Introduction: Navigating the Global Market for alcantara fabric for sale

In today’s competitive landscape, sourcing high-quality Alcantara fabric for sale poses a significant challenge for international B2B buyers. As industries ranging from automotive to fashion increasingly prioritize both aesthetics and functionality, understanding the diverse applications and types of Alcantara is crucial. This guide aims to illuminate the complexities of the Alcantara market, offering insights into the various fabric types—including unbacked, backed, multilayer, and outdoor options—as well as their specific applications in luxury vehicles, upholstery, and fashion.

Navigating the global market for Alcantara fabric requires more than just identifying suppliers; it demands a thorough vetting process to ensure quality and compliance with industry standards. Additionally, understanding pricing structures, shipping logistics, and potential customization options can significantly impact purchasing decisions. This comprehensive resource is designed to empower B2B buyers from Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia, by providing actionable insights that facilitate informed choices.

With a focus on quality, sustainability, and innovation, this guide will equip you with the knowledge needed to make strategic purchasing decisions in the Alcantara fabric marketplace, ensuring your business stays ahead of the curve.

Table Of Contents

- Top 8 Alcantara Fabric For Sale Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara fabric for sale

- Understanding alcantara fabric for sale Types and Variations

- Key Industrial Applications of alcantara fabric for sale

- 3 Common User Pain Points for ‘alcantara fabric for sale’ & Their Solutions

- Strategic Material Selection Guide for alcantara fabric for sale

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric for sale

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric for sale’

- Comprehensive Cost and Pricing Analysis for alcantara fabric for sale Sourcing

- Alternatives Analysis: Comparing alcantara fabric for sale With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara fabric for sale

- Navigating Market Dynamics and Sourcing Trends in the alcantara fabric for sale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric for sale

- Strategic Sourcing Conclusion and Outlook for alcantara fabric for sale

- Important Disclaimer & Terms of Use

Understanding alcantara fabric for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Panel | Unbacked, lightweight, high stretchability | Vehicle headliners, dashboards | Pros: Lightweight, easy to work with. Cons: Less durability compared to backed options. |

| Alcantara Cover | Backed with 65/35 Poly Cotton scrim, high durability | Automotive seats, furniture upholstery | Pros: Strong and durable. Cons: Less flexible than unbacked types. |

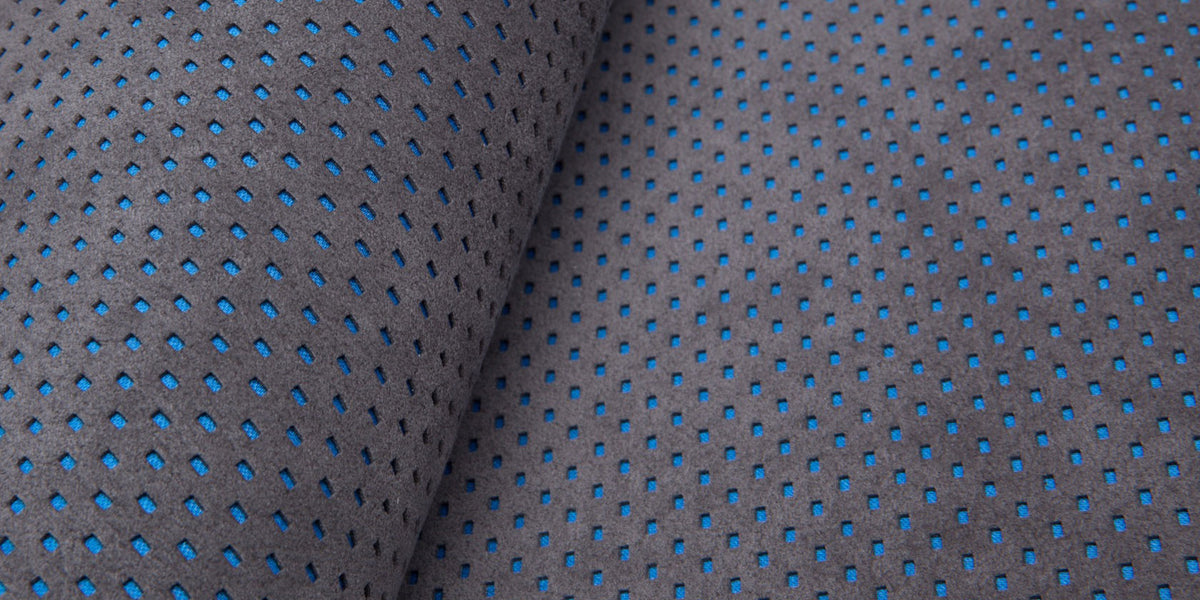

| Alcantara Multilayer | Soft lamination for added thickness, one-way stretch | Steering wheels, car seats | Pros: Increased strength, ideal for high-wear areas. Cons: Limited use in non-automotive applications. |

| Alcantara EXO | Enhanced UV and water resistance | Outdoor furniture, marine upholstery | Pros: Suitable for harsh conditions, easy maintenance. Cons: Typically higher cost due to specialized treatment. |

| Alcantara Soft | Foam-backed for added comfort | Headliners, luxury upholstery | Pros: Soft feel, good insulation. Cons: May not be as durable as other options. |

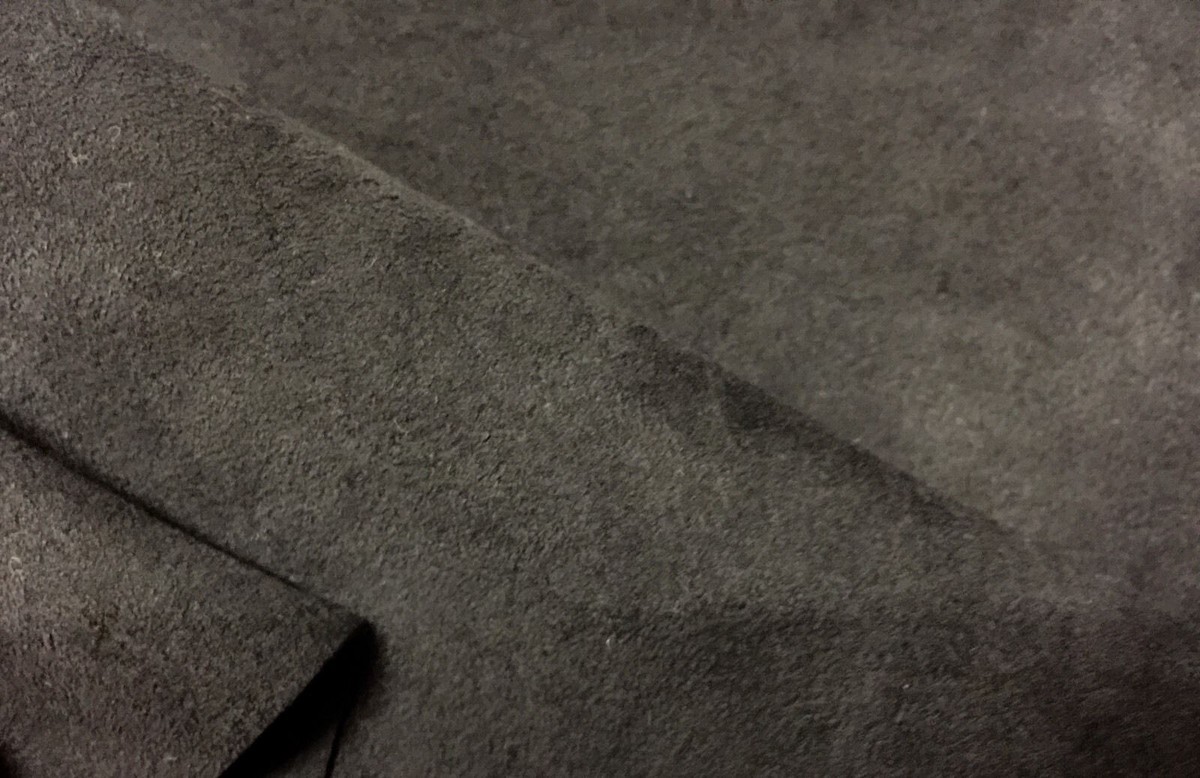

What Are the Key Characteristics of Alcantara Panel Fabric?

Alcantara Panel is an unbacked fabric recognized for its lightweight and high stretchability. This makes it particularly suitable for applications where a sleek, minimalistic design is desired, such as vehicle headliners and dashboards. B2B buyers should consider its ease of handling and installation, but also be aware that its durability may not match that of backed variations, necessitating careful application in lower-touch areas.

How Does Alcantara Cover Differ from Other Variations?

Alcantara Cover is distinguished by its backing with a laminated 65/35 Poly Cotton scrim, enhancing its strength and durability. This variation is primarily used in automotive seats and furniture upholstery, where resilience to wear is critical. Buyers should note that while it offers superior durability, it sacrifices some flexibility compared to unbacked options, which may impact design choices for certain projects.

Why Choose Alcantara Multilayer for Automotive Interiors?

Alcantara Multilayer features a soft lamination that adds thickness and provides one-way stretch capabilities. This makes it particularly effective for applications like steering wheels and car seats, where high wear is common. B2B buyers should weigh its increased strength against its more specialized use, as it may not be suitable for broader applications outside of the automotive sector.

What Benefits Does Alcantara EXO Offer for Outdoor Applications?

Alcantara EXO is engineered for outdoor use, featuring enhanced UV and water resistance. This makes it ideal for applications in outdoor furniture and marine upholstery, where exposure to the elements is a concern. Buyers looking for durable, low-maintenance options should consider the EXO range, though they may face a higher price point due to its specialized properties.

How Does Alcantara Soft Enhance Comfort in Upholstery?

Alcantara Soft is foam-backed, providing a luxurious feel while maintaining good insulation properties. This variation is commonly used in headliners and high-end upholstery applications. B2B buyers should appreciate its comfort and aesthetic appeal, but should also be cautious of its durability, as it may not withstand heavy wear as effectively as other Alcantara types.

Key Industrial Applications of alcantara fabric for sale

| Industry/Sector | Specific Application of alcantara fabric for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery for luxury vehicles | Enhances aesthetic appeal, durability, and comfort | Look for high-quality, UV-resistant variants with customization options. |

| Fashion & Apparel | High-end clothing and accessories | Provides a luxurious feel while ensuring durability | Consider color variety and texture options for brand alignment. |

| Aviation | Aircraft interiors and seating | Lightweight, fire-retardant properties enhance safety | Ensure compliance with aviation safety regulations for materials. |

| Furniture & Upholstery | Premium furniture coverings | Offers stain resistance and easy maintenance | Check for eco-friendly options and custom color matching. |

| Marine | Upholstery for boats and outdoor furniture | Water-resistant and UV-protected for longevity | Source materials that withstand harsh marine environments. |

How is Alcantara Fabric Used in the Automotive Industry?

In the automotive sector, Alcantara fabric is primarily utilized for interior upholstery, including seats, dashboards, and door panels. Its luxurious appearance and tactile experience enhance the overall aesthetic of high-end vehicles, making it a favorite among luxury car manufacturers. The fabric’s durability and resistance to wear and tear ensure long-lasting performance, addressing common issues related to upholstery degradation. For international buyers, particularly from regions like the Middle East and Europe, sourcing Alcantara that meets specific automotive standards, including UV resistance and ease of cleaning, is crucial.

Illustrative image related to alcantara fabric for sale

What Role Does Alcantara Play in Fashion and Apparel?

In the fashion industry, Alcantara fabric is employed in the creation of high-end clothing and accessories, such as bags and footwear. Its soft, suede-like texture provides a luxurious feel, while its durability ensures that products maintain their quality over time. This material addresses challenges such as wear and tear and the need for stylish yet functional designs. B2B buyers in South America and Africa should prioritize sourcing options that offer a variety of colors and textures to align with current fashion trends and consumer preferences.

How is Alcantara Fabric Beneficial in Aviation?

Alcantara fabric is increasingly used in aviation for aircraft interiors, particularly in seating and paneling. Its lightweight nature contributes to overall weight reduction, improving fuel efficiency, while its fire-retardant properties comply with stringent aviation safety standards. This fabric also enhances passenger comfort, addressing the need for durable and aesthetically pleasing materials in commercial and private aircraft. Buyers from the aviation sector must ensure that sourced Alcantara meets specific certifications for fire safety and durability to comply with industry regulations.

Why Choose Alcantara for Furniture and Upholstery Projects?

In the furniture and upholstery market, Alcantara is favored for its premium quality and practicality. It is commonly used in high-end furniture pieces, providing a stain-resistant surface that is easy to clean and maintain. This addresses the common issues of fabric wear in frequently used items. B2B buyers, especially from Europe and the Middle East, should consider sourcing Alcantara that offers eco-friendly options and customization capabilities to meet diverse client demands.

Illustrative image related to alcantara fabric for sale

What Makes Alcantara Ideal for Marine Applications?

Alcantara’s versatility extends to marine applications, where it is used for boat upholstery and outdoor furniture. The fabric’s water-resistant properties and UV protection make it an excellent choice for environments exposed to sun and moisture. This application solves the problem of fabric degradation in harsh marine conditions, ensuring longevity and performance. When sourcing Alcantara for marine use, buyers should focus on materials specifically designed for outdoor durability, ensuring resistance to fading and water damage.

3 Common User Pain Points for ‘alcantara fabric for sale’ & Their Solutions

Scenario 1: Sourcing Quality Alcantara Fabric for Diverse Applications

The Problem: B2B buyers often encounter challenges when sourcing high-quality Alcantara fabric that meets specific application requirements, such as automotive interiors, fashion, or upholstery. The wide variety of Alcantara types—such as unbacked, backed, and multilayer—can create confusion. Additionally, buyers may worry about inconsistent quality, leading to concerns about durability and aesthetic appeal in their final products. This uncertainty can affect production timelines and customer satisfaction.

The Solution: To ensure you source high-quality Alcantara fabric, start by partnering with reputable suppliers who provide comprehensive product information, including certifications and material specifications. Request samples before making bulk purchases, allowing you to evaluate the texture, color fidelity, and overall quality. When specifying your order, clearly outline the intended application (e.g., automotive seating or fashion items) and any performance requirements like fire resistance or UV protection. Suppliers can then recommend the most suitable Alcantara type, ensuring it aligns with your project needs. Engaging in direct communication with suppliers can also facilitate customized solutions, enhancing your product’s quality and performance.

Scenario 2: Understanding Alcantara Fabric Maintenance and Longevity

The Problem: Buyers may be concerned about the maintenance and longevity of Alcantara fabric, particularly in high-traffic environments like automotive interiors or commercial furniture. Misunderstanding the cleaning and care requirements can lead to premature wear, color fading, or staining, which can diminish the perceived value of the product and lead to costly replacements.

The Solution: Educate yourself on the specific maintenance requirements for the type of Alcantara you are sourcing. Generally, Alcantara fabric is easy to clean and maintain; however, the cleaning method may vary based on the type of backing and application. For example, foam-backed Alcantara is typically more forgiving and can be cleaned with a damp cloth and mild detergent, while unbacked versions may require specialized cleaning products. Provide your clients or end-users with clear care instructions, including recommendations on avoiding harsh chemicals and regular maintenance schedules. This proactive approach will enhance the fabric’s longevity and maintain its aesthetic appeal, ultimately protecting your investment.

Scenario 3: Navigating Global Sourcing and Shipping Challenges

The Problem: International B2B buyers frequently face logistical issues when sourcing Alcantara fabric, particularly when dealing with suppliers from different countries. Challenges include customs delays, fluctuating shipping costs, and potential language barriers that can complicate communication. These issues can result in increased lead times and unexpected costs, disrupting production schedules and impacting customer satisfaction.

The Solution: To mitigate these challenges, choose suppliers with experience in international shipping and a strong understanding of customs regulations in your region. Establish clear communication channels, including preferred languages and time zones, to streamline interactions. Utilize freight forwarders or logistics companies that specialize in fabric shipping to navigate customs efficiently and ensure timely delivery. Additionally, consider establishing a strategic partnership with suppliers who can provide local warehousing options in your region. This strategy can reduce shipping times and costs, allowing for a more flexible supply chain that can adapt to changing demand.

Strategic Material Selection Guide for alcantara fabric for sale

What Are the Key Properties of Alcantara Fabric for B2B Buyers?

Alcantara fabric is a synthetic textile that combines polyester and polyurethane, resulting in a luxurious feel akin to suede. Its unique manufacturing process provides durability and aesthetic appeal, making it suitable for various applications, including automotive interiors, upholstery, and fashion. Understanding the specific types of Alcantara available can help B2B buyers make informed decisions based on their project requirements.

How Do Different Types of Alcantara Fabric Perform in Various Applications?

1. Alcantara Panel (Unbacked)

Key Properties: Alcantara Panel is the thinnest variant, unbacked and unlined, offering flexibility and lightweight characteristics. It is ideal for applications requiring a soft touch and minimal bulk.

Pros & Cons:

– Pros: Highly workable, excellent for vehicle headliners and dashboards, and provides a high-quality aesthetic.

– Cons: Lacks durability compared to backed alternatives, making it less suitable for high-wear applications.

Impact on Application: Best suited for low-touch surfaces in vehicles, where weight savings are crucial. However, it may not withstand heavy use over time.

Considerations for International Buyers: Compliance with automotive standards is essential, particularly in regions like Europe and the Middle East, where safety regulations are stringent.

2. Alcantara Cover (Backed)

Key Properties: This variant is backed with a laminated 65/35 poly-cotton scrim, enhancing its strength and durability.

Pros & Cons:

– Pros: Excellent for seating applications due to its durability and resistance to wear.

– Cons: Slightly heavier than unbacked options, which may impact design choices.

Impact on Application: Ideal for automotive seats, where maximum strength is required. It ensures longevity and maintains aesthetic appeal.

Considerations for International Buyers: Buyers must ensure that the material meets specific automotive safety standards (e.g., ASTM, DIN) relevant to their region.

3. Alcantara EXO (Outdoor)

Key Properties: Designed for outdoor use, Alcantara EXO features a laminated middle layer that offers water repellency and UV protection.

Pros & Cons:

– Pros: Highly resistant to environmental factors, making it suitable for outdoor furniture and marine applications.

– Cons: May not be as soft as other variants, which could affect tactile comfort.

Impact on Application: Perfect for applications exposed to harsh weather conditions, ensuring longevity and performance in diverse climates.

Considerations for International Buyers: Compliance with environmental regulations is critical, especially in regions like Africa and South America, where outdoor usage is prevalent.

4. Alcantara Soft (Foam-Backed)

Key Properties: This variant consists of a thin layer of Alcantara backed with foam, providing added softness and comfort.

Pros & Cons:

– Pros: Offers a plush feel while maintaining durability, ideal for headliners and luxury seating.

– Cons: The foam backing may add to the cost and complexity of manufacturing.

Impact on Application: Suitable for high-end automotive interiors where comfort and aesthetics are paramount.

Considerations for International Buyers: Ensure that the foam backing complies with fire safety standards, particularly in regions with strict regulations.

Summary Table of Alcantara Fabric Types

| Material | Typical Use Case for alcantara fabric for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Panel | Vehicle headliners, dashboards | Lightweight and highly workable | Less durable for high-wear areas | Medium |

| Alcantara Cover | Automotive seats | Excellent durability and strength | Heavier than unbacked options | High |

| Alcantara EXO | Outdoor furniture, marine applications | Water and UV resistant | Less tactile comfort | Medium |

| Alcantara Soft | Luxury automotive interiors | Plush feel with durability | Increased manufacturing complexity | High |

This strategic material selection guide aims to assist B2B buyers in making informed decisions about Alcantara fabric, considering their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric for sale

What Are the Main Stages in the Manufacturing Process of Alcantara Fabric?

The manufacturing process of Alcantara fabric involves several critical stages, ensuring that the final product meets the high standards expected by B2B buyers in various industries, including automotive, fashion, and upholstery.

1. Material Preparation

The first stage in the manufacturing process is material preparation. Alcantara is primarily composed of 68% polyester and 32% polyurethane. This mixture is meticulously formulated to achieve the desired texture and durability. The raw materials undergo extensive quality checks to ensure consistency in fiber quality, which is essential for maintaining the fabric’s performance characteristics.

2. Forming

Once the materials are prepared, they are subjected to a forming process. This involves combining the polyester and polyurethane to create a homogeneous mixture. The mixture is then extruded into sheets, which are subsequently processed to achieve the characteristic suede-like texture of Alcantara. This stage is crucial as it directly influences the fabric’s softness, grip, and overall aesthetic appeal.

3. Assembly

In the assembly phase, the formed sheets are cut and shaped according to specific applications. Different variations of Alcantara, such as unbacked panels, foam-backed options, and multilayer fabrics, are produced during this stage. Each type of Alcantara serves unique purposes; for example, Alcantara Cover is designed for maximum durability in seating applications, while Alcantara EXO is tailored for outdoor use.

4. Finishing

The final stage of the manufacturing process is finishing, where the fabric is treated to enhance its properties. This may include dyeing, applying protective coatings, or adding treatments for fire resistance or UV protection. The finishing process not only improves the aesthetic qualities of Alcantara but also boosts its durability and functionality, making it suitable for a wide range of applications.

How Is Quality Assurance Implemented in Alcantara Fabric Production?

Quality assurance (QA) is a critical component in the production of Alcantara fabric, ensuring that the final products meet international standards and customer expectations.

International Standards for Quality Assurance

Alcantara manufacturers often adhere to internationally recognized quality standards, such as ISO 9001, which specifies requirements for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements, thereby enhancing customer satisfaction. Additionally, industry-specific certifications, such as CE marking for compliance with European health and safety standards, may also be relevant, especially for products intended for automotive and aerospace applications.

Quality Control Checkpoints

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting the raw materials upon delivery to ensure they meet the specified quality standards before production begins. Materials that do not meet these standards are rejected or returned.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor production parameters and ensure compliance with quality standards. This includes visual inspections and mechanical testing to assess the fabric’s properties.

-

Final Quality Control (FQC): Once the manufacturing process is complete, the finished Alcantara fabric undergoes thorough inspections. This includes checking for color consistency, texture, and overall quality before the products are packaged and shipped.

What Common Testing Methods Are Used to Ensure Alcantara Quality?

Various testing methods are employed to verify the quality and performance of Alcantara fabric. These tests assess durability, safety, and compliance with industry standards.

-

Durability Testing: This includes abrasion resistance tests to determine how well the fabric withstands wear over time. Alcantara is known for its durability, making this test essential for applications in high-traffic areas, such as automotive interiors.

-

Stain Resistance Testing: Alcantara fabric is treated to be stain-resistant, and testing ensures that it maintains its appearance after exposure to common stains. This is particularly important for B2B buyers in the automotive and fashion industries, where fabric longevity is crucial.

-

Flammability Testing: Compliance with fire safety standards is vital, especially for fabrics used in automotive and aviation applications. Manufacturers may conduct tests according to FAR 25.853 or similar standards to verify that the fabric meets fire safety requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers adhere to stringent quality control measures. Here are some effective strategies for verifying supplier QC:

Illustrative image related to alcantara fabric for sale

Supplier Audits

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Audits can provide insights into the manufacturing facilities, quality management systems, and adherence to international standards. Buyers can establish a checklist of criteria based on their specific requirements and conduct on-site inspections or request third-party audit reports.

Quality Reports and Certifications

Requesting quality reports and certifications from suppliers can also provide assurance of product quality. Suppliers should be able to provide documentation that demonstrates compliance with relevant international standards, such as ISO 9001 and CE marking. Reviewing these documents allows buyers to make informed decisions about their suppliers’ reliability.

Third-Party Inspections

Engaging third-party inspection services can further ensure that the products meet the expected quality standards. These independent entities can conduct inspections at various stages of production, providing unbiased evaluations of the fabric’s quality.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

Illustrative image related to alcantara fabric for sale

Regional Compliance Requirements

Different regions may have specific compliance requirements and standards that must be adhered to when importing fabrics. Buyers should familiarize themselves with local regulations, including any necessary certifications for safety and environmental standards.

Cultural Sensitivity in Quality Expectations

Cultural differences can also influence quality expectations. For instance, buyers in the Middle East may prioritize luxurious aesthetics, while those in Europe may emphasize durability and sustainability. Understanding these nuances can help buyers communicate their requirements effectively and foster stronger supplier relationships.

Logistics and Supply Chain Considerations

International shipping can present challenges related to quality assurance, such as damage during transit or delays. B2B buyers should discuss logistics with suppliers to establish protocols for handling and packaging that protect the quality of Alcantara fabric during shipping.

By understanding the manufacturing processes and quality assurance measures associated with Alcantara fabric, B2B buyers can make informed purchasing decisions that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric for sale’

Introduction

Navigating the procurement process for Alcantara fabric can be challenging, especially for international B2B buyers seeking high-quality materials for diverse applications. This practical sourcing guide offers a step-by-step checklist to streamline your purchasing journey, ensuring you secure the right fabric from reputable suppliers while meeting your specific project needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential before beginning your search for Alcantara fabric. Consider factors such as the intended application (automotive, fashion, upholstery), desired texture, color, and durability requirements. This will help you communicate effectively with suppliers and ensure you receive materials that align with your project goals.

- Applications: Determine if you need Alcantara for high-performance automotive interiors, outdoor furniture, or fashion items.

- Specifications: Identify the type of Alcantara (e.g., Panel, Cover, EXO) that fits your project needs.

Step 2: Research Reliable Suppliers

Thoroughly researching potential suppliers is critical for ensuring you partner with reputable companies. Look for suppliers who specialize in Alcantara and have a proven track record in the industry. Utilize online resources, trade shows, and industry contacts to compile a list of potential vendors.

- Online Reviews: Check platforms such as Trustpilot or industry-specific forums for customer feedback.

- Supplier Experience: Prioritize suppliers with extensive experience in your target market.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is vital to conduct a comprehensive evaluation. Request company profiles, case studies, and references from other buyers in similar industries or regions. A thorough vetting process minimizes risks associated with quality and reliability.

- Certifications: Ensure the supplier complies with international standards and has necessary certifications for sustainable practices.

- Product Samples: Ask for samples to assess the quality, texture, and color fidelity of the Alcantara fabric.

Step 4: Verify Supply Chain Transparency

Understanding the supply chain of your chosen supplier is essential for maintaining ethical sourcing practices. Investigate where the Alcantara is produced and the sustainability measures in place. Suppliers should be transparent about their sourcing and manufacturing processes.

Illustrative image related to alcantara fabric for sale

- Sustainability: Look for suppliers who prioritize eco-friendly materials and manufacturing practices.

- Traceability: Confirm that the supplier can trace the origin of their Alcantara fabric.

Step 5: Assess Pricing and Terms

Once you have shortlisted suppliers, evaluate their pricing structures and terms of sale. Request detailed quotes that include shipping costs, bulk discounts, and payment terms. This will allow you to compare offers and choose the most cost-effective option without compromising on quality.

- Bulk Orders: Inquire about pricing for larger orders, as many suppliers offer significant discounts for bulk purchases.

- Payment Flexibility: Understand the payment terms and conditions, including any upfront deposits required.

Step 6: Establish Communication and Support Channels

Effective communication is key to a successful supplier relationship. Establish clear lines of communication with your chosen supplier to address any questions or concerns throughout the procurement process. Ensure they provide adequate support for any issues that may arise.

- Response Time: Assess how quickly the supplier responds to inquiries during your initial interactions.

- Customer Support: Confirm that the supplier offers ongoing support, including assistance with product selection and troubleshooting.

Step 7: Finalize the Agreement

After evaluating your options and establishing a preferred supplier, finalize the agreement. Ensure all terms are clearly documented, including delivery timelines, payment schedules, and quality assurance measures. A solid contract protects both parties and sets expectations for the business relationship.

- Legal Review: Consider having the contract reviewed by legal counsel to ensure all terms are favorable.

- Documentation: Keep all correspondence and agreements organized for future reference.

By following this checklist, B2B buyers can navigate the complexities of sourcing Alcantara fabric more effectively, ensuring they make informed decisions that align with their business needs.

Illustrative image related to alcantara fabric for sale

Comprehensive Cost and Pricing Analysis for alcantara fabric for sale Sourcing

When considering the cost structure for sourcing Alcantara fabric, B2B buyers must analyze several key components that contribute to the overall pricing. Understanding these elements can aid in making informed purchasing decisions and optimizing procurement strategies.

What Are the Key Cost Components in Alcantara Fabric Pricing?

-

Materials: The primary material used in Alcantara is a blend of polyester and polyurethane, which influences the cost significantly. The quality and source of these raw materials can vary, impacting the final price. For instance, Alcantara that has undergone additional treatments (like fire rating or UV protection) may incur higher material costs.

-

Labor: The labor involved in manufacturing Alcantara fabric encompasses skilled workers who ensure quality control and precision in production. Labor costs can vary depending on the region of production, with countries offering lower labor rates potentially providing more competitive pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility management. Efficient production processes can help reduce overhead, but premium suppliers often pass these costs onto the buyer.

-

Tooling: For custom orders, tooling costs can be significant. This includes the expenses related to creating molds or machinery adjustments necessary for specialized fabric designs or sizes.

-

Quality Control (QC): Ensuring that the fabric meets industry standards requires rigorous testing and inspection processes, which contribute to the overall cost. Buyers should verify that suppliers have robust QC protocols in place.

-

Logistics: Shipping costs can vary widely based on distance, volume, and chosen Incoterms. International buyers should consider additional fees such as tariffs and customs duties, which can significantly impact total costs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure profitability. This margin can fluctuate based on market demand, competition, and supplier reputation.

What Influences Pricing of Alcantara Fabric for International Buyers?

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with higher order volumes. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Customized Alcantara fabric (e.g., specific colors, patterns, or treatments) may come with additional costs. Buyers should clearly communicate their specifications to avoid unexpected charges.

-

Quality Certifications: Alcantara fabrics with certifications for durability, environmental standards, or safety ratings can command higher prices. However, these certifications may be essential for certain applications, such as automotive interiors.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a strong track record may charge a premium, but the assurance of quality and service can justify the cost.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. For instance, “FOB” (Free on Board) requires buyers to manage shipping once the goods are loaded, while “CIF” (Cost, Insurance, and Freight) includes shipping costs, potentially simplifying budgeting.

What Buyer Tips Can Enhance Cost Efficiency?

-

Negotiation: Buyers should approach negotiations with a clear understanding of their requirements and market rates. Leveraging quotes from multiple suppliers can strengthen negotiating positions.

-

Total Cost of Ownership (TCO): Consider the TCO beyond the initial purchase price. Assess factors such as durability, maintenance, and potential replacement costs to determine the best value.

-

Pricing Nuances for International Buyers: Understanding regional market dynamics is crucial. For instance, buyers from Africa or South America may encounter different supply chain logistics compared to those in Europe or the Middle East.

-

Sample Testing: Before committing to large orders, request samples to assess quality and performance. This can prevent costly mistakes and ensure the selected fabric meets project needs.

Conclusion

Sourcing Alcantara fabric involves a multifaceted cost structure influenced by various factors. By understanding these components and pricing influencers, B2B buyers can make strategic decisions that align with their budget and quality requirements. Always remember that prices can fluctuate, and obtaining multiple quotes will help secure the best deal possible.

Alternatives Analysis: Comparing alcantara fabric for sale With Other Solutions

Exploring Alternatives to Alcantara Fabric: A Comparative Analysis

When considering materials for high-end upholstery, automotive interiors, or fashion applications, Alcantara fabric stands out for its luxurious feel, durability, and versatility. However, it is essential for B2B buyers to explore viable alternatives that may align better with specific project requirements or budget constraints. This analysis will compare Alcantara fabric with two notable alternatives: synthetic suede and natural leather, evaluating performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Alcantara Fabric For Sale | Synthetic Suede | Natural Leather |

|---|---|---|---|

| Performance | High durability, stain-resistant, soft texture | Good durability, less grip than Alcantara | Excellent durability, luxurious feel |

| Cost | Moderate to high price per yard | Generally lower cost per yard | Higher price, varies significantly based on quality |

| Ease of Implementation | Easy to cut and sew, available in various formats | Easy to work with, available in sheets or rolls | Requires specific tools for cutting and stitching |

| Maintenance | Easy to clean, machine washable | Easy to maintain, often stain-resistant | Requires regular conditioning and cleaning |

| Best Use Case | Automotive interiors, luxury upholstery, fashion | Budget-friendly upholstery, fashion accessories | High-end furniture, luxury goods |

Synthetic Suede: A Cost-Effective Alternative

Synthetic suede is a popular alternative to Alcantara, offering a soft texture and good durability at a lower price point. It mimics the appearance of natural suede while being easier to clean and maintain. However, while it provides satisfactory performance for many applications, it may not match the luxurious feel and grip of Alcantara, particularly in automotive settings where performance is critical. Synthetic suede is ideal for budget-conscious projects or applications where high levels of wear are not anticipated.

Illustrative image related to alcantara fabric for sale

Natural Leather: The Classic Luxury Choice

Natural leather is renowned for its durability and classic aesthetic appeal. It offers a luxurious touch and exceptional resilience, making it a favorite for high-end furniture and luxury goods. However, leather typically comes with a higher price tag and requires ongoing maintenance to preserve its appearance and longevity. Additionally, it may not provide the same level of stain resistance or ease of cleaning as Alcantara, making it less suitable for certain applications, particularly in automotive interiors where spills and wear are common.

Conclusion: Choosing the Right Solution for Your Needs

In the quest for the perfect material, B2B buyers must weigh the specific requirements of their projects against the characteristics of each option. Alcantara fabric excels in high-performance environments, especially where aesthetics and durability are paramount. However, if budget constraints are a significant factor, synthetic suede presents a viable alternative, while natural leather remains an excellent choice for those seeking a timeless, luxurious finish. Ultimately, the decision should be guided by the intended use case, required performance attributes, and overall budget considerations to ensure the best fit for the project at hand.

Essential Technical Properties and Trade Terminology for alcantara fabric for sale

What Are the Key Technical Properties of Alcantara Fabric for B2B Buyers?

When considering Alcantara fabric for various applications, understanding its technical specifications is crucial for making informed purchasing decisions. Here are several key properties that define the quality and suitability of Alcantara for different uses:

-

Material Composition

Alcantara is primarily composed of 68% polyester and 32% polyurethane. This unique blend gives the fabric its characteristic soft, suede-like texture while ensuring durability and ease of maintenance. For B2B buyers, this composition is significant as it guarantees a product that can withstand wear and tear, making it ideal for high-traffic applications in automotive and fashion industries. -

Weight and Thickness

The weight of Alcantara fabric typically ranges from 200 to 400 grams per square meter (gsm), depending on the specific type (e.g., Panel, Cover, Soft). The thickness varies as well, influencing its application. For instance, thinner variants are more suitable for upholstery, while thicker options are preferred for high-use areas like vehicle interiors. Understanding these metrics helps buyers select the appropriate type for their specific needs. -

Durability and Abrasion Resistance

Alcantara is renowned for its high abrasion resistance, which allows it to maintain its aesthetic and functional qualities over time. This is particularly important for B2B buyers in sectors such as automotive and furniture, where longevity is a key consideration. The fabric’s ability to resist pilling and wear ensures that products maintain their premium look and feel even after extensive use. -

Stain Resistance and Cleanability

One of the standout features of Alcantara is its inherent stain-resistant properties. This makes it exceptionally easy to clean and maintain, offering significant value for industries that prioritize hygiene and appearance. Buyers should consider this property as it can lead to reduced maintenance costs and enhanced customer satisfaction. -

Fire Resistance

Certain variants of Alcantara, such as the Avant series, are treated to meet specific fire safety standards (FAR 25.853). For B2B buyers, especially in the aviation and automotive sectors, this certification is critical to ensure compliance with safety regulations, making it a vital factor in procurement decisions.

Which Trade Terms Should B2B Buyers Understand When Purchasing Alcantara Fabric?

Familiarizing oneself with industry terminology can streamline the purchasing process and enhance communication with suppliers. Here are some essential trade terms related to Alcantara fabric:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Alcantara, OEM clients might utilize the fabric in their products, such as automotive interiors. Understanding this term helps buyers identify potential partnerships and sourcing strategies. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Alcantara fabric, MOQs can vary significantly based on the type and supplier. Buyers should be aware of these quantities to align their purchasing plans with supplier capabilities and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products. For Alcantara fabric, issuing an RFQ can help buyers gauge market pricing and compare offers effectively, ensuring they receive competitive rates. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and tariffs. Familiarity with these terms is crucial for B2B buyers sourcing Alcantara from international suppliers, as it clarifies the logistics and costs involved in the procurement process. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving it. Understanding lead times is essential for B2B buyers to manage inventory levels and production schedules effectively, particularly when dealing with custom Alcantara orders. -

Custom Solutions

Many suppliers offer customized Alcantara solutions tailored to specific requirements. This can include color matching, texture adjustments, or special treatments. Recognizing the availability of custom solutions allows buyers to meet unique project needs and differentiate their offerings in competitive markets.

Understanding these properties and terms will empower B2B buyers to make informed decisions regarding Alcantara fabric, ensuring they select the right materials for their applications while optimizing their procurement processes.

Illustrative image related to alcantara fabric for sale

Navigating Market Dynamics and Sourcing Trends in the alcantara fabric for sale Sector

What Are the Current Market Dynamics and Key Trends in Alcantara Fabric Sourcing?

The global alcantara fabric market is experiencing significant growth, driven by increasing demand in the automotive, fashion, and upholstery sectors. The luxurious feel and durability of Alcantara make it a preferred choice among high-end manufacturers and designers. Notably, luxury automotive brands in Europe are leading the charge, utilizing Alcantara for interiors due to its superior tactile qualities and performance. Emerging markets, particularly in Africa and South America, are beginning to embrace Alcantara as a viable alternative to traditional materials, with growth expected as local industries expand.

In terms of sourcing trends, international B2B buyers are increasingly leveraging digital platforms for procurement. Online marketplaces and dedicated fabric distributors are streamlining the buying process, allowing for easier access to diverse product lines and customization options. Furthermore, advancements in supply chain technology, such as blockchain, are enhancing transparency and efficiency, enabling buyers to track the origin and quality of their materials. This trend is particularly relevant for markets in the Middle East and Europe, where regulatory compliance and quality assurance are critical.

How Is Sustainability and Ethical Sourcing Influencing the Alcantara Fabric Market?

Sustainability has become a cornerstone of sourcing strategies for B2B buyers in the alcantara fabric sector. As environmental concerns rise, manufacturers are increasingly focusing on ethical sourcing practices and the environmental impact of their materials. Alcantara, known for its eco-friendly production processes, is 100% made in Italy and crafted from recycled materials, appealing to buyers who prioritize sustainability.

Illustrative image related to alcantara fabric for sale

Ethical supply chains are essential for building brand reputation and consumer trust. Brands that incorporate green certifications or sustainable materials into their offerings often enjoy a competitive edge, particularly in markets sensitive to environmental issues. Buyers should look for suppliers who provide certifications and transparent information regarding their sourcing practices. This not only ensures compliance with global sustainability standards but also aligns with the growing consumer preference for ethically produced goods.

What Is the Historical Context of Alcantara Fabric and Its Relevance Today?

Developed in the 1970s in Italy, Alcantara fabric was designed to mimic the luxurious texture of suede while offering enhanced durability and ease of maintenance. Its innovative composition, combining polyester and polyurethane, revolutionized the textile industry by providing a high-performance alternative to natural materials. Over the decades, Alcantara has established itself as a staple in luxury automotive interiors and high-end fashion, with its applications expanding into various sectors such as home furnishings and outdoor products.

Today, the fabric’s historical significance is underscored by its continued evolution in response to market demands. As B2B buyers seek versatile and sustainable materials, Alcantara stands out not only for its aesthetic appeal but also for its commitment to ethical production. Understanding its origins helps buyers appreciate the value it brings to their projects, making it a strategic choice for businesses aiming to enhance their product offerings while adhering to modern sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric for sale

-

How do I ensure the quality of Alcantara fabric before purchasing?

To ensure the quality of Alcantara fabric, request samples from suppliers to assess texture, durability, and color accuracy. Establish a quality assurance process that includes checking certifications, such as ISO standards, which indicate adherence to quality manufacturing practices. Additionally, inquire about the supplier’s return policy and warranty offerings to safeguard your investment. Building a relationship with suppliers who can provide transparency about their sourcing and production methods can also enhance trust in the quality of the materials. -

What is the best type of Alcantara for automotive applications?

For automotive applications, Alcantara Cover is often the best choice due to its durability and strength. This type is backed with a laminated scrim, making it ideal for high-wear areas like seats where maximum strength is essential. Alcantara EXO is also suitable for outdoor or convertible vehicles, as it offers added water resistance and UV protection. Evaluate your specific requirements for durability, aesthetic appeal, and functionality to select the most appropriate Alcantara type for your project. -

What customization options are available for Alcantara fabric?

Alcantara fabric can be customized in various ways, including color selection, texture, and backing options. Many suppliers offer a wide palette of colors and the ability to create bespoke patterns. You can also choose from different types of backing, such as foam or laminated scrim, to enhance functionality based on your application needs. When discussing customization, ensure that your supplier can accommodate minimum order quantities (MOQs) and provide mock-ups or samples before finalizing your order. -

What are the minimum order quantities (MOQs) for Alcantara fabric?

Minimum order quantities for Alcantara fabric can vary by supplier and type of fabric. Typically, MOQs may range from a few yards to full rolls (e.g., 55 yards) depending on the customization and backing options. It’s crucial to confirm these details with your supplier early in the negotiation process to ensure that your order aligns with your project needs and budget. Consider discussing potential flexibility in MOQs for future orders as your business scales. -

What payment terms should I expect when sourcing Alcantara fabric internationally?

Payment terms for international orders of Alcantara fabric can differ significantly among suppliers. Common terms include payment in advance, letters of credit, or net 30/60 days after delivery, depending on the relationship and trust established. Ensure that you clarify the payment methods accepted, such as bank transfers, credit cards, or escrow services. Negotiating favorable terms can help manage cash flow and mitigate risks, especially when dealing with larger orders or new suppliers. -

How can I vet suppliers of Alcantara fabric to ensure reliability?

To vet suppliers of Alcantara fabric, start by researching their reputation through online reviews and industry references. Request information about their production processes, certifications, and compliance with international standards. Engaging in direct communication can also reveal their responsiveness and willingness to address concerns. Consider visiting their facilities or requesting third-party audits to further validate their reliability. Building relationships with trusted industry contacts can also provide insights into supplier credibility. -

What logistics considerations should I keep in mind when importing Alcantara fabric?

When importing Alcantara fabric, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate whether air freight or sea freight is more suitable for your timeline and budget. Understand the import duties and taxes applicable in your country, as these can significantly affect overall costs. Collaborating with a logistics partner familiar with textile imports can streamline the process and ensure compliance with international trade regulations. -

What are the best practices for storing Alcantara fabric to maintain its quality?

To maintain the quality of Alcantara fabric, store it in a cool, dry environment away from direct sunlight, which can fade colors and degrade materials. Keep the fabric rolled or flat in a manner that prevents creasing or damage. Avoid exposure to excessive humidity, which can lead to mold growth. Regularly check stored fabric for signs of wear or damage and ensure it is properly covered to protect it from dust and pollutants.

Top 8 Alcantara Fabric For Sale Manufacturers & Suppliers List

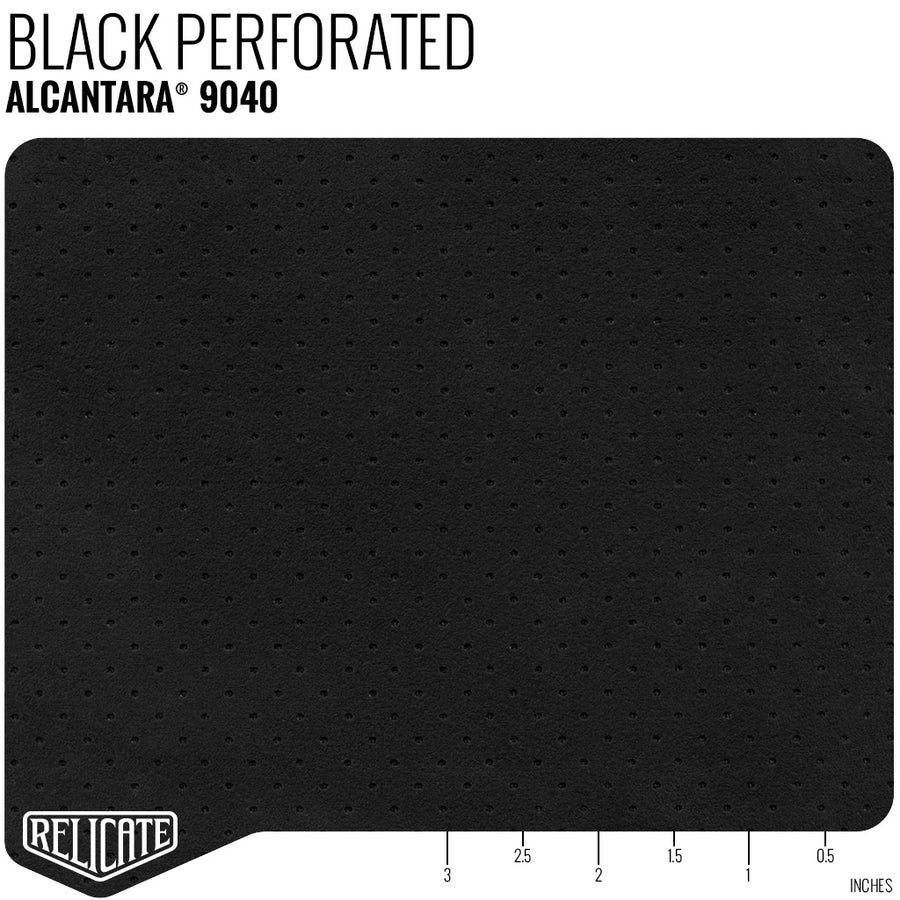

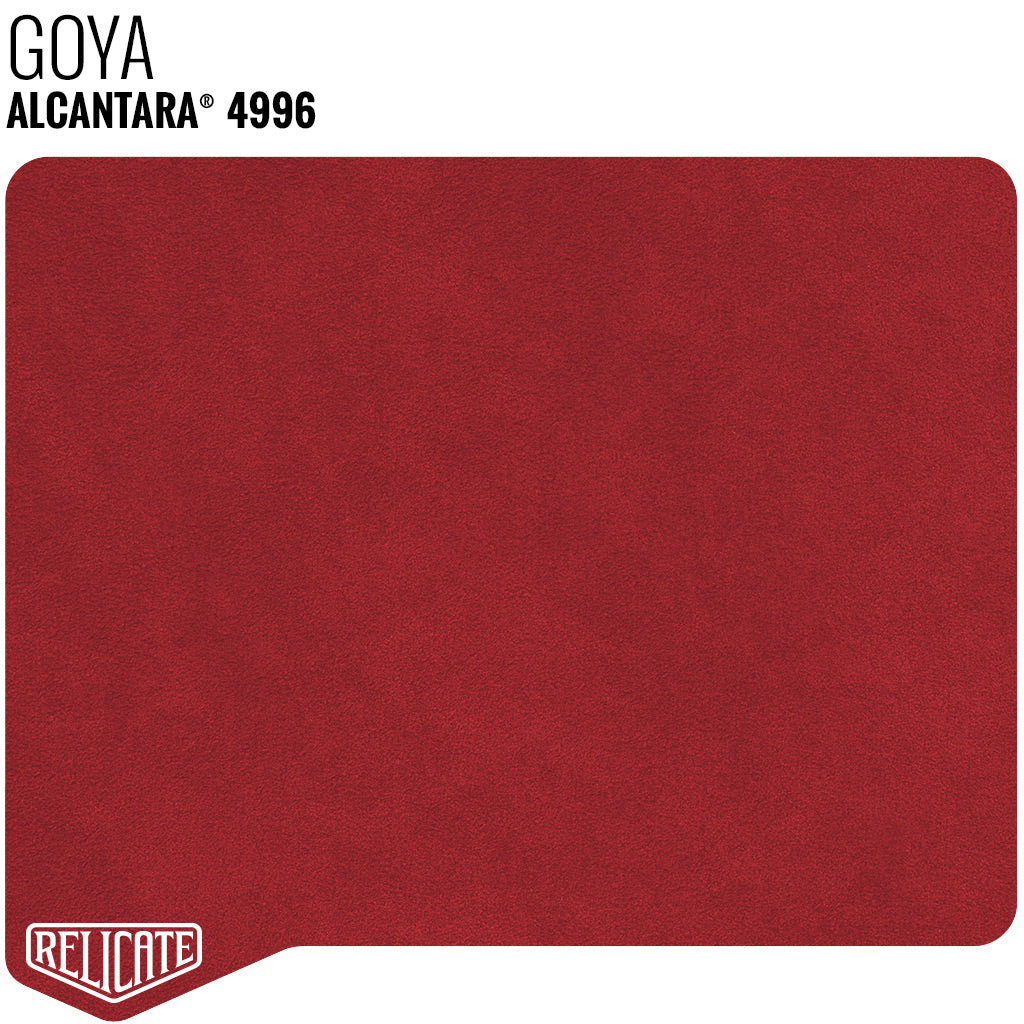

1. Relicate – Alcantara by the Linear Foot

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Alcantara by the Linear Foot – Price: $55.00. Available in various colors including 9040 Black, 9002 Anthracite, 9052 Dark Charcoal, 2957 Chic Grey, 2934 Silver Grey, 4978 Pearl Grey, 1452 Lemon Yellow, 2969 Mango, 4996 Goya, 2916 Rubin, 9076 Burgundy, 6322 Tiffany Blue, 7586 Cobalt, 6408 Infanta/Nogaro Blue, 9041 Navy Blue, 4914 Hide, 2930 Hazelnut, 6833 Raw Amber, 9500 Dark Brown, 2911 Pearl Whi…

2. Keystone Bros – Alcantara Suede Automotive Fabric

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Alcantara Suede – Automotive Fabric. Product options include Alcantara Cover, Alcantara Soft, Alcantara Pannel, Alcantara EXO, Alcantara Pannel MB-4 Perf, and Alcantara Pannel S-2000 Perf. Pricing requires login to view. Features include various roll sizes, cleaning codes, abrasion ratings, and UFAC Class 1 compliance.

3. Hydes Leather – Alcantara Products

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather is the official distributor of Alcantara in North America, offering a complete range of Alcantara products used by luxury auto brands in Europe. Alcantara is 100% made in Italy and is known for its style, elegance, and functionality while being environmentally friendly. The product range includes: 1. Alcantara Panel: Unbacked, thin, and workable fabric for headliners, doors, and dash…

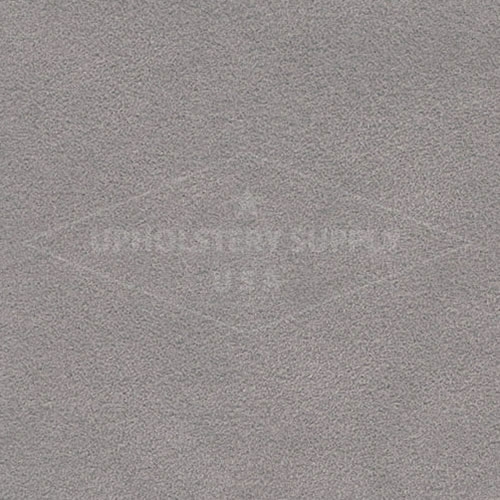

4. Upholstery Supply USA – Alcantara for Panels – Anthracite Black

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: Alcantara for Panels – Anthracite Black (#9002)\nPrice: $135.00 per Yard (1 to 9 yards), $130.00 per Yard (10 to 24 yards), $125.00 per Yard (25+ yards)\nRoll Width: 56 inches\nThickness: 1.0 mm\nMaterial: Genuine Alcantara Textile, Made in Italy\nApplications: Automotive Interior (door panels, headliners, and more)\nCare Instructions: See the “Documents” tab for a .pdf of the Care and Maintenance…

5. Alcantara – Versatile Sustainable Material

Domain: alcantara.com

Registered: 1996 (29 years)

Introduction: Alcantara is a 100% Italian brand known for its versatility and commitment to sustainability. It combines aesthetics and performance, making it suitable for various applications in art, design, fashion, luxury, and automotive industries. The material is characterized by its emotional feel, technological innovation, and endless possibilities for customization. Alcantara has a strong presence in glo…

6. Alcantara Craft Fabric – Premium Material Options

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Alcantara Craft Fabric available for sale on eBay. Key details include:

– Material: Alcantara and various blends (Chiffon, Cotton, Faux Fur, Faux Leather, etc.)

– Sizes: Available in squares, by the yard, less than 1 yard, and panels.

– Colors: Options include Beige, Black, Blue, Brown, Gray, Green, Multicolor, Orange, Red, and more.

– Suitable for: Car upholstery, quilting, apparel (coats, jacket…

7. DLT Corporation – Alcantara Soft (Foam-backed)

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft (Foam-backed) is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Pricing starts at $134.99 for various colors, including Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black,…

8. Source of Fabric – Alcantara Fabric

Domain: sourceoffabric.com

Registered: 2011 (14 years)

Introduction: Alcantara fabric is a synthetic textile known for its luxurious look and feel, developed in the 1970s in Italy. It mimics the texture of natural suede while providing durability and lightweight properties. Key features include high durability, stain resistance, comfort, breathability, thermal insulation, and a wide variety of colors and textures for customization. It is suitable for applications i…

Strategic Sourcing Conclusion and Outlook for alcantara fabric for sale

Alcantara fabric represents a fusion of luxury and practicality, making it an ideal choice for various applications across automotive, fashion, and upholstery sectors. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek high-quality materials, understanding the nuances of Alcantara sourcing is essential. Key takeaways include recognizing the diverse types of Alcantara available, such as Panel, Cover, EXO, and Soft variants, each tailored for specific uses and environments.

Strategic sourcing of Alcantara fabric not only enhances product offerings but also aligns with sustainability goals, as it is a 100% made-in-Italy product that respects environmental standards. By leveraging suppliers who can provide custom solutions and extensive inventories, buyers can ensure they meet the high expectations of their clientele.

Looking ahead, the demand for Alcantara fabric is poised to grow, driven by trends in luxury and eco-conscious design. We encourage B2B buyers to engage with reputable suppliers, explore the full range of options, and consider the long-term benefits of integrating Alcantara into their product lines. Connect with industry leaders today to stay ahead in this competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to alcantara fabric for sale