Introduction: Navigating the Global Market for how do you make leather waterproof

In the competitive landscape of leather goods, understanding how to make leather waterproof is essential for businesses aiming to enhance the longevity and appeal of their products. With varying climate conditions across regions, such as the humid tropics of Africa and the wet winters in Europe, the challenge lies in sourcing effective waterproofing solutions that cater to diverse leather types and applications. This guide offers a comprehensive overview, covering critical aspects such as the different types of leather, suitable waterproofing products, and the best practices for application.

By focusing on supplier vetting, cost considerations, and regional preferences, international B2B buyers from Africa, South America, the Middle East, and Europe—including markets like Vietnam and Germany—will be equipped with the knowledge needed to make informed purchasing decisions. This resource not only addresses the intricacies of leather care but also emphasizes the importance of selecting the right waterproofing techniques to protect investments against environmental damage. As we delve deeper into this guide, you will discover actionable insights that can transform your leather products into resilient, water-resistant assets, ensuring they withstand the test of time and usage.

Table Of Contents

- Top 7 How Do You Make Leather Waterproof Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you make leather waterproof

- Understanding how do you make leather waterproof Types and Variations

- Key Industrial Applications of how do you make leather waterproof

- 3 Common User Pain Points for ‘how do you make leather waterproof’ & Their Solutions

- Strategic Material Selection Guide for how do you make leather waterproof

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you make leather waterproof

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you make leather waterproof’

- Comprehensive Cost and Pricing Analysis for how do you make leather waterproof Sourcing

- Alternatives Analysis: Comparing how do you make leather waterproof With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you make leather waterproof

- Navigating Market Dynamics and Sourcing Trends in the how do you make leather waterproof Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you make leather waterproof

- Strategic Sourcing Conclusion and Outlook for how do you make leather waterproof

- Important Disclaimer & Terms of Use

Understanding how do you make leather waterproof Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wax-Based Treatment | Creates a protective barrier; often includes natural waxes like beeswax. | Footwear, bags, outdoor gear | Pros: Effective water resistance; enhances durability. Cons: Requires regular reapplication. |

| Spray-On Waterproofing | Easy to apply; provides a thin, even coating; often suitable for various leather types. | Fashion accessories, upholstery | Pros: Quick application; dries fast. Cons: May not penetrate deeply; less effective on heavily worn items. |

| Cream Conditioning | Combines conditioning and waterproofing; penetrates deeply into leather fibers. | High-end leather goods, furniture | Pros: Nourishes leather; long-lasting protection. Cons: Requires more time for application and drying. |

| Silicone-Based Products | Offers a strong waterproof barrier; often used in industrial applications. | Workwear, heavy-duty gear | Pros: Excellent water resistance; durable. Cons: Can alter the appearance of leather; may not be suitable for all types. |

| Natural Oil Treatment | Utilizes oils like mink or neatsfoot; enhances water resistance while conditioning. | Outdoor equipment, artisan goods | Pros: Natural ingredients; maintains leather suppleness. Cons: Slower drying time; may darken leather. |

What are the Characteristics of Wax-Based Treatments for Waterproofing Leather?

Wax-based treatments are renowned for their ability to create a robust protective barrier on leather surfaces. These products typically feature natural waxes, such as beeswax, which not only repel water but also enhance the leather’s natural durability. B2B buyers in sectors like footwear and outdoor gear will appreciate the effectiveness of wax treatments in providing long-lasting protection against moisture, though regular reapplication is necessary to maintain their efficacy.

How Does Spray-On Waterproofing Work for Leather?

Spray-on waterproofing solutions are designed for convenience and ease of use. They provide a thin, even coating that dries quickly, making them ideal for a range of leather goods, from fashion accessories to upholstery. However, while these sprays are effective for light protection, they may not penetrate deeply enough for heavily worn items. B2B buyers should consider the frequency of use and the leather’s condition when opting for this method.

Why Choose Cream Conditioning for Leather Waterproofing?

Cream conditioning products combine the benefits of waterproofing with deep conditioning, making them suitable for high-end leather goods and furniture. These creams penetrate deeply into the leather fibers, providing long-lasting protection and nourishment. B2B buyers should keep in mind that while these products offer superior leather care, they require a more time-consuming application process and longer drying times.

What are the Benefits of Silicone-Based Products for Leather?

Silicone-based waterproofing products are favored in industrial applications due to their robust water resistance. These products create a strong barrier that is particularly useful for workwear and heavy-duty gear. However, B2B buyers should be cautious, as silicone treatments can alter the leather’s appearance and may not be compatible with all leather types. Understanding the specific needs of the leather in question is crucial when considering this option.

How Effective are Natural Oil Treatments for Leather Waterproofing?

Natural oil treatments utilize oils such as mink or neatsfoot to enhance water resistance while conditioning the leather. This method is particularly popular among artisans and in outdoor equipment applications. While natural oil treatments maintain the leather’s suppleness, they have longer drying times and may darken the leather. B2B buyers should weigh the benefits of using natural ingredients against the potential changes in appearance when selecting this treatment.

Key Industrial Applications of how do you make leather waterproof

| Industry/Sector | Specific Application of how do you make leather waterproof | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Waterproofing leather shoes and boots | Enhances product durability and customer satisfaction | Sourcing high-quality waterproofing agents and treatments that are compatible with different leather types. |

| Automotive | Leather upholstery for vehicles | Increases lifespan of interior materials and maintains aesthetic quality | Ensuring compliance with industry standards for durability and safety, and sourcing products that are effective against UV and wear. |

| Fashion Accessories | Waterproofing leather bags and wallets | Protects investment and enhances product appeal | Selecting eco-friendly waterproofing solutions that align with brand values and customer expectations. |

| Outdoor Gear | Leather gear for outdoor activities (e.g., jackets, gloves) | Improves performance and user experience in harsh conditions | Finding treatments that provide long-lasting protection while being breathable for comfort. |

| Furniture Manufacturing | Waterproofing leather furniture | Maintains quality and extends the life of products | Sourcing versatile waterproofing solutions that cater to various leather types and finishes. |

How is Leather Waterproofing Applied in the Footwear Manufacturing Sector?

In the footwear manufacturing industry, waterproofing leather shoes and boots is essential to enhance durability and customer satisfaction. By applying effective waterproofing treatments, manufacturers can ensure that their products withstand the rigors of various weather conditions, thereby reducing returns and increasing customer loyalty. When sourcing waterproofing agents, it is crucial to consider compatibility with different leather types, as some treatments may not be suitable for specific materials.

What Role Does Leather Waterproofing Play in Automotive Upholstery?

Leather upholstery in vehicles benefits significantly from waterproofing techniques, which help maintain the aesthetic quality and longevity of interior materials. By implementing waterproofing treatments, automotive manufacturers can prevent damage from spills and moisture, ensuring that seats and interiors remain in pristine condition. Key sourcing considerations include compliance with industry standards for safety and durability, as well as sourcing products that offer protection against UV rays and wear.

How Can Fashion Accessories Benefit from Waterproofing Leather?

In the fashion accessories sector, waterproofing leather bags and wallets protects against environmental damage and enhances product appeal. This is particularly important for brands that emphasize quality and longevity. When sourcing waterproofing solutions, businesses should prioritize eco-friendly products that align with consumer demand for sustainability. Additionally, treatments should be effective without compromising the leather’s natural texture and appearance.

Why is Waterproofing Important for Outdoor Gear?

Waterproofing leather gear, such as jackets and gloves, is crucial in the outdoor industry, where products are exposed to challenging weather conditions. Effective waterproofing improves performance and user experience, ensuring that outdoor enthusiasts remain comfortable and dry. Buyers should look for treatments that provide long-lasting protection while allowing the leather to breathe, ensuring comfort during extended wear. Sourcing high-quality, specialized waterproofing agents is key to meeting the demands of this market.

Illustrative image related to how do you make leather waterproof

How Does Leather Waterproofing Impact Furniture Manufacturing?

In the furniture manufacturing sector, waterproofing leather helps maintain the quality and extends the life of products, which is vital for customer satisfaction and brand reputation. Manufacturers should focus on sourcing versatile waterproofing solutions that cater to various leather types and finishes to ensure compatibility and effectiveness. Additionally, considering the aesthetic impact of treatments on the final product is essential for maintaining the desired look and feel of leather furniture.

3 Common User Pain Points for ‘how do you make leather waterproof’ & Their Solutions

Scenario 1: Inadequate Product Knowledge for Waterproofing Leather

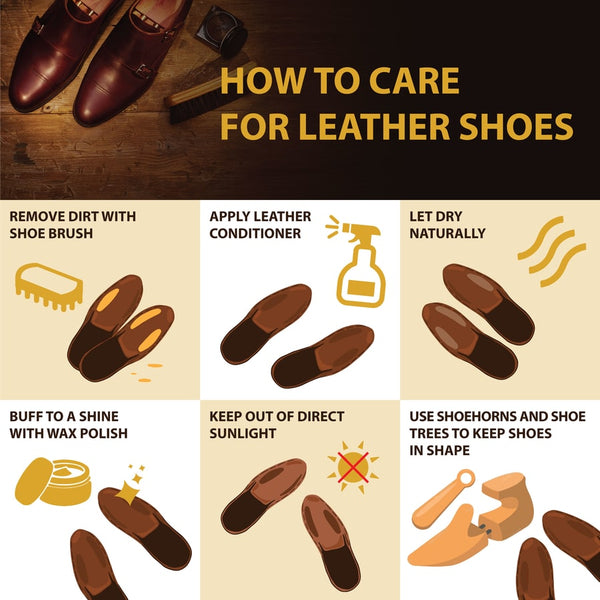

The Problem: B2B buyers often face a steep learning curve when it comes to selecting the right waterproofing products for different types of leather. With an abundance of options—such as sprays, creams, and waxes—buyers may struggle to identify which product suits their specific leather type, such as full-grain, suede, or nubuck. This lack of clarity can lead to improper application, resulting in ineffective waterproofing, damage to the leather, or even product returns.

The Solution: To overcome this challenge, it’s essential for buyers to conduct thorough research on the leather types they are working with and the corresponding waterproofing solutions. Partnering with reputable suppliers who offer detailed product specifications and guides can streamline this process. For instance, leather suppliers often provide insights into their products, outlining which waterproofing agents are best suited for each leather type. Additionally, attending workshops or webinars hosted by manufacturers can help buyers gain hands-on experience and understand the nuances of leather care. By arming themselves with this knowledge, B2B buyers can make informed decisions that enhance the longevity and performance of their leather products.

Scenario 2: Poor Application Techniques Lead to Ineffective Protection

The Problem: Even after sourcing the right waterproofing products, many buyers encounter issues during application. Incorrect techniques, such as uneven application or neglecting to clean the leather beforehand, can compromise the waterproofing effect. This can lead to unsightly water stains, stiffness, or even mold growth, which not only damages the product but also affects the brand’s reputation in the market.

The Solution: To ensure effective application, buyers should follow a structured approach. Start by cleaning the leather thoroughly using a damp cloth to remove dirt and grime, allowing it to dry completely. Next, perform a patch test in an inconspicuous area to confirm compatibility with the chosen waterproofing product. When applying the product, use a clean, lint-free cloth and work in small sections, ensuring even coverage while paying special attention to seams and stitching. Establishing a standard operating procedure (SOP) for waterproofing can help maintain consistency across products and batches. Furthermore, suppliers can offer training sessions or instructional videos to guide buyers through the application process, thereby reducing the risk of damage and enhancing product performance.

Scenario 3: Lack of Ongoing Maintenance and Care

The Problem: Many B2B buyers mistakenly believe that waterproofing is a one-time task, leading to deterioration over time. Without regular maintenance, leather items can lose their water resistance, become discolored, and suffer from wear and tear. This lack of ongoing care can result in unsatisfied customers and increased returns, which negatively impacts profitability and brand loyalty.

The Solution: To address this issue, it is crucial for buyers to implement a regular maintenance schedule for their leather products. This includes reapplying waterproofing agents every few months, especially for frequently used items like bags and shoes. Buyers should also educate their customers on the importance of leather care, providing them with care kits that include cleaning solutions and conditioning agents. Suppliers can assist by offering bundled maintenance products tailored to specific leather types, making it easier for buyers to provide comprehensive care solutions. Additionally, creating informative content—such as care guides or instructional videos—can empower end-users with the knowledge needed to maintain their leather items effectively, ensuring longevity and satisfaction.

Strategic Material Selection Guide for how do you make leather waterproof

When considering how to make leather waterproof, several materials can be employed, each with distinct properties and implications for performance, cost, and suitability for various applications. This analysis focuses on four common materials: beeswax, silicone-based sprays, fluoropolymer treatments, and natural oils. Each material’s characteristics and considerations for international B2B buyers are discussed below.

Illustrative image related to how do you make leather waterproof

What Are the Key Properties of Beeswax for Waterproofing Leather?

Beeswax is a natural wax produced by honeybees, known for its excellent water-repellent properties. It forms a protective barrier on the leather surface, enhancing its water resistance while allowing the material to breathe. This is crucial for maintaining the leather’s suppleness and preventing mold growth.

Pros & Cons: Beeswax is relatively inexpensive and easy to apply, making it suitable for small-scale operations or artisanal products. However, its effectiveness can diminish over time, necessitating regular reapplication. Additionally, it may not provide as robust a barrier as synthetic alternatives in extreme conditions.

Impact on Application: Beeswax is particularly effective for light to moderate exposure to moisture, making it ideal for leather goods such as bags and shoes used in everyday environments.

Considerations for International Buyers: Buyers should ensure that the beeswax used complies with local regulations regarding natural products. In regions like Europe, adherence to environmental standards is essential.

How Do Silicone-Based Sprays Enhance Leather Waterproofing?

Silicone-based sprays are popular for their ease of use and effectiveness in creating a waterproof layer on leather. These sprays penetrate the leather fibers, providing a flexible barrier that repels water while maintaining the leather’s natural feel.

Illustrative image related to how do you make leather waterproof

Pros & Cons: The primary advantage of silicone sprays is their quick application and immediate effectiveness. They are suitable for a wide range of leather types and offer long-lasting protection. However, they may require reapplication after exposure to heavy rain or prolonged use. Additionally, some users may find that silicone can alter the leather’s appearance or texture.

Impact on Application: Silicone sprays are versatile and can be used on various leather products, including outdoor gear and fashion items. Their compatibility with different leather types makes them an excellent choice for manufacturers catering to diverse markets.

Considerations for International Buyers: Buyers should check for compliance with local chemical regulations, particularly in regions like the Middle East and Europe, where environmental standards may be stringent.

What Are the Benefits of Fluoropolymer Treatments for Leather?

Fluoropolymer treatments are advanced waterproofing solutions that create a durable, protective layer on leather. These treatments are designed to repel water and oil, offering superior protection against stains and moisture.

Pros & Cons: Fluoropolymer treatments provide long-lasting protection and are highly effective in extreme conditions. However, they tend to be more expensive than other options and may require specialized application processes, increasing manufacturing complexity.

Impact on Application: These treatments are ideal for high-performance leather products, such as outdoor footwear and specialized gear, where durability and resistance to harsh conditions are critical.

Considerations for International Buyers: Buyers should be aware of the regulatory landscape surrounding fluorinated compounds, as some regions may have restrictions on their use. Compliance with standards such as ASTM in the U.S. or DIN in Germany is essential for market acceptance.

How Do Natural Oils Contribute to Leather Waterproofing?

Natural oils, such as mink oil or neatsfoot oil, are traditional methods for waterproofing leather. They penetrate the leather fibers, conditioning the material while providing a degree of water resistance.

Illustrative image related to how do you make leather waterproof

Pros & Cons: Natural oils are relatively inexpensive and enhance the leather’s suppleness. However, they may darken the leather and require frequent reapplication to maintain effectiveness. Additionally, their performance may not match that of synthetic alternatives in heavy rain.

Impact on Application: Natural oils are suitable for leather goods that require flexibility and comfort, such as gloves or belts, but may not be ideal for items exposed to significant moisture.

Considerations for International Buyers: Buyers should ensure that the oils comply with local regulations regarding animal products, particularly in regions with strict animal welfare standards.

Summary Table of Material Selection for Leather Waterproofing

| Material | Typical Use Case for how do you make leather waterproof | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Beeswax | Bags, shoes, and light leather goods | Natural, easy application | Requires regular reapplication | Low |

| Silicone-based Spray | Outdoor gear, fashion items | Quick application, versatile | May alter appearance, requires reapplication | Medium |

| Fluoropolymer Treatment | High-performance footwear and gear | Long-lasting, superior protection | Higher cost, complex application | High |

| Natural Oils | Gloves, belts, and flexible leather goods | Inexpensive, conditions leather | Darkens leather, frequent reapplication | Low |

This strategic material selection guide provides B2B buyers with essential insights into waterproofing leather, enabling informed decisions that align with product requirements and market standards.

Illustrative image related to how do you make leather waterproof

In-depth Look: Manufacturing Processes and Quality Assurance for how do you make leather waterproof

What Are the Main Stages in the Manufacturing Process of Waterproof Leather?

The manufacturing process for waterproof leather involves several critical stages that ensure both functionality and aesthetic appeal. These stages include material preparation, forming, assembly, and finishing. Each stage is crucial for achieving a product that not only meets consumer expectations but also adheres to industry standards.

How Is Material Prepared for Waterproof Leather?

The first step in the manufacturing process involves selecting high-quality leather, typically full-grain or top-grain, known for their durability and natural water resistance. The leather is then subjected to a thorough cleaning process to remove any impurities or residues. This is often achieved through gentle washing and drying methods, ensuring that the leather retains its natural properties.

Once clean, the leather is inspected for any defects such as scars or discoloration. This quality control measure is essential, as it helps manufacturers select only the best hides for waterproofing. After inspection, the leather is treated with specific waterproofing agents, which may include waxes, oils, or synthetic compounds. These treatments enhance the leather’s ability to repel water while maintaining its breathability.

What Techniques Are Used in the Forming and Assembly Stages?

In the forming stage, the treated leather is cut and shaped into the desired patterns for products like bags, shoes, or jackets. Precision cutting tools and die-cutting machines are commonly employed to ensure uniformity and reduce waste. The shaping process may also involve techniques like molding or stitching, which are critical for assembling the final product.

During assembly, manufacturers must pay close attention to stitching and seam techniques. Waterproofing can be compromised if seams are not properly sealed or if inappropriate thread is used. Many manufacturers use water-resistant threads and sealants to enhance the durability of seams. Some may even apply additional waterproofing treatments to the seams after assembly to provide an extra layer of protection.

How Is the Finishing Stage Conducted for Waterproof Leather?

The finishing stage is where the aesthetic appeal of the product is finalized. This may involve dyeing, polishing, or applying protective coatings that enhance water resistance. Manufacturers often apply a final layer of waterproofing spray or cream, which can further bolster the product’s resistance to moisture.

Quality assurance is crucial during this stage, as any inconsistencies in finishing can affect both the appearance and performance of the leather. Final products are carefully inspected for quality, and any that do not meet standards are either reworked or discarded.

What Quality Assurance Measures Are Essential for Waterproof Leather Production?

Quality assurance (QA) is a critical aspect of waterproof leather manufacturing, ensuring that products meet both international standards and consumer expectations. Various quality control checkpoints are integrated into the manufacturing process.

Which International Standards Should Be Considered for Leather Waterproofing?

For B2B buyers, understanding international standards like ISO 9001 is vital. This standard outlines the requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. Compliance with ISO 9001 not only ensures quality products but also enhances brand reputation.

Illustrative image related to how do you make leather waterproof

Additionally, specific industry standards such as CE marking and API (American Petroleum Institute) certifications may apply, depending on the end-use of the leather products. CE marking, for example, is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in Leather Manufacturing?

Quality control checkpoints in leather manufacturing typically include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before they enter the production process. It ensures that only high-quality leather is used.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the quality of workmanship, adherence to specifications, and effectiveness of waterproofing treatments.

-

Final Quality Control (FQC): Once the products are completed, a thorough inspection is performed to ensure they meet all quality standards and specifications before they are shipped to buyers.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers have several options for verifying supplier quality control. Conducting audits is one of the most effective methods. An on-site audit allows buyers to assess the manufacturing processes, quality control measures, and adherence to international standards firsthand.

Buyers can also request quality control reports, which should detail the results of various inspections and tests conducted throughout the manufacturing process. Third-party inspections can provide an impartial assessment of the supplier’s quality control practices, adding an extra layer of assurance.

Illustrative image related to how do you make leather waterproof

What Are the Common Testing Methods for Waterproof Leather?

Testing methods for waterproof leather typically include:

-

Water Repellency Tests: These tests measure how effectively leather can resist water penetration. Techniques may involve applying water to the leather surface and observing the absorption rate.

-

Flexibility Tests: As waterproofing agents can sometimes alter the leather’s flexibility, these tests evaluate the material’s pliability before and after treatment.

-

Durability Tests: Assessing how well the waterproofing holds up under various conditions, such as exposure to UV light, heat, and moisture, is crucial for long-term product reliability.

What Should B2B Buyers Know About QC and Certification Nuances?

B2B buyers, especially those sourcing from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of the varying standards and regulations that may apply. For instance, certain countries may have specific certifications required for leather goods, particularly for those intended for export.

Understanding these nuances can help buyers navigate compliance issues and avoid potential pitfalls. It is advisable to establish clear communication with suppliers regarding their certification status and quality control measures to ensure that products meet the necessary standards for international markets.

In conclusion, the manufacturing processes and quality assurance measures for waterproof leather are multi-faceted, requiring careful attention to detail at every stage. By understanding these processes, B2B buyers can make informed decisions and ensure that the leather products they source will meet their needs for quality and durability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you make leather waterproof’

Introduction

Waterproofing leather is a critical process for extending the lifespan and maintaining the aesthetic appeal of leather products, from footwear to accessories. This guide offers a practical checklist for B2B buyers who are looking to source the best waterproofing solutions for their leather goods. By following these steps, you can ensure that your procurement process is efficient and effective, resulting in high-quality, durable leather products.

Step 1: Identify the Type of Leather

Understanding the specific type of leather you are dealing with is paramount. Different leather types—such as full-grain, suede, or nubuck—require tailored waterproofing treatments. This knowledge will guide you in selecting the appropriate products that will not compromise the leather’s integrity.

Illustrative image related to how do you make leather waterproof

- Full-grain leather: More durable but may require specialized treatments.

- Suede and nubuck: Require gentle, specific waterproofing methods to avoid damage.

Step 2: Research Waterproofing Products

Before procurement, conduct thorough research on available waterproofing products. Look for options such as sprays, creams, and waxes, each with its own application techniques and effectiveness levels.

- Sprays: Ideal for even application but may need frequent reapplication.

- Waxes: Provide a robust barrier but require careful application to avoid stiffness.

Step 3: Evaluate Supplier Certifications

It’s vital to verify that potential suppliers meet industry standards and certifications. Quality assurance certifications can indicate the reliability of waterproofing products and their effectiveness in protecting leather.

- ISO certifications: Ensure that the supplier adheres to international quality standards.

- Product safety certifications: Look for approvals that confirm the safety of the chemicals used in their products.

Step 4: Request Product Samples

Before finalizing your order, request samples of the waterproofing products. This step allows you to test the products on various leather types to evaluate their effectiveness and compatibility.

Illustrative image related to how do you make leather waterproof

- Patch tests: Conduct tests on inconspicuous areas to assess colorfastness and texture changes.

- Performance testing: Evaluate how well the product repels water and withstands environmental conditions.

Step 5: Assess Environmental Impact

Sustainability is increasingly important in product selection. Investigate whether the waterproofing products are environmentally friendly and free from harmful chemicals.

- Biodegradable options: Consider products that minimize environmental harm.

- Eco-certifications: Look for labels that indicate sustainable sourcing and production methods.

Step 6: Establish a Maintenance Plan

Waterproofing is not a one-time solution; it requires ongoing maintenance. Develop a plan for regular assessments and reapplications of waterproofing products to ensure long-lasting protection.

- Frequency of reapplication: Determine how often products should be reapplied based on usage and exposure.

- Storage conditions: Educate your team on proper storage practices to extend the lifespan of leather goods.

Step 7: Review Supplier Terms and Conditions

Finally, carefully review the terms and conditions offered by your suppliers. This includes return policies, warranties, and customer support services, which can significantly impact your experience.

- Return policy: Understand the terms for returning unsatisfactory products.

- Customer support: Ensure that the supplier provides adequate support for product application and troubleshooting.

By following these steps, B2B buyers can make informed decisions when sourcing waterproofing solutions for leather goods, ensuring both quality and longevity in their products.

Comprehensive Cost and Pricing Analysis for how do you make leather waterproof Sourcing

What Are the Key Cost Components for Waterproofing Leather?

When considering the waterproofing of leather, various cost components contribute to the overall expenditure. The primary elements include:

Illustrative image related to how do you make leather waterproof

-

Materials: The cost of waterproofing products such as waxes, creams, and sprays can vary significantly based on quality and formulation. Natural ingredients, like beeswax or specialized conditioning oils, tend to be more expensive but offer better protection and longevity.

-

Labor: The labor cost involved in the application of waterproofing treatments can vary depending on the complexity of the process and the expertise required. Skilled labor may demand higher wages but can ensure a more effective application.

-

Manufacturing Overhead: This includes the costs associated with maintaining production facilities, utilities, and indirect labor. Efficient production processes can help minimize these costs.

-

Tooling: The investment in specialized tools for applying waterproofing agents, such as spray equipment or conditioning applicators, also affects the overall cost. These tools may require regular maintenance and replacement.

-

Quality Control (QC): Implementing rigorous QC measures to ensure the effectiveness of waterproofing treatments can incur additional costs. However, this is essential for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping and handling costs, especially for international buyers, can significantly impact the final price. Understanding Incoterms is crucial for estimating these costs accurately.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand, competition, and product uniqueness.

What Influences Pricing for Waterproofing Leather Solutions?

Several factors can influence the pricing structure for waterproofing leather products:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often attract discounts, making it cost-effective for businesses to buy larger quantities. Understanding the MOQ requirements of suppliers can help in negotiating better rates.

-

Specifications and Customization: Custom formulations or specific application methods may incur additional costs. Buyers seeking tailored solutions should be prepared for potential price increases.

-

Materials and Quality Certifications: Higher-quality materials, such as premium waxes or organic compounds, will generally cost more. Certifications that guarantee the safety and efficacy of products can also add to the cost but may be necessary for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may command higher prices but offer better service and product quality.

How Can Buyers Negotiate for Better Pricing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance cost-efficiency:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term benefits and savings associated with waterproofing treatments. Investing in higher-quality products may reduce maintenance costs and extend the life of leather goods.

-

Negotiate Terms and Conditions: Open discussions regarding payment terms, delivery schedules, and warranties can lead to more favorable pricing arrangements. Being flexible with order quantities or payment terms can incentivize suppliers to offer discounts.

-

Research Market Trends: Keeping abreast of market dynamics and competitor pricing can empower buyers during negotiations. Awareness of seasonal trends, demand fluctuations, and emerging suppliers can provide leverage.

-

Consider Incoterms Carefully: Understanding the implications of different Incoterms can help buyers manage logistics costs more effectively. Clear agreements on who bears the shipping costs can influence the overall price.

Conclusion

The cost and pricing analysis for waterproofing leather involves a complex interplay of materials, labor, and logistics, among other factors. By understanding these components and the influencers of pricing, B2B buyers can make informed decisions that maximize their investment while ensuring the longevity and quality of their leather products. Always remember that indicative prices may vary based on fluctuating market conditions and specific buyer requirements.

Alternatives Analysis: Comparing how do you make leather waterproof With Other Solutions

Exploring Alternatives for Waterproofing Leather

When it comes to waterproofing leather, various solutions and methods are available to enhance the material’s durability and longevity. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific needs, budget constraints, and the types of leather products they are handling. Below, we compare a traditional leather waterproofing method with two alternative approaches: silicone-based treatments and synthetic leather options.

Illustrative image related to how do you make leather waterproof

| Comparison Aspect | How Do You Make Leather Waterproof | Silicone-Based Treatments | Synthetic Leather Options |

|---|---|---|---|

| Performance | Provides water resistance; requires regular maintenance | Excellent water resistance; long-lasting | Inherently waterproof; no maintenance required |

| Cost | Moderate (varies by product) | Moderate to high | Typically lower than high-end leather |

| Ease of Implementation | Requires cleaning, application, and drying time | Easy to apply; quick drying | No application needed; ready to use |

| Maintenance | Regular reapplication needed | Minimal; reapply occasionally | No maintenance necessary |

| Best Use Case | Ideal for high-quality leather goods requiring preservation | Suitable for outdoor leather items | Perfect for budget-conscious consumers or mass production |

Silicone-Based Treatments: Are They Worth the Investment?

Silicone-based waterproofing treatments are popular due to their ease of application and effective water resistance. These products can be sprayed or wiped on and typically dry quickly, making them convenient for businesses that require rapid turnaround times. However, they can be more expensive than traditional wax-based products and may not offer the same level of conditioning, potentially leading to a stiffer leather feel over time. Additionally, while they provide excellent short-term protection, they may require reapplication more frequently than traditional methods.

Synthetic Leather: A Cost-Effective Alternative to Natural Leather

Synthetic leather, often made from polyurethane or PVC, is inherently waterproof, making it an attractive option for manufacturers looking to reduce costs and maintenance efforts. This alternative is particularly appealing for mass production or budget-conscious consumers. However, synthetic leather lacks the aesthetic appeal and tactile qualities of genuine leather, which can be a significant drawback for luxury brands. Furthermore, environmental concerns surrounding synthetic materials may deter eco-conscious buyers.

Conclusion: Choosing the Right Waterproofing Solution for Your Leather Goods

When selecting a waterproofing method for leather, B2B buyers must consider their specific use cases, budgets, and the desired qualities of the finished product. Traditional waterproofing methods, such as wax and conditioning treatments, are ideal for high-quality leather goods that require care and maintenance. In contrast, silicone-based treatments offer quick application and strong resistance, while synthetic leather provides a low-maintenance, cost-effective alternative. Ultimately, understanding the performance, cost, ease of implementation, and maintenance requirements will empower buyers to choose the best solution that aligns with their business objectives and customer expectations.

Illustrative image related to how do you make leather waterproof

Essential Technical Properties and Trade Terminology for how do you make leather waterproof

What Are the Key Technical Properties for Making Leather Waterproof?

When considering the waterproofing of leather, several technical properties are crucial to ensure the effectiveness and longevity of the treatment. Here are some essential specifications:

-

Water Resistance Rating: This property indicates the level of resistance leather has to water penetration. It is often measured in terms of water column height (e.g., mm). Higher ratings signify better resistance, which is vital for products exposed to wet conditions, ensuring that they maintain their quality over time.

-

Leather Type and Grade: Different types of leather (e.g., full-grain, top-grain, suede) possess varying inherent properties, affecting their waterproofing needs. Full-grain leather, for instance, is more durable and requires specific treatments compared to suede, which is more porous. Understanding the leather grade helps in selecting the appropriate waterproofing method and product.

-

Breathability: This refers to the ability of leather to allow moisture vapor to escape while resisting liquid water. A balance between breathability and waterproofing is essential, especially for apparel and footwear, as it prevents moisture buildup inside the item, reducing the risk of mold and odors.

-

Durability of Treatment: The longevity of waterproofing treatments is critical. This includes understanding how many wear cycles a treatment can withstand before needing reapplication. Products with longer-lasting effects reduce maintenance costs and ensure that leather goods remain protected for extended periods.

-

Environmental Resistance: This encompasses the leather’s ability to withstand various environmental factors, including UV rays and temperature fluctuations. Treatments that enhance environmental resistance are crucial for maintaining the aesthetic and functional properties of leather, particularly in diverse climates.

-

Application Method Compatibility: Different waterproofing products (sprays, creams, waxes) have unique application methods. Understanding which method works best for specific leather types ensures optimal adhesion and effectiveness of the treatment. This is important for manufacturers and retailers aiming to provide quality products to customers.

What Are Common Trade Terms Related to Leather Waterproofing?

Understanding industry terminology is essential for effective communication and negotiation in the leather waterproofing market. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end product. In leather goods, an OEM might be responsible for manufacturing waterproof leather treatments that are later branded by another company.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers as it helps in planning inventory and managing cash flow, especially when sourcing waterproofing treatments.

-

RFQ (Request for Quotation): An RFQ is a standard business process where a buyer solicits bids from suppliers for specific products or services. This is particularly important in the leather industry to ensure competitive pricing for waterproofing solutions.

-

Incoterms: Short for International Commercial Terms, these are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers in shipping goods, including waterproof leather products. Understanding Incoterms helps mitigate risks and manage logistics effectively.

-

Lead Time: This refers to the amount of time from the placement of an order to the delivery of the product. For leather waterproofing materials, understanding lead times is vital for inventory management and meeting customer demands.

-

Warranty Terms: These are conditions under which a manufacturer guarantees the performance of their waterproofing products. Knowing the warranty terms helps buyers assess the risk and reliability of the products they are purchasing.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing waterproof leather solutions, ultimately enhancing their product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the how do you make leather waterproof Sector

What Are the Current Market Dynamics and Key Trends in Leather Waterproofing?

The global leather waterproofing market is driven by a growing demand for high-quality, durable leather goods across various industries, including fashion, automotive, and furniture. As consumers increasingly seek products that combine functionality with aesthetics, the need for waterproof leather has gained prominence. Emerging trends indicate a shift towards innovative waterproofing solutions that enhance the longevity of leather while maintaining its natural characteristics. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Technological advancements in waterproofing treatments are reshaping the landscape, with a focus on eco-friendly solutions. Buyers are increasingly inclined to invest in products that offer superior water resistance without compromising the leather’s breathability. Additionally, the rise of e-commerce has facilitated easier access to specialized waterproofing products, enabling buyers to explore a wider range of options from global suppliers.

Another notable trend is the increasing preference for multifunctional leather goods that integrate waterproofing as a standard feature. This shift is particularly relevant for markets like Vietnam and Germany, where consumers prioritize durability and long-term value in their purchases. B2B buyers must remain attuned to these evolving preferences to effectively meet the demands of their clientele.

How Are Sustainability and Ethical Sourcing Impacting the Leather Waterproofing Industry?

Sustainability is becoming a pivotal consideration in the leather waterproofing sector, with increasing scrutiny on the environmental impact of traditional leather production and treatment processes. B2B buyers are now more than ever seeking suppliers that prioritize ethical sourcing and environmentally friendly practices. The use of biodegradable waterproofing agents and natural waxes is gaining traction, appealing to businesses that aim to enhance their sustainability credentials.

Illustrative image related to how do you make leather waterproof

Ethical supply chains are not only a moral imperative but also a market differentiator. Companies that can demonstrate a commitment to sustainable practices often enjoy a competitive edge, particularly in regions with stringent environmental regulations. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming vital for suppliers looking to establish credibility in the marketplace.

Moreover, the demand for ‘green’ materials extends to waterproofing agents, with buyers increasingly favoring products free from harmful chemicals. This trend is particularly significant in regions like Europe, where consumers are highly conscious of the ecological footprint of their purchases. For international B2B buyers, aligning with suppliers that adhere to these sustainable practices not only fulfills regulatory requirements but also resonates with an environmentally aware customer base.

How Has the Leather Waterproofing Sector Evolved Over Time?

The evolution of leather waterproofing can be traced back centuries, with early techniques focused on natural oils and waxes derived from animal fats. Historically, leather was treated using rudimentary methods that offered limited protection against water, often leading to deterioration over time. As industrialization progressed, synthetic waterproofing agents emerged, providing enhanced durability and ease of application.

Illustrative image related to how do you make leather waterproof

In recent decades, the industry has shifted towards a more sophisticated understanding of leather’s properties, recognizing that while leather is inherently water-resistant, it is not waterproof. This realization has spurred the development of specialized waterproofing products designed to enhance leather’s natural attributes while addressing its vulnerabilities.

Today, the market continues to innovate, with advancements in nanotechnology and eco-friendly treatments leading the way. This evolution reflects a broader trend towards quality, sustainability, and consumer demand for products that not only perform well but also align with ethical considerations. B2B buyers must stay informed about these historical developments to better appreciate the current landscape and anticipate future trends in leather waterproofing.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you make leather waterproof

-

How do I make leather waterproof?

To make leather waterproof, start by cleaning the leather thoroughly with a damp cloth to remove any dirt or grime. Once clean, apply a suitable waterproofing product such as a spray, cream, or wax designed for the specific leather type. Ensure even application, particularly around seams, and allow the leather to dry completely. Regular maintenance is essential; reapply the waterproofing treatment as needed to maintain protection against moisture. -

What is the best waterproofing product for leather?

The best waterproofing product for leather depends on the leather type. For full-grain leather, wax-based products are highly effective as they create a durable barrier. For suede or nubuck, specialized sprays are recommended to avoid altering texture. Always read product labels for compatibility and application instructions, ensuring you choose a product that meets the specific needs of your leather goods. -

How often should I waterproof my leather items?

The frequency of waterproofing leather items largely depends on usage and exposure to the elements. For items used regularly, such as shoes and bags, it’s advisable to reapply waterproofing treatments every few months. For less frequently used items, a biannual check may suffice. Regular inspections for wear and damage will help determine when reapplication is necessary, ensuring optimal protection. -

What are the international shipping considerations for leather waterproofing products?

When sourcing leather waterproofing products internationally, consider regulations regarding the transportation of chemicals, especially sprays and waxes. Check import restrictions and customs regulations specific to your country. Additionally, ensure that the supplier can provide necessary documentation, such as Material Safety Data Sheets (MSDS), to facilitate smooth customs clearance and compliance with local laws. -

How can I vet suppliers of leather waterproofing products?

To vet suppliers effectively, check their reputation through online reviews and industry references. Request samples of their waterproofing products to evaluate quality. Additionally, inquire about their manufacturing processes, sourcing of materials, and compliance with international standards. Establish communication with previous clients to gather feedback on reliability and service quality. -

What customization options are available for leather waterproofing products?

Many suppliers offer customization options, such as private labeling or tailored formulations. When contacting suppliers, specify your requirements regarding product type, scent, packaging, and branding. Customization can help differentiate your offerings in the market. However, be mindful of minimum order quantities (MOQs) that may apply to customized products. -

What payment terms should I expect when sourcing waterproofing products?

Payment terms can vary significantly among suppliers. Common options include upfront payments, partial payments before shipping, or net terms post-delivery. Always clarify payment methods accepted (e.g., bank transfer, credit card, letters of credit) and negotiate terms that suit your cash flow needs. Ensure all agreements are documented to avoid misunderstandings. -

How do I ensure quality assurance for leather waterproofing products?

To ensure quality assurance, establish clear specifications and standards with your supplier before placing orders. Request certifications that demonstrate compliance with relevant safety and quality regulations. Implement a quality control process that includes inspecting samples before bulk orders and considering third-party inspections for larger shipments to verify product quality and consistency.

Top 7 How Do You Make Leather Waterproof Manufacturers & Suppliers List

1. Coach – Backpack

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Coach backpack – natural brown leather, designed for daily use in city living. 2. Waterproofing options discussed: acrylic finish (plastic layer), wax (slight help), homemade blend of almond oil and beeswax (for unfinished leather), commercial waterproofing products (recommended for pigmented finish). 3. Specific products mentioned: Sno-seal, Silicone Water Guard (available at Home Depot), Fieb…

2. Tandy Leather – Conditioning Creams and Waxes

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Conditioning Creams and Waxes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Instructables – Homemade Leather Preserver

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Home-made Leather Preserver and Waterproofing Ingredients: 200 ml of Extra Virgin Olive Oil, 50g Beeswax, 20 drops of Lavender essential oil (optional), 10 drops of Tea Tree essential oil (optional). Method: Melt Beeswax into Olive Oil in a jar placed in a pan of cold water, stir until melted, add essential oils, and stir until cooled and stiffened. Uses: Softens and weatherproofs leather items su…

4. Billy Tannery – Leather Care Kit

Domain: billytannery.co.uk

Registered: 2016 (9 years)

Introduction: Billy Tannery Leather Care Kit includes: 1. Collonil Wax Leather premium waterproofing cream (containing beeswax and conditioning oils) 2. A quality cotton cloth for removing excess wax and polishing 3. A polishing cloth for polishing fittings. The kit is designed to make leather waterproof and extend the lifetime of leather goods.

5. Buffalo Jackson – Waterproofing Solutions

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: 1. Waterproofing Options: Commercial waterproofing spray or beeswax cream. 2. Beeswax Cream Ingredients: 1 cup extra virgin olive oil, 2 ounces beeswax, glass jar, medium pan of cold water, clean soft buffing cloth. 3. Leather Care Products: Leather cleaner for dirt and grime removal, leather conditioner for protection and restoration.

6. Leatherworker – Beeswax Finishing Solution

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1. Beeswax, Boiled Linseed Oil (BLO), and Turpentine Solution: Recipe includes 1 lb pure/filtered beeswax, 8 oz BLO, and 8 oz turpentine.

2. Application Methods:

– Method 1: Melt the entire can worth of compound and apply with a dedicated paintbrush, heat with a heat gun to absorb, then polish.

– Method 2: Triple the recipe, heat the entire can, submerge the project for about 20 seconds, …

7. Shoegazing – Smooth Leather Care

Domain: shoegazing.com

Registered: 2019 (6 years)

Introduction: Waterproofing sprays are not recommended for regular smooth full grain leather shoes as they hinder the penetration of nourishing ingredients from shoe creams, risking the leather drying out. Instead, smooth leather should be treated with conditioners, shoe creams, and wax polish to maintain its health and longevity.

Strategic Sourcing Conclusion and Outlook for how do you make leather waterproof

What Are the Key Takeaways for Waterproofing Leather in B2B Sourcing?

In conclusion, understanding how to effectively waterproof leather is crucial for maintaining its quality and longevity, especially for B2B buyers involved in the leather goods industry. The primary takeaway is the importance of selecting the right waterproofing products tailored to specific leather types—be it full-grain, suede, or nubuck. Regular maintenance, including cleaning and reapplication of protective treatments, is vital to ensure that leather items remain resistant to water, stains, and environmental factors.

Strategic sourcing plays a pivotal role in this process. By partnering with reliable suppliers who offer high-quality waterproofing solutions, businesses can safeguard their investments and enhance customer satisfaction. This is particularly important for international markets in Africa, South America, the Middle East, and Europe, where varied climate conditions can impact leather products.

As you move forward, consider integrating advanced waterproofing techniques into your supply chain. Explore partnerships with reputable manufacturers and invest in training for your teams to ensure that proper application methods are followed. By prioritizing these strategies, you not only protect your leather goods but also position your brand as a leader in quality and durability in the competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how do you make leather waterproof

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.