Introduction: Navigating the Global Market for custom leather printing

In an increasingly competitive global market, sourcing high-quality custom leather printing solutions can be a daunting challenge for international B2B buyers. Whether you are in Nigeria, Germany, Brazil, or the UAE, understanding the intricacies of custom leather printing—ranging from the selection of materials to the nuances of print technology—is crucial for ensuring your products stand out. This guide delves deep into the various types of custom leather printing available, their diverse applications across industries, and essential criteria for vetting suppliers effectively.

Navigating the complexities of cost structures, quality standards, and delivery timelines is vital for making informed purchasing decisions. By exploring topics such as the latest printing technologies, the benefits of vegan leather options, and tips for maximizing your design potential, this comprehensive resource equips you with the insights needed to enhance your procurement strategies.

As the demand for personalized and distinctive leather products continues to rise, leveraging the right information can lead to significant competitive advantages. This guide is tailored for forward-thinking businesses ready to capitalize on the opportunities presented by custom leather printing, ensuring that you remain at the forefront of innovation while meeting the diverse needs of your clientele.

Table Of Contents

- Top 7 Custom Leather Printing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather printing

- Understanding custom leather printing Types and Variations

- Key Industrial Applications of custom leather printing

- 3 Common User Pain Points for ‘custom leather printing’ & Their Solutions

- Strategic Material Selection Guide for custom leather printing

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather printing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather printing’

- Comprehensive Cost and Pricing Analysis for custom leather printing Sourcing

- Alternatives Analysis: Comparing custom leather printing With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather printing

- Navigating Market Dynamics and Sourcing Trends in the custom leather printing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather printing

- Strategic Sourcing Conclusion and Outlook for custom leather printing

- Important Disclaimer & Terms of Use

Understanding custom leather printing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Smooth Nappa Leather | Soft texture, high color accuracy, durable | Fashion apparel, accessories, upholstery | Pros: Luxurious feel, versatile; Cons: Higher cost compared to other leathers. |

| Textured Nappa Leather | Unique surface patterns, retains original leather feel | Bags, shoes, furniture | Pros: Distinctive look, good durability; Cons: May require specific care. |

| Vegan Leather | Made from synthetic materials, eco-friendly options | Sustainable fashion, promotional items | Pros: Animal-friendly, lightweight; Cons: Can lack the authentic feel of real leather. |

| Suede | Soft, velvety texture, typically less durable | Fashion accessories, home décor | Pros: Elegant appearance, good for fashion; Cons: Prone to staining and damage. |

| Pineapple Leather | Made from pineapple leaf fibers, sustainable alternative | Eco-friendly products, fashion items | Pros: Unique texture, sustainable; Cons: Limited availability and higher price point. |

What Are the Characteristics of Smooth Nappa Leather?

Smooth Nappa leather is known for its soft texture and high color accuracy, making it an ideal choice for high-end fashion apparel and accessories. This type of leather is often used in luxury handbags, jackets, and upholstery. When considering a purchase, B2B buyers should assess the potential for customization, as well as the durability and maintenance requirements, given its premium nature and higher cost.

How Does Textured Nappa Leather Differ from Smooth Options?

Textured Nappa leather features unique surface patterns that add visual interest while retaining the original leather feel. This makes it suitable for a variety of applications, including bags and shoes, where a distinctive look is desired. B2B buyers should consider the aesthetic appeal versus the care requirements, as textured leather may need specific cleaning methods to maintain its appearance.

Why Choose Vegan Leather for Your Products?

Vegan leather is made from synthetic materials, providing an eco-friendly alternative to traditional leather. It is increasingly popular in sustainable fashion and promotional items. B2B buyers should weigh the benefits of being animal-friendly and lightweight against the potential drawbacks, such as the lack of authenticity and durability compared to real leather. Understanding the target market’s values can influence purchasing decisions.

What Are the Key Considerations for Using Suede?

Suede is characterized by its soft, velvety texture, often used in fashion accessories and home décor. While it offers an elegant appearance, it is typically less durable than other types of leather and is more susceptible to staining. B2B buyers should consider the application and the likelihood of wear and tear when selecting suede, ensuring that it aligns with the intended use and customer expectations.

Illustrative image related to custom leather printing

How Does Pineapple Leather Serve as a Sustainable Option?

Pineapple leather is made from the fibers of pineapple leaves, making it a sustainable alternative to traditional leather. Its unique texture appeals to eco-conscious consumers, particularly in fashion items. However, B2B buyers should be aware of its limited availability and potentially higher price point. Evaluating the target market’s preferences for sustainability can help determine whether pineapple leather is a viable option for product lines.

Key Industrial Applications of custom leather printing

| Industry/Sector | Specific Application of custom leather printing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather garments like jackets and bags | Differentiation through unique designs and branding | Quality of leather, printing technology, lead times |

| Automotive | Custom interiors for cars | Enhanced aesthetics and personalization options | Durability, fire resistance, and colorfastness |

| Furniture & Home Decor | Upholstery for furniture | Increased product appeal and marketability | Material sourcing, design capabilities, and finish |

| Promotional Products | Customized leather goods for branding | Strengthened brand visibility and customer loyalty | Cost-effectiveness, minimum order quantities, and design flexibility |

| Luxury Goods | High-end accessories like wallets and belts | Exclusivity and premium positioning in the market | Material quality, customization options, and supply chain reliability |

How is Custom Leather Printing Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, custom leather printing is increasingly utilized to create unique garments such as jackets, skirts, and bags. This technique allows designers to incorporate distinctive patterns and logos that reflect their brand identity, providing a competitive edge in a saturated market. Buyers should prioritize high-quality leather and advanced printing technology to ensure the durability and vibrancy of the designs. Additionally, understanding local regulations regarding material sourcing and production standards is crucial for international buyers from regions like Africa and Europe.

What Are the Applications of Custom Leather Printing in the Automotive Sector?

The automotive industry leverages custom leather printing to enhance vehicle interiors, offering personalized designs for seats, dashboards, and door panels. This application not only elevates the aesthetic appeal of cars but also allows manufacturers to cater to customer preferences for luxury and individuality. For B2B buyers, sourcing durable and fire-resistant leather that meets safety standards is essential. Furthermore, understanding the logistical challenges of importing materials into different regions, such as the Middle East, can impact project timelines and costs.

How is Custom Leather Printing Transforming Furniture & Home Decor?

In the furniture and home decor industry, custom leather printing is used for upholstery, enabling brands to offer unique styles that stand out in the marketplace. This application enhances the visual appeal of products like sofas and chairs while allowing for customization that meets consumer demands. Buyers should consider the sourcing of high-quality leather that can withstand wear and tear, as well as the design capabilities of suppliers. For international buyers, ensuring compliance with local regulations and standards in materials is vital.

Why Are Promotional Products Enhanced with Custom Leather Printing?

Custom leather printing finds significant application in the realm of promotional products, where businesses create personalized leather items like keychains, wallets, and tags. This not only bolsters brand visibility but also fosters customer loyalty through unique and thoughtful gifts. Companies should focus on cost-effectiveness, minimum order quantities, and the flexibility of designs when sourcing these products. For buyers in regions such as South America, understanding local market preferences and trends can enhance the effectiveness of promotional campaigns.

Illustrative image related to custom leather printing

What Role Does Custom Leather Printing Play in the Luxury Goods Market?

In the luxury goods sector, custom leather printing is utilized for high-end accessories such as wallets, belts, and handbags. This application allows brands to convey exclusivity and premium quality through bespoke designs that resonate with affluent consumers. Buyers must ensure they source top-grade leather and have access to advanced printing techniques to maintain product quality. Additionally, for international buyers from Europe, establishing reliable supply chains and understanding market trends can significantly influence sales and brand positioning.

3 Common User Pain Points for ‘custom leather printing’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Custom Leather Printing

The Problem: B2B buyers often face challenges in ensuring the quality of custom leather prints. With varying standards across suppliers, it can be difficult to assess if the final product will meet expectations. Concerns about color accuracy, durability, and texture can lead to costly returns or reprints, which not only strain budgets but also disrupt timelines, especially for fashion and accessory brands that depend on timely deliveries.

The Solution: To mitigate these risks, B2B buyers should conduct thorough due diligence when selecting a supplier for custom leather printing. Start by requesting sample swatches to evaluate the material quality and print fidelity firsthand. Establish clear specifications regarding color profiles, finishes, and durability tests—such as rub tests—to ensure the printed leather meets your standards. Additionally, consider suppliers that utilize advanced digital printing technologies, as these often yield higher accuracy and richer colors. Regular communication with the supplier during the production process can also help address any potential issues before they escalate, ensuring that the final product aligns with your expectations.

Illustrative image related to custom leather printing

Scenario 2: Managing Design Complexity for Custom Leather Projects

The Problem: Many B2B buyers struggle with the complexity of translating intricate designs into printed leather. This often leads to frustration when the final print does not accurately represent the original artwork, resulting in mismatched expectations and potential loss of business. Additionally, the lack of expertise in handling file formats and color profiles can further complicate the process, leading to delays and increased costs.

The Solution: To streamline the design process, B2B buyers should invest in understanding the requirements for custom leather printing. Collaborate closely with graphic designers to ensure that artwork is created using the right dimensions, resolution, and color settings suitable for leather printing. Utilizing vector graphics can enhance the clarity of intricate designs. Prior to finalizing the order, it’s beneficial to request a digital proof from the supplier, which provides a mock-up of how the design will appear on the leather. This step allows for adjustments to be made before production begins, ensuring that the final product meets the intended design specifications.

Scenario 3: Addressing Sustainability Concerns in Leather Sourcing

The Problem: As global awareness of sustainability grows, B2B buyers in the custom leather printing sector are increasingly faced with the challenge of sourcing environmentally friendly materials. With the leather industry often criticized for its environmental impact, buyers must balance quality and ethical sourcing, particularly when catering to eco-conscious consumers or industries.

The Solution: To address sustainability concerns, B2B buyers should prioritize suppliers that offer eco-friendly leather options, such as vegan leather or leather sourced from sustainable practices. When selecting a supplier, inquire about their sourcing processes, chemical treatments, and waste management practices. Look for certifications or partnerships with organizations that promote sustainable leather production. Additionally, consider adopting a transparent communication strategy with your customers about the sourcing and production processes of the leather products, which can enhance brand trust and loyalty. By aligning your sourcing practices with sustainability goals, you not only meet consumer demand but also contribute positively to the industry’s environmental impact.

Strategic Material Selection Guide for custom leather printing

What Are the Key Properties of Common Materials for Custom Leather Printing?

When selecting materials for custom leather printing, it is essential to consider their properties, advantages, and disadvantages in relation to product performance and application suitability. Below, we analyze four common materials used in this process: Nappa Leather, Vegan Leather, Suede, and Pineapple Leather.

Illustrative image related to custom leather printing

Nappa Leather: A Classic Choice for Custom Leather Printing

Nappa leather is a full-grain bovine-calf leather known for its softness and durability. It typically has a temperature and pressure rating that allows it to withstand everyday wear and tear, making it suitable for high-end fashion items and accessories.

Pros: Nappa leather offers a luxurious feel and excellent print quality due to its smooth surface, which allows for vibrant colors and detailed designs. It is also highly durable, maintaining its integrity over time.

Cons: The primary drawback is its cost, as Nappa leather tends to be on the higher end of the price spectrum. Additionally, it requires careful maintenance to prevent damage from moisture and stains.

Illustrative image related to custom leather printing

Impact on Application: Nappa leather is ideal for luxury products such as handbags, jackets, and wallets, where aesthetics and durability are paramount.

Considerations for International Buyers: Compliance with local regulations regarding animal products is crucial. For example, buyers in Germany may require adherence to EU regulations on leather sourcing and treatment.

Vegan Leather: An Ethical Alternative

Vegan leather, often made from polyurethane (PU) or other synthetic materials, is a popular choice for brands focusing on sustainability and animal welfare.

Pros: This material is generally more affordable than genuine leather and offers a wide range of colors and textures. It is also easier to clean and maintain, making it suitable for various applications.

Illustrative image related to custom leather printing

Cons: Vegan leather may not offer the same level of durability as natural leather, particularly in high-stress applications. Additionally, some buyers may perceive it as less luxurious.

Impact on Application: Vegan leather is commonly used in fashion accessories, upholstery, and promotional items, appealing to eco-conscious consumers.

Considerations for International Buyers: Buyers in regions like Africa may appreciate the ethical implications of vegan leather, while European buyers might focus on compliance with environmental standards.

Illustrative image related to custom leather printing

Suede: The Soft Touch for Custom Leather Printing

Suede, a type of leather made from the underside of animal hides, is known for its soft texture and unique aesthetic.

Pros: Suede provides a distinctive look and feel, making it an attractive option for fashion items and home décor. It also allows for good ink absorption, resulting in vibrant prints.

Cons: However, suede is less durable than other leather types, particularly when exposed to moisture. It can also be more challenging to clean and maintain.

Illustrative image related to custom leather printing

Impact on Application: Suede is often used for clothing, shoes, and accessories where a soft touch is desired, but it may not be suitable for items requiring high durability.

Considerations for International Buyers: Buyers should be aware of the specific care requirements for suede and ensure compliance with local standards for leather treatment and sourcing.

Pineapple Leather: The Innovative Sustainable Option

Pineapple leather, made from the fibers of pineapple leaves, is an innovative alternative that aligns with sustainable practices.

Pros: This material is biodegradable, lightweight, and offers a unique texture. It is also a conversation starter, appealing to brands looking to differentiate themselves.

Cons: While it is a sustainable option, pineapple leather may not have the same durability as traditional leather, limiting its use in high-wear applications.

Impact on Application: Pineapple leather is suitable for fashion items, accessories, and eco-friendly products, appealing to a niche market.

Considerations for International Buyers: Buyers from South America may find this material particularly relevant due to its regional sourcing, while European buyers may focus on compliance with sustainability certifications.

Illustrative image related to custom leather printing

Summary Table of Material Selection for Custom Leather Printing

| Material | Typical Use Case for Custom Leather Printing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nappa Leather | High-end fashion items and accessories | Luxurious feel and durability | Higher cost and maintenance needs | High |

| Vegan Leather | Fashion accessories and upholstery | Affordable and easy to maintain | Less durable than genuine leather | Medium |

| Suede | Clothing, shoes, and soft accessories | Unique texture and aesthetic | Less durable, difficult to clean | Medium |

| Pineapple Leather | Eco-friendly fashion items and accessories | Biodegradable and lightweight | Limited durability | Medium |

This comprehensive analysis provides international B2B buyers with actionable insights to make informed decisions regarding material selection for custom leather printing, considering both performance and compliance factors relevant to their regions.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather printing

What Are the Key Stages in the Manufacturing Process of Custom Leather Printing?

The manufacturing process for custom leather printing involves several critical stages, each contributing to the final quality of the product. Understanding these stages allows B2B buyers to appreciate the complexity and craftsmanship involved in producing high-quality printed leather goods.

Material Preparation: What Steps Are Involved?

The first step in the manufacturing process is material preparation. This includes selecting the right type of leather based on the intended application—ranging from Nappa leather for clothing to more robust options for accessories. The leather is sourced from reputable tanneries, ensuring that it has been treated and tanned properly to achieve the desired durability and aesthetic qualities.

Once the leather is selected, it undergoes thorough inspection to identify any imperfections. This quality check is crucial, as blemishes or inconsistencies can affect the final print. After this, the leather is cut into manageable sizes, ready for the printing stage.

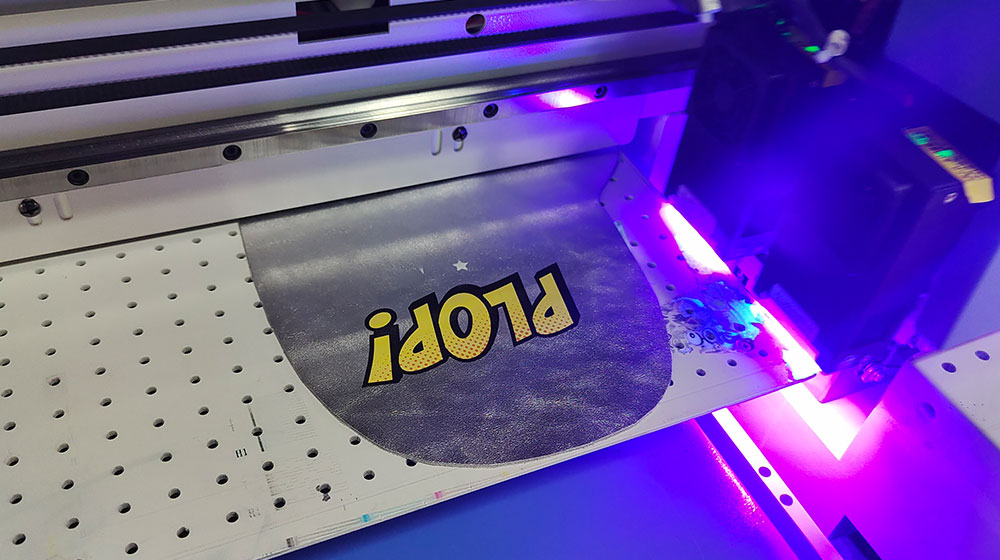

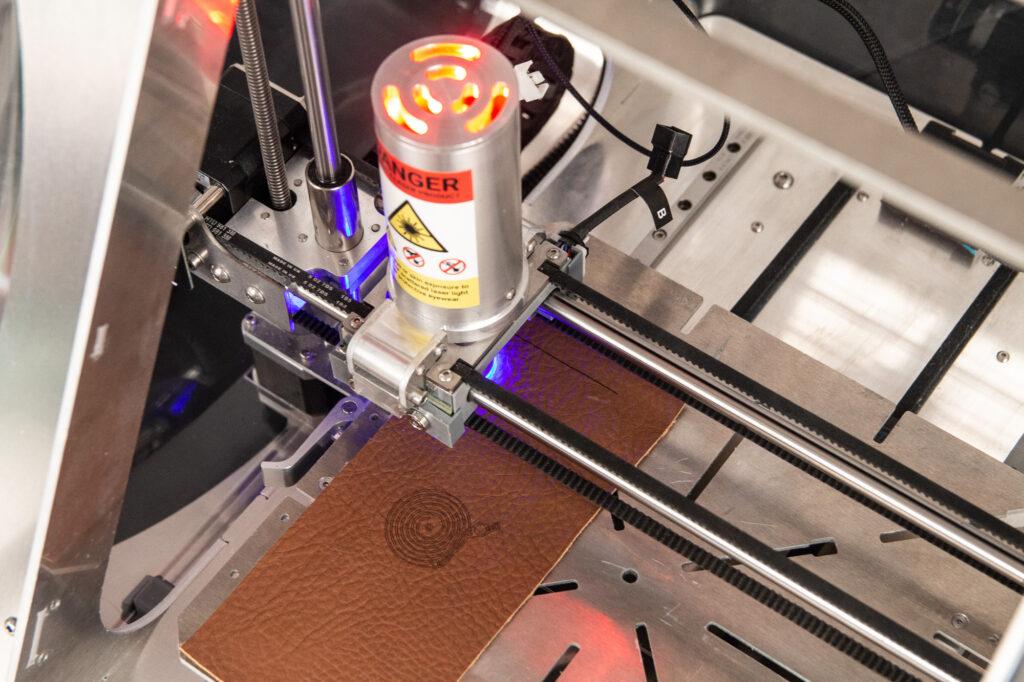

How is the Forming Process Conducted?

After preparation, the forming stage involves the actual printing process. Digital printing technology is typically employed, allowing for precise and vibrant designs to be applied directly onto the leather surface. This method penetrates the leather fibers, ensuring that the ink bonds well, which enhances the durability and colorfastness of the print.

Illustrative image related to custom leather printing

The choice of inks is also critical; high-quality, eco-friendly dyes are preferred as they not only yield exceptional color accuracy but also comply with international safety standards. This is especially important for B2B buyers from regions with strict environmental regulations.

What Happens During Assembly and Finishing?

Following the printing process, the leather pieces are assembled into the final product. This may involve stitching, adding hardware, or other finishing touches that enhance both aesthetics and functionality. Quality assurance checks are integrated at this stage to ensure that all components meet the required specifications.

Finishing processes may include treatments to enhance water resistance or to give the leather a particular texture or sheen. These additional steps can significantly affect the product’s marketability, particularly in regions where climate and usage conditions vary widely.

Illustrative image related to custom leather printing

What Quality Assurance Measures Are Essential for Custom Leather Printing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the final product meets both internal standards and international regulations. For B2B buyers, understanding these measures can help in selecting reliable suppliers.

Which International Standards Apply to Custom Leather Printing?

One of the most widely recognized international quality standards is ISO 9001, which focuses on quality management systems. Suppliers adhering to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction. Additionally, specific industry standards, such as CE marking for safety in the European Union, may also apply, particularly for products intended for consumer markets.

For buyers in regions like Africa and South America, understanding the local regulatory landscape is crucial. Some countries may have their own standards for leather goods, so it’s essential to verify compliance with local laws as well.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that standards are met. These include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements. For leather, this might mean checking for thickness, texture, and color consistency.

-

In-Process Quality Control (IPQC): During the printing and assembly stages, ongoing checks are essential to monitor the process and catch any deviations from quality standards early. This might involve regular sampling of printed items to check for color accuracy and adherence to design specifications.

-

Final Quality Control (FQC): Once the products are completed, a final inspection ensures that they meet all quality requirements before shipment. This includes checking for defects, verifying dimensions, and ensuring that all specifications are met.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers should take proactive steps to ensure that their suppliers maintain robust quality assurance processes. Here are several methods to verify supplier compliance:

What Audit Processes Should Be Implemented?

Conducting regular audits of suppliers is one of the most effective ways to ensure compliance with quality standards. Audits can be performed by the buying company or by a third-party organization specializing in quality assurance. These audits should assess the supplier’s adherence to both internal and international standards.

What Documentation Should Be Requested?

Requesting documentation such as quality assurance reports, certifications, and compliance statements can provide insight into a supplier’s commitment to quality. Look for evidence of compliance with ISO standards, CE marking, and any other relevant certifications.

How Can Third-Party Inspections Help?

Engaging third-party inspection services can further validate a supplier’s quality claims. These independent organizations can conduct thorough inspections and testing, providing an unbiased assessment of product quality before shipment.

Illustrative image related to custom leather printing

What Nuances Should International Buyers Consider?

For international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, several nuances should be considered:

-

Cultural Differences: Understanding cultural norms and expectations in different regions can help in negotiating quality standards. For example, buyers from Germany may have different expectations regarding quality documentation than those from Nigeria.

-

Logistical Challenges: Shipping and customs regulations can affect product quality upon arrival. Ensuring that suppliers are familiar with international shipping standards can mitigate risks associated with damage during transport.

-

Market Variability: Different markets may have varying demands for leather quality and types. Suppliers should be able to adapt to these demands while maintaining consistent quality.

By taking these aspects into account, B2B buyers can make informed decisions when selecting suppliers for custom leather printing, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather printing’

In the competitive world of custom leather printing, sourcing the right supplier is crucial for ensuring high-quality products that meet your specific needs. This checklist serves as a comprehensive guide for B2B buyers looking to procure custom leather printing services, helping you navigate the complexities of the process with confidence.

1. Identify Your Project Requirements

Begin by clearly defining your project’s specifications, including the type of leather, design complexity, and intended use. This step is vital as it will guide your supplier search and ensure that you find a partner capable of meeting your unique demands. Consider factors such as:

– Leather Type: Determine whether you need genuine leather, vegan options, or specialty leathers like suede.

– Design Elements: Consider the intricacy of your designs, color requirements, and any specific finishing techniques needed.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in custom leather printing. Look for companies with a strong online presence and positive reviews from previous clients. This step is essential to establish a shortlist of reputable suppliers. Focus on:

– Experience: Suppliers with years of experience in the industry are more likely to understand your needs and deliver quality.

– Portfolio: Review their past work to gauge their ability to handle projects similar to yours.

3. Evaluate Supplier Capabilities

Once you have a shortlist, assess each supplier’s capabilities to ensure they can meet your project requirements. This evaluation should include their printing technology, leather sourcing practices, and production capacity. Key points to consider:

– Technology: Ensure they use modern digital printing techniques that provide vibrant, durable prints.

– Sustainability Practices: Check if they source leather ethically and offer eco-friendly options, which can be a selling point for your customers.

4. Request Samples

Before making a final decision, request samples of printed leather to evaluate the quality of their work firsthand. This step is critical as it allows you to assess the texture, print accuracy, and overall finish. When requesting samples, keep in mind:

– Variety: Ask for samples from different types of leather to understand how various materials interact with their printing processes.

– Test Durability: Check how the samples perform under stress, such as bending or abrasion, to ensure they will withstand the intended use.

5. Verify Certifications and Compliance

Ensure that potential suppliers comply with industry standards and regulations. This verification is crucial to avoid legal issues and ensure product quality. Consider looking for:

– Quality Certifications: Such as ISO or other relevant quality management systems.

– Environmental Compliance: Certifications like OEKO-TEX or GOTS for eco-friendly practices.

6. Discuss Pricing and Terms

Engage in discussions regarding pricing, minimum order quantities, and payment terms. This step is important to align expectations and ensure you stay within budget. When negotiating, consider:

– Cost Transparency: Ensure there are no hidden fees that could affect your overall expenditure.

– Flexibility in Orders: Check if they can accommodate varying order sizes, especially if you anticipate changes in demand.

7. Establish a Communication Plan

Finally, set up a clear communication plan with your chosen supplier. Effective communication is key to a successful partnership, especially when dealing with design revisions or production timelines. Ensure that:

– Contact Points: Identify key contacts for both parties to streamline communication.

– Regular Updates: Agree on a schedule for updates throughout the production process to keep everything on track.

Illustrative image related to custom leather printing

By following this checklist, B2B buyers can confidently navigate the sourcing process for custom leather printing, ensuring they select the right supplier to meet their specific needs and achieve successful project outcomes.

Comprehensive Cost and Pricing Analysis for custom leather printing Sourcing

What Are the Key Cost Components in Custom Leather Printing?

When sourcing custom leather printing, understanding the cost structure is essential for B2B buyers. The primary components include:

-

Materials: The choice of leather significantly impacts costs. High-quality materials such as Nappa or full-grain leather are more expensive but offer superior durability and aesthetic appeal. Vegan options may also be available, often at a different price point.

-

Labor: Skilled labor is required for printing and finishing processes. The complexity of the design and the expertise of the workforce will affect labor costs. Regions with higher labor costs, such as Western Europe, may yield higher overall prices compared to emerging markets.

-

Manufacturing Overhead: This includes operational costs such as utilities, equipment maintenance, and facility expenses. Efficient manufacturing practices can help keep these costs in check.

-

Tooling: If custom tooling or specific equipment is needed for unique designs, this will incur additional costs. Buyers should inquire about any tooling fees upfront.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the final product meets standards. However, this adds to the overall cost. Buyers should assess the quality assurance measures in place to gauge if they justify the pricing.

-

Logistics: Shipping costs can vary widely based on the destination, the size of the order, and the chosen shipping method. Understanding Incoterms is crucial, as they define the responsibilities of buyers and sellers regarding shipping costs and risks.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, competition, and the uniqueness of the offering.

How Do Pricing Influencers Affect Custom Leather Printing Costs?

Several factors influence pricing in the custom leather printing landscape:

-

Volume/MOQ (Minimum Order Quantity): Generally, larger orders lead to lower per-unit costs. Suppliers often offer tiered pricing based on volume, making it essential for buyers to assess their needs.

-

Specifications and Customization: Highly customized designs require more intricate printing techniques, which can drive up costs. Buyers should consider the balance between customization and budget.

-

Material Quality and Certifications: Premium materials with certifications (like eco-friendly or sustainable sourcing) often come at a higher price but can provide added value in terms of marketability.

-

Supplier Factors: The reputation, location, and capacity of the supplier play significant roles in pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: The choice of shipping terms (such as FOB, CIF, etc.) will affect the total landed cost. Buyers should negotiate terms that minimize their exposure to unexpected costs.

What Tips Can Help Buyers Optimize Costs in Custom Leather Printing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

Illustrative image related to custom leather printing

-

Negotiate Effectively: Build relationships with suppliers to negotiate better terms. Understanding their cost structure can provide leverage during discussions.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term value of the product, including durability and maintenance. A higher initial investment may lead to lower costs over time.

-

Research Pricing Nuances: Different regions may have varying pricing strategies. For example, buyers in Germany may face different logistics costs compared to those in Nigeria due to regional supply chains.

-

Request Samples: Before placing large orders, request samples to assess quality and ensure it meets expectations. This can prevent costly mistakes later.

-

Stay Informed About Market Trends: Keep an eye on global leather prices and trends. Fluctuations in supply and demand can impact costs, and being informed can help in timing purchases more strategically.

Conclusion

Understanding the comprehensive cost structure and pricing influencers in custom leather printing is vital for B2B buyers. By leveraging these insights and strategies, businesses can make informed decisions that align with their budget and quality requirements. Always consider reaching out to multiple suppliers to compare offerings and ensure competitive pricing. Note that prices mentioned in this guide are indicative and may vary based on specific project requirements and supplier negotiations.

Alternatives Analysis: Comparing custom leather printing With Other Solutions

In the realm of custom leather solutions, businesses often seek alternatives that can meet specific needs while balancing quality, cost, and ease of use. Custom leather printing offers unique advantages, but it’s essential to consider other methods available in the market. Below, we compare custom leather printing with two viable alternatives: embossed leather and synthetic leather manufacturing. This analysis aims to guide international B2B buyers from regions like Africa, South America, the Middle East, and Europe in making informed decisions.

| Comparison Aspect | Custom Leather Printing | Embossed Leather | Synthetic Leather Manufacturing |

|---|---|---|---|

| Performance | High color accuracy and detail; durable | Good texture but limited design options | Varies widely; can mimic real leather but lacks authenticity |

| Cost | Moderate to high, depending on material | Generally lower than printing | Typically the lowest cost option |

| Ease of Implementation | Requires specialized equipment and skills | Easier and faster to implement | Simple manufacturing process |

| Maintenance | Requires care to maintain appearance | Durable and low maintenance | Easy to clean, but may wear over time |

| Best Use Case | Custom fashion items, accessories | High-end products needing texture | Mass production of affordable goods |

What are the pros and cons of embossed leather as an alternative?

Embossed leather involves creating a raised design on the surface of the leather, enhancing its aesthetic appeal. This method is particularly effective for products where texture adds value, such as luxury handbags and wallets. The primary advantage of embossed leather is its cost-effectiveness compared to custom printing, allowing manufacturers to produce visually appealing products without the need for specialized printing equipment. However, embossed leather may lack the intricate detail and color vibrancy that custom leather printing can provide, making it less suitable for designs requiring high levels of customization.

How does synthetic leather manufacturing compare?

Synthetic leather, or faux leather, is made from plastic materials that mimic the look and feel of real leather. This alternative is often the most cost-effective option, making it attractive for businesses aiming for affordability in mass production. Synthetic leather can be produced in various colors and patterns without the constraints of natural leather. However, it generally lacks the durability and luxurious feel of genuine leather, which can affect its appeal in high-end markets. Furthermore, synthetic options may not offer the same environmental benefits as responsibly sourced natural leather.

How can B2B buyers choose the right solution for their specific needs?

When selecting a leather solution, B2B buyers should evaluate their specific project requirements, including design complexity, budget constraints, and target market preferences. For businesses focused on high-end, custom products, investing in custom leather printing may yield the best results, offering unique designs and quality that resonate with customers. Conversely, if cost is a significant factor and the products are intended for mass-market consumption, embossed or synthetic leather could be more appropriate. Ultimately, aligning the choice with brand values, customer expectations, and production capabilities will lead to the most effective outcomes in the competitive B2B landscape.

Illustrative image related to custom leather printing

Essential Technical Properties and Trade Terminology for custom leather printing

What Are the Key Technical Properties in Custom Leather Printing?

In the realm of custom leather printing, understanding the technical properties of the materials involved is crucial for B2B buyers. Here are some essential specifications to consider:

-

Material Grade

Material grade refers to the quality of leather used in printing. Common grades include full-grain, top-grain, and corrected grain. Full-grain leather is considered the highest quality due to its natural texture and durability. Understanding material grade is vital for businesses aiming to maintain brand reputation and customer satisfaction, as higher grades typically result in longer-lasting products. -

Ink Penetration

This property describes how deeply the printing ink penetrates the leather fibers. A deeper penetration generally results in more vibrant and durable prints, as it reduces the likelihood of wear and fading over time. For B2B buyers, ensuring that their printing partner uses advanced digital printing technology that allows for optimal ink penetration can enhance product quality and longevity. -

Rub Resistance

Rub resistance indicates how well the printed surface can withstand abrasion and wear. This property is particularly important for products that will be frequently handled, such as handbags or apparel. A high rub resistance rating ensures that the printed designs remain intact, which is crucial for maintaining the aesthetic appeal of the product over time. -

Flexibility and Handle

Flexibility refers to how well the leather can bend and conform without cracking or losing its integrity. A good handle ensures that the leather feels pleasant to the touch and maintains its shape. For B2B buyers, selecting a leather that balances durability with flexibility is essential, especially for fashion and accessory applications. -

Environmental Compliance

With increasing scrutiny on sustainable practices, it’s vital to consider whether the leather and printing processes comply with environmental regulations. Eco-friendly options, such as vegan leather or low-VOC inks, can appeal to socially responsible brands. This compliance not only protects the environment but can also enhance brand image and marketability. -

Finish and Texture

The finish refers to the surface treatment applied to the leather, which can affect both appearance and performance. Common finishes include matte, glossy, and textured. Understanding the desired finish helps businesses align their product offerings with customer preferences, ensuring that the final product meets market demands.

What Are Common Trade Terms in Custom Leather Printing?

Navigating the world of custom leather printing also involves familiarizing oneself with industry jargon. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In custom leather printing, an OEM might be a leather manufacturer that produces materials for brands looking to create bespoke products. Understanding OEM relationships can help buyers identify reliable suppliers for their manufacturing needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to produce or sell. This term is crucial for B2B buyers as it directly affects inventory costs and production planning. Knowing the MOQ helps companies manage budgets and assess the feasibility of new product lines. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process helps buyers gather pricing information and compare suppliers. An effective RFQ can streamline procurement and ensure that companies get the best value for their investments. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. They clarify aspects such as shipping costs, insurance, and risk management. Understanding Incoterms is essential for B2B buyers involved in cross-border transactions, as it helps mitigate potential disputes. -

Lead Time

Lead time refers to the amount of time required from placing an order to receiving the finished product. In the custom leather printing industry, lead times can vary significantly based on factors like material availability and production capacity. Being aware of lead times enables buyers to plan effectively and manage customer expectations. -

Customization Options

This term encompasses the range of choices available for personalizing leather products, including print design, color, and texture. Understanding customization options allows businesses to tailor their offerings to specific market needs, enhancing customer satisfaction and competitive advantage.

In summary, being well-versed in both the technical properties of custom leather printing and the relevant trade terminology can significantly enhance decision-making for B2B buyers. This knowledge not only aids in product quality assessments but also facilitates smoother transactions and partnerships within the industry.

Navigating Market Dynamics and Sourcing Trends in the custom leather printing Sector

What are the Current Market Trends in Custom Leather Printing?

The custom leather printing sector is experiencing significant growth driven by several global factors. An increase in demand for personalized and unique products is reshaping consumer preferences, particularly in markets such as Africa, South America, the Middle East, and Europe. Countries like Nigeria and Germany are witnessing a surge in bespoke leather goods, as businesses and consumers alike seek distinctive branding and unique fashion statements. Digital printing technology has emerged as a game-changer, allowing for intricate designs and vibrant colors that were previously unattainable with traditional methods. This technology not only enhances product offerings but also reduces lead times, making it easier for businesses to respond to market demands swiftly.

Illustrative image related to custom leather printing

Emerging trends include the rise of e-commerce platforms dedicated to custom leather products, which facilitate direct-to-consumer sales and broaden market access for international B2B buyers. Furthermore, an increasing number of suppliers are adopting automation and AI-driven solutions to streamline production processes, which enhances efficiency and lowers operational costs. As businesses look to differentiate themselves, leveraging these technological advancements will be crucial for staying competitive in the evolving market landscape.

How Does Sustainability Influence Sourcing in Custom Leather Printing?

Sustainability has become a pivotal concern for international B2B buyers in the custom leather printing sector. The environmental impact of leather production—often criticized for its carbon footprint and water usage—has prompted businesses to seek ethical sourcing alternatives. This shift is especially pronounced in regions like Europe, where consumers are increasingly aware of the ecological implications of their purchases.

To address these concerns, suppliers are now offering eco-friendly leather options, including vegetable-tanned leather and synthetic alternatives like vegan leather, which appeal to environmentally conscious buyers. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming important benchmarks for ethical sourcing, enabling buyers to identify suppliers committed to sustainable practices. By prioritizing suppliers with these certifications, businesses can build trust with their customers and enhance their brand image, ultimately leading to increased market share in a competitive landscape.

What is the Historical Context of Custom Leather Printing?

The history of leather printing dates back centuries, originating from the need to enhance the natural beauty of leather hides for various applications. Traditionally, leather was dyed and embossed using rudimentary techniques, which limited design possibilities. However, the advent of digital printing technology in the late 20th century revolutionized the industry. This innovation allowed for detailed imagery and complex patterns to be printed directly onto leather, significantly expanding creative possibilities for manufacturers and designers.

Today, custom leather printing has evolved into a sophisticated sector within the fashion and home décor industries, characterized by high-quality finishes and rapid production capabilities. This evolution reflects broader trends in consumerism, where personalization and quality are paramount, particularly for B2B buyers looking to cater to discerning end consumers. The fusion of craftsmanship with modern technology positions custom leather printing as a vital component in the global marketplace, appealing to diverse industries from fashion to automotive.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather printing

1. How do I ensure the quality of custom leather prints?

To ensure high-quality custom leather prints, it’s essential to select a reputable supplier who uses advanced digital printing technology. Request samples of their printed leather to assess color accuracy, texture, and durability. Additionally, inquire about their quality assurance processes, including rub tests and material sourcing. Establishing clear communication regarding your design specifications and expectations can also help ensure that the final product meets your quality standards.

2. What types of leather can be used for custom printing?

Various types of leather are suitable for custom printing, including Nappa leather, which is known for its softness and smooth finish, and textured or bubble Nappa for added character. Vegan leather options are also available, providing a sustainable alternative. When selecting leather, consider the intended application—whether for fashion items, accessories, or upholstery—as different leathers offer unique properties that affect both appearance and durability.

3. What is the minimum order quantity (MOQ) for custom leather printing?

Minimum order quantities can vary significantly between suppliers. Typically, MOQs for custom leather printing range from 10 to 50 units, depending on the complexity of the design and the type of leather used. It’s advisable to discuss your specific needs with the supplier to determine their MOQ and explore options for small batch orders if necessary, especially for startups or projects with limited budgets.

4. How can I customize my leather print design?

Customizing your leather print design involves uploading your artwork or design files to the supplier’s design interface. Ensure that your designs are high-resolution for optimal print quality. Most suppliers offer templates or guidelines to help you format your designs correctly. Additionally, you can choose from various leather types, colors, and finishes to enhance your custom leather product’s uniqueness and appeal.

Illustrative image related to custom leather printing

5. What payment terms should I expect when ordering custom leather prints?

Payment terms for custom leather printing can vary by supplier and may include options such as upfront payment, partial payment upon order confirmation, and balance upon delivery. It’s important to clarify payment methods accepted, including wire transfers, credit cards, or trade financing options. Discussing payment terms early in the negotiation process can help avoid misunderstandings and ensure a smooth transaction.

6. How do I vet potential suppliers for custom leather printing?

Vetting suppliers for custom leather printing involves researching their reputation, industry experience, and customer reviews. Request references from previous clients and inquire about their production capabilities and lead times. It’s also beneficial to ask for samples of their work and check their compliance with international trade regulations. Establishing direct communication can provide insights into their responsiveness and customer service quality.

7. What logistics considerations should I keep in mind for international shipping?

When arranging international shipping for custom leather prints, consider factors such as shipping costs, delivery times, and customs regulations in your destination country. Collaborate with your supplier to understand their shipping policies and any associated fees. Ensure that the supplier is experienced in handling international logistics and can provide tracking information. It’s advisable to work with a freight forwarder who can navigate customs clearance and ensure timely delivery.

8. How can I address issues with my custom leather order?

If issues arise with your custom leather order, such as defects or discrepancies in design, promptly contact your supplier to discuss your concerns. Most reputable suppliers have a return or exchange policy in place. Document the issues with photos and provide clear feedback to facilitate resolution. Maintaining open communication can help resolve problems efficiently and uphold a positive working relationship.

Top 7 Custom Leather Printing Manufacturers & Suppliers List

1. Contrado – Custom Printed Leather

Domain: contrado.com

Registered: 2004 (21 years)

Introduction: Printed Leather allows you to create custom leather prints using your artwork or designs. Options include Smooth Nappa Leather, Textured Nappa Leather, Bubble Nappa Leather, Vegan Leather, Furnishing Leatherette, and Suede. The printing method uses specific dyes that penetrate deep into the fibers of the leather, ensuring strong and rich colors. The leather has a white base color for exceptional c…

2. GVT Fast – Custom Printed Leather

Domain: gvtfast.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Custom Printed Leather”, “price_range”: “€100,00 – €190,00”, “VAT”: “22% not included”, “leather_types”: [{“type”: “Whole white chrome-tanned calfskin”, “thickness”: “1.4-1.6 mm”}, {“type”: “Half calf vegetable tanned”, “thickness”: “2.0-2.2 mm”}], “printing_options”: [{“size”: “60×60 cm panel”}, {“size”: “Allover”}], “suggested_use”: [“Leathergoods”, “Small leathergoods”], “tann…

3. Leathergenix – Custom Leather Printing

Domain: leathergenix.com

Registered: 2009 (16 years)

Introduction: Leathergenix specializes in custom leather printing, offering high-end luxury leather products. They can print any image on leather for various applications including jackets, handbags, shoes, and aviation seat interiors. Their services extend to interior design with custom printed leather for hospitality environments, furniture, automotive interiors, and private jets. They also provide lifestyle …

4. Rainbow Leather – Custom Foiling & Printing Solutions

Domain: rainbowleather.com

Registered: 1999 (26 years)

Introduction: Foiling: Special effect for standout designs. Digital Printing: Customizable colors and effects. Embossing: Custom plates or extensive library options. Cutting: Custom plates or extensive library options. Perforation: Custom plates or extensive library options. Monogramming: Custom gold, silver, and blind embossed options. Cork Catalog: Customizable natural cork sheets. Cow Suede Catalog: Availabl…

5. QinPrinting – Eco-Friendly Leather-Bound Book Printing

Domain: qinprinting.com

Registered: 2017 (8 years)

Introduction: QinPrinting offers leather-bound book printing services with eco-friendly imitation leather that is cruelty-free. Custom options include foil-stamped or debossed text, patterns, and logos. Suitable for memoirs, notebooks, yearbooks, and other premium book types. Minimum order quantity is 100 pieces. Custom and standard sizes available (width: 3.74″-12.6″, height: 3.74″-16.5″). Binding options incl…

6. Beautiful Displays – Custom Patent Leather Printing Services

Domain: beautifuldisplays.com

Registered: 2002 (23 years)

Introduction: Patent Leather Printing Services | Custom Printed Leather

1. Easy Ordering Process:

– Step 1: Find & Purchase – Browse and purchase online or call 800.697.4670 for assistance.

– Step 2: Art & Approval – Upload print-ready files or work with the design team. Electronic proof sent within one business day.

– Step 3: Relax! – After proof approval, production begins and tracking information i…

7. Pip Supply – Custom Printed Faux Leather Sheets

Domain: pipsupply.com

Registered: 2018 (7 years)

Introduction: Custom Printed Faux Leather Sheets – CPSIA compliant faux leather – Free Domestic Shipping for orders $75 and up – Current Processing Time: 4-8 Business Days

Strategic Sourcing Conclusion and Outlook for custom leather printing

How Can Strategic Sourcing Enhance Your Custom Leather Printing Experience?

In conclusion, strategic sourcing is pivotal for businesses seeking to leverage custom leather printing effectively. By understanding the diverse range of materials—such as smooth Nappa, vegan leather, and suede—buyers can select the best options that align with their product goals and market demands. Additionally, leveraging advanced digital printing technology ensures vibrant, durable designs, enhancing product appeal and longevity.

Illustrative image related to custom leather printing

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable suppliers who offer high-quality leather and reliable service. This not only improves product quality but also fosters innovation in design, catering to unique regional tastes and preferences.

As the market for custom leather products continues to evolve, staying informed about trends and advancements in printing technology will be crucial. Embrace the opportunity to customize and differentiate your offerings in a competitive landscape. Connect with suppliers who can support your vision, and take the next step towards transforming your ideas into exceptional leather products that resonate with your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom leather printing

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.