Introduction: Navigating the Global Market for dream factory leather

In the dynamic world of leather crafting, sourcing the right tools and materials is often a daunting challenge for international B2B buyers. Whether you are seeking high-quality leatherwork tools from Dream Factory or looking to enhance your production capabilities, understanding the nuances of the global market is crucial. This guide is designed to navigate you through the complexities of acquiring Dream Factory leather products, detailing various types of tools, their applications, and best practices for supplier vetting.

Buyers from diverse regions—including Africa, South America, the Middle East, and Europe—face unique challenges in sourcing premium leather tools that meet their specific needs. With a focus on cost-effectiveness and quality assurance, this comprehensive resource empowers you to make informed purchasing decisions. From exploring the innovative designs of adjustable stitching ponies to understanding the benefits of embossing machines, you will gain insights into how these tools can elevate your leather crafting experience.

By providing actionable advice and expert recommendations, this guide aims to simplify your sourcing journey, ensuring you can confidently select the right Dream Factory leather tools to enhance your production efficiency and product quality. Embrace the opportunity to elevate your craft, streamline your operations, and ultimately achieve greater success in the competitive leather goods market.

Table Of Contents

- Top 3 Dream Factory Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for dream factory leather

- Understanding dream factory leather Types and Variations

- Key Industrial Applications of dream factory leather

- 3 Common User Pain Points for ‘dream factory leather’ & Their Solutions

- Strategic Material Selection Guide for dream factory leather

- In-depth Look: Manufacturing Processes and Quality Assurance for dream factory leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘dream factory leather’

- Comprehensive Cost and Pricing Analysis for dream factory leather Sourcing

- Alternatives Analysis: Comparing dream factory leather With Other Solutions

- Essential Technical Properties and Trade Terminology for dream factory leather

- Navigating Market Dynamics and Sourcing Trends in the dream factory leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dream factory leather

- Strategic Sourcing Conclusion and Outlook for dream factory leather

- Important Disclaimer & Terms of Use

Understanding dream factory leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adjustable Folding Stitching Pony | Lightweight, portable, adjustable angles, magnetic needle holder | Small workshops, mobile leathercraft, education | Pros: Easy to transport, versatile; Cons: May lack stability for heavy-duty projects. |

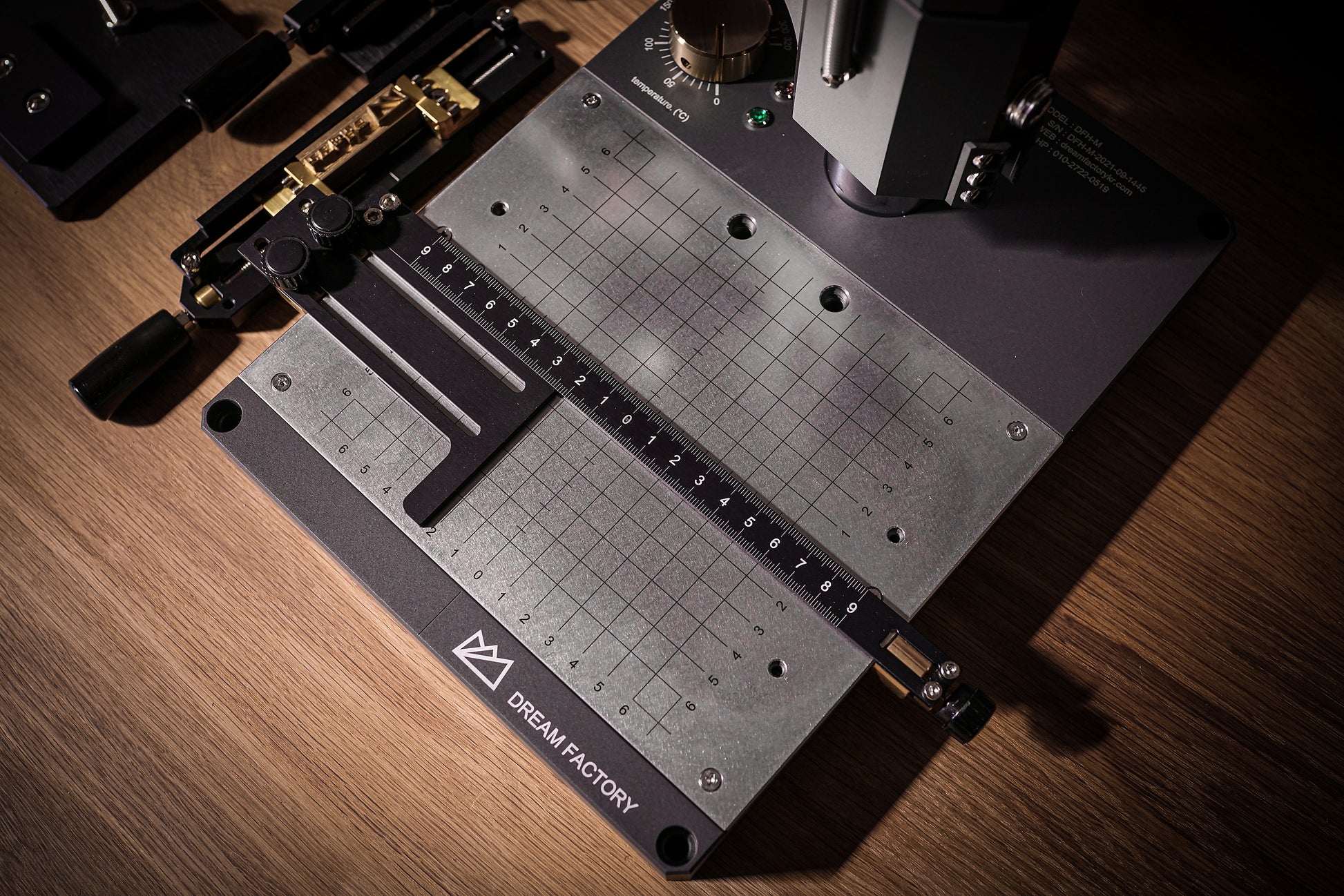

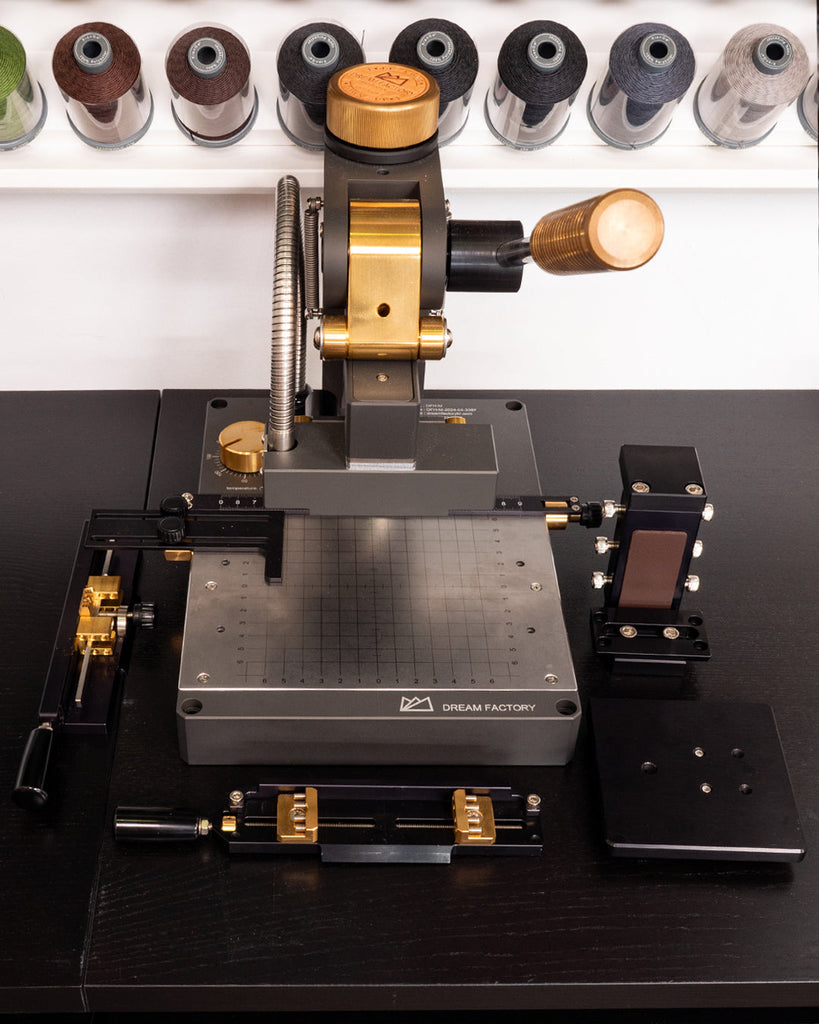

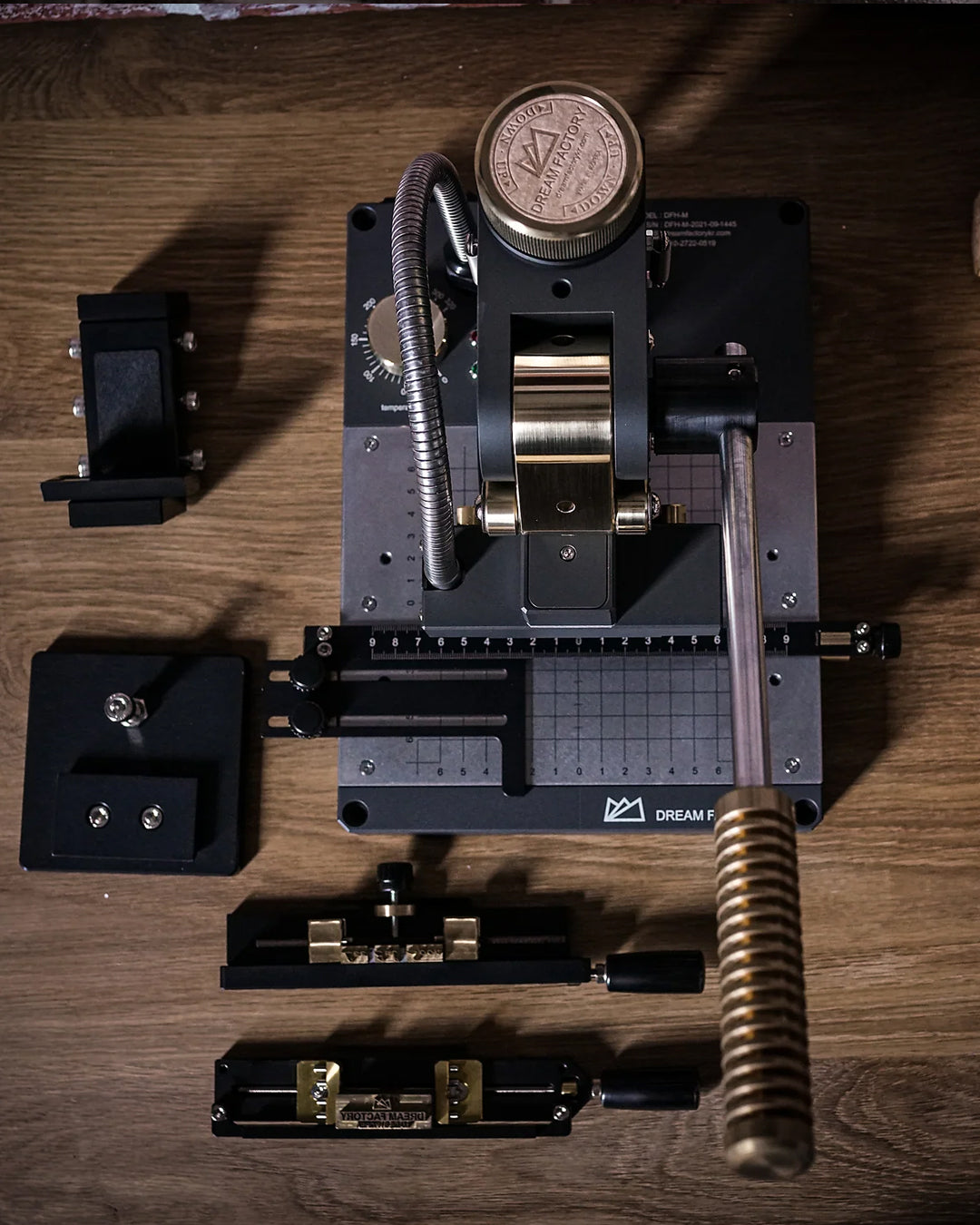

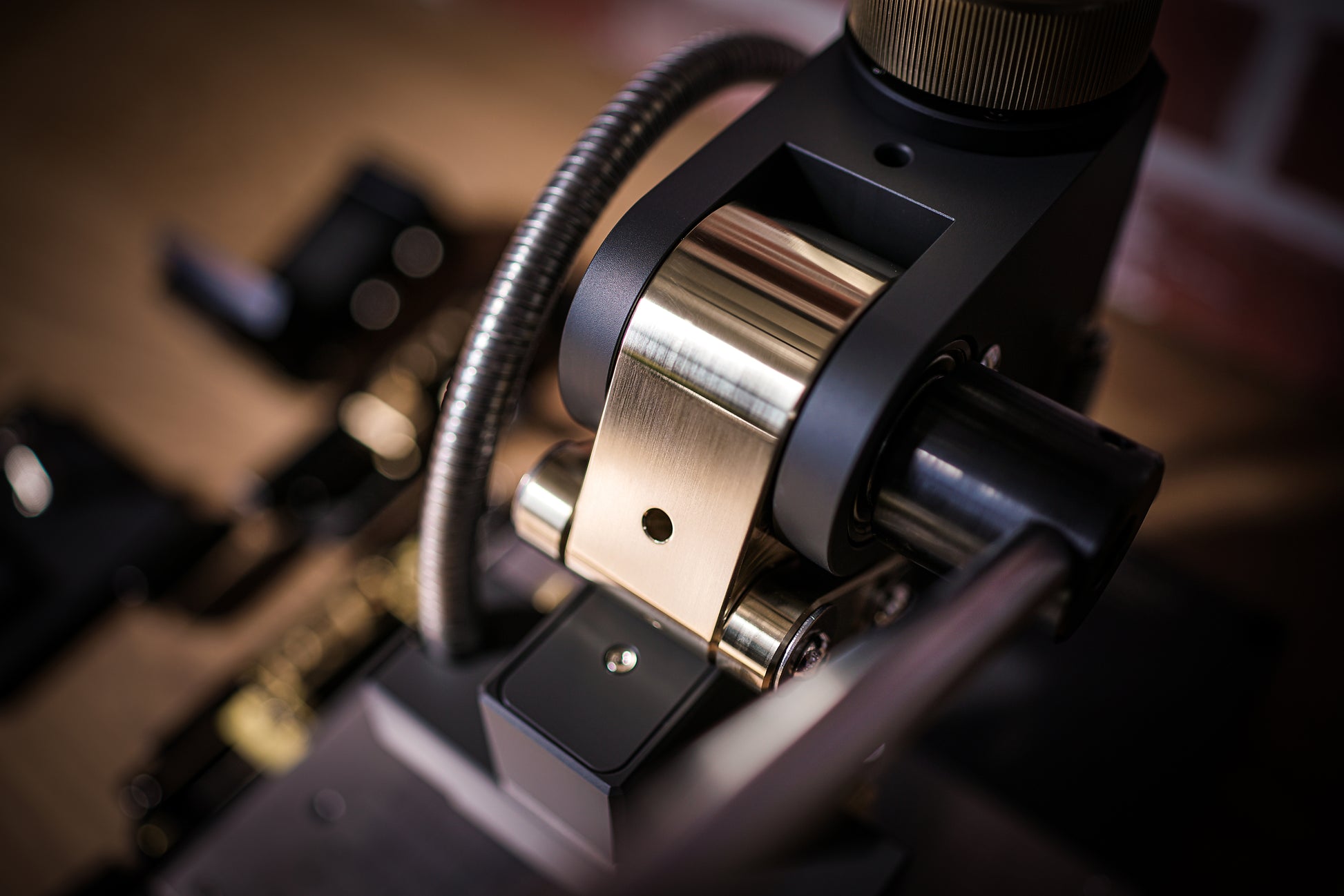

| Hot Stamping Machine | Precision stamping, adjustable height, multiple designs | Branding, custom leather goods, production lines | Pros: High customization, efficient production; Cons: Higher initial investment. |

| Premium Leather Roller | Smooth finish, ergonomic design, multiple sizes available | Edge finishing, surface preparation | Pros: Ensures professional quality; Cons: Requires practice for optimal use. |

| Clicker Press | High-pressure cutting, various die options available | Mass production, intricate designs | Pros: Increases efficiency, reduces manual labor; Cons: Requires space and setup. |

| Stamping Machine | Multiple stamping options, user-friendly interface | Customization of leather goods, branding | Pros: Versatile applications, easy to use; Cons: Limited to specific materials. |

What are the Characteristics of the Adjustable Folding Stitching Pony?

The Adjustable Folding Stitching Pony is designed for artisans who value portability and functionality. Its lightweight construction allows for easy transport, making it ideal for mobile leatherworking or small workshops. The adjustable angles and magnetic needle holder enhance usability, enabling users to stitch with precision. B2B buyers should consider the pony’s suitability for educational institutions or artisans who frequently travel, keeping in mind that while it excels in versatility, it may not provide the same stability as heavier models for larger projects.

Illustrative image related to dream factory leather

How Does the Hot Stamping Machine Enhance Production?

The Hot Stamping Machine is a vital tool for businesses looking to add branding or custom designs to leather goods. Its precision stamping capabilities and adjustable height allow for intricate designs, making it suitable for production lines and custom leatherwork. B2B buyers should evaluate the machine’s capacity for high-volume production against its initial investment cost. While the upfront expense can be significant, the potential for increased customization and efficiency can lead to higher profit margins in the long term.

Why Invest in a Premium Leather Roller for Edge Finishing?

The Premium Leather Roller is essential for achieving a smooth, professional finish on leather edges. Its ergonomic design and availability in various sizes make it adaptable to different project requirements. Businesses focusing on high-quality leather goods should consider this tool for edge finishing and surface preparation. While it ensures a polished result, users may need to practice to master its application effectively, which could be a consideration for buyers looking to train staff in its use.

What Advantages Does a Clicker Press Offer for Mass Production?

A Clicker Press significantly enhances efficiency in mass production environments, allowing for high-pressure cutting of various materials with precision. It is particularly beneficial for businesses producing intricate designs or large quantities of leather products. B2B buyers should assess their production scale and space availability, as the clicker press requires a dedicated setup. Although it streamlines the manufacturing process and reduces manual labor, the investment may be substantial, necessitating careful financial planning.

How Does a Stamping Machine Facilitate Customization?

The Stamping Machine offers versatile applications for customizing leather goods, allowing businesses to imprint logos, designs, or patterns with ease. Its user-friendly interface makes it accessible for both experienced artisans and newcomers. B2B buyers should consider the machine’s limitations regarding specific materials and the types of stamps it can accommodate. While it provides a cost-effective solution for adding unique touches to products, businesses should ensure it aligns with their creative vision and production needs.

Key Industrial Applications of dream factory leather

| Industry/Sector | Specific Application of Dream Factory Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Leather garment production | High-quality tools ensure precision and durability in crafting premium leather goods. | Look for tools that enhance efficiency and minimize waste in production. |

| Footwear | Custom shoe manufacturing | Facilitates intricate designs and custom fittings, enhancing customer satisfaction. | Sourcing should consider the adaptability of tools for various shoe styles. |

| Automotive | Interior leather upholstery | Tools enable high-quality finishes and custom designs, increasing vehicle value. | Ensure tools are compatible with different types of leather and materials. |

| Furniture and Home Décor | Leather furniture crafting | High-quality craftsmanship tools improve product aesthetics and longevity. | Consider sourcing tools that cater to large-scale production needs and customization. |

| Craft and Hobby | DIY leather crafting projects | Provides enthusiasts with professional-grade tools, elevating their craft quality. | Look for versatile tools that cater to various skill levels and project types. |

How is Dream Factory Leather Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, Dream Factory leather tools are essential for producing high-quality leather garments. These tools, such as adjustable stitching ponies and precise cutting machines, allow artisans to create intricate designs and achieve superior finishes. The precision offered by these tools helps reduce material waste, ultimately enhancing production efficiency. For international buyers, particularly in Africa and Europe, sourcing reliable tools that can withstand varying climates and materials is crucial to maintaining consistent quality.

Illustrative image related to dream factory leather

What Role Does Dream Factory Leather Play in Footwear Manufacturing?

Dream Factory leather tools are pivotal in custom shoe manufacturing, where precision and personalization are paramount. Tools like the hot stamping machine and embossing tools enable manufacturers to craft unique designs and ensure perfect fits for customers. This customization not only enhances customer satisfaction but also allows brands to differentiate themselves in a competitive market. Buyers in regions like South America should focus on sourcing tools that are adaptable for different shoe styles, ensuring they can meet diverse consumer preferences.

How Does Dream Factory Leather Enhance Automotive Upholstery?

In the automotive industry, Dream Factory leather tools contribute significantly to the production of high-quality interior upholstery. The tools facilitate the crafting of intricate designs and finishes, which are critical for enhancing the overall value of vehicles. For businesses in the Middle East, where luxury vehicles are prevalent, sourcing tools that ensure precision and durability is vital. Additionally, compatibility with various leather types and finishes should be a key consideration for international buyers.

What Benefits Does Dream Factory Leather Provide in Furniture and Home Décor?

Dream Factory leather tools are invaluable in the crafting of leather furniture and home décor items. These tools enable artisans to achieve exceptional craftsmanship and aesthetic appeal, which are crucial for attracting discerning customers. For businesses in Europe, sourcing tools that support large-scale production while allowing for customization can significantly enhance market competitiveness. Furthermore, durability and ease of use are important factors to consider when selecting tools for this application.

How Can Hobbyists Benefit from Dream Factory Leather Tools?

For craft and hobby enthusiasts, Dream Factory leather tools provide the opportunity to create professional-grade leather projects. Tools designed for ease of use, such as the 5-in-1 leather craft multi-tool, enable hobbyists to elevate their crafting skills and produce high-quality items. International buyers, particularly in emerging markets, should prioritize sourcing versatile tools that cater to various skill levels, ensuring that both beginners and experienced crafters can achieve excellent results.

3 Common User Pain Points for ‘dream factory leather’ & Their Solutions

Scenario 1: Quality Assurance in Bulk Orders for Leather Tools

The Problem: B2B buyers often face challenges when ordering leather tools in bulk from suppliers like Dream Factory Leather. They may encounter inconsistencies in quality, which can lead to production delays and affect the overall craftsmanship of their leather products. The fear of receiving subpar tools can deter businesses from making large purchases, ultimately affecting their bottom line and reputation in the market.

The Solution: To mitigate quality concerns, B2B buyers should establish a clear communication channel with Dream Factory Leather prior to placing bulk orders. This includes discussing specific requirements and requesting samples of tools to assess quality firsthand. It’s also beneficial to ask about quality control processes during manufacturing. Buyers can create a detailed checklist of specifications they require, ensuring that every tool meets their standards. Additionally, establishing a long-term partnership with Dream Factory may provide the opportunity for better insights into their production practices, leading to increased confidence in future orders.

Scenario 2: Navigating Import Regulations and Logistics Challenges

The Problem: International buyers, particularly those from regions like Africa and South America, often struggle with navigating import regulations and logistics when sourcing tools from Dream Factory Leather. Delays due to customs issues, unexpected tariffs, or logistical challenges can disrupt supply chains and impact production schedules. This is particularly concerning for businesses that rely on timely deliveries to meet customer demands.

Illustrative image related to dream factory leather

The Solution: To streamline the import process, buyers should conduct thorough research on the specific import regulations in their country regarding leather tools. Partnering with a local logistics provider who specializes in international shipping can significantly ease the process. Additionally, B2B buyers should inquire with Dream Factory about their experience with shipping to their region and any recommendations they may have for navigating customs. Maintaining flexibility in delivery timelines and having backup suppliers can also help mitigate risks associated with logistics issues.

Scenario 3: Training Staff on New Leather Tools and Techniques

The Problem: When investing in high-quality tools from Dream Factory Leather, B2B buyers may find that their staff lacks the necessary skills or training to use these tools effectively. This can lead to underutilization of the equipment, inefficient production processes, and ultimately, a decrease in product quality. Companies often struggle to find suitable training resources or experienced trainers who understand the specific tools and techniques associated with Dream Factory’s product line.

The Solution: To overcome this training gap, businesses should proactively seek out training resources that focus on Dream Factory tools. This could involve arranging workshops with the manufacturer, either virtually or in-person, to provide hands-on training for staff. Additionally, buyers can leverage online resources, such as video tutorials or webinars specifically designed for Dream Factory tools. Encouraging a culture of continuous learning within the organization will empower employees to experiment with and maximize the use of their new tools. Establishing a mentorship program where experienced staff share their knowledge can also help integrate the new tools into daily operations more effectively.

By addressing these common pain points, B2B buyers can enhance their experience with Dream Factory Leather, ensuring that they not only source high-quality tools but also optimize their operations for greater efficiency and success.

Strategic Material Selection Guide for dream factory leather

When selecting materials for Dream Factory leather products, it is crucial to understand the properties, advantages, and limitations of various materials. This knowledge empowers international B2B buyers to make informed decisions that align with their production needs and market demands.

Illustrative image related to dream factory leather

What Are the Key Properties of Common Leather Materials?

-

Full-Grain Leather

– Key Properties: Full-grain leather is made from the top layer of the hide, retaining the natural grain and imperfections. It is highly breathable and durable, with a temperature tolerance that allows it to withstand various environmental conditions.

– Pros & Cons: The primary advantage of full-grain leather is its exceptional durability and ability to develop a rich patina over time. However, it is also the most expensive type of leather, and its production can be complex, requiring skilled craftsmanship.

– Impact on Application: Full-grain leather is ideal for high-end products such as luxury handbags and furniture, where aesthetics and longevity are paramount.

– Considerations for International Buyers: Buyers from regions like Europe and the Middle East often seek full-grain leather due to its premium quality. Compliance with standards such as the European REACH regulation is essential, ensuring that the leather is free from harmful chemicals. -

Top-Grain Leather

– Key Properties: Top-grain leather is slightly less durable than full-grain but is more affordable. It is sanded and finished, which provides a uniform appearance and enhances its resistance to stains.

– Pros & Cons: The main advantage is its balance between quality and cost, making it suitable for a wide range of products. However, it is less breathable than full-grain leather and may not develop the same character over time.

– Impact on Application: Top-grain leather is commonly used for everyday items such as wallets and belts, where a good appearance and moderate durability are required.

– Considerations for International Buyers: Buyers in Africa and South America may prefer top-grain leather for its cost-effectiveness. Understanding local market preferences and compliance with standards like ASTM is vital for successful transactions. -

Suede

– Key Properties: Suede is made from the underside of the hide, providing a soft texture and a unique aesthetic. It is less durable than full-grain and top-grain leather but offers a luxurious feel.

– Pros & Cons: Suede is favored for its softness and versatility in fashion applications. However, it is more susceptible to stains and damage from moisture, which limits its use in certain environments.

– Impact on Application: Suede is often used in clothing and accessories where a soft touch is desired. Its aesthetic appeal makes it popular in fashion markets.

– Considerations for International Buyers: Buyers from Europe may appreciate suede for its fashion-forward applications. However, they must ensure compliance with specific textile regulations and standards to avoid issues with product quality. -

Bonded Leather

– Key Properties: Bonded leather is made from scraps and fibers that are bonded together with latex or polyurethane. It is less expensive and can mimic the look of genuine leather.

– Pros & Cons: The primary advantage is its affordability and ease of production. However, it lacks the durability and longevity of natural leathers, making it less suitable for high-end applications.

– Impact on Application: Bonded leather is often used in budget-friendly products like notebooks and low-cost furniture.

– Considerations for International Buyers: Buyers in emerging markets may find bonded leather appealing due to its lower price point. However, they should be aware of varying quality standards and consumer perceptions regarding its authenticity.

Summary Table of Material Selection for Dream Factory Leather

| Material | Typical Use Case for dream factory leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags, high-end furniture | Exceptional durability and patina | High cost and complex manufacturing | High |

| Top-Grain Leather | Wallets, belts | Good balance of quality and cost | Less breathable than full-grain | Medium |

| Suede | Fashion clothing, accessories | Soft texture and aesthetic appeal | Susceptible to stains and moisture | Medium |

| Bonded Leather | Notebooks, low-cost furniture | Affordable and easy to produce | Lacks durability and authenticity | Low |

This guide provides a comprehensive overview of the materials relevant to Dream Factory leather products, enabling international B2B buyers to align their selections with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dream factory leather

What Are the Main Stages of the Manufacturing Process for Dream Factory Leather?

The manufacturing process for Dream Factory leather products is meticulously structured to ensure high-quality output. The process can be divided into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with the selection of premium raw materials. Dream Factory sources high-quality leather, often from reputable tanneries known for their sustainable practices. This step includes inspecting the leather for defects, cutting it into appropriate sizes, and preparing it for the next stages. Materials are also treated to enhance durability and resistance to wear and tear, which is vital for B2B buyers seeking longevity in their products.

-

Forming: In this stage, the prepared leather is shaped into the desired form. Techniques such as die-cutting, which utilizes precise clicker presses, are employed to achieve clean and accurate shapes. Dream Factory utilizes advanced machinery alongside traditional handcrafting methods, ensuring a blend of efficiency and artisanal quality. This dual approach allows for both high-volume production and intricate designs, catering to varying buyer needs.

-

Assembly: After forming, the individual components are stitched or glued together. Dream Factory prioritizes the use of strong, reliable adhesives and high-quality stitching techniques to enhance the structural integrity of the products. This stage also includes the attachment of any hardware, such as buckles or zippers, ensuring that every piece meets the functional requirements set by international standards.

-

Finishing: The final stage involves detailing and quality enhancement. This includes edge finishing, polishing, and applying protective coatings to improve aesthetics and durability. Dream Factory pays close attention to this stage, as a well-finished product not only attracts buyers but also signifies the brand’s commitment to quality. Customization options, such as embossing, can also be offered at this stage, allowing B2B buyers to personalize products according to their brand needs.

How Does Quality Assurance Work in Dream Factory Leather Production?

Quality assurance is a cornerstone of Dream Factory’s manufacturing philosophy. The company adheres to several international standards, including ISO 9001, which emphasizes a systematic approach to managing processes and ensuring product quality. This commitment is crucial for B2B buyers who require consistency and reliability in their supply chain.

-

International Standards Compliance: Dream Factory’s adherence to ISO 9001 ensures that their manufacturing processes are regularly reviewed and improved. This certification is recognized globally and assures buyers that the products meet high-quality benchmarks. Additionally, compliance with CE (Conformité Européenne) standards is essential for products sold in Europe, as it indicates conformity with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Throughout the manufacturing process, several critical quality control (QC) checkpoints are established:

– Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet specified standards before they enter the production line.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and identify any deviations from quality standards.

– Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is carried out to ensure that each item meets the required specifications. This includes functional tests and visual inspections. -

Common Testing Methods: Dream Factory employs various testing methods, including tensile strength tests, color fastness tests, and durability assessments. These tests help determine the performance and longevity of leather products, which are critical factors for B2B buyers in industries such as fashion, automotive, and furniture.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is paramount. Here are actionable steps to ensure quality assurance before entering into a business relationship:

-

Conduct Supplier Audits: Buyers should perform regular audits of their suppliers. This involves visiting manufacturing facilities to assess the production processes and quality control systems in place. An on-site inspection allows buyers to gauge the operational standards and commitment to quality firsthand.

-

Request Quality Assurance Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents should detail any testing methods used and the results obtained, giving buyers confidence in the supplier’s commitment to quality.

-

Utilize Third-party Inspection Services: Engaging third-party inspection agencies can provide unbiased assessments of a supplier’s quality control practices. These agencies can conduct independent audits, product inspections, and testing to verify compliance with international standards.

-

Understand Certification Nuances: Different regions may have specific certifications that are relevant to the industry. For instance, buyers from the EU may require CE certification, while those in the Middle East might look for Gulf Conformity Mark (G Mark) compliance. Understanding these nuances can help buyers make informed decisions when selecting suppliers.

What Should B2B Buyers Know About International Quality Control Nuances?

International B2B buyers must navigate a complex landscape of quality control standards and regulations. The following insights can help streamline the procurement process:

-

Variability in Standards: Quality standards can differ significantly between regions. Buyers should familiarize themselves with both local and international regulations that pertain to leather products. This knowledge is essential for ensuring compliance and avoiding potential legal issues.

-

Cultural Differences in Quality Expectations: Different cultures may have varying expectations regarding product quality and craftsmanship. Understanding these differences can aid in effective communication with suppliers and help set realistic quality expectations.

-

Build Strong Relationships: Establishing strong relationships with suppliers can facilitate better quality assurance practices. Open communication channels allow buyers to discuss quality concerns and work collaboratively towards solutions.

-

Leverage Technology for Quality Tracking: Utilizing software solutions for supply chain management can enhance visibility into the quality control processes of suppliers. This technology can track compliance, generate reports, and provide real-time insights, helping buyers make informed decisions.

In conclusion, understanding the manufacturing processes and quality assurance mechanisms of Dream Factory leather products is essential for B2B buyers. By leveraging this knowledge, businesses can make informed purchasing decisions, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dream factory leather’

Introduction

This guide provides a step-by-step checklist for international B2B buyers seeking to procure Dream Factory leather tools and machines. The focus is on ensuring a smooth sourcing process that emphasizes quality, reliability, and suitability for your specific leatherworking needs. With a commitment to high-quality craftsmanship, Dream Factory tools can enhance your leather production capabilities, making this checklist essential for informed purchasing decisions.

Step 1: Identify Your Specific Needs

Begin by clearly defining what tools or machines you require from Dream Factory. Consider the types of leatherwork you intend to undertake—whether it’s crafting, embossing, or stitching. This will help you focus on products that align with your operational objectives.

Illustrative image related to dream factory leather

- Types of Tools: Are you looking for hand tools, stamping machines, or specialty equipment like adjustable stitching ponies?

- Volume Requirements: Understand how many units you may need based on your production scale.

Step 2: Research Supplier Credentials

Before selecting a supplier, conduct thorough research to verify their credentials. This includes checking their experience, reputation, and any industry certifications.

- Company Background: Look for suppliers with a proven history in the leather tooling market.

- Customer Reviews: Seek testimonials and case studies from other businesses that have sourced from them.

Step 3: Evaluate Product Quality

Assess the quality of Dream Factory products by examining materials and craftsmanship. High-quality tools are essential for achieving superior results in leatherwork.

- Material Composition: Ensure the tools are made from durable materials such as high-grade metals and sturdy woods.

- Design Features: Look for innovative designs that enhance usability, such as adjustable components and ergonomic features.

Step 4: Request Samples or Demonstrations

Before finalizing a purchase, ask for product samples or demonstrations. This allows you to evaluate the tools’ performance and suitability for your specific tasks.

- Hands-On Experience: Testing the tools can provide insights into their ease of use and effectiveness.

- Compatibility Checks: Ensure that the tools work seamlessly with your existing processes and materials.

Step 5: Negotiate Pricing and Terms

Engage in negotiations regarding pricing, payment terms, and delivery schedules. Understanding the financial aspects is crucial for maintaining your budget.

- Bulk Discounts: Inquire about pricing structures for larger orders, as many suppliers offer discounts.

- Payment Flexibility: Discuss payment options to find a plan that suits your financial workflow.

Step 6: Verify Shipping and Handling Procedures

Confirm the supplier’s shipping and handling procedures to avoid any delays or complications. Understanding logistics is essential for timely delivery.

Illustrative image related to dream factory leather

- Lead Times: Ask about estimated delivery times based on your location and order size.

- Customs and Duties: Ensure you are aware of any import duties or customs regulations that may apply.

Step 7: Establish Ongoing Communication

Once you have procured the tools, maintain open lines of communication with your supplier. This is important for addressing any future needs or issues that may arise.

- Feedback Loop: Regularly provide feedback on product performance to help the supplier improve their offerings.

- Future Orders: Discuss potential future orders or additional tools that may benefit your operations.

By following this checklist, B2B buyers can strategically navigate the sourcing process for Dream Factory leather tools, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for dream factory leather Sourcing

What Are the Key Cost Components in Dream Factory Leather Sourcing?

Understanding the cost structure of sourcing Dream Factory leather products involves dissecting several core components: materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The quality of leather and other raw materials used significantly impacts the cost. Dream Factory is known for its premium Korean leather, which commands a higher price due to its durability and aesthetic appeal. Buyers should inquire about the specific types of leather available and the associated costs.

-

Labor: Skilled craftsmanship is crucial in leatherworking, and labor costs can vary widely depending on the region. In South Korea, where Dream Factory is based, skilled labor can be more expensive than in other parts of the world. Buyers should consider the labor cost implications when evaluating the pricing of finished goods.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and equipment used in production. Dream Factory’s commitment to innovation and quality means that their manufacturing processes may incur higher overhead costs, which can be reflected in the final pricing.

-

Tooling: Investment in specialized tools and machinery is essential for producing high-quality leather goods. The cost of these tools is amortized over time and can influence pricing. Buyers looking for customized products should be aware that tooling costs can increase if specialized equipment is required.

-

Quality Control (QC): Ensuring that products meet high-quality standards involves rigorous QC processes. This is particularly important for B2B buyers, as defects can lead to costly returns and damage to reputation. Expect to see QC costs integrated into the overall pricing.

-

Logistics: Shipping costs, customs duties, and insurance are crucial factors in the total cost of ownership. For international buyers, understanding the Incoterms (International Commercial Terms) that govern shipping agreements is essential for budgeting accurately.

-

Margin: Suppliers typically add a profit margin to cover their costs and generate revenue. This margin can vary based on competition and market demand.

How Do Price Influencers Affect Sourcing Decisions for Dream Factory Leather?

Several factors influence the pricing of Dream Factory leather products, which can significantly impact sourcing decisions:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to reduced prices per unit. Buyers should assess their needs and negotiate MOQs to optimize cost efficiency.

-

Specifications and Customization: Custom designs or specifications can increase costs. Buyers should weigh the benefits of customization against the additional expenses it incurs.

-

Materials and Quality Certifications: Products made from higher-quality materials or those that have certifications (such as environmental sustainability) may come at a premium. Buyers should consider the long-term value of investing in certified products.

-

Supplier Factors: Relationships with suppliers can influence pricing. Building a strong partnership can lead to better terms, discounts, and priority in production schedules.

-

Incoterms: Understanding Incoterms is critical for international buyers. They determine who is responsible for shipping, insurance, and duties, which can affect overall costs.

What Are Effective Buyer Tips for Negotiating Dream Factory Leather Prices?

B2B buyers should adopt strategic approaches when negotiating prices for Dream Factory leather products:

Illustrative image related to dream factory leather

-

Negotiate Smartly: Leverage your purchasing volume to negotiate better terms. Suppliers may offer discounts for larger orders or long-term commitments.

-

Focus on Cost-Efficiency: Assess the Total Cost of Ownership (TCO), including shipping, customs, and potential tariffs, to understand the true cost beyond the initial price tag.

-

Be Aware of Pricing Nuances: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be cognizant of regional pricing differences due to local economic conditions, tariffs, and import regulations.

-

Request Samples: Before committing to large orders, request samples to evaluate the quality and craftsmanship. This can also serve as a negotiation tool when discussing price.

-

Stay Informed: Keep abreast of market trends and competitor pricing. This knowledge can empower you in negotiations and ensure you are getting a fair deal.

By considering these elements, B2B buyers can make informed decisions that optimize their sourcing strategy for Dream Factory leather products, ensuring quality and cost-efficiency.

Alternatives Analysis: Comparing dream factory leather With Other Solutions

Exploring Alternatives in Leather Crafting Tools and Solutions

When selecting the right tools for leather crafting, it’s essential to consider various alternatives to ensure optimal performance and value. This section provides a comparative analysis of Dream Factory Leather tools against two prominent alternatives: Tandy Leather Tools and Weaver Leather Supply. Each option presents unique features, cost structures, and suitability for different crafting needs, enabling B2B buyers to make informed decisions.

| Comparison Aspect | Dream Factory Leather | Tandy Leather Tools | Weaver Leather Supply |

|---|---|---|---|

| Performance | High precision and durability | Good quality but variable | Consistent quality |

| Cost | Mid to high range, premium | Affordable to mid-range | Mid-range pricing |

| Ease of Implementation | User-friendly, intuitive design | Moderate learning curve | Easy to use |

| Maintenance | Low maintenance required | Moderate, some tools need care | Low maintenance |

| Best Use Case | Professional artisans & hobbyists | Beginners to advanced artisans | Large scale production |

What Are the Advantages and Disadvantages of Tandy Leather Tools?

Tandy Leather Tools offer a wide range of products at varying price points, making them accessible for both beginners and seasoned artisans. The affordability of Tandy’s tools makes them attractive for those starting their leather crafting journey. However, the quality can be inconsistent, as some tools may not perform to the same standards as premium brands. This variability can affect the overall crafting experience, especially for professionals who require reliable tools for detailed work.

How Does Weaver Leather Supply Stand Out?

Weaver Leather Supply is known for its focus on quality and consistency, making it a preferred choice for businesses engaged in large-scale leather production. Their tools are designed for durability and efficiency, which can significantly enhance productivity. However, while Weaver’s products are generally easy to use, they may not offer the same level of innovation and specialized features found in Dream Factory tools. This could be a consideration for artisans looking for advanced crafting capabilities.

In Conclusion: How Should B2B Buyers Choose the Right Leather Tool Solution?

When choosing between Dream Factory Leather and its alternatives, B2B buyers should assess their specific needs and budget constraints. For professionals seeking high-quality, innovative tools that enhance precision and creativity, Dream Factory stands out as a premier option. Conversely, if cost-effectiveness is paramount or if the buyer is catering to beginners, Tandy Leather Tools may be the right fit. For businesses focused on large-scale production with a demand for consistent quality, Weaver Leather Supply offers solid performance. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to select the most suitable leather crafting tools for their operations.

Essential Technical Properties and Trade Terminology for dream factory leather

What Are the Key Technical Properties of Dream Factory Leather Tools?

Understanding the technical properties of Dream Factory leather tools is essential for B2B buyers aiming to make informed purchasing decisions. Here are several critical specifications and their importance in the leatherworking industry:

-

Material Grade

Dream Factory leather tools are primarily made from high-quality materials such as birch plywood and brass. The material grade impacts durability, usability, and the overall quality of the finished product. For B2B buyers, investing in high-grade tools ensures longevity, reducing the need for frequent replacements and maintaining operational efficiency. -

Precision Tolerance

Tools like clicker presses and embossing machines have specific precision tolerances, which dictate how accurately they can perform tasks. High precision tolerances are crucial for tasks requiring intricate detailing, such as embossing or stitching. For businesses, this means the difference between a flawless product and one that may require costly rework. -

Weight and Portability

Many Dream Factory tools are designed to be lightweight and portable, such as the adjustable folding stitching pony. This property is particularly beneficial for artisans who attend trade shows or work in various locations. For B2B buyers, the ability to transport tools easily can enhance productivity and flexibility in operations. -

Adjustability Features

Tools like the adjustable folding stitching pony offer features that allow users to modify settings for different projects. This adaptability is vital for meeting diverse customer needs and improving efficiency. Buyers should consider how adjustable features can streamline workflows and reduce the learning curve for new users. -

Durability Ratings

The durability of leather tools is often rated based on their resistance to wear and tear over time. Tools made with robust materials and superior craftsmanship are essential for maintaining consistent performance in high-demand environments. B2B buyers should prioritize products with high durability ratings to minimize downtime and maximize return on investment.

What Are the Common Trade Terms Used in the Leather Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are several key terms that B2B buyers in the leather sector should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Dream Factory tools, understanding OEM relationships can help buyers source high-quality components that meet their production needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers who must meet specific order thresholds to benefit from wholesale pricing. Knowing the MOQ can help businesses effectively manage inventory and cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. In the leather industry, sending an RFQ allows buyers to gather pricing information and compare offers from different suppliers, enabling better decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help buyers understand shipping responsibilities, insurance, and liability, reducing the risk of misunderstandings and disputes during the procurement process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for B2B buyers as it affects inventory management and project timelines. Businesses should communicate their lead time expectations clearly to ensure timely deliveries. -

Craftsmanship Standards

This term encompasses the quality benchmarks that tools must meet to be considered acceptable in the leather industry. Recognizing craftsmanship standards helps buyers assess product quality and ensure they are investing in tools that will enhance their production capabilities.

Being well-versed in these technical properties and trade terms can empower B2B buyers to make strategic decisions, fostering successful partnerships in the leatherworking industry.

Illustrative image related to dream factory leather

Navigating Market Dynamics and Sourcing Trends in the dream factory leather Sector

What Are the Key Market Drivers and Trends in the Dream Factory Leather Sector?

The global leather market is witnessing significant transformations influenced by various drivers, particularly in the dream factory leather segment. Key trends include the increasing demand for high-quality, innovative leather tools and machinery that streamline production processes for artisans and manufacturers. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Nigeria) seek to enhance their craftsmanship and productivity, the focus has shifted towards sourcing premium-grade tools that improve efficiency and output quality.

Emerging technologies, such as automation in leather crafting and digital platforms for sourcing, are reshaping how businesses operate. Buyers are increasingly leveraging e-commerce platforms to access a diverse range of leatherworking tools, enabling them to compare prices and features easily. Moreover, the trend toward customization is gaining traction, with customers preferring tools that can adapt to specific crafting needs.

Additionally, the growing interest in artisanal products has led to a resurgence in traditional leatherworking techniques, creating a demand for tools that support these practices. Companies like Dream Factory, known for their innovative designs and high-quality materials, are well-positioned to meet these evolving demands, thereby enhancing their appeal to international buyers looking for reliability and excellence in their sourcing decisions.

How Is Sustainability and Ethical Sourcing Shaping the Dream Factory Leather Market?

Sustainability and ethical sourcing are becoming paramount in the leather industry, significantly influencing B2B purchasing decisions. Buyers are increasingly aware of the environmental impacts associated with leather production, prompting a shift towards sustainable practices. Dream factory leather tools are being crafted with a focus on minimizing waste and using environmentally friendly materials.

Ethical supply chains are critical for brands looking to maintain a competitive edge in the market. Companies that prioritize transparency and sustainability in their sourcing are more likely to attract discerning international buyers. Certifications such as Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming essential benchmarks for assessing environmental and ethical practices.

Illustrative image related to dream factory leather

Moreover, the use of sustainable materials and eco-friendly production methods not only enhances brand reputation but also aligns with the growing consumer preference for ethically produced goods. As B2B buyers increasingly seek suppliers who demonstrate a commitment to sustainability, Dream Factory’s dedication to innovation and responsible sourcing positions them favorably in this evolving landscape.

How Has the Dream Factory Leather Sector Evolved Over Time?

Founded in South Korea, Dream Factory has evolved from its humble beginnings into a leading name in the leatherworking tools sector. Established by Mister Lee Ho-Myung, the company initially focused on creating high-quality tools for personal use, eventually expanding to meet the needs of professional artisans and hobbyists worldwide.

The introduction of innovative products, such as the adjustable folding stitching pony, marked a significant turning point for the brand. This tool, designed for versatility and ease of use, quickly gained popularity among leatherworkers, propelling Dream Factory into the international market. As the company continued to innovate, it introduced a range of tools that emphasized user-friendly designs and high performance, catering to both novices and seasoned professionals.

Today, Dream Factory stands as a testament to quality craftsmanship and innovative design in the leather industry, continuously adapting to the changing needs of B2B buyers across diverse global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of dream factory leather

-

1. How do I ensure the quality of Dream Factory leather tools before purchasing?

To ensure the quality of Dream Factory leather tools, consider sourcing samples or visiting trade shows where these products are showcased. Request detailed product specifications, including materials used and manufacturing processes. Additionally, verify the supplier’s reputation by checking reviews and testimonials from other B2B buyers. Establishing a clear communication channel with the supplier can also help address any specific quality concerns you may have, ensuring that the tools meet your standards before placing a larger order. -

2. What factors should I consider when selecting the best leather tools for my business?

When selecting leather tools for your business, evaluate the tool’s functionality, durability, and ergonomic design. Look for tools that cater to your specific crafting needs, such as stitching, cutting, or embossing. Additionally, consider the supplier’s reputation and the availability of customer support for troubleshooting. Comparing pricing and warranty options can also help you find the best value without compromising on quality, ensuring that the tools will enhance your production efficiency. -

3. What are the minimum order quantities (MOQs) for Dream Factory leather products?

Minimum order quantities (MOQs) for Dream Factory leather products can vary by supplier and product type. Typically, MOQs can range from a few units to several dozen depending on the specific tools or machines you wish to purchase. It’s advisable to discuss MOQs directly with your chosen supplier to understand their policies, especially if you’re considering custom orders or bulk purchases. Understanding MOQs can help you manage your inventory effectively and align your orders with market demand. -

4. How can I customize Dream Factory leather tools for my specific needs?

Customization options for Dream Factory leather tools often depend on the supplier’s capabilities. Many suppliers offer personalized branding, such as engraving your company logo on tools, or modifications to design features. To explore customization, contact your supplier directly to discuss your requirements and inquire about the feasibility, lead times, and additional costs associated with custom orders. This approach can enhance your brand visibility and cater to your specific operational needs. -

5. What payment terms are typically offered for international purchases of Dream Factory leather?

Payment terms for international purchases of Dream Factory leather tools can vary widely among suppliers. Common options include upfront payments, partial deposits with the balance due upon shipment, or net payment terms (e.g., net 30 or net 60 days). It is crucial to negotiate favorable terms that align with your cash flow and financial policies. Ensure you also discuss acceptable payment methods, such as wire transfers or letters of credit, to facilitate secure transactions. -

6. How do I handle logistics and shipping for Dream Factory leather tools?

Handling logistics and shipping for Dream Factory leather tools involves coordinating with your supplier to determine the most efficient shipping methods. Consider factors such as shipping times, costs, and customs regulations in your country. Many suppliers can assist with logistics by providing options for air or sea freight, and they may have partnerships with freight forwarders. Ensure that you have a clear understanding of shipping terms, insurance coverage, and any additional fees that may apply to avoid unexpected costs. -

7. What quality assurance processes should I expect from Dream Factory suppliers?

Quality assurance processes from Dream Factory suppliers should include thorough inspection of products before shipment, adherence to international quality standards, and documentation of compliance. Inquire about the specific QA measures they implement, such as testing for durability and precision. A reputable supplier will be transparent about their processes and may provide certifications or reports that validate the quality of their tools. Establishing these expectations upfront can help ensure that you receive products that meet your quality requirements. -

8. How do I vet suppliers of Dream Factory leather tools for reliability?

Vetting suppliers for reliability involves a multi-step approach. Begin by researching their business history, customer reviews, and industry reputation. Look for certifications or affiliations with recognized industry organizations that indicate credibility. Request references from other B2B buyers and assess their experiences with the supplier. Additionally, consider conducting a site visit or arranging virtual meetings to evaluate the supplier’s operations and responsiveness. This thorough vetting process can help you establish a trustworthy partnership.

Top 3 Dream Factory Leather Manufacturers & Suppliers List

1. DreamFactory – Clicker Press

Domain: dreamfactorytools.com

Registered: 2019 (6 years)

Introduction: {“products”:[{“name”:”Clicker press, Hand clicker”,”regular_price”:”$2,399.00 USD”,”sale_price”:”$1,999.00 USD”},{“name”:”Stamping Machine”,”regular_price”:”$1,400.00 USD”,”sale_price”:”From $50.00 USD”},{“name”:”Font Holder”,”regular_price”:”$100.00 USD”,”sale_price”:”$100.00 USD”},{“name”:”Stamp Holder (Standard jaw ver’)”,”regular_price”:”$100.00 USD”,”sale_price”:”$100.00 USD”},{“name”:”Stamp …

2. Dream Factory – Premium Adjustable Folding Stitching Pony

Domain: leatherbox.com

Registered: 2003 (22 years)

Introduction: Dream Factory Leatherwork Tools – Premium Quality at Leatherbox. Key products include: 1. Premium adjustable folding stitching pony – available in 3 sizes, priced from €99.95. 2. Dream Factory 5 in 1 Leather Craft Multi tool – priced at €79.95. 3. Dream Factory Hot Stamping Machine – priced from €1,525.00. 4. Dream Factory Alphabet Letter Sets – priced at €775.00. 5. Premium leather roller – avail…

3. DreamFactory – Stamping Machine

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: DreamFactory Stamping Machine features: 1. Compatibility with pricking irons for quieter operation. 2. Capable of embossing and gold foil stamping. 3. Can be used as a clicker press for wallet templates. 4. Users report good stamping function and consistent results. 5. Stitching chisel attachment has a learning curve but is effective. 6. Smaller clicker press bed requires multiple presses for larg…

Strategic Sourcing Conclusion and Outlook for dream factory leather

In the evolving landscape of leather craftsmanship, strategic sourcing from Dream Factory Leather offers substantial advantages for international B2B buyers. By partnering with a brand recognized for its high-quality, innovative leather tools, businesses can significantly enhance their production capabilities and product offerings. Dream Factory’s commitment to functionality and craftsmanship ensures that every tool, from stitching ponies to stamping machines, is designed to simplify the crafting process while delivering exceptional results.

Illustrative image related to dream factory leather

The value of strategic sourcing lies not only in accessing superior products but also in cultivating long-term relationships with reliable suppliers. This approach can lead to improved pricing, consistent quality, and a competitive edge in the marketplace. As demand for premium leather goods continues to rise, leveraging the expertise and technology of Dream Factory positions businesses to meet this growing need effectively.

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to explore the extensive range of Dream Factory tools. By investing in these premium resources, companies can elevate their craftsmanship and drive innovation in their product lines. Begin your journey towards excellence in leatherwork today by embracing the strategic advantages that Dream Factory Leather offers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to dream factory leather