Introduction: Navigating the Global Market for leather tools and supplies

In today’s competitive landscape, sourcing high-quality leather tools and supplies can be a daunting task for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the challenge lies not only in identifying reliable suppliers but also in ensuring that the products meet your specific needs for quality, functionality, and cost-effectiveness. This guide is designed to help you navigate the global market for leather tools and supplies, offering insights into various types of tools, their applications, and the best practices for supplier vetting.

Our comprehensive resource covers a broad spectrum of topics, including an overview of essential leatherworking tools, industry trends, pricing strategies, and tips for negotiating favorable terms with suppliers. By delving into the intricacies of the leathercrafting supply chain, this guide empowers you to make informed purchasing decisions that align with your business goals.

With a focus on key markets such as Brazil and Saudi Arabia, we address regional considerations that may impact your sourcing strategy, helping you identify opportunities for collaboration and growth. Ultimately, this guide serves as your roadmap to successfully navigate the complexities of the leather tools and supplies market, ensuring that your business is equipped with the best resources to thrive in a dynamic industry.

Table Of Contents

- Top 6 Leather Tools And Supplies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather tools and supplies

- Understanding leather tools and supplies Types and Variations

- Key Industrial Applications of leather tools and supplies

- 3 Common User Pain Points for ‘leather tools and supplies’ & Their Solutions

- Strategic Material Selection Guide for leather tools and supplies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather tools and supplies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather tools and supplies’

- Comprehensive Cost and Pricing Analysis for leather tools and supplies Sourcing

- Alternatives Analysis: Comparing leather tools and supplies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather tools and supplies

- Navigating Market Dynamics and Sourcing Trends in the leather tools and supplies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather tools and supplies

- Strategic Sourcing Conclusion and Outlook for leather tools and supplies

- Important Disclaimer & Terms of Use

Understanding leather tools and supplies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hand Tools | Manual operation, often portable, includes knives, punches, and chisels | Custom leather goods, small-scale production | Pros: Versatile, low initial investment. Cons: Labor-intensive, requires skilled labor. |

| Sewing Machines | Motorized or manual, designed for leather stitching, various stitch types | Mass production, repairs, high-volume output | Pros: Increases efficiency, consistent quality. Cons: Higher upfront costs, maintenance required. |

| Cutting Tools | Includes rotary cutters, knives, and dies, designed for precision cutting | Pattern making, leather goods manufacturing | Pros: Precision and speed, reduces waste. Cons: Requires proper handling and sharpening. |

| Finishing Supplies | Dyes, conditioners, and sealants for leather treatment | Product enhancement, quality assurance | Pros: Improves aesthetics and durability. Cons: May require additional training for application. |

| Hardware & Fasteners | Buckles, rivets, snaps, and other metal components | Functional and decorative elements in products | Pros: Variety enhances product appeal, easy to source. Cons: Quality varies, affecting end product durability. |

What are the Characteristics of Hand Tools in Leather Crafting?

Hand tools are essential for artisans focusing on custom leatherwork. These tools, such as knives, punches, and chisels, are characterized by their manual operation, allowing for precision and creativity in crafting. They are ideal for small-scale production where detail and craftsmanship are paramount. When purchasing, B2B buyers should consider the durability of materials, ergonomics for user comfort, and the variety of tools available to meet specific project needs. While they require skilled labor and can be labor-intensive, they offer versatility at a lower initial investment.

How Do Sewing Machines Enhance Leather Production Efficiency?

Sewing machines designed for leatherwork are invaluable for businesses looking to scale production. These machines can be motorized or manual and are capable of executing various stitch types, making them suitable for mass production of leather goods. Key considerations for B2B buyers include the machine’s speed, stitch quality, and compatibility with different leather thicknesses. While the upfront costs can be significant, the efficiency gained in production and the consistent quality of stitching often justify the investment, especially for high-volume operations.

Why are Cutting Tools Vital for Precision in Leather Goods?

Cutting tools are crucial for ensuring precision in leather crafting. This category includes rotary cutters, knives, and specialized dies that facilitate accurate pattern cutting. B2B buyers should look for tools that offer sharpness, ease of use, and the ability to handle various leather types. The benefits of using high-quality cutting tools include increased speed and reduced material waste, which can significantly improve profitability. However, they require careful handling and regular maintenance to maintain their effectiveness.

What Role Do Finishing Supplies Play in Leather Quality?

Finishing supplies, such as dyes, conditioners, and sealants, play a critical role in enhancing the quality of leather products. These materials are used to improve the aesthetics, durability, and water resistance of leather goods. B2B buyers must consider the compatibility of these products with the leather type they are working with, as well as the application methods required. While these supplies can significantly elevate the final product, they may necessitate additional training for proper application, impacting initial production timelines.

How Can Hardware and Fasteners Enhance Leather Product Appeal?

Hardware and fasteners, including buckles, rivets, and snaps, are essential components that add both functionality and aesthetic appeal to leather goods. They come in various styles and finishes, allowing businesses to customize their products to meet market demands. When sourcing these components, B2B buyers should evaluate the quality and durability of materials, as well as the supply chain reliability. While they are relatively easy to source, ensuring high-quality hardware is crucial, as it directly affects the durability and perceived value of the final product.

Key Industrial Applications of leather tools and supplies

| Industry/Sector | Specific Application of leather tools and supplies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Handbag and accessory production | High-quality tools ensure durability and aesthetics | Look for suppliers with a wide range of tools and materials for customization. |

| Automotive | Upholstery and interior leatherwork | Enhances vehicle aesthetics and comfort | Ensure suppliers provide specialized leather suitable for automotive applications. |

| Footwear | Shoe manufacturing and repair | Precision tools improve fit and longevity | Seek suppliers that offer tools for both mass production and bespoke items. |

| Home Decor | Leather furniture and decorative items | Unique, durable products increase market appeal | Consider sourcing from suppliers that provide eco-friendly leather options. |

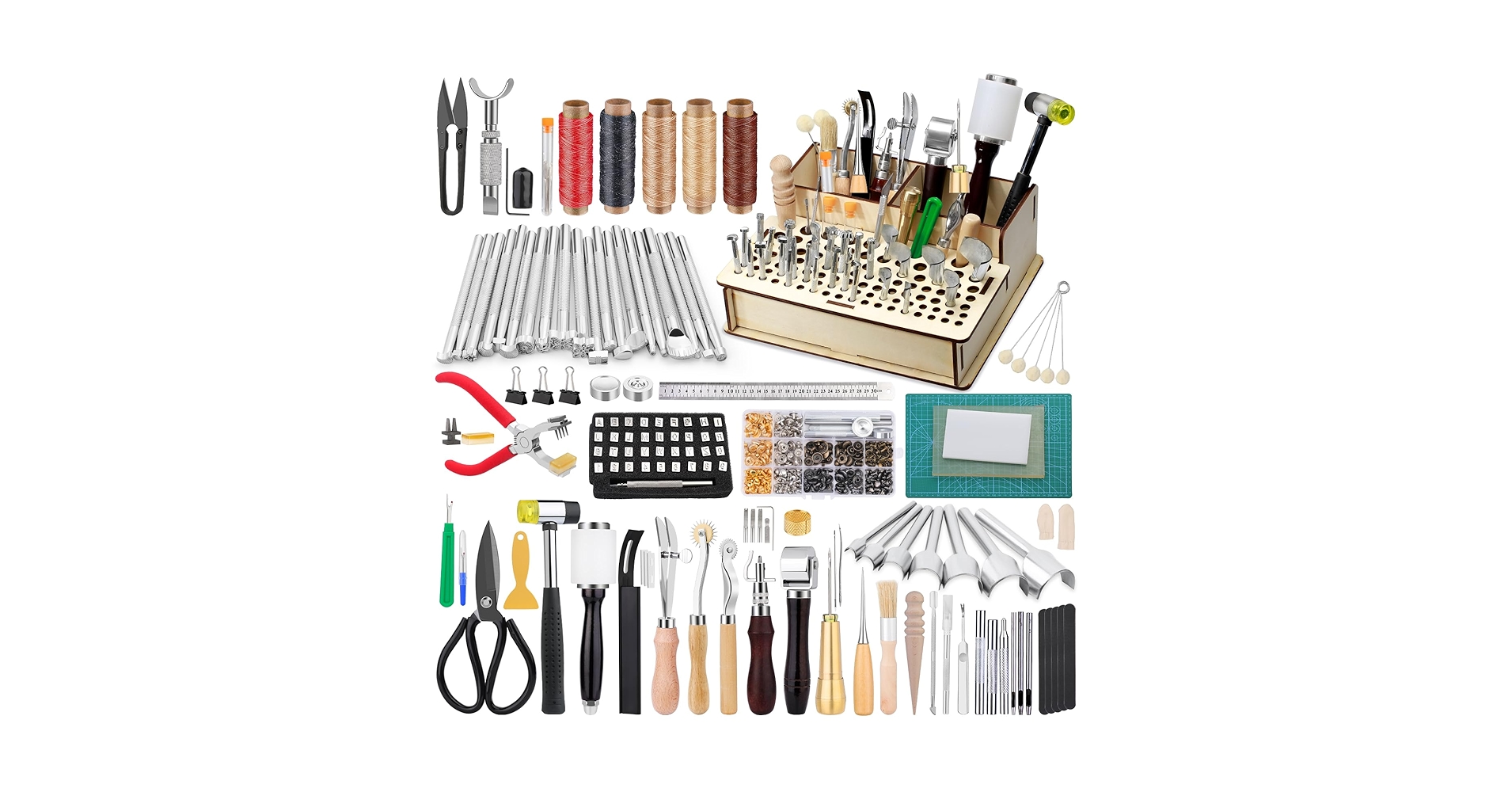

| Craft and Hobby | DIY leather crafting and small-scale production | Encourages creativity and personal branding | Look for comprehensive kits and a variety of tools for different skill levels. |

How Are Leather Tools and Supplies Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, leather tools and supplies are essential for the production of handbags, belts, and other accessories. High-quality cutting, stitching, and finishing tools enable manufacturers to create durable and aesthetically pleasing products that meet consumer demands. For international buyers, particularly from regions like Africa and Europe, sourcing tools that offer versatility and precision is crucial, as these can significantly reduce production time while enhancing product quality.

What Role Do Leather Tools Play in Automotive Upholstery?

Leather tools are vital in the automotive industry, specifically for upholstery and interior finishes. Tools such as specialized sewing machines and cutting dies facilitate the precise crafting of leather seats and trims, enhancing both aesthetics and comfort. Buyers from the Middle East and South America should focus on sourcing leather that meets industry standards for durability and safety, ensuring compliance with local regulations while maintaining high-quality finishes.

Illustrative image related to leather tools and supplies

How Are Leather Tools Utilized in Footwear Production?

In footwear manufacturing, leather tools are used for cutting, stitching, and finishing shoes. Precision tools help ensure a proper fit and enhance the longevity of the products. B2B buyers, especially from Brazil and Europe, should consider suppliers that offer both mass production tools and custom solutions to accommodate bespoke designs, allowing for a diverse range of footwear styles that cater to different market segments.

What Are the Applications of Leather Tools in Home Decor?

The home decor industry employs leather tools for crafting furniture and decorative items. High-quality tools facilitate the creation of unique, durable products that appeal to consumers looking for luxury home furnishings. For buyers from Africa and the Middle East, sourcing eco-friendly leather options can enhance brand appeal and align with growing sustainability trends in home decor.

How Do Leather Tools Support Craft and Hobby Projects?

Leather tools are essential for DIY enthusiasts and small-scale producers in the craft sector. These tools allow individuals to create personalized leather goods, from wallets to decorative items, fostering creativity and brand individuality. Buyers, particularly from South America and Europe, should seek suppliers that offer comprehensive kits and a variety of tools suitable for different skill levels, enabling both beginners and experienced crafters to engage in leatherworking.

Illustrative image related to leather tools and supplies

3 Common User Pain Points for ‘leather tools and supplies’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather Tools

The Problem: B2B buyers often face the challenge of sourcing high-quality leather tools that meet specific project requirements. Many suppliers offer a wide variety of tools, but not all are created equal. Buyers may struggle with distinguishing between genuine, durable tools and low-quality imitations, which can lead to project delays and increased costs. For international buyers, such as those from Africa or South America, shipping times and customs can exacerbate these issues, making it critical to ensure that the right tools are selected from the outset.

The Solution: To effectively source high-quality leather tools, B2B buyers should establish relationships with reputable suppliers who specialize in leathercraft. Conduct thorough research on suppliers, including reading reviews and verifying their credentials. It’s also beneficial to request samples of tools before making larger orders. Buyers should focus on suppliers that provide detailed specifications and descriptions for each tool, which can help in assessing quality. Additionally, consider sourcing tools that have a warranty or return policy, which offers extra assurance of their durability and functionality.

Scenario 2: Managing Inventory and Supply Chain Challenges

The Problem: Inventory management can be a significant pain point for B2B buyers in the leather goods industry. Fluctuating demand, combined with long lead times for sourcing materials, can create gaps in supply. For example, a buyer may underestimate the demand for a particular leather type or tool, leading to stockouts. Conversely, overestimating demand can result in excess inventory, tying up capital and storage space. These challenges are particularly pronounced for businesses operating in regions with less reliable supply chains.

The Solution: To effectively manage inventory, B2B buyers should implement an inventory management system that tracks usage patterns and forecasts demand based on historical data. This system should allow for real-time updates and alerts when stock levels fall below a certain threshold. Establishing partnerships with multiple suppliers can also provide flexibility and reduce the risk of stockouts. Additionally, consider using just-in-time (JIT) inventory practices to minimize excess stock while ensuring that essential materials are always available. Building a strong communication line with suppliers regarding lead times and potential delays will also help in better planning and inventory management.

Scenario 3: Navigating Compliance and Quality Standards

The Problem: International buyers of leather tools and supplies often encounter complex compliance and quality standards that vary by region. This can be particularly challenging for companies looking to export their leather goods, as they must adhere to both their country’s regulations and those of the target market. Failing to meet these standards can result in costly fines, product recalls, and damage to reputation, making compliance a critical issue.

The Solution: B2B buyers should invest time in understanding the compliance and quality standards relevant to their markets, including certifications for leather materials and tools. This may involve collaborating with local industry associations or regulatory bodies to stay updated on changes. It’s also advisable to work with suppliers who have a proven track record of compliance and can provide necessary documentation, such as certifications and safety data sheets. Additionally, regular quality audits of both suppliers and products can help ensure ongoing adherence to standards, protecting the business from potential compliance issues down the line.

Strategic Material Selection Guide for leather tools and supplies

What Are the Key Materials for Leather Tools and Supplies?

When selecting materials for leather tools and supplies, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: stainless steel, aluminum, plastic, and wood. Each material has unique characteristics that impact performance, durability, and application suitability.

How Does Stainless Steel Perform in Leather Tool Manufacturing?

Stainless steel is a popular choice for leatherworking tools due to its excellent strength and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Tools made from stainless steel, such as knives and punches, maintain sharpness over time, providing consistent performance.

Pros: High durability and resistance to rust and corrosion, ensuring longevity. Stainless steel tools are also easy to clean and maintain.

Cons: The initial cost can be higher compared to other materials, and manufacturing can be complex due to the need for specialized equipment.

Impact on Application: Stainless steel tools are compatible with various leather types and are ideal for precision work, making them suitable for high-end leather goods.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM and DIN for quality assurance. In regions like the Middle East and Europe, preference for high-quality, durable tools is prevalent.

Illustrative image related to leather tools and supplies

What Role Does Aluminum Play in Leather Tool Production?

Aluminum is lightweight and offers good corrosion resistance, making it a suitable material for tools that require frequent handling. It is often used in components like handles and frames.

Pros: Its lightweight nature reduces fatigue during prolonged use, and it is generally less expensive than stainless steel.

Cons: While aluminum is durable, it is softer than stainless steel and may wear down more quickly under heavy use.

Impact on Application: Aluminum tools are ideal for less intensive tasks and are often used in crafting lighter leather goods like bags and wallets.

Illustrative image related to leather tools and supplies

Considerations for International Buyers: Buyers should verify that aluminum tools meet regional safety and quality standards, especially in markets where durability is critical.

How Does Plastic Contribute to Leather Tool Functionality?

Plastic is often used for various components in leather tools, such as handles or non-critical parts. Its versatility and low cost make it an attractive option for many manufacturers.

Pros: Plastic tools are lightweight, cost-effective, and can be molded into various shapes, allowing for ergonomic designs.

Cons: Plastic lacks the durability of metal and may not withstand high temperatures or heavy loads, limiting its use in professional-grade tools.

Impact on Application: Suitable for hobbyists and entry-level leatherworkers, plastic tools can be effective for basic projects but may not meet the demands of professional applications.

Considerations for International Buyers: Buyers should be aware of the environmental impact of plastic and seek suppliers who comply with regulations regarding plastic waste management.

Why Is Wood Still Relevant in Leather Tool Manufacturing?

Wood is traditionally used for tools like mallets and stitching ponies. It offers a unique aesthetic and tactile quality that many artisans appreciate.

Pros: Wood tools can absorb shock, providing a comfortable user experience. They are also biodegradable, making them environmentally friendly.

Cons: Wood can be susceptible to moisture and may warp or crack over time, affecting performance.

Impact on Application: Wooden tools are often favored for their craftsmanship and are suitable for artisans focusing on traditional leatherworking techniques.

Considerations for International Buyers: Buyers should consider the sourcing of wood and ensure it adheres to sustainability standards, particularly in regions with strict environmental regulations.

Summary Table of Material Selection for Leather Tools and Supplies

| Material | Typical Use Case for leather tools and supplies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Knives, punches, and heavy-duty tools | High durability and corrosion resistance | Higher initial cost | High |

| Aluminum | Handles and lighter tools | Lightweight and cost-effective | Softer than stainless steel | Medium |

| Plastic | Non-critical components and beginner tools | Lightweight and versatile | Less durable under heavy use | Low |

| Wood | Mallets and stitching tools | Comfortable to use and biodegradable | Susceptible to moisture | Medium |

This comprehensive overview of material selection aids international B2B buyers in making informed decisions tailored to their specific needs in the leather tools and supplies market.

In-depth Look: Manufacturing Processes and Quality Assurance for leather tools and supplies

What Are the Key Stages in the Manufacturing Process of Leather Tools and Supplies?

The manufacturing of leather tools and supplies involves several critical stages, each essential for ensuring the quality and performance of the final products. Understanding these stages helps B2B buyers evaluate suppliers more effectively.

1. Material Preparation: What Goes Into Crafting Leather Tools?

Material preparation is the first step in the manufacturing process. High-quality leather tools typically start with premium raw materials, including various types of leather, metals for hardware, and synthetic materials for handles or grips. Suppliers often source leather from reputable tanneries known for their ethical practices and consistent quality.

Illustrative image related to leather tools and supplies

During this phase, materials undergo rigorous inspection to ensure they meet specifications for weight, thickness, and texture. For instance, vegetable-tanned leather is preferred for its durability and natural finish. Additionally, metals used in tools are assessed for corrosion resistance and strength.

2. Forming: How Are Leather Tools Shaped and Molded?

The forming stage involves shaping the prepared materials into the desired tool designs. This can include cutting leather into specific patterns, stamping, and molding metal parts. Advanced techniques such as CNC machining and laser cutting are often employed to enhance precision and reduce waste.

In this phase, tools might be crafted using hand tools or automated machinery, depending on the complexity and scale of production. For example, precision tools like hole punches may require high-end machining to ensure they deliver consistent results.

3. Assembly: What Techniques Are Used to Assemble Leather Tools?

Once the components are formed, they move on to the assembly stage. This process can involve stitching, riveting, or welding parts together. For leather tools, stitching is particularly crucial, as it affects both aesthetics and durability. Hand-stitching techniques are often used for high-end products, while sewing machines may be employed for mass production.

Quality control at this stage is vital; any misalignment or poor stitching can compromise the tool’s functionality. Skilled craftsmen typically oversee this stage to ensure that every product meets the established quality standards.

4. Finishing: What Are the Final Touches Applied to Leather Tools?

The finishing stage enhances the appearance and performance of the leather tools. This includes processes like dyeing, polishing, and applying protective coatings. For leather tools, using environmentally friendly dyes and finishes is becoming increasingly important, particularly for buyers focused on sustainability.

Finishing also involves quality checks to ensure that the final products are free from defects and meet aesthetic criteria. This stage is essential for ensuring that tools not only function well but also appeal to the end-user.

Illustrative image related to leather tools and supplies

What Quality Assurance Practices Are Essential for Leather Tool Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing leather tools and supplies. It ensures that products meet both internal and external standards, which is particularly important for B2B buyers operating in diverse international markets.

Relevant International Standards: What Certifications Should B2B Buyers Look For?

B2B buyers should look for suppliers who comply with international quality standards such as ISO 9001, which outlines criteria for effective quality management systems. Additionally, certain industry-specific certifications, such as CE marking for products sold in Europe or API standards for tools used in industrial applications, may also be relevant.

These certifications indicate that the manufacturing processes have been independently verified to meet high-quality standards. Suppliers who hold these certifications can provide assurance of their commitment to quality.

What Are the Common Quality Control Checkpoints During Manufacturing?

Quality control in leather tool manufacturing typically involves several key checkpoints:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During production, samples are regularly tested to ensure that every stage of manufacturing adheres to quality standards. This can include checks for dimensions, material properties, and assembly integrity.

- Final Quality Control (FQC): After assembly, each product undergoes a final inspection to verify that it meets all specifications and is free from defects.

These checkpoints help identify and rectify issues early in the manufacturing process, ultimately reducing waste and improving product quality.

Illustrative image related to leather tools and supplies

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of potential suppliers is crucial for B2B buyers, especially when sourcing from different regions, such as Africa, South America, the Middle East, and Europe. Here are some actionable strategies:

1. Conduct Supplier Audits: What Should Be Included?

Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should consider including the following aspects in their audits:

- Evaluation of compliance with international standards (e.g., ISO, CE).

- Review of quality control documentation and procedures.

- Assessment of the manufacturing facility and equipment.

2. Request Quality Reports: What Information Is Essential?

B2B buyers should request quality reports from suppliers, which can include data on defect rates, quality control processes, and any corrective actions taken in the past. These reports help assess the supplier’s reliability and commitment to quality.

3. Third-Party Inspections: How Do They Enhance Trust?

Engaging third-party inspection services can add another layer of assurance. These independent entities can conduct thorough assessments of suppliers, verifying compliance with quality standards and providing unbiased reports on manufacturing practices.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must navigate additional complexities in quality assurance due to variations in regulations, standards, and market expectations across different regions.

For example, buyers from Europe may have stricter regulations concerning environmental impact, while those in Africa may prioritize cost and availability. Understanding these nuances is essential for establishing successful partnerships.

Furthermore, language barriers and differences in business practices can affect communication about quality expectations. Establishing clear guidelines and maintaining open lines of communication can help mitigate these challenges.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in Leather Tools

Understanding the manufacturing processes and quality assurance practices is vital for B2B buyers in the leather tools and supplies industry. By evaluating suppliers based on their manufacturing stages and quality control measures, buyers can ensure they are sourcing products that meet their specifications and expectations. Ultimately, investing time in understanding these processes can lead to better partnerships and higher-quality products that drive business success.

Illustrative image related to leather tools and supplies

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather tools and supplies’

The following guide serves as a comprehensive checklist for B2B buyers looking to procure leather tools and supplies. It is designed to streamline the sourcing process, ensuring that you acquire high-quality products from reliable suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the leather tools and supplies meet your operational needs. Consider the types of leather products you will be crafting and the specific tools required for each task. This includes evaluating the weight, thickness, and finish of the leather, as well as the necessary tools like cutting, stitching, and finishing equipment.

- Key Considerations:

- Types of leather (e.g., vegetable-tanned, chrome-tanned).

- Specific tools for tasks (e.g., rotary cutters, stitching awls).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather tools and supplies. Look for suppliers with a solid reputation in the industry, and ensure they have experience serving businesses similar to yours.

Illustrative image related to leather tools and supplies

- Where to Look:

- Online marketplaces and leathercraft forums.

- Industry trade shows and exhibitions.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier, verify their certifications and compliance with industry standards. This step is crucial for ensuring product quality and safety, especially if you plan to export your leather goods.

- What to Check:

- ISO certifications.

- Compliance with local and international regulations.

Step 4: Request Samples

Request samples of the leather tools and supplies you are considering. This allows you to assess the quality and suitability of the products firsthand. A supplier willing to provide samples demonstrates confidence in their offerings.

- Considerations for Samples:

- Evaluate the craftsmanship and durability.

- Test functionality for your specific applications.

Step 5: Review Pricing and Payment Terms

Analyze the pricing structures offered by potential suppliers and compare them against your budget. Understand the payment terms, including any discounts for bulk purchases or early payments.

- Negotiation Points:

- Volume discounts for large orders.

- Payment flexibility options, such as net 30 or net 60 terms.

Step 6: Assess Shipping and Delivery Options

Evaluate the shipping methods and delivery timelines proposed by suppliers. Reliable shipping is critical to maintaining your production schedule, particularly if you are sourcing internationally.

- Shipping Considerations:

- Shipping costs and potential customs duties.

- Estimated delivery times and tracking capabilities.

Step 7: Establish a Communication Plan

Set up a communication plan with your selected supplier to facilitate ongoing dialogue. Clear communication is vital for addressing any issues that may arise during the procurement process and for future orders.

Illustrative image related to leather tools and supplies

- Communication Tips:

- Establish points of contact for order updates and inquiries.

- Schedule regular check-ins to discuss upcoming needs or product changes.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for leather tools and supplies, ensuring that they select the right products and suppliers for their business needs.

Comprehensive Cost and Pricing Analysis for leather tools and supplies Sourcing

What Are the Key Cost Components in Leather Tools and Supplies Sourcing?

When sourcing leather tools and supplies, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of leather type significantly impacts pricing. Full-grain and vegetable-tanned leathers are often more expensive due to their quality and durability compared to lower-grade options. Additionally, specialty materials like exotic leathers or eco-friendly alternatives can also drive costs up.

-

Labor: Labor costs vary depending on the region and the complexity of the products being made. Skilled labor is essential for high-quality leather crafting, and this can be a significant portion of the overall cost, especially if custom tooling or intricate designs are involved.

-

Manufacturing Overhead: This includes costs associated with running a facility, such as utilities, rent, and equipment maintenance. For international buyers, understanding how local economic conditions affect these overhead costs can provide insights into pricing.

-

Tooling: Custom tools or molds for specific designs can lead to higher upfront costs. However, they can also yield savings over time through increased production efficiency.

-

Quality Control (QC): Ensuring product quality often involves rigorous inspection processes, which add to overall costs. Buyers should inquire about the QC measures implemented by suppliers to ensure they meet international standards.

-

Logistics: Shipping and handling costs can vary widely based on the shipping method, distance, and volume. International buyers should be aware of additional duties or tariffs that may apply when importing leather goods.

-

Margin: Suppliers typically mark up prices to cover their operating costs and profit margins. Understanding the margin expectations in different regions can help buyers negotiate better pricing.

How Do Price Influencers Affect Leather Tools and Supplies Costs?

Several factors can influence the pricing of leather tools and supplies:

-

Volume and Minimum Order Quantities (MOQs): Bulk purchases often lead to discounts. Suppliers may offer more favorable pricing for larger orders, making it essential for buyers to assess their needs and negotiate accordingly.

-

Specifications and Customization: Custom orders typically incur higher costs. Buyers should weigh the benefits of customization against their budget constraints and consider whether standard options may suffice.

-

Material Quality and Certifications: High-quality materials often come with certifications that can add to the cost but provide assurance of ethical sourcing and environmental standards. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Well-established suppliers with strong track records may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can dictate who bears the cost and responsibility during transit, affecting the total landed cost for international buyers.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Tools and Supplies Procurement?

For B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, strategic procurement can lead to significant cost savings:

Illustrative image related to leather tools and supplies

-

Negotiation: Engaging in open discussions with suppliers about pricing, especially for larger orders, can yield better rates. Building relationships with suppliers may also lead to additional discounts or favorable terms.

-

Total Cost of Ownership (TCO): Beyond initial purchase prices, consider the long-term costs associated with maintenance, durability, and potential wastage. Investing in higher-quality tools may result in lower TCO over time.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and regional economic conditions. These factors can significantly impact the final cost when importing goods.

-

Research and Comparison: Conduct thorough market research to compare prices across suppliers. This can help identify competitive pricing and enable informed decision-making.

-

Leverage Technology: Utilize online platforms and tools that facilitate price comparisons and supplier evaluations. This can streamline the sourcing process and enhance transparency.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier policies, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing leather tools and supplies With Other Solutions

Exploring Alternatives to Leather Tools and Supplies

When evaluating leather tools and supplies, B2B buyers should consider various alternatives that could fulfill similar roles in leather crafting or manufacturing. Understanding the strengths and weaknesses of these alternatives can guide businesses in making informed purchasing decisions tailored to their specific operational needs.

| Comparison Aspect | Leather Tools And Supplies | Alternative 1: Synthetic Leather Tools | Alternative 2: Textile Tools |

|---|---|---|---|

| Performance | High durability and precision for crafting leather goods. | Moderate durability; may lack the same precision for intricate designs. | Generally suitable for basic sewing; lacks specialized tools for leather. |

| Cost | Higher upfront investment due to quality materials. | Typically lower initial cost; may require replacements more frequently. | Generally lower cost, but may need additional tools for leather-like results. |

| Ease of Implementation | Requires specialized knowledge and training for optimal use. | Easier for beginners; less technical skill needed. | Basic tools are user-friendly; specialized techniques may still require training. |

| Maintenance | Regular maintenance required to ensure longevity and performance. | Minimal maintenance; synthetic materials are easier to care for. | Low maintenance, but tools may not be suitable for long-term use with leather. |

| Best Use Case | Ideal for high-quality leather goods and detailed craftsmanship. | Best for mass production of synthetic leather items or non-leather goods. | Suitable for textile-based products, but limited in applications for leather. |

Detailed Breakdown of Alternatives

Synthetic Leather Tools

Synthetic leather tools cater to manufacturers looking for cost-effective solutions in the production of non-leather goods. These tools are often easier to use, making them a good choice for beginners or businesses aiming for rapid production cycles. However, they may not provide the same level of durability or precision as traditional leather tools, especially for intricate designs. Additionally, while the initial investment is lower, the need for frequent replacements can lead to higher long-term costs.

Textile Tools

Textile tools are versatile and generally more affordable than specialized leather tools. They are widely available and easy to use, making them an attractive option for businesses that do not focus exclusively on leather products. However, textile tools are limited in their effectiveness when it comes to working with leather materials. For businesses that occasionally incorporate leather into their offerings, textile tools might suffice, but for dedicated leather crafting, they fall short in providing the necessary precision and durability.

Illustrative image related to leather tools and supplies

Conclusion: Choosing the Right Solution for Your Needs

When selecting between leather tools and supplies and their alternatives, B2B buyers must carefully assess their specific requirements. If the goal is to produce high-quality leather goods, investing in specialized leather tools is advisable despite the higher initial cost. Conversely, for businesses prioritizing cost-efficiency and versatility in production, synthetic leather tools or textile tools may be more appropriate. Ultimately, the decision should align with the company’s product focus, production volume, and desired quality standards to ensure long-term success in the market.

Essential Technical Properties and Trade Terminology for leather tools and supplies

What Are the Essential Technical Properties of Leather Tools and Supplies?

When sourcing leather tools and supplies, understanding specific technical properties is crucial for ensuring quality and compatibility with production needs. Here are some of the key specifications to consider:

-

Material Grade

– Leather tools can be made from various materials including stainless steel, carbon steel, or even specialized alloys. The material grade indicates the tool’s durability, corrosion resistance, and overall performance. Higher-grade materials generally translate to longer tool life and reduced replacement costs, making it essential for B2B buyers to evaluate the material specifications when making purchasing decisions. -

Tolerance Levels

– Tolerance refers to the acceptable limits of variation in a tool’s dimensions. For example, a leather punch may have a specified tolerance of ±0.5 mm. Understanding these tolerances is vital for ensuring that tools fit together correctly and function as intended, especially in high-volume production settings where precision impacts quality and efficiency. -

Weight and Balance

– The weight and balance of a tool, such as a maul or a knife, affect its ease of use and the quality of the work produced. A well-balanced tool reduces fatigue during prolonged use, increasing productivity and precision. B2B buyers should assess these properties to ensure their workforce can operate tools comfortably and effectively. -

Cutting Edge Durability

– This property indicates how long a cutting tool will maintain its sharpness under normal operating conditions. Tools with superior cutting edge durability require less frequent sharpening, minimizing downtime. For businesses, investing in tools with high edge durability can lead to significant long-term savings. -

Finish Quality

– The finish of a tool affects not only its aesthetic appeal but also its resistance to wear and tear. A smooth finish can reduce friction and prevent rust, contributing to the tool’s longevity. B2B buyers should prioritize finish quality to ensure that their tools can withstand the demands of leatherworking. -

Ergonomics

– Ergonomically designed tools enhance user comfort and reduce the risk of repetitive strain injuries. Features like padded grips and appropriate weight distribution are crucial for maintaining operator efficiency. In a B2B context, investing in ergonomic tools can lead to increased worker satisfaction and productivity.

What Are Common Trade Terms in the Leather Tools and Supplies Industry?

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms to know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In leather tools, an OEM might design specialized tools that are then branded by a larger company. Understanding OEM relationships can help businesses identify reliable suppliers and negotiate better deals. -

MOQ (Minimum Order Quantity)

– MOQ denotes the smallest number of units that a supplier is willing to sell. This is significant for B2B buyers as it influences inventory management and cash flow. Knowing the MOQ can help businesses plan their purchasing strategy and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to suppliers to solicit price quotes for specific products. In the leather tools sector, an RFQ allows companies to compare prices, terms, and conditions from various suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, which help clarify the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for B2B buyers to manage shipping costs, risk, and delivery timelines effectively. -

Lead Time

– This term refers to the amount of time it takes from placing an order to receiving the product. In the leather tools industry, lead time can affect production schedules, making it crucial for buyers to understand and negotiate this aspect to ensure timely delivery. -

Certification Standards

– Various certifications (such as ISO or ASTM) indicate that products meet specific industry standards for quality and safety. Familiarity with these standards can help B2B buyers ensure that the tools and supplies they purchase comply with international regulations, thereby reducing risks in their supply chain.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately leading to better quality products and more efficient operations.

Illustrative image related to leather tools and supplies

Navigating Market Dynamics and Sourcing Trends in the leather tools and supplies Sector

What Are the Key Market Trends Influencing Leather Tools and Supplies?

The leather tools and supplies sector is experiencing significant growth, driven by a resurgence in artisanal craftsmanship and the rising demand for high-quality leather goods. Global factors such as increased consumer interest in handmade products and sustainable practices are shaping market dynamics. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide not only quality materials but also innovative tools that enhance productivity.

Emerging technologies, such as advanced manufacturing techniques and e-commerce platforms, are transforming the sourcing landscape. For instance, suppliers are leveraging online marketplaces to reach international buyers directly, reducing lead times and costs. Moreover, businesses are adopting digital tools for inventory management and customer relationship management (CRM), facilitating smoother operations and better customer engagement.

In terms of product offerings, there is a noticeable shift towards multifunctional tools that cater to various leathercrafting needs. This trend is particularly appealing to smaller workshops and individual artisans who require versatility without a significant investment in specialized equipment. Additionally, there is an increasing demand for leathercraft kits, which simplify the buying process for novice crafters, enhancing market accessibility.

How Is Sustainability Shaping the Leather Tools and Supplies Sector?

Sustainability has become a critical concern for B2B buyers in the leather tools and supplies sector. The environmental impact of leather production, including water usage, deforestation, and chemical waste, has prompted a shift towards more responsible sourcing practices. Buyers are increasingly prioritizing suppliers who emphasize ethical supply chains and transparent sourcing methods.

The demand for ‘green’ certifications is on the rise, with buyers seeking suppliers who offer environmentally friendly materials and production processes. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming essential in the decision-making process for businesses aiming to align with consumer values. Additionally, the use of vegetable-tanned leather and recycled materials is gaining traction, as these options significantly reduce the environmental footprint associated with traditional leather production.

Furthermore, suppliers are investing in sustainable practices, such as waste reduction and energy-efficient manufacturing techniques, to meet the expectations of conscientious buyers. By adopting these sustainable practices, businesses not only enhance their brand reputation but also tap into a growing market of eco-conscious consumers.

Illustrative image related to leather tools and supplies

What Is the Historical Context of Leather Tools and Supplies in B2B Markets?

The leather tools and supplies industry has a rich history that dates back centuries, evolving from basic hand tools used by artisans to advanced machinery that streamlines production processes. Historically, leathercraft was a skill passed down through generations, with each culture contributing unique techniques and styles.

In the modern era, the demand for leather products surged with the advent of industrialization, leading to mass production techniques that significantly changed the landscape. However, recent years have seen a resurgence in traditional craftsmanship, as consumers increasingly value quality and uniqueness over mass-produced goods.

This evolution is significant for B2B buyers, as it highlights the importance of sourcing from suppliers who respect traditional methods while integrating modern efficiencies. Understanding this historical context allows buyers to appreciate the craftsmanship involved and make informed decisions that align with their business values and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of leather tools and supplies

-

How do I choose the right leather tools for my business needs?

Selecting the appropriate leather tools hinges on understanding the specific requirements of your projects. Begin by assessing the types of leather goods you plan to produce, such as bags, belts, or wallets. Different projects may require specialized tools like stitching machines, hole punches, or cutting dies. It’s also beneficial to consult with suppliers about the best tools for your intended applications, and consider investing in quality over quantity to ensure durability and efficiency in your production process. -

What is the best type of leather for crafting high-quality goods?

The best type of leather often depends on the end product’s intended use. Full-grain leather is preferred for high-end products due to its durability and natural look, while top-grain leather is more affordable and still offers quality. For items requiring flexibility, such as handbags, softer leathers like lambskin may be ideal. Always source leather that meets international quality standards, and ensure it is suitable for your specific crafting techniques. -

How can I verify the credibility of a leather tools supplier?

To ensure you’re dealing with a reputable supplier, start by researching their history and customer reviews. Request references from other businesses they have supplied to, and check their certifications, such as ISO or other quality assurance standards. Additionally, engaging in direct communication can provide insights into their customer service and responsiveness. Consider visiting their facilities if possible, or attend trade shows to meet them in person and assess their offerings firsthand. -

What are the typical minimum order quantities (MOQs) for leather tools and supplies?

Minimum order quantities can vary significantly between suppliers and products. Some suppliers may offer flexible MOQs for smaller businesses, while others may have strict requirements based on production costs. It is advisable to inquire directly with potential suppliers about their MOQs and whether they can accommodate your specific needs. Establishing a good relationship may also lead to more favorable terms, especially for bulk orders or repeat business. -

What payment terms should I expect when sourcing leather tools internationally?

Payment terms can vary widely by supplier and region. Common practices include upfront payments, partial payments, or net payment terms (e.g., net 30, 60 days). It’s important to negotiate terms that suit your cash flow while ensuring you comply with international trade regulations. Consider using secure payment methods such as letters of credit or escrow services for larger transactions to mitigate risks associated with international purchases. -

How do I ensure quality assurance for leather tools and supplies?

To maintain high quality in your leather tools and supplies, establish clear quality assurance criteria with your supplier. This could include specifications on materials, craftsmanship, and performance standards. Request samples before committing to larger orders and consider implementing a quality inspection process upon receipt of goods. Regular communication with your supplier regarding any quality issues will also help maintain standards and improve future orders. -

What logistics considerations should I be aware of when importing leather supplies?

When importing leather supplies, consider logistics factors such as shipping costs, customs duties, and delivery times. Ensure you understand the import regulations in your country, including any restrictions on leather products. Working with a reliable freight forwarder can help streamline the process and provide insights into the best shipping methods. Additionally, plan for potential delays and factor them into your project timelines to avoid disruptions in production. -

Can I customize leather tools and supplies for my brand?

Yes, many suppliers offer customization options for leather tools and supplies, including branding, color choices, and specific dimensions. Discuss your requirements with potential suppliers to understand their capabilities and the minimum order quantities for customized items. Customization can enhance your brand identity and product appeal, so it’s worth exploring these options to differentiate your offerings in the marketplace.

Top 6 Leather Tools And Supplies Manufacturers & Suppliers List

1. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies including various types of leather (ChahinLeather®, Hermann Oak® Veg Tan, Chrome Tanned, Water Buffalo, Specialty Leather), leather cuts (double shoulders, backs, bends, panels, half sides, fringes, sides, whole hide, bellies), textures (top grain, pebbled, smooth, pull-up, waxy, matte), and tools (cutting too…

2. Buckleguy – BG Awl Needles

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: Buckleguy offers a wide range of leather working tools and supplies, including cutting tools, edge tools, hammers, mallets, gauges, punches, machines, measuring tools, needles, awls, pricking irons, setters, and stamping & carving tools. Key products include:

– BG Awl Needles (Multiple Shapes) – $10.62 – $14.13

– BG Leather Bone Folder/Edge Slicker (Multi-Function) – $28.94

– BG Stitching Punch Re…

3. Artisan Leather Supply – Essential Leather Tools

Domain: artisanleathersupply.com

Registered: 2020 (5 years)

Introduction: Corner Punch: From $14, Electric Creaser Tip: From $17, Titanium-Coated Hole Punch: From $5.50, Premium Wing Divider: From $32, Locking Pins (pack of 5): From $5, ARTISAN Pen Knife: From $11, Sanding Block: From $7, Premium Leather Roughing Tool: $20, Specialty Creaser Tips: From $15, Acrylic Zipper Glue Guide: $8, Premium Thread Scissor/Nipper: $21, Leather Paring Knife: From $17.50, Starter Seri…

4. Sailrite – Awls & Groovers

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Awls & Groovers: Diamond Awl, Scratch Awl, Stitch Groover, Wing Divider; Edge Bevelers & Skivers: French Edger, Edge Bevelers, Super Skiver; Hammers & Mallets: Various types of mallets; Knives & Cutting: French Angled Knife, Mini Round Knife, Pricking Irons, Rotary Punch/Punch Set, Skiving Knife, Straight Utility Knife.

5. Reddit – Essential Leatherworking Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Sharp blade (box knives are fine) 2. Self-healing cutting board 3. Rubber or rawhide mallet 4. Punches and stamps as necessary 5. Punch pad 6. Leather needles 7. Thread 8. 6″ stainless steel ruler 9. Wood edge burnisher 10. Mini pair of wing dividers 11. Blunt pointed awl 12. Scratch awl 13. C. S. Osborne #144-43 awl 14. NT Cutter Pro auto-lock graphic knife 15. Utility knife with extra sharp F…

6. Tandy Leather – Essential Hand Tools

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: Essential Leather Hand Tools for precise crafting. Free shipping on orders over $149. Various language and currency options available.

Strategic Sourcing Conclusion and Outlook for leather tools and supplies

In the evolving landscape of leather tools and supplies, strategic sourcing is paramount for international B2B buyers seeking to enhance their competitive edge. By leveraging relationships with reliable suppliers across diverse regions—including Africa, South America, the Middle East, and Europe—buyers can access a wide array of high-quality products tailored to their specific needs. Key insights include understanding regional market trends, prioritizing quality and sustainability in sourcing practices, and investing in innovative tools that can streamline production processes.

Illustrative image related to leather tools and supplies

Additionally, as the demand for bespoke leather goods continues to rise, embracing technological advancements in leatherworking tools will not only improve efficiency but also elevate the craftsmanship of finished products. Buyers are encouraged to explore partnerships that offer comprehensive support, including training and resources that can enhance their teams’ skills and capabilities.

Looking ahead, the global leather market presents abundant opportunities for growth and innovation. By adopting a proactive approach to sourcing, B2B buyers can position themselves to capitalize on emerging trends and consumer preferences, ultimately driving business success. Engage with suppliers today to secure the tools and materials that will empower your next project and set the stage for future endeavors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.