Introduction: Navigating the Global Market for custom leather welding hoods

In an increasingly competitive global landscape, sourcing custom leather welding hoods presents unique challenges for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. These specialized protective gear items are not only essential for safety and compliance but also reflect the quality and reputation of the businesses that utilize them. With varying supplier standards, material quality, and design preferences, navigating this market can be daunting.

This comprehensive guide delves into the intricacies of the custom leather welding hood market, covering an array of topics including types of hoods, their specific applications in various industries, and essential criteria for supplier vetting. Buyers will gain insights into cost considerations, delivery timelines, and customization options that can meet their operational needs. Furthermore, we will explore market trends and innovations that are shaping the future of welding safety gear.

By empowering international B2B buyers with actionable insights and strategic guidance, this guide aims to simplify the purchasing process, enabling informed decisions that enhance both safety and productivity. Whether you’re looking to outfit a large industrial operation or fulfill niche requirements, our guide will serve as a valuable resource in your sourcing journey.

Table Of Contents

- Top 5 Custom Leather Welding Hoods Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather welding hoods

- Understanding custom leather welding hoods Types and Variations

- Key Industrial Applications of custom leather welding hoods

- 3 Common User Pain Points for ‘custom leather welding hoods’ & Their Solutions

- Strategic Material Selection Guide for custom leather welding hoods

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather welding hoods

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather welding hoods’

- Comprehensive Cost and Pricing Analysis for custom leather welding hoods Sourcing

- Alternatives Analysis: Comparing custom leather welding hoods With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather welding hoods

- Navigating Market Dynamics and Sourcing Trends in the custom leather welding hoods Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather welding hoods

- Strategic Sourcing Conclusion and Outlook for custom leather welding hoods

- Important Disclaimer & Terms of Use

Understanding custom leather welding hoods Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chopped Leather Top Welding Hood | Lightweight, customizable designs, available with various bibs | General welding, construction, and fabrication | Pros: Affordable, customizable; Cons: May lack durability compared to heavier models. |

| Pipeliner Welding Hood | Slim profile, designed for pipe welding, often includes goatee bibs | Pipe welding, industrial projects | Pros: Enhanced visibility, comfort; Cons: Limited protection for non-pipe welding tasks. |

| Futura Welding Hood | High-visibility lenses, ergonomic design, available in multiple colors | Specialty welding, artistic applications | Pros: Stylish, functional; Cons: Higher price point, may not be suitable for all industries. |

| Carbon Fiber Leather Welding Hood | Combination of leather and carbon fiber, increased durability | Heavy-duty welding, extreme environments | Pros: Superior protection, lightweight; Cons: More expensive, may require specialized care. |

| Exotic Leather Welding Hood | Unique materials and designs, often handcrafted | High-end applications, fashion-focused welding | Pros: Aesthetic appeal, premium quality; Cons: Higher cost, longer lead times. |

What are the Key Characteristics of Chopped Leather Top Welding Hoods?

Chopped leather top welding hoods are popular for their lightweight design and versatility, making them suitable for a variety of welding tasks. They can be customized with different bibs, such as goatee or standard styles, allowing for personalization based on user preference. These hoods are particularly favored in general welding and construction environments where comfort and affordability are paramount. However, buyers should consider that while they are cost-effective, they may not offer the same durability as heavier models.

How Do Pipeliner Welding Hoods Enhance Welding Efficiency?

Pipeliner welding hoods are specifically designed for pipe welding applications, featuring a slim profile that allows for ease of movement in tight spaces. Many models come with goatee bibs, which help protect the neck while offering enhanced visibility during welding. This type of hood is ideal for industrial projects where precision is key. Buyers should evaluate the hood’s fit and comfort, as these factors can significantly impact performance during long hours of work.

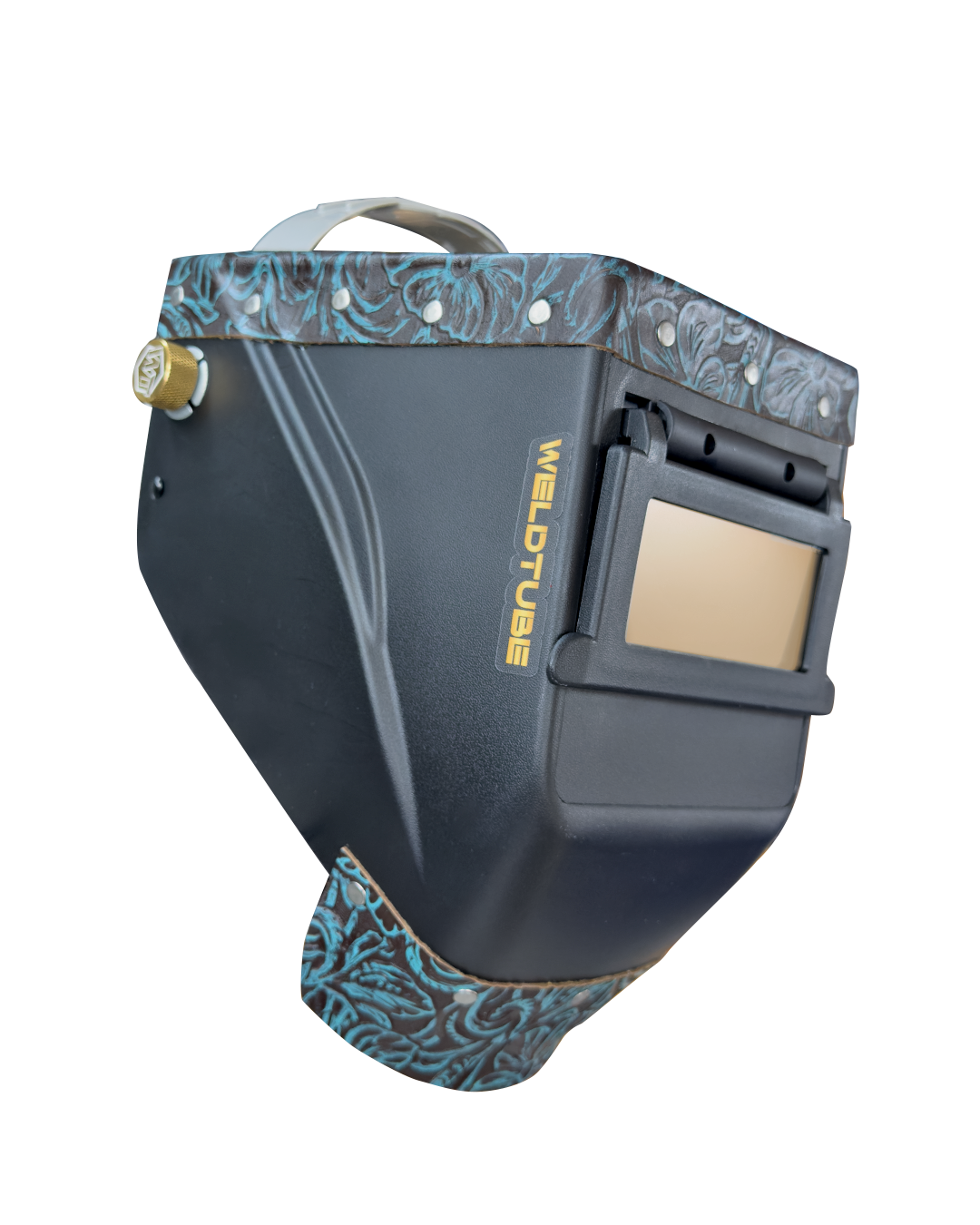

Illustrative image related to custom leather welding hoods

Why Choose Futura Welding Hoods for Specialty Applications?

Futura welding hoods are characterized by their high-visibility lenses and ergonomic designs, making them suitable for specialty welding tasks and artistic applications. They come in various colors, allowing welders to express their personal style while maintaining functionality. Though these hoods are stylish and practical, they tend to be at a higher price point, which may be a consideration for budget-conscious buyers.

What Advantages Do Carbon Fiber Leather Welding Hoods Offer?

Combining leather with carbon fiber, these welding hoods provide exceptional durability and protection, making them ideal for heavy-duty welding tasks and extreme environments. Their lightweight nature enhances comfort during prolonged use. While they are more expensive than traditional leather hoods, the investment can be worthwhile for businesses that prioritize safety and longevity in their equipment.

What Makes Exotic Leather Welding Hoods Stand Out?

Exotic leather welding hoods are unique due to their handcrafted designs and the use of distinctive materials. They cater to high-end applications and are often sought after by those in the fashion-focused welding sector. While their aesthetic appeal and premium quality can justify the higher cost, buyers should be prepared for longer lead times and potentially higher maintenance requirements associated with these specialized products.

Illustrative image related to custom leather welding hoods

Key Industrial Applications of custom leather welding hoods

| Industry/Sector | Specific Application of custom leather welding hoods | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Pipelining and welding operations | Enhanced protection against high temperatures and sparks, leading to improved safety and reduced injury claims. | Custom designs for specific welding processes and environmental conditions. |

| Construction | Structural steel fabrication | Durable and long-lasting protection for welders, reducing the frequency of replacements and downtime. | Availability of various styles and fits to accommodate different tasks and environments. |

| Automotive Manufacturing | Body welding and repair | Improved comfort and visibility for welders, resulting in higher productivity and quality of work. | Sourcing from suppliers with a focus on ergonomic designs and high-quality materials. |

| Shipbuilding | Hull welding and repairs | Custom hoods that withstand harsh marine environments, enhancing safety and longevity of gear. | Consideration of waterproofing and resistance to corrosive elements. |

| Metal Fabrication | General welding and metalworking | Tailored solutions that meet specific operational needs, improving overall efficiency and worker satisfaction. | Ensuring compliance with industry standards and regulations for safety gear. |

What are the Key Applications of Custom Leather Welding Hoods in the Oil and Gas Sector?

In the oil and gas industry, custom leather welding hoods are essential for pipelining and welding operations. These hoods provide robust protection against intense heat, sparks, and potential chemical exposure, which are common in this sector. By investing in high-quality custom hoods, companies can significantly reduce injury claims and enhance worker safety. Buyers should consider sourcing hoods that are specifically designed for the unique environmental conditions encountered in oil and gas operations, ensuring durability and functionality.

How Do Custom Leather Welding Hoods Benefit the Construction Industry?

In construction, particularly during structural steel fabrication, custom leather welding hoods offer welders superior protection and comfort. The durability of leather ensures that these hoods can withstand the rigors of outdoor work, reducing the need for frequent replacements. This not only saves costs but also minimizes downtime, contributing to project efficiency. Buyers should prioritize designs that cater to varying tasks, ensuring that the hoods provide adequate protection while allowing for ease of movement.

Why are Custom Leather Welding Hoods Important in Automotive Manufacturing?

The automotive manufacturing sector benefits greatly from custom leather welding hoods during body welding and repair processes. These hoods enhance the comfort and visibility of welders, which are crucial for maintaining high productivity levels and ensuring quality workmanship. Sourcing from suppliers who focus on ergonomic designs can lead to better employee satisfaction and retention. Buyers should also consider customization options that align with specific welding techniques used in automotive applications.

What Role Do Custom Leather Welding Hoods Play in Shipbuilding?

In shipbuilding, custom leather welding hoods are vital for hull welding and repairs, where welders face unique challenges due to harsh marine environments. These hoods are designed to withstand moisture and corrosion, providing welders with reliable protection that extends the lifespan of their gear. When sourcing, it is important for buyers to ensure that the hoods are not only durable but also offer features such as waterproofing and resistance to saltwater.

Illustrative image related to custom leather welding hoods

How Can Custom Leather Welding Hoods Enhance Metal Fabrication Operations?

In the metal fabrication industry, custom leather welding hoods are tailored to meet specific operational needs, providing welders with the necessary protection against sparks and heat. This customization leads to improved efficiency and worker satisfaction, as welders can perform their tasks without discomfort or distraction. Buyers should ensure compliance with industry safety standards when selecting hoods, as this not only protects workers but also enhances the company’s reputation for prioritizing safety.

3 Common User Pain Points for ‘custom leather welding hoods’ & Their Solutions

Scenario 1: Delays in Custom Orders Impacting Project Timelines

The Problem: Many B2B buyers often face significant delays when ordering custom leather welding hoods. With a typical turnaround time of 5-9 business days before shipment, projects can be put on hold, leading to frustration and potential financial loss. This is especially critical for buyers in industries like construction or manufacturing, where timely delivery is essential to meet project deadlines and contractual obligations. Additionally, buyers may not be aware of potential delays due to customs clearance or other logistical issues, compounding their challenges.

The Solution: To mitigate delays, buyers should establish clear communication with suppliers regarding lead times and shipping methods. It’s advisable to request a detailed timeline that includes production and shipping estimates. Utilizing local suppliers or those with a strong logistics network can reduce shipping times significantly. Additionally, consider placing orders well in advance of project start dates, allowing for any unexpected delays. Setting up a reliable reorder schedule based on project timelines can also help maintain a steady supply of custom hoods, minimizing downtime.

Scenario 2: Inadequate Customization Leading to Poor Fit and Comfort

The Problem: Buyers frequently encounter issues with the fit and comfort of custom leather welding hoods. A poorly fitted hood can lead to safety hazards, decreased productivity, and dissatisfaction among welders who rely on comfortable gear for long hours. In many cases, buyers may not fully understand the customization options available, leading to choices that do not meet the specific ergonomic needs of their workforce.

The Solution: To ensure the right fit, it’s essential to conduct thorough measurements and engage in direct communication with the supplier about the specific requirements of the welding team. Buyers should consider creating a comprehensive specification sheet that includes head sizes, preferred styles, and additional features such as bib length or ventilation options. Furthermore, requesting samples or prototypes before placing bulk orders can help assess comfort and fit. Engaging workers in the selection process can also ensure the end product meets their needs, fostering a sense of ownership and satisfaction.

Illustrative image related to custom leather welding hoods

Scenario 3: Concerns About Durability and Safety Standards

The Problem: B2B buyers often worry about the durability and safety compliance of custom leather welding hoods. Given the high-risk nature of welding, ensuring that the hoods can withstand extreme conditions while providing adequate protection is paramount. However, many buyers may find it challenging to ascertain whether the materials used meet industry standards or if the product will hold up under continuous use.

The Solution: Buyers should prioritize sourcing leather welding hoods from reputable manufacturers who provide transparent information about their materials and safety certifications. Request documentation that verifies compliance with relevant safety standards, such as ANSI or ISO certifications, which can assure buyers of the product’s reliability. Additionally, engaging in discussions with suppliers about the sourcing of materials and their durability testing processes can provide deeper insights into product longevity. Establishing a long-term relationship with suppliers who offer warranties or guarantees can also be beneficial, as it underscores their commitment to quality and customer satisfaction.

Strategic Material Selection Guide for custom leather welding hoods

When selecting materials for custom leather welding hoods, several factors must be considered to ensure optimal performance, safety, and compliance with international standards. Below is an analysis of four common materials used in the production of these hoods, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What are the Key Properties of Cowhide Leather for Welding Hoods?

Cowhide leather is the most widely used material for welding hoods due to its robust nature. It offers excellent resistance to heat and abrasion, withstanding temperatures up to 300°F (149°C) without significant degradation. This material is also naturally water-resistant, providing additional protection in wet environments.

Pros: Cowhide leather is durable and provides a high degree of comfort due to its flexibility. It is relatively easy to work with during manufacturing, allowing for intricate designs and customizations.

Cons: The primary drawback is its cost; high-quality cowhide can be expensive. Additionally, while it offers decent heat resistance, prolonged exposure to extreme temperatures can lead to wear over time.

Illustrative image related to custom leather welding hoods

Impact on Application: Cowhide leather is suitable for various welding processes, including MIG and TIG welding, making it a versatile choice for many industrial applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the cowhide used meets local environmental and ethical standards. Compliance with ASTM or ISO standards may also be necessary.

How Does Split Leather Compare for Custom Welding Hoods?

Split leather, derived from the fibrous part of the hide, is another option for welding hoods. It is less expensive than full-grain leather and offers good resistance to heat and sparks.

Pros: The affordability of split leather makes it an attractive option for budget-conscious buyers. It also provides decent flexibility and comfort.

Cons: However, split leather is generally less durable than cowhide and may not withstand high temperatures as effectively. It can also absorb moisture, which may compromise its protective qualities.

Illustrative image related to custom leather welding hoods

Impact on Application: Split leather is best suited for less intense welding applications, such as light fabrication work, where extreme heat exposure is minimal.

Considerations for International Buyers: Buyers should be aware of the varying quality of split leather and ensure that it meets relevant safety standards in their regions, particularly in Europe, where compliance with EN standards is crucial.

What are the Benefits of Using Fire-Resistant Leather for Welding Hoods?

Fire-resistant leather is specially treated to enhance its heat resistance, making it ideal for high-temperature welding environments.

Pros: This material can withstand temperatures exceeding 500°F (260°C), providing superior protection for welders in extreme conditions. It also maintains its integrity longer than untreated leathers.

Illustrative image related to custom leather welding hoods

Cons: The main limitation is the higher cost associated with fire-resistant treatments. Additionally, the manufacturing process can be more complex, leading to longer lead times for custom orders.

Impact on Application: Fire-resistant leather is particularly beneficial for heavy industrial applications, such as pipeline welding, where exposure to intense heat and sparks is common.

Considerations for International Buyers: Buyers should verify that the fire-resistant leather meets international safety standards such as ASTM E84 for flame spread and smoke development.

Illustrative image related to custom leather welding hoods

How Does Carbon Fiber Leather Enhance Welding Hood Performance?

Carbon fiber leather is a composite material that combines leather with carbon fiber, resulting in a lightweight yet highly durable product.

Pros: This material offers excellent heat resistance and is significantly lighter than traditional leather, enhancing comfort during long hours of use. Its durability makes it suitable for heavy-duty applications.

Cons: The primary disadvantage is the cost, as carbon fiber leather is among the most expensive options available. Additionally, the manufacturing process can be intricate, requiring specialized equipment.

Impact on Application: Carbon fiber leather is ideal for high-performance welding tasks, particularly in industries where both weight and heat resistance are critical.

Illustrative image related to custom leather welding hoods

Considerations for International Buyers: Buyers should ensure that carbon fiber leather complies with international standards and regulations, particularly in regions with strict safety guidelines, such as Europe and the Middle East.

Summary Table of Material Selection for Custom Leather Welding Hoods

| Material | Typical Use Case for custom leather welding hoods | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | General welding applications (MIG, TIG) | Durable and flexible | Higher cost, limited extreme heat resistance | Medium |

| Split Leather | Light fabrication work | Affordable | Less durable, moisture absorption | Low |

| Fire-Resistant Leather | Heavy industrial applications | Superior heat resistance | Higher cost, complex manufacturing | High |

| Carbon Fiber Leather | High-performance welding tasks | Lightweight and durable | Expensive, intricate manufacturing | High |

This guide should aid international B2B buyers in making informed decisions about material selection for custom leather welding hoods, ensuring compliance with local standards and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather welding hoods

What Are the Key Stages in the Manufacturing Process of Custom Leather Welding Hoods?

The manufacturing process for custom leather welding hoods involves several critical stages that ensure both functionality and durability. Understanding these stages is crucial for B2B buyers looking to source high-quality products.

Illustrative image related to custom leather welding hoods

Material Preparation: How Are Raw Materials Chosen and Processed?

The first stage in the manufacturing process is the selection and preparation of raw materials. High-quality leather is the primary material used, often sourced from reputable suppliers who adhere to sustainable and ethical practices. The leather is typically treated to enhance its resistance to heat and sparks, essential for welding applications.

Once the leather is sourced, it undergoes a meticulous preparation process. This includes cutting the leather into specific patterns based on the design of the welding hood. The cutting must be precise to ensure that all pieces fit together seamlessly during assembly. In addition to leather, other materials such as aluminum fasteners and high-visibility lenses are prepared for integration into the final product.

How Are Custom Leather Welding Hoods Formed and Assembled?

Following material preparation, the next stage is forming the leather into the desired shape. This is achieved through techniques such as wet molding and heat forming, which allow the leather to be shaped into the contours necessary for a comfortable and protective fit.

Illustrative image related to custom leather welding hoods

Assembly involves stitching the leather pieces together using heavy-duty thread that can withstand the rigors of welding environments. Quality craftsmanship is vital at this stage to ensure durability. Additionally, components such as headgear and visors are integrated into the assembly, often using aluminum fasteners for strength and longevity.

What Finishing Techniques Enhance the Quality of Welding Hoods?

The finishing stage is crucial for both aesthetic appeal and functional performance. Hoods may undergo treatments such as dyeing, waterproofing, and adding flame-resistant coatings to improve their performance. Quality finishing not only enhances the look of the product but also extends its lifespan and functionality.

A final inspection is typically conducted to ensure that all components are securely attached and that the product meets the required specifications before being packaged for shipping.

Illustrative image related to custom leather welding hoods

What International Standards Govern Quality Assurance for Leather Welding Hoods?

Quality assurance in the manufacturing of custom leather welding hoods is governed by several international and industry-specific standards. ISO 9001 is a widely recognized standard that outlines criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, welding hoods must comply with specific industry standards such as the CE marking in Europe and API standards in the oil and gas sector. These certifications indicate that the product meets safety and performance criteria, which is crucial for buyers in various international markets.

What Are the Key Quality Control Checkpoints in Leather Hood Production?

Quality control (QC) is an integral part of the manufacturing process, with multiple checkpoints established to maintain product integrity. The key stages of QC include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to identify any deviations from quality standards. This might include checking stitching quality, component alignment, and overall craftsmanship.

- Final Quality Control (FQC): A thorough inspection occurs before the product is packaged. This includes checking for defects, ensuring all components function correctly, and verifying compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure they are sourcing high-quality products. Here are several strategies:

Illustrative image related to custom leather welding hoods

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, materials used, and adherence to quality standards firsthand. This can also include reviewing the supplier’s quality management system documentation.

-

Requesting Quality Reports: Buyers should ask for quality control reports that detail inspection results and compliance with international standards. These documents can provide insights into the supplier’s reliability.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased evaluation of the supplier’s production processes and product quality. This is particularly important for buyers in regions with specific compliance requirements, such as Africa and South America.

What Are the Unique QC Considerations for International Buyers?

International buyers must also consider specific quality control nuances that may vary by region. For instance, compliance with local regulations and standards is critical, as requirements may differ significantly between markets in Europe, the Middle East, and Africa.

Additionally, cultural factors can influence manufacturing practices. Understanding the local context can help buyers foster better relationships with suppliers and ensure that quality expectations are clearly communicated.

Conclusion: Ensuring Quality in Custom Leather Welding Hoods

In conclusion, the manufacturing processes and quality assurance practices for custom leather welding hoods are designed to deliver high-performance products that meet stringent safety standards. By understanding these processes and implementing robust verification methods, B2B buyers can ensure they source reliable and high-quality welding hoods that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather welding hoods’

To assist international B2B buyers in sourcing custom leather welding hoods effectively, this practical guide outlines essential steps that ensure quality, compliance, and satisfaction with the final product. Follow these steps to streamline your procurement process.

Illustrative image related to custom leather welding hoods

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to clearly define your requirements. Determine the specific type of leather welding hoods you need, including style (e.g., pipeliner, chopped top), size, and any additional features like high-visibility lenses or custom fittings.

– Consider durability and comfort: Ensure the materials used can withstand the rigors of welding while providing comfort for the user.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather welding hoods. Look for companies with a strong online presence and positive reviews.

– Use industry directories and trade shows: This can help you find reputable manufacturers with proven track records in your region.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify the certifications and compliance of potential suppliers. Certifications can include ISO standards or safety certifications relevant to welding equipment.

– Assess manufacturing processes: Ensure that suppliers adhere to industry best practices for quality and safety, which can significantly affect the reliability of the hoods.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of their products. This step is crucial to evaluate the quality of materials and craftsmanship firsthand.

– Inspect for quality: Look for any signs of poor stitching, material defects, or inconsistencies in design that could impact performance.

Illustrative image related to custom leather welding hoods

Step 5: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms with your selected suppliers. Custom products often have varying costs based on specifications and order volume.

– Negotiate bulk discounts: If you plan on making large orders, inquire about potential discounts or favorable payment terms to improve your bottom line.

Step 6: Review Lead Times and Delivery Options

Inquire about the lead times for production and delivery. Custom leather welding hoods typically have a turnaround time of 5-9 business days, not including shipping.

– Plan accordingly: Ensure that the delivery timeline aligns with your project schedules to avoid unnecessary delays in your operations.

Step 7: Establish a Clear Communication Channel

Establishing effective communication with your supplier is essential for a successful partnership. Confirm how you will communicate (e.g., email, phone, or instant messaging) and set expectations for response times.

– Document everything: Keep a record of communications and agreements to prevent misunderstandings and ensure accountability throughout the sourcing process.

Illustrative image related to custom leather welding hoods

By following these steps, you can effectively navigate the complexities of sourcing custom leather welding hoods, ensuring that you partner with a supplier who meets your quality standards and operational needs.

Comprehensive Cost and Pricing Analysis for custom leather welding hoods Sourcing

What Are the Key Cost Components in Custom Leather Welding Hoods?

When sourcing custom leather welding hoods, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The type of leather used significantly impacts the overall cost. High-quality, durable leather that meets safety standards is essential for welding applications. Exotic leathers may incur higher costs due to rarity and sourcing complexities.

-

Labor: Skilled artisans are required to craft custom hoods, and labor costs will vary by region and complexity of the design. Countries with lower labor costs may offer more competitive pricing but can sometimes compromise on quality.

-

Manufacturing Overhead: This encompasses the indirect costs related to production, including utilities, rent, and administrative expenses. Efficient production processes can help reduce overhead, ultimately affecting pricing.

-

Tooling: Custom designs often necessitate specialized tools or molds, which can be a significant upfront investment. Buyers should inquire about tooling costs, especially if they plan to order multiple units.

-

Quality Control (QC): Ensuring that each hood meets safety and quality standards is paramount. QC processes may add to the labor and time costs, impacting the overall price.

-

Logistics: Shipping costs can vary significantly based on the destination. International buyers must consider freight charges, customs duties, and potential tariffs, which can considerably affect the final cost.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary widely based on market dynamics, competition, and perceived value.

How Do Price Influencers Affect Custom Leather Welding Hood Sourcing?

Several factors can influence pricing for custom leather welding hoods, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Higher order quantities often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for larger orders, making it beneficial for businesses to consolidate their purchasing.

-

Specifications/Customization: Unique designs or additional features, such as specialized lenses or enhanced safety features, can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Materials Quality/Certifications: Hoods that meet specific safety certifications (e.g., ANSI, ISO) may carry a premium. Buyers should verify that the materials used comply with necessary regulations to avoid liability issues.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record of quality and service, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The agreed-upon Incoterms dictate who is responsible for shipping costs and risks during transport. Understanding these terms can help buyers manage costs effectively and avoid unexpected fees.

What Tips Can Help Buyers Negotiate Better Pricing?

When negotiating pricing for custom leather welding hoods, international B2B buyers should consider the following tips to enhance cost-efficiency:

-

Conduct Market Research: Understanding the typical price range for similar products can provide leverage during negotiations. Buyers should compare multiple suppliers to identify competitive rates.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial price, consider long-term costs such as durability, maintenance, and potential replacement. Investing in higher-quality hoods may yield savings over time.

-

Be Transparent About Needs: Clear communication regarding specifications, volume, and timeline can foster better relationships with suppliers. This transparency can lead to more favorable pricing or terms.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Suppliers may offer loyalty discounts or prioritize orders for repeat customers.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, trade agreements, and local market conditions that may affect pricing. Understanding these nuances can aid in making informed decisions.

Disclaimer on Pricing

The prices mentioned in various sources for custom leather welding hoods are indicative and can vary based on several factors including market conditions, customization requests, and supplier pricing strategies. It is advisable for buyers to request formal quotes and confirm pricing details with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing custom leather welding hoods With Other Solutions

Understanding Alternatives to Custom Leather Welding Hoods

In the welding industry, safety and performance are paramount. Custom leather welding hoods are popular for their durability and comfort, but several alternative solutions exist that may also meet the needs of B2B buyers. This section explores these alternatives, helping international buyers make informed decisions based on performance, cost, and usability.

| Comparison Aspect | Custom Leather Welding Hoods | Fiberglass Welding Helmets | Carbon Fiber Welding Helmets |

|---|---|---|---|

| Performance | Excellent heat and spark resistance, provides superior protection | Good protection but can be less durable under extreme conditions | High durability and lightweight, excellent heat resistance |

| Cost | Ranges from $189.99 to $239.99 depending on customization | Generally lower, around $50 to $150 | Higher cost, typically $200 to $300 |

| Ease of Implementation | Customization requires time (5-9 business days) | Readily available off-the-shelf | Available but may require customization |

| Maintenance | Requires regular cleaning and inspection | Low maintenance, easy to clean | Low maintenance, easy to clean |

| Best Use Case | Ideal for specialized welding applications needing custom fit | Suitable for general welding tasks | Best for high-performance applications requiring lightweight gear |

In-Depth Look at Alternatives

Fiberglass Welding Helmets

Fiberglass welding helmets are an affordable alternative that offers decent protection against UV and IR radiation. They are typically lightweight and can be found in various designs and styles. The major advantage of fiberglass helmets is their cost-effectiveness, making them accessible for smaller companies or those just starting in welding. However, they may not provide the same level of heat resistance as leather or carbon fiber options, making them less suitable for intense welding environments.

Carbon Fiber Welding Helmets

Carbon fiber welding helmets stand out due to their high strength-to-weight ratio. These helmets are lightweight yet provide excellent durability and protection against heat and sparks. They are ideal for welders who work in demanding conditions and require gear that won’t weigh them down. However, the price point for carbon fiber helmets is significantly higher than that of other options, which may deter budget-conscious buyers. Additionally, while they offer superior performance, they might not be customizable to the same extent as leather options.

Making the Right Choice for Your Needs

When selecting a welding hood, B2B buyers should consider their specific operational requirements, including the type of welding performed, the environment, and budget constraints. Custom leather welding hoods provide unmatched protection and comfort for specialized applications, making them an excellent investment for serious welders. However, for those needing a quick, cost-effective solution, fiberglass helmets may suffice. Conversely, if performance and weight are critical factors, carbon fiber helmets present a high-end option worth considering. Ultimately, the choice will depend on balancing safety, functionality, and budget to find the best fit for your business needs.

Essential Technical Properties and Trade Terminology for custom leather welding hoods

What Are the Key Technical Properties of Custom Leather Welding Hoods?

When evaluating custom leather welding hoods, several technical properties are critical to ensure safety, durability, and performance. Understanding these specifications can help B2B buyers make informed purchasing decisions.

1. Material Grade

The material grade of leather used in welding hoods significantly affects their heat resistance and durability. High-grade leather, such as cowhide, is commonly preferred for its robustness and ability to withstand extreme temperatures. This property is vital for ensuring the safety of welders in high-heat environments, making it an essential consideration for procurement managers.

2. Tolerance Levels

Tolerance refers to the acceptable limits of variation in the dimensions of the welding hood. Precise tolerances are crucial for ensuring a snug fit, which enhances safety by minimizing exposure to harmful sparks and debris. B2B buyers should confirm that manufacturers can meet specific tolerance requirements to ensure that the hoods will perform effectively in the field.

Illustrative image related to custom leather welding hoods

3. Weight and Balance

The weight of a welding hood can impact the comfort and usability for the welder. Lighter hoods reduce fatigue during prolonged use, while proper balance prevents neck strain. Buyers should consider the ergonomic design and weight specifications to enhance user experience, as this can lead to increased productivity and reduced workplace injuries.

4. Flame Resistance Rating

Welding hoods must comply with specific flame resistance standards, which are crucial for protecting welders from sparks and molten metal. Understanding the flame resistance rating helps buyers ensure that the hoods will provide adequate protection under various working conditions. This rating is not just a safety feature; it can also be a regulatory requirement in many industries.

5. Visibility Features

The quality of the lens used in welding hoods is essential for visibility during work. High-definition (HD) lenses enhance clarity, allowing welders to see their work more effectively. B2B buyers should prioritize hoods that offer superior visibility features, as this can lead to better precision and quality in welding tasks.

What Trade Terminology Should B2B Buyers Know for Custom Leather Welding Hoods?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms related to custom leather welding hoods:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of leather welding hoods, understanding OEM relationships can help buyers identify reliable suppliers and assess the quality of products based on the manufacturer’s reputation.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their purchasing strategy and manage inventory effectively. This term often influences the overall cost and feasibility of sourcing custom leather welding hoods.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to submit price proposals for specific products or services. By issuing an RFQ for custom leather welding hoods, buyers can gather competitive pricing and terms, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risk management when sourcing custom leather welding hoods from different countries.

5. Customization Options

Customization refers to the ability to tailor products to specific requirements, such as material choice, design features, and branding. For buyers, knowing the extent of customization options available can be a significant factor in meeting unique operational needs and enhancing brand identity.

By understanding these technical properties and trade terms, B2B buyers can navigate the procurement process for custom leather welding hoods more effectively, ensuring they make choices that align with their operational safety and performance standards.

Illustrative image related to custom leather welding hoods

Navigating Market Dynamics and Sourcing Trends in the custom leather welding hoods Sector

What Are the Current Market Dynamics and Key Trends for Custom Leather Welding Hoods?

The global market for custom leather welding hoods is experiencing a notable transformation driven by several key factors. Firstly, the increasing demand for personalized protective gear that combines functionality with style is reshaping buyer preferences. This trend is especially prominent among international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where local industries are diversifying and modernizing their equipment. Moreover, advancements in manufacturing technology, such as 3D printing and automated cutting, are enabling quicker turnarounds and enhanced customization options. For example, manufacturers now offer custom designs with varying leather types, colors, and features to cater to specific welding applications, thus meeting the unique needs of diverse markets.

Another significant trend is the rising emphasis on safety standards and compliance. With stricter regulations around workplace safety in many countries, buyers are increasingly prioritizing high-quality, certified products that meet or exceed these standards. Additionally, the growth of e-commerce platforms has simplified the sourcing process, allowing international buyers to access a wider range of options and compare prices effectively. This is particularly beneficial for B2B buyers in emerging markets who may have previously faced challenges in sourcing specialized equipment locally.

How Is Sustainability Shaping the Sourcing of Custom Leather Welding Hoods?

Sustainability and ethical sourcing have become pivotal in the custom leather welding hood market. With heightened awareness about environmental impacts, buyers are increasingly seeking products made from sustainably sourced materials and environmentally friendly production processes. This shift is not just a trend but a necessity, as consumers and businesses alike are prioritizing sustainability in their purchasing decisions.

For custom leather welding hoods, this means sourcing leather from tanneries that adhere to strict environmental standards, minimizing waste, and using non-toxic dyes. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) can provide assurance to B2B buyers about the ethical sourcing of materials. Furthermore, manufacturers are exploring alternative materials that offer similar protective benefits without the environmental footprint associated with traditional leather, such as synthetic leathers derived from recycled materials.

Incorporating sustainability into the supply chain not only enhances brand reputation but also aligns with the growing consumer demand for responsible business practices. As international buyers become more conscientious, they are likely to favor suppliers who demonstrate a commitment to sustainability, thereby influencing sourcing decisions significantly.

What Is the Evolution of Custom Leather Welding Hoods?

The evolution of custom leather welding hoods reflects broader changes in the welding industry and protective gear standards. Historically, welding hoods were primarily utilitarian, focusing on basic protection against sparks and heat. Over time, as welding techniques advanced and safety regulations tightened, the demand for more specialized and comfortable gear grew. The introduction of customizable options allowed welders to express their individuality while ensuring safety.

In recent years, the market has seen a surge in innovative designs and materials, including lightweight options that enhance mobility without compromising protection. This evolution is driven by a combination of technological advancements and a deeper understanding of ergonomics, leading to products that are not only safer but also more comfortable for prolonged use. As such, the custom leather welding hood market continues to evolve, meeting the dynamic needs of international B2B buyers seeking quality, safety, and personalization in their protective equipment.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather welding hoods

-

How do I ensure the quality of custom leather welding hoods?

To guarantee the quality of custom leather welding hoods, it’s essential to vet suppliers thoroughly. Look for manufacturers with a proven track record in leather products, ideally with certifications related to quality standards. Request samples to assess the leather’s durability, stitching quality, and overall craftsmanship. Additionally, inquire about their quality assurance processes, including any testing protocols they follow to ensure compliance with safety and industry standards. -

What is the best material for custom leather welding hoods?

The best material for custom leather welding hoods is high-quality leather, specifically treated to withstand high temperatures and provide adequate protection from sparks and spatter. Full-grain leather is often preferred for its durability and resistance to wear. Some manufacturers also offer options like carbon fiber for added strength and lighter weight. Always confirm the leather’s specifications and its suitability for the specific welding processes your team engages in. -

How can I customize my leather welding hood?

Customization options for leather welding hoods can vary by supplier. Generally, you can choose aspects like the type of leather, color, design features, and size to fit specific needs. Some manufacturers may offer additional features, such as integrated bibs, ventilation systems, or specific cut styles tailored for particular welding techniques. Ensure you communicate your requirements clearly and request a prototype if possible before placing a bulk order. -

What are the typical minimum order quantities (MOQs) for custom leather welding hoods?

Minimum order quantities (MOQs) for custom leather welding hoods can differ significantly between suppliers. Many manufacturers set MOQs between 10 to 50 units per design, while others may accommodate smaller orders. It’s crucial to clarify MOQs upfront to avoid unexpected costs and ensure your order aligns with your budget and inventory needs. Some suppliers might offer flexibility for first-time buyers or larger contracts, so don’t hesitate to negotiate. -

What payment terms should I expect when ordering custom leather welding hoods?

Payment terms for custom leather welding hood orders vary widely by supplier. Common practices include a 30% deposit upfront with the balance due upon shipment, while others may require full payment before production starts. Ensure you understand the payment options available, including any international transaction fees or currency exchange considerations. Establishing clear payment terms in the contract can help prevent misunderstandings later. -

How long does it typically take to receive a custom leather welding hood?

The turnaround time for custom leather welding hoods generally ranges from 5 to 9 business days after the order is confirmed, depending on the complexity of the design and the supplier’s workload. International shipping may add additional time, so it’s advisable to plan ahead and account for potential delays, especially when importing goods from overseas. Always confirm shipping timelines with the supplier to align your project schedules accordingly. -

What should I consider regarding logistics when importing welding hoods?

When importing custom leather welding hoods, consider logistics factors such as shipping methods, customs clearance, and potential tariffs. Determine whether air or sea freight is more suitable for your timeline and budget. Work with a freight forwarder familiar with importing leather goods to navigate customs regulations efficiently. Additionally, ensure that the supplier provides necessary documentation, including invoices and certificates of origin, to facilitate smooth customs processing. -

How can I evaluate potential suppliers for custom leather welding hoods?

Evaluating potential suppliers involves several steps. Start by researching their reputation through online reviews, testimonials, and case studies. Request references from past clients to gauge their experience and satisfaction. Assess their production capabilities and quality control measures by asking for samples. Additionally, ensure they have experience with international orders, especially if you are sourcing from regions like Africa or South America, as they may have specific logistical considerations.

Top 5 Custom Leather Welding Hoods Manufacturers & Suppliers List

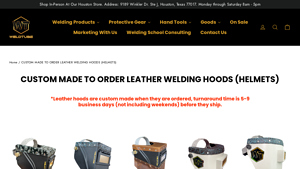

1. WeldLife – Custom Leather Welding Hoods

Domain: weldlife.com

Registered: 2009 (16 years)

Introduction: CUSTOM MADE TO ORDER LEATHER WELDING HOODS (HELMETS)

– Turnaround time: 5-9 business days (not including weekends) before shipping.

Product Options:

1. Chopped Leather Top LOWPRO Welding Helmet WITH FIBRE-METAL HEADGEAR, Aluminum Fasteners & High Visibility HD Lens – $209.99

2. Chopped Leather Top LOWPRO Welding Helmet WITH FIBRE-METAL HEADGEAR, GOATEE BIB, Aluminum Fasteners & High Visibility HD…

2. Skind Leathers – Premium Leather Welding Hoods

Domain: skindleathers.com

Registered: 2023 (2 years)

Introduction: High-Quality Welding Hoods, Custom Leather Welding Hoods, Exotic Welding Hoods, Pipeliner Welding Hoods. Premium quality leather, designed for both function and beauty, made from the highest quality leather and hardware, sourced from sustainable and ethical suppliers.

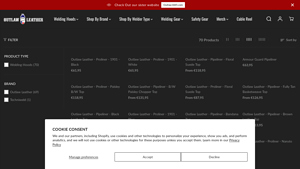

3. Outlaw Leather – Welding Hoods

Domain: outlawleather.com

Registered: 2012 (13 years)

Introduction: Welding hoods designed for protection and comfort, featuring adjustable headgear, lightweight materials, and various styles for different welding applications. Available in multiple colors and designs, suitable for professional and hobbyist welders.

4. Southern Leather Works – Chopped Tiger Hoods

Domain: southernleatherworks.net

Registered: 2023 (2 years)

Introduction: Key Products:

1. FFA Chopped Tiger Hood – $99.99

2. Tan Indian Chopped Tiger Hood – $99.99

3. Black and Grey Floral Chopped Tiger Hood – $150.00

4. Custom Pink Jackson Pirarucu Top Futura – $200.00

5. Red Tiger Panther Chopped Tiger Hood – $99.99

6. Green Chopped Tiger Hood – $99.99

7. Rust USA Chopped Tiger Hood – $99.99

8. Chevy Emblem Girl Chopped Tiger Hood – $99.99

9. Skull Chopped T…

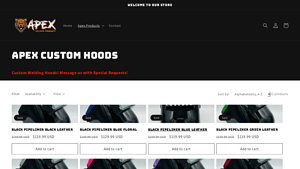

5. Apex – Custom Hoods Collection

Domain: weldwithapex.com

Registered: 2023 (2 years)

Introduction: Collection: Apex Custom Hoods

Availability: In stock (21 products)

Price Range: From $119.99 to $129.99

Products:

1. Black Pipeliner Black Leather – Sale price: $119.99 (Regular price: $159.99)

2. Black Pipeliner Blue Floral – Sale price: $129.99 (Regular price: $149.99)

3. Black Pipeliner Blue Leather – Sale price: $119.99 (Regular price: $159.99)

4. Black Pipeliner Green Leather – Sale price: $1…

Strategic Sourcing Conclusion and Outlook for custom leather welding hoods

How Can Strategic Sourcing Enhance Your Procurement of Custom Leather Welding Hoods?

In the competitive landscape of custom leather welding hoods, strategic sourcing emerges as a pivotal approach for international B2B buyers. By focusing on quality, customization options, and supplier reliability, businesses can ensure they procure products that not only meet their operational needs but also align with their brand values. The insights gained from evaluating suppliers based on material quality, production capabilities, and turnaround times are essential for maintaining a competitive edge.

Additionally, understanding the diverse offerings available—ranging from traditional leather hoods to innovative designs—enables buyers to cater to specific market demands, particularly in regions such as Africa, South America, the Middle East, and Europe. By leveraging strategic partnerships, companies can enhance their supply chain resilience and drive down costs while ensuring compliance with regional safety standards.

Looking ahead, the demand for custom leather welding hoods is poised to grow, driven by advancements in welding technology and a heightened focus on worker safety. International buyers are encouraged to engage with suppliers who prioritize sustainable practices and product longevity. Embrace this opportunity to elevate your procurement strategy and secure high-quality welding hoods that empower your workforce.

Illustrative image related to custom leather welding hoods

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.