Introduction: Navigating the Global Market for custom leather bags

Navigating the global market for custom leather bags presents a unique challenge for B2B buyers, particularly when it comes to sourcing high-quality products that meet diverse regional preferences and standards. As businesses expand their reach into markets across Africa, South America, the Middle East, and Europe, understanding the intricacies of custom leather bag manufacturing becomes essential. This guide aims to equip international buyers with the knowledge necessary to make informed purchasing decisions by covering various aspects, including types of custom leather bags, their applications across different industries, effective supplier vetting strategies, and insights into pricing structures.

With the growing demand for personalized and bespoke leather products, buyers need to discern the quality and craftsmanship that align with their brand values. This guide not only highlights the importance of customization options—from color choices to unique design features—but also emphasizes the role of supplier reliability and ethical practices in the leather industry. By delving into the nuances of sourcing custom leather bags, this comprehensive resource empowers B2B buyers to navigate the complexities of international trade, ensuring they select suppliers who can deliver products that resonate with their target markets, whether in Nigeria, Germany, or beyond. The insights provided here will enable businesses to forge strong partnerships and create lasting impressions with their clients through exquisite leather offerings.

Table Of Contents

- Top 4 Custom Leather Bags Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather bags

- Understanding custom leather bags Types and Variations

- Key Industrial Applications of custom leather bags

- 3 Common User Pain Points for ‘custom leather bags’ & Their Solutions

- Strategic Material Selection Guide for custom leather bags

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather bags

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather bags’

- Comprehensive Cost and Pricing Analysis for custom leather bags Sourcing

- Alternatives Analysis: Comparing custom leather bags With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather bags

- Navigating Market Dynamics and Sourcing Trends in the custom leather bags Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather bags

- Strategic Sourcing Conclusion and Outlook for custom leather bags

- Important Disclaimer & Terms of Use

Understanding custom leather bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Tote Bags | Spacious, open-top design with handles; often personalized. | Retail, promotional events, corporate gifts. | Pros: Versatile and functional; Cons: Less secure. |

| Bespoke Briefcases | Tailored to individual specifications, often with multiple compartments. | Professional use, executive gifts, branding. | Pros: Highly personalized; Cons: Longer lead time. |

| Personalized Backpacks | Customizable size, pockets, and colors; suitable for casual or business use. | Education, travel, corporate branding. | Pros: Practical and trendy; Cons: May not suit formal settings. |

| Custom Messenger Bags | Adjustable straps, sleek design, often with branding options. | Delivery services, tech companies, promotions. | Pros: Stylish and functional; Cons: Limited capacity. |

| Luxury Handcrafted Bags | Made from premium materials with artisanal craftsmanship; fully customizable. | High-end retail, luxury branding, gifts. | Pros: Unique and high-quality; Cons: Higher cost. |

What Are the Characteristics of Custom Tote Bags?

Custom tote bags are characterized by their spacious, open-top design, making them ideal for carrying various items. They are often made from durable leather and can be personalized with logos, colors, or initials, enhancing brand visibility during promotional events. B2B buyers in retail and corporate sectors find tote bags useful for giveaways or as part of merchandise. However, their open design may compromise security, which is a consideration for businesses focusing on safety.

How Do Bespoke Briefcases Stand Out in the Market?

Bespoke briefcases are designed entirely to meet individual specifications, including size, compartments, and finishes. They are popular among professionals who require organization and style in their daily commute. These bags can be tailored to reflect a company’s brand through custom colors and logos. B2B buyers should consider the longer lead times associated with bespoke orders, as well as the potential for a higher price point due to the level of craftsmanship involved.

Why Choose Personalized Backpacks for Corporate Use?

Personalized backpacks offer a blend of functionality and style, making them suitable for various applications, from educational settings to corporate branding. They can be customized in size, pocket configurations, and colors to align with a company’s identity. Businesses targeting younger demographics or casual environments find these bags particularly appealing. However, it’s important to note that while backpacks are practical, they may not fit formal business settings.

What Are the Benefits of Custom Messenger Bags?

Custom messenger bags are designed with adjustable straps and a sleek profile, often featuring branding options for corporate identity. They cater to professionals, especially in tech and delivery services, due to their easy access and stylish appearance. B2B buyers appreciate their practicality, but the limited capacity might be a drawback for those needing to carry larger items regularly.

How Do Luxury Handcrafted Bags Differ from Other Custom Options?

Luxury handcrafted bags are distinguished by their premium materials and artisanal craftsmanship, allowing for full customization. These bags appeal to high-end retail markets and are often given as executive gifts. The uniqueness of each piece adds significant value, making them an attractive option for B2B buyers looking to impress clients or enhance brand prestige. However, the higher cost associated with these bags may limit their accessibility for some businesses.

Key Industrial Applications of custom leather bags

| Industry/Sector | Specific Application of custom leather bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom handbags for brand differentiation | Enhances brand identity and customer loyalty | Quality of leather, craftsmanship, and customization options |

| Corporate Gifting | Personalized leather bags for employee recognition | Builds employee morale and strengthens corporate culture | Customization capabilities, lead times, and bulk order discounts |

| Travel & Tourism | Customized luggage and travel accessories | Increases brand visibility and customer satisfaction | Durability, weight, and design options for different travel needs |

| Promotional Merchandise | Branded leather bags for events and marketing campaigns | Effective marketing tool that promotes brand awareness | Minimum order quantities, branding options, and delivery timelines |

| Education & Training | Custom bags for educational institutions and training programs | Enhances student engagement and institutional branding | Size, design, and material specifications for educational purposes |

How Are Custom Leather Bags Used in the Fashion Retail Sector?

In the fashion retail industry, custom leather bags serve as a vital tool for brand differentiation. Retailers can offer bespoke handbags that reflect their unique design ethos, allowing them to stand out in a competitive market. These bags often feature customizations like monograms, specific color combinations, and unique hardware, which not only enhance the product’s appeal but also foster brand loyalty among consumers. B2B buyers should focus on sourcing high-quality leather and craftsmanship to ensure that the final product meets the brand’s luxury standards.

What Are the Benefits of Custom Leather Bags in Corporate Gifting?

Corporate gifting has evolved into a strategic initiative for enhancing employee recognition and engagement. Custom leather bags serve as ideal gifts that can be personalized with employee names or company logos, reinforcing a sense of belonging and appreciation. This practice not only boosts morale but also strengthens corporate culture. When sourcing these items, businesses should consider the customization options available, lead times, and the potential for bulk order discounts to maximize their investment.

How Do Custom Leather Bags Enhance Travel and Tourism Experiences?

In the travel and tourism sector, customized luggage and travel accessories can significantly enhance customer satisfaction and brand visibility. Travel companies can offer bespoke bags that reflect their brand identity, making them memorable to customers. These bags can be tailored for durability and functionality, catering to the specific needs of travelers. B2B buyers should prioritize sourcing options that offer a range of designs and materials suited for various travel purposes, ensuring the products are both appealing and practical.

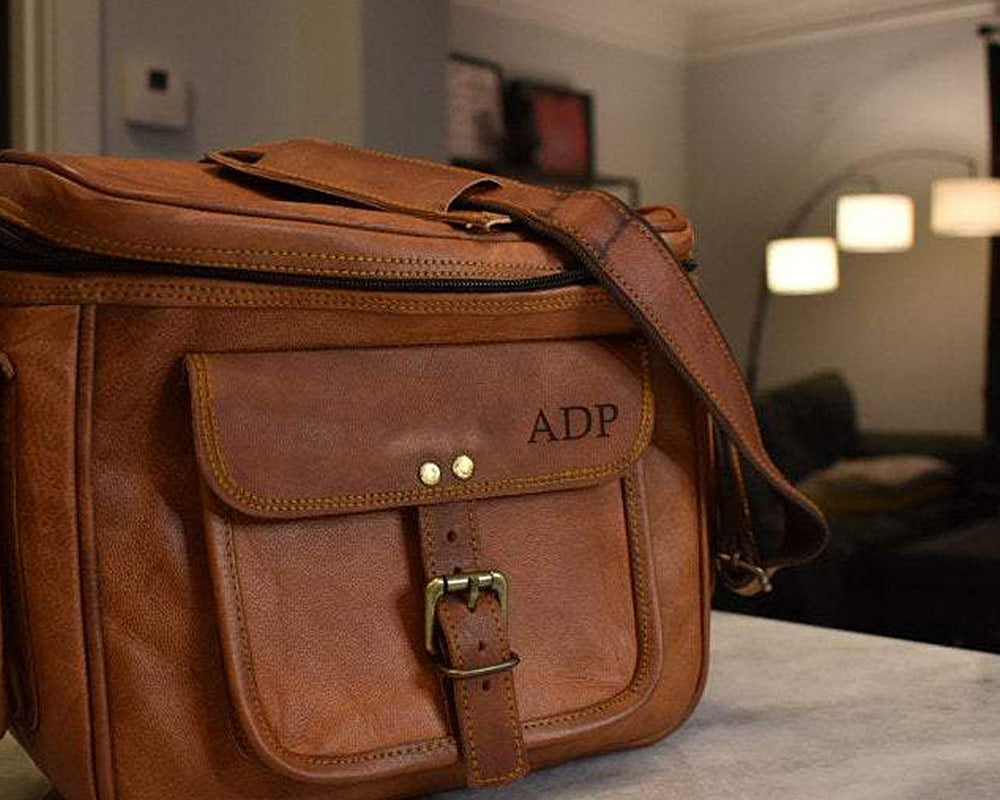

Illustrative image related to custom leather bags

Why Are Custom Leather Bags Effective for Promotional Merchandise?

Custom leather bags are increasingly used as promotional merchandise during events and marketing campaigns. These bags serve as effective marketing tools, providing high visibility for brands while also offering utility to customers. The ability to customize bags with logos and event-specific designs can significantly enhance brand awareness. Buyers should consider minimum order quantities, branding options, and delivery timelines when sourcing these products to ensure they align with marketing strategies and budget constraints.

How Can Educational Institutions Benefit from Custom Leather Bags?

Educational institutions can leverage custom leather bags for various purposes, including student engagement and branding. Customized bags can be provided to students during orientation or as part of promotional materials for training programs, enhancing the overall experience and institutional identity. Buyers in this sector should focus on specific requirements such as size, design, and material specifications that cater to the academic environment, ensuring that the products are functional and appealing to students.

3 Common User Pain Points for ‘custom leather bags’ & Their Solutions

Scenario 1: Quality Assurance for Bulk Orders of Custom Leather Bags

The Problem: When sourcing custom leather bags, B2B buyers often face the challenge of ensuring consistent quality across bulk orders. This is particularly crucial for businesses planning to resell these products or use them as corporate gifts. Variability in craftsmanship, leather quality, and finishing can lead to customer dissatisfaction and harm the buyer’s brand reputation. Additionally, with international sourcing, buyers may struggle to assess quality without physically inspecting samples, leading to potential discrepancies in expectations versus reality.

The Solution: To mitigate quality concerns, B2B buyers should establish clear specifications and standards before placing bulk orders. This includes detailing the types of leather, stitching methods, and finishes required. Conducting a thorough supplier evaluation is also essential; seek out manufacturers with a proven track record in producing high-quality leather goods. Request samples of previous work and set up video calls to discuss quality control processes. Additionally, consider implementing quality assurance checkpoints during the production process, where the supplier provides updates and samples for approval before mass production begins. This proactive approach helps ensure that the final products meet expectations and reduces the risk of costly returns or dissatisfied customers.

Scenario 2: Overcoming Communication Barriers in Customization Requests

The Problem: Customization is a major draw for B2B buyers of leather bags, but miscommunication regarding design specifications can lead to frustration and wasted resources. International buyers may encounter language barriers, cultural differences, or unfamiliarity with design terminology, which complicates the process of conveying unique requirements. This can result in products that do not align with the buyer’s vision, necessitating costly revisions or replacements.

The Solution: To streamline communication, B2B buyers should invest time in creating comprehensive design briefs. This document should include clear visuals, detailed descriptions of desired features, and any specific materials or colors. Using design software to create mock-ups can significantly enhance understanding. Engaging in direct communication with suppliers, whether through video conferencing or in-person meetings, can also foster better relationships and clarify expectations. Furthermore, consider involving a local agent or intermediary who understands both parties’ languages and cultural nuances to facilitate smoother negotiations. This approach minimizes the risk of miscommunication and ensures that the final products reflect the buyer’s needs accurately.

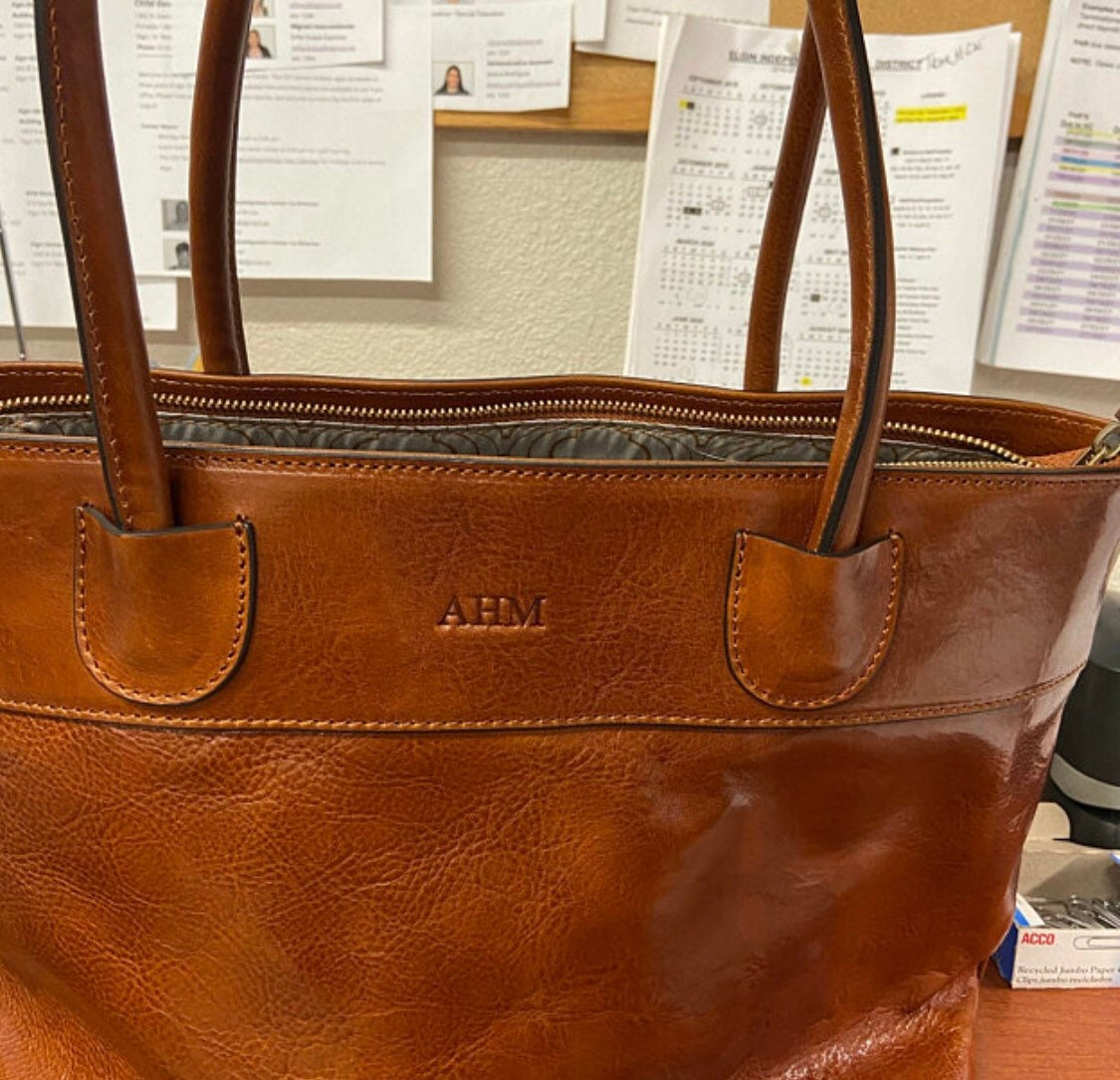

Illustrative image related to custom leather bags

Scenario 3: Managing Lead Times and Delivery Expectations

The Problem: One of the most pressing challenges for B2B buyers of custom leather bags is managing lead times and delivery expectations. Buyers often face pressure to meet tight deadlines for product launches or promotional events. However, custom leather products typically have longer lead times due to the intricate craftsmanship involved. Unexpected delays can disrupt business plans and lead to financial losses.

The Solution: To effectively manage lead times, B2B buyers should establish a detailed timeline with their suppliers at the outset of the order process. This timeline should account for each phase of production, from design approval to final delivery. Buyers should also build in buffer time to accommodate potential delays, ensuring they are not left scrambling at the last minute. Regular check-ins with the supplier can provide updates on production status and allow for timely adjustments if any issues arise. Additionally, exploring partnerships with multiple suppliers can provide alternative options if one supplier experiences delays. By proactively managing expectations and timelines, buyers can mitigate the risks associated with lead times and maintain smooth operational flow.

Strategic Material Selection Guide for custom leather bags

What Are the Key Materials for Custom Leather Bags?

When selecting materials for custom leather bags, understanding the properties, advantages, and limitations of each material is crucial for B2B buyers. This guide analyzes four common materials used in the production of custom leather bags: full-grain leather, top-grain leather, suede, and synthetic leather. Each material presents unique characteristics that can affect the performance and appeal of the final product.

How Does Full-Grain Leather Perform in Custom Leather Bags?

Full-grain leather is the highest quality leather available, known for its durability and natural look. It retains the original grain of the hide, making each piece unique. This material is resistant to wear and develops a beautiful patina over time, enhancing its aesthetic appeal. Its temperature and pressure ratings are excellent, making it suitable for various climates.

Pros: Full-grain leather is extremely durable and age-resistant, providing longevity for custom bags. It is also breathable, which helps maintain the integrity of the bag’s contents.

Cons: The cost of full-grain leather is typically high, and its manufacturing process can be complex due to the need for skilled craftsmanship. Additionally, it may require special care to maintain its appearance.

For international buyers, particularly from regions like Africa and Europe, compliance with environmental standards is essential. Full-grain leather often meets stringent regulations, making it a reliable choice for eco-conscious brands.

What Are the Benefits of Top-Grain Leather for Custom Bags?

Top-grain leather is the second-highest quality leather, made by sanding down the top layer of the hide to remove imperfections. This process gives it a more uniform appearance while retaining some of the leather’s natural characteristics.

Pros: It is more affordable than full-grain leather while still offering good durability and a refined look. It is easier to clean and maintain, making it suitable for everyday use.

Cons: While still durable, top-grain leather is less resistant to scratches and wear compared to full-grain leather. It may not develop the same rich patina over time, which can be a drawback for some customers.

Illustrative image related to custom leather bags

For buyers in South America and the Middle East, top-grain leather can be a cost-effective option that still meets quality expectations, particularly for products aimed at a mid-range market.

How Does Suede Compare as a Material for Custom Leather Bags?

Suede, made from the underside of animal hides, offers a soft texture and a unique aesthetic. Its porous nature allows for breathability, making it a popular choice for fashion-forward designs.

Pros: Suede provides a luxurious feel and is available in various colors, allowing for creative customization options. It is lightweight, which can be advantageous for certain bag designs.

Cons: Suede is less durable than full-grain or top-grain leather and is more susceptible to stains and water damage. It requires careful maintenance to preserve its appearance.

For international buyers, especially in humid climates, understanding the care requirements for suede is essential. Compliance with local regulations regarding animal welfare and material sourcing should also be considered.

Illustrative image related to custom leather bags

What Role Does Synthetic Leather Play in Custom Bag Manufacturing?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative to traditional leather. It mimics the look and feel of genuine leather while being more affordable and easier to maintain.

Pros: Synthetic leather is highly versatile, resistant to stains, and available in various colors and textures. It is also a cruelty-free option, appealing to eco-conscious consumers.

Cons: While durable, synthetic leather may not offer the same longevity as genuine leather. It can also lack the unique character and aging qualities that natural leather possesses.

For buyers in Europe and Africa, synthetic leather can be an attractive option due to its cost-effectiveness and compliance with vegan and environmental standards.

Summary Table of Material Selection for Custom Leather Bags

| Material | Typical Use Case for Custom Leather Bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags, high-end backpacks | Exceptional durability and unique patina | High cost and requires special care | High |

| Top-Grain Leather | Everyday bags, mid-range products | Affordable with good durability | Less resistant to wear than full-grain | Medium |

| Suede | Fashion bags, trendy accessories | Soft texture and variety of colors | Less durable and requires careful maintenance | Medium |

| Synthetic Leather | Budget-friendly bags, vegan options | Cost-effective and easy to maintain | May lack longevity and unique character | Low |

This strategic material selection guide aims to equip B2B buyers with the knowledge needed to make informed decisions when sourcing custom leather bags, ensuring that the chosen materials align with market demands and compliance standards.

Illustrative image related to custom leather bags

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather bags

What Are the Main Stages in the Manufacturing Process of Custom Leather Bags?

The manufacturing of custom leather bags involves several meticulous stages that ensure both quality and personalization. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in crafting high-quality leather bags is the careful selection and preparation of materials. Leather types vary significantly, from full-grain to top-grain and corrected grain, each offering different textures and durability. After selecting the leather, it undergoes conditioning to enhance its flexibility and prevent damage during the manufacturing process. Additionally, other materials such as linings, hardware, and stitching threads are also sourced, ensuring they meet quality standards.

How Is the Forming Process Conducted?

Once materials are prepared, the next stage is forming. This involves cutting the leather into the desired shapes and sizes based on the bag design. Advanced cutting techniques, such as die-cutting and laser cutting, are often employed to achieve precision. This stage is critical as it lays the foundation for the bag’s structure.

Illustrative image related to custom leather bags

What Happens During the Assembly of Custom Leather Bags?

The assembly process follows forming, where individual leather pieces are stitched together. Skilled artisans often handle this stage to ensure that the stitching is not only functional but also aesthetically pleasing. Techniques such as saddle stitching and machine stitching are commonly used, depending on the bag’s design and intended use. Additionally, any custom features, such as compartments or personalized engravings, are incorporated during this phase.

How Is the Finishing Process Executed?

Finishing is the final stage in the manufacturing process. This involves applying treatments to enhance the leather’s appearance and durability. Common techniques include dyeing, polishing, and applying protective coatings. Quality control at this stage is vital, as the finishing touches significantly influence the bag’s overall appeal and longevity.

What Quality Assurance Standards Are Relevant for Custom Leather Bags?

Quality assurance (QA) is crucial in ensuring that the final products meet both international standards and customer expectations. For custom leather bags, several key standards and checkpoints are utilized.

Which International Standards Should B2B Buyers Consider?

B2B buyers should look for compliance with ISO 9001, an international standard that sets criteria for quality management systems. This certification indicates that the manufacturer has established processes to ensure quality throughout the production cycle. Other relevant certifications may include CE marking for safety and compliance within the European market.

What Are the Key Quality Control Checkpoints in Leather Bag Manufacturing?

Quality control in leather bag manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint focuses on the quality of raw materials before production begins. Materials are inspected for defects and compliance with specifications.

-

In-Process Quality Control (IPQC): During the assembly and finishing stages, IPQC ensures that the manufacturing process adheres to quality standards. Regular inspections are conducted to catch any deviations early.

-

Final Quality Control (FQC): Once the bags are complete, a thorough inspection is performed to assess the finished product’s quality. This includes checking for stitching integrity, finishing quality, and overall craftsmanship.

What Testing Methods Are Commonly Used in Quality Assurance for Leather Bags?

B2B buyers should be aware of the common testing methods used to ensure the durability and quality of custom leather bags. These may include:

Illustrative image related to custom leather bags

-

Tensile Strength Testing: Measures the leather’s ability to withstand pulling forces without tearing.

-

Color Fastness Testing: Assesses how well the dye holds up against exposure to light and moisture, ensuring that colors do not fade over time.

-

Water Resistance Testing: Evaluates the bag’s ability to repel water, which is crucial for customer satisfaction in various climates.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps.

What Are the Best Practices for Auditing Leather Bag Manufacturers?

Conducting audits is an effective way to verify a supplier’s quality control practices. Buyers should request:

-

Quality Control Reports: These documents detail the results of inspections and testing conducted at various stages of production.

-

Factory Audits: Buyers can conduct on-site audits to assess manufacturing practices, equipment, and overall working conditions.

-

Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly important for buyers from regions such as Africa and South America, where manufacturing practices may vary widely.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Control Certifications?

International buyers, especially from Europe and the Middle East, must be aware of the nuances in quality control certifications. Certification requirements may differ based on local regulations and market standards. For instance, while ISO certifications are widely recognized, certain regions may have additional certifications that enhance marketability or compliance with local laws.

Understanding these nuances can help buyers select suppliers that not only meet their quality expectations but also align with regional regulations and consumer preferences.

Conclusion

In summary, the manufacturing process and quality assurance for custom leather bags encompass a range of meticulous stages and standards. By understanding these processes and actively verifying supplier practices, B2B buyers can ensure they source high-quality, durable products that meet their specifications. As the market for custom leather goods continues to grow, maintaining stringent quality assurance practices will be vital for success in the competitive landscape.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather bags’

In the competitive landscape of custom leather bags, B2B buyers must navigate a comprehensive sourcing process to ensure they procure high-quality products that meet their specific needs. This step-by-step checklist will guide you through the essential stages of sourcing custom leather bags effectively.

Illustrative image related to custom leather bags

Step 1: Define Your Technical Specifications

Clearly outline the specifications for your custom leather bags. This includes dimensions, materials, design features, and any branding requirements. Defining these parameters ensures that suppliers understand your needs, reducing the risk of misunderstandings and ensuring a smoother production process.

- Material Selection: Specify whether you require genuine leather, synthetic alternatives, or specific finishes (e.g., pebbled or smooth).

- Functionality: Determine the intended use of the bags, which will influence design elements like compartments and closures.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather bags. Look for manufacturers with a solid reputation and experience in producing similar products.

- Review Portfolios: Examine their previous work to assess quality and craftsmanship.

- Check Certifications: Ensure they adhere to industry standards and sustainability practices, which can be particularly important in regions with stringent regulations.

Step 3: Evaluate Supplier Capabilities

Once you’ve shortlisted suppliers, evaluate their production capabilities. It’s crucial to understand their capacity to handle your order volume and customization requests.

Illustrative image related to custom leather bags

- Production Capacity: Ask about their lead times and the maximum order quantities they can manage.

- Customization Options: Inquire about the extent of customization available—can they accommodate unique designs or alterations to existing models?

Step 4: Request Samples

Before finalizing your order, request samples of the bags you are interested in. This step allows you to assess the quality of materials and craftsmanship firsthand.

- Quality Assessment: Inspect the stitching, leather quality, and overall finish.

- Functionality Check: Test the bags for usability, ensuring they meet your specifications.

Step 5: Negotiate Terms and Pricing

Discuss pricing and payment terms with your chosen supplier. Ensure that both parties have a clear understanding of costs, including any additional fees for customization or shipping.

- Transparent Pricing: Request a detailed breakdown of costs to avoid hidden charges.

- Payment Options: Consider flexible payment terms that may be beneficial for your cash flow.

Step 6: Establish Communication Protocols

Set up clear communication channels to maintain a smooth dialogue with your supplier throughout the production process. Effective communication can prevent issues and misunderstandings.

- Regular Updates: Agree on a schedule for progress updates.

- Point of Contact: Designate a representative from both sides to streamline communication.

Step 7: Finalize Contracts and Agreements

Once you are satisfied with the terms, finalize contracts that outline all agreed-upon specifications, pricing, and timelines. This legal document protects both parties and ensures accountability.

- Clear Deliverables: Include detailed descriptions of the products, timelines, and quality standards.

- Dispute Resolution: Establish procedures for addressing any potential disputes that may arise during the project.

By following this checklist, you can effectively navigate the complexities of sourcing custom leather bags, ensuring that you partner with the right supplier to meet your business needs.

Comprehensive Cost and Pricing Analysis for custom leather bags Sourcing

What Are the Key Cost Components in Custom Leather Bags Sourcing?

When sourcing custom leather bags, a comprehensive understanding of the cost structure is essential. The primary cost components include:

-

Materials: The choice of leather significantly impacts costs. High-quality calf leather, for instance, commands a premium price compared to synthetic alternatives. Additional materials for linings, zippers, and embellishments also contribute to the overall material cost.

-

Labor: Skilled artisans are required for the intricate craftsmanship involved in custom leather bag production. Labor costs can vary based on the region and the level of expertise. In countries with lower labor costs, such as parts of South America or Africa, you may find competitive pricing, but quality assurance is crucial.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, equipment maintenance, and other indirect costs associated with the production process. Efficient operations can lower these costs, allowing for more competitive pricing.

-

Tooling: Custom designs often require unique molds or tools, which can be an upfront investment. This cost is typically amortized over the volume of bags produced, making it crucial to negotiate favorable minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring that each bag meets specified standards incurs costs related to inspection, testing, and potential rework. A robust QC process is essential for maintaining brand reputation, especially in international markets.

-

Logistics: Shipping costs can vary widely based on the destination, chosen Incoterms, and the urgency of delivery. International buyers should account for customs duties and taxes, which can add to the total landed cost.

-

Margin: Suppliers will typically add a markup to cover their costs and ensure profitability. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect Custom Leather Bags Sourcing?

Several factors influence the pricing of custom leather bags, which B2B buyers should consider:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating MOQs can significantly impact pricing.

-

Specifications/Customization: The level of customization (e.g., unique designs, materials, and features) can increase costs. Providing clear specifications can help suppliers offer accurate quotes.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., environmentally friendly practices) typically result in higher prices. Buyers should weigh the benefits of these factors against their budget constraints.

-

Supplier Factors: Established suppliers with a good reputation may charge higher prices due to perceived quality and reliability. Conversely, new or lesser-known suppliers may offer lower prices but could pose risks regarding quality and delivery times.

-

Incoterms: Understanding Incoterms is vital for cost management. Different terms dictate who bears the cost of shipping, insurance, and customs, affecting the total cost of ownership.

What Negotiation Strategies Can Help Achieve Cost-Efficiency in Custom Leather Bags?

For international B2B buyers, especially from diverse markets like Africa, South America, the Middle East, and Europe, effective negotiation can lead to substantial savings. Here are key strategies:

-

Establish Clear Requirements: Providing detailed specifications can minimize miscommunication and unexpected costs during production.

-

Research Market Prices: Understanding the market landscape helps in negotiating better prices. Comparing multiple suppliers can give leverage in discussions.

-

Build Long-Term Relationships: Fostering strong relationships with suppliers can lead to better terms and pricing over time. Loyalty often results in preferential treatment and lower costs.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also factors like shipping, potential tariffs, and maintenance costs over the product’s life cycle.

-

Be Open to Flexible Terms: Propose alternative arrangements, such as flexible payment terms or staggered deliveries, which might be beneficial for both parties.

Conclusion: Why is Understanding Pricing Nuances Crucial for International Buyers?

Navigating the complex landscape of custom leather bag sourcing requires an awareness of cost structures and pricing influencers. By understanding these nuances, B2B buyers can make informed decisions that align with their budgetary constraints while ensuring product quality. Always remember that indicative prices may fluctuate based on market conditions, so continuous engagement with suppliers is vital to staying updated on trends and costs.

Illustrative image related to custom leather bags

Alternatives Analysis: Comparing custom leather bags With Other Solutions

In the realm of personalized accessories, custom leather bags have carved out a significant niche. However, various alternatives also exist that serve similar purposes, appealing to different customer segments and preferences. Understanding these alternatives can help B2B buyers make informed decisions that align with their specific requirements.

| Comparison Aspect | Custom Leather Bags | Canvas Tote Bags | Synthetic Leather Bags |

|---|---|---|---|

| Performance | High durability and luxury feel | Good for casual use but less durable | Moderate durability; may not withstand wear over time |

| Cost | Generally higher price point due to craftsmanship | Affordable, typically budget-friendly | Varies, generally lower than leather but higher than canvas |

| Ease of Implementation | Custom orders may take longer due to personalization | Readily available in various styles | Widely available; easy to source |

| Maintenance | Requires care to maintain appearance | Easy to clean, generally machine washable | Low maintenance; resistant to stains |

| Best Use Case | Corporate gifts, luxury branding, high-end retail | Casual outings, promotional giveaways | Budget-conscious clients, short-term use |

What Are the Advantages and Disadvantages of Canvas Tote Bags?

Canvas tote bags are a popular alternative to custom leather bags, especially for businesses looking for cost-effective promotional items. They are lightweight, easy to clean, and can be produced in bulk at a lower cost. However, while they serve well for casual use, they lack the durability and luxurious appeal of leather, making them less suitable for high-end markets or corporate gifts. Their lifespan is generally shorter, which may not align with a brand’s commitment to quality.

How Do Synthetic Leather Bags Compare to Custom Leather Bags?

Synthetic leather bags offer a more affordable option that mimics the look of real leather without the associated costs. They are easier to source and maintain, appealing to buyers looking for quick and budget-friendly solutions. However, they often do not match the durability or premium feel of custom leather bags, which can affect customer perception and satisfaction. Brands that prioritize sustainability may also find synthetic options less appealing, as they are typically made from petroleum-based materials.

Making the Right Choice for Your Business Needs

When choosing between custom leather bags and alternative options like canvas or synthetic leather bags, B2B buyers should assess their target market, brand positioning, and budget constraints. Custom leather bags are ideal for businesses looking to convey quality and exclusivity, whereas canvas tote bags or synthetic options might be better suited for promotional campaigns or budget-sensitive projects. Understanding the nuances of each alternative will empower buyers to select the best solution that aligns with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather bags

What Are the Essential Technical Properties of Custom Leather Bags?

When sourcing custom leather bags, understanding their technical properties is crucial for making informed purchasing decisions. Here are several key specifications that influence product quality and customer satisfaction:

Illustrative image related to custom leather bags

1. Material Grade

The grade of leather used in manufacturing significantly affects the durability and aesthetic appeal of the bags. Full-grain leather, for instance, is the highest quality, showcasing natural imperfections and providing exceptional durability. In contrast, bonded leather, made from scraps, offers a more affordable option but lacks the longevity and luxurious feel of higher grades. For B2B buyers, selecting the right material grade ensures that the final product meets their quality standards and customer expectations.

2. Tolerance Levels

Tolerance levels refer to the acceptable variations in dimensions and characteristics during production. This specification is critical in custom leather bags where precise measurements impact functionality and design, such as strap lengths or compartment sizes. Ensuring strict adherence to tolerance levels helps avoid costly production errors and enhances the overall customer experience by delivering products that meet precise requirements.

3. Stitching Techniques

The stitching technique used in leather bags not only contributes to the bag’s aesthetic but also its strength. For example, double stitching is preferred for high-stress areas, providing enhanced durability, while single stitching may be adequate for less demanding sections. B2B buyers should inquire about stitching methods to ensure that the bags can withstand daily use and maintain their structural integrity over time.

Illustrative image related to custom leather bags

4. Finish Type

The finish applied to leather impacts both its appearance and functionality. Common finishes include matte, glossy, and distressed. Each finish serves a specific purpose, such as enhancing water resistance or providing a vintage look. Understanding the types of finishes available allows B2B buyers to select options that align with their brand image and customer preferences.

5. Weight Capacity

Understanding the weight capacity of custom leather bags is essential for ensuring they meet their intended use, whether for travel, daily commutes, or specialized purposes like photography or sports. Manufacturers often provide guidelines on weight limits based on the materials and construction methods used. This information helps buyers select bags that will not only be functional but also safe for their customers.

What Common Trade Terms Should B2B Buyers Know When Purchasing Custom Leather Bags?

Navigating the world of custom leather bags requires familiarity with industry terminology. Here are some essential terms that can aid B2B buyers in their procurement processes:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are then marketed by another company under its brand name. In the context of custom leather bags, working with an OEM allows buyers to leverage established manufacturing capabilities while focusing on branding and market strategies.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers to determine whether a supplier can meet their demand without incurring excess costs. Buyers should negotiate MOQs to align with their inventory management strategies.

Illustrative image related to custom leather bags

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other information for specified products. It is a critical step in the procurement process, allowing buyers to compare different suppliers’ offerings and make informed purchasing decisions.

4. Incoterms

Incoterms (International Commercial Terms) are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, ensuring smoother transactions across borders.

5. Customization Options

This term refers to the various choices available to buyers when ordering custom leather bags, such as color, size, material, and design features. Understanding the scope of customization options allows buyers to create products that meet specific market needs and differentiate themselves from competitors.

By grasping these essential technical properties and trade terms, B2B buyers can enhance their purchasing strategies for custom leather bags, ensuring they meet both their quality expectations and market demands.

Illustrative image related to custom leather bags

Navigating Market Dynamics and Sourcing Trends in the custom leather bags Sector

What Are the Key Trends Shaping the Custom Leather Bags Market?

The custom leather bags market is experiencing a significant transformation, driven by evolving consumer preferences and technological advancements. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking personalized products that reflect individual tastes and brand identities. This demand for customization is further fueled by the rise of e-commerce platforms that facilitate direct interactions between manufacturers and consumers.

Emerging technologies such as 3D printing and AI-driven design tools are enhancing the customization process, allowing businesses to offer unique, made-to-order products efficiently. Furthermore, the integration of digital supply chains is streamlining operations, improving transparency, and reducing lead times. As a result, B2B buyers can expect quicker turnaround times for custom orders, making it easier to meet market demands.

Another critical trend is the increasing focus on quality and craftsmanship. Buyers are gravitating toward brands that emphasize artisanal techniques and high-quality materials. This shift is particularly evident in regions with a strong heritage of leather craftsmanship, such as Italy and Argentina. As buyers become more discerning, they are willing to invest in premium products that promise durability and unique design elements.

How Is Sustainability Influencing Sourcing Practices in Custom Leather Bags?

Sustainability has emerged as a pivotal concern in the custom leather bags sector, influencing sourcing practices for B2B buyers globally. The environmental impact of traditional leather production, which often involves harmful chemicals and practices, has prompted a shift toward more sustainable alternatives. Buyers are increasingly seeking suppliers who prioritize ethical sourcing and sustainable manufacturing processes, including the use of vegetable-tanned leathers and recycled materials.

Illustrative image related to custom leather bags

The demand for transparency in the supply chain is also on the rise. Buyers are looking for certifications that guarantee the ethical origins of materials and the sustainability of production practices. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential benchmarks for assessing potential suppliers.

Furthermore, the trend toward circular economy practices is gaining traction. Brands that offer repair services, recycling programs, or upcycling options are resonating well with environmentally conscious consumers. B2B buyers should consider collaborating with suppliers who align with these sustainable practices, as they not only enhance brand reputation but also cater to the growing consumer preference for eco-friendly products.

What Is the Historical Context of Custom Leather Bags?

The history of custom leather bags is rich and deeply intertwined with human civilization. Leather has been used for millennia, initially for functional purposes such as clothing and armor. As societies evolved, so did the craftsmanship associated with leather goods, transitioning from mere utility to artistry. By the Middle Ages, bespoke leather items began to gain popularity among the affluent, leading to the establishment of guilds dedicated to leather craftsmanship.

In the modern era, the custom leather bags market has expanded significantly, driven by fashion trends and consumer demand for individuality. The late 20th century saw a resurgence in artisanal craftsmanship, with brands emerging that prioritize bespoke services and high-quality materials. Today, the market is characterized by a blend of traditional techniques and modern technology, allowing for a diverse range of customization options that cater to a global clientele. This evolution underscores the importance of understanding historical craftsmanship in order to appreciate the current trends and future directions of the custom leather bags sector.

Illustrative image related to custom leather bags

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather bags

-

How can I customize a leather bag to meet my specific needs?

To customize a leather bag, begin by reaching out to your supplier with detailed specifications, including design preferences, materials, colors, and any additional features like compartments or personalization options. Many manufacturers offer the ability to modify existing designs or create entirely bespoke pieces tailored to your requirements. Providing sketches or examples of what you envision can facilitate the process and ensure that your final product aligns with your expectations. -

What is the minimum order quantity (MOQ) for custom leather bags?

The MOQ for custom leather bags varies by manufacturer and can depend on factors like the complexity of the design and materials used. Generally, MOQs can range from as few as 10 units to several hundred. It’s crucial to discuss your order size with potential suppliers upfront to understand their policies and negotiate terms that suit your business needs, especially if you are a smaller retailer or startup. -

What payment terms should I expect when ordering custom leather bags?

Payment terms for custom leather bag orders typically include a deposit upfront—usually 30-50%—with the balance due before shipping. Some suppliers may also offer flexible payment options such as credit terms, especially for established buyers. Ensure you clarify payment methods (credit card, bank transfer) and any potential additional fees for international transactions during your discussions with the supplier. -

What quality assurance processes should I look for when sourcing custom leather bags?

When sourcing custom leather bags, inquire about the supplier’s quality assurance (QA) processes. Look for manufacturers who perform inspections at various stages of production, from material selection to final assembly. Certifications such as ISO or adherence to specific quality standards can also indicate a commitment to maintaining high quality. Request samples or detailed product specifications to assess craftsmanship before placing a larger order. -

How long does it take to produce and deliver custom leather bags?

Production and delivery times for custom leather bags can vary widely based on the supplier and the complexity of the order. Generally, you can expect a lead time of 2-6 weeks after finalizing the design and payment. Factors like order size, customization requirements, and shipping methods can influence delivery times, so it’s advisable to establish a clear timeline with your supplier to manage expectations. -

What are the import duties and taxes I need to consider when sourcing custom leather bags internationally?

Import duties and taxes on custom leather bags can vary significantly by country. It’s essential to research the regulations in your region, including tariffs that may apply to leather goods. Consulting with a customs broker or logistics provider can help you navigate these complexities, ensuring you understand all costs involved and avoid unexpected expenses upon importation. -

How can I vet suppliers of custom leather bags to ensure reliability?

To vet suppliers, start by checking their industry reputation through online reviews and testimonials. Request references from past clients and evaluate their responsiveness and professionalism during initial communications. It’s also beneficial to visit their production facilities, if possible, to assess their operations and quality standards. Certifications and membership in trade organizations can further indicate reliability and adherence to industry standards. -

What shipping options are available for custom leather bags, and how do I choose the best one?

Shipping options for custom leather bags typically include air freight for quicker delivery or sea freight for cost-effective bulk shipping. Your choice will depend on factors such as urgency, budget, and destination. Evaluate shipping times, costs, and reliability by discussing options with your supplier and logistics provider. Consider using a freight forwarder to simplify the shipping process and ensure compliance with international shipping regulations.

Top 4 Custom Leather Bags Manufacturers & Suppliers List

1. Del Giudice Roma – Bespoke Leather Bags

Domain: delgiudiceroma.com

Registered: 2013 (12 years)

Introduction: Bespoke and Custom Leather Bags from Del Giudice Roma are high-quality, hand-crafted products made from soft calf leather. Customers can customize existing designs or create bespoke items tailored to their specifications. Options include altering designs, selecting leather finishes (smooth or pebbled), and choosing from a variety of colors. Specific examples of customizable bags include the Hobo B…

2. The Jacket Maker – Custom Leather Bags

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom leather bags for women and men, customizable in color, style, material, finish, and detail. Options include custom handbags, tote bags, backpacks, messenger bags, briefcases, weekender & duffel bags, portfolio bags, and clutch purses.

3. Maxwell Scott – Italian Leather Handbags & Briefcases

Domain: us.maxwellscottbags.com

Registered: 2004 (21 years)

Introduction: This company, Maxwell Scott – Italian Leather Handbags & Briefcases, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Intertwined for Good – Huipil Weekender

Domain: intertwinedforgood.com

Registered: 2022 (3 years)

Introduction: Handmade Leather & Artisan Bags – Ethical & Sustainable Accessories. Curated collection of ethically made, sustainable leather and artisan bags. Handcrafted by skilled artisans in Morocco, Guatemala, and Nepal. Products include: Huipil Weekender ($329.00), Huipil Mini-Weekender ($309.00), Kilim Weekender ($329.00), Leather Circle Purse (Red) ($199.00), Woven Leather Trimmed Circle Purse ($59.00), …

Strategic Sourcing Conclusion and Outlook for custom leather bags

In conclusion, strategic sourcing for custom leather bags presents a unique opportunity for international B2B buyers to capitalize on high-quality craftsmanship and personalization options. By leveraging partnerships with reliable manufacturers, businesses can ensure that they receive products tailored to their specific market needs, enhancing customer satisfaction and brand loyalty. Key takeaways include the importance of understanding supplier capabilities, evaluating customization options, and maintaining clear communication throughout the sourcing process.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for bespoke leather products is expected to grow. By embracing these trends and investing in strategic sourcing, businesses can differentiate themselves in a competitive landscape. Now is the time for B2B buyers to explore partnerships that not only meet their immediate requirements but also align with their long-term vision for quality and innovation in custom leather goods. Engage with potential suppliers today to secure your position in this flourishing market and transform your offerings into truly unique leather experiences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather bags