Introduction: Navigating the Global Market for custom design leather jackets

Navigating the global market for custom design leather jackets presents a unique challenge for international B2B buyers seeking quality, style, and tailored solutions. With a growing demand for personalized fashion across regions like Africa, South America, the Middle East, and Europe, sourcing the right suppliers can be daunting. This comprehensive guide addresses key aspects of the custom leather jacket market, including types of jackets available, their applications in various industries, and essential tips for vetting suppliers. Additionally, it delves into cost considerations, ensuring buyers can make informed decisions that align with their business objectives.

Understanding the intricacies of custom design leather jackets is vital for businesses looking to enhance their product offerings or establish a distinctive brand identity. From selecting the finest leathers to incorporating unique design elements such as embroidery and personalized fittings, this guide empowers B2B buyers with actionable insights. By providing a roadmap to navigate the complexities of sourcing, production, and logistics, we aim to equip you with the knowledge to confidently engage with suppliers and secure high-quality, customized leather products. Whether you’re a retailer in Nigeria looking to expand your catalog or a fashion designer in Vietnam seeking to create bespoke pieces, this guide serves as your essential resource for success in the custom leather jacket market.

Table Of Contents

- Top 9 Custom Design Leather Jackets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom design leather jackets

- Understanding custom design leather jackets Types and Variations

- Key Industrial Applications of custom design leather jackets

- 3 Common User Pain Points for ‘custom design leather jackets’ & Their Solutions

- Strategic Material Selection Guide for custom design leather jackets

- In-depth Look: Manufacturing Processes and Quality Assurance for custom design leather jackets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom design leather jackets’

- Comprehensive Cost and Pricing Analysis for custom design leather jackets Sourcing

- Alternatives Analysis: Comparing custom design leather jackets With Other Solutions

- Essential Technical Properties and Trade Terminology for custom design leather jackets

- Navigating Market Dynamics and Sourcing Trends in the custom design leather jackets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom design leather jackets

- Strategic Sourcing Conclusion and Outlook for custom design leather jackets

- Important Disclaimer & Terms of Use

Understanding custom design leather jackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Biker Jackets | Heavy-duty leather, often with padding, zippers, and pockets. | Motorcycle gear retailers, fashion brands | Pros: Durable, stylish; Cons: May not suit all markets. |

| Bomber Jackets | Short, fitted style with ribbed cuffs and waist, often lined. | Casual wear brands, promotional items | Pros: Versatile, trendy; Cons: Limited formal appeal. |

| Blazers and Coats | Tailored design, suitable for formal occasions, often with linings. | Corporate gifts, high-end fashion | Pros: Professional look; Cons: Higher price point. |

| Varsity Jackets | Sporty style, often featuring patches and custom embroidery. | Schools, sports teams, promotional gifts | Pros: Customizable, appealing to youth; Cons: Seasonal demand. |

| Printed/Embroidered Jackets | Unique designs with logos or artwork, customizable finishes. | Branding for businesses, events | Pros: High visibility for branding; Cons: Longer lead times. |

What Are the Characteristics of Biker Jackets in Custom Design?

Biker jackets are designed for durability and protection, making them ideal for motorcycle enthusiasts. Typically made from heavy leather, they feature zippers and additional padding for safety. These jackets are often adorned with pockets and decorative elements, appealing to a rugged aesthetic. For B2B buyers, these jackets are suitable for motorcycle gear retailers and fashion brands looking to attract a niche audience. However, their specific style may not appeal to all markets, which is a consideration when selecting inventory.

How Do Bomber Jackets Stand Out in Custom Design Options?

Bomber jackets are characterized by their short, fitted design and ribbed cuffs, providing a casual yet trendy look. They are often lined for comfort and can be made from various leather types, allowing for customization in color and style. Their versatility makes them suitable for a range of applications, from casual wear brands to promotional items. B2B buyers should note that while bomber jackets are fashionable, they may lack the formal appeal required for corporate environments, limiting their market reach.

Why Choose Blazers and Coats for Custom Leather?

Blazers and coats offer a tailored look, making them suitable for formal occasions and professional settings. These jackets can be lined with different materials for added warmth and comfort, and they often feature elegant designs that appeal to high-end fashion markets. B2B applications include corporate gifts and upscale fashion lines. Buyers should be aware that the higher price point associated with these jackets might limit their appeal in more budget-conscious markets.

What Makes Varsity Jackets a Popular Choice?

Varsity jackets are a sporty option often featuring patches and custom embroidery, making them highly customizable. They are popular among schools and sports teams, serving as promotional gifts that foster team spirit. The youthful appeal of these jackets can attract a younger demographic, but B2B buyers should be mindful of their seasonal demand, as they may sell better during back-to-school periods or sports seasons.

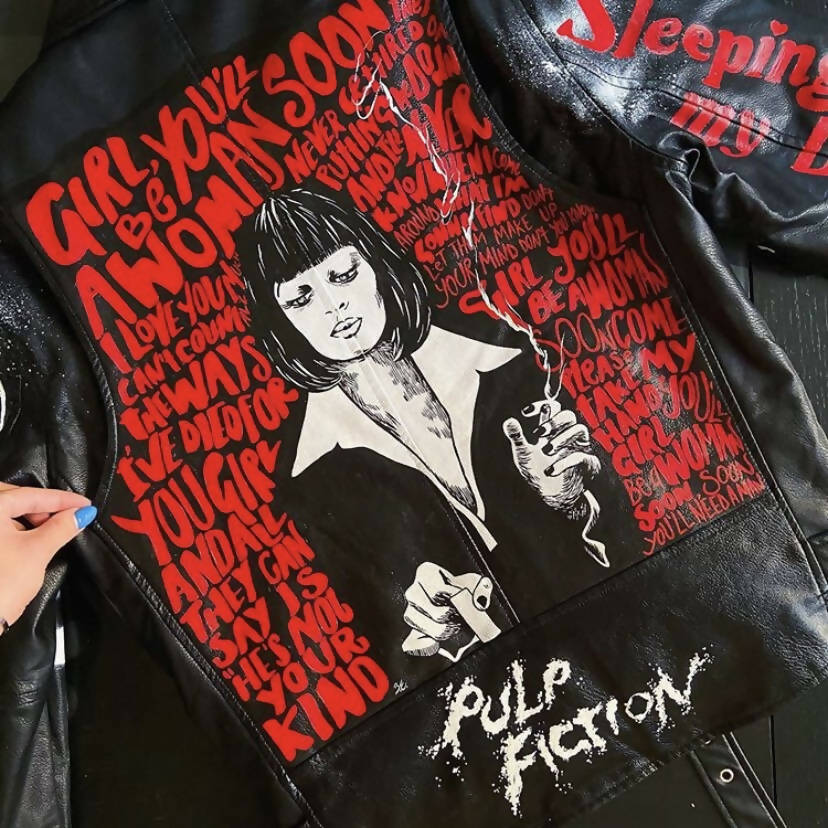

How Can Printed and Embroidered Jackets Enhance Brand Visibility?

Printed and embroidered jackets allow businesses to showcase logos or unique designs, making them excellent for branding at events or as promotional giveaways. These jackets can be customized to fit various styles and preferences, catering to diverse markets. However, B2B buyers should consider that the production of these custom designs may involve longer lead times, which can impact inventory management and promotional strategies.

Key Industrial Applications of custom design leather jackets

| Industry/Sector | Specific Application of custom design leather jackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Customized fashion lines for boutiques | Enhances brand uniqueness and customer loyalty | Quality of leather, customization options, lead time |

| Automotive | Branded jackets for dealerships and events | Promotes brand identity and customer engagement | Durability, logo placement, and fit customization |

| Entertainment & Film | Replicas of iconic jackets for merchandise | Increases merchandise sales and fan engagement | Authenticity, design accuracy, and material quality |

| Corporate Branding | Employee jackets with company logos | Strengthens corporate identity and team unity | Customization options, bulk pricing, and delivery times |

| Motorcycle Clubs | Custom biker jackets for members | Fosters community identity and loyalty | Quality of leather, fit options, and design flexibility |

How are Custom Design Leather Jackets Used in the Fashion Retail Industry?

In the fashion retail sector, custom design leather jackets serve as unique offerings for boutiques aiming to differentiate themselves in a competitive market. By allowing customers to personalize their jackets with specific styles, colors, and embroidery options, retailers can cultivate a loyal customer base that appreciates exclusivity. International buyers, particularly from regions like Africa and South America, often seek high-quality leather that reflects local tastes and preferences, making sourcing from reputable tanneries essential for success.

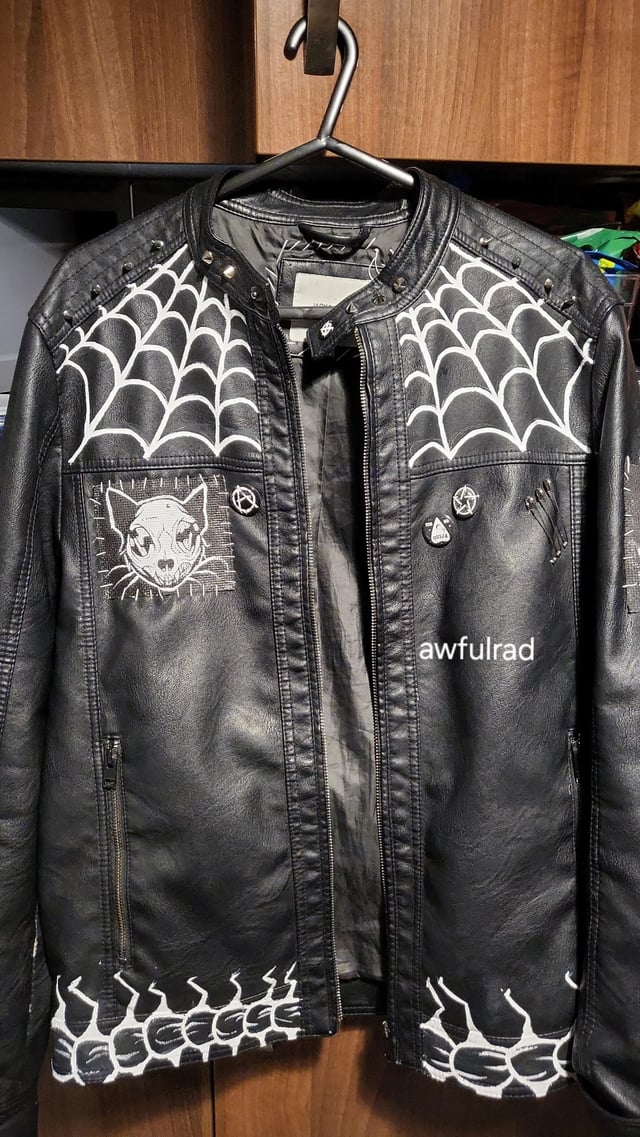

Illustrative image related to custom design leather jackets

What Role Do Custom Leather Jackets Play in the Automotive Industry?

Automotive dealerships utilize custom leather jackets as promotional items to enhance brand identity during events or as part of customer loyalty programs. These jackets can feature dealership logos and colors, creating a cohesive brand experience for customers. For international buyers, it’s crucial to ensure that the jackets are durable and comfortable, as they may be used in various climates, particularly in regions like the Middle East where heat can impact material performance.

How Does the Entertainment & Film Sector Benefit from Custom Leather Jackets?

In the entertainment and film industry, custom design leather jackets are often used to create replicas of iconic styles for merchandise purposes. This not only appeals to fans but also serves as a significant revenue stream for studios. Buyers must focus on achieving design accuracy and material quality to ensure that replicas meet fan expectations. This is particularly important for international markets where cultural significance and authenticity may vary.

Why Are Custom Leather Jackets Important for Corporate Branding?

For companies looking to enhance their corporate identity, custom leather jackets can serve as effective employee uniforms or promotional giveaways. By adding company logos and ensuring a tailored fit, businesses can foster a sense of unity and professionalism among their staff. Buyers from Europe and other regions should consider bulk pricing and customization options to maximize value while ensuring that the jackets meet the specific branding requirements of their organization.

What Benefits Do Motorcycle Clubs Gain from Custom Leather Jackets?

Motorcycle clubs often use custom leather jackets to build community identity and foster loyalty among members. These jackets can be personalized with club insignias, member names, and unique designs, making them a symbol of belonging. For buyers, sourcing high-quality leather that can withstand wear and tear is essential, especially in regions with diverse weather conditions. Additionally, flexibility in design options allows clubs to create jackets that resonate with their specific culture and values.

3 Common User Pain Points for ‘custom design leather jackets’ & Their Solutions

Scenario 1: Navigating Sizing Challenges in Custom Leather Jackets

The Problem: One of the most significant challenges B2B buyers face when sourcing custom design leather jackets is ensuring the correct sizing for their target market. Miscommunication about sizes can lead to high return rates, dissatisfied customers, and ultimately, financial loss. This problem is especially acute for businesses catering to diverse body types across different regions, where sizing standards may vary significantly. Buyers often worry about the implications of getting sizes wrong, such as tarnishing their brand’s reputation and incurring additional costs related to alterations or restocking.

Illustrative image related to custom design leather jackets

The Solution: To address sizing challenges effectively, B2B buyers should establish a clear and detailed measurement guide that aligns with their target demographics. This guide should include comprehensive instructions on how to take measurements accurately, accounting for different body shapes and sizes. Partnering with manufacturers who offer a fitting consultation service can significantly enhance the accuracy of sizing. By utilizing technology, such as virtual fitting rooms or 3D body scanning, companies can provide a more personalized experience. Additionally, implementing a flexible return policy that accommodates size-related issues can help mitigate the risk of returns and enhance customer satisfaction.

Scenario 2: Ensuring Quality Control in Custom Leather Production

The Problem: B2B buyers often grapple with quality control issues when commissioning custom leather jackets. Variations in leather quality, craftsmanship, and finishing can lead to inconsistencies that affect the end product. This is particularly concerning for brands that pride themselves on delivering high-quality goods. Buyers may find it challenging to verify the quality of materials used and the expertise of artisans, especially when sourcing from international suppliers. The fear of receiving subpar products can lead to hesitation in placing large orders.

The Solution: To overcome quality control challenges, it is crucial for buyers to establish strong relationships with reputable suppliers known for their craftsmanship and material quality. Conducting factory visits, or leveraging third-party quality assurance services, can help ensure that the production meets specified standards. Buyers should also request samples before committing to large orders, allowing them to evaluate the leather’s texture, durability, and overall craftsmanship. Additionally, setting up clear quality metrics and communication channels will facilitate ongoing dialogue about quality expectations, allowing for adjustments during production if necessary.

Illustrative image related to custom design leather jackets

Scenario 3: Customization Limitations Affecting Brand Identity

The Problem: Another pain point for B2B buyers is the limitations they encounter in customizing leather jackets to reflect their brand identity. Businesses often seek unique designs that resonate with their audience, but many manufacturers may offer restricted options for customization. This can lead to generic products that fail to stand out in a competitive market, diminishing a brand’s ability to express its unique identity and connect with customers.

The Solution: To ensure a high level of customization that aligns with their brand identity, buyers should work closely with manufacturers who specialize in bespoke designs. This collaboration should start with a thorough discussion of design elements, such as color, fabric types, and additional features like embroidery or logos. Buyers should explore suppliers that offer advanced customization options, including design software that allows for real-time visualizations. This not only enhances the creative process but also fosters a sense of ownership over the design. Furthermore, establishing a feedback loop with the supplier can enable iterative adjustments throughout the design process, ensuring the final product truly embodies the brand’s vision.

Strategic Material Selection Guide for custom design leather jackets

What Are the Key Properties of Common Materials Used in Custom Design Leather Jackets?

When selecting materials for custom design leather jackets, understanding the properties and performance characteristics of various leathers is essential. Here, we analyze four common materials: Lambskin, Cowhide, Goatskin, and Buffalo Hide. Each material offers unique attributes that can significantly influence the final product’s quality, durability, and suitability for specific applications.

How Does Lambskin Perform in Custom Leather Jackets?

Lambskin is renowned for its softness and luxurious feel. This material is lightweight and provides excellent comfort, making it ideal for fashion-forward designs. However, lambskin is less durable than other leathers, which may limit its use in rugged environments. It typically has a lower temperature and pressure rating, making it less suitable for extreme conditions.

Illustrative image related to custom design leather jackets

Pros: Exceptional softness, lightweight, and a premium appearance.

Cons: Less durable, higher susceptibility to wear and tear, and higher maintenance needs.

Impact on Application: Best suited for fashion-oriented jackets rather than functional outerwear.

Considerations for International Buyers: Buyers should ensure compliance with local leather quality standards and consider the need for specialized care instructions.

What Are the Advantages of Cowhide for Leather Jackets?

Cowhide is one of the most commonly used materials for leather jackets due to its durability and resistance to wear. It offers a good balance between comfort and sturdiness, making it suitable for both casual and rugged designs. Cowhide typically has a higher temperature rating, providing better insulation in colder climates.

Pros: High durability, good abrasion resistance, and versatile for various designs.

Cons: Heavier than other leathers, can be less breathable, and may require more complex manufacturing processes.

Impact on Application: Ideal for motorcycle jackets and outdoor wear due to its robustness.

Considerations for International Buyers: Compliance with ASTM and DIN standards for durability and safety is crucial, especially in regions with strict regulations.

How Does Goatskin Compare for Custom Leather Jackets?

Goatskin is another popular choice, known for its unique grain and flexibility. It offers a softer feel than cowhide while maintaining good durability. Goatskin is also more resistant to water, making it suitable for various weather conditions. However, it may be more expensive than cowhide, impacting cost considerations for bulk orders.

Pros: Softness, flexibility, and water resistance.

Cons: Higher cost compared to cowhide, potential for color variations, and may have limited availability.

Impact on Application: Great for stylish jackets that require both comfort and performance.

Considerations for International Buyers: Buyers should be aware of regional preferences for leather texture and color, which can vary significantly.

Illustrative image related to custom design leather jackets

What Makes Buffalo Hide a Unique Choice for Leather Jackets?

Buffalo hide is known for its exceptional toughness and ruggedness. This material is thicker than cowhide and offers excellent abrasion resistance, making it ideal for heavy-duty applications. However, its weight may limit its use in fashion-oriented designs.

Pros: Outstanding durability, excellent abrasion resistance, and unique texture.

Cons: Heavier and less flexible, which may affect comfort.

Impact on Application: Perfect for work jackets and outdoor gear designed for extreme conditions.

Considerations for International Buyers: Compliance with local environmental and manufacturing regulations is essential, especially in regions focused on sustainable practices.

Summary of Material Selection for Custom Design Leather Jackets

| Material | Typical Use Case for custom design leather jackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lambskin | Fashion-oriented jackets | Exceptional softness | Less durable | Medium |

| Cowhide | Motorcycle and outdoor jackets | High durability | Heavier | Medium |

| Goatskin | Stylish and flexible jackets | Water resistance | Higher cost | High |

| Buffalo Hide | Heavy-duty work jackets | Outstanding durability | Heavier | Medium |

This guide provides a comprehensive overview of material selection for custom design leather jackets, equipping international B2B buyers with the knowledge to make informed decisions based on their specific needs and market preferences.

Illustrative image related to custom design leather jackets

In-depth Look: Manufacturing Processes and Quality Assurance for custom design leather jackets

What Are the Main Stages of Manufacturing Custom Design Leather Jackets?

The manufacturing process for custom design leather jackets involves several critical stages that ensure both quality and precision. Understanding these stages is essential for B2B buyers seeking to ensure that their suppliers adhere to high standards.

1. Material Preparation

The first stage of manufacturing begins with the selection and preparation of leather. Suppliers typically source leather from reputable tanneries, focusing on various types such as lambskin, sheepskin, goatskin, buffalo hide, and cowhide. Each type of leather possesses unique characteristics, influencing both the aesthetic and functional qualities of the final product.

In this phase, the leather is treated to enhance its durability and appearance. This may involve processes such as dyeing, conditioning, and surface finishing. The leather is then cut into patterns that will form the jacket, taking care to minimize waste and ensure optimal use of materials.

2. Forming

Once the leather pieces are cut, they move to the forming stage. This involves shaping the leather to fit the design specifications. Techniques such as stitching, folding, and molding are employed to create the structure of the jacket.

Advanced machinery may be used for precision cutting and stitching, ensuring consistent quality across batches. Manual techniques are also vital, particularly in custom orders where artisans may hand-stitch intricate designs or details as specified by the buyer.

Illustrative image related to custom design leather jackets

3. Assembly

Following the forming process, the leather pieces are assembled into the final jacket structure. This includes attaching components such as zippers, buttons, and lining materials. High-quality zippers, such as those from YKK, are often preferred for their durability and reliability.

During assembly, attention is paid to the fit and finish of the jacket. Custom features, such as embroidery or printed logos, can be added at this stage. This is also when any special requests from the buyer, such as specific pocket placements or additional insulation, are integrated into the jacket.

4. Finishing

The final stage is finishing, where the jacket undergoes quality checks and aesthetic enhancements. This can include polishing, additional conditioning, and final inspections to ensure all components are correctly installed and functioning.

During this stage, the jackets are also prepared for packaging and shipping. Buyers may request specific packaging options, particularly for high-value orders, to ensure the jackets arrive in pristine condition.

Illustrative image related to custom design leather jackets

How is Quality Assurance Implemented in the Manufacturing of Custom Leather Jackets?

Quality assurance (QA) is a critical component of the manufacturing process for custom design leather jackets. It ensures that every product meets the established standards and specifications before reaching the buyer.

International Standards and Industry-Specific Certifications

Many manufacturers adhere to international quality management standards such as ISO 9001, which focuses on effective quality management systems. Compliance with these standards demonstrates a commitment to maintaining high-quality processes throughout production.

Additionally, industry-specific certifications, such as CE marking for safety and compliance in the European market or API for specific industrial applications, can be crucial for certain B2B buyers. These certifications assure buyers that the products meet regulatory requirements and industry standards.

Illustrative image related to custom design leather jackets

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to catch defects and ensure compliance with quality standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival at the manufacturing facility. Leather is checked for defects, color consistency, and thickness.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to ensure that the assembly and stitching processes meet quality standards. This can include checking for alignment, stitch quality, and adherence to design specifications.

-

Final Quality Control (FQC): Once the jackets are completed, a thorough inspection is conducted to check for overall quality, including fit, finishing, and functionality of components like zippers and buttons.

Which Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to verify the quality of leather jackets. These can include:

-

Physical Testing: Assessing the durability of the leather, including tear strength and abrasion resistance, ensures that the jackets can withstand wear and tear.

-

Chemical Testing: This may involve testing the leather for harmful substances or ensuring it meets environmental standards.

-

Visual Inspection: A detailed visual inspection is conducted to check for aesthetic issues such as color consistency, stitching quality, and overall craftsmanship.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers need to be proactive in verifying the quality control processes of their suppliers. Here are some effective strategies:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can be done through on-site visits or third-party audits.

-

Request Quality Reports: Suppliers should be able to provide detailed reports on their quality control processes, including inspection results and compliance with international standards.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection services can help ensure that products meet specified quality standards before shipment. This is particularly valuable for international buyers who may not have direct access to the manufacturing facilities.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Considerations include:

-

Cultural Differences: Different regions may have varying standards for quality and craftsmanship. Buyers should clearly communicate their expectations and ensure alignment with suppliers.

-

Regulatory Compliance: International regulations can impact product acceptance in specific markets. Buyers must ensure that their suppliers comply with local regulations to avoid customs issues.

-

Logistics and Shipping: Quality control doesn’t stop at manufacturing. Ensuring that jackets are properly packaged and shipped can prevent damage during transit, which is crucial for maintaining quality standards.

By understanding the manufacturing processes and quality assurance practices associated with custom design leather jackets, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom design leather jackets’

In the competitive world of custom design leather jackets, navigating the sourcing process requires precision and clarity. This guide serves as a practical checklist for B2B buyers looking to procure custom leather jackets that meet their specific needs while ensuring quality, compliance, and value.

Step 1: Identify Your Requirements

Understanding your specific needs is critical before initiating the sourcing process. Determine the type of leather jacket required, including style, color, and customization options. Consider factors such as target demographics, regional preferences, and seasonal trends that may influence your design choices.

Illustrative image related to custom design leather jackets

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in custom leather jackets. Look for companies with a solid reputation, extensive experience, and a diverse portfolio. Utilize platforms like trade shows, industry directories, and online reviews to gather insights about potential partners.

Step 3: Verify Supplier Certifications

Before proceeding, ensure that your potential suppliers adhere to industry standards and regulations. Check for certifications related to leather quality, environmental compliance, and ethical labor practices. This step is crucial to mitigate risks associated with sourcing unethical or substandard products.

Step 4: Request Samples and Prototypes

Once you shortlist suppliers, request samples or prototypes of their custom leather jackets. This allows you to assess the quality of materials, craftsmanship, and overall fit. Pay close attention to the stitching, leather texture, and any custom features that are important to your brand’s identity.

Illustrative image related to custom design leather jackets

Step 5: Discuss Customization Options

Engage in detailed discussions with suppliers about customization possibilities. This includes choices for leather types, colors, linings, and design elements such as embroidery or printing. Understanding the limits and capabilities of each supplier will help you align your vision with what they can deliver.

Step 6: Evaluate Pricing and Payment Terms

Gather detailed quotations from your selected suppliers, ensuring transparency in pricing structures. Look for hidden costs related to customization, shipping, and potential alterations. Additionally, discuss payment terms that are favorable for both parties, considering factors such as deposits and payment schedules.

Step 7: Establish Communication Protocols

Effective communication is vital throughout the sourcing process. Set clear expectations regarding timelines, order updates, and any potential issues. Establishing a reliable communication channel will help streamline the process and build a strong partnership with your supplier.

By following this checklist, B2B buyers can enhance their sourcing strategy for custom design leather jackets, ensuring they secure high-quality products that meet their business objectives.

Comprehensive Cost and Pricing Analysis for custom design leather jackets Sourcing

What Are the Key Cost Components for Custom Design Leather Jackets?

When sourcing custom design leather jackets, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of leather significantly impacts costs. High-quality leathers like lambskin or buffalo-hide can range from $200 to $500 per jacket. Moreover, the inclusion of specialty materials for linings or insulation adds to the base price.

-

Labor: Skilled labor is necessary for crafting high-quality leather jackets. Depending on the complexity of the design and the region, labor costs can vary. In countries with lower labor costs, like Vietnam, prices may be more competitive compared to Europe or North America.

-

Manufacturing Overhead: This includes costs related to the operation of the facility, utilities, and other indirect costs associated with production. Generally, overhead can account for 10-20% of the total manufacturing cost.

-

Tooling: Custom designs may require specific tooling or molds, which can add significant upfront costs. Tooling expenses can vary based on the complexity of the design and the technology used.

-

Quality Control (QC): Ensuring that each jacket meets quality standards incurs additional costs. A robust QC process is essential, especially for B2B buyers focused on brand reputation.

-

Logistics: Shipping costs can be substantial, especially for international orders. Factors like distance, shipping method, and Incoterms will influence the total logistics cost.

-

Margin: Suppliers typically include a profit margin, which can range from 20% to 50%, depending on the market and competition.

How Do Price Influencers Affect the Sourcing of Custom Leather Jackets?

Several factors influence the pricing of custom leather jackets:

-

Volume/MOQ: Bulk orders often attract discounts. Minimum Order Quantities (MOQs) can vary, so negotiating favorable terms can lead to significant cost savings.

-

Specifications and Customization: The more customized the jacket, the higher the cost. Buyers should be clear about their design requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Jackets made from premium materials or those that meet specific quality certifications will generally command higher prices. Buyers should assess the material quality and any certifications that may affect pricing.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Different terms can impact who bears the costs and risks during transport, affecting the overall price.

What Buyer Tips Can Help Negotiate Better Prices for Custom Leather Jackets?

International B2B buyers should consider the following strategies for cost efficiency:

-

Negotiate Terms: Engage in negotiations to secure better pricing, especially for large orders. Discuss potential discounts for future orders or long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, potential returns, and quality issues. A slightly higher upfront cost may be justified by lower long-term costs.

-

Understand Pricing Nuances: Different regions have varying pricing structures. Buyers from Africa, South America, and the Middle East should be aware of currency fluctuations and economic conditions that might impact pricing.

-

Leverage Local Suppliers: Whenever possible, consider sourcing from local suppliers to minimize shipping costs and lead times. This can also facilitate easier communication regarding design specifications.

-

Request Samples: Before placing a large order, request samples to assess quality and fit. This can prevent costly mistakes and ensure the final product meets expectations.

Conclusion

Understanding the cost structure and pricing dynamics of custom design leather jackets is essential for international B2B buyers. By considering the various cost components, price influencers, and negotiation strategies, buyers can make informed decisions that align with their business objectives. Always remember to factor in all costs associated with your purchase to achieve the best value for your investment.

Alternatives Analysis: Comparing custom design leather jackets With Other Solutions

Introduction to Alternative Solutions for Custom Design Leather Jackets

When considering the procurement of leather jackets, businesses often explore various options to meet their specific needs. Custom design leather jackets provide a unique solution tailored to individual preferences, but there are alternatives available that may suit different requirements, budgets, or operational strategies. This analysis compares custom design leather jackets with two viable alternatives: ready-made leather jackets and synthetic leather jackets, examining their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Custom Design Leather Jackets | Ready-Made Leather Jackets | Synthetic Leather Jackets |

|---|---|---|---|

| Performance | High durability and quality, tailored fit | Good quality, but standard sizing may not fit perfectly | Varies; generally less durable than leather, but can mimic appearance |

| Cost | Higher initial investment, typically $300+ | Moderate cost, typically $100-$500 depending on brand | Lower cost, typically $50-$200 |

| Ease of Implementation | Requires design consultation and customization process | Immediate availability, no customization needed | Readily available, no customization required |

| Maintenance | Requires careful cleaning and conditioning | Standard leather care practices | Easy to clean, less maintenance required |

| Best Use Case | High-end fashion, unique branding, personalized gifts | Retail sales, fashion collections, bulk orders | Budget-conscious consumers, promotional items |

Detailed Breakdown of Alternatives

1. Ready-Made Leather Jackets

Ready-made leather jackets offer a practical solution for businesses looking to quickly stock fashionable items without the complexities of customization. These jackets are mass-produced and readily available, making them ideal for retailers who prioritize speed and cost-effectiveness. However, the downside is that they often come in standard sizes, which may not cater to all customers, leading to potential fit issues. The quality can also vary significantly based on the brand, so buyers must conduct thorough research to ensure they are selecting high-quality options.

2. Synthetic Leather Jackets

Synthetic leather jackets are an increasingly popular alternative due to their affordability and ease of maintenance. They offer a similar aesthetic to genuine leather but at a fraction of the cost, making them an attractive option for budget-conscious buyers. Additionally, synthetic materials are often easier to clean and require less care than real leather. However, the longevity and durability of synthetic jackets are generally inferior to that of genuine leather, which could lead to higher replacement costs over time. Businesses targeting environmentally conscious consumers may also want to consider the environmental impact of synthetic materials.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating options for leather jackets, B2B buyers should carefully consider their specific needs and objectives. Custom design leather jackets excel in providing tailored solutions that emphasize individuality and branding, making them suitable for high-end fashion or personalized gifts. In contrast, ready-made jackets offer quick availability and lower costs, making them ideal for bulk purchases. Meanwhile, synthetic leather jackets present an economical choice with lower maintenance requirements, though they may lack the durability of genuine leather. Ultimately, the right solution will depend on factors such as budget, target market, and brand positioning.

Essential Technical Properties and Trade Terminology for custom design leather jackets

What Are the Key Technical Properties for Custom Design Leather Jackets?

In the realm of custom design leather jackets, understanding the technical properties is essential for making informed purchasing decisions. Here are some critical specifications that every B2B buyer should be aware of:

-

Material Grade

Leather quality significantly influences the durability and aesthetic appeal of jackets. Common grades include full-grain, top-grain, and corrected grain. Full-grain leather, being the highest quality, retains the natural grain and texture, making it ideal for high-end products. For B2B buyers, specifying material grade ensures that the final product meets the desired quality standards, enhancing brand reputation and customer satisfaction. -

Leather Type

Different types of leather—such as lambskin, cowhide, goatskin, and buffalo hide—offer various textures and strengths. Lambskin is soft and supple, ideal for fashion jackets, while cowhide is robust and better suited for protective gear. Understanding the appropriate leather type for specific designs helps buyers align product offerings with market demands. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions and features of the leather jacket during production. Establishing clear tolerance levels ensures that the final product fits well and meets design specifications. This is crucial for B2B transactions, as it minimizes returns and enhances customer satisfaction. -

Color Fastness

This property measures how well the leather retains its color when exposed to various conditions, such as sunlight or washing. High color fastness is essential for maintaining the appearance of the jacket over time. For B2B buyers, specifying color fastness helps in ensuring product longevity and client satisfaction. -

Lining Materials

The choice of lining, which can include polyester, silk, or cotton, affects the comfort and insulation of the jacket. Customization options for lining materials can enhance the jacket’s appeal, particularly in regions with varying climates. B2B buyers should consider lining choices based on their target market’s preferences.

Which Trade Terms Are Commonly Used in Custom Leather Jacket Transactions?

Familiarity with trade terminology is equally important for smooth business dealings in the custom leather jacket industry. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of leather jackets, it often indicates that a buyer can have jackets produced under their brand name. Understanding OEM relationships can help businesses leverage manufacturing capabilities while maintaining brand integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and financial planning. Knowing the MOQ allows buyers to assess whether a supplier meets their volume needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For custom leather jackets, an RFQ can outline design specifications, materials, and quantities. Using RFQs effectively helps buyers obtain competitive pricing and ensures that all suppliers provide comparable offers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, such as who pays for shipping and insurance. Understanding these terms can prevent misunderstandings and ensure smooth logistics when sourcing leather jackets from global suppliers. -

Lead Time

Lead time is the period between placing an order and receiving the finished product. It encompasses production time and shipping. For B2B buyers, knowing the lead time is vital for planning inventory and meeting customer demands efficiently. -

Customization Options

This refers to the various ways a buyer can alter the design, materials, or features of a jacket to meet specific needs. Customization enhances product differentiation and allows brands to cater to niche markets. Understanding available customization options can significantly influence purchasing decisions.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of sourcing custom design leather jackets more effectively, ensuring they meet both market demands and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the custom design leather jackets Sector

What are the Global Drivers and Key Trends Influencing the Custom Design Leather Jackets Market?

The custom design leather jackets market is experiencing a notable transformation driven by several global factors. One significant driver is the increasing consumer demand for personalization and individuality in fashion, particularly among younger demographics. This trend is further amplified by social media’s influence, where unique, custom items gain visibility and desirability. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly interested in sourcing high-quality, tailor-made leather jackets that cater to local fashion preferences and cultural nuances.

Emerging technologies in the supply chain, such as 3D design software and virtual fitting rooms, are revolutionizing the customization process. These tools enable manufacturers to offer more accurate fittings and quicker turnarounds, enhancing customer satisfaction. Additionally, the rise of e-commerce platforms has made it easier for international buyers to connect with suppliers, allowing them to source products directly from manufacturers without intermediary costs.

Another key trend is the growing importance of quality and craftsmanship. Buyers are increasingly seeking out suppliers who can demonstrate expertise in leather tanning and garment construction. As the market becomes more competitive, suppliers that emphasize artisanal skills and bespoke services will likely stand out, particularly in regions with a rich tradition of leather craftsmanship.

How is Sustainability and Ethical Sourcing Shaping the Custom Leather Jackets Industry?

Sustainability has become a critical consideration for B2B buyers in the custom design leather jackets sector. The environmental impact of leather production, particularly in terms of water usage, chemical runoff, and deforestation, is prompting buyers to seek out suppliers that prioritize eco-friendly practices. Ethical sourcing is also gaining traction, with buyers increasingly interested in knowing the origins of the leather they are purchasing and the conditions under which it was produced.

Suppliers that can offer transparency in their supply chains and utilize sustainable materials, such as vegetable-tanned leather or recycled fabrics, are more likely to attract discerning buyers. Certifications like the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) audit can enhance a supplier’s credibility and appeal to international markets that prioritize ethical sourcing.

Moreover, the emphasis on reducing waste through the use of upcycled leather and innovative manufacturing techniques is becoming a selling point. B2B buyers are recognizing that aligning with sustainable practices not only meets consumer demand but also positions their brands favorably in a market that is increasingly prioritizing environmental responsibility.

What is the Historical Context of Custom Design Leather Jackets in the B2B Space?

The custom design leather jackets market has evolved significantly over the decades, transitioning from a niche market to a mainstream fashion segment. Historically, leather jackets were primarily associated with specific subcultures, such as motorcyclists and rock musicians. However, as fashion trends have evolved, leather jackets have become a staple in various wardrobes globally, appealing to a wide range of consumers.

Illustrative image related to custom design leather jackets

In the early 2000s, the rise of fast fashion began to overshadow bespoke leather goods, but recent years have seen a resurgence of interest in custom and artisanal products. This shift has been fueled by a growing consumer preference for quality over quantity, as well as a desire for unique items that reflect personal style. B2B buyers today are tapping into this trend, recognizing the market potential for custom leather jackets that offer individuality and craftsmanship in an increasingly homogenized fashion landscape.

As the sector continues to grow, understanding these dynamics is essential for international buyers seeking to capitalize on the opportunities presented by the custom design leather jackets market.

Frequently Asked Questions (FAQs) for B2B Buyers of custom design leather jackets

-

How do I ensure the quality of custom design leather jackets from suppliers?

To guarantee the quality of custom leather jackets, start by vetting potential suppliers through online reviews and testimonials. Request samples of their previous work to assess craftsmanship and material quality. Additionally, inquire about their sourcing practices, such as the types of leather used and their tanneries’ reputations. Establish a clear quality assurance process that includes specific criteria for materials, stitching, and finishing. Regular communication throughout the production process can also help address any quality concerns before the final product is delivered. -

What is the best way to communicate my design specifications for a custom leather jacket?

The most effective way to communicate design specifications is to create a detailed design brief that includes sketches, color swatches, and fabric types. Use visual aids such as photos of similar jackets or mood boards to illustrate your vision. Additionally, schedule a consultation with the supplier to discuss your requirements in depth, ensuring both parties have a mutual understanding of the project. Clear and open communication, coupled with written documentation of all agreements, can help prevent misunderstandings during the production process. -

What are the typical minimum order quantities (MOQs) for custom leather jackets?

Minimum order quantities for custom leather jackets can vary significantly by supplier, often ranging from 10 to 50 units per order. Factors influencing MOQs include the complexity of the design, material availability, and production capabilities. When sourcing, it’s essential to discuss MOQs upfront to ensure they align with your business needs. Some suppliers may offer flexibility for first-time orders or smaller businesses, so it’s worth negotiating based on your specific requirements. -

How can I manage logistics and shipping for international orders of leather jackets?

Managing logistics for international orders involves choosing reliable shipping partners that specialize in international freight. Discuss shipping options with your supplier, including standard and expedited services, and consider the impact of customs duties and taxes on your overall costs. Use a logistics management platform to track shipments and stay informed about potential delays. Establish clear timelines for delivery and communicate with your supplier about any logistics challenges that may arise. -

What payment terms are common when sourcing custom leather jackets?

Common payment terms in the B2B leather goods industry typically include a deposit upon order confirmation (usually 30-50%) and the balance before shipment. Some suppliers may offer net payment terms, allowing you to pay within a specified period after delivery. It’s crucial to discuss and agree on payment terms before finalizing the order to avoid any misunderstandings. Consider using escrow services for large transactions to provide additional security for both parties. -

What customization options are available for leather jackets?

Customization options for leather jackets can be extensive, including choices for leather type (lambskin, cowhide, etc.), color, style, lining, and hardware. Buyers can also request unique features such as embroidery, printed designs, or personalized logos. During the design process, work closely with the supplier to explore all available options and ensure that your specific branding and style preferences are met. Always confirm the supplier’s capabilities to deliver the desired customizations before placing an order. -

How do I handle quality assurance and returns for custom leather jackets?

To handle quality assurance, establish clear criteria for inspection upon receipt of the jackets. This can include checking for stitching quality, color accuracy, and overall fit. Many suppliers offer a satisfaction guarantee, allowing for returns or alterations if the product does not meet specified requirements. Discuss the return policy upfront, including timelines and conditions, to ensure a smooth process in case adjustments are needed after delivery. -

What should I consider when selecting a supplier for custom leather jackets?

When selecting a supplier, consider their experience in the leather industry, production capabilities, and client testimonials. Evaluate their design flexibility and willingness to collaborate on custom projects. Research their manufacturing practices, including sustainability and ethical sourcing, as these factors can impact your brand’s reputation. Finally, assess their communication efficiency and responsiveness to inquiries, as these traits are essential for a successful long-term partnership.

Top 9 Custom Design Leather Jackets Manufacturers & Suppliers List

1. The Jacket Maker – Custom Leather Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom Leather Jackets & Coats available for men and women. Options include Bomber Jackets, Biker Jackets, Suede Jackets, Varsity Jackets, Fur & Shearling Leather Blazers, Aviator Jackets, Hooded Leather Jackets, Leather Vests, and more. Customization options include adding embroidery, logos, and color choices. Quantity discounts available for orders of 1 to 50+. Various styles of coats including …

2. Lusso Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Custom Leather Jackets – Design Your Own Leather Jacket

Regular price: $484.00

Sale price: $367.00

Free Shipping and 30 days for Returns/Alterations

Available Sizes: XSmall, Small, Medium, Large, Xlarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $431.00

Customization options include:

– Selection of fabrics and leathers

– Custom embroidery, sublimation printing, logos, graphics, le…

3. Magnoli Clothiers – Custom Leather Jackets

Domain: magnoliclothiers.com

Registered: 2006 (19 years)

Introduction: Custom leather jacket made by Magnoli Clothiers. Available in various styles and sizes. High-quality leather material. Tailored fit for comfort and style. Options for customization include color, lining, and additional features. Perfect for both casual and formal occasions.

4. Mahi – Branded Leather Jacket

Domain: mahileather.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Branded Leather Jacket”, “price”: “$215.46”, “original_price”: “$239.40”, “discount”: “10% OFF”, “material”: “premium leather”, “shipping”: “Free Worldwide Shipping”, “warranty”: “1 Year Warranty”, “return_policy”: “30 day returns”, “delivery_time”: “Delivered to most destinations in 5 business days”, “sizes”: [“Small”, “Medium”, “Large”], “colors”: [“White”, “Grey”, “Black”, “Na…

5. Urban Luxe – Custom Leather Jacket

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom-made leather jacket, high-quality material and craftsmanship, fit to measure, premium/luxury quality, budget of $1000-$2000, preference for European vendors, looking for urban-modern style, slim fit, soft leathers, accordion arms.

6. The Cast – Custom Leather Jackets & Vests

Domain: thecast.com

Registered: 1999 (26 years)

Introduction: CUSTOM LEATHER JACKETS & VESTS – MADE IN NYC

– Premium Custom Leather Jackets and Vests

– Superior quality & craftsmanship

– Made locally in New York City

– Customization options: choose style, leather, lining, hardware, and made-to-measure specs

– Styles available: Bowery, Essex, Bronx, Rivington, Downtown, The ’68, Johnnie

– Leather options: Premium Cowhide, CalfSkin, Horsehide, Hair on Hide Ani…

7. Aero Leather – Custom Leather Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Custom leather jackets made to order, expertly hand-crafted by Aero Leather Jackets since 1981. Extensive range of vintage designs from the 1920s to 1960s, with over 100 classic coats available. Customization options include various leather and lining combinations, stitch color, and more. The Aero brand is known for top-quality leather jackets and flexibility in design. Available for order through…

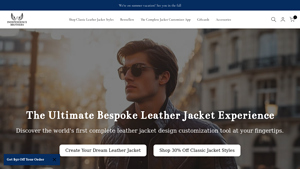

8. Independence Brothers – Custom Leather Jackets

Domain: independencebrothers.com

Registered: 2016 (9 years)

Introduction: Custom leather jackets designed for a perfect fit and unique style. Made from premium, ethically sourced materials including high-quality, semi-aniline leather. Features include personalized consultations, a complete leather jacket design customization tool, and options for various leather types such as lambskin and cowhide. Each jacket is tailored to individual measurements, ensuring comfort and …

9. Denver Leather – Custom Fur and Leather Jackets

Domain: denverleather.net

Registered: 2012 (13 years)

Introduction: Custom fur and leather jackets designed and manufactured in-house in Denver, CO. Options available for custom designs based on customer ideas or replacements for old jackets or pants. Extensive selection of leather samples in various colors. Services include fur storage, alterations, repairs, and cleaning.

Strategic Sourcing Conclusion and Outlook for custom design leather jackets

As the demand for custom design leather jackets continues to rise across global markets, strategic sourcing emerges as a pivotal factor for international B2B buyers. By partnering with reputable manufacturers who prioritize quality and customization, businesses can ensure they meet the specific needs of their clientele while maintaining a competitive edge. Key takeaways emphasize the importance of understanding regional preferences in design, material selection, and pricing strategies.

Investing in strong supplier relationships will not only streamline the production process but also enhance product offerings that resonate with diverse markets, particularly in Africa, South America, the Middle East, and Europe. Emphasizing customizability, such as bespoke sizes and personalized designs, will cater to a broader audience, increasing brand loyalty and customer satisfaction.

Looking ahead, the landscape of custom leather jackets is poised for growth, driven by innovation and consumer demand for unique styles. International buyers are encouraged to explore these opportunities by engaging with suppliers committed to excellence and sustainability in their sourcing practices. Now is the time to elevate your offerings and position your business as a leader in the custom leather market.

Illustrative image related to custom design leather jackets

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.