Introduction: Navigating the Global Market for custom leather holster makers list

In the competitive landscape of custom leather holster makers, international B2B buyers face the challenge of sourcing high-quality, durable products that meet specific needs and preferences. This comprehensive guide serves as a vital resource for businesses looking to connect with reputable suppliers of custom leather holsters. From understanding the different types of holsters available to exploring their various applications, this guide covers essential aspects that influence purchasing decisions.

Buyers will gain insights into the vetting process for suppliers, ensuring they partner with manufacturers known for their craftsmanship and reliability. Additionally, we delve into cost considerations, providing a clear picture of pricing structures across different markets, including Africa, South America, the Middle East, and Europe, with a particular focus on countries like Brazil and Germany.

By equipping buyers with actionable knowledge, this guide empowers them to make informed decisions that enhance their product offerings and meet the evolving demands of their customers. Whether you’re a retailer seeking to expand your inventory or a distributor aiming to establish long-term relationships with holster makers, understanding the global market landscape is crucial for success in this niche industry.

Table Of Contents

- Top 6 Custom Leather Holster Makers List Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather holster makers list

- Understanding custom leather holster makers list Types and Variations

- Key Industrial Applications of custom leather holster makers list

- 3 Common User Pain Points for ‘custom leather holster makers list’ & Their Solutions

- Strategic Material Selection Guide for custom leather holster makers list

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather holster makers list

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather holster makers list’

- Comprehensive Cost and Pricing Analysis for custom leather holster makers list Sourcing

- Alternatives Analysis: Comparing custom leather holster makers list With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather holster makers list

- Navigating Market Dynamics and Sourcing Trends in the custom leather holster makers list Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather holster makers list

- Strategic Sourcing Conclusion and Outlook for custom leather holster makers list

- Important Disclaimer & Terms of Use

Understanding custom leather holster makers list Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OWB (Outside the Waistband) | Sits outside the waistband, provides quick access, available in various styles | Law enforcement, military, competitive shooting | Pros: Quick draw, customizable designs; Cons: May be less concealable for everyday carry. |

| IWB (Inside the Waistband) | Designed to be worn inside the waistband, offers concealment | Personal defense, concealed carry markets | Pros: Enhanced concealment, comfortable for long wear; Cons: Limited access compared to OWB. |

| Shoulder Holsters | Worn over the shoulder, distributes weight evenly | Law enforcement, tactical operations | Pros: Comfortable for extended wear, good for concealment; Cons: Can be bulky, may require a jacket for concealment. |

| Chest Holsters | Positioned on the chest, often used for outdoor activities | Hunting, hiking, tactical applications | Pros: Excellent for carrying larger firearms, easy access; Cons: Limited to specific use cases, may not suit all body types. |

| Specialty Holsters | Includes custom designs for specific firearms or unique uses | Collectors, specialized law enforcement | Pros: Tailored solutions, can enhance firearm functionality; Cons: Typically higher cost, longer lead times for production. |

What are the Characteristics of OWB (Outside the Waistband) Holsters?

OWB holsters are designed to sit outside the waistband, allowing for rapid firearm access. They come in various styles, including pancake, drop leg, and more, catering to different preferences and needs. B2B buyers in law enforcement and military sectors often prefer these holsters for their quick-draw capabilities and customizable options. However, they may not be ideal for everyday concealed carry due to their visibility.

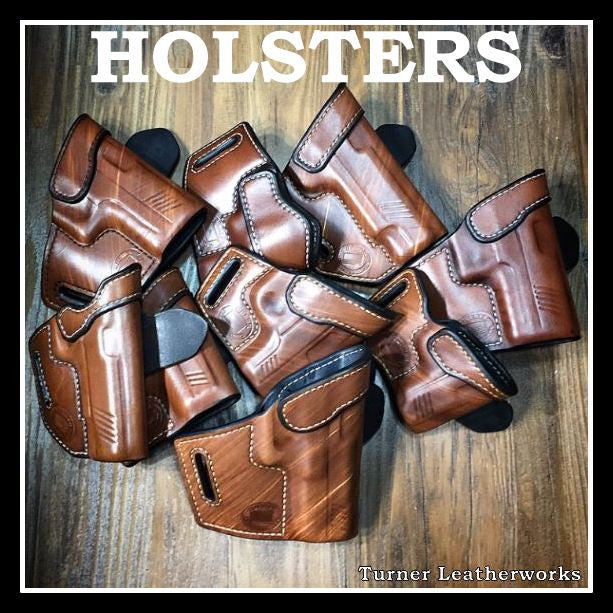

Illustrative image related to custom leather holster makers list

Why Choose IWB (Inside the Waistband) Holsters for Concealed Carry?

IWB holsters are made to fit inside the waistband, making them a popular choice for concealed carry. Their design allows for better concealment, which is essential for personal defense markets. B2B buyers should consider the comfort and fit, as prolonged wear can be a concern. While they offer excellent concealment, the access speed can be slower compared to OWB options.

What are the Benefits of Using Shoulder Holsters?

Shoulder holsters distribute the weight of the firearm across the shoulders, making them comfortable for long periods. They are particularly favored in law enforcement and tactical operations where quick access is needed. B2B buyers should note that these holsters can be bulkier and often require an outer garment for concealment. However, their comfort and accessibility make them a preferred choice for many professionals.

How Do Chest Holsters Work for Outdoor Activities?

Chest holsters are designed for outdoor activities like hunting and hiking, allowing users to carry larger firearms comfortably. They provide excellent access and are often adjustable to fit various body types. B2B buyers in outdoor and tactical markets will find these holsters beneficial for specific applications. However, their bulkiness may limit their appeal for everyday carry scenarios.

What Makes Specialty Holsters Unique?

Specialty holsters are tailored for specific firearms or unique uses, appealing to collectors and specialized law enforcement. These holsters can enhance the functionality of the firearm and often come with unique features that standard holsters do not offer. B2B buyers should be aware that these custom solutions typically come at a higher price point and may require longer production times, but they provide unmatched quality and fit.

Illustrative image related to custom leather holster makers list

Key Industrial Applications of custom leather holster makers list

| Industry/Sector | Specific Application of custom leather holster makers list | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom holsters for firearms used by officers | Enhanced safety and accessibility for officers | Durability, comfort, retention features, and compatibility with various firearm models. |

| Military and Defense | Tactical holsters for military personnel | Improved operational efficiency and soldier safety | Customization options for different missions, materials suited for various environments, and ease of access. |

| Outdoor and Sporting Goods | Holsters for hunting and shooting sports | Increased comfort and functionality during activities | Weather resistance, fit for specific firearms, and ease of wear during prolonged use. |

| Security Services | Holsters for private security personnel | Professional appearance and secure firearm carrying | Aesthetic appeal, durability, and versatility for different types of uniforms. |

| E-commerce and Retail | Custom holsters for online retailers | Diverse product offerings to attract customers | Quality assurance, shipping logistics, and adaptability to market trends. |

How Are Custom Leather Holster Makers Applied in Law Enforcement?

In law enforcement, custom leather holsters play a crucial role in ensuring that officers can access their firearms quickly and securely. These holsters are designed to meet specific requirements such as durability, comfort, and retention features. For international buyers, especially from regions like Africa and the Middle East, sourcing holsters that can withstand harsh environments while providing reliable performance is essential. Customization options allow law enforcement agencies to tailor holsters to their operational needs, enhancing both safety and efficiency.

What Are the Applications in Military and Defense Sectors?

Military personnel require tactical holsters that can adapt to various mission profiles. Custom leather holster makers provide solutions that prioritize operational efficiency and soldier safety. These holsters often feature modular designs that accommodate different firearms and tactical gear. For buyers in Europe and South America, sourcing holsters that offer durability and ease of access in high-stress situations is paramount. Custom options can also include camouflage patterns or specific military insignia, enhancing both functionality and unit cohesion.

How Are Custom Holsters Used in Outdoor and Sporting Goods?

In the outdoor and sporting goods sector, custom leather holsters are essential for hunters and shooting sports enthusiasts. These holsters enhance comfort and functionality, allowing users to carry their firearms securely during activities. Buyers in regions with active hunting cultures, such as parts of Africa and South America, often seek holsters that are weather-resistant and designed for specific firearm models. Custom leather options offer the added benefit of personalization, which can appeal to discerning customers looking for quality and style in their gear.

Illustrative image related to custom leather holster makers list

What Benefits Do Security Services Gain from Custom Holsters?

Private security personnel rely on holsters that not only secure their firearms but also present a professional appearance. Custom leather holsters can be tailored to match uniforms while providing the necessary functionality. For businesses in this sector, sourcing holsters that blend aesthetics with practicality is essential. Buyers from Europe and the Middle East may prioritize features such as lightweight materials and adjustable fits to accommodate various body types and operational scenarios.

How Do E-commerce and Retail Benefit from Custom Holsters?

E-commerce platforms and retail stores can significantly enhance their product offerings by incorporating custom leather holsters into their inventory. This diversification attracts a broader customer base looking for unique, high-quality items. Key considerations for sourcing include quality assurance and the ability to adapt to market trends, ensuring that the holsters meet customer expectations. Retailers in South America and Africa, for instance, may focus on local preferences and styles to cater to their specific markets effectively.

3 Common User Pain Points for ‘custom leather holster makers list’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Custom Leather Holster Makers

The Problem: B2B buyers often struggle with identifying reliable and high-quality custom leather holster makers. With numerous options available globally, particularly from regions like Africa, South America, and Europe, it can be overwhelming to sift through makers who provide subpar products or inconsistent craftsmanship. Additionally, buyers may find it challenging to navigate language barriers or cultural differences that could affect communication and negotiations.

The Solution: To effectively source reliable custom leather holster makers, B2B buyers should start by leveraging industry-specific platforms and forums. Engaging in community discussions on platforms like High Power Collectors can yield personal recommendations and insights about the reliability and quality of various makers. Furthermore, creating a checklist of key criteria such as craftsmanship quality, customer service responsiveness, and delivery times can help narrow down choices. Buyers should also consider requesting samples or small test orders to evaluate quality before committing to larger orders. Utilizing social media and professional networks like LinkedIn can also facilitate connections with reputable makers in specific regions.

Scenario 2: Inconsistent Quality Across Orders

The Problem: A common pain point for B2B buyers is experiencing inconsistency in product quality across different orders from the same custom leather holster maker. Variations in leather quality, stitching, and overall finish can lead to customer dissatisfaction and damage brand reputation. This inconsistency can be particularly pronounced when sourcing from makers in different geographic regions where production techniques and materials may vary.

Illustrative image related to custom leather holster makers list

The Solution: To mitigate quality inconsistencies, buyers should establish clear specifications and guidelines for each order placed. This includes detailed descriptions of materials, finishes, and design elements. Implementing a quality assurance process, such as requiring pre-production samples or prototypes, can further ensure that the final product aligns with expectations. Buyers should also maintain open lines of communication with the maker throughout the production process, encouraging regular updates and photos of the items being crafted. Additionally, fostering a long-term relationship with a chosen maker can promote better understanding and adherence to quality standards over time.

Scenario 3: Limited Customization Options and Flexibility

The Problem: Many B2B buyers encounter challenges when seeking specific customization options that cater to their unique needs. Some makers may have rigid product lines, limiting the ability to modify designs or incorporate specific features that clients require. This lack of flexibility can be frustrating, especially for businesses looking to create bespoke products for niche markets.

The Solution: To address the limitations in customization, buyers should prioritize makers who specialize in bespoke solutions and are open to collaboration. When reviewing potential partners, assess their portfolio to see examples of custom work they’ve done in the past. Engaging in direct conversations about specific needs and modifications can also help gauge a maker’s willingness to accommodate unique requests. Establishing a collaborative relationship where feedback and iterative design are encouraged can lead to more tailored solutions. Additionally, buyers can consider involving designers or consultants in the initial discussions to better articulate their vision and ensure the maker understands the desired outcome.

Illustrative image related to custom leather holster makers list

Strategic Material Selection Guide for custom leather holster makers list

What Are the Key Materials Used by Custom Leather Holster Makers?

When selecting materials for custom leather holsters, it is essential to consider various factors that impact performance, durability, and suitability for specific applications. Here, we analyze four common materials used by holster makers, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Vegetable-Tanned Leather Perform in Holster Manufacturing?

Vegetable-tanned leather is a popular choice among custom holster makers due to its natural tanning process, which enhances its durability and aesthetic appeal. This type of leather is known for its rigidity and ability to retain shape, making it suitable for holsters that require a snug fit.

Pros: It offers excellent durability and is resistant to wear and tear. The natural finish allows for easy dyeing and tooling, providing customization options.

Cons: Vegetable-tanned leather can be more expensive compared to synthetic alternatives. It may also require more maintenance to prevent drying and cracking over time.

Illustrative image related to custom leather holster makers list

Impact on Application: This leather is compatible with various climates, but it may absorb moisture, potentially affecting performance in humid conditions.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the leather complies with local regulations regarding animal products. Understanding the tanning process is crucial, as some countries may have restrictions on specific chemicals used in leather production.

What Role Does Kydex Play in Holster Design?

Kydex is a thermoplastic material that has gained popularity for its lightweight and durable properties. It is often used in holster manufacturing due to its ability to mold to the shape of the firearm, ensuring a secure fit.

Illustrative image related to custom leather holster makers list

Pros: Kydex is water-resistant and does not absorb moisture, making it ideal for various environmental conditions. It is also easy to clean and maintain.

Cons: While it is durable, Kydex can be less comfortable against the skin compared to leather. Additionally, it may not provide the same level of aesthetic appeal as traditional leather.

Impact on Application: Kydex holsters are particularly suitable for tactical applications where durability and moisture resistance are critical.

Considerations for International Buyers: Buyers should verify that Kydex products meet local safety and environmental standards. In Europe, for example, compliance with REACH regulations is essential for materials used in consumer products.

Why Is Nylon Considered for Holster Manufacturing?

Nylon is a synthetic fabric that is often used for holsters due to its lightweight and flexible nature. It is commonly found in tactical and military applications.

Pros: Nylon is highly resistant to abrasion and tearing, making it suitable for rugged use. It is also cost-effective and available in various colors and patterns.

Cons: While durable, nylon may not offer the same level of protection against impacts as leather or Kydex. It can also absorb moisture, which may lead to mold growth if not properly maintained.

Impact on Application: Nylon holsters are ideal for casual and tactical use but may not be suitable for formal or high-end applications.

Considerations for International Buyers: Buyers should ensure that nylon products comply with international textile standards, such as OEKO-TEX certification, which guarantees the absence of harmful substances.

How Does Suede Compare in Holster Applications?

Suede, a type of leather with a napped finish, is sometimes used in holster manufacturing for its unique texture and aesthetic appeal.

Illustrative image related to custom leather holster makers list

Pros: Suede offers a soft feel and is often used for interior linings in holsters, providing additional protection for the firearm.

Cons: It is less durable than full-grain leather and can be more susceptible to staining and damage from moisture.

Impact on Application: Suede is best suited for applications where aesthetics are prioritized over durability, such as in fashion holsters.

Considerations for International Buyers: Buyers should be aware of the care requirements for suede, especially in humid climates where it may require additional protection.

Illustrative image related to custom leather holster makers list

Summary Table of Material Selection for Custom Leather Holster Makers

| Material | Typical Use Case for custom leather holster makers list | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end custom holsters | Durable and customizable | Higher cost, requires maintenance | High |

| Kydex | Tactical holsters | Lightweight and moisture-resistant | Less comfortable, less aesthetic | Medium |

| Nylon | Casual and tactical holsters | Cost-effective and abrasion-resistant | Absorbs moisture, less impact protection | Low |

| Suede | Fashion holsters | Soft texture and aesthetic appeal | Less durable, susceptible to stains | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers in the custom leather holster market, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather holster makers list

Manufacturing custom leather holsters involves a combination of traditional craftsmanship and modern production techniques. B2B buyers seeking high-quality leather goods should understand the typical manufacturing processes and quality assurance measures that reputable makers employ.

What Are the Main Stages of the Manufacturing Process for Custom Leather Holsters?

The manufacturing process for custom leather holsters typically involves four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

The journey begins with the selection of high-quality leather, often sourced from reputable tanneries. Leather types may vary, including full-grain, top-grain, or suede, depending on the desired finish and functionality. After selection, the leather is conditioned to ensure optimal flexibility and durability. This process may involve cleaning, dyeing, and cutting the leather into patterns that will form the holster. -

Forming

Once the leather is prepared, the forming stage begins. This involves shaping the leather into the desired holster configuration, often using molds or jigs to achieve precise dimensions. Techniques such as wet molding can be employed to create a snug fit for specific firearm models. This stage may also include the incorporation of additional features such as retention straps or reinforced areas for durability. -

Assembly

During the assembly phase, individual components of the holster are stitched together. Skilled artisans use heavy-duty threads and specialized stitching techniques, such as double-stitching, to enhance strength. The assembly process may also involve adding hardware such as snaps, buckles, or belt loops, which must be securely attached to ensure functionality. -

Finishing

The final stage focuses on detailing and quality enhancement. This includes trimming excess leather, polishing edges, and applying protective finishes to improve water resistance and longevity. Custom branding may also be added at this stage, providing an opportunity for B2B buyers to request personalized designs or logos.

How Do Custom Leather Holster Makers Ensure Quality Assurance?

Quality assurance is critical in maintaining the high standards expected by B2B buyers. Established manufacturers adhere to both international and industry-specific standards to guarantee product reliability.

-

What International Standards Are Relevant for Custom Leather Holsters?

Many custom leather holster makers comply with international quality management systems, such as ISO 9001. This standard outlines requirements for a quality management system, including consistent product quality, continuous improvement, and customer satisfaction. Compliance with ISO standards indicates a commitment to quality and process efficiency. -

What Industry-Specific Certifications Should Buyers Look For?

Buyers should also consider holster manufacturers that hold industry-specific certifications such as CE marking for European markets, which indicates compliance with health, safety, and environmental protection standards. Additionally, manufacturers may adhere to specific firearm safety standards, which can vary by region.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that each holster meets established standards before reaching the customer. The following checkpoints are commonly employed:

-

Incoming Quality Control (IQC)

This stage occurs when raw materials, such as leather and hardware, are received. Each batch is inspected for quality, ensuring that only materials meeting specified criteria are used in production. -

In-Process Quality Control (IPQC)

During production, regular inspections are conducted to monitor adherence to specifications. This may involve checking dimensions, stitching quality, and overall craftsmanship at various stages of assembly. -

Final Quality Control (FQC)

Before shipping, a final inspection is conducted to ensure that the completed holster meets all design and quality standards. This may include functionality tests, aesthetic evaluations, and packaging checks.

What Common Testing Methods Are Used in Quality Assurance?

Custom leather holster manufacturers often utilize various testing methods to verify the quality and performance of their products. Some common methods include:

- Tensile Strength Testing: Measures the durability of stitching and leather under stress to ensure it can withstand regular use.

- Water Resistance Tests: Assesses the effectiveness of any protective finishes applied to the leather.

- Fit and Retention Tests: Evaluates how well the holster fits specific firearm models, ensuring secure retention and ease of draw.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure reliability and quality when sourcing from custom leather holster makers, B2B buyers should take proactive steps to verify supplier practices:

Illustrative image related to custom leather holster makers list

-

Conduct Audits

Requesting a factory audit can provide insights into the manufacturer’s processes, quality control measures, and adherence to international standards. This may include reviewing production facilities and observing QC practices firsthand. -

Review Quality Reports

Buyers should ask suppliers for documentation that details their quality control processes, including any certifications and results from quality tests. This transparency can build trust and demonstrate the supplier’s commitment to quality. -

Engage Third-Party Inspections

Utilizing third-party inspection services can offer an unbiased evaluation of the manufacturer’s quality control practices. These services can conduct random inspections during production and provide detailed reports to the buyer.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding quality nuances is essential. Different regions may have varying regulations and standards that affect product quality, shipping, and customs clearance. It is crucial for buyers to be aware of these differences to ensure compliance and avoid potential issues during the import process.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures used by custom leather holster makers can significantly impact B2B purchasing decisions. By prioritizing manufacturers that adhere to recognized standards and maintain rigorous QC practices, buyers can ensure they are sourcing high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather holster makers list’

Introduction

In the competitive landscape of custom leather holster manufacturing, international B2B buyers must navigate a variety of suppliers to find the best fit for their needs. This guide provides a step-by-step checklist to help you effectively source custom leather holster makers, ensuring you partner with reliable and high-quality manufacturers. By following these steps, you can streamline your procurement process and make informed decisions.

Step 1: Identify Your Specific Requirements

Before diving into the sourcing process, clearly define what you need from a custom leather holster maker. Consider factors such as the type of holster (e.g., OWB, IWB, shoulder), materials (genuine leather vs. synthetic), and any specific design features (e.g., retention systems, custom colors).

- Why It Matters: Understanding your requirements helps you filter suppliers that can meet your exact specifications.

- Tip: Document your requirements in detail to use as a reference when evaluating potential suppliers.

Step 2: Research Potential Suppliers

Compile a list of potential custom leather holster makers. Use online directories, trade shows, and industry forums to identify reputable manufacturers.

Illustrative image related to custom leather holster makers list

- Why It Matters: A comprehensive list ensures you have multiple options and can compare quality, pricing, and services.

- Tip: Look for suppliers with a strong online presence and customer reviews to gauge their reputation.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each potential supplier by reviewing their product offerings, manufacturing processes, and customization options.

- Why It Matters: Not all suppliers will have the same level of craftsmanship or technology. Understanding their capabilities helps you choose a manufacturer that aligns with your needs.

- Tip: Request samples or prototypes to evaluate the quality of their work firsthand.

Step 4: Check Certifications and Compliance

Verify that the suppliers you are considering hold relevant certifications, such as ISO standards or quality management certifications.

- Why It Matters: Certifications indicate a commitment to quality and compliance with international standards, which is particularly important for buyers in regulated markets.

- Tip: Ask for documentation to confirm their certifications and compliance history.

Step 5: Request References and Case Studies

Ask for references from previous clients and case studies that demonstrate the supplier’s experience and success in producing custom leather holsters.

- Why It Matters: Testimonials and case studies provide insights into a supplier’s reliability and quality, helping you make a more informed decision.

- Tip: Reach out to these references to gain firsthand knowledge about the supplier’s performance.

Step 6: Negotiate Terms and Pricing

Once you have narrowed down your options, initiate discussions regarding pricing, minimum order quantities, lead times, and payment terms.

Illustrative image related to custom leather holster makers list

- Why It Matters: Clear negotiation ensures you understand the financial implications and can budget accordingly. It also helps establish a mutually beneficial relationship.

- Tip: Be transparent about your budget and expectations to foster open communication.

Step 7: Finalize the Agreement

After agreeing on terms, finalize the contract with detailed specifications, delivery schedules, and payment terms clearly outlined.

- Why It Matters: A well-defined contract protects both parties and ensures accountability throughout the manufacturing process.

- Tip: Consider consulting with a legal professional to review the contract before signing.

By following this practical sourcing guide, B2B buyers can confidently navigate the process of procuring custom leather holsters, ensuring they partner with the right manufacturers for their needs.

Comprehensive Cost and Pricing Analysis for custom leather holster makers list Sourcing

What Are the Key Cost Components in Custom Leather Holster Production?

When sourcing custom leather holsters, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: High-quality leather, linings, and hardware are essential for durability and aesthetics. The choice of leather (e.g., cowhide vs. exotic leathers) significantly impacts costs, with premium options driving prices higher.

-

Labor: Skilled craftsmanship is vital in producing custom holsters. Labor costs can vary based on the complexity of the design and the expertise required. Artisans with specialized skills typically command higher wages.

-

Manufacturing Overhead: This includes the costs associated with the facility, utilities, and administrative expenses. Efficient operations can help mitigate overhead costs.

-

Tooling: Custom molds and tools for specific designs can be a significant upfront investment. Buyers should inquire about these costs, especially if they plan to place large orders.

-

Quality Control (QC): Ensuring product quality may involve additional inspection and testing processes, which contribute to overall costs.

-

Logistics: Shipping costs can vary based on distance, weight, and the method of transport. International buyers should consider customs duties and taxes that may apply.

-

Margin: Manufacturers typically mark up costs to ensure profitability. Understanding the pricing strategy of suppliers can aid in negotiation.

How Do Price Influencers Impact Custom Leather Holster Costs?

Several factors can influence the pricing of custom leather holsters:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should inquire about volume discounts.

-

Specifications and Customization: Unique designs or specifications may increase costs. Clearly defining requirements can help manage expectations and pricing.

-

Material Quality and Certifications: Premium materials or eco-friendly certifications may lead to higher prices. Buyers should weigh the importance of these factors against budget constraints.

-

Supplier Factors: The reputation and location of the supplier can affect pricing. Established suppliers may charge more due to their brand reputation and reliability.

-

Incoterms: Understanding shipping terms can help buyers anticipate total costs, including responsibilities for shipping, insurance, and customs clearance.

What Negotiation Tips Can Help B2B Buyers Optimize Costs?

To achieve cost efficiency when sourcing custom leather holsters, consider the following negotiation strategies:

Illustrative image related to custom leather holster makers list

-

Establish Clear Requirements: Provide detailed specifications to suppliers upfront. This minimizes the risk of misunderstandings that could lead to cost overruns.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQ thresholds. This approach can significantly reduce costs per unit.

-

Explore Multiple Suppliers: Obtain quotes from several manufacturers. Comparing prices and terms can provide leverage in negotiations.

-

Discuss Total Cost of Ownership (TCO): Emphasize the importance of long-term value rather than just initial costs. Highlighting durability and performance can justify higher upfront prices.

What Should International Buyers Be Aware Of When Sourcing Leather Holsters?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider specific nuances:

-

Cultural Differences: Understanding the supplier’s business culture can aid in building strong relationships. This can lead to better terms and communication.

-

Currency Fluctuations: Be aware of exchange rates that may impact pricing. Locking in prices or using forward contracts can mitigate risks.

-

Regulatory Compliance: Ensure that products meet local regulations and standards, especially when importing leather goods. Non-compliance can lead to fines or product recalls.

-

Logistical Challenges: Plan for potential delays in shipping and customs clearance. Building a buffer into timelines can help avoid disruptions.

Disclaimer on Pricing

Prices for custom leather holsters can vary widely based on the aforementioned factors. Always consult with multiple suppliers to obtain accurate quotes and ensure that you are making informed purchasing decisions.

Alternatives Analysis: Comparing custom leather holster makers list With Other Solutions

Understanding Alternative Solutions for Custom Leather Holsters

In the realm of custom leather holsters, buyers often seek various solutions that fulfill their specific needs. While a comprehensive list of custom leather holster makers provides a valuable resource, alternative methods and products can also meet the demands of discerning customers. This analysis compares the “custom leather holster makers list” against two viable alternatives: mass-produced synthetic holsters and modular holster systems.

Illustrative image related to custom leather holster makers list

Comparison Table

| Comparison Aspect | Custom Leather Holster Makers List | Mass-Produced Synthetic Holsters | Modular Holster Systems |

|---|---|---|---|

| Performance | High-quality, tailored fit | Standardized fit, moderate quality | Versatile, adjustable fit |

| Cost | Higher due to craftsmanship | Generally lower, budget-friendly | Mid-range, varies by components |

| Ease of Implementation | Requires research and selection | Quick purchase, readily available | Requires initial setup |

| Maintenance | Durable, may require conditioning | Generally low maintenance | Varies by material used |

| Best Use Case | Collectors, enthusiasts, unique needs | Everyday carry, general use | Tactical, varied carry options |

What Are the Benefits and Drawbacks of Mass-Produced Synthetic Holsters?

Mass-produced synthetic holsters are a popular choice for buyers looking for cost-effective and readily available options. These holsters are typically made from materials like Kydex or nylon, providing a lightweight and durable alternative to leather. The primary advantage of synthetic holsters is their affordability and ease of access, as they can be found in most sporting goods stores or online marketplaces. However, the trade-off comes in the form of limited customization and a less tailored fit compared to custom leather options. For those who prioritize budget over personalized aesthetics, synthetic holsters can be an appealing choice.

Why Consider Modular Holster Systems for Flexibility?

Modular holster systems offer a unique approach, allowing users to customize their holster configuration based on specific needs. These systems typically consist of interchangeable components, such as clips, attachments, and shells, that can be adapted for different firearms and carry styles. The primary benefit is versatility; users can switch configurations to suit various scenarios, from concealed carry to open carry. However, the initial setup can be complex and may require a learning curve. Additionally, while modular systems can be cost-effective in the long run, their upfront investment might be higher than a single synthetic holster.

Making the Right Choice as a B2B Buyer

When choosing between custom leather holster makers and alternative solutions, B2B buyers should consider their specific needs, budget, and intended use. For those seeking a high-quality, bespoke product that enhances brand identity or customer experience, a custom leather holster is often worth the investment. Conversely, businesses focused on bulk purchasing for everyday use may find that mass-produced synthetic holsters or modular systems provide the best balance of cost and functionality. Ultimately, understanding the unique characteristics of each option will enable buyers to select the solution that best aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather holster makers list

What Are the Key Technical Properties for Custom Leather Holster Makers?

When sourcing custom leather holsters, understanding the technical specifications is crucial for ensuring quality and performance. Here are some essential properties that B2B buyers should consider:

Illustrative image related to custom leather holster makers list

-

Material Grade

The quality of leather used in holster production can significantly affect durability and comfort. Common grades include full-grain, top-grain, and corrected-grain leather. Full-grain leather, which retains the natural grain and imperfections, is typically the most durable and ages beautifully. In contrast, corrected-grain leather has been sanded and treated, making it less durable but often more affordable. Selecting the right material grade ensures that the holster meets the intended use—be it for daily carry, tactical operations, or aesthetic appeal. -

Stitching Quality

The stitching in a leather holster plays a critical role in its strength and longevity. B2B buyers should look for holsters that employ double stitching or reinforced seams, which provide added durability and resistance to wear and tear. High-quality thread, such as nylon or polyester, is often more resilient than cotton. Understanding stitching quality helps in assessing the overall craftsmanship of the holster. -

Fit and Retention

A well-designed holster must securely fit the specific firearm model while allowing for easy access. Custom holster makers often utilize CAD technology to create precise molds that ensure optimal fit. Retention features, such as adjustable tension screws or molded contours, are also vital, as they keep the firearm secure during movement. Buyers should inquire about these specifications to ensure the holster will perform reliably under various conditions. -

Finish and Treatment

The finish applied to leather can impact its resistance to moisture, stains, and wear. Common treatments include oil finishes, wax coatings, or waterproofing sprays. For instance, a holster intended for outdoor use may require a more robust finish to withstand environmental factors. Understanding the type of finish helps buyers select holsters that align with their specific operational needs. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during the manufacturing process. In leather holster production, tighter tolerances ensure a snug fit for the firearm, enhancing safety and usability. When evaluating suppliers, buyers should inquire about their manufacturing processes and tolerance levels to ensure consistency and quality.

What Are Common Trade Terms in the Custom Leather Holster Industry?

Navigating the custom leather holster market involves familiarizing oneself with industry jargon. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are branded by another company. In the holster industry, an OEM might produce custom designs for firearm manufacturers or retailers. Understanding OEM relationships can help buyers identify quality suppliers and leverage branding opportunities. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. For custom leather holsters, MOQs can vary significantly based on the complexity of the design and materials used. Buyers must be aware of MOQs to effectively manage inventory and cost implications when placing orders. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and details for specific products or services. B2B buyers should use RFQs to obtain competitive pricing and terms, enabling informed decision-making when sourcing holsters. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), can help buyers negotiate better shipping terms and avoid unexpected costs. -

Lead Time

This refers to the time taken from placing an order to delivery. Lead times can vary based on the complexity of the holster design and the supplier’s production capacity. Understanding lead times is essential for B2B buyers to plan inventory and manage customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions in sourcing custom leather holsters, ensuring they meet both quality standards and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the custom leather holster makers list Sector

What are the Key Market Trends Impacting Custom Leather Holster Makers?

The global market for custom leather holster makers is experiencing significant growth, driven by increased demand for personalized and high-quality leather goods. Factors such as rising disposable incomes, growing interest in outdoor activities, and heightened awareness around personal safety are propelling this sector forward. Notably, the rise of e-commerce platforms has enabled smaller artisans and manufacturers to reach international buyers, expanding their market reach beyond local boundaries.

Emerging technologies are also transforming the sourcing landscape. Automation in leather processing, along with advanced design software, allows for greater customization options and faster turnaround times. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in holsters that cater to specific firearm models and user preferences. This has led to increased collaboration between manufacturers and buyers to develop unique designs that meet local market needs.

Illustrative image related to custom leather holster makers list

Additionally, the global trend towards more sustainable and ethical manufacturing practices is influencing sourcing decisions. Buyers are increasingly seeking suppliers who can demonstrate a commitment to environmental stewardship and fair labor practices. This trend is particularly pronounced in Europe and North America, where consumers are willing to pay a premium for products that align with their values.

How are Sustainability and Ethical Sourcing Shaping the Custom Leather Holster Sector?

The environmental impact of leather production has led to a growing emphasis on sustainability within the custom leather holster sector. B2B buyers are increasingly aware of the ecological footprint associated with leather goods, prompting them to seek manufacturers who prioritize sustainable practices. This includes sourcing leather from tanneries that utilize vegetable tanning methods, which are less harmful to the environment compared to traditional chemical processes.

Furthermore, ethical sourcing is becoming a vital consideration for international buyers. Companies that can demonstrate transparency in their supply chains and adherence to fair labor standards are more likely to attract business. Certifications such as the Leather Working Group (LWG) certification can serve as valuable indicators for B2B buyers looking for sustainable and ethically produced leather products.

In addition, innovations in alternative materials, such as synthetic leathers and recycled materials, are gaining traction. Buyers are increasingly exploring these options as they seek to reduce their environmental impact while still meeting the demand for high-quality holsters. By aligning their sourcing strategies with sustainability goals, B2B buyers can not only enhance their brand reputation but also contribute positively to the global leather industry’s transition towards more responsible practices.

How Has the Custom Leather Holster Sector Evolved Over Time?

The custom leather holster market has evolved significantly over the past few decades. Initially dominated by traditional artisans, the sector has seen a shift towards mass production due to advances in technology and changing consumer preferences. However, the resurgence of interest in handcrafted goods has led to a renewed focus on bespoke leather products, where craftsmanship and personalization take center stage.

Illustrative image related to custom leather holster makers list

Historically, leather holsters were primarily utilitarian, designed for functionality rather than aesthetics. Today, manufacturers are not only prioritizing comfort and utility but also incorporating design elements that appeal to consumers’ tastes. This evolution reflects a broader trend in the leather goods market, where consumers are increasingly looking for products that combine style with functionality.

As the market continues to grow, international B2B buyers are encouraged to stay informed about these trends and to seek partnerships with manufacturers who can offer both quality and innovation in their product lines. This proactive approach will enable buyers to better meet the diverse needs of their customers while capitalizing on emerging market opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather holster makers list

-

How do I choose the right custom leather holster maker for my needs?

Choosing the right custom leather holster maker involves assessing their reputation, product quality, and specialization. Research potential suppliers by reviewing their portfolios, customer testimonials, and any relevant certifications. It’s also beneficial to inquire about their experience with the specific type of holster you need, whether it’s for firearms or other applications. Establishing clear communication about your requirements, such as design features and functionality, will help ensure that the maker can meet your expectations. -

What customization options should I consider when sourcing leather holsters?

When sourcing leather holsters, consider customization options such as size, color, leather type, and design features like retention mechanisms or attachment methods. Additionally, evaluate whether the maker can incorporate personalized elements, such as logos or specific stitching patterns. Discussing these options upfront will help align your vision with the manufacturer’s capabilities, ensuring that the final product meets your specifications and enhances your brand’s identity. -

What are the minimum order quantities (MOQ) for custom leather holsters?

Minimum order quantities (MOQ) for custom leather holsters can vary significantly between manufacturers. Some may accept small orders for initial samples or prototypes, while others might require larger quantities for cost-effectiveness. It’s essential to clarify MOQ with potential suppliers during the negotiation phase, as this will impact your budget and inventory planning. Additionally, some manufacturers may offer tiered pricing based on order size, so exploring these options could lead to better deals. -

What payment terms are typically offered by custom leather holster makers?

Payment terms can differ among custom leather holster makers, often influenced by order size and buyer-seller relationships. Common arrangements include upfront payments, partial deposits with the balance upon delivery, or net payment terms after receipt of goods. Clarifying payment terms before placing an order is crucial, as it impacts cash flow and financial planning. Additionally, inquire about accepted payment methods, such as bank transfers, credit cards, or letters of credit, especially for international transactions. -

How can I ensure quality assurance when sourcing custom leather holsters?

To ensure quality assurance when sourcing custom leather holsters, establish clear quality standards and specifications with your supplier. Request samples or prototypes before placing a bulk order to evaluate craftsmanship and materials. Additionally, consider implementing a third-party quality control inspection service, especially for larger orders, to verify compliance with your standards before shipment. Regular communication with the manufacturer throughout the production process can also help address any concerns proactively. -

What logistics considerations should I keep in mind when importing leather holsters?

When importing leather holsters, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling leather goods to navigate international shipping complexities. Familiarize yourself with import tariffs and duties applicable to leather products in your country to avoid unexpected costs. Additionally, plan for potential delays in shipping due to customs inspections or global supply chain issues, especially for international orders. -

How can I vet potential suppliers of custom leather holsters?

Vetting potential suppliers involves a thorough assessment of their business practices, reputation, and compliance with industry standards. Begin by checking their online presence, including customer reviews and ratings on platforms like LinkedIn or industry-specific forums. Request references from previous clients and inquire about their experience with the supplier. Additionally, consider conducting a factory visit if feasible, or utilize third-party auditing services to verify the supplier’s operational capabilities and ethical practices. -

What are the best practices for communicating with custom leather holster makers?

Effective communication with custom leather holster makers is crucial for successful collaboration. Start by clearly articulating your needs, specifications, and timelines to avoid misunderstandings. Utilize visual aids, such as sketches or photos, to convey your ideas accurately. Maintain open lines of communication throughout the production process, providing feedback and addressing any concerns promptly. Establishing a professional rapport can foster a positive working relationship, leading to better outcomes and potential long-term partnerships.

Top 6 Custom Leather Holster Makers List Manufacturers & Suppliers List

1. Alphono’s Gun Leather – Custom Holsters

Domain: forums.sassnet.com

Registered: 1997 (28 years)

Introduction: Alphono’s Gun Leather: https://alfonsosgunleather.com/western.html; Artistic Blades Western: http://www.artisticbladeswestern.com/Products.html; Aspen Filly’s One of a kind Custom Holsters: https://www.facebook.com/Aspen-Fillys-Merchandise-103794366328467, voice call or text-303-434-1204; Black Hills Leather: https://www.blackhillsleather.com/product-category/western-rigs-leather/western-rigs/; Bo…

2. Wright Leather Works – Hand-Crafted Leather Holsters

Domain: wrightleatherworks.com

Registered: 2012 (13 years)

Introduction: Wright Leather Works® LLC offers hand-crafted leather holsters with a current lead time of 6-8 weeks. All products are 100% made in America. The product range includes EDC Holster Kits, OWB Holsters, IWB Holsters, Optics-Ready Holsters, Shoulder Holsters, Pocket Holsters, Pistol Holsters, Magazine Holsters, Holsters for Women, Belts, Wallets, and Accessories. They provide a custom leather holster …

3. Holster Makers – Custom Leather Solutions

Domain: highpowercollectors.proboards.com

Registered: 1999 (26 years)

Introduction: Compiled list of holster makers including: Adams Holsters, Lobo Gun Leather, Bob Mernickle, Murray Custom Leather, Jacques Tredoux Trading Post, 5 Shot Leather, A.E. Nelson, A&G Custom Gun Leather, Andrews Leather, Barranti Leather Company, Bell Charter Oak Holsters, Bianchi, Black Hills Leather, Boston Leather, Brigade Gunleather, Brommeland Gunleather, Bullard Leather, Bulman Gunleather, C. Rust…

4. Holster Manufacturers – Key Brands

Domain: sigtalk.com

Registered: 2010 (15 years)

Introduction: A list of various holster manufacturers including:

1. Viridian Green Gun Laser Sights

2. artofthehide.com

3. Alfonsos gunleather

4. Hedley Pocket Holsters

5. Aker International, Inc.

6. Andrews Leather

7. azraelscustomleather.com

8. Beltster

9. Bianchi Leather Holsters

10. BLACKHAWK!

11. Blade Tech

12. Blueline Leather

13. Brigade Custom Holsters

14. C. Rusty Sherrick Custom Leather …

5. Barrantile Leather – Custom Leather Holsters

Domain: barrantileather.com

Registered: 2007 (18 years)

Introduction: Custom leather holsters for hunting and concealed carry, Classic Gunleather, and custom leather goods.

6. Pistolsmith – Custom Gun Holsters

Domain: pistolsmith.com

Registered: 1999 (26 years)

Introduction: This company, Pistolsmith – Custom Gun Holsters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom leather holster makers list

In conclusion, the landscape of custom leather holster makers offers a wealth of opportunities for B2B buyers across Africa, South America, the Middle East, and Europe. By strategically sourcing from a diverse array of skilled artisans and established manufacturers, buyers can ensure access to high-quality products that meet specific needs, whether for personal use or distribution. The emphasis on craftsmanship, particularly in regions like South Africa and Germany, highlights the importance of quality and reliability in procurement decisions.

As international buyers, it’s essential to evaluate suppliers not just on price, but also on their reputation, product range, and customer service. Engaging with niche makers who specialize in bespoke solutions can lead to unique offerings that differentiate your business in competitive markets.

Looking ahead, the demand for custom leather holsters is expected to grow, driven by increasing interest in personal defense and outdoor activities. We encourage you to explore the comprehensive list of makers provided and initiate conversations with potential partners. By taking proactive steps in your sourcing strategy, you can secure quality products that enhance your market position and drive business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather holster makers list