Introduction: Navigating the Global Market for make leather holster

In the competitive landscape of leather holster manufacturing, B2B buyers face the pressing challenge of sourcing high-quality products that meet diverse needs across various markets. As you delve into the world of leather holster making, this guide will serve as your comprehensive resource, covering everything from the types of holsters available to the intricacies of supplier vetting. We’ll explore the applications of leather holsters in different industries, discuss cost considerations, and provide insights into the materials and techniques that ensure durability and functionality.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of the leather holster market is crucial. This guide empowers you to make informed purchasing decisions by equipping you with the knowledge to evaluate suppliers effectively and select holsters that align with your specific requirements. Whether you’re looking to cater to law enforcement agencies, outdoor enthusiasts, or everyday consumers, our insights will help you navigate the complexities of this global market, ensuring that you find the right products that not only meet quality standards but also resonate with your target audience.

Prepare to enhance your sourcing strategy and elevate your business offerings with expertly crafted leather holsters that stand the test of time.

Table Of Contents

- Top 4 Make Leather Holster Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for make leather holster

- Understanding make leather holster Types and Variations

- Key Industrial Applications of make leather holster

- 3 Common User Pain Points for ‘make leather holster’ & Their Solutions

- Strategic Material Selection Guide for make leather holster

- In-depth Look: Manufacturing Processes and Quality Assurance for make leather holster

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘make leather holster’

- Comprehensive Cost and Pricing Analysis for make leather holster Sourcing

- Alternatives Analysis: Comparing make leather holster With Other Solutions

- Essential Technical Properties and Trade Terminology for make leather holster

- Navigating Market Dynamics and Sourcing Trends in the make leather holster Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of make leather holster

- Strategic Sourcing Conclusion and Outlook for make leather holster

- Important Disclaimer & Terms of Use

Understanding make leather holster Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OWB Holster | Outside the waistband, easy access, and versatile fit | Law enforcement, tactical gear | Pros: Quick draw, comfortable for extended wear. Cons: Less concealed than IWB. |

| IWB Holster | Inside the waistband, offers maximum concealment | Everyday carry, personal defense | Pros: Highly concealable, secure fit. Cons: May be uncomfortable for prolonged use. |

| Shoulder Holster | Suspended from the shoulder, distributes weight evenly | Law enforcement, tactical use | Pros: Comfortable for heavy firearms, allows for easy concealment. Cons: Slower draw compared to OWB. |

| Custom Holster | Tailored to specific firearm models and user preferences | Specialty markets, custom orders | Pros: Perfect fit, enhanced retention. Cons: Higher cost and longer lead time. |

| Crossdraw Holster | Designed for drawing across the body | Hunters, tactical applications | Pros: Quick access while seated, good for vehicle use. Cons: Less secure than traditional holsters. |

What Are the Key Characteristics of OWB Holsters?

OWB (Outside the Waistband) holsters are designed to be worn on the outside of the waistband, providing easy access to the firearm. They are typically favored by law enforcement and tactical personnel due to their quick draw capabilities and comfort during extended use. When sourcing OWB holsters, B2B buyers should consider the materials used, as high-quality leather can enhance durability and aesthetics. Additionally, the design should accommodate various firearm sizes for broader market appeal.

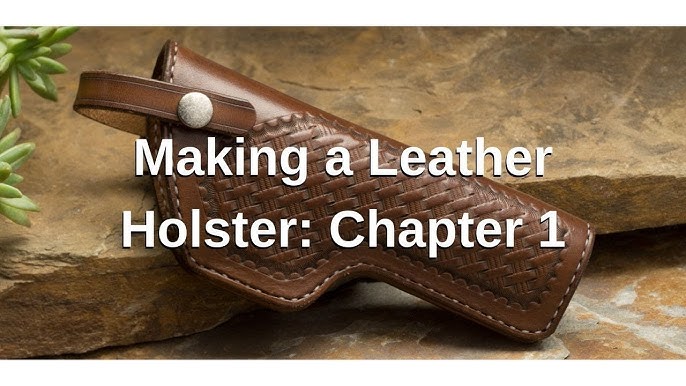

Illustrative image related to make leather holster

How Do IWB Holsters Enhance Concealment?

IWB (Inside the Waistband) holsters offer maximum concealment by fitting inside the waistband, making them ideal for everyday carry and personal defense. Their snug fit ensures that the firearm remains hidden from view, catering to buyers in regions with strict gun laws. When purchasing IWB holsters, B2B buyers should prioritize comfort and adjustability, as these factors significantly impact user satisfaction. Also, consider the leather thickness to balance concealability with durability.

What Advantages Do Shoulder Holsters Provide?

Shoulder holsters are designed to distribute the weight of the firearm across the shoulders, allowing for comfortable wear, especially with heavier firearms. They are popular among law enforcement and tactical users who may need to conceal their weapon under a jacket. B2B buyers should look for adjustable straps and breathable materials to enhance comfort. Additionally, a secure retention system is crucial to ensure the firearm remains safely in place during movement.

Why Consider Custom Holsters for Your Business?

Custom holsters are tailored to fit specific firearm models and user preferences, making them highly sought after in specialty markets. They provide a perfect fit and enhanced retention, appealing to discerning customers willing to invest in quality. B2B buyers should evaluate the manufacturer’s expertise and the customization options available, such as color, stitching, and additional features. Although they come at a higher price point, the potential for higher margins and customer loyalty makes them a valuable addition to any product line.

What Are the Benefits of Crossdraw Holsters?

Crossdraw holsters are designed for drawing across the body, making them particularly advantageous for hunters and those who spend time seated, such as in vehicles. They allow for quick access to the firearm while maintaining a low profile. When considering crossdraw holsters, B2B buyers should assess the design for ease of access and comfort. Additionally, the retention mechanism is essential to ensure the firearm remains secure during movement, especially in outdoor environments.

Illustrative image related to make leather holster

Key Industrial Applications of make leather holster

| Industry/Sector | Specific Application of make leather holster | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Duty holsters for firearms | Enhanced safety and accessibility for officers | Durable, high-quality leather; compliance with regulations |

| Military | Tactical holsters for operational use | Improved weapon retention and quick access | Customization options; lightweight materials for mobility |

| Outdoor & Hunting | Holsters for hunting firearms | Secure storage and easy transport of weapons | Weather-resistant leather; compatibility with various firearm models |

| Sports & Recreation | Holsters for competitive shooting events | Performance enhancement and comfort for users | Ergonomic designs; adaptability for different shooting styles |

| Retail & E-commerce | Custom holsters for gun enthusiasts | Unique product offerings that cater to niche markets | Sourcing from reputable manufacturers; variety in styles and finishes |

How is ‘make leather holster’ utilized in Law Enforcement?

In the law enforcement sector, leather holsters are essential for officers carrying firearms. These duty holsters provide enhanced safety by securing the weapon while allowing quick access when needed. The choice of durable, high-quality leather ensures longevity and reliability, crucial for daily use. International buyers, particularly from regions with varying firearm regulations, must ensure that the holsters comply with local laws, which may dictate specific designs or materials.

What role do leather holsters play in Military applications?

Military personnel rely on tactical leather holsters designed for operational use. These holsters facilitate improved weapon retention and quick access in high-pressure situations. The ability to customize holsters for specific firearms is vital, as soldiers often use various models. Lightweight materials are also a consideration for mobility in the field, making it essential for suppliers to offer options that balance durability with ease of movement.

Why are leather holsters important for Outdoor & Hunting?

In the outdoor and hunting industries, leather holsters serve as secure storage solutions for firearms. They protect the weapon from environmental elements while allowing hunters easy access during use. Buyers in this sector should prioritize weather-resistant leather to ensure durability in various conditions. Compatibility with a range of firearm models is also crucial, as hunters may use different types of guns depending on the game.

Illustrative image related to make leather holster

How do leather holsters enhance performance in Sports & Recreation?

For competitive shooting events, leather holsters are designed to enhance performance and provide comfort. These holsters allow shooters to draw their weapons quickly and efficiently, contributing to better scores in competitions. Ergonomic designs that cater to different shooting styles are important for buyers looking for an edge in performance. Additionally, international buyers should consider the specific requirements of different shooting sports, which may influence holster design.

What is the significance of leather holsters in Retail & E-commerce?

In the retail and e-commerce sectors, custom leather holsters attract gun enthusiasts looking for unique offerings. The ability to source holsters that reflect personal style or specific needs can set businesses apart in a competitive market. Suppliers should focus on sourcing from reputable manufacturers to ensure quality and variety in styles and finishes. This allows retailers to cater to niche markets and build customer loyalty through tailored products.

3 Common User Pain Points for ‘make leather holster’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Holster Production

The Problem: B2B buyers often struggle with sourcing high-quality leather suitable for making durable holsters. Many suppliers may offer cheaper options, such as chrome-tanned leather, which is not only less durable but can also rust firearms, leading to significant liability issues. This can create frustration as buyers seek to balance cost with quality, particularly in regions where quality leather may not be readily available.

The Solution: To ensure the production of quality leather holsters, buyers should focus on establishing relationships with reputable suppliers who specialize in vegetable-tanned full-grain leather. This type of leather is not only more durable but also environmentally friendly and safe for firearms. It is essential to conduct thorough research and possibly visit suppliers to verify the quality of their leather before placing bulk orders. Additionally, buyers can benefit from leveraging online platforms and forums to connect with other leatherworkers and get recommendations for reliable sources. By prioritizing quality over cost, businesses can enhance their reputation and reduce the risk of product returns due to material failures.

Scenario 2: Designing Custom Holsters That Fit Multiple Firearm Models

The Problem: Many B2B buyers in the leather holster market face the challenge of designing holsters that accommodate a variety of firearm models. This can lead to increased production times and costs if every holster requires a unique mold or pattern. In regions with a diverse range of firearm preferences, this issue can severely hinder operational efficiency.

Illustrative image related to make leather holster

The Solution: Implementing a modular design approach can significantly streamline the production of custom holsters. By creating adjustable patterns or using a basic template that can be modified slightly for different models, manufacturers can reduce the time and resources spent on producing individual molds. Additionally, utilizing CAD (Computer-Aided Design) software can help in quickly adapting designs to fit different firearms without starting from scratch. Offering a range of sizes and adjustments not only simplifies production but also appeals to a broader customer base, allowing businesses to cater to varying firearm preferences more efficiently.

Scenario 3: Ensuring Proper Stitching Techniques for Durability

The Problem: Buyers often encounter issues with the stitching of leather holsters, which can lead to product failure over time. Incorrect stitching methods can compromise the integrity of the holster, resulting in costly returns and damage to brand reputation. This is especially critical in competitive markets where quality assurance is paramount.

The Solution: To address stitching-related issues, B2B buyers should invest in training and resources that emphasize the importance of proper stitching techniques, such as saddle stitching. Utilizing high-quality thread and investing in appropriate tools like pricking irons and stitching ponies can enhance the stitching process. Additionally, providing employees with access to detailed tutorials and workshops can help standardize best practices across production teams. Establishing a quality control protocol that includes regular assessments of stitching quality can further ensure that each holster meets durability standards, thereby reducing the likelihood of returns and fostering customer loyalty.

Strategic Material Selection Guide for make leather holster

What Are the Key Materials for Making Leather Holsters?

When selecting materials for crafting leather holsters, it is crucial to consider various factors such as durability, cost, and application suitability. Below, we analyze four common materials used in leather holster production, providing insights tailored for international B2B buyers.

How Does Vegetable-Tanned Leather Perform in Holster Making?

Vegetable-tanned leather is often the top choice for holster makers due to its natural properties. This leather is treated with tannins derived from plant sources, making it environmentally friendly and biodegradable. Key properties include excellent durability and resistance to wear, which are critical for holsters that must withstand daily use.

Pros: Vegetable-tanned leather is robust, offers a good grip, and can be molded to fit specific firearm shapes, enhancing retention and comfort. It also ages beautifully, developing a rich patina over time.

Cons: The main drawback is its higher cost compared to chrome-tanned leather and the longer tanning process, which may affect production timelines. Additionally, it can be less resistant to moisture unless treated with a waterproofing agent.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations regarding leather sourcing and treatment processes.

What Advantages Does Chrome-Tanned Leather Offer?

Chrome-tanned leather is another popular option, known for its flexibility and resistance to water. The tanning process involves chromium salts, which allow for quicker production times and a more consistent finish.

Pros: This type of leather is generally more affordable and easier to work with, making it suitable for mass production. Its water resistance is beneficial in humid climates.

Illustrative image related to make leather holster

Cons: However, chrome-tanned leather can lead to corrosion of firearms due to the salts used in the tanning process. Additionally, it lacks the breathability and natural aesthetics of vegetable-tanned leather.

International Considerations: Buyers should be aware of the potential health and environmental concerns associated with chrome tanning, particularly in regions with strict regulations like Europe.

How Do Synthetic Leathers Compare in Holster Production?

Synthetic leathers, such as polyurethane (PU) or polyvinyl chloride (PVC), are increasingly used in holster manufacturing. These materials mimic the look and feel of real leather while offering unique advantages.

Pros: Synthetic leathers are lightweight, often more affordable, and resistant to moisture and stains. They can also be produced in various colors and textures, appealing to diverse consumer preferences.

Illustrative image related to make leather holster

Cons: The primary limitation is their durability compared to genuine leather; they may not withstand the same level of wear and tear. Additionally, they may not provide the same level of grip and comfort for users.

International Considerations: B2B buyers should evaluate the environmental impact of synthetic materials, especially in regions prioritizing sustainability. Compliance with international standards for synthetic materials is also essential.

What Role Does Full-Grain Leather Play in Holster Durability?

Full-grain leather is considered the highest quality leather available, as it retains the natural grain and imperfections of the hide. This type of leather is known for its strength and durability, making it ideal for high-end holsters.

Pros: Full-grain leather is incredibly durable and develops a unique character over time. It offers excellent breathability and moisture resistance, making it suitable for various climates.

Cons: The main drawback is the cost, as full-grain leather is typically the most expensive option. Additionally, it requires more care and maintenance to preserve its appearance.

International Considerations: Buyers in Europe and the Middle East may prefer full-grain leather due to its premium quality and craftsmanship, but they should ensure that the sourcing aligns with ethical practices.

Summary Table of Material Analysis

| Material | Typical Use Case for make leather holster | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Custom holsters for firearms | Durable and moldable | Higher cost and longer production | High |

| Chrome-Tanned Leather | Mass-produced holsters | Affordable and flexible | Potential corrosion of firearms | Medium |

| Synthetic Leather | Budget-friendly holsters | Lightweight and moisture-resistant | Less durable than genuine leather | Low |

| Full-Grain Leather | Premium holsters | Exceptional durability and aesthetics | Most expensive and requires care | High |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to make informed decisions when sourcing materials for leather holster production. Understanding the properties, advantages, and limitations of each material will aid in selecting the best fit for specific applications and market demands.

Illustrative image related to make leather holster

In-depth Look: Manufacturing Processes and Quality Assurance for make leather holster

What Are the Main Stages in the Manufacturing Process of Leather Holsters?

The manufacturing process of leather holsters can be broken down into four main stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring the final product meets quality and functionality standards.

How is Material Prepared for Leather Holster Manufacturing?

The first step involves selecting high-quality leather, typically 7-8 oz vegetable-tanned full-grain leather. This type of leather is preferred due to its durability and resistance to wear. Sourcing from reputable suppliers is crucial, as the quality of leather directly affects the holster’s longevity and performance.

Once the leather is sourced, it undergoes a careful inspection to check for any defects or inconsistencies. The hides are then cut into the required patterns, often using precision tools to ensure accuracy. It’s essential to cut from the back part of the hide, as it provides a smoother surface and better strength compared to the belly or neck areas.

Illustrative image related to make leather holster

What Techniques Are Used in the Forming Stage of Leather Holster Production?

After cutting, the leather pieces are shaped to form the holster’s structure. This can involve techniques such as wet forming, where leather is dampened and molded around a form to achieve the desired fit and shape. This step is critical, especially for custom-fitted holsters that need to accommodate specific firearm models.

Tools like mallets and pricking irons are often used in this stage to create stitching holes and to shape the leather accurately. The use of a stitching pony can enhance this process, allowing for more precision and control during assembly.

How Are Leather Holsters Assembled?

Assembly typically involves stitching the pre-formed leather pieces together. This can be done using either machine stitching or hand stitching. Machine stitching is faster and more uniform, while hand stitching, though time-consuming, can provide a more artisanal finish.

Before stitching, a suitable adhesive, like a low-VOC PVA glue, is applied to hold the pieces in place. This allows for adjustments before the final stitching is completed. It’s essential to ensure that the stitch line is consistent and tight to prevent any separation over time.

What Finishing Techniques Are Commonly Used for Leather Holsters?

Finishing is the final stage in the manufacturing process, where the holster is prepared for sale. This includes edge finishing, dyeing, and applying protective coatings. Edge finishing is crucial for aesthetic purposes and durability, while dyeing can enhance the appearance and provide a unique character to each holster.

Protective coatings are often applied to improve water resistance and overall durability. The finishing process may also involve buffing and polishing to give the holster a professional look. Quality control checks should be performed at each step to ensure consistency and adherence to standards.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is paramount in leather holster manufacturing, particularly for international B2B buyers. Adhering to international standards, such as ISO 9001, ensures that suppliers implement quality management systems that lead to consistent product quality.

Illustrative image related to make leather holster

Which Industry-Specific Standards Are Relevant for Leather Holster Manufacturing?

In addition to general quality standards, certain industry-specific certifications may apply. For example, CE marking is important in the European market, indicating compliance with health, safety, and environmental protection standards. Other certifications, such as those from the American Petroleum Institute (API), may also be relevant depending on the intended use of the holsters.

What Are the Key Quality Control Checkpoints in Leather Holster Production?

Quality control (QC) should be integrated throughout the manufacturing process, with specific checkpoints established:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing stages ensure that each process aligns with quality standards.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures it meets all design and functional requirements before shipping.

Common testing methods include visual inspections, strength tests for stitching, and water resistance tests for finished products.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should conduct thorough due diligence when selecting suppliers. This includes:

- Audits: Regular audits of the supplier’s manufacturing facilities can provide insights into their quality control processes.

- Reports: Requesting quality assurance reports can help buyers understand the supplier’s compliance with relevant standards and any historical quality issues.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality systems and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

For buyers in regions such as Africa, South America, the Middle East, and Europe, it is crucial to understand the local regulations and standards that may impact quality assurance. Different countries may have specific requirements regarding material sourcing, environmental impact, and product safety.

Illustrative image related to make leather holster

Additionally, language barriers and cultural differences may affect communication regarding quality expectations. Establishing clear agreements and specifications upfront can mitigate misunderstandings and ensure that the final product meets the buyer’s expectations.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing leather holsters, ensuring they receive products that meet their quality standards and functional requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘make leather holster’

Introduction

This practical sourcing guide aims to assist B2B buyers in procuring high-quality materials and services necessary for making leather holsters. By following this step-by-step checklist, businesses can streamline their procurement process, ensuring they select the right suppliers and materials to meet their specific needs.

Step 1: Define Your Technical Specifications

Before sourcing materials, clearly define the specifications for the leather holsters you plan to manufacture. Consider the type of leather (e.g., vegetable-tanned full grain), thickness (ideally 7-8 oz), and any specific features like stitching styles or reinforcement requirements. This clarity will help you communicate your needs effectively to potential suppliers.

Illustrative image related to make leather holster

Step 2: Research Quality Leather Suppliers

Identifying reliable leather suppliers is crucial. Look for suppliers who specialize in high-quality vegetable-tanned leather that meets your specifications. Verify their reputation by checking reviews and seeking recommendations from other businesses in the leather industry, especially those in your target regions such as Africa and South America.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to thoroughly vet potential suppliers. Request company profiles, case studies, and references from clients in similar sectors. Look for evidence of their production capacity, quality control processes, and experience in leather crafting to ensure they can meet your demands.

- Supplier Certifications: Check for relevant certifications that demonstrate compliance with industry standards.

- Production Lead Times: Understand their delivery timelines to align with your project schedules.

Step 4: Assess Material Quality

Once you have shortlisted suppliers, obtain samples of their leather. Evaluate the texture, durability, and color consistency to ensure it meets your standards for holster production. Remember that high-quality leather should not stretch excessively and should feel robust to the touch.

Step 5: Understand Pricing Structures

Engage in discussions about pricing with your selected suppliers. Request a detailed breakdown of costs, including material prices, shipping fees, and any additional charges for customizations. Understanding the pricing structure helps in budgeting and allows for effective comparison between different suppliers.

- Negotiation Opportunities: Be prepared to negotiate terms, especially for bulk orders, to secure the best rates.

Step 6: Verify Production Capabilities

Ensure that the suppliers you are considering have the necessary equipment and expertise to produce leather holsters that meet your specifications. Inquire about their production processes, including cutting, stitching, and finishing techniques. This knowledge is vital to assess whether they can consistently deliver high-quality products.

Step 7: Establish Clear Communication Channels

Finally, establish clear communication channels with your chosen suppliers. Regular updates on production progress and any potential issues are essential for maintaining a smooth workflow. Discuss how you will handle quality assurance and any potential adjustments needed during the manufacturing process.

By following these steps, B2B buyers can effectively source materials and services for making leather holsters, ensuring a successful procurement process that meets their business needs.

Comprehensive Cost and Pricing Analysis for make leather holster Sourcing

What Are the Key Cost Components in Leather Holster Manufacturing?

When sourcing leather holsters, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary components include:

-

Materials: The choice of leather significantly impacts cost. High-quality vegetable-tanned full-grain leather (7-8 oz) is preferred for durability and safety, as chrome-tanned leather can lead to rusting of firearms. Additional materials like stitching threads, glues (such as low-VOC PVA), and finishing agents also contribute to overall material costs.

-

Labor: Skilled labor is essential in the crafting of leather holsters. The complexity of the design, whether custom-fitted or standardized, influences labor costs. Handcrafted holsters require more time and expertise, resulting in higher labor expenses compared to mass-produced options.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, equipment maintenance, and other operational expenses. As production scales, overhead costs can be distributed over more units, potentially reducing the cost per unit.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Investment in quality tools (like pricking irons and sewing machines) is necessary for precision and quality. Buyers should consider these costs when evaluating suppliers.

-

Quality Control (QC): Implementing stringent QC measures ensures that each holster meets safety and quality standards. This process adds to the overall cost but is vital for maintaining brand reputation, especially in international markets where quality expectations may vary.

-

Logistics: Shipping costs, including international freight charges, customs duties, and insurance, can significantly affect total costs. The choice of shipping methods and Incoterms (e.g., FOB, CIF) will also influence overall expenses.

-

Margin: Suppliers will factor in their profit margins, which can vary based on their market position and the competitive landscape. Understanding these margins can help buyers negotiate better deals.

How Do Price Influencers Affect Leather Holster Sourcing?

Several factors influence pricing and should be considered by buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically yield lower prices per unit due to economies of scale. Buyers should negotiate MOQs that align with their purchasing needs.

-

Specifications and Customization: Custom-designed holsters generally come at a premium. Buyers should clearly define their specifications to avoid unexpected costs associated with alterations.

-

Material Quality and Certifications: Premium materials and certifications (like eco-friendly or hypoallergenic standards) can increase costs but may be essential for certain markets. Understanding local preferences can guide material selection.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can impact pricing. Suppliers with established networks may offer better logistics solutions, potentially reducing total costs.

What Are Effective Buyer Tips for Negotiating Leather Holster Prices?

B2B buyers should consider the following strategies to maximize cost-efficiency:

-

Negotiation: Engage in discussions with suppliers to explore discounts for bulk purchases or long-term contracts. Building a relationship can lead to better terms and pricing flexibility.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with the holsters, including maintenance, durability, and potential returns. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local regulations that may affect pricing. Utilizing local suppliers can sometimes mitigate these challenges.

Disclaimer on Pricing

Prices for leather holsters can vary widely based on customization, material choice, and supplier capabilities. The figures mentioned in various contexts are indicative and should be verified with suppliers for current pricing tailored to specific requirements. Always seek quotes that reflect your unique needs and market conditions.

Alternatives Analysis: Comparing make leather holster With Other Solutions

Introduction to Alternatives for Leather Holster Production

When considering options for leather holster production, it’s essential to evaluate various methods and technologies that can meet the needs of B2B buyers. While creating a leather holster offers customization and quality, alternative solutions may provide different benefits, such as cost-effectiveness or rapid production. This analysis will compare the traditional method of making leather holsters with two viable alternatives: synthetic holster production and molded plastic holsters.

Comparison Table

| Comparison Aspect | Make Leather Holster | Synthetic Holster Production | Molded Plastic Holsters |

|---|---|---|---|

| Performance | High durability, custom fit | Good durability, less custom | Moderate durability, lightweight |

| Cost | Higher due to materials | Moderate, cost-effective | Low-cost manufacturing |

| Ease of Implementation | Requires skill and time | Easier, less skill required | Very easy, quick production |

| Maintenance | Requires care and conditioning | Minimal maintenance needed | Low maintenance |

| Best Use Case | Custom applications, high-end markets | Mid-range markets, general use | Budget-friendly, mass production |

Detailed Breakdown of Alternatives

Synthetic Holster Production

Synthetic holsters, often made from materials like nylon or polymer blends, offer a cost-effective alternative to leather. They are typically more affordable, making them attractive for businesses looking to minimize expenses. However, while they provide decent durability and performance, they lack the bespoke quality and aesthetic appeal of leather. Synthetic materials may not offer the same level of comfort or fit, especially for specialized applications. B2B buyers may find synthetic options suitable for general use or for markets where cost is a primary concern.

Illustrative image related to make leather holster

Molded Plastic Holsters

Molded plastic holsters are designed through injection molding techniques, resulting in a lightweight and often more affordable option. They excel in ease of implementation due to their rapid production capabilities, making them ideal for large-scale orders. However, the performance may not match that of leather or even synthetic options, particularly in terms of comfort and longevity. Molded plastic holsters are best suited for budget-conscious markets where functionality is prioritized over aesthetic and custom fit. They are commonly used in law enforcement and military applications where quick deployment is essential.

Conclusion: Choosing the Right Holster Solution for Your Needs

In selecting the appropriate holster solution, B2B buyers must consider their specific requirements, including budget, intended use, and the desired level of customization. Leather holsters are ideal for high-end applications requiring durability and bespoke fitting. In contrast, synthetic and molded plastic options cater to broader, cost-sensitive markets where rapid production and ease of maintenance are prioritized. By evaluating these alternatives against their unique business needs, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for make leather holster

What Are the Key Technical Properties of Leather Holsters?

When sourcing materials for leather holsters, understanding the technical specifications is crucial for ensuring durability, functionality, and compliance with industry standards. Here are several key properties to consider:

-

Material Grade:

– Definition: This refers to the quality of leather used, with full-grain vegetable-tanned leather being the highest standard for holsters.

– B2B Importance: Full-grain leather retains the natural grain and is less prone to wear and tear. It offers excellent durability, which is essential for products that experience frequent use. Buyers should prioritize high-grade materials to ensure longevity and customer satisfaction. -

Leather Thickness (Oz):

– Definition: Measured in ounces, the thickness of leather typically used for holsters ranges from 7 to 8 oz.

– B2B Importance: The right thickness ensures that the holster can securely hold a firearm while also being comfortable to wear. Thicker leather provides better retention and protection, making it a critical specification for manufacturers. -

Stretch Resistance:

– Definition: This property refers to the leather’s ability to maintain its shape under stress.

– B2B Importance: Stretch resistance is vital for holsters that need to fit snugly around firearms. Leather that stretches too much can compromise the holster’s fit and retention, leading to potential safety issues for end-users. -

Finish Type:

– Definition: The finish applied to the leather can vary, including oiled, waxed, or aniline finishes.

– B2B Importance: Different finishes affect the leather’s appearance, water resistance, and aging process. A well-chosen finish can enhance the product’s aesthetic appeal while providing necessary protection against environmental factors. -

Stitching Specification:

– Definition: This refers to the type and density of stitching used in the construction of the holster, typically around 6-8 stitches per inch.

– B2B Importance: Strong stitching is crucial for the durability and structural integrity of the holster. Manufacturers must ensure that the stitching is robust enough to withstand regular use, thereby reducing returns and enhancing customer satisfaction.

Which Trade Terms Are Commonly Used in Leather Holster Manufacturing?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to leather holster manufacturing:

-

OEM (Original Equipment Manufacturer):

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Buyers seeking to create custom holsters may collaborate with OEMs to produce unique designs or specifications, ensuring tailored solutions for their markets. -

MOQ (Minimum Order Quantity):

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is essential for buyers, as it can affect inventory costs and cash flow. Negotiating favorable MOQs can lead to better pricing and reduced waste. -

RFQ (Request for Quotation):

– Definition: A document issued by a buyer requesting a price quote from suppliers for specific products or services.

– Importance: RFQs help buyers compare pricing and terms from different suppliers, allowing for informed decision-making in procurement. -

Incoterms (International Commercial Terms):

– Definition: A set of predefined international trade terms that outline the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risk management during international transactions, which is crucial for smooth cross-border trade. -

Lead Time:

– Definition: The time taken from placing an order to receiving the goods.

– Importance: Knowing the lead time helps buyers plan their inventory and ensure that they can meet customer demand promptly.

By grasping these technical properties and trade terminology, B2B buyers can make more informed decisions when sourcing leather holsters, leading to better product quality and enhanced business relationships.

Navigating Market Dynamics and Sourcing Trends in the make leather holster Sector

What are the Key Market Dynamics and Trends in the Leather Holster Sector?

The leather holster market is witnessing significant growth, driven by a rising demand for personalized and high-quality firearm accessories. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking tailored solutions that blend craftsmanship with functionality. Customization is a key trend, with buyers favoring holsters that cater to specific firearm models and individual preferences. The integration of technology in the design and manufacturing process, such as 3D modeling and CNC cutting, is enhancing precision and efficiency, making it easier for manufacturers to meet diverse customer requirements.

Moreover, the shift towards direct-to-consumer sales is reshaping traditional distribution channels. International buyers are leveraging online platforms to source products directly from manufacturers, reducing costs and improving supply chain efficiency. This trend is particularly evident in emerging markets like Brazil and Vietnam, where e-commerce growth is rapid. Additionally, the demand for eco-friendly leather alternatives is influencing sourcing strategies, as buyers prioritize sustainability in their procurement processes.

How is Sustainability Influencing the Sourcing of Leather Holsters?

The environmental impact of leather production has prompted B2B buyers to prioritize sustainable and ethical sourcing practices. Leather holster manufacturers are increasingly adopting vegetable-tanned leather, which is less harmful to the environment compared to chrome-tanned alternatives. This shift not only aligns with the growing consumer preference for eco-friendly products but also mitigates potential health risks associated with harmful chemicals used in traditional tanning processes.

Buyers are also looking for suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming crucial for businesses aiming to demonstrate their commitment to sustainability. By choosing suppliers with these certifications, international buyers can enhance their brand reputation and appeal to a more environmentally-conscious customer base.

What is the Historical Context of Leather Holster Manufacturing?

The art of leather holster making dates back centuries, evolving from simple pouches used for carrying weapons to intricately designed holsters tailored for specific firearms. Traditionally, leather was sourced from local tanneries, where craftsmanship was passed down through generations. The demand for functional and aesthetically pleasing holsters surged with the rise of firearms, leading to innovations in design and materials.

In the modern era, the leather holster industry has adapted to technological advancements, allowing for mass production while still catering to the bespoke needs of discerning customers. This blend of tradition and innovation continues to define the sector, positioning it for sustained growth as international markets expand and consumer preferences evolve.

Conclusion

Understanding the dynamics of the leather holster market is essential for international B2B buyers looking to navigate sourcing trends effectively. By focusing on customization, sustainability, and leveraging technological advancements, buyers can align themselves with market demands and build a competitive edge in the growing global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of make leather holster

-

How do I ensure the quality of leather used in holster production?

To guarantee high-quality leather for holster production, request samples from potential suppliers. Look for vegetable-tanned, full-grain leather with a thickness of 7-8 oz, which offers durability and resilience. Avoid chrome-tanned leather, as it can damage firearms and is generally less robust. Verify that the leather is sourced from reputable tanneries and inquire about their quality control processes. Establishing a long-term partnership with a supplier who prioritizes material quality will enhance your product’s reputation. -

What are the customization options available for leather holsters?

Customization options for leather holsters can include size adjustments, design modifications, and personalized features such as logos or unique stitching patterns. Discuss your specific requirements with suppliers, as many are willing to accommodate custom orders. Ensure they provide a clear outline of the customization process, including lead times and any additional costs. This not only helps meet market demands but also allows you to differentiate your products in competitive markets. -

What is the typical minimum order quantity (MOQ) for leather holsters?

Minimum order quantities (MOQs) for leather holsters can vary significantly depending on the supplier and customization requests. Generally, MOQs may range from 50 to 500 units. It’s essential to communicate your needs upfront and negotiate terms that suit both parties. Some manufacturers may offer flexible MOQs for new customers or initial trial orders, allowing you to assess product quality before committing to larger purchases. -

What payment terms are commonly accepted by leather holster suppliers?

Payment terms can differ among suppliers, but common practices include upfront payments, deposits (typically 30-50%), and net payment terms (30, 60, or 90 days post-delivery). It’s crucial to clarify payment conditions before finalizing orders to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection. Establishing a trustworthy relationship with your supplier can often lead to more favorable payment arrangements over time. -

How can I vet potential suppliers for leather holsters?

To effectively vet potential suppliers, conduct thorough research by checking their business credentials, customer reviews, and industry reputation. Request references from previous clients and verify their experience in producing leather holsters. Utilize platforms like Alibaba or ThomasNet for supplier ratings and feedback. Additionally, consider visiting their facilities if possible, which allows you to assess their production capabilities and quality control measures firsthand. -

What are the logistics considerations when sourcing leather holsters internationally?

When sourcing leather holsters internationally, logistics considerations include shipping costs, customs regulations, and lead times. Ensure you understand the import/export laws of your country and the supplier’s location. Consider partnering with freight forwarders who specialize in international shipping to streamline the process. Additionally, factor in potential delays due to customs clearance or unforeseen global shipping disruptions, and plan your inventory accordingly. -

What quality assurance measures should I expect from my supplier?

A reputable leather holster supplier should implement stringent quality assurance (QA) measures throughout the production process. This includes raw material inspections, in-process quality checks, and final product evaluations. Request documentation of their QA processes and any certifications they hold (e.g., ISO standards). Regular audits and feedback loops can help maintain quality standards, ensuring that the products meet your specifications consistently. -

How do I handle disputes or quality issues with my leather holster supplier?

In the event of disputes or quality issues, maintain open communication with your supplier to address concerns promptly. Establish a clear dispute resolution process in your contract, outlining steps for negotiation and potential mediation. Document all issues with photos and detailed descriptions to support your claims. If necessary, involve third-party arbitration or legal counsel, but aim for a collaborative approach to preserve the business relationship.

Top 4 Make Leather Holster Manufacturers & Suppliers List

1. Mr. Lentz – Leather Holster Tutorial

Domain: mrlentz.com

Registered: 2009 (16 years)

Introduction: How to Make a Leather Holster tutorial by Mr. Lentz. Key materials needed: 7-8 oz vegetable tanned full grain leather (approximately 2 sq. ft.), mallet, 5/16 hole punch, PVA leather glue (Reina Aquilim 315), silicon tipped glue spreader, 6 stitch per inch marking wheel, beveler for tight curves (size #2), stitch line marking tool, scratch awl, red speedball pen, utility knife, scissors (preferably…

2. Tandy Leather – Holster Design Tutorial

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Holster Design Tutorial, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Leatherworker.net – Hand Stitching vs. Machine Sewing

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1) Hand stitching – relatively inexpensive method for leather holster making. 2) Machine sewing – relatively expensive method, with prices starting from $1000 USD for a basic hand-operated sewing machine and $2800 USD for a motorized sewing machine. Recommended machines include: Juki DNU – 1541S, Juki DU – 1181N, Singer 29K – 71 (1949), Chinese Patcher (Tinkers Delight), Warlock TSC-441, Techsew 2…

4. Reddit – Holster Making Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Holster making techniques, leather thickness (8-10 oz recommended for hard use), pattern making tips (trace gun shape, leave room for stitching), advice on leather quantity for holster, gunbelt, and cartridge loops.

Strategic Sourcing Conclusion and Outlook for make leather holster

In the competitive landscape of leather holster manufacturing, strategic sourcing emerges as a pivotal factor for success. By prioritizing high-quality materials, such as 7-8 oz vegetable-tanned full-grain leather, manufacturers can enhance product durability and appeal to discerning consumers. Establishing robust supplier relationships ensures consistent access to premium materials, which is essential for meeting growing demand in diverse markets across Africa, South America, the Middle East, and Europe.

Furthermore, investing in skilled craftsmanship and innovative techniques—like custom fitting and precise stitching—can significantly elevate product quality. Buyers should also consider leveraging technology, such as design software for pattern making, to streamline production processes and minimize waste. The trend toward personalized and custom products is gaining traction, making it crucial for manufacturers to adapt and innovate.

As international B2B buyers, your strategic decisions in sourcing and production will shape the future of your leather holster offerings. Embrace these insights to strengthen your supply chain and enhance your competitive edge. Together, let’s forge a path toward excellence in leather craftsmanship, ensuring a prosperous future in this dynamic industry.

Illustrative image related to make leather holster

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.