Introduction: Navigating the Global Market for custom leather fire helmets

In the ever-evolving landscape of firefighting equipment, sourcing custom leather fire helmets presents unique challenges for international buyers. Fire departments across Africa, South America, the Middle East, and Europe, including markets like Brazil and Vietnam, often grapple with finding helmets that marry tradition with modern safety standards. This guide aims to demystify the complexities of the global market for custom leather fire helmets, providing insights into various types, applications, and essential supplier vetting processes.

Understanding the nuances of these helmets is crucial, as they are not just protective gear but also symbols of heritage and professionalism in firefighting. This comprehensive resource covers everything from the specifications and features of popular models, such as the Phenix TL-2 and RagTop N5A, to the customization options that cater to specific departmental needs. Additionally, we delve into cost considerations, lead times, and the importance of compliance with safety standards like NFPA 1971.

By equipping B2B buyers with actionable insights and best practices, this guide empowers you to make informed purchasing decisions that enhance your firefighting capabilities. With a focus on quality, comfort, and compliance, you’ll be well-prepared to navigate the global marketplace and select the right helmets that ensure safety and satisfaction for your team.

Table Of Contents

- Top 7 Custom Leather Fire Helmets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather fire helmets

- Understanding custom leather fire helmets Types and Variations

- Key Industrial Applications of custom leather fire helmets

- 3 Common User Pain Points for ‘custom leather fire helmets’ & Their Solutions

- Strategic Material Selection Guide for custom leather fire helmets

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire helmets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire helmets’

- Comprehensive Cost and Pricing Analysis for custom leather fire helmets Sourcing

- Alternatives Analysis: Comparing custom leather fire helmets With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather fire helmets

- Navigating Market Dynamics and Sourcing Trends in the custom leather fire helmets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire helmets

- Strategic Sourcing Conclusion and Outlook for custom leather fire helmets

- Important Disclaimer & Terms of Use

Understanding custom leather fire helmets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Leather Helmet | Classic design, heavy-duty leather, customizable colors | Fire departments, safety equipment suppliers | Pros: Durable, traditional aesthetic. Cons: Heavier than modern materials. |

| NFPA Compliant Helmet | Meets NFPA standards, lightweight, ergonomic design | Compliance-focused organizations, safety regulators | Pros: Safety certified, comfort-focused. Cons: Higher price point. |

| Specialty Fire Helmets | Unique designs for specific roles (e.g., wildland, rescue) | Specialized firefighting units, niche markets | Pros: Tailored for specific tasks. Cons: Limited availability and customization options. |

| Customizable Helmets | Wide range of features and accessories available | Custom orders for departments, unique branding | Pros: Fully tailored to department needs. Cons: Longer lead times for production. |

| Refurbished Leather Helmets | Restored helmets with new features and finishes | Budget-conscious departments, historical preservation | Pros: Cost-effective, retains historical value. Cons: May not meet current safety standards. |

What Are the Characteristics of Traditional Leather Helmets?

Traditional leather helmets are renowned for their classic design and robust construction. Typically made from heavy-duty leather, they offer a timeless aesthetic that many fire departments prefer. These helmets can be customized in various colors and styles, allowing departments to maintain their unique branding. While they provide excellent durability, buyers should consider their weight, which can lead to neck fatigue during prolonged use.

Why Choose NFPA Compliant Helmets?

NFPA compliant helmets are specifically designed to meet the safety standards set by the National Fire Protection Association. These helmets are lightweight and ergonomically designed, making them ideal for firefighters who need to maintain comfort during extended operations. They often include features such as adjustable suspension systems and reflective materials for visibility. The investment in NFPA compliant helmets is justified by the enhanced safety they offer, although they typically come at a higher price point.

How Do Specialty Fire Helmets Cater to Specific Needs?

Specialty fire helmets are designed for unique firefighting scenarios, such as wildland firefighting or technical rescue operations. These helmets feature designs that accommodate specific equipment and performance needs, such as additional ventilation or enhanced visibility. While they are invaluable for specialized units, buyers should be aware that availability may be limited, and customization options may not be as extensive as traditional models.

What Advantages Do Customizable Helmets Offer?

Customizable helmets allow fire departments to select features and accessories that best meet their operational needs. From unique color schemes to specific protective gear integrations, these helmets can be tailored to fit a department’s identity and requirements. However, potential buyers should be prepared for longer lead times due to the customization process, as well as potential price variations based on selected features.

Why Consider Refurbished Leather Helmets?

Refurbished leather helmets offer a cost-effective solution for fire departments looking to preserve historical pieces while ensuring functionality. These helmets are restored to a usable state, often with new features added to enhance performance. While they are budget-friendly, departments should verify that refurbished helmets meet current safety standards to ensure the protection of their personnel.

Key Industrial Applications of custom leather fire helmets

| Industry/Sector | Specific Application of custom leather fire helmets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Firefighting Services | Use in municipal and volunteer fire departments | Enhanced safety, comfort, and visibility for firefighters | Compliance with NFPA standards, customization options, lead times |

| Oil & Gas Industry | Emergency response teams in oil refineries | Protection in hazardous environments, lightweight design | Durability under extreme conditions, availability of accessories |

| Mining Operations | Fire safety for underground mining crews | High visibility and protection in low-light conditions | Compliance with safety regulations, custom fit for equipment |

| Industrial Manufacturing | Emergency response in manufacturing plants | Robust protection against fire hazards, ergonomic design | Custom branding options, compatibility with safety gear |

| Construction | Safety gear for construction site fire response | Increased firefighter safety and operational efficiency | Custom color options for branding, quick shipping requirements |

How Are Custom Leather Fire Helmets Used in Firefighting Services?

Custom leather fire helmets are integral in municipal and volunteer fire departments across various regions. These helmets provide essential protection against heat and falling debris while ensuring comfort during long hours on the job. The lightweight design reduces neck fatigue, which is crucial for firefighters who may be on the scene for extended periods. Buyers in this sector should prioritize helmets that comply with NFPA standards, offer customization options, and consider lead times for manufacturing and delivery, especially in regions like Africa and South America where logistics can vary significantly.

Illustrative image related to custom leather fire helmets

What Role Do Custom Leather Fire Helmets Play in the Oil & Gas Industry?

In the oil and gas sector, emergency response teams rely on custom leather fire helmets to navigate hazardous environments, such as oil refineries and drilling sites. These helmets are designed to withstand extreme temperatures and offer high visibility, which is vital for safety in emergency situations. Buyers should focus on sourcing helmets that are durable, lightweight, and equipped with necessary accessories like face shields and reflective materials. Additionally, understanding the specific requirements of local regulations in regions like the Middle East can influence purchasing decisions.

How Are Custom Leather Fire Helmets Utilized in Mining Operations?

Mining operations often present unique challenges regarding fire safety, particularly in underground settings. Custom leather fire helmets are employed to provide protection against potential fire hazards while ensuring visibility in low-light conditions. The ergonomic design is essential for comfort, as miners may wear these helmets for extended periods. Buyers in this industry must ensure that helmets meet safety regulations and can be tailored to fit comfortably with other equipment, which is particularly important in regions with varying mining standards, such as Brazil and Vietnam.

Why Are Custom Leather Fire Helmets Important in Industrial Manufacturing?

In industrial manufacturing, custom leather fire helmets are vital for emergency response teams tasked with handling potential fire incidents. These helmets offer robust protection against flames and debris while ensuring ergonomic comfort for the wearer. The ability to customize these helmets with company branding and specific features enhances visibility and team identity. When sourcing, businesses should consider compliance with safety regulations, the availability of accessories, and the customization options that align with their operational needs.

How Do Custom Leather Fire Helmets Benefit Construction Sites?

On construction sites, custom leather fire helmets serve as critical safety gear for fire response teams. These helmets not only provide essential fire protection but also enhance operational efficiency by allowing workers to focus on their tasks without compromising safety. Buyers should look for helmets that offer quick shipping options and the ability to customize colors for branding purposes. Understanding local regulations and the specific needs of construction environments is crucial for ensuring that the helmets meet safety standards and enhance worker protection.

3 Common User Pain Points for ‘custom leather fire helmets’ & Their Solutions

Scenario 1: Long Lead Times Affecting Operational Readiness

The Problem: B2B buyers often encounter long lead times when ordering custom leather fire helmets, which can significantly impact their operational readiness. For instance, a fire department in Brazil may require new helmets to replace outdated gear before the start of wildfire season. However, with typical production times ranging from 4 to 16 weeks, there is a risk that the helmets will not arrive in time, leaving firefighters vulnerable and unprepared. This situation not only jeopardizes safety but also creates logistical challenges in training and deployment.

Illustrative image related to custom leather fire helmets

The Solution: To mitigate the impact of long lead times, buyers should proactively engage with manufacturers to understand their production schedules and capabilities. Establishing a relationship with a reputable supplier who communicates regularly about order status is crucial. Additionally, consider placing orders well in advance, ideally during off-peak seasons, to secure faster delivery. Utilizing pre-order options for helmets that are in stock can also be beneficial. Finally, explore bulk purchasing discounts or collaborative purchasing agreements with neighboring departments to streamline orders and potentially shorten lead times through combined demand.

Scenario 2: Inadequate Customization Options Leading to Inefficiency

The Problem: Another common pain point for B2B buyers is the lack of adequate customization options for leather fire helmets. For example, a fire department in South Africa may require helmets that not only meet safety standards but also incorporate specific department colors, insignia, and unique features such as built-in communication systems. If manufacturers do not offer the necessary customization, departments may end up with helmets that do not fully meet their operational needs, leading to inefficiencies and dissatisfaction among the crew.

The Solution: Buyers should conduct thorough research to identify manufacturers that specialize in customizable leather fire helmets. When requesting quotes, provide detailed specifications outlining all desired features, including color, insignia placement, and any additional accessories. Establishing clear communication with the manufacturer during the design phase is essential to ensure that all requirements are understood and met. Additionally, consider consulting with other departments or industry experts to gather insights on customization options that enhance functionality. Engaging in pilot programs for new designs can also provide valuable feedback for future orders.

Scenario 3: Misunderstanding Regulatory Compliance Requirements

The Problem: B2B buyers often struggle with understanding the regulatory compliance requirements for custom leather fire helmets. For instance, a buyer in the Middle East may not be fully aware of the National Fire Protection Association (NFPA) standards that helmets must meet to ensure firefighter safety. This lack of knowledge can lead to purchasing helmets that do not comply, resulting in wasted funds and potential safety hazards for firefighters during operations.

The Solution: To navigate compliance requirements effectively, buyers should familiarize themselves with relevant safety standards, such as NFPA 1971, and ensure they are communicated clearly to manufacturers. It’s advisable to request documentation and certification for helmets to verify compliance. Engaging with industry associations or attending trade shows can also provide valuable insights into the latest regulations and best practices. Furthermore, buyers should consider working with consultants who specialize in fire safety equipment to help them make informed purchasing decisions that adhere to local and international safety standards.

Illustrative image related to custom leather fire helmets

Strategic Material Selection Guide for custom leather fire helmets

What Are the Key Materials Used in Custom Leather Fire Helmets?

When selecting materials for custom leather fire helmets, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: vegetable-tanned leather, chrome-tanned leather, synthetic leather, and fiberglass composites. Each material has unique characteristics that can significantly influence helmet performance, durability, and compliance with international standards.

How Does Vegetable-Tanned Leather Perform in Fire Helmets?

Vegetable-tanned leather is a traditional material known for its durability and comfort. It offers excellent heat resistance, making it suitable for high-temperature environments. Additionally, this type of leather is breathable, which enhances comfort during prolonged use.

Pros:

– High durability and resistance to wear and tear.

– Naturally breathable, providing comfort for extended wear.

– Environmentally friendly due to the tanning process.

Cons:

– Higher cost compared to synthetic alternatives.

– Requires regular maintenance to preserve its properties.

– May not be as water-resistant as chrome-tanned leather.

For international buyers, especially in regions like Africa and the Middle East, compliance with standards such as NFPA 1971 is crucial. Vegetable-tanned leather helmets can meet these requirements but may require additional treatments for water resistance.

Illustrative image related to custom leather fire helmets

What Are the Benefits of Chrome-Tanned Leather?

Chrome-tanned leather is another popular choice for fire helmets. This material is known for its flexibility and resistance to moisture, making it ideal for various weather conditions. It also offers good abrasion resistance and can withstand higher levels of humidity without degrading.

Pros:

– Excellent water and moisture resistance.

– Flexible and comfortable for the wearer.

– Generally lower cost than vegetable-tanned leather.

Cons:

– Less environmentally friendly due to the tanning process.

– May not offer the same level of breathability as vegetable-tanned leather.

– Can be less durable over time compared to vegetable-tanned options.

For B2B buyers in South America and Europe, chrome-tanned leather helmets often comply with regional standards, but it’s essential to verify specific requirements, especially regarding environmental regulations.

Illustrative image related to custom leather fire helmets

How Does Synthetic Leather Compare in Fire Helmet Applications?

Synthetic leather, often made from polyurethane or PVC, is increasingly used in fire helmets due to its lightweight and cost-effective nature. It offers good resistance to water and chemicals, making it suitable for various firefighting environments.

Pros:

– Lightweight, reducing neck fatigue during prolonged use.

– Cost-effective, making it accessible for budget-conscious departments.

– Resistant to chemicals and easy to clean.

Cons:

– May not provide the same level of heat resistance as natural leathers.

– Less durable over time, especially in high-stress environments.

– Can be less comfortable due to reduced breathability.

International buyers should consider the specific firefighting conditions in their regions. For example, in humid climates like Vietnam, synthetic leather may require additional ventilation features to enhance comfort.

What Role Do Fiberglass Composites Play in Fire Helmet Design?

Fiberglass composites are used in some modern fire helmets, providing a lightweight yet robust alternative to traditional leathers. These materials are engineered for high-temperature resistance and can be molded into various shapes, offering versatility in design.

Illustrative image related to custom leather fire helmets

Pros:

– Lightweight and highly durable, reducing fatigue.

– Excellent heat resistance, suitable for extreme conditions.

– Can be customized easily for different designs and features.

Cons:

– Typically higher manufacturing complexity and cost.

– May lack the traditional aesthetic of leather helmets.

– Not as comfortable as leather due to reduced breathability.

For buyers in Europe and the Middle East, fiberglass helmets may meet stringent safety standards, but it’s important to ensure compliance with local regulations, particularly regarding fire safety equipment.

Summary Table of Material Properties for Custom Leather Fire Helmets

| Material | Typical Use Case for custom leather fire helmets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-temperature firefighting environments | High durability and breathability | Requires maintenance, higher cost | High |

| Chrome-Tanned Leather | Versatile firefighting in various climates | Excellent water resistance | Less eco-friendly, less breathable | Medium |

| Synthetic Leather | Budget-friendly helmets for general use | Lightweight and easy to clean | Lower heat resistance, less durable | Low |

| Fiberglass Composites | Extreme conditions requiring robust protection | Lightweight and highly durable | Higher manufacturing complexity | High |

This analysis provides a comprehensive overview of the materials used in custom leather fire helmets, helping B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

Illustrative image related to custom leather fire helmets

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire helmets

What Are the Main Stages in the Manufacturing Process of Custom Leather Fire Helmets?

The manufacturing process of custom leather fire helmets involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages is essential for B2B buyers looking to procure helmets that meet their specific needs.

Material Preparation: What Raw Materials Are Used?

The first stage in the manufacturing process is material preparation. High-quality leather, typically vegetable-tanned, is the primary material used due to its durability and heat resistance. Suppliers often source leather from reputable tanneries that adhere to international environmental standards. In addition to leather, other materials such as fire-resistant liners, suspension systems, and chin straps are prepared during this phase.

How Are Leather Fire Helmets Formed?

Once the materials are prepared, the next step is forming. This involves cutting the leather into specific shapes and sizes based on design specifications. Advanced techniques like die-cutting may be employed to ensure precision. After cutting, the leather pieces are shaped using heat and moisture, allowing them to conform to the desired helmet structure. This step is crucial, as the fit and comfort of the helmet significantly impact its usability in emergency situations.

What Techniques Are Used in Assembling Leather Fire Helmets?

The assembly stage is where the individual components come together to create the finished helmet. Skilled craftsmen stitch the leather pieces, often utilizing heavy-duty thread to enhance durability. The assembly process may also involve attaching various components such as visors, earflaps, and reflective strips to ensure compliance with safety standards.

In some cases, manufacturers offer customization options, allowing buyers to select features such as color, size, and additional accessories. This flexibility is particularly appealing to international buyers who may have unique preferences or requirements.

Illustrative image related to custom leather fire helmets

How Is the Finishing Process Conducted for Quality Assurance?

The final stage of manufacturing is finishing. This includes applying protective coatings to the leather to enhance its resistance to water and heat. Finishing also involves polishing the helmet to achieve a professional appearance. Quality manufacturers conduct thorough inspections during this stage to ensure that the helmets meet both aesthetic and functional standards.

What Quality Assurance Standards Are Relevant for Custom Leather Fire Helmets?

Quality assurance (QA) is a critical component of the manufacturing process, especially for products used in life-threatening situations like fire helmets. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking and compliance with NFPA (National Fire Protection Association) standards are vital. These certifications ensure that helmets meet safety and performance criteria relevant to firefighting operations. Buyers should look for suppliers that display these certifications prominently.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves systematic checks at various stages of production. Key checkpoints include:

-

Incoming Quality Control (IQC): This occurs when raw materials arrive at the manufacturing facility. Inspectors assess the quality of leather and other materials to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections help identify any deviations from quality standards. This includes monitoring stitching quality and component assembly.

-

Final Quality Control (FQC): Once helmets are completed, a comprehensive inspection is conducted. This includes testing for durability, heat resistance, and compliance with safety standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure quality:

Illustrative image related to custom leather fire helmets

-

Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s quality management practices. During these audits, buyers should assess compliance with international standards and observe manufacturing processes firsthand.

-

Quality Assurance Reports: Request detailed QA reports from suppliers. These reports should outline the results of various inspections and tests conducted throughout the manufacturing process. Transparency in reporting is a good indicator of a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of product quality. These services often include sampling and testing to verify compliance with applicable standards.

What Nuances Should International Buyers Consider for Quality Control?

When sourcing custom leather fire helmets, international buyers should be aware of specific nuances in quality control that may affect their procurement strategy. For instance:

-

Regulatory Compliance: Different countries have varying regulations regarding safety equipment. Buyers must ensure that the helmets meet local standards in their respective markets. Familiarity with these regulations can prevent costly compliance issues.

-

Cultural Preferences: In regions like Africa and South America, cultural factors may influence helmet design preferences. Customization options that accommodate local tastes can enhance market acceptance.

-

Supply Chain Reliability: The global supply chain can be unpredictable, especially during crises. Buyers should assess suppliers’ ability to maintain quality and delivery timelines amidst disruptions.

By understanding the manufacturing processes and quality assurance standards for custom leather fire helmets, B2B buyers can make informed decisions that prioritize safety, comfort, and compliance. This knowledge not only aids in selecting the right supplier but also ensures that the helmets will perform effectively in critical situations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire helmets’

Introduction

Sourcing custom leather fire helmets requires careful consideration and attention to detail to ensure you acquire high-quality products that meet safety standards and cater to the specific needs of your fire department. This checklist will guide you through the critical steps to streamline your procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications required for your custom leather fire helmets. Consider factors such as compliance with NFPA standards, weight, and design features.

Illustrative image related to custom leather fire helmets

- Key Features: Look for options like reflective strips, customizable colors, and specific liners that can enhance comfort and safety during use.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of custom leather fire helmets. Utilize online directories, trade shows, and industry recommendations to compile a list.

- Supplier Background: Investigate their history, customer reviews, and experience in the firefighting industry to ensure they have a solid track record.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that suppliers possess the necessary certifications to manufacture and distribute fire safety equipment. This includes compliance with local and international safety standards.

- Certification Types: Check for certifications like NFPA, OSHA, or ISO, which indicate adherence to safety and quality protocols.

Step 4: Request Samples and Customization Options

Once you have shortlisted potential suppliers, request samples of their helmets to assess quality and craftsmanship. Additionally, inquire about customization options available for your helmets.

- Customization Scope: Explore features such as helmet colors, insignia, and accessories that can enhance functionality and aesthetics.

Step 5: Understand Pricing and Payment Terms

Engage with suppliers to understand their pricing structures and payment terms. Be clear about your budget and any additional costs for customizations.

- Payment Arrangements: Many suppliers may require a deposit upfront, so ensure you understand the total cost and payment timeline before finalizing your order.

Step 6: Review Shipping and Fulfillment Times

Inquire about the estimated shipping and fulfillment timelines for your order. Custom helmets can have varying lead times based on the supplier’s production schedule.

- Logistical Considerations: Factor in potential delays, especially if your order is time-sensitive, and ensure that the supplier can provide regular updates on your order status.

Step 7: Establish After-Sales Support and Warranty Terms

Before completing your purchase, confirm the after-sales support and warranty terms offered by the supplier. This is crucial for addressing any issues that may arise post-delivery.

- Support Services: Check if they offer maintenance services, replacement parts, and customer service accessibility to assist you in the future.

Following this checklist will help you navigate the procurement process for custom leather fire helmets efficiently, ensuring you select a supplier that meets your department’s needs while adhering to safety standards.

Comprehensive Cost and Pricing Analysis for custom leather fire helmets Sourcing

What Are the Key Cost Components for Custom Leather Fire Helmets?

When sourcing custom leather fire helmets, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of leather significantly affects pricing. High-quality, vegetable-tanned leather tends to be more expensive but offers durability and comfort. Additionally, other materials used for padding, straps, and chinstraps also contribute to the overall material costs.

-

Labor: Skilled labor is essential in crafting custom helmets. The complexity of the design and the level of craftsmanship required can lead to variations in labor costs. Customization often involves more intricate work, increasing the labor component.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Overhead expenses can vary by region and supplier, impacting the final pricing.

-

Tooling: Custom molds and tools for specific helmet designs can incur significant upfront costs. These expenses may be amortized over larger orders, making them less impactful per unit when purchasing in bulk.

-

Quality Control (QC): Ensuring that helmets meet safety standards (like NFPA compliance) necessitates rigorous quality checks. This process can add to the overall cost but is vital for ensuring product safety and reliability.

-

Logistics: Shipping costs can fluctuate based on the origin and destination of the helmets. Factors such as shipping method, distance, and customs duties play a significant role in the logistics cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market conditions, competition, and the uniqueness of the product.

How Do Price Influencers Impact the Cost of Custom Leather Fire Helmets?

Several factors influence the pricing of custom leather fire helmets:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: The more customized the helmet, the higher the price. Features like color, additional safety components, and personalized engravings can drive costs up.

-

Materials and Quality Certifications: Helmets made from premium materials and those that meet specific safety certifications usually come at a higher price point. Ensure that the helmets align with local safety regulations, particularly in international markets.

-

Supplier Factors: Relationships with suppliers can lead to better pricing. Long-term partnerships may yield discounts or preferential terms, especially if you consistently place orders.

-

Incoterms: The terms of shipping and delivery can significantly influence costs. Understanding Incoterms can help clarify who is responsible for shipping costs, insurance, and customs duties, thus impacting the overall expenditure.

What Buyer Tips Can Help with Cost-Efficiency in Sourcing?

To enhance cost-efficiency when sourcing custom leather fire helmets, consider the following strategies:

-

Negotiation: Engage in negotiations with suppliers to secure favorable terms. Leverage your purchasing power and long-term potential as a customer to achieve better pricing.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, durability, and replacement costs over the helmet’s lifespan. Investing in higher-quality helmets may yield savings in the long run.

-

Pricing Nuances for International Buyers: Be aware of the additional costs associated with international transactions, such as tariffs and taxes. Research local regulations regarding fire safety equipment to ensure compliance, which can affect pricing.

-

Market Research: Conduct thorough market research to compare suppliers and their offerings. Understanding the competitive landscape can provide insights into fair pricing and product quality.

In conclusion, a comprehensive understanding of the cost components and pricing influencers for custom leather fire helmets is essential for B2B buyers. By applying these insights and strategies, you can make informed purchasing decisions that align with your organization’s needs and budget constraints.

Alternatives Analysis: Comparing custom leather fire helmets With Other Solutions

Introduction: Understanding Alternatives in Firefighter Headgear

In the firefighting industry, the choice of headgear is crucial for ensuring safety, comfort, and performance. While custom leather fire helmets are renowned for their durability and traditional appeal, various alternative solutions exist that may better suit specific operational needs. This analysis compares custom leather fire helmets with alternative options such as composite fire helmets and advanced helmet systems, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Custom Leather Fire Helmets | Composite Fire Helmets | Advanced Helmet Systems |

|---|---|---|---|

| Performance | High durability; traditional safety features | Lightweight; may lack some traditional features | Enhanced safety; integrated technology for communication and environmental monitoring |

| Cost | Higher upfront cost (approx. $1,200+) | Moderate cost (approx. $500-$900) | Variable cost; can exceed $1,500 depending on features |

| Ease of Implementation | Customization requires time (4-14 weeks) | Quick delivery; minimal customization | Complex setup; training required for advanced features |

| Maintenance | Requires regular care and upkeep | Low maintenance; durable materials | High maintenance; technology updates needed |

| Best Use Case | Traditional firefighting with historical value | Urban firefighting; scenarios requiring agility | High-tech scenarios; wildland firefighting with communication needs |

Detailed Breakdown of Alternatives

Composite Fire Helmets

Composite fire helmets are constructed from lightweight materials such as fiberglass or thermoplastics. They offer excellent protection while significantly reducing weight, which can enhance comfort during prolonged use. Their moderate price point makes them accessible for many fire departments. However, they may lack the historical significance and aesthetic appeal of leather helmets, which some firefighters prefer for traditional firefighting contexts. Additionally, while they provide adequate safety features, they may not match the durability of leather in extreme conditions.

Illustrative image related to custom leather fire helmets

Advanced Helmet Systems

Advanced helmet systems incorporate technology such as integrated communication devices, heads-up displays, and environmental monitoring sensors. These helmets are designed for modern firefighting challenges, particularly in high-tech environments. While they offer cutting-edge features that can enhance situational awareness and safety, they come at a higher price point and require thorough training for effective use. Maintenance can also be more demanding due to the technology involved, making them less practical for departments with budget constraints or those focused solely on traditional firefighting methods.

Conclusion: Making an Informed Choice for Firefighting Equipment

When selecting the right headgear for firefighting, B2B buyers must consider their specific operational needs, budget constraints, and the environments in which they will be working. Custom leather fire helmets offer unparalleled durability and a sense of tradition, making them ideal for departments valuing historical significance. On the other hand, composite helmets provide a cost-effective and lightweight alternative for urban firefighting. For those in high-tech or specialized firefighting roles, advanced helmet systems present innovative solutions but may involve higher costs and complexity. Ultimately, the decision should align with the department’s mission, operational requirements, and the safety of its personnel.

Essential Technical Properties and Trade Terminology for custom leather fire helmets

What Are the Key Technical Properties of Custom Leather Fire Helmets?

Understanding the essential technical properties of custom leather fire helmets is crucial for B2B buyers. These specifications not only influence the performance and safety of the helmets but also impact purchasing decisions for fire departments and organizations across various regions.

1. Material Grade

Leather fire helmets are primarily made from high-grade, vegetable-tanned leather. This type of leather is not only durable but also offers excellent heat resistance and flexibility. For B2B buyers, the material grade is pivotal, as it directly correlates with the helmet’s lifespan and protective capabilities. Higher-quality materials can lead to lower replacement costs over time, making it a smart investment.

2. Weight

The weight of a helmet is a critical specification that affects comfort and usability during extended firefighting operations. Many modern leather helmets, such as the Phenix TL-2, weigh approximately 55 ounces. A lighter helmet reduces neck fatigue, allowing firefighters to perform more effectively in high-stress situations. Buyers should consider weight as a key factor when assessing options for their teams.

3. Compliance Standards

Custom leather fire helmets must meet industry standards, such as NFPA 1971, which outlines the performance requirements for firefighting protective equipment. Compliance ensures that helmets provide adequate protection against heat, impact, and other hazards. B2B buyers must verify that the helmets they are purchasing are certified to these standards to ensure the safety of their personnel.

4. Customization Options

Customization is a significant aspect of B2B purchases in the firefighting sector. Options can include different colors, sizes, and additional features like reflective strips or ventilation systems. The ability to customize helmets allows departments to meet specific operational needs and personal preferences, enhancing both functionality and morale among firefighters.

Illustrative image related to custom leather fire helmets

5. Suspension System

A well-designed suspension system is critical for comfort and safety. It allows for adjustments in size and fit, ensuring that the helmet stays securely in place during use. Many helmets offer adjustable suspension liners that accommodate a range of head sizes. This is essential for B2B buyers aiming to provide a good fit for all team members, enhancing safety and comfort.

What Are Common Trade Terms Related to Custom Leather Fire Helmets?

Familiarity with industry jargon is essential for effective communication and decision-making in B2B transactions related to custom leather fire helmets. Below are several key terms that buyers should understand.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of fire helmets, understanding OEM relationships can help buyers identify the quality and reliability of the products being offered.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For custom leather fire helmets, understanding the MOQ is crucial for budget planning and inventory management. Departments must assess their needs to ensure they meet the supplier’s requirements without overcommitting financially.

Illustrative image related to custom leather fire helmets

3. RFQ (Request for Quotation)

An RFQ is a document used by businesses to solicit price quotes from suppliers for specific products or services. In the context of custom leather fire helmets, submitting an RFQ helps buyers compare pricing and features across different manufacturers, enabling informed purchasing decisions.

4. Incoterms

Incoterms are a series of pre-defined international trade terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in the shipping process. For B2B buyers of custom leather fire helmets, understanding Incoterms helps in negotiating terms of sale, delivery, and risk management.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. In the custom leather helmet market, lead times can vary significantly based on customization options and manufacturing schedules. Buyers need to account for lead times in their planning to ensure they receive products when needed, especially in emergency service scenarios.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right custom leather fire helmets for their teams.

Navigating Market Dynamics and Sourcing Trends in the custom leather fire helmets Sector

What Are the Current Market Dynamics Influencing Custom Leather Fire Helmets?

The custom leather fire helmets sector is experiencing notable growth driven by several global trends. An increasing emphasis on safety standards and regulations, particularly in firefighting, has led to a surge in demand for high-quality, compliant equipment. Fire departments worldwide, particularly in regions like Africa, South America, the Middle East, and Europe, are investing in advanced safety gear to protect their personnel effectively. This trend is compounded by the growing recognition of the ergonomic advantages offered by modern leather helmets, such as reduced neck fatigue and enhanced comfort during extended wear.

Emerging technologies, including advanced manufacturing techniques and customization options, are reshaping the sourcing landscape. B2B buyers are increasingly seeking suppliers that offer tailored solutions that meet specific departmental needs. For instance, options for lightweight materials, custom colors, and specialized features are becoming essential selling points. International buyers are also leveraging digital platforms for procurement, which streamlines the ordering process and enhances supply chain transparency.

Moreover, the impact of global supply chain disruptions has made buyers more cautious, prompting them to diversify their sourcing strategies. B2B buyers are now prioritizing suppliers with reliable delivery timelines and strong communication channels to mitigate risks associated with delays. As a result, the ability to provide clear shipping and fulfillment timelines has become a competitive differentiator in the market.

How Is Sustainability Shaping the Custom Leather Fire Helmets Industry?

Sustainability has become a critical concern in the custom leather fire helmets sector, influencing both sourcing decisions and product development. The environmental impact of leather production is under scrutiny, prompting manufacturers to adopt more sustainable practices. Ethical sourcing of leather, including the use of vegetable-tanned leather and adherence to responsible farming practices, is increasingly important for buyers who wish to minimize their ecological footprint.

Additionally, the demand for “green” certifications is rising. Buyers are looking for products that not only meet safety standards but also adhere to environmental regulations. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification can enhance the marketability of custom leather fire helmets and assure buyers of their commitment to sustainability.

Illustrative image related to custom leather fire helmets

Furthermore, companies that prioritize ethical supply chains are gaining a competitive edge. Transparency in sourcing, manufacturing processes, and labor practices is becoming a decisive factor for international buyers. This shift toward sustainability is not just a compliance measure; it is increasingly viewed as a brand differentiator that resonates with environmentally conscious consumers and organizations.

What Is the Historical Evolution of Custom Leather Fire Helmets?

The evolution of custom leather fire helmets is rooted in a rich history that reflects the advancements in firefighting practices. Leather helmets have been a staple in the fire service for centuries, with their origins tracing back to the 19th century when they were prized for their durability and protective qualities. Initially, these helmets were crafted from thick leather, providing essential protection against heat and falling debris.

Over time, technological innovations have transformed the design and functionality of leather helmets. Modern helmets are now engineered to be lighter and more ergonomic, incorporating advanced materials that enhance comfort and safety. The introduction of customizable features allows fire departments to tailor helmets to their specific needs, ensuring that they not only meet safety standards but also reflect the identity of the firefighting community.

Today, custom leather fire helmets symbolize a blend of tradition and innovation, serving as a testament to the evolution of firefighting gear in response to both technological advancements and the changing landscape of safety regulations. As the sector continues to develop, the commitment to quality and customization remains a key focus for manufacturers and buyers alike.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire helmets

-

How do I choose the right custom leather fire helmet for my needs?

Selecting the appropriate custom leather fire helmet involves understanding your specific requirements, such as compliance with safety standards (e.g., NFPA), desired features (e.g., weight, color, customization options), and the intended use. Consider the environment where the helmets will be used, as some models may offer better ventilation or insulation. It’s also beneficial to consult with your firefighting team to gather feedback on preferences, as comfort and fit are crucial for long-term use. -

What is the best type of leather fire helmet for international buyers?

The best type of leather fire helmet for international buyers typically combines safety, comfort, and durability. Helmets like the Phenix TL2 are known for their lightweight design and compliance with NFPA standards, making them suitable for various firefighting conditions. When sourcing, consider helmets that offer customization options to meet specific regional regulations and preferences. Prioritize suppliers with a solid reputation for quality and customer service. -

What are the typical payment terms for ordering custom leather fire helmets?

Payment terms can vary by supplier, but a common practice is to require a 50% deposit upon order confirmation, with the remaining balance due upon completion of the helmet or prior to shipping. Some suppliers may offer flexible payment options, including credit terms for repeat customers. Always clarify payment methods accepted, such as wire transfers or credit cards, and ensure that invoices detail all costs, including customization and shipping. -

What is the lead time for ordering custom leather fire helmets?

Lead times for custom leather fire helmets can range from 4 to 14 weeks, depending on the manufacturer and the complexity of the customization. It’s essential to communicate with suppliers about their production schedules and any potential delays due to materials or shipping logistics. For urgent needs, some manufacturers may offer expedited services for an additional fee, but this should be confirmed in advance. -

How can I ensure the quality of custom leather fire helmets?

To ensure quality, start by vetting suppliers through reviews, testimonials, and references from other buyers. Request samples or detailed specifications of the helmets to assess materials and craftsmanship. Confirm that the helmets comply with relevant safety standards, such as NFPA or OSHA. Additionally, inquire about the warranty and return policies to safeguard your investment in case of defects or dissatisfaction. -

What are the customization options available for leather fire helmets?

Customization options for leather fire helmets often include color choices, size adjustments, and features like earflaps, chin straps, and reflective decals. Some suppliers may also offer personalization, such as department insignias or individual names. Discuss your specific requirements with the supplier to understand what can be tailored to fit your needs and any associated costs. -

Are there minimum order quantities (MOQs) for purchasing custom leather fire helmets?

Many suppliers set minimum order quantities (MOQs) to ensure production efficiency and cost-effectiveness. MOQs can range from a single unit to several dozen, depending on the manufacturer. For international buyers, it’s advisable to check with suppliers about their MOQs and whether they can accommodate smaller orders, especially for first-time purchases or trial orders. -

What logistics considerations should I keep in mind when importing custom leather fire helmets?

When importing custom leather fire helmets, consider shipping methods, customs duties, and import regulations specific to your country. Work with suppliers who can provide clear shipping timelines and tracking information. It’s also wise to collaborate with a logistics provider experienced in international shipping to navigate any potential challenges. Lastly, ensure that all documentation, such as invoices and compliance certificates, is accurately completed to facilitate smooth customs clearance.

Top 7 Custom Leather Fire Helmets Manufacturers & Suppliers List

1. Ragtop Fire – Custom N5A Leather Helmet

Domain: ragtopfire.com

Registered: 2011 (14 years)

Introduction: Custom N5A Leather Helmet specifications include: factory black paint, lime/yellow tets, factory bend, cushion liner with 6″ black earflaps, GSP Bourkes, standard quick-release chinstrap, adjustable ratchet, silver acorn nuts, silver lock nuts, and a carved eagle front holder. A 50% deposit is required to place an order, with the remaining payment due after the helmet arrives at the shop. Estimate…

2. Engine Company – Build Your TL2 Leather Helmet (NFPA) Pre-Order

Domain: enginecompanyleather.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Build Your TL2 Leather Helmet (NFPA) Pre-Order”, “sku”: “”, “price”: “$1,219.85”, “availability”: “Unavailable”, “wait_time”: “4-14 weeks”, “features”: [“Lightest NFPA compliant leather helmet”, “Lightweight ergonomic design”, “Standard and deluxe comfort options available”, “Includes ESS FirePro goggles with long strap”], “color_options”: [“Flat Black”, “Black”, “Red”, “Scarlet …

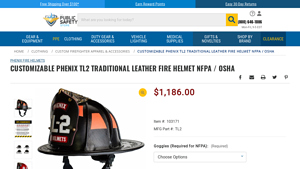

3. Phenix – TL2 Traditional Leather Fire Helmet

Domain: thepublicsafetystore.com

Registered: 2008 (17 years)

Introduction: Customizable Phenix TL2 Traditional Leather Fire Helmet NFPA / OSHA

– MSRP: $1,186.00

– Weight: Just under 3.5 pounds (55 ounces)

– NFPA compliant with required goggles (ESS or ATAC) for NFPA certification

– Custom options include:

– Nape Strap Ratchet Color

– Earlaps (NFPA or OSHA)

– Tetrahedrons (NFPA colors: Lime Green/Yellow, Red/Orange; OSHA colors: Silver, Black, None)

– Chin Strap (…

4. Dinges Fire Company – Leather Fire Helmets

Domain: dingesfire.com

Registered: 2016 (9 years)

Introduction: Leather Fire Helmets – American Heritage and TL2 Leather Fire Helmets from Dinges Fire Company. Features include durable construction with tanned leather and fiberglass, lightweight options, and customizable features such as name stamping. Available for NFPA and OSHA compliance. Helmets are sourced from industry-leading manufacturers like LION and Phenix. Additional accessories and parts for helme…

5. Fully Involved Leatherworks – Stitched Leather Fire Helmet Chin Strap

Domain: fullyinvolvedleatherworks.com

Registered: 2014 (11 years)

Introduction: Stitched Leather Fire Helmet Chin Strap by Fully Involved Leatherworks

– Width: 5/8″

– Leather Thickness: 9/10 oz American Zebu Hides

– Overall Length: 29″ when extended

– Features: Stitched edges, postman slide buckle for quick tightening, oversized side squeeze connection buckle for quick helmet release

– Color Options: Black w/ Black Stitching, Black w/ Red Stitching, Blue w/ Black Stitching, G…

6. West Coast Fire Helmets – Leather Firefighting Helmets

Domain: westcoast-firehelmets.com

Registered: 2023 (2 years)

Introduction: West Coast Fire Helmets specializes in leather firefighting helmets, including Cairns MSA, Phenix Technologies, and Legacy Series 1866-1849 presentation helmets. They offer a variety of parts and upgrade options, including 5 Alarm Leather Chin Straps, Leatherhead concepts NFPA leather chin straps, DKE tetrahedrons, GSP Bourkes, Liberty art Works Shield Holders, Abbey Brass hardware, Monster spikes…

7. Box31 Leather – Custom Leather Helmet Fronts

Domain: box31leather.com

Registered: 2019 (6 years)

Introduction: This company, Box31 Leather – Custom Leather Helmet Fronts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom leather fire helmets

In the ever-evolving landscape of firefighting equipment, strategic sourcing of custom leather fire helmets presents a unique opportunity for international buyers. By understanding the diverse options available—from lightweight ergonomic designs to customizable features—purchasers can ensure they select helmets that enhance safety and comfort for their teams. The emphasis on NFPA compliance underscores the importance of investing in quality products that meet rigorous safety standards, thereby reducing long-term costs associated with injuries or equipment failures.

Establishing relationships with reputable manufacturers not only streamlines the procurement process but also guarantees access to the latest innovations in helmet technology. As global demand for high-quality firefighting gear continues to rise, especially in regions such as Africa, South America, the Middle East, and Europe, buyers are encouraged to evaluate suppliers who demonstrate reliability and responsiveness.

Looking ahead, the integration of advanced materials and customization options will likely redefine the standards of firefighter safety and performance. Now is the time for international buyers to leverage strategic sourcing to enhance their firefighting capabilities, ensuring that their teams are equipped with the best tools for the job. Engage with trusted suppliers today to secure the finest custom leather fire helmets for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather fire helmets