Catalog

Material Insight: Custom Leather Cushions

Custom Leather Cushions: The Essential B2B Performance Solution

In high-traffic commercial environments—from luxury hospitality lounges and premium healthcare facilities to modern office lobbies and public transit—cushions face relentless demands. They require exceptional durability, effortless maintenance, consistent aesthetics, and alignment with evolving sustainability mandates. Custom leather cushions are not merely furnishings; they are critical brand touchpoints and long-term investments where material choice directly impacts operational costs, user satisfaction, and environmental responsibility.

Why Premium Faux Leather is the Optimal Choice for Custom Cushions

Choosing the right material for custom cushions is a strategic decision. Genuine leather, while traditional, presents significant limitations for commercial applications: inconsistent texture, vulnerability to stains and UV fading, high maintenance costs, ethical concerns, and variable supply chains. Premium faux leather, specifically engineered for performance, delivers decisive advantages:

- Superior Durability & Consistency: Engineered for high abrasion resistance and uniform texture, faux leather withstands heavy daily use without cracking, peeling, or developing patina inconsistencies—ensuring brand image remains pristine across all installations.

- Effortless Maintenance & Hygiene: Resists stains, spills, and microbial growth; cleaned with simple, non-toxic solutions. Critical for healthcare, hospitality, and public spaces where sanitation and quick turnaround are non-negotiable.

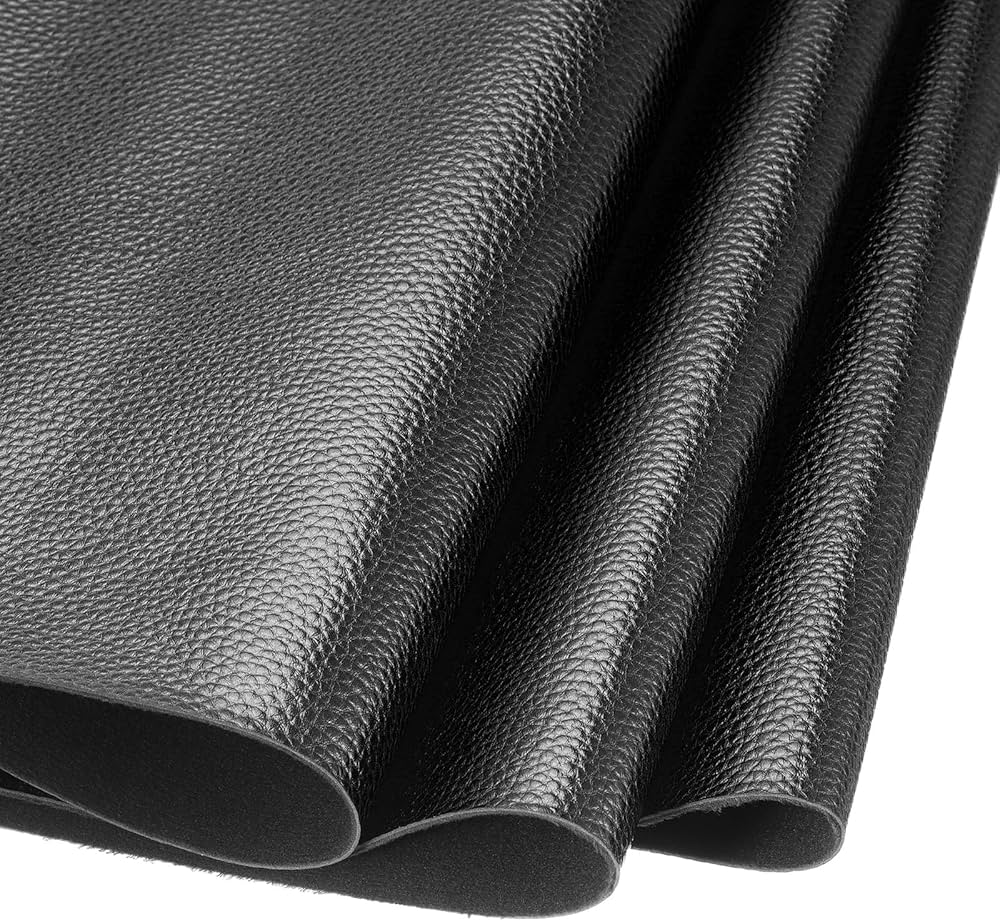

- Total Design Flexibility: Achieve exact color matching, unique textures (suede, pebble, smooth), and precise thickness for seamless integration with any aesthetic vision—without the natural variations of genuine hide.

- Ethical & Traceable Sourcing: Eliminates animal welfare concerns and volatile livestock market dependencies. Full supply chain transparency supports corporate ESG goals and resonates with conscious consumers.

- Predictable Cost Efficiency: Stable pricing, minimal waste during cutting (consistent roll goods), and extended lifespan reduce total cost of ownership versus genuine leather, which requires frequent refinishing or replacement.

- Eco-Performance Innovation: Modern premium synthetics integrate recycled content (e.g., ocean-bound plastics), waterless dyeing, and low-VOC formulations—delivering genuine sustainability without sacrificing performance.

WINIW: Your Trusted Partner in Engineered Leather Excellence

For over 20 years, WINIW has been at the forefront of sustainable, high-performance synthetic leather innovation. We don’t just supply materials—we partner with forward-thinking B2B manufacturers to solve complex upholstery challenges. Our deep expertise in polymer science, coupled with rigorous environmental stewardship, ensures every custom cushion solution delivers:

- Unmatched Technical Precision: Proprietary formulations for ultimate tear strength, cold crack resistance (-30°C), and lightfastness (ISO 105-B02 Level 7+), guaranteeing longevity in demanding settings.

- Authentic Eco-Credentials: Industry-leading use of recycled PET (up to 40% content), OEKO-TEX® STANDARD 100 certification, and GRS compliance—providing verifiable sustainability for your LEED or BREEAM projects.

- End-to-End Customization: From bespoke color development and specialized backings (knit, scrim, foam-laminated) to rapid prototyping, we collaborate to meet exact functional and aesthetic specifications.

- Global Reliability: Consistent quality across all production runs, backed by robust logistical support and deep understanding of international commercial upholstery standards.

When you choose WINIW for custom leather cushions, you choose a future-proof solution: sustainable by design, engineered for endurance, and crafted to elevate your brand’s promise of quality and responsibility. Let’s redefine comfort, together.

Technical Performance & Standards

WINIW Custom Leather Cushions – B2B Product Guide

WINIW’s Custom Leather Cushions are engineered for commercial and industrial applications requiring high performance, aesthetic flexibility, and long-term reliability. Designed with a focus on sustainability and regulatory compliance, our synthetic leather cushions deliver exceptional value across furniture, transportation, healthcare, and hospitality sectors.

Technical Advantages

-

Cost-Effective Production: WINIW utilizes advanced manufacturing processes that reduce material waste and energy consumption, enabling competitive pricing without compromising quality. The synthetic leather formulation eliminates dependency on volatile rawhide markets, ensuring stable long-term costs.

-

Superior Durability: Our cushions are constructed with high-density polyurethane (PU) foam bonded to abrasion-resistant synthetic leather. The surface withstands over 50,000 double rubs (Martindale test), resists tearing, and maintains structural integrity under repeated compression, making them ideal for high-traffic environments.

-

Customizable Colors & Finishes: WINIW offers full color customization with a palette of over 300 standard options and the ability to match Pantone® or RAL codes. Surface textures—including matte, glossy, soft-touch, and embossed grain—can be tailored to brand or design specifications.

-

REACH Compliant: All materials used in WINIW’s custom leather cushions meet REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations. Our products are free from SVHC (Substances of Very High Concern), phthalates, heavy metals, and other hazardous substances, ensuring safety for users and the environment.

-

ISO 9001-Certified Quality Management: WINIW operates under an ISO 9001-certified quality management system, ensuring consistent product performance, traceability, and continuous improvement across all stages of production, from raw material sourcing to final inspection.

Product Specifications

| Specification | Detail |

|---|---|

| Material Composition | PU Synthetic Leather + High-Density Polyurethane Foam |

| Thickness Range | 20 mm – 100 mm (customizable) |

| Density | 30 – 60 kg/m³ (adjustable based on support requirements) |

| Abrasion Resistance | ≥ 50,000 double rubs (Martindale, dry) |

| Color Options | 300+ standard colors; Pantone®/RAL matching available |

| Surface Finish | Matte, Glossy, Soft-Touch, Embossed (custom patterns on request) |

| Fire Resistance | Meets BS 5852, CAL 117, or DIN 4102 upon request |

| REACH Compliance | Fully compliant; no SVHCs, phthalates, or restricted substances |

| ISO Certification | ISO 9001:2015 certified manufacturing processes |

| Customization Lead Time | 15–25 days (based on order volume and complexity) |

| Minimum Order Quantity (MOQ) | 500 units (negotiable for long-term contracts) |

WINIW’s Custom Leather Cushions combine technical excellence with environmental responsibility, offering B2B partners a scalable, compliant, and high-performance solution for premium seating and support applications.

Why Choose Synthetic over Real Leather

WINIW Synthetic Leather: B2B Guide to Custom Leather Cushions vs. Real Leather

For manufacturers and designers seeking premium, sustainable materials, WINIW offers high-performance synthetic leather solutions engineered for commercial applications. Our custom leather cushions provide a strategic alternative to traditional real leather, addressing critical business needs in cost efficiency, longevity, and environmental responsibility. Below is a comparative analysis to inform your material selection.

Key Advantages of WINIW Custom Leather Cushions

- Precision Customization: Tailored thickness, texture, color, and performance properties (e.g., UV resistance, flame retardancy) to meet exact project specifications.

- Resource Efficiency: 100% cruelty-free production with significantly lower water and energy consumption versus animal-derived leather.

- Consistent Supply: Unaffected by seasonal or agricultural variables, ensuring reliable lead times and material uniformity.

- Lower Lifetime Cost: Reduced maintenance expenses and extended product lifespan decrease total cost of ownership.

- Eco-Certified: Compliant with REACH, OEKO-TEX® STANDARD 100, and GRS (Global Recycled Standard) for traceable sustainability.

Comparative Analysis: WINIW Custom Leather Cushions vs. Real Leather

| Criteria | WINIW Custom Leather Cushions | Real Leather |

|---|---|---|

| Cost | Moderate initial cost; up to 30% lower lifetime cost due to minimal maintenance and longer replacement cycles. | High initial cost; significant ongoing expenses for conditioning, cleaning, and early replacement due to wear. |

| Durability | Exceptional resistance to abrasion, UV fading, stains, and cracking. Engineered for 10,000+ double-rub cycles. Ideal for high-traffic commercial use (e.g., hospitality, automotive). | Prone to drying, cracking, and staining without rigorous upkeep. Natural variations create weak spots; typically lasts 5–7 years in commercial settings. |

| Eco-Friendliness | Carbon-neutral production (scope 1 & 2); 60–100% recycled content options; zero toxic tanning chemicals; fully recyclable at end-of-life. | High environmental burden: 15,000–20,000L water per hide, toxic chromium tanning, methane emissions from livestock, and non-recyclable waste. |

Strategic Recommendation for B2B Partners

WINIW’s custom leather cushions deliver superior value for commercial applications where sustainability, cost predictability, and performance consistency are non-negotiable. While real leather carries traditional prestige, its ecological impact, supply chain volatility, and hidden maintenance costs make it increasingly misaligned with modern ESG mandates and circular economy goals. WINIW empowers brands to innovate responsibly—without compromising on luxury or longevity.

Elevate your product line with materials engineered for the future. Request WINIW’s technical datasheets or a sample kit to validate performance for your specific application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, operating from a state-of-the-art production facility spanning 100,000 square meters. Strategically located to support global supply chains, our factory integrates advanced manufacturing technologies with sustainable practices to deliver premium materials for demanding international markets.

Our large-scale production capacity enables us to meet high-volume orders efficiently while maintaining consistent quality across batches. This extensive infrastructure supports agile manufacturing cycles, ensuring timely delivery for B2B partners across industries such as automotive, fashion, furniture, and technical textiles.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 50 engineers and material scientists focused on innovation in durability, texture, and eco-friendly formulations.

- Continuous investment in research to develop low-VOC, recycled, and bio-based synthetic leather solutions aligned with global sustainability standards.

- Fully integrated production lines that allow tight control over every stage—from base fabric preparation to coating, finishing, and inspection.

Quality is central to our manufacturing philosophy. WINIW enforces a strict quality control (QC) system that adheres to international standards. Every product undergoes rigorous testing for:

- Color fastness and abrasion resistance

- Tensile and tear strength

- Environmental compliance (REACH, RoHS, CA Prop 65, and others)

Our QC protocols are verified through third-party certifications and regular audits, ensuring reliability for partners in highly regulated markets.

WINIW exports to over 50 countries, with a strong presence in Europe and the USA. Our global logistics network and local service teams support seamless collaboration with brand owners, converters, and Tier-1 suppliers. By combining scale, innovation, and compliance, WINIW delivers synthetic leather solutions that meet the performance and sustainability expectations of today’s forward-thinking businesses.

Contact Us for Samples

WINIW™ Premium Synthetic Leather: B2B Product Guide for High-Performance Cushion Applications

WINIW delivers innovative, eco-conscious synthetic leather solutions engineered specifically for demanding commercial and industrial cushion applications. Our materials combine uncompromising durability, exceptional comfort, and verified sustainability—meeting the rigorous standards of furniture manufacturers, automotive suppliers, and contract interior designers. Backed by decades of R&D and global certifications, WINIW provides the performance edge your products require while reducing environmental impact.

Core Advantages for Cushion Manufacturing

- Superior Durability & Wear Resistance: Engineered for 50,000+ double rubs (Martindale test), ensuring longevity in high-traffic commercial seating, automotive interiors, and healthcare settings.

- Enhanced Comfort & Softness: Microfiber base structure mimics natural leather’s suppleness while offering consistent thickness and breathability for all-day comfort.

- Eco-Certified Production: OEKO-TEX® STANDARD 100 Class I (skin-friendly), ISO 14001 certified facilities, and 30%+ post-consumer recycled content options available.

- Streamlined Manufacturing: Uniform thickness, minimal stretch, and excellent cutting yield reduce waste by up to 15% compared to traditional leather.

- Customizable Performance: Tailor color fastness (light/rub), flame resistance (FMVSS 302, CAL 117), and antimicrobial properties to your exact specifications.

WINIW Cushion-Grade Material Specifications

| Property | Standard Performance | Premium Cushion Grade | Test Method |

|---|---|---|---|

| Abrasion Resistance | 30,000 double rubs | 50,000+ double rubs | ASTM D4157 |

| Tensile Strength | 180 N | 220 N | ISO 1767 |

| Color Fastness (Light) | Grade 4 | Grade 5 | ISO 105-B02 |

| Breathability | 800 g/m²/24h | 1,200 g/m²/24h | ISO 5636-4 |

| Recycled Content | 0-15% | 30%+ | GRST Certified |

| Lead Time (Custom) | 15-20 days | 10-15 days | – |

Custom Leather Cushion Solutions

WINIW excels in creating bespoke synthetic leather for cushion cores, upholstery, and trim. Our technical team collaborates with your design and engineering departments to:

– Develop exclusive textures (suede, pebbled, smooth) optimized for cushion ergonomics.

– Integrate memory foam compatibility without delamination or compression set.

– Achieve precise color matching (Pantone®/RAL) with UV-stable pigments.

– Certify materials to global safety standards (e.g., REACH, Prop 65, GREENGUARD).

Ready to elevate your cushion performance sustainably?

Request FREE samples of our premium cushion-grade synthetic leather and experience WINIW’s quality firsthand. Our technical specialists will help you select or develop the ideal material for your next project—reducing costs, lead times, and environmental footprint.

→ Contact WINIW’s B2B Solutions Team Today

Email: MKT88@MicrofiberLeather.com

Subject Line: “Custom Cushion Sample Request – [Your Company Name]”

Samples ship within 48 hours. Volume pricing and technical datasheets available upon inquiry.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.