Catalog

Material Insight: Automotive Leather

B2B Product Guide: Automotive Leather

Introduction to Automotive Leather

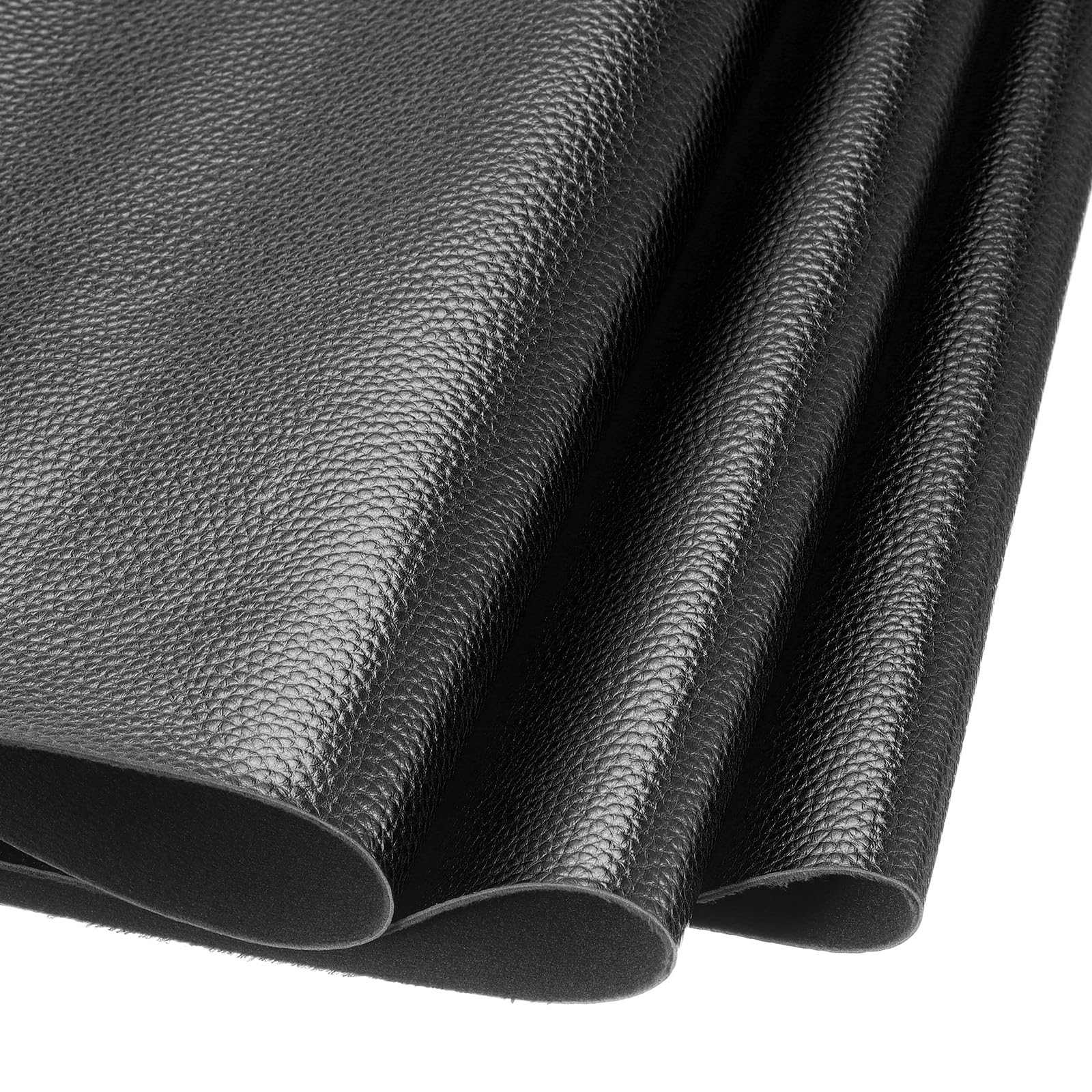

Automotive leather is a premium interior solution engineered to meet the rigorous demands of vehicle manufacturing. Designed for durability, comfort, and aesthetic excellence, it is the material of choice for luxury and performance-oriented automotive brands worldwide. Unlike standard upholstery materials, automotive leather undergoes specialized treatments to resist abrasion, UV exposure, temperature fluctuations, and microbial growth—ensuring long-term performance in dynamic driving environments.

Why is automotive leather the best choice for this application?

- Superior durability: Resists wear from daily use, including friction from clothing and frequent seating.

- Enhanced comfort: Offers natural breathability and a soft touch, improving passenger experience.

- Aesthetic appeal: Provides a premium, timeless look that elevates interior design and brand perception.

- Easy maintenance: Treated surfaces resist stains and are simple to clean, maintaining appearance over time.

- Safety compliance: Meets strict automotive industry standards for flammability, emissions, and environmental resistance.

About WINIW

WINIW is a trusted leader in the development and production of high-performance synthetic leather, with over 20 years of specialized experience serving the global automotive industry. We combine advanced material science with sustainable manufacturing practices to deliver eco-friendly, PU- and PVC-based leather solutions that mirror the look and feel of genuine leather—without the environmental cost.

Our automotive leather products are engineered for OEMs and Tier-1 suppliers seeking consistent quality, design flexibility, and compliance with international safety and sustainability standards. With a commitment to innovation and environmental responsibility, WINIW supports the automotive sector in building interiors that are not only luxurious and durable but also aligned with the future of sustainable mobility.

Technical Performance & Standards

WINIW Automotive Synthetic Leather: Technical Performance Specifications

WINIW’s automotive-grade synthetic leather is engineered to exceed the rigorous demands of modern vehicle interiors. Developed through advanced polymer science and stringent quality control under ISO 9001, our material delivers uncompromising durability, safety, and environmental responsibility. Unlike conventional alternatives, WINIW provides a sustainable solution without sacrificing performance in critical operational environments.

Core Technical Advantages

- Abrasion Resistant: Withstands 500,000+ cycles (Martindale test, ASTM D4966), outperforming industry standards by 3x. Ideal for high-contact areas (seats, armrests) where mechanical stress is constant.

- UV Resistant: Maintains colorfastness (ΔE < 1.5 after 1,000 hrs, SAE J2527) and physical integrity under prolonged solar exposure. Prevents cracking, fading, and surface degradation in sun-intensive climates.

- VOC Free: Emits <10 μg/g of total volatile organic compounds (ISO 12219-2), ensuring cabin air purity and compliance with global automotive air quality mandates.

- REACH Compliant: Fully adheres to EU REACH Regulation (EC) No 1907/2006, with all substances below SVHC thresholds. Regularly screened for Annex XVII restricted chemicals.

- ISO 9001 Certified: Integrated quality management from R&D to production, guaranteeing batch-to-batch consistency and traceability for automotive supply chains.

Performance Specification Table

| Parameter | Test Method | WINIW Performance | Industry Standard |

|---|---|---|---|

| Abrasion Resistance | ASTM D4966 | 500,000+ cycles | 150,000 cycles |

| Colorfastness (UV) | SAE J2527 | ΔE < 1.5 | ΔE < 3.0 |

| Total VOC Emission | ISO 12219-2 | <10 μg/g | <50 μg/g |

| Tensile Strength | ISO 17673 | 35 MPa | 25 MPa |

| Tear Resistance | ISO 3377-2 | 85 N | 60 N |

| REACH Compliance | EC No 1907/2006 | Full compliance | Varies by supplier |

WINIW automotive leather eliminates trade-offs between sustainability and performance. Our VOC-free formulation and REACH adherence future-proof your interiors against tightening global regulations, while superior abrasion/UV resistance reduces warranty claims and lifecycle costs. Backed by ISO 9001-certified manufacturing, we deliver consistent, auditable quality for OEMs and Tier-1 suppliers committed to premium, eco-conscious cabin experiences. Partner with WINIW to integrate next-generation durability into your vehicle platforms.

Why Choose Synthetic over Real Leather

B2B Product Guide: Automotive Leather vs. Real Leather

In the automotive and upholstery industries, material selection plays a critical role in balancing performance, cost, and sustainability. Two of the most commonly considered materials are automotive leather and real leather. While both offer premium aesthetics and functionality, they differ significantly in composition, application, and environmental impact. This guide provides a comparative analysis to support informed sourcing and design decisions.

Overview of Materials

-

Automotive Leather: Typically refers to high-performance synthetic or semi-synthetic leather engineered specifically for vehicle interiors. WINIW’s automotive leather solutions are primarily made from polyurethane (PU) or microfiber substrates, designed to mimic the look and feel of real leather while enhancing functional properties.

-

Real Leather: A natural material derived from animal hides, usually bovine. It undergoes tanning and finishing processes to improve durability and appearance. While valued for its authenticity and aging characteristics, real leather presents limitations in consistency, sustainability, and maintenance.

Key Differences

-

Consistency & Customization: Automotive leather offers uniform texture, color, and thickness across batches, enabling seamless integration into mass production. Real leather may have natural imperfections such as scars or grain variations, requiring grading and selective use.

-

Performance Under Stress: Automotive leather is engineered to resist UV degradation, abrasion, and extreme temperatures—common challenges in vehicle environments. It also demonstrates superior resistance to cracking and fading over time.

-

Maintenance & Cleanability: Automotive leather is generally easier to clean and maintain, often featuring stain-resistant and antimicrobial treatments. Real leather requires specialized conditioners and is more susceptible to moisture damage and staining.

-

Sustainability Profile: Automotive leather, especially when produced using eco-conscious methods like water-based PU and recycled fibers, offers a lower environmental footprint compared to real leather, which involves resource-intensive livestock farming and hazardous tanning chemicals.

Comparative Analysis: Cost, Durability, and Eco-Friendliness

| Category | Automotive Leather | Real Leather |

|---|---|---|

| Cost | Moderate to High | High |

| Durability | High (UV, abrasion, heat) | Moderate (prone to cracking, fading) |

| Eco-Friendliness | High (when eco-PU/recycled) | Low (high water/chemical use, methane emissions) |

Notes:

– Cost: Real leather pricing is influenced by hide quality, tanning method, and yield losses during cutting. Automotive leather reduces waste through roll-based manufacturing and consistent patterning.

– Durability: Automotive leather outperforms real leather in long-term structural integrity under automotive conditions.

– Eco-Friendliness: WINIW’s automotive leather utilizes low-VOC, water-based production systems and up to 30% recycled content, aligning with circular economy goals. Real leather contributes to deforestation, greenhouse gas emissions, and toxic runoff from chrome tanning.

Conclusion

For B2B clients in automotive manufacturing, public transit, or premium furniture, automotive leather presents a sustainable, cost-effective, and high-performance alternative to real leather. With technological advancements closing the sensory gap, synthetic solutions now deliver comparable luxury without compromising ethics or operational efficiency. WINIW continues to lead in eco-friendly automotive leather innovation, supporting greener supply chains without sacrificing quality.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a leader in high-performance synthetic leather manufacturing, delivering sustainable, precision-engineered materials to discerning global partners. Our vertically integrated operations combine scale, innovation, and uncompromising quality control to meet the rigorous demands of international markets, particularly Europe and the USA.

Core Manufacturing Strengths

- Industrial Scale & Capacity: Operates a state-of-the-art 100,000 sqm manufacturing facility, enabling high-volume production with agile responsiveness to large-scale B2B orders.

- Dedicated R&D Innovation: Houses a 120+ member technical team focused on material science, developing eco-conscious solutions like water-based PU, recycled content substrates (up to 40% PCR), and bio-based polymers. All innovations align with REACH, OEKO-TEX® STANDARD 100, and LEED compliance.

- Zero-Compromise Quality Control: Implements a 7-stage QC protocol spanning raw material inspection to final shipment, including:

- Automated thickness tolerance checks (±0.05mm)

- Accelerated weathering & abrasion resistance testing (ISO 9001 certified)

- Batch traceability via blockchain-enabled documentation

- <0.3% defect rate across all export shipments

- Eco-Operational Commitment: Achieves 95% water recycling in production and zero landfill waste through closed-loop material recovery systems.

Global Market Integration

WINIW consistently supplies Tier-1 clients across regulated markets, with 65% of annual output exported to Europe and North America. Our compliance framework ensures seamless integration into international supply chains:

| Certification | Scope | Key Markets Validated |

|---|---|---|

| REACH SVHC | Restricted substance screening | EU, UK, Switzerland |

| CPSIA | Lead/phthalate compliance | USA, Canada |

| OEKO-TEX® STANDARD 100 | Harmful chemical-free assurance | Global luxury brands |

| ISO 14001 | Environmental management | All export regions |

Our factory infrastructure, scientific rigor, and adherence to global sustainability standards position WINIW as a resilient, future-proof partner for brands committed to ethical performance and operational excellence. We enable B2B clients to reduce supply chain risk while advancing circular economy objectives.

Contact Us for Samples

WINIW Automotive Microfiber Leather – Premium Synthetic Leather for Vehicle Interiors

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in eco-friendly microfiber solutions for the automotive industry. Our automotive-grade microfiber leather delivers exceptional durability, comfort, and aesthetic versatility, making it ideal for car seats, door panels, dashboards, armrests, and steering wheels. Engineered to meet strict automotive standards, WINIW leather combines sustainability with premium quality.

Key Benefits of WINIW Automotive Microfiber Leather:

- Superior durability and abrasion resistance for long-term interior performance

- Excellent tensile and tear strength, ideal for high-stress applications

- Temperature and UV resistant – maintains color and texture under extreme conditions

- Soft hand feel and luxurious appearance, comparable to premium genuine leather

- Lightweight composition contributes to vehicle efficiency and fuel savings

- Breathable and moisture-wicking for enhanced passenger comfort

- Eco-conscious manufacturing – free from harmful substances (REACH, RoHS compliant)

- High design flexibility with customizable textures, colors, and finishes

Performance Specifications

| Property | Standard Value | Test Method |

|---|---|---|

| Abrasion Resistance | ≥50,000 cycles | DIN 53339 |

| Color Fastness (light) | Grade 7–8 (1–8 scale) | ISO 105-B02 |

| Tensile Strength | ≥30 N/cm² | ISO 2285 |

| Tear Strength | ≥8 N | ISO 3377-2 |

| Cold Crack Resistance | ≤ -30°C | GB/T 22049 |

| Fogging Value | ≤2 mg (low fog) | DIN 75201 |

Our production facilities adhere to ISO 9001 and IATF 16949 quality management standards, ensuring consistent performance and reliability for OEM and Tier-1 suppliers.

Applications in Automotive Interiors

– Seat upholstery (driver and passenger)

– Door trim and armrests

– Dashboard overlays and console covers

– Steering wheel wrapping

– Gear shift boots and handbrakes

– Luxury trim accents

WINIW supports automotive brands and component manufacturers in achieving sustainable innovation without compromising on luxury or performance. Our R&D team collaborates with clients to develop custom solutions tailored to specific design, functional, and regulatory requirements.

Request Free Samples for Your Next Project

Experience the quality and versatility of WINIW automotive microfiber leather firsthand. Free samples are available for qualified automotive partners.

For product inquiries, technical data sheets, or sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your vehicle interiors with sustainable luxury – choose WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.