Introduction: Navigating the Global Market for printed leatherette

The global market for printed leatherette presents a unique challenge for B2B buyers: how to source high-quality materials that meet diverse aesthetic and functional requirements while navigating varying supplier standards and regulations. As a versatile alternative to genuine leather, printed leatherette is increasingly favored across multiple industries, from fashion and upholstery to automotive and interior design. This guide delves deep into the world of printed leatherette, covering essential aspects such as types, applications, cost considerations, and effective supplier vetting strategies.

By providing a comprehensive overview, this resource empowers international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—to make informed purchasing decisions. Whether you’re a small business in Nigeria seeking unique designs for accessories or a large manufacturer in Brazil looking to streamline your supply chain, understanding the intricacies of printed leatherette can significantly enhance your product offerings.

With insights into current trends, quality benchmarks, and market dynamics, this guide is designed to equip you with the knowledge needed to confidently navigate the global landscape of printed leatherette. By leveraging this information, you can ensure that your sourcing decisions not only meet your operational needs but also resonate with your target market’s preferences, thereby driving growth and innovation in your business.

Table Of Contents

- Top 7 Printed Leatherette Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for printed leatherette

- Understanding printed leatherette Types and Variations

- Key Industrial Applications of printed leatherette

- 3 Common User Pain Points for ‘printed leatherette’ & Their Solutions

- Strategic Material Selection Guide for printed leatherette

- In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette’

- Comprehensive Cost and Pricing Analysis for printed leatherette Sourcing

- Alternatives Analysis: Comparing printed leatherette With Other Solutions

- Essential Technical Properties and Trade Terminology for printed leatherette

- Navigating Market Dynamics and Sourcing Trends in the printed leatherette Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette

- Strategic Sourcing Conclusion and Outlook for printed leatherette

- Important Disclaimer & Terms of Use

Understanding printed leatherette Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Printed Faux Leather | Vibrant colors, customizable patterns, UV printing | Fashion accessories, upholstery, bags | Pros: High customization, unique designs. Cons: Longer lead times for custom orders. |

| Embossed Printed Leatherette | Textured surface with patterns like reptile or floral | Upholstery, fashion items, crafts | Pros: Aesthetic appeal, durable. Cons: May be pricier than standard options. |

| Pebble Grain Leatherette | Pebbled texture, easy to clean and maintain | Automotive interiors, furniture | Pros: Practicality, water-resistant. Cons: Limited design options. |

| Metallic Finish Leatherette | Shiny, reflective surface, available in various hues | High-end fashion, promotional items | Pros: Eye-catching, stands out. Cons: Can show scratches easily. |

| Eco-Friendly Leatherette | Made from recycled materials, sustainable production | Eco-conscious brands, children’s products | Pros: Appeals to green consumers, compliant with safety standards. Cons: May have a higher cost. |

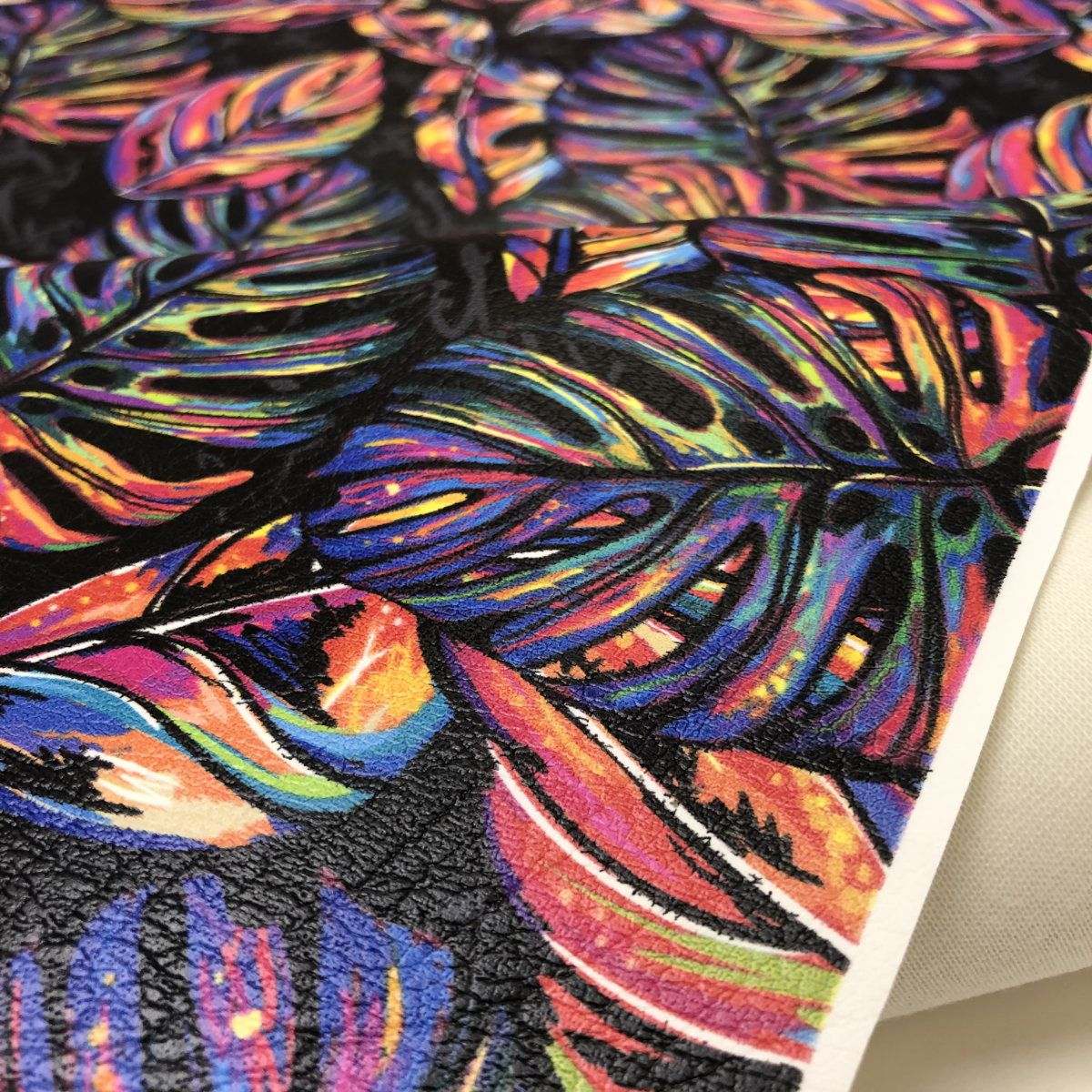

What Are the Characteristics of Custom Printed Faux Leather?

Custom printed faux leather stands out due to its vibrant colors and customizable patterns, often achieved through UV printing techniques. This type is particularly suitable for businesses looking to create unique fashion accessories, upholstery, or bags that reflect their brand identity. Buyers should consider the lead time for custom orders, as production can take longer compared to off-the-shelf options. The ability to create bespoke designs makes this type highly appealing for brands aiming to differentiate themselves in competitive markets.

How Does Embossed Printed Leatherette Differ from Other Types?

Embossed printed leatherette features a textured surface that mimics natural materials such as reptile skin or floral designs, providing an upscale look. It is often used in upholstery and fashion items, appealing to businesses focused on aesthetics and durability. While embossed options can add significant value to products, they may come at a higher price point. Buyers should weigh the added visual appeal against their budget constraints when considering this type.

Illustrative image related to printed leatherette

What Are the Advantages of Pebble Grain Leatherette?

Pebble grain leatherette is characterized by its pebbled texture, which not only enhances its visual appeal but also makes it easy to clean and maintain. This type is commonly used in automotive interiors and furniture applications where durability and practicality are essential. While it offers a water-resistant feature, buyers may find that design options are somewhat limited compared to other types. Businesses should assess their specific needs for aesthetic versus functional qualities when selecting this material.

Why Choose Metallic Finish Leatherette for High-End Products?

Metallic finish leatherette boasts a shiny, reflective surface available in various hues, making it an excellent choice for high-end fashion items and promotional products. Its eye-catching quality can help brands stand out in crowded marketplaces. However, it is important to note that this type can be prone to showing scratches, which may detract from its appearance over time. Buyers should consider the intended use and potential wear when selecting this type for their products.

How Does Eco-Friendly Leatherette Benefit Sustainable Brands?

Eco-friendly leatherette is made from recycled materials, making it an attractive option for brands committed to sustainability. It is particularly suitable for eco-conscious businesses and products aimed at children, as it often complies with safety standards. While it can be more expensive than traditional options, the appeal to environmentally aware consumers can justify the investment. Brands should evaluate their target market’s values and willingness to pay for sustainable products when considering this type.

Illustrative image related to printed leatherette

Key Industrial Applications of printed leatherette

| Industry/Sector | Specific Application of Printed Leatherette | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom Bags and Wallets | Enhances product appeal with unique designs; lightweight and durable. | Ensure compliance with safety standards; assess print quality and durability. |

| Furniture & Interiors | Upholstery for Chairs and Sofas | Offers aesthetic versatility while being cost-effective and easy to maintain. | Evaluate fabric durability; consider colorfastness and ease of cleaning. |

| Automobilindustrie | Interior Trimming and Upholstery | Provides a premium look at lower costs; resistant to wear and tear. | Focus on material specifications for automotive standards; check for UV resistance. |

| Home Décor | Decorative Pillows and Wall Art | Allows for customization that meets consumer preferences; lightweight and easy to handle. | Consider design scalability; assess fire retardancy and eco-friendliness of materials. |

| Crafting & DIY | Craft Projects and Custom Items | Enables creativity with customizable patterns; suitable for a wide range of applications. | Ensure availability in various sizes and patterns; check for ease of use with common tools. |

How is Printed Leatherette Used in the Fashion & Accessories Industry?

In the fashion sector, printed leatherette is widely used for creating custom bags and wallets. Its ability to mimic the luxurious look of genuine leather while being more affordable makes it an attractive option for designers and retailers. The lightweight nature of printed leatherette also enhances the functionality of products, making them easier to carry. Buyers should ensure that the materials comply with safety standards, particularly when targeting markets in Africa and South America, where regulations may vary.

What Role Does Printed Leatherette Play in Furniture & Interiors?

Printed leatherette serves as a popular choice for upholstery in chairs and sofas, offering a blend of aesthetic appeal and practicality. Its diverse range of colors and patterns allows businesses to cater to various interior design styles, while its durability ensures long-lasting use. For international buyers, especially from the Middle East and Europe, it’s crucial to evaluate the fabric’s durability and ease of cleaning to ensure customer satisfaction and compliance with local market preferences.

How is Printed Leatherette Utilized in Automotive Applications?

In the automotive industry, printed leatherette is commonly used for interior trimming and upholstery. It provides a premium appearance at a fraction of the cost of traditional leather while being resistant to wear and tear. Buyers in this sector should focus on sourcing materials that meet automotive standards, including specifications for UV resistance and easy maintenance, to ensure longevity and customer satisfaction.

What Are the Applications of Printed Leatherette in Home Décor?

Printed leatherette finds extensive use in home décor, particularly for decorative pillows and wall art. Its customizable nature allows businesses to meet consumer preferences effectively, while the lightweight material makes it easy to handle and display. Buyers should consider the scalability of designs and the fire retardancy of materials, especially when targeting markets in regions with strict safety regulations, such as Europe.

How is Printed Leatherette Beneficial for Crafting & DIY Projects?

In the crafting and DIY sector, printed leatherette is favored for its versatility in creating custom items. Crafters can utilize it for various projects, from key fobs to home décor accents, thanks to its ease of use and the availability of unique patterns. For international buyers, especially in regions like Brazil and Nigeria, it’s important to ensure that the material is available in various sizes and patterns to meet diverse crafting needs.

Illustrative image related to printed leatherette

3 Common User Pain Points for ‘printed leatherette’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Print Quality

The Problem:

Many B2B buyers experience challenges when it comes to achieving the desired print quality on printed leatherette. This issue often stems from a lack of understanding about the material’s specific properties and how they interact with different printing techniques. For instance, low-resolution images or inappropriate color profiles can lead to disappointing results, including pixelation or color inaccuracies. Buyers may find themselves frustrated when the final product does not align with their expectations, leading to wasted materials and increased costs.

The Solution:

To ensure optimal print quality, it’s critical to use high-resolution images (at least 300 dpi) and to consult with suppliers about the best practices for printing on leatherette. Buyers should also request samples before placing bulk orders to evaluate how their designs translate onto the material. Additionally, utilizing color calibration tools can help align the colors on screen with the actual print output. By establishing clear communication with printing partners regarding design specifications and expectations, businesses can mitigate quality issues and enhance customer satisfaction.

Scenario 2: Managing Inventory and Supply Chain Disruptions

The Problem:

B2B buyers often face inventory management challenges when sourcing printed leatherette, particularly due to supply chain disruptions. Variability in lead times, fluctuating prices, and unexpected shortages can significantly impact production schedules and customer commitments. In regions such as Africa and South America, where logistics may be less predictable, buyers might struggle to maintain a consistent supply, leading to project delays and potential revenue loss.

The Solution:

To combat these challenges, B2B buyers should diversify their supplier base and consider establishing relationships with multiple vendors across different regions. This strategy helps mitigate risks associated with supply chain disruptions. Additionally, implementing inventory management software can provide real-time visibility into stock levels and demand forecasts. Buyers should also negotiate long-term contracts with suppliers to secure stable pricing and availability. By planning ahead and adopting a proactive approach, businesses can better navigate the complexities of the supply chain and ensure smoother operations.

Scenario 3: Ensuring Compliance with Safety Standards

The Problem:

Compliance with safety standards is a significant concern for B2B buyers dealing with printed leatherette, especially in industries like fashion and children’s products. Buyers may struggle to ensure that the materials meet local regulations and international safety standards, which can vary widely by region. Non-compliance not only poses risks to consumer safety but can also lead to legal repercussions and damage to brand reputation.

Illustrative image related to printed leatherette

The Solution:

To ensure compliance, B2B buyers should prioritize sourcing printed leatherette from suppliers that provide certifications and documentation proving adherence to relevant safety standards, such as CPSIA in the United States or REACH in Europe. Buyers should request detailed information on the materials used in the leatherette, including any chemicals involved in the printing process. Additionally, conducting periodic audits of suppliers can help verify that they consistently meet compliance requirements. By maintaining a rigorous supplier evaluation process and staying informed about regulatory changes, businesses can safeguard their products and build trust with their customers.

Strategic Material Selection Guide for printed leatherette

What Are the Key Materials Used in Printed Leatherette?

When selecting materials for printed leatherette, it is essential for B2B buyers to consider various factors that influence product performance, cost, and suitability for specific applications. Below are analyses of four common materials used in the production of printed leatherette, focusing on their properties, advantages, disadvantages, and considerations for international markets.

1. Polyurethane (PU) Leatherette

Key Properties: Polyurethane leatherette is known for its flexibility, durability, and resistance to wear and tear. It can withstand moderate temperatures and is resistant to moisture, making it suitable for various applications.

Pros & Cons: The advantages of PU leatherette include its soft texture and ability to mimic the look of genuine leather, making it appealing for fashion and upholstery. However, it can be less durable than other materials under extreme conditions and may not perform well in high-heat environments.

Impact on Application: PU leatherette is commonly used in fashion items, upholstery, and accessories. Its compatibility with various printing techniques allows for vibrant designs and patterns.

Illustrative image related to printed leatherette

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the PU leatherette meets local compliance standards, such as ASTM or ISO certifications. Understanding the environmental regulations regarding the use of synthetic materials is also crucial.

2. PVC (Polyvinyl Chloride) Leatherette

Key Properties: PVC leatherette is known for its high durability and resistance to abrasion, chemicals, and moisture. It can handle high-pressure applications and is often used in environments where durability is paramount.

Pros & Cons: The primary advantage of PVC leatherette is its cost-effectiveness and long-lasting nature. However, it can be less breathable compared to PU, leading to discomfort in certain applications, such as clothing.

Illustrative image related to printed leatherette

Impact on Application: PVC leatherette is frequently used in automotive interiors, bags, and outdoor furniture due to its resilience. Its compatibility with various printing methods allows for intricate designs.

Considerations for International Buyers: Buyers should be aware of the regulations regarding the use of PVC in their regions, especially in Europe, where there are stringent guidelines on chemical safety. Compliance with standards such as REACH is essential.

3. Recycled Leatherette

Key Properties: Made from recycled materials, this leatherette variant is eco-friendly and has a unique texture. It offers moderate durability and is often treated to enhance its performance.

Pros & Cons: The key advantage of recycled leatherette is its sustainability, appealing to environmentally conscious consumers. However, it may not match the durability of virgin materials like PU or PVC, potentially limiting its applications.

Impact on Application: Recycled leatherette is suitable for fashion accessories and eco-friendly products. Its unique texture can add value to the final product, making it attractive for niche markets.

Considerations for International Buyers: Buyers should verify the sustainability certifications of recycled leatherette, as well as its compliance with local environmental regulations. This is particularly important in markets like Europe, where sustainability is a significant selling point.

4. Microfiber Leatherette

Key Properties: Microfiber leatherette is lightweight, breathable, and offers high durability. It has excellent water resistance and is easy to clean, making it suitable for various applications.

Illustrative image related to printed leatherette

Pros & Cons: The primary advantage of microfiber leatherette is its softness and comfort, making it ideal for upholstery and clothing. However, it can be more expensive than other synthetic options, which may impact budget considerations.

Impact on Application: Microfiber leatherette is widely used in high-end fashion, upholstery, and automotive applications due to its luxurious feel and durability.

Considerations for International Buyers: Buyers should consider the cost implications of importing microfiber leatherette, especially in regions with high shipping costs. Compliance with international quality standards is also necessary to ensure product reliability.

Summary Table of Material Selection for Printed Leatherette

| Material | Typical Use Case for printed leatherette | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Fashion items, upholstery, accessories | Soft texture, good design compatibility | Less durable under extreme conditions | Medium |

| PVC | Automotive interiors, bags, outdoor furniture | High durability, cost-effective | Less breathable, can be uncomfortable | Low |

| Recycled Leatherette | Eco-friendly fashion accessories | Sustainable, unique texture | Moderate durability compared to virgin materials | Medium |

| Mikrofaser | High-end fashion, upholstery, automotive | Luxurious feel, easy to clean | Higher cost compared to other synthetics | Hoch |

This guide should assist B2B buyers in making informed decisions regarding material selection for printed leatherette, ensuring that they choose the best options for their specific applications and market requirements.

Illustrative image related to printed leatherette

In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette

What Are the Main Stages in the Manufacturing Process of Printed Leatherette?

The manufacturing of printed leatherette involves several critical stages, each contributing to the quality and performance of the final product. Understanding these stages helps B2B buyers assess the capabilities of their suppliers.

1. Material Preparation

The process begins with selecting high-quality synthetic materials, typically polyurethane or PVC, which serve as the base for leatherette. These materials are chosen for their durability, flexibility, and ease of printing. The preparation phase includes cutting the raw materials into sheets and treating them to enhance adhesion properties for subsequent printing.

2. Forming and Printing

Once the materials are prepared, they undergo a forming process where they are shaped according to specifications. This may include rolling or laminating techniques. The printing phase is crucial, employing methods such as UV printing or digital printing to apply designs onto the leatherette. This stage requires precision to ensure that colors are vibrant and patterns align correctly.

3. Assembly

In the assembly phase, the printed leatherette is cut into desired shapes and sizes for various applications, such as upholstery, bags, or fashion accessories. This involves sewing or bonding the pieces together, depending on the product requirements. High-quality stitching and bonding techniques are vital for ensuring product longevity and aesthetic appeal.

Illustrative image related to printed leatherette

4. Finishing

The finishing stage enhances the surface characteristics of the printed leatherette. This can include applying coatings for added durability, texture treatments for a more authentic leather feel, and quality control checks to ensure that the product meets specifications. This stage often involves meticulous attention to detail, as any imperfections can affect the product’s marketability.

How Is Quality Assurance Managed in Printed Leatherette Production?

Quality assurance (QA) is paramount in the manufacturing of printed leatherette, ensuring that products meet international standards and customer expectations. B2B buyers should be familiar with various QA processes and standards to effectively vet their suppliers.

International Standards and Certifications

Adherence to international standards such as ISO 9001 is essential for manufacturers. This standard outlines requirements for a quality management system (QMS) and ensures consistent product quality. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the intended use of the leatherette. These certifications demonstrate compliance with safety and performance requirements, which are crucial for gaining trust in global markets.

Quality Control Checkpoints

Quality control in printed leatherette manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial phase inspects raw materials upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During production, ongoing checks are performed to identify any deviations from quality standards. This may involve testing adhesion properties, color accuracy, and dimensional consistency.

- Final Quality Control (FQC): Once the product is complete, final inspections are conducted to ensure that it meets all quality criteria before shipping. This includes visual inspections and functional testing where applicable.

Common Testing Methods for Printed Leatherette

Testing methods for printed leatherette vary but typically include:

- Adhesion Tests: Ensuring that prints do not peel or flake off.

- Flexural Tests: Assessing the material’s resistance to bending and folding.

- Colorfastness Tests: Evaluating how well the printed colors withstand washing, light exposure, and abrasion.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

Conducting Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should request to visit production facilities or engage third-party auditors who can conduct comprehensive assessments of quality management systems, production capabilities, and compliance with international standards.

Illustrative image related to printed leatherette

Requesting Quality Control Reports

Suppliers should be willing to provide detailed quality control reports that outline their testing methods, results, and compliance with relevant standards. These documents should include information on the frequency of tests conducted and any corrective actions taken in response to quality issues.

Third-Party Inspection Services

Engaging third-party inspection services can add an extra layer of assurance. These services can conduct independent assessments of products before shipment, ensuring that they meet agreed-upon specifications and standards. This is particularly important for B2B transactions involving large volumes of printed leatherette, where quality consistency is paramount.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances in quality control when sourcing printed leatherette. Understanding these factors can help mitigate risks and ensure satisfactory product quality.

Variability in Standards and Regulations

Different regions may have varying standards and regulations regarding material safety and environmental compliance. Buyers should familiarize themselves with local regulations in their target markets, ensuring that the products they purchase from suppliers comply with these requirements.

Cultural and Communication Barriers

Cultural differences can impact quality perceptions and communication. Buyers should establish clear lines of communication with suppliers and ensure that quality expectations are explicitly defined. Regular updates and feedback can help bridge gaps and foster a collaborative relationship.

Illustrative image related to printed leatherette

Supply Chain Transparency

Buyers should prioritize suppliers who maintain transparency in their supply chain. This includes clear information on sourcing materials, production methods, and quality control processes. A transparent supply chain can enhance trust and facilitate better collaboration between buyers and suppliers.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing printed leatherette, ensuring they partner with reliable suppliers who meet their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette’

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing printed leatherette. It provides actionable steps to ensure you find quality materials that meet your specific needs while navigating the complexities of international procurement.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the specifications for your printed leatherette. This includes dimensions, thickness, texture, and printing quality. Defining these parameters will help you communicate effectively with suppliers and ensure that the materials you receive meet your project requirements.

Illustrative image related to printed leatherette

- Consider Applications: Think about how you will use the printed leatherette, whether for fashion accessories, upholstery, or promotional items.

- Quality Standards: Establish the quality standards required for your end products, including durability and aesthetic appeal.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in printed leatherette. Look for companies with a solid reputation and experience in your target market.

- Check Reviews and Testimonials: Look for customer feedback and case studies that demonstrate the supplier’s reliability and product quality.

- Assess Market Experience: Focus on suppliers with experience in regions like Africa, South America, the Middle East, and Europe, as they may better understand local requirements.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify the certifications and compliance of your shortlisted suppliers. This ensures that their products meet industry standards and regulations.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance certifications that indicate adherence to manufacturing standards.

- Safety Compliance: Ensure that the materials comply with safety regulations, especially if they will be used in products for children or other sensitive applications.

Step 4: Request Samples

Always request samples before finalizing your order. This step allows you to assess the quality, texture, and color accuracy of the printed leatherette firsthand.

- Evaluate Print Quality: Check for clarity, vibrancy, and alignment of the printed designs.

- Test Durability: Assess how the material holds up under stress, including bending, cutting, and exposure to elements.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to agree on pricing, payment terms, and delivery schedules. This is crucial for managing your budget and timelines effectively.

- Volume Discounts: Inquire about bulk pricing or discounts for larger orders.

- Payment Flexibility: Discuss payment terms that suit both parties, such as partial payments upfront and the remainder upon delivery.

Step 6: Finalize Logistics and Shipping

Coordinate the logistics of your order, including shipping methods and timelines. Understanding the logistics will help you manage expectations regarding delivery.

Illustrative image related to printed leatherette

- Shipping Options: Evaluate different shipping methods, considering cost and delivery speed.

- Customs and Duties: Familiarize yourself with import regulations and potential duties in your country to avoid unexpected costs.

Step 7: Establish a Quality Control Process

Implement a quality control process upon receiving your order. This ensures that the printed leatherette meets your specifications and is free from defects.

- Inspection Checklist: Create a checklist to evaluate the quality upon delivery, including checking for correct dimensions and print fidelity.

- Feedback Loop: Establish a feedback mechanism with your supplier to address any quality issues promptly and improve future orders.

By following this checklist, B2B buyers can streamline the sourcing process for printed leatherette, ensuring they select the right materials for their business needs while maintaining quality and compliance.

Comprehensive Cost and Pricing Analysis for printed leatherette Sourcing

Understanding the cost structure and pricing dynamics of printed leatherette is crucial for international B2B buyers looking to make informed sourcing decisions. This analysis covers the essential cost components, price influencers, and practical tips for negotiating and managing costs effectively.

Illustrative image related to printed leatherette

What Are the Key Cost Components in Printed Leatherette Sourcing?

The cost structure for printed leatherette comprises several components:

-

Materials: The primary cost driver is the quality of the base material used. Leatherette can vary significantly in terms of texture, durability, and appearance. Higher quality materials often command a premium, which can impact the overall price.

-

Labor: Labor costs encompass the workforce involved in manufacturing and printing. Depending on the region, labor costs can fluctuate, affecting the final pricing. Countries with lower labor costs may offer more competitive pricing, but it’s essential to consider the quality of craftsmanship.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer more attractive pricing.

-

Tooling: Custom tooling for specific designs can add to initial costs. Buyers should be aware that one-time tooling fees may apply for customized patterns or specifications, which can influence the overall project budget.

-

Quality Control (QC): Ensuring that printed leatherette meets quality standards requires investment in QC processes. This cost is critical, as it helps prevent defects and ensures product reliability, especially for international buyers concerned about compliance with local regulations.

-

Logistics: Transportation and shipping costs can vary widely based on the supplier’s location and the buyer’s destination. For international shipments, factors such as customs duties and freight charges can significantly impact total costs.

-

Margin: Supplier margins vary based on market conditions and competition. Understanding the typical margin range in your sourcing region can provide insight into price negotiations.

How Do Price Influencers Affect Printed Leatherette Costs?

Several factors influence the pricing of printed leatherette:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders typically lead to lower per-unit costs, making it beneficial for buyers with significant production needs.

-

Specifications and Customization: Custom designs, colors, and textures will typically incur additional costs. Buyers should evaluate whether the added expense aligns with their branding and product strategy.

-

Material Quality and Certifications: Certifications for safety and environmental compliance can impact costs. Buyers seeking certified materials may face higher prices but can benefit from enhanced marketability.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers may charge more due to their reliability and quality assurance, while newer or less reputable suppliers may offer lower prices but carry higher risks.

-

Incoterms: Understanding shipping terms (Incoterms) is essential for pricing. Options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers can adopt several strategies to enhance cost-efficiency in their sourcing efforts:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Flexibility in order sizes or payment plans can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial price to evaluate the TCO, which includes logistics, potential waste, and quality issues. A higher upfront cost may lead to savings over time through reduced defects or lower shipping fees.

-

Research Local Markets: For international buyers, understanding local market conditions and supplier dynamics can provide leverage in negotiations. Familiarity with regional pricing trends can inform your discussions.

-

Utilize Samples: Requesting samples can help assess quality before committing to larger orders. This practice can mitigate risks associated with poor-quality products and help ensure that the chosen supplier meets your specifications.

-

Stay Informed: Keeping abreast of market trends and material innovations can provide insights into potential cost-saving opportunities. Subscribing to industry publications or joining relevant trade groups can enhance your knowledge base.

In summary, understanding the comprehensive cost structure and pricing dynamics of printed leatherette is essential for making informed sourcing decisions. By leveraging the insights provided, international B2B buyers can optimize their procurement strategies and achieve better value in their sourcing endeavors.

Alternatives Analysis: Comparing printed leatherette With Other Solutions

Introduction to Alternatives in Printed Leatherette Solutions

When considering materials for products requiring durability and aesthetic appeal, printed leatherette emerges as a popular choice. However, various alternatives exist that may suit different business needs and budget constraints. This analysis aims to compare printed leatherette with other viable solutions, including traditional leather and synthetic vinyl, highlighting their respective advantages and disadvantages to assist international B2B buyers in making informed decisions.

Comparison Table

| Comparison Aspect | Printed Leatherette | Traditionelles Leder | Synthetic Vinyl |

|---|---|---|---|

| Performance | High durability, water-resistant | Exceptional durability, natural feel | Good durability, less breathable |

| Cost | Moderate, often more affordable | High initial cost | Low cost, budget-friendly |

| Ease of Implementation | Easy to cut and sew; versatile | Requires specialized tools and skills | Simple to use, minimal tools needed |

| Wartung | Low maintenance, easy to clean | Requires regular conditioning | Very low maintenance, easy to clean |

| Best Use Case | Fashion accessories, upholstery | High-end fashion, luxury goods | Promotional items, low-cost products |

Detailed Breakdown of Alternatives

Traditionelles Leder

Traditional leather is renowned for its luxurious feel and exceptional durability. It is often the preferred material for high-end fashion products, such as handbags and shoes, due to its natural aesthetic and ability to age beautifully. However, traditional leather comes with a significant cost and requires ongoing maintenance, such as conditioning and cleaning, to preserve its appearance. Additionally, sourcing leather can involve ethical considerations, which may not align with all brands’ values.

Illustrative image related to printed leatherette

Synthetic Vinyl

Synthetic vinyl is a cost-effective alternative that offers good durability and resistance to wear. It is often used for promotional items and low-cost products due to its low price point. The ease of implementation is a significant advantage, as synthetic vinyl can be easily cut and sewn with minimal tools. However, it lacks the breathability and natural feel of leatherette, which may detract from its appeal for fashion-forward applications. While synthetic vinyl is easy to clean, it may not provide the same level of long-term durability as leatherette or traditional leather.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right material for your products requires careful consideration of various factors, including performance, cost, and intended use. Printed leatherette offers a balanced solution, combining aesthetic appeal with affordability, making it ideal for fashion accessories and upholstery. In contrast, traditional leather may be more suitable for luxury markets where durability and natural feel are paramount, albeit at a higher cost. Meanwhile, synthetic vinyl serves as an excellent option for budget-conscious projects where ease of use and low maintenance are priorities. Ultimately, understanding your specific needs and target market will guide you in making the most suitable choice for your business.

Essential Technical Properties and Trade Terminology for printed leatherette

What Are the Key Technical Properties of Printed Leatherette?

When sourcing printed leatherette, understanding its technical properties is crucial for making informed purchasing decisions. Here are the essential specifications to consider:

1. Material Composition

Printed leatherette is typically made from polyurethane (PU) or polyvinyl chloride (PVC). PU is preferred for its softness, durability, and eco-friendliness, while PVC offers a cost-effective solution with decent performance. Buyers should assess the material based on the intended application, such as upholstery, fashion accessories, or automotive interiors.

Illustrative image related to printed leatherette

2. Thickness

The thickness of printed leatherette can vary, usually ranging from 0.5mm to 3mm. This property is vital as it affects the fabric’s drape, durability, and suitability for different uses. For instance, thicker materials are ideal for heavy-duty applications, while thinner options are better for lightweight projects like clothing or decorative items.

3. Tensile Strength

Tensile strength measures the material’s resistance to being pulled apart and is expressed in Newtons. A higher tensile strength indicates greater durability and longevity, making it a critical factor for products subjected to stress, such as bags and upholstery. For B2B buyers, ensuring the tensile strength meets industry standards helps prevent product failures.

4. UV Resistance

UV resistance is the ability of printed leatherette to withstand sunlight without fading or degrading. This property is particularly important for products used outdoors or in well-lit environments. Buyers should look for materials with a UV resistance rating to ensure longevity and maintain aesthetic appeal.

5. Water Resistance

Water resistance refers to the fabric’s ability to repel water and moisture. This property is essential for applications like upholstery in humid climates or items exposed to spills. Buyers should verify the water-resistant rating to ensure the material can withstand the intended environmental conditions.

Illustrative image related to printed leatherette

6. Color Fastness

Color fastness measures how well the colors in printed leatherette resist fading due to washing, rubbing, or exposure to light. A high color fastness rating ensures that the product maintains its visual appeal over time, which is crucial for maintaining brand integrity in consumer-facing products.

What Are Common Trade Terms in the Printed Leatherette Industry?

Familiarity with industry terminology can streamline communication and enhance negotiations between buyers and suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of printed leatherette, it may involve companies that source materials for integration into their products. Understanding OEM relationships can help buyers navigate sourcing and production partnerships effectively.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers as it impacts budgeting and inventory management. Suppliers often set MOQs based on production costs, so negotiating favorable terms can lead to cost savings.

Illustrative image related to printed leatherette

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Crafting a comprehensive RFQ ensures that potential suppliers provide accurate and competitive quotes, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade transactions. Familiarity with these terms helps clarify shipping costs, risks, and responsibilities, ensuring smooth logistics and compliance with international trade regulations.

5. Lead Time

Lead time is the duration from placing an order to receiving the product. Understanding lead times is essential for effective supply chain management, allowing buyers to plan their production schedules and inventory levels accordingly.

6. Custom Printing

Custom printing refers to the process of applying unique designs or patterns to leatherette materials. This service enables businesses to differentiate their products in the market, making it a vital consideration for brands looking to enhance their offerings.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing printed leatherette, ultimately improving their product quality and market competitiveness.

Illustrative image related to printed leatherette

Navigating Market Dynamics and Sourcing Trends in the printed leatherette Sector

What Are the Key Trends Shaping the Printed Leatherette Market for International B2B Buyers?

The printed leatherette sector is currently experiencing robust growth, driven by increased demand across various industries, including fashion, automotive, and furniture. Global factors such as rising disposable incomes in emerging markets like Nigeria and Brazil are fueling consumer interest in high-quality, aesthetically pleasing materials. Notably, the trend towards customization is gaining traction, with businesses seeking unique designs that resonate with their brand identity. This demand for bespoke solutions is supported by advancements in digital printing technologies, allowing for intricate designs and shorter production runs without compromising quality.

Moreover, sustainability is becoming a central theme in sourcing decisions. B2B buyers are increasingly favoring suppliers that utilize eco-friendly materials and processes. The integration of smart supply chain technologies, such as blockchain for tracking materials and ensuring authenticity, is also on the rise. This trend is particularly relevant for buyers in Africa and South America, where transparency in sourcing is gaining importance due to regulatory pressures and consumer expectations.

How Important Is Sustainability and Ethical Sourcing in the Printed Leatherette Industry?

Sustainability and ethical sourcing are paramount in the printed leatherette market, particularly as global consumers become more environmentally conscious. The production of synthetic leather, while often more sustainable than traditional leather, still poses environmental challenges, including resource consumption and waste. B2B buyers are now prioritizing suppliers who can demonstrate responsible sourcing practices and offer materials certified by recognized environmental standards.

Illustrative image related to printed leatherette

Green certifications, such as OEKO-TEX and GOTS (Global Organic Textile Standard), are becoming essential for establishing credibility in the marketplace. These certifications ensure that the materials used in printed leatherette products meet stringent environmental and safety standards. Additionally, many buyers are exploring alternatives to PVC-based leatherette, opting for polyurethane (PU) options that are less harmful to the environment. By aligning purchasing decisions with sustainability goals, businesses can enhance their brand image and meet the growing consumer demand for ethical products.

What Is the Historical Context of Printed Leatherette and Its Evolution in the B2B Space?

The printed leatherette industry has evolved significantly over the past few decades. Initially, synthetic leather was primarily produced as a cost-effective alternative to genuine leather, catering to a wide range of applications from upholstery to fashion accessories. With advancements in technology, particularly in printing techniques, printed leatherette has transformed from a purely functional material into a highly customizable and aesthetically appealing option.

This evolution has been accelerated by the rise of digital printing, which allows for intricate designs and patterns to be applied with precision. As a result, printed leatherette is no longer viewed merely as a substitute but has emerged as a preferred material in various sectors, including high-end fashion and automotive interiors. The increasing focus on sustainability and ethical sourcing has further shaped its development, prompting manufacturers to innovate and adopt more environmentally friendly practices. This historical context is crucial for B2B buyers, as it highlights the material’s versatility and the industry’s responsiveness to changing consumer preferences and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette

-

How do I choose the right supplier for printed leatherette?

Choosing the right supplier involves a few key steps. First, assess the supplier’s reputation through reviews and testimonials from previous clients, particularly in your region. Verify their production capabilities, including customization options and minimum order quantities (MOQs). Request samples to evaluate the quality of their printed leatherette. Additionally, inquire about their compliance with international standards and regulations relevant to your market. Finally, ensure they have efficient logistics and a clear understanding of shipping requirements to your location. -

What customization options are available for printed leatherette?

Most suppliers offer a range of customization options, including various sizes, colors, and patterns. You can often upload your own designs or choose from their existing catalog. Customization may also include different finishes, such as matte or glossy, and the option to add adhesive backing. Be sure to clarify the specifics of customization, such as file formats accepted, resolution requirements, and any associated costs or lead times. Always confirm your rights regarding any uploaded designs to avoid copyright issues. -

What are the typical minimum order quantities (MOQ) for printed leatherette?

Minimum order quantities can vary significantly between suppliers, typically ranging from a few sheets to several hundred. Some suppliers may allow smaller orders for sample purposes, while others might require larger quantities for cost-effectiveness. It’s essential to discuss MOQs upfront to ensure they align with your business needs. If you are looking to test a new design, inquire whether the supplier offers flexibility in their MOQ for initial orders. -

What payment terms should I expect when sourcing printed leatherette?

Payment terms can differ widely among suppliers. Many require a deposit upfront, often around 30-50% of the total order value, with the balance due before shipping. Some suppliers may offer credit terms for established customers or larger orders. Always clarify payment methods accepted, such as bank transfers, credit cards, or PayPal, and check for any additional fees associated with international transactions. Understanding these terms early can help you manage your cash flow effectively. -

How do I ensure quality assurance for printed leatherette products?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Consider asking for samples before placing a bulk order to assess the material’s durability, print quality, and color accuracy. Additionally, inquire whether they conduct regular quality checks during production. Some companies may offer third-party quality inspection services, which can provide added assurance that your products meet your expectations before shipment. -

What are the shipping options and lead times for printed leatherette orders?

Shipping options typically include standard and expedited services, depending on your urgency and budget. Lead times can vary based on the supplier’s production schedule, with custom orders generally taking longer than standard items. It’s crucial to discuss shipping methods, costs, and estimated delivery times during the ordering process. For international shipping, be aware of customs regulations and potential delays, especially during peak seasons. -

What are the common uses for printed leatherette in various industries?

Printed leatherette is versatile and widely used across multiple industries. Common applications include fashion accessories like bags and wallets, upholstery for furniture, and automotive interiors. It’s also popular in crafting and promotional items due to its vibrant prints and durability. Understanding the specific needs of your target market can help you select the right type of printed leatherette that aligns with your business goals. -

How can I manage import duties and taxes when sourcing printed leatherette?

Import duties and taxes vary by country and can significantly impact your overall cost. It’s essential to research the specific regulations in your country regarding imported goods, including any tariffs applicable to printed leatherette. Consider consulting with a customs broker or trade specialist who can help you navigate these complexities. Additionally, suppliers may provide necessary documentation to facilitate the customs clearance process, so ensure you request all required paperwork with your shipment.

Top 7 Printed Leatherette Manufacturers & Suppliers List

1. Contrado – Custom Printed Faux Leather Fabric

Domain: contrado.com

Registered: 2004 (21 years)

Introduction: Custom Printed Faux Leather Fabric

– Price: From $37.50

– Composition: 85% PVC, 15% Polyester

– Max Width: 1.39yd

– Weight: 20.65oz

– Certification: Greenguard Certified

– Features: Soft polyester back, PVC face, fire rated, suitable for upholstery, bags, and more.

– Printing: Digital printed leatherette with a super bright white base for vibrant designs.

– Care Instructions: Surface wipe only; cl…

2. Zipper Valley – Printed Faux Leather

Domain: zippervalley.com

Registered: 2020 (5 years)

Introduction: Printed Faux Leather is pliable, vibrant, and bursting with personality. It is easy to cut and sews beautifully, even on domestic machines. Ideal for bags, wallets, key fobs, embroidery, and other creative projects. Available styles include various printed pebble designs. In stock items include 11 options, while 3 are out of stock. Regular prices range from $6.99 to $12.49, with discounts on selec…

3. PIP Supply – Custom Printed Faux Leather Sheets

Domain: pipsupply.com

Registered: 2018 (7 years)

Introduction: Custom Printed Faux Leather Sheets – CPSIA compliant faux leather – Free Domestic Shipping for orders $75 and up – Current Processing Time: 4-8 Business Days

4. Leatherette Lane – Custom Printed Fabric Rolls

Domain: leatherettelane.co.uk

Registered: 2024 (1 years)

Introduction: Custom Printed Leatherette fabric rolls available in various designs including animals, floral, seasonal, and special occasions. Free UK delivery on orders over £40 and free international delivery on orders over £150.

5. Frog Jelly Leather – Faux Leather Sheets & Fabrics

Domain: frogjellyleather.com

Registered: 2016 (9 years)

Introduction: Faux Leather Sheets & Synthetics: Various products including Faux Leather Scrap Strips ($4.99), Faux Leather Remnants – Printed Marine Vinyl (from $4.99), Holiday Printed Faux Leather Scrap Pack (from $4.99), Cork Fabric Sheets (from $6.99), Rose Printed Cork Fabric (from $6.99), Buffalo Plaid Hearts Marine Vinyl Faux Leather ($4.25), Red Buffalo Plaid Marine Vinyl Faux Leather ($4.25), Heart Cand…

6. Duke and Dexter – Leather UV Printing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Duke and Dexter prints on leather using UV printing techniques. Users have mentioned that they utilize Mimaki UV machines with LUS-120 ink, and that the leather must be treated beforehand to prevent ink absorption. There are suggestions that printing on leather can be an industrial secret and may require developing a custom method or seeking a specialized printing company or tannery.

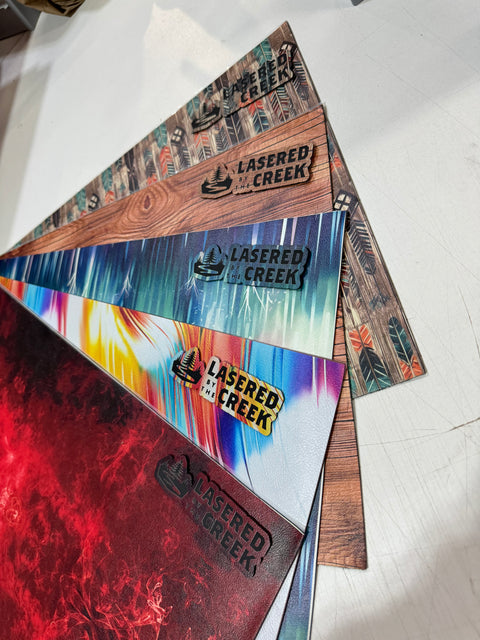

7. Thunder Laser – UV Printed Premium Leatherette® Sheets

Domain: shop.thunderlaserusa.com

Registered: 2018 (7 years)

Introduction: {“product_name”:”UV Printed Premium Leatherette® Sheets”,”dimensions”:”12×24 inches”,”material”:”Leatherette”,”features”:”UV printed, durable, versatile for various applications”,”usage”:”Ideal for crafting, signage, and promotional items”,”color”:”Available in multiple colors”,”quantity”:”Sold individually”}

Strategic Sourcing Conclusion and Outlook for printed leatherette

In the rapidly evolving market for printed leatherette, strategic sourcing is paramount for international B2B buyers seeking to stay competitive. The diverse applications of printed leatherette—from fashion accessories to home decor—present significant opportunities for businesses across Africa, South America, the Middle East, and Europe. Understanding the nuances of sourcing high-quality materials, including customization options and supplier reliability, can enhance product offerings and customer satisfaction.

Moreover, leveraging the latest trends in printed leatherette can differentiate your brand in a crowded marketplace. The ability to source unique, vibrant designs tailored to specific regional tastes can create a strong competitive edge. As sustainability continues to influence purchasing decisions, opting for eco-friendly printed leatherette options will resonate well with conscious consumers and stakeholders.

Illustrative image related to printed leatherette

Looking ahead, B2B buyers should actively explore partnerships with reputable suppliers who prioritize quality, innovation, and sustainability. Engaging in proactive sourcing strategies will not only streamline operations but also position your business to capitalize on emerging trends. Embrace the potential of printed leatherette today to elevate your brand’s presence and drive growth in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.