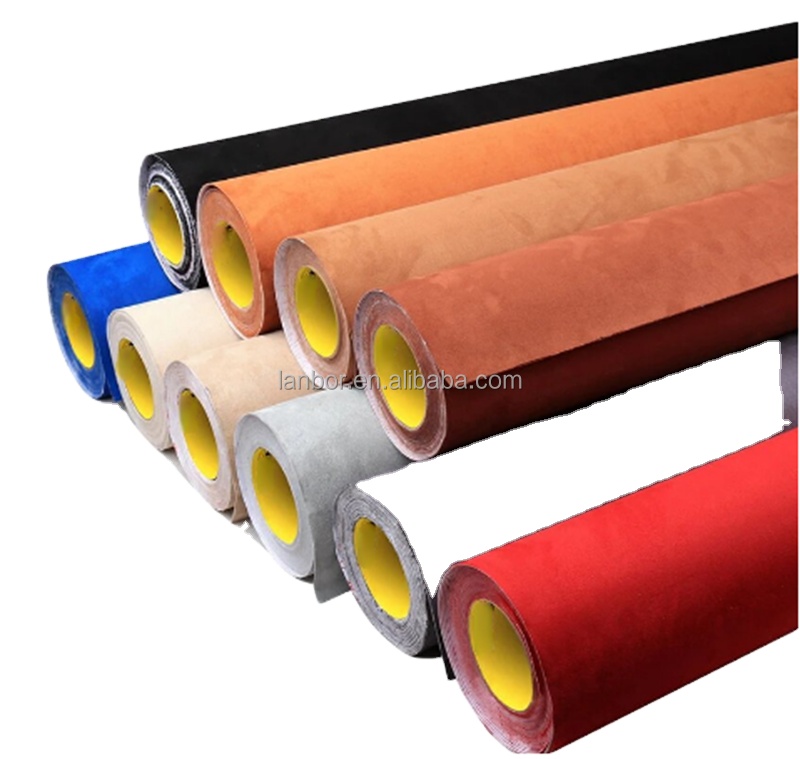

How Does Microsuede Compare to Other Materials?

Microsuede, often made from polyester or nylon, is a synthetic alternative to genuine suede. Its key properties include water resistance, ease of cleaning, and a lightweight nature. Microsuede is also less prone to fading and staining compared to natural materials, making it suitable for various applications.

Pros & Cons: The primary advantage of microsuede is its affordability and low maintenance requirements. However, it may lack the luxurious feel of genuine suede and can be less durable under heavy use, potentially leading to quicker wear and tear.

Impact on Application: Microsuede is often used in budget-conscious markets, making it popular in mass-produced goods. International buyers should consider the environmental impact of synthetic materials and ensure compliance with relevant regulations regarding textile production.

What Are the Benefits of Synthetic Suede for Lining?

Synthetic suede, which can encompass various blends of polyester and other fibers, offers a unique set of properties. It is generally more resistant to moisture and stains, making it suitable for items exposed to varying environmental conditions. Additionally, synthetic suede can be produced in a wide range of colors and textures.

Pros & Cons: The key advantage of synthetic suede is its versatility and cost-effectiveness, making it an attractive option for manufacturers. However, it may not provide the same level of breathability and comfort as genuine suede, potentially affecting user experience.

Illustrative image related to suede lining

Impact on Application: Synthetic suede is frequently used in applications where durability and ease of maintenance are prioritized, such as in upholstery and automotive interiors. Buyers should be aware of potential compliance issues related to synthetic fibers in their respective markets.

Why Choose Sheepskin Suede for Lining Applications?

Sheepskin suede is known for its softness and lightweight nature, making it an appealing option for luxury items. Its key properties include excellent insulation and a plush texture, which enhances the tactile experience of products.

Pros & Cons: The main advantage of sheepskin suede is its luxurious feel and lightweight characteristics, ideal for high-end fashion items. However, it may not be as durable as other options, and sourcing can be limited based on availability.

Impact on Application: Sheepskin suede is often favored in luxury markets, particularly in regions where craftsmanship is highly valued. Buyers should ensure that they are sourcing from reputable suppliers who adhere to ethical practices.

Summary Table of Material Selection for Suede Lining

| Material | Typical Use Case for suede lining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather Suede | Luxury handbags and footwear | Premium quality and aesthetic appeal | Higher cost and care requirements | High |

| Microsuede | Mass-produced goods and upholstery | Affordable and easy to clean | Lacks luxurious feel and durability | Low |

| Synthetic Suede | Upholstery and automotive interiors | Versatile and cost-effective | Less breathable and comfortable | Medium |

| Sheepskin Suede | High-end fashion items | Luxurious feel and lightweight | Limited durability and availability | High |

This strategic material selection guide provides B2B buyers with critical insights into the various options available for suede lining, enabling informed decision-making that aligns with market demands and compliance standards.

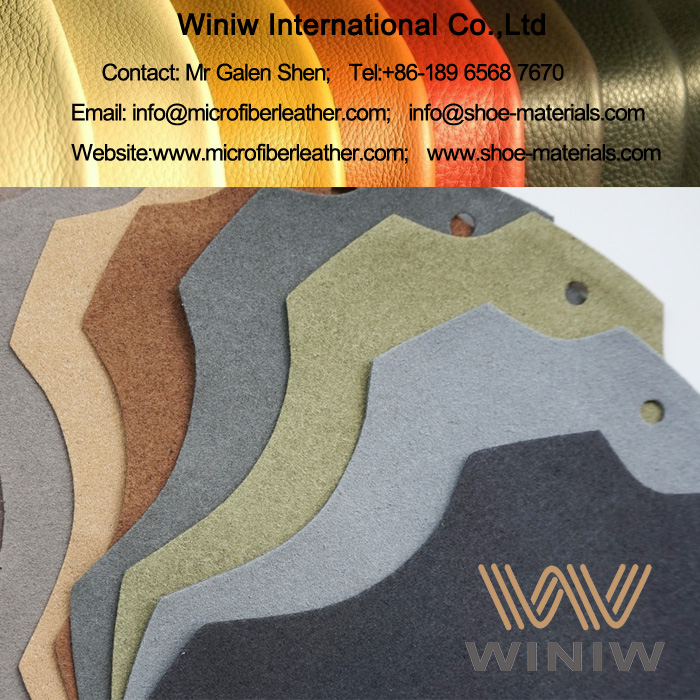

Illustrative image related to suede lining

In-depth Look: Manufacturing Processes and Quality Assurance for suede lining

What Are the Main Stages of Manufacturing Suede Lining?

The manufacturing of suede lining involves several critical stages, each contributing to the final product’s quality and durability. Understanding these stages can aid B2B buyers in making informed decisions when selecting suppliers.

Material Preparation: How Is Suede Sourced and Prepared?

The first step in the manufacturing process is sourcing the raw materials. High-quality suede typically originates from the hides of various animals, with calfskin being one of the most sought-after due to its softness and durability. After sourcing, the hides undergo a tanning process, which can be vegetable-based or chrome-based, depending on the desired characteristics. This process preserves the hide and enhances its texture.

Once tanned, the hides are inspected for defects. This initial quality check is crucial as it ensures that only the best materials proceed to the next stages. The hides are then cut into manageable pieces, taking care to maintain the grain direction and reduce waste, which is vital for cost-effective production.

Forming: What Techniques Are Used to Shape Suede?

The forming stage involves cutting the prepared suede into specific patterns and shapes for various applications, such as linings for bags, shoes, or garments. Precision cutting techniques, including die-cutting and laser cutting, are often employed to ensure accuracy and consistency. These methods allow for intricate designs and reduce the likelihood of material waste.

Additionally, manufacturers may employ bonding techniques where suede is adhered to other materials, such as fabrics or foams, to enhance functionality, such as insulation or durability. This step is particularly important for products that require additional support or structure.

Assembly: How Are Suede Products Constructed?

Assembly encompasses the stitching and joining of the suede lining to other components of the product. This process often involves skilled craftsmanship, especially in high-end applications where aesthetic appeal is paramount. Various stitching techniques, such as double-stitched seams, are used to enhance durability and provide a polished finish.

Quality control checkpoints are integrated during assembly. Inspectors check for alignment, stitching integrity, and overall appearance to ensure that the final product meets specified standards.

Finishing: What Steps Are Taken to Ensure Quality and Aesthetics?

The finishing stage is where the suede lining receives its final treatments. This may include dyeing, buffing, and applying protective coatings to enhance water resistance and durability. The finishing process also plays a crucial role in the aesthetic appeal of the suede, as it influences the texture and color vibrancy.

Quality assurance during this phase is vital. Manufacturers often conduct tests for colorfastness, abrasion resistance, and softness to ensure that the suede meets the desired specifications.

What Quality Assurance Standards Are Relevant for Suede Lining?

Quality assurance in the suede lining manufacturing process is paramount, especially for B2B buyers who require consistency and reliability in their supply chain. International standards, such as ISO 9001, provide a framework for quality management systems, ensuring that manufacturers adhere to best practices throughout their operations.

Which Industry-Specific Certifications Should Buyers Look For?

In addition to general quality standards, industry-specific certifications can provide assurance regarding the safety and performance of suede products. Certifications like CE (Conformité Européenne) for European markets ensure that products meet essential health, safety, and environmental protection standards. Buyers should also consider looking for certifications from recognized industry organizations, such as the American Leather Chemists Association (ALCA), which can further validate a supplier’s commitment to quality.

Illustrative image related to suede lining

What Are the Key Quality Control Checkpoints in Suede Manufacturing?

Quality control checkpoints are integral to ensuring that suede linings meet industry standards and customer expectations. Typical checkpoints include:

-

Incoming Quality Control (IQC): This initial check assesses raw materials upon arrival at the manufacturing facility. It verifies that the hides meet specified quality criteria before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is essential. Inspectors check for defects at various stages, including cutting, assembly, and finishing, to catch issues early in the process.

-

Final Quality Control (FQC): Before products are shipped, a comprehensive final inspection ensures that the finished suede linings meet all quality standards. This includes checking for visual defects, measuring dimensions, and performing functional tests.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should implement a thorough verification process to ensure supplier quality control. This can include:

-

Supplier Audits: Conducting regular audits of suppliers can help assess their compliance with quality standards and practices. Audits should evaluate the entire production process, from material sourcing to final inspections.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes and any certifications they hold. This transparency can help buyers gauge the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an impartial evaluation of the manufacturing process and final products. These services can verify compliance with international standards and offer additional assurance regarding product quality.

What Nuances Should International B2B Buyers Consider?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider in quality assurance processes:

Illustrative image related to suede lining

-

Cultural and Regulatory Differences: Different regions may have varying standards and regulations regarding materials and manufacturing processes. Buyers must be aware of these differences to ensure compliance with local laws.

-

Logistics and Supply Chain Challenges: International shipping can introduce risks related to product quality. Buyers should discuss packaging and handling procedures with suppliers to minimize damage during transit.

-

Communication Barriers: Language differences can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and documentation can help mitigate this risk.

In conclusion, understanding the manufacturing processes and quality assurance measures for suede lining is essential for B2B buyers aiming for superior products. By focusing on the stages of production, relevant quality standards, and effective verification methods, businesses can enhance their supply chain management and ensure they source the best suede linings available.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘suede lining’

In the competitive landscape of B2B procurement, sourcing high-quality suede lining is crucial for ensuring the durability and luxury appeal of your leather goods. This guide aims to provide a structured approach to help international buyers effectively navigate the sourcing process for suede lining materials.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as the type of suede (e.g., real leather vs. microsuede), thickness, color, and intended application. Specifying these details not only streamlines communication with suppliers but also ensures that the final product meets your quality standards.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in suede lining materials. Look for reputable companies that have a track record of supplying to businesses in your industry. Utilize online marketplaces, industry directories, and trade shows to compile a list of potential suppliers that align with your sourcing goals.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key aspects to investigate include:

– Experience: How long has the supplier been in business?

– Clientele: Do they supply to well-known brands or companies in your sector?

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, always request samples of the suede lining. This allows you to evaluate the texture, durability, and overall quality of the material. Pay attention to:

– Color Consistency: Ensure the color matches your specifications.

– Feel and Finish: Assess the softness and finish quality, which are critical for luxury products.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers adhere to industry standards and regulations. This is particularly important for businesses operating in markets with strict environmental and labor laws. Look for certifications such as:

– ISO Certifications: Indicating quality management systems.

– Sustainability Certifications: Confirming ethical sourcing practices.

Step 6: Negotiate Pricing and Terms

Once you have shortlisted suppliers, initiate negotiations on pricing, payment terms, and delivery schedules. Be transparent about your budget constraints while ensuring that you don’t compromise on quality. Discuss:

– Bulk Order Discounts: Many suppliers offer price breaks for larger quantities.

– Shipping Terms: Clarify responsibilities for shipping costs and timelines.

Step 7: Establish a Trial Order

Before finalizing a long-term partnership, place a trial order to assess the supplier’s reliability in terms of quality, delivery, and customer service. This step is essential for building trust and ensuring that the supplier can consistently meet your expectations.

By following this checklist, B2B buyers can effectively navigate the sourcing process for suede lining, ensuring they select high-quality materials that enhance their products and meet market demands.

Illustrative image related to suede lining

Comprehensive Cost and Pricing Analysis for suede lining Sourcing

What Are the Key Cost Components for Suede Lining Sourcing?

When analyzing the cost structure for suede lining sourcing, it’s essential to consider several components. The primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The choice between genuine suede and alternatives like microsuede significantly affects pricing. Genuine suede, particularly high-quality Italian calf suede, commands a premium due to its superior texture and durability. Synthetic options, while cheaper, may not provide the same luxury feel, impacting overall product quality.

-

Labor: Skilled craftsmanship is crucial in the production of suede lining, especially when dealing with genuine leather. Labor costs can vary based on geographic location and the skill level required. For instance, sourcing from regions with lower labor costs may yield savings, but this could compromise quality.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities and equipment depreciation. Efficient production processes can help minimize these overheads, which is particularly important for bulk orders.

-

Tooling: The initial investment in tools and machinery for cutting and finishing suede can be significant. However, this cost is often amortized over large production runs, making it less impactful on a per-unit basis for bulk orders.

-

Quality Control: Ensuring the suede meets specified quality standards involves additional costs. This includes inspections, certifications, and potentially returns or reworks if the material does not meet buyer expectations.

-

Logistics: Shipping costs can vary based on distance, weight, and shipping method. Understanding Incoterms is vital for international transactions, as they define who is responsible for shipping costs, insurance, and tariffs.

-

Margin: Supplier margins can vary widely, influenced by brand reputation, product exclusivity, and market demand. Premium suppliers may charge higher margins for luxury products, while more competitive suppliers might offer lower margins to attract bulk buyers.

How Do Price Influencers Impact Suede Lining Costs?

Several factors influence the final pricing of suede linings, affecting how buyers should approach their sourcing strategies:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Suppliers often provide discounts for larger orders, making bulk purchases more cost-effective. Buyers should evaluate their needs to optimize order sizes.

-

Specifications/Customization: Customization requests, such as specific colors or finishes, can increase costs due to the need for specialized production runs. Buyers should balance customization against the potential for higher pricing.

-

Materials and Quality Certifications: The choice of material directly impacts cost. Higher quality materials typically come with certifications that validate their authenticity and safety, adding to the overall price.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer higher quality but at a premium, while newer entrants might compete on price. Conducting due diligence on suppliers is essential.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Costs can vary significantly based on whether the supplier or buyer is responsible for freight and insurance, influencing the total landed cost.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings:

-

Leverage Volume Discounts: Always inquire about pricing tiers based on order volume. Presenting a commitment to larger orders can incentivize suppliers to offer better rates.

-

Assess Total Cost of Ownership: Consider not only the purchase price but also associated costs, such as shipping, duties, and potential wastage due to quality issues. A lower upfront cost may not always lead to the best value.

-

Explore Payment Terms: Flexible payment options can ease cash flow concerns. Propose terms that allow for staggered payments based on delivery milestones to minimize risk.

-

Build Relationships: Developing a good rapport with suppliers can lead to better pricing and terms over time. Trust and reliability can often outweigh the need for strict contractual terms.

-

Stay Informed on Market Trends: Keeping abreast of market fluctuations and trends in suede pricing can provide leverage during negotiations. Knowledge of competitor pricing can also strengthen your position.

Disclaimer on Indicative Prices

It’s important to note that the prices mentioned in various sources can fluctuate based on market conditions, availability, and supplier pricing strategies. Always request current quotes and consider multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing suede lining With Other Solutions

Understanding Alternatives to Suede Lining in B2B Applications

When evaluating materials for lining in leather goods, it is essential for B2B buyers to consider alternatives to suede lining. While suede offers a luxurious feel and aesthetic appeal, other materials can provide different advantages depending on the application and end-user requirements. This section compares suede lining with two viable alternatives: microsuede and synthetic linings.

Illustrative image related to suede lining

Comparison Table

| Comparison Aspect | Suede Lining | Microsuede | Synthetic Linings |

|---|---|---|---|

| Performance | High durability, luxurious feel | Good durability, soft texture | Varies; generally less durable |

| Cost | Moderate to high cost | Cost-effective | Low to moderate cost |

| Ease of Implementation | Requires skilled craftsmanship | Easy to cut and sew | Simple to handle and install |

| Maintenance | Requires special care (dry cleaning) | Machine washable | Easy to clean, often waterproof |

| Best Use Case | High-end leather goods | Everyday items, budget-conscious | Casual or functional applications |

In-Depth Look at Alternatives

What Are the Benefits and Drawbacks of Microsuede?

Microsuede, a synthetic alternative to natural suede, is composed of polyester fibers and mimics the soft texture of real suede. One of its main advantages is cost; it is significantly cheaper than genuine suede, making it appealing for budget-conscious businesses. Additionally, microsuede is machine washable, which simplifies maintenance. However, it may lack the luxurious feel and durability of real suede, particularly in high-end applications. Buyers should consider microsuede for products like everyday bags or casual wear where cost efficiency is prioritized over luxury.

How Do Synthetic Linings Compare to Suede?

Synthetic linings include a variety of materials, often featuring waterproof or stain-resistant properties. These linings are typically the most affordable option and can be manufactured in bulk, which is advantageous for mass production. They are also easy to clean and maintain, making them suitable for products expected to endure heavy use. However, synthetic linings may not provide the same aesthetic appeal or tactile experience as suede, making them less desirable for luxury items. B2B buyers should consider synthetic linings for functional applications such as work gear, where performance and cost are more critical than luxury.

How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate lining material hinges on understanding the target market and the intended use of the product. Buyers should assess factors such as budget constraints, the desired aesthetic, and the expected durability of the product. For high-end leather goods aimed at discerning customers, genuine suede remains the best choice. Conversely, for products designed for mass-market appeal or everyday use, microsuede or synthetic linings may offer better value without compromising too much on quality. Ultimately, aligning the material choice with the product’s purpose and target demographic will lead to better customer satisfaction and business success.

Essential Technical Properties and Trade Terminology for suede lining

What Are the Key Technical Properties of Suede Lining?

When evaluating suede lining for various applications, several critical specifications determine its suitability for high-quality products. Understanding these properties can aid B2B buyers in making informed purchasing decisions.

-

Material Grade

Suede lining can be made from various grades of leather, including calfskin, lambskin, and synthetic alternatives like microsuede. Higher-grade materials, such as Italian calf suede, offer superior softness, durability, and a luxurious aesthetic, which can enhance the perceived value of the final product. In contrast, lower-grade materials may compromise quality and longevity. -

Thickness

The thickness of suede lining typically ranges from 0.5mm to 2mm. A thickness of 0.5mm is ideal for lining larger items like bags, providing a lightweight feel without sacrificing quality. Thicker options may be used for products requiring more structure or durability, such as footwear. Buyers should consider the intended application to choose the appropriate thickness. -

Color Fastness

This property refers to the ability of the suede lining to retain its color when exposed to various conditions such as sunlight, washing, or abrasion. Color fastness is crucial for maintaining the aesthetic appeal of a product over time, especially in items like bags and apparel that are frequently used. Buyers should inquire about color fastness ratings to ensure longevity in their products. -

Tensile Strength

This specification measures the material’s ability to withstand tension before breaking. Suede lining with high tensile strength is essential for products that experience significant wear and tear, such as belts or shoes. Understanding tensile strength helps buyers select materials that can endure daily use without compromising structural integrity. -

Finish Type

The finish applied to suede lining can affect its appearance, feel, and resistance to stains or moisture. Common finishes include brushed, polished, or coated options. A suitable finish enhances the product’s functionality and aesthetic, allowing buyers to align the material with their brand’s quality standards.

What Common Trade Terms Should B2B Buyers Know?

Navigating the procurement process for suede lining involves understanding several industry-specific terms that can impact negotiations and logistics.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end product. Understanding OEM relationships is vital for buyers looking to source suede lining as part of a larger manufacturing process. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For suede lining, MOQs can vary significantly based on the supplier and the quality of the material. Buyers should clarify MOQs to ensure they can meet their production needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. B2B buyers often utilize RFQs to gather competitive bids for suede lining, ensuring they secure the best possible terms and pricing for their projects. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers involved in international procurement of suede lining, as they clarify who bears the risk and cost at each stage of the shipping process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the context of suede lining, lead times can vary based on material availability and production schedules. Buyers should account for lead times in their planning to avoid delays in their supply chain. -

Quality Assurance (QA)

QA refers to the processes and procedures that ensure products meet specific quality standards. B2B buyers should prioritize suppliers with robust QA processes to ensure the suede lining they receive aligns with their quality expectations, which is critical for maintaining brand reputation.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies for suede lining, ensuring they select the best materials for their applications while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the suede lining Sector

What Are the Current Market Dynamics and Key Trends in the Suede Lining Sector?

The suede lining market is influenced by a combination of global drivers, emerging technologies, and shifting consumer preferences. Increasing demand for luxury goods across markets in Africa, South America, the Middle East, and Europe is a key factor. High-end brands are increasingly adopting suede linings to enhance product appeal and provide a tactile experience that resonates with consumers seeking quality. The rise of e-commerce platforms has also transformed sourcing strategies, enabling international buyers to access a diverse array of suppliers and materials.

Additionally, innovations in production techniques, such as the development of microsuede and other synthetic alternatives, have gained traction. These alternatives offer cost-effective solutions without compromising on aesthetics, making them attractive for mass-market products. However, traditional suede, particularly from reputable sources like Italian tanneries, continues to hold value among luxury brands for its authenticity and superior quality. B2B buyers should remain aware of these dynamics and consider both traditional and innovative sources to meet market demands.

Illustrative image related to suede lining

How Is Sustainability and Ethical Sourcing Impacting Suede Lining Procurement?

Sustainability and ethical sourcing are becoming paramount in the suede lining sector. Environmental concerns related to leather production, including water use and chemical processing, have prompted buyers to seek suppliers who adhere to sustainable practices. B2B buyers are increasingly demanding transparency in the supply chain to ensure that materials are sourced responsibly. This shift is not merely a trend; it reflects a growing recognition of the importance of ethical consumerism across global markets.

Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) can serve as benchmarks for buyers looking to source sustainable suede linings. These certifications assure that the materials are produced with minimal environmental impact and ethical labor practices. Furthermore, brands that prioritize sustainability often enjoy enhanced brand loyalty and market differentiation, making ethical sourcing a strategic imperative in today’s competitive landscape.

What Is the Brief Evolution and History of Suede Lining in the B2B Context?

The use of suede as a lining material has evolved significantly over the years. Initially favored for its luxurious feel and aesthetic appeal, suede gained traction in the fashion industry during the mid-20th century. Its adoption was largely driven by the luxury sector, where high-quality suede linings became synonymous with premium craftsmanship.

As global markets expanded, the suede lining sector diversified, with advancements in tanning techniques and synthetic alternatives emerging. Today, B2B buyers have access to a wide range of suede products, from traditional leather options to modern microsuede, catering to varying consumer needs and price points. This evolution reflects not only changing consumer preferences but also technological advancements that have reshaped sourcing and production in the leather goods industry. Understanding this history is crucial for B2B buyers aiming to make informed sourcing decisions in a rapidly changing market.

Illustrative image related to suede lining

Frequently Asked Questions (FAQs) for B2B Buyers of suede lining

-

How do I choose the right type of suede lining for my products?

When selecting suede lining, consider the end application of your products. For luxury bags and high-end footwear, genuine Italian calf suede offers unmatched quality and a rich texture, enhancing the product’s overall appeal. Conversely, microsuede is a cost-effective alternative that provides a soft finish while being easier to maintain. Evaluate factors such as durability, softness, and color options to ensure the lining aligns with your brand’s image and customer expectations. -

What are the key factors to consider when sourcing suede lining internationally?

Key factors include the supplier’s reputation, quality assurance processes, and compliance with international standards. Verify the source of the suede, ensuring it meets ethical and environmental regulations. Additionally, assess their production capabilities, lead times, and flexibility in order quantities. Engaging in direct communication with potential suppliers can also help clarify any concerns regarding material specifications and payment terms. -

What minimum order quantities (MOQs) should I expect when purchasing suede lining?

MOQs for suede lining can vary significantly based on the supplier and the specific type of suede. Generally, you might encounter MOQs ranging from 10 to 100 square meters. If you’re looking for customization options, MOQs may increase due to additional processing requirements. Always discuss your needs upfront with the supplier to negotiate favorable terms, especially if you are a new buyer. -

What payment terms are typically offered by suppliers of suede lining?

Payment terms can vary widely among suppliers. Many international suppliers require a deposit (usually 30-50%) upfront, with the balance payable before shipment. Some may offer net 30 or net 60 terms for established buyers. It’s crucial to clarify these terms before finalizing an order to avoid any misunderstandings that could impact your cash flow. -

How can I ensure the quality of suede lining before making a large purchase?

Request samples to assess the quality of the suede lining firsthand. A reputable supplier should provide swatches or small panels for your evaluation. Additionally, inquire about their quality control processes, including testing for durability, colorfastness, and material consistency. Establishing a clear agreement on quality standards in your purchase contract can also safeguard against receiving subpar materials. -

What logistics considerations should I be aware of when importing suede lining?

When importing suede lining, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling textile imports to navigate these complexities. It’s also wise to familiarize yourself with your country’s import duties and ensure that all necessary documentation, such as certificates of origin and compliance, is in order to avoid delays. -

Can I customize the suede lining in terms of color and texture?

Yes, many suppliers offer customization options for suede lining, including color matching and varying textures. However, customization may come with increased MOQs and longer lead times. Discuss your specific requirements with the supplier to determine available options and any additional costs associated with bespoke requests. -

What are the most common uses for suede lining in B2B applications?

Suede lining is predominantly used in luxury bags, footwear, and leather goods, providing a soft touch and aesthetic appeal. It is also utilized in upholstery, automotive interiors, and even high-end fashion accessories. Understanding the diverse applications can help you identify potential market opportunities and align your product offerings with industry trends.

Top 3 Suede Lining Manufacturers & Suppliers List

1. District Leathers – Premium Suede and Shearling

Domain: districtleathers.com

Registered: 2016 (9 years)

Introduction: Product Types: Pig Suede, Italian Goat Suede, Italian Nappa Lamb, Metallic Lamb, Italian Vegetable Tanned Shadow Lamb, Calf Suede, Kid Hide, Ironed Merino Shearlings, Aviator Shearling with Leather Back, Merino Shearling, Buttery Waxy Nappa Lamb, Accessories Nappa Lamb, Double-Sided Curly Merino Shearling, Glazed Lamb, Sports Shearling with Matte Leather Back, Thin Evan Goat Nappa, Shelby Lamb, Go…

2. Marcellino – Luxury Handmade Briefcases

Domain: marcellinony.com

Registered: 2015 (10 years)

Introduction: Italian Calf Suede Lining, High-end handmade locks, Front straps, Briefcase & mini case pockets, Art of hand stitching, Original Marcellino latch, Knuckles handle, Traditional English bridle leather, Natural leather lining, Option for sheepskin suede lining, Wide array of suede colors available, Commitment to quality and craftsmanship.

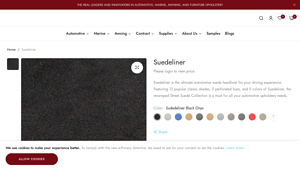

3. Keystone Bros – Suedeliner Automotive Headliner

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Suedeliner is an automotive suede headliner designed to enhance the interior of vehicles. It features 12 popular classic shades, 9 perforated hues, and 9 colors in the revamped Street Suede Collection. The product is made of 100% polyester, has a width of 59.5 inches, and weighs 19.8 oz/linear yard. It passes FMVSS 302 flame retardancy standards and has an abrasion resistance of 45,000 DR.

Strategic Sourcing Conclusion and Outlook for suede lining

As the demand for high-quality suede lining continues to grow in the global market, strategic sourcing emerges as a pivotal approach for B2B buyers in various regions, including Africa, South America, the Middle East, and Europe. Sourcing from reputable suppliers ensures access to premium materials like Italian calf suede and microsuede, which offer distinct advantages in terms of luxury appeal, durability, and customer satisfaction. Understanding the nuances between synthetic and genuine suede can help buyers make informed decisions that align with their brand values and market expectations.

Investing in quality suede linings not only enhances product aesthetics but also reinforces brand reputation, particularly in luxury and fashion segments. Buyers should consider leveraging partnerships with established manufacturers and suppliers to secure competitive pricing, ensure consistent quality, and facilitate timely delivery.

Looking ahead, the suede lining market is poised for innovation, driven by evolving consumer preferences and sustainability trends. International B2B buyers are encouraged to stay ahead of the curve by exploring new sourcing opportunities and technologies that can enhance their product offerings. Embrace the potential of suede lining to elevate your brand’s positioning in the market and cater to the discerning tastes of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.