Introduction: Navigating the Global Market for custom leather sheath

In the competitive landscape of the global market for custom leather sheaths, B2B buyers face the crucial challenge of sourcing high-quality products that meet their specific needs while ensuring reliability and craftsmanship. This guide serves as a comprehensive resource, addressing key aspects such as the various types of custom leather sheaths available, their diverse applications across industries, and the nuances of supplier vetting processes. With detailed insights into cost factors, material quality, and design options, international buyers from regions like Africa, South America, the Middle East, and Europe—including countries like Germany and Saudi Arabia—will find the information vital for making informed purchasing decisions.

The custom leather sheath market is characterized by a blend of traditional craftsmanship and modern innovation, offering an array of styles tailored for different knives and uses. Whether you are looking for sheaths for outdoor survival knives, tactical blades, or collectible pieces, understanding the market dynamics is essential. This guide empowers buyers by providing actionable insights into supplier selection, quality assessment, and negotiation tactics, ensuring that you can procure products that not only enhance your offerings but also align with your brand’s values. By navigating this guide, you will be equipped to tackle challenges in sourcing and elevate your product portfolio with premium custom leather sheaths that resonate with your clientele.

Table Of Contents

- Top 7 Custom Leather Sheath Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather sheath

- Understanding custom leather sheath Types and Variations

- Key Industrial Applications of custom leather sheath

- 3 Common User Pain Points for ‘custom leather sheath’ & Their Solutions

- Strategic Material Selection Guide for custom leather sheath

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sheath

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sheath’

- Comprehensive Cost and Pricing Analysis for custom leather sheath Sourcing

- Alternatives Analysis: Comparing custom leather sheath With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather sheath

- Navigating Market Dynamics and Sourcing Trends in the custom leather sheath Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sheath

- Strategic Sourcing Conclusion and Outlook for custom leather sheath

- Important Disclaimer & Terms of Use

Understanding custom leather sheath Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pancake Sheath | Flat design, often with a belt attachment, allowing for easy carry. | Outdoor gear manufacturers, retailers | Pros: Slim profile, easy access. Cons: Limited blade protection compared to bulkier designs. |

| Dangler Sheath | Features a removable dangler for versatile carry options. | Survival gear suppliers, custom knife makers | Pros: Adaptable for various carrying styles. Cons: May require additional hardware. |

| Cross Draw Sheath | Designed for cross-body carry, enhancing accessibility. | Tactical equipment suppliers, hunters | Pros: Quick access, comfortable for long periods. Cons: May not fit all body types comfortably. |

| Multi-tool Sheath | Designed to hold multi-tools along with knives, often with extra pockets. | Outdoor and camping gear retailers | Pros: Versatile, accommodates various tools. Cons: Can be bulkier than standard sheaths. |

| Lined Sheath | Features additional lining for enhanced protection and durability. | High-end knife manufacturers, collectors | Pros: Superior protection, aesthetically pleasing. Cons: Higher cost, may require longer production time. |

What are the Characteristics of Pancake Sheaths?

Pancake sheaths are characterized by their flat, minimalist design that hugs the body closely. This type of sheath is ideal for outdoor gear manufacturers and retailers who prioritize easy access and a slim profile. Buyers should consider the sheath’s ability to provide adequate protection for the blade while maintaining a lightweight feel. The pancake style is particularly popular among users who prefer a low-profile carry option, making it suitable for everyday use.

How Do Dangler Sheaths Enhance Versatility?

Dangler sheaths include a removable attachment that allows for various carrying positions, catering to the diverse needs of outdoor enthusiasts and survivalists. These sheaths are particularly appealing to survival gear suppliers and custom knife makers who want to offer their clients adaptable solutions. When purchasing, businesses should evaluate the quality of the hardware and the sheath’s compatibility with different knife models, ensuring that it meets the specific requirements of their target market.

What are the Benefits of Cross Draw Sheaths?

Cross draw sheaths are designed for cross-body carry, providing quick access to the blade without compromising comfort. This type is favored by tactical equipment suppliers and hunters who require immediate access to their knives in the field. When considering a cross draw sheath, B2B buyers should assess the fit and comfort for various body types, as well as the sheath’s retention capabilities to ensure safety during movement.

Why Choose Multi-tool Sheaths for Outdoor Applications?

Multi-tool sheaths are designed to accommodate both knives and multi-tools, often featuring additional pockets for accessories. This versatility makes them a popular choice among outdoor and camping gear retailers. Buyers should focus on the sheath’s capacity to securely hold various tools while ensuring easy access. The added functionality can enhance customer satisfaction and encourage repeat purchases, making it a strategic addition to product lines.

Illustrative image related to custom leather sheath

How Do Lined Sheaths Provide Superior Protection?

Lined sheaths incorporate an inner layer that offers additional protection for the blade, making them ideal for high-end knife manufacturers and collectors. These sheaths not only provide enhanced durability but also add an aesthetic appeal that can attract discerning customers. Businesses should consider the materials used for lining and the overall craftsmanship, as these factors can significantly impact the product’s value and customer perception.

Key Industrial Applications of custom leather sheath

| Industry/Sector | Specific Application of custom leather sheath | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor & Adventure Gear | Custom sheaths for knives and multi-tools used in expeditions | Enhanced product offerings that cater to outdoor enthusiasts | Quality of leather, craftsmanship, and customization options |

| Military & Defense | Sheaths for tactical knives and survival tools | Improved gear reliability and functionality in critical situations | Compliance with military specifications and durability standards |

| Culinary & Hospitality | Sheaths for chef knives and culinary tools | Protection of high-value knives, enhancing safety and longevity | Material quality, design aesthetics, and ergonomic features |

| Craftsmanship & Artistry | Custom sheaths for handmade knives and art pieces | Unique branding opportunities and differentiation in the market | Artisan craftsmanship, bespoke designs, and material sourcing |

| Agriculture & Farming | Sheaths for farming and utility knives | Increased efficiency and safety for agricultural tasks | Durability, resistance to environmental factors, and custom fit |

How Are Custom Leather Sheaths Used in the Outdoor & Adventure Gear Sector?

In the outdoor and adventure gear industry, custom leather sheaths are essential for protecting knives and multi-tools used during expeditions. These sheaths not only safeguard the blades from damage but also provide a secure carry option for outdoor enthusiasts. Buyers in this sector often seek high-quality leather that can withstand various environmental conditions, as well as customizable features like belt attachments and specific designs. For international buyers, sourcing from reputable manufacturers who can deliver consistent quality is crucial.

What Role Do Custom Leather Sheaths Play in the Military & Defense Industry?

The military and defense sector relies on custom leather sheaths for tactical knives and survival tools. These sheaths ensure that the knives are readily accessible while providing protection and durability in challenging environments. Military buyers typically require sheaths that meet specific durability and performance standards, often necessitating rigorous testing. Additionally, compliance with military specifications is a key consideration, making it essential for suppliers to demonstrate their products’ reliability under extreme conditions.

How Are Custom Leather Sheaths Beneficial in the Culinary & Hospitality Sector?

In the culinary and hospitality industry, custom leather sheaths are used to protect high-quality chef knives and culinary tools. These sheaths enhance safety by preventing accidental cuts and prolonging the lifespan of expensive knives. Buyers in this sector often prioritize aesthetics and functionality, seeking sheaths that complement their branding while offering practical features. International buyers must consider local culinary traditions and preferences when sourcing, ensuring that the sheath designs align with regional styles.

Illustrative image related to custom leather sheath

Why Are Custom Leather Sheaths Important for Craftsmanship & Artistry?

Craftsmanship and artistry sectors utilize custom leather sheaths for handmade knives and art pieces, providing a unique branding opportunity. These sheaths not only serve as functional accessories but also enhance the overall presentation of the crafted items. Buyers typically look for artisan craftsmanship, bespoke designs, and the use of high-quality materials to reflect the artistry involved. International buyers should focus on suppliers with a strong reputation for quality and creativity, ensuring that the final product resonates with their target market.

How Do Custom Leather Sheaths Enhance Efficiency in Agriculture & Farming?

In agriculture and farming, custom leather sheaths are used to protect utility knives and farming tools. These sheaths contribute to increased efficiency and safety by ensuring that tools are easily accessible and protected from wear and tear. Buyers in this sector often require durable materials that can withstand harsh working conditions, as well as designs that allow for easy attachment to work gear. When sourcing internationally, buyers should consider local agricultural practices and environmental factors that may influence material choice and design specifications.

3 Common User Pain Points for ‘custom leather sheath’ & Their Solutions

Scenario 1: Sizing Challenges for Custom Leather Sheaths

The Problem: One of the most common issues faced by B2B buyers is obtaining an accurate size for the custom leather sheath. Miscommunication regarding the knife dimensions can lead to a sheath that is either too loose or too tight, which can compromise safety and functionality. This is particularly critical for businesses that require high-quality sheaths for knives used in precise applications, such as in culinary settings or outdoor expeditions. Ensuring that the sheath fits correctly is essential to prevent damage to the blade and to facilitate easy access during use.

Illustrative image related to custom leather sheath

The Solution: To avoid sizing discrepancies, buyers should provide detailed specifications when ordering a custom leather sheath. This includes not only the knife length and width but also the blade shape and handle dimensions. A practical approach is to create a standardized form that includes all the necessary measurements and pictures of the knife, allowing manufacturers to visualize the product clearly. Furthermore, consider establishing a communication protocol where buyers can discuss the requirements directly with the sheath maker before finalizing the order. This can include video calls or sending the knife for a precise fit, which is a common practice among reputable manufacturers.

Scenario 2: Quality Assurance in Custom Leather Sheaths

The Problem: Quality concerns are another significant pain point for B2B buyers, especially when sourcing custom leather sheaths from international suppliers. The fear of receiving subpar materials or poorly constructed products can hinder purchasing decisions. This is particularly relevant for buyers in regions where the market is flooded with cheaper, lower-quality options that do not stand up to rigorous use, leading to costly returns and dissatisfaction among end-users.

The Solution: To ensure high-quality purchases, B2B buyers should implement a thorough vetting process for suppliers. This includes requesting samples of leather, examining stitching quality, and reviewing testimonials from other businesses. Engaging in a trial order can also be beneficial; start with a small batch to assess quality before committing to a larger order. Additionally, consider suppliers who offer guarantees or warranties, as these can be indicators of their confidence in the product quality. Building a long-term relationship with a reputable supplier can also ensure consistent quality and reliability.

Scenario 3: Design Limitations and Customization Options

The Problem: Another challenge faced by buyers is the limitation in design options for custom leather sheaths. Many suppliers may offer a narrow range of styles, colors, or features, which can restrict a buyer’s ability to match the sheath with their brand identity or specific functional needs. This limitation can lead to dissatisfaction, particularly for businesses that prioritize aesthetics and branding in their tools and equipment.

Illustrative image related to custom leather sheath

The Solution: To overcome design limitations, buyers should engage with manufacturers that specialize in bespoke solutions. Clearly articulate your design vision, including preferred colors, textures, and functional features, such as additional pockets or attachment options. Suppliers that pride themselves on craftsmanship often welcome creative input and can accommodate unique requests. Additionally, asking for previous examples of custom work can provide inspiration and help buyers understand the range of possibilities. Establishing a collaborative relationship where buyers can discuss their design ideas openly can lead to innovative and personalized sheath solutions that meet both functional and branding needs.

Strategic Material Selection Guide for custom leather sheath

What Are the Key Materials Used in Custom Leather Sheaths?

When selecting materials for custom leather sheaths, several options stand out based on their properties, performance, and suitability for various applications. Understanding these materials is crucial for international B2B buyers seeking to meet specific requirements in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Full-Grain Leather Perform in Custom Leather Sheaths?

Full-grain leather is often considered the premier choice for custom leather sheaths due to its durability and natural aesthetics. It retains the hide’s original texture, which not only enhances its visual appeal but also provides superior resistance to wear and tear. Full-grain leather can withstand significant pressure and is less prone to cracking or peeling over time.

Illustrative image related to custom leather sheath

Pros: This material offers excellent durability and a luxurious finish, making it suitable for high-end products. Its breathability and moisture-wicking properties also help in maintaining the integrity of the knife housed within.

Cons: However, full-grain leather can be more expensive and may require more complex manufacturing processes, which could increase lead times. Additionally, it may need regular maintenance to keep it looking its best.

Impact on Application: Full-grain leather is compatible with various climates, making it ideal for international markets. Buyers should ensure compliance with local leather treatment standards, such as those set by ASTM or DIN.

What Are the Advantages of Top-Grain Leather for Sheaths?

Top-grain leather is a slightly more affordable alternative to full-grain leather while still offering good durability and a refined appearance. It is sanded and finished to remove imperfections, resulting in a smoother surface.

Illustrative image related to custom leather sheath

Pros: This material is easier to work with and can be produced more quickly, making it suitable for high-volume orders. It also offers a good balance between cost and quality, appealing to a broader range of buyers.

Cons: While it is still durable, top-grain leather is not as robust as full-grain leather and may show signs of wear faster. It is also less breathable, which could affect the longevity of the knife it protects.

Impact on Application: Top-grain leather is widely accepted in various markets, but buyers should be aware of any specific local regulations regarding leather sourcing and treatment.

How Does Synthetic Leather Compare to Natural Options?

Synthetic leather, or faux leather, has gained popularity due to its lower cost and ethical considerations. It is made from plastic materials, providing a waterproof option that can be advantageous in humid or wet environments.

Illustrative image related to custom leather sheath

Pros: Synthetic leather is generally more resistant to stains and easier to clean than natural leather. It can also be produced in a variety of colors and textures, allowing for customization.

Cons: However, synthetic leather may not offer the same level of durability or aesthetic appeal as natural leather. It can wear out more quickly and may not provide the same level of protection for the knife.

Impact on Application: This material is particularly appealing to buyers in regions where cost is a significant factor. However, compliance with environmental regulations regarding plastics should be considered.

What Role Does Suede Leather Play in Custom Sheath Applications?

Suede leather, made from the underside of the hide, is known for its soft texture and unique appearance. It is often used for decorative elements in custom sheaths.

Pros: Suede offers a distinctive look and feel that can enhance the overall design of the sheath. It is also lightweight and flexible, making it easy to work with.

Illustrative image related to custom leather sheath

Cons: On the downside, suede is less durable than other leather types and is more susceptible to stains and moisture damage. It may require special care to maintain its appearance.

Impact on Application: Buyers should consider the specific use case for suede sheaths, particularly in markets where aesthetics are prioritized over durability. Compliance with local leather standards is also essential.

Summary of Material Selection for Custom Leather Sheaths

| Material | Typical Use Case for custom leather sheath | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end custom sheaths | Superior durability and aesthetics | Higher cost and maintenance needs | Hoch |

| Top-Grain Leather | Mid-range custom sheaths | Good balance of quality and cost | Less durable than full-grain | Medium |

| Synthetic Leather | Budget-friendly options | Waterproof and easy to clean | Less durable and appealing | Low |

| Suede Leather | Decorative elements | Unique look and feel | Susceptible to stains and moisture | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in various international markets, ensuring they can make informed decisions based on performance, cost, and compliance considerations.

Illustrative image related to custom leather sheath

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sheath

What Are the Key Stages in the Manufacturing Process of Custom Leather Sheaths?

The manufacturing process of custom leather sheaths involves several crucial stages, each contributing to the final product’s quality and functionality. Understanding these stages helps B2B buyers assess suppliers more effectively.

Material Preparation: How Is Leather Selected and Prepared?

The first step in manufacturing custom leather sheaths is the selection of high-quality leather. Suppliers typically use materials like English bridle leather, known for its durability and aesthetic appeal. Once selected, the leather undergoes several preparatory processes, including:

- Tanning: This process preserves the leather, making it resistant to decay and enhancing its durability. Different tanning methods, such as vegetable tanning, can affect the leather’s texture and appearance.

- Cutting: After tanning, the leather is cut to the specific dimensions required for the sheath. Accurate cutting is crucial for ensuring a snug fit for the knife it will house.

Forming: What Techniques Are Used to Shape the Leather?

Forming is the stage where the leather is shaped into the desired sheath design. Key techniques include:

- Wet Molding: This technique involves soaking the leather in water to make it pliable. The leather is then molded around the knife to ensure a perfect fit. This step is vital for achieving optimal retention and functionality.

- Stitching: Hand-stitching or machine-stitching is employed to assemble the sheath components. Hand-stitching is often preferred for custom sheaths due to its strength and aesthetic quality.

Assembly: How Are Components Joined Together?

During the assembly stage, the various parts of the sheath are joined. This can involve:

- Adding Hardware: Depending on the design, additional elements like rivets, snaps, and straps may be incorporated. Military-grade hardware is often utilized for enhanced durability, especially for outdoor and tactical applications.

- Quality Control Checkpoints: At this stage, manufacturers typically conduct an initial quality control check to ensure that all components meet the specifications.

Finishing: What Final Touches Are Applied to the Sheath?

The finishing stage enhances the sheath’s appearance and durability. Common processes include:

- Edge Finishing: Edges are trimmed and treated to prevent fraying and enhance aesthetics.

- Dyeing and Conditioning: Leather may be dyed to achieve the desired color, followed by conditioning to maintain suppleness and prevent cracking.

- Final Quality Check: A comprehensive final quality check (FQC) ensures that the sheath meets all design and functional specifications before shipping.

How Is Quality Assurance Managed in Custom Leather Sheath Manufacturing?

Quality assurance (QA) is critical in the custom leather sheath manufacturing process, ensuring that the final products meet international standards and customer expectations.

Illustrative image related to custom leather sheath

What International Standards Apply to Leather Sheath Manufacturing?

For B2B buyers, understanding applicable international standards is essential for ensuring product quality. Common standards include:

- ISO 9001: This standard sets out criteria for a quality management system and is based on principles such as customer focus, leadership, and continual improvement. Manufacturers adhering to ISO 9001 demonstrate their commitment to quality and customer satisfaction.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Effective quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet required specifications.

- In-Process Quality Control (IPQC): During manufacturing, processes are monitored to catch defects early. This may involve regular checks of stitching accuracy, leather thickness, and hardware placement.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures that it meets design specifications, functions correctly, and is free from defects.

How Can B2B Buyers Verify a Supplier’s Quality Control Practices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial.

What Methods Can Be Used to Assess Supplier Quality?

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and working conditions directly. This can provide insights into the supplier’s commitment to quality.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s QC practices and any issues encountered during production.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality.

What Nuances Should International Buyers Consider Regarding Quality Control?

Understanding quality control nuances is essential for international B2B buyers. Here are some considerations:

- Cultural Differences: Different regions may have varying standards and practices concerning quality control. Buyers should be aware of these differences to ensure effective communication and expectation management.

- Regulatory Compliance: Buyers must ensure that suppliers comply with local regulations, which may differ significantly across countries. Understanding these regulations is essential for avoiding legal issues and ensuring product safety.

Conclusion: Ensuring Quality in Custom Leather Sheaths

In summary, the manufacturing processes for custom leather sheaths are intricate and require meticulous attention to detail at every stage. By understanding the manufacturing stages and the importance of quality assurance, B2B buyers can make informed decisions when selecting suppliers. Ensuring compliance with international standards and conducting thorough quality checks can significantly enhance the reliability and satisfaction of custom leather sheath products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sheath’

When sourcing custom leather sheaths, it’s essential to follow a structured approach that ensures quality, functionality, and alignment with your specific needs. This guide provides a step-by-step checklist to help international B2B buyers effectively navigate the procurement process.

Illustrative image related to custom leather sheath

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical requirements of the custom leather sheath you need. This includes details such as the knife dimensions (length, width), the style of the sheath (e.g., pancake, pouch, or cross-draw), and the type of leather (e.g., vegetable-tanned or English bridle leather).

– Considerations: Ensure to note any specific features such as retention methods, carry orientation (right or left side), and additional accessories like belt loops or clips.

Step 2: Research Potential Suppliers

Invest time in researching various suppliers who specialize in custom leather goods. Look for companies with a proven track record in producing high-quality leather sheaths.

– Resources: Utilize online directories, trade shows, and industry forums to gather a list of potential manufacturers. Pay attention to their reviews and testimonials, particularly from clients in your region.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist of suppliers, assess their manufacturing capabilities. This includes checking their production processes, craftsmanship, and quality control measures.

– Key Questions: Inquire about the types of leather they use, their stitching techniques, and whether they offer customization options such as color and design. A supplier’s ability to meet your specific needs is crucial for a successful partnership.

Step 4: Request Samples and Prototypes

Before making a bulk order, request samples or prototypes of the sheath. This step allows you to evaluate the quality, fit, and overall aesthetics of the product.

– Why It Matters: Physical samples can reveal the craftsmanship level and help you gauge whether the supplier’s offerings align with your expectations. Consider providing your own knife for a tailored fit if necessary.

Step 5: Verify Supplier Certifications

Ensure that the suppliers you are considering meet necessary industry standards and certifications. This may include compliance with environmental regulations, quality management systems, and ethical sourcing practices.

– Importance: Certifications can provide assurance of the supplier’s commitment to quality and sustainability, which is increasingly important for B2B buyers in international markets.

Step 6: Discuss Terms and Conditions

Before finalizing your order, have a clear discussion about payment terms, lead times, and shipping arrangements. Transparency in these areas can prevent misunderstandings later in the process.

– Considerations: Ensure you understand the supplier’s policies on returns, defects, and warranty coverage, as these can significantly impact your satisfaction and operational efficiency.

Step 7: Establish a Communication Plan

Effective communication is key to successful sourcing. Establish a clear plan for how you will communicate with your supplier throughout the process.

– Best Practices: Set regular check-ins and updates, and use collaborative tools to share designs and modifications. This proactive approach can help address any issues promptly and foster a strong working relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom leather sheaths, ensuring they partner with the right suppliers to meet their specific needs.

Comprehensive Cost and Pricing Analysis for custom leather sheath Sourcing

What Are the Key Cost Components for Custom Leather Sheath Production?

When sourcing custom leather sheaths, understanding the cost structure is crucial. The primary components influencing the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of leather significantly impacts cost. High-quality leathers such as English bridle leather or exotic leathers may raise material costs. Additionally, hardware and accessories, such as snaps and buckles, add to the expense.

-

Labor: Skilled craftsmanship is essential for producing durable and aesthetically pleasing sheaths. Labor costs can vary based on the complexity of the design, the expertise required, and the region where production occurs.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment. Efficient production processes can help minimize overhead, but high-quality craftsmanship often requires more time and resources.

-

Tooling: Custom designs may require specialized tools or molds, which can incur additional costs. These costs are often amortized over production runs, so larger orders may benefit from lower per-unit tooling costs.

-

Quality Control: Rigorous QC processes ensure that each sheath meets buyer specifications. This step is vital for maintaining quality, particularly for B2B buyers who may have specific standards or certifications.

-

Logistics: Shipping costs can vary significantly based on the destination, particularly for international shipments. Understanding Incoterms can help buyers anticipate logistics expenses.

-

Margin: Suppliers will incorporate a profit margin into their pricing, which can vary based on competition, market demand, and the supplier’s business model.

How Do Price Influencers Affect Custom Leather Sheath Costs?

Several factors can influence the pricing of custom leather sheaths, making it essential for buyers to consider these when negotiating:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders typically result in lower per-unit costs due to economies of scale.

-

Specifications and Customization: The level of customization directly impacts price. More intricate designs, unique materials, or specialized features will increase costs.

-

Quality and Certifications: Products that meet specific industry standards or certifications may command higher prices due to the assurance of quality and compliance.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: Understanding the terms of trade, including who is responsible for shipping and insurance, can help buyers manage logistics costs effectively.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

Illustrative image related to custom leather sheath

-

Establish Relationships: Building a strong relationship with suppliers can lead to better pricing and terms over time. Frequent communication and trust can enhance negotiations.

-

Leverage Volume: If possible, consolidate orders to meet MOQ thresholds, which can lower costs per unit. Consider long-term contracts for better pricing stability.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial pricing, consider the TCO, which includes maintenance, durability, and potential returns on investment. A higher initial cost may yield savings in the long run if the product is more durable.

-

Understand Regional Pricing Nuances: International buyers should be aware of pricing variations due to local market conditions, tariffs, and exchange rates. Always clarify these factors before finalizing a deal.

Conclusion: What Should Buyers Keep in Mind Regarding Indicative Prices?

While indicative prices for custom leather sheaths can range widely—often starting around $95 for simpler designs and exceeding $250 for highly customized options—buyers should approach these figures as starting points. Customization, material choice, and order size are critical in determining final pricing. Engaging in thorough research and effective negotiation can help buyers secure the best possible terms for their custom leather sheath needs.

Alternatives Analysis: Comparing custom leather sheath With Other Solutions

When considering the protection and portability of knives, a custom leather sheath is a popular choice. However, there are alternative solutions available that may better suit specific business needs. This analysis will compare custom leather sheaths against two viable alternatives: synthetic sheaths and Kydex sheaths.

| Comparison Aspect | Custom Leather Sheath | Synthetic Sheath | Kydex Sheath |

|---|---|---|---|

| Performance | High durability, excellent aesthetic appeal | Moderate durability, less aesthetic | High durability, excellent retention |

| Cost | Typically higher (e.g., $250) | Lower cost (e.g., $50 – $100) | Moderate cost (e.g., $100 – $150) |

| Ease of Implementation | Requires custom measurements and craftsmanship | Readily available, minimal customization | Custom molds available, easy to order |

| Wartung | Requires conditioning and care | Low maintenance | Low maintenance |

| Best Use Case | Personalized, high-end knives | General use, budget-conscious buyers | Tactical applications, high retention |

What Are the Advantages and Disadvantages of Synthetic Sheaths?

Synthetic sheaths are often made from materials such as nylon or other polymers. One of the primary advantages of synthetic sheaths is their cost-effectiveness, making them a suitable choice for businesses on a budget. They are readily available in various sizes and styles, which simplifies the ordering process. However, synthetic materials may not offer the same level of durability or aesthetic appeal as leather, and they can wear out more quickly under heavy use. Additionally, they may not provide the same level of retention and protection for high-end blades.

Illustrative image related to custom leather sheath

How Do Kydex Sheaths Compare in Terms of Functionality?

Kydex sheaths are made from a thermoplastic material that is known for its strength and durability. These sheaths offer excellent retention, ensuring that knives stay securely in place during transport. Kydex is also resistant to moisture and environmental conditions, making it a practical choice for outdoor or tactical applications. However, they often lack the visual appeal of custom leather sheaths, as they tend to have a more utilitarian design. Additionally, Kydex sheaths may require specific molds for custom knives, which can increase the lead time for production.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a sheath for knives, B2B buyers should evaluate their specific requirements, including budget, desired aesthetics, and intended use. Custom leather sheaths may be ideal for businesses looking to offer premium products that enhance brand image and customer satisfaction. Conversely, if cost and practicality are higher priorities, synthetic or Kydex sheaths could provide adequate protection without breaking the bank. Ultimately, understanding the unique needs of the target market will help buyers make an informed decision that aligns with their business goals.

Essential Technical Properties and Trade Terminology for custom leather sheath

What Are the Key Technical Properties of a Custom Leather Sheath?

Understanding the essential technical properties of a custom leather sheath is crucial for B2B buyers to make informed purchasing decisions. Below are critical specifications that define the quality and functionality of these products:

1. Material Grade

The quality of leather used in the sheath significantly impacts its durability and performance. High-grade leather, such as full-grain or English bridle leather, is preferred for its strength, flexibility, and resistance to wear. B2B buyers should prioritize suppliers who provide detailed information about the leather grade to ensure longevity and customer satisfaction.

2. Thickness

Leather thickness typically ranges from 4 to 8 ounces, affecting the sheath’s rigidity and protection level. Thicker leather offers better protection for the blade but may add weight. Buyers should consider the intended use of the sheath—whether for everyday carry or specialized environments—to choose the appropriate thickness.

Illustrative image related to custom leather sheath

3. Stitching Quality

The stitching method used in the sheath construction can determine its durability and aesthetic appeal. Hand-stitched sheaths are often seen as superior due to the precision and craftsmanship involved. B2B buyers should inquire about the stitching techniques used, such as saddle stitching, which provides added strength and resilience compared to machine stitching.

4. Retention Mechanism

Retention mechanisms, such as snaps, friction fit, or magnetic closures, are essential for securing the knife within the sheath. The choice of retention method affects ease of access and security during transport. Buyers should assess their specific requirements based on how frequently the knife will be used and the environments in which it will be carried.

5. Customization Options

Customization capabilities, including size adjustments, color choices, and unique design elements, are critical for meeting the specific needs of clients. Many suppliers offer a range of customization options, allowing B2B buyers to tailor the sheath to their brand or customer preferences, enhancing marketability.

6. Warranty and Return Policies

A robust warranty and clear return policy are indicators of the manufacturer’s confidence in their product. Buyers should seek suppliers that offer lifetime warranties or satisfaction guarantees, ensuring that they can trust the quality and durability of their investment.

What Are Common Trade Terms Related to Custom Leather Sheaths?

Familiarizing oneself with industry terminology is essential for effective communication and negotiation in the B2B sector. Here are some common jargon and trade terms relevant to custom leather sheaths:

Illustrative image related to custom leather sheath

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of custom leather sheaths, an OEM might create sheaths for knife manufacturers who sell them under their own brand. Understanding OEM relationships can help buyers identify potential sources for bespoke products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For custom leather sheaths, MOQs can vary significantly based on the manufacturer and the complexity of the customization. B2B buyers should clarify MOQs to ensure that their order aligns with their business needs without incurring excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For custom leather sheaths, issuing an RFQ allows buyers to gather detailed pricing and availability information, enabling them to compare offers and make informed purchasing decisions.

Illustrative image related to custom leather sheath

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized standard trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for B2B buyers to understand shipping costs and risk management associated with purchasing custom leather sheaths from global suppliers.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. Understanding lead times for custom leather sheaths is crucial for planning inventory and meeting customer demands. Buyers should always confirm lead times with suppliers to ensure timely delivery.

6. Custom Duty

Custom duty is a tax imposed on goods when they are transported across international borders. Buyers should be aware of any applicable customs duties when importing custom leather sheaths, as these costs can significantly affect the overall price and budgeting for their procurement strategy.

By understanding these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing custom leather sheaths more effectively, ensuring that their purchases meet both quality standards and business requirements.

Illustrative image related to custom leather sheath

Navigating Market Dynamics and Sourcing Trends in the custom leather sheath Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Sheath Sector?

The custom leather sheath market is currently experiencing a significant surge, driven by several global factors. The increasing popularity of outdoor activities, such as hiking and camping, has led to a heightened demand for high-quality, durable knife sheaths. Additionally, the rise of artisanal craftsmanship in the leather goods sector has encouraged consumers and businesses alike to seek out custom solutions that offer a blend of functionality and aesthetic appeal. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide tailored products that meet specific needs, whether for personal use or commercial resale.

Emerging technologies, such as 3D printing and advanced leather treatment methods, are also reshaping the sourcing landscape. These innovations enable manufacturers to create intricate designs and enhance the durability of leather products, appealing to businesses that prioritize quality and customization. Furthermore, the rise of e-commerce platforms has simplified the procurement process, allowing international buyers to easily connect with manufacturers across the globe. As a result, B2B buyers are now more empowered than ever to negotiate terms, explore various options, and make informed purchasing decisions.

How Is Sustainability and Ethical Sourcing Influencing the Custom Leather Sheath Market?

Sustainability has become a pivotal concern for B2B buyers in the custom leather sheath sector. The environmental impact of leather production, including deforestation and pollution from tanning processes, has prompted a shift towards ethical sourcing practices. Buyers are increasingly prioritizing suppliers who use eco-friendly materials and sustainable production methods. This includes sourcing leather from tanneries that adhere to strict environmental regulations and utilize vegetable-tanned leather, which is less harmful to the environment compared to traditional chrome-tanned options.

Moreover, certifications such as the Leather Working Group (LWG) certification and other ‘green’ labels are gaining traction in the market. These certifications assure buyers that the leather products they purchase are sourced responsibly and produced with minimal environmental impact. By choosing suppliers with a commitment to sustainability, B2B buyers not only contribute to environmental conservation but also align their brands with consumer preferences for ethically produced goods, enhancing their market appeal.

What Is the Historical Context Behind Custom Leather Sheaths?

The evolution of custom leather sheaths can be traced back to the traditional craftsmanship that has characterized leatherworking for centuries. Historically, artisans crafted leather sheaths to protect blades, often employing techniques passed down through generations. As the demand for knives and outdoor tools grew, so did the need for specialized sheaths that catered to various styles and functionalities.

In recent decades, the rise of outdoor culture and survivalism has revitalized interest in custom leather goods. Modern consumers seek not only utility but also personalization in their leather products, driving innovation in design and materials. This historical context is crucial for B2B buyers, as it underscores the importance of craftsmanship and quality in the current market, informing their sourcing decisions in a landscape that values both tradition and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sheath

-

How do I select the right supplier for custom leather sheaths?

Choosing the right supplier involves assessing several factors. Start by reviewing their portfolio to gauge craftsmanship and design capabilities. Look for suppliers with positive customer testimonials and industry experience. Ensure they can accommodate your specific requirements, such as materials, dimensions, and customization options. Verify their quality assurance processes and whether they offer guarantees on their products. Communication is key; suppliers who respond promptly and thoroughly are often more reliable. -

What customization options are available for leather sheaths?

Customization options for leather sheaths are extensive. Buyers can specify dimensions, leather type, color, and style, as well as additional features such as stitching patterns, inlays, and closures. Some suppliers may also offer personalized branding options, like embossing logos or names. Discuss your specific needs with the supplier to explore the full range of available customizations, ensuring the final product meets your branding and functional requirements. -

What are the typical minimum order quantities (MOQ) for custom leather sheaths?

Minimum order quantities can vary widely among suppliers. Many manufacturers set an MOQ to offset production costs, which can range from as low as 10 to over 100 units, depending on the complexity of the design and materials used. It’s essential to confirm MOQs before engaging in negotiations, especially if you are a smaller business or starting a new product line. Some suppliers may offer flexibility for first-time orders or special projects. -

What payment terms should I expect when ordering custom leather sheaths?

Payment terms for custom orders typically involve a deposit, usually ranging from 30% to 50% of the total order cost, with the balance due upon completion or shipment. Some suppliers may offer net payment terms based on your business relationship and order history. Always clarify payment options, including accepted methods (e.g., wire transfer, credit card) and any potential additional fees for international transactions, to avoid misunderstandings. -

How can I ensure quality assurance for my custom leather sheaths?

To ensure quality assurance, request samples or prototypes before placing a bulk order. Discuss the supplier’s quality control processes, including material inspections and craftsmanship checks. Many reputable suppliers will provide details about their standards and any certifications they hold. Establish clear communication regarding your quality expectations and consider setting up regular updates during the production process to address any concerns early. -

What are the logistics considerations for importing custom leather sheaths?

When importing custom leather sheaths, consider shipping methods, transit times, and customs regulations. Work with suppliers who have experience in international shipping to navigate documentation, tariffs, and taxes. Establishing a reliable logistics partner can help streamline the process and minimize delays. Additionally, ensure that the supplier can provide necessary paperwork, such as certificates of origin, to facilitate smooth customs clearance in your country. -

How long does it typically take to receive a custom leather sheath order?

Lead times for custom leather sheath orders can vary based on the complexity of the design and the supplier’s workload. Generally, expect a timeframe of 4 to 12 weeks from order confirmation to delivery. Factors such as material availability, production capacity, and shipping can influence this timeline. It’s advisable to discuss and confirm expected delivery dates during the ordering process to align with your project timelines. -

What should I do if my order does not meet my expectations?

If your order does not meet your expectations, promptly communicate with the supplier. Document the issues with photos and detailed descriptions to provide clear feedback. Most reputable suppliers will have a return or revision policy, allowing for corrections or replacements. Addressing concerns early can often lead to a satisfactory resolution, whether through adjustments or refunds, maintaining a positive business relationship.

Top 7 Custom Leather Sheath Manufacturers & Suppliers List

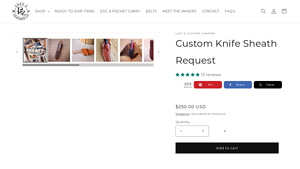

1. Lazy 3 Leather Company – Custom Knife Sheath

Domain: lazy3leatherco.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “Custom Knife Sheath Request”, “brand”: “Lazy 3 Leather Company”, “sku”: “”, “price”: “$250.00 USD”, “shipping”: “calculated at checkout”, “material”: “high-quality US sourced English bridle leather”, “customization_details”: {“knife_length”: “required”, “blade_width”: “required”, “handle_width”: “required”, “style_of_sheath”: “required”, “leather_color”: [“brown”, “black”, “natur…

2. Leather by Storm – Custom Leather Sheaths

Domain: leatherbystorm.com

Registered: 2024 (1 years)

Introduction: Products: The Drifter ($95.00), The Expedition ($140.00), The Pioneer ($125.00), The Rumor ($125.00), The Traveler ($125.00), The Ranger ($125.00), The Explorer ($125.00), The Frontiersman ($140.00). Features: Custom built leather knife sheaths, multi tool sheaths, EDC pouches, hand-stitched, made from high quality English Bridle leathers, military grade hardware, lifetime warranty.

3. Diomedes Industries – Custom Knife Sheaths

Domain: diomedesindustries.com

Registered: 2016 (9 years)

Introduction: Custom Sheaths for Custom Knives by Diomedes Industries, with over 10 years of experience. Recent projects include: 1. Nicole Apelian’s Cross Draw: Pancake-style sheath with ¾ top opening and unique closure system, handmade cold-forged buckle. 2. Melissa Miller’s Baldric System: Extra-long baldric strap and sheath setup, Paul Long style for versatility. 3. A Lined Bowie Sheath: Made with two layer…

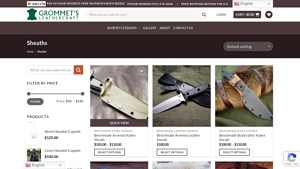

4. Grommets Leathercraft – Kydex and Leather Sheaths

Domain: grommetsleathercraft.com

Registered: 2017 (8 years)

Introduction: Sheaths available in various materials including Kydex and leather. Product categories include: Benchmade Kydex Sheaths, Chris Reeve Kydex Sheaths, Ka-Bar Kydex Sheaths, TOPS Kydex Sheaths, Benchmade Leather Sheaths, Chris Reeve Leather Sheaths, Ka-Bar Leather Sheaths, and TOPS Leather Sheaths. Price range for products varies from $50.00 to $500.00. Specific products include: Wool Hooded Capelet (…

5. Ramos Customs – Handcrafted Leather Sheaths

Domain: ramoscustoms.com

Registered: 2012 (13 years)

Introduction: Custom leather sheaths handcrafted in Northern New Jersey since 2010. Made from high-quality, vegetable-tanned hides sourced from top American tanneries. 100% handmade, offering a unique and tailored experience. Designed to last more than a lifetime, surpassing mass-produced items in quality. Small batch production for custom knife makers, with notable clients including Creely Knives, Marfione Cus…

6. R Grizzle Leather – Grizzle Special Knife Sheath

Domain: rgrizzleleather.com

Registered: 2008 (17 years)

Introduction: Knife Sheaths and Other Gear: Prices vary based on knife size and material (cowhide, exotic, horsehide). Key products include: 1. Grizzle Special: Pouch style sheath, hard rolled horsehide, 2/3 oz veg tanned cowhide lining. Price: $125 (without firesteel loop), $145 (with firesteel loop) for 4″-5″ blades. Dangler style available for an additional $20. 2. Dangler Sheaths: Starts at $100 (cowhide, n…

7. Seward Leather – Custom Knife Sheaths

Domain: sewardleather.com

Registered: 2019 (6 years)

Introduction: Custom leather knife sheaths made in Austin, AR. Options include carved, exotic, utility, and tooled designs. The process involves three steps: getting a quote, shipping your knife for a custom fit, and receiving the completed sheath. Features include synchronized tooling and carving, custom mixed die colors, and unique designs that coordinate with the knife. No pre-payment is required, and carefu…

Strategic Sourcing Conclusion and Outlook for custom leather sheath

As the demand for custom leather sheaths continues to rise globally, particularly in markets across Africa, South America, the Middle East, and Europe, strategic sourcing has never been more critical. Key takeaways emphasize the importance of high-quality materials, such as English bridle leather, and the value of craftsmanship that meets specific buyer needs. Understanding your unique requirements, from knife dimensions to style preferences, is essential for ensuring optimal fit and functionality.

Engaging with reputable manufacturers who offer bespoke solutions can enhance customer satisfaction and loyalty, while fostering long-term business relationships. The insights gathered from industry leaders highlight the significance of clear communication and detailed specifications during the sourcing process.

Looking ahead, the landscape for custom leather sheaths is poised for growth. International buyers should actively seek partnerships with artisans and manufacturers who demonstrate flexibility and a commitment to quality. By prioritizing strategic sourcing, businesses can capitalize on emerging trends and innovations within the leather goods sector. Embrace this opportunity to differentiate your offerings and establish a strong market presence. Reach out today to explore customized solutions that align with your business goals.

Illustrative image related to custom leather sheath

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.