Introduction: Navigating the Global Market for custom leather worker near me

In the intricate world of global commerce, sourcing the right custom leather worker near me can pose significant challenges for B2B buyers, especially those operating across diverse regions like Africa, South America, the Middle East, and Europe, including key markets such as Germany and Saudi Arabia. Buyers often grapple with finding reliable suppliers who not only meet their quality standards but also understand local preferences and compliance requirements. This guide aims to streamline that process, offering valuable insights into various types of leather craftsmanship, applications ranging from bespoke handbags to corporate gifts, and essential tips for vetting suppliers effectively.

Throughout this comprehensive resource, we will explore the diverse offerings available in the custom leather market, including bespoke designs, repair services, and specialized leather goods. We will also delve into pricing structures and factors that influence costs, helping you establish a clear budget while maximizing value. Additionally, this guide equips international buyers with the knowledge necessary to make informed decisions, ensuring that your sourcing strategies align with both your business objectives and market expectations. By empowering you with actionable insights, we aim to transform your approach to sourcing custom leather products, paving the way for successful collaborations and sustainable partnerships in the global marketplace.

Table Of Contents

- Top 5 Custom Leather Worker Near Me Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather worker near me

- Understanding custom leather worker near me Types and Variations

- Key Industrial Applications of custom leather worker near me

- 3 Common User Pain Points for ‘custom leather worker near me’ & Their Solutions

- Strategic Material Selection Guide for custom leather worker near me

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather worker near me

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather worker near me’

- Comprehensive Cost and Pricing Analysis for custom leather worker near me Sourcing

- Alternatives Analysis: Comparing custom leather worker near me With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather worker near me

- Navigating Market Dynamics and Sourcing Trends in the custom leather worker near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather worker near me

- Strategic Sourcing Conclusion and Outlook for custom leather worker near me

- Important Disclaimer & Terms of Use

Understanding custom leather worker near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Leather Goods Maker | Specializes in bespoke items like bags, wallets, and belts | Corporate gifts, promotional items | Pros: Unique products, tailored designs. Cons: Higher costs, longer lead times. |

| Leather Repair Specialist | Focuses on repairing and restoring leather goods | Maintenance for corporate leather products | Pros: Extends product life, cost-effective. Cons: Limited to existing items, may not match original quality. |

| Leather Embossing/Engraving | Offers personalization through embossing or engraving | Branding, customized gifts | Pros: Enhances brand visibility, unique identifiers. Cons: Additional costs for customization, turnaround time may vary. |

| Leather Alterations Tailor | Provides alterations for fit and functionality | Customization for uniforms, corporate attire | Pros: Improved fit, tailored solutions. Cons: Requires precise measurements, not suitable for all items. |

| Leather Craft Supply Store | Supplies raw materials and tools for leather crafting | DIY projects, small business production | Pros: Variety of materials, supports creative projects. Cons: Requires crafting skills, potential wastage. |

What Are the Characteristics of Custom Leather Goods Makers?

Custom leather goods makers are artisans who create bespoke products tailored to client specifications. They often work with high-quality leather to produce unique items such as bags, wallets, and belts. B2B buyers, particularly those in retail or corporate sectors, benefit from these services by acquiring distinctive products that can serve as promotional items or corporate gifts. Considerations for purchasing include the maker’s reputation, material quality, and the ability to meet specific design requirements.

How Do Leather Repair Specialists Serve B2B Needs?

Leather repair specialists focus on restoring and maintaining leather goods, including handbags, luggage, and shoes. They offer services such as stitching, cleaning, and hardware replacement, making them invaluable for businesses that rely on leather products. B2B companies can save costs by extending the life of their leather items instead of purchasing new ones. When selecting a repair specialist, buyers should consider turnaround times, service guarantees, and the extent of repairs offered.

What Benefits Do Leather Embossing and Engraving Services Provide?

Leather embossing and engraving services allow businesses to personalize their leather products, enhancing brand visibility and appeal. This service is particularly useful for creating customized gifts or promotional items that stand out. B2B buyers should evaluate the provider’s design capabilities, the quality of the embossing or engraving, and the lead time for custom orders. While these services add unique value, they also come with additional costs that need to be factored into the budget.

Why Are Leather Alterations Tailors Important for Businesses?

Leather alterations tailors specialize in modifying leather garments and accessories to achieve the perfect fit. This service is essential for businesses that provide uniforms or corporate attire, ensuring that employees present a polished image. Buyers should consider the tailor’s expertise, the range of alterations available, and the precision of their work. While alterations can significantly enhance the appearance and functionality of leather items, they require accurate measurements and may not be suitable for all products.

Illustrative image related to custom leather worker near me

How Can Leather Craft Supply Stores Support B2B Projects?

Leather craft supply stores provide raw materials and tools necessary for crafting leather products. They cater to DIY enthusiasts and small businesses looking to create their own leather goods. B2B buyers can benefit from a diverse range of materials, allowing for customization and creativity in product development. However, purchasing from supply stores requires crafting skills and may lead to wastage if not managed carefully. Buyers should assess the quality of materials and the range of products available to ensure they meet their project needs.

Key Industrial Applications of custom leather worker near me

| Industry/Sector | Specific Application of custom leather worker near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather garments (jackets, pants, etc.) | High-quality, tailored products that enhance brand image | Sourcing sustainable materials; skilled craftsmanship; lead times for custom orders |

| Automotive | Custom leather interiors for vehicles | Enhanced luxury appeal and customer satisfaction | Compatibility with vehicle models; durability standards; customization options |

| Hospitality & Events | Leather goods for branding (bags, wallets) | Unique promotional items that strengthen brand identity | Quality of leather; customization capabilities; bulk order discounts |

| E-commerce & Retail | Personalized leather products (wallets, belts) | Differentiation in a competitive market; customer loyalty | Minimum order quantities; turnaround times; shipping logistics |

| Sports & Recreation | Custom leather gear (bags, protective wear) | Increased functionality and durability in products | Material specifications; compliance with safety standards; customization options |

How Can Custom Leather Workers Enhance the Fashion & Apparel Industry?

In the fashion and apparel sector, custom leather workers provide tailored garments, such as jackets and pants, that meet specific style and fit requirements. This service addresses challenges like mass production inadequacies, allowing brands to offer unique, high-quality items that elevate their market position. International buyers should consider sustainable sourcing and the craftsmanship level of the leather, ensuring it aligns with their brand ethos while also understanding the lead times involved in custom orders.

What Role Do Custom Leather Workers Play in Automotive Customization?

The automotive industry benefits significantly from custom leather workers who specialize in creating bespoke leather interiors for vehicles. This application enhances the luxury appeal of vehicles, contributing to customer satisfaction and retention. Buyers in this sector need to ensure that the leather used meets durability standards and is compatible with various vehicle models, while also exploring customization options that reflect brand identity.

Illustrative image related to custom leather worker near me

How Do Custom Leather Goods Serve the Hospitality & Events Sector?

In the hospitality and events industry, custom leather goods such as branded bags and wallets serve as unique promotional items that strengthen brand identity. This application helps businesses differentiate themselves in a crowded market. B2B buyers should focus on the quality of leather, customization capabilities, and potential bulk order discounts, ensuring that the products align with their brand image and marketing strategies.

Why Are Custom Leather Products Important for E-commerce & Retail?

E-commerce and retail sectors leverage personalized leather products like wallets and belts to enhance customer loyalty and differentiation in a competitive landscape. The ability to offer customizations creates a unique shopping experience that can drive sales. Buyers should be mindful of minimum order quantities, turnaround times, and shipping logistics, as these factors can significantly impact their operational efficiency and customer satisfaction.

How Do Custom Leather Workers Contribute to Sports & Recreation?

In the sports and recreation sector, custom leather workers provide tailored gear, including bags and protective wear, which enhances both functionality and durability. This application meets the specific needs of athletes and sports enthusiasts, ensuring that products can withstand rigorous use. Buyers should consider material specifications, compliance with safety standards, and available customization options to ensure that products meet their performance criteria.

Illustrative image related to custom leather worker near me

3 Common User Pain Points for ‘custom leather worker near me’ & Their Solutions

Scenario 1: Inconsistent Quality of Custom Leather Products

The Problem: B2B buyers often face the challenge of inconsistent quality when sourcing custom leather products. This inconsistency can arise from variations in material sourcing, craftsmanship levels, and manufacturing processes among different leather workers. As a result, buyers may receive products that do not meet their quality standards, leading to customer dissatisfaction and potential loss of business reputation.

The Solution: To ensure high-quality outcomes, B2B buyers should conduct thorough research before selecting a custom leather worker. Start by requesting samples of previous work, focusing on the quality of materials, stitching, and finish. Establish clear specifications for the leather type, color, and treatment processes required. Creating a detailed request for proposal (RFP) can help communicate your exact needs, which can include requirements for durability, aesthetics, and sustainability. Additionally, consider visiting the workshop if possible, to assess their capabilities firsthand. Building a strong relationship with the leather worker can also encourage better quality control and responsiveness to your specific needs.

Scenario 2: Long Lead Times Affecting Business Operations

The Problem: Many B2B buyers experience long lead times when ordering custom leather goods, which can disrupt their supply chain and delay product launches. This is particularly problematic for businesses that require rapid turnaround times due to market demands or seasonal sales cycles. Long wait times can lead to missed opportunities and customer dissatisfaction.

The Solution: To mitigate this issue, it is essential to have open communication regarding timelines with your chosen custom leather worker. Discuss your timelines upfront and inquire about their capacity and current workload. To streamline the process, consider placing orders well in advance of peak seasons or product launches. Another effective strategy is to establish a partnership with multiple leather workers to diversify your sources. This way, if one supplier faces delays, you have alternatives ready to fulfill your requirements. Implementing a just-in-time inventory system can also help manage stock levels effectively, reducing the impact of lead time variability.

Scenario 3: Difficulty in Finding Specialized Leather Workers

The Problem: B2B buyers often struggle to find custom leather workers who specialize in specific products or techniques, such as embossing, dyeing, or crafting unique designs. This can limit their ability to offer diverse product lines or cater to niche markets, ultimately affecting their competitive edge.

The Solution: To address this challenge, buyers should utilize specialized directories and industry networks to identify leather workers with the specific skills they need. Participate in industry trade shows, leather fairs, or exhibitions to connect with artisans who showcase their unique capabilities. Online platforms such as LinkedIn or specialized leather forums can also be valuable resources for finding experts in particular leather crafts. When reaching out, be clear about your project requirements and any specialized techniques needed. Building a network of trusted artisans can enable buyers to have a reliable pool of talent to draw from, ensuring they can meet diverse customer demands efficiently.

Strategic Material Selection Guide for custom leather worker near me

What Are the Key Materials Used by Custom Leather Workers?

When selecting materials for custom leatherwork, understanding the properties, advantages, and limitations of different leather types is crucial for B2B buyers. This analysis focuses on four common materials: Full-Grain Leather, Top-Grain Leather, Suede, and Bonded Leather. Each material has unique characteristics that influence product performance, durability, and suitability for various applications.

How Does Full-Grain Leather Perform in Custom Leather Products?

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain, which provides excellent breathability and durability. This material can withstand high temperatures and is resistant to wear and tear, making it ideal for products like high-end bags, shoes, and furniture.

Pros: Full-grain leather is highly durable and develops a unique patina over time, enhancing its aesthetic appeal. It is also resistant to moisture and can be treated for additional protection against stains.

Cons: The cost of full-grain leather is relatively high, which may not be suitable for all budgets. Additionally, its manufacturing process can be complex, requiring skilled labor to ensure quality.

Illustrative image related to custom leather worker near me

Impact on Application: Full-grain leather is compatible with a variety of media, including dyes and finishes, allowing for customization. However, it may not be the best choice for products requiring extensive stitching or intricate designs due to its thickness.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should consider compliance with local regulations regarding leather sourcing and environmental impact. Standards such as ASTM may apply, especially for products intended for export.

What Are the Benefits of Top-Grain Leather in Custom Leather Goods?

Top-grain leather is the second-highest quality leather, made by sanding down the surface of full-grain leather to remove imperfections. This process makes it more pliable and easier to work with, which can be advantageous for custom designs.

Illustrative image related to custom leather worker near me

Pros: Top-grain leather is generally more affordable than full-grain leather while still offering good durability and a refined appearance. It is also easier to clean and maintain, making it suitable for everyday use items.

Cons: While top-grain leather is durable, it is less robust than full-grain leather and may not develop the same rich patina over time. Its surface is also more susceptible to scratches and wear.

Impact on Application: This leather type is ideal for products like wallets, belts, and bags, where a balance of aesthetics and functionality is essential. However, its reduced durability may limit its use in high-stress applications.

Illustrative image related to custom leather worker near me

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prioritize sustainability and ethical sourcing practices. Compliance with EU regulations on leather production and processing is essential.

How Does Suede Compare for Custom Leather Applications?

Suede is made from the underside of the hide, resulting in a soft, velvety texture. It is often used for fashion items and accessories due to its luxurious feel.

Pros: Suede is lightweight and offers a unique aesthetic appeal, making it popular for trendy products like jackets, shoes, and bags. It can also be dyed in various colors, enhancing design flexibility.

Cons: Suede is less durable than full-grain and top-grain leather, making it more prone to stains and damage from moisture. It requires special care and maintenance to preserve its appearance.

Impact on Application: Suede is best suited for items that are not exposed to harsh conditions. Its compatibility with various dyes allows for creative designs, but its fragility limits its use in heavy-duty applications.

Illustrative image related to custom leather worker near me

Considerations for International Buyers: Buyers from South America may need to consider local climate conditions when choosing suede, as its performance can be affected by humidity and exposure to elements.

What Role Does Bonded Leather Play in Custom Leather Products?

Bonded leather is made from leftover scraps of leather that are bonded together with adhesives. It offers a cost-effective alternative to genuine leather.

Pros: Bonded leather is significantly cheaper than traditional leather options, making it accessible for budget-conscious projects. It can mimic the appearance of real leather, providing an attractive finish for various applications.

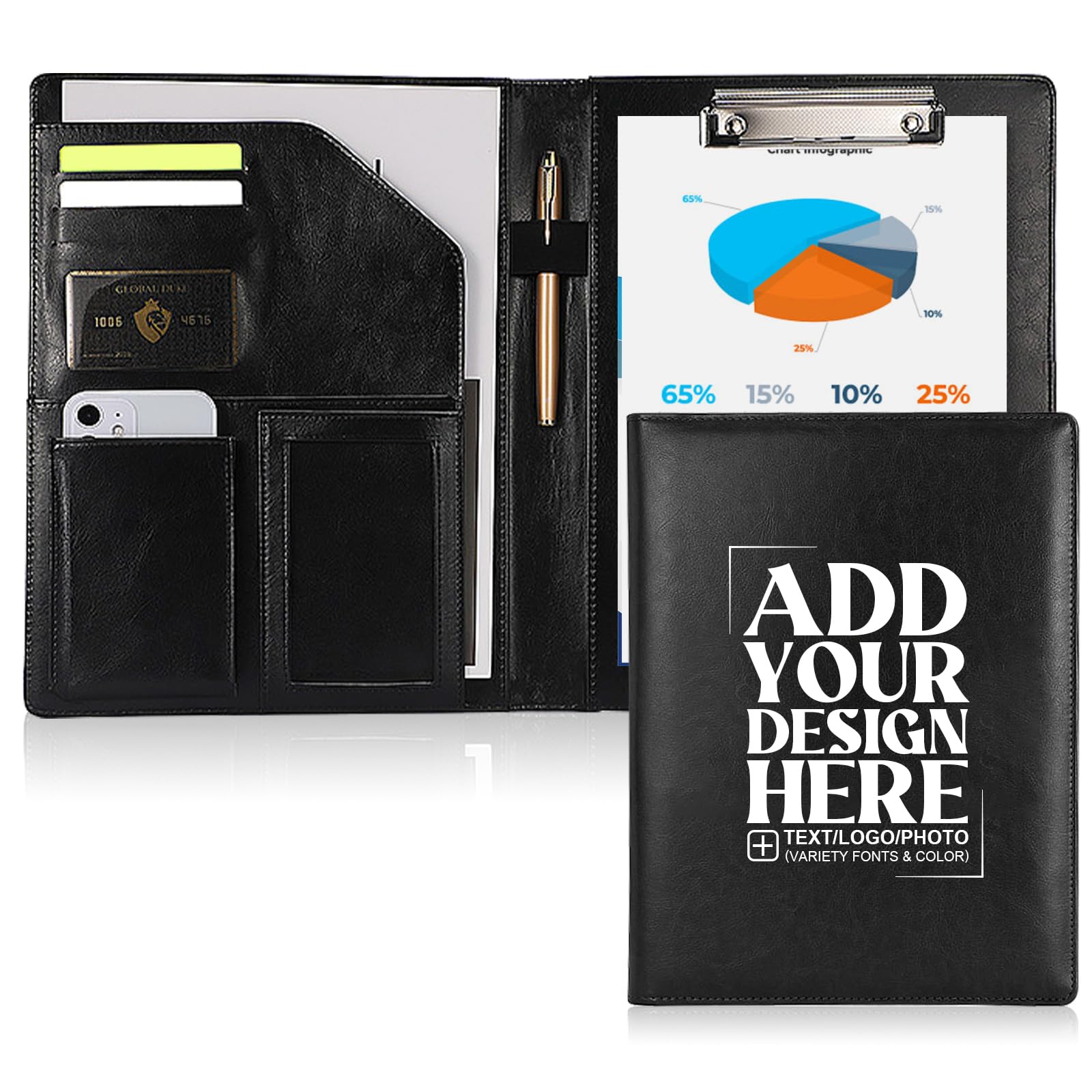

Illustrative image related to custom leather worker near me

Cons: The durability of bonded leather is inferior to that of full-grain and top-grain leather. It is prone to peeling and wear, making it unsuitable for high-quality or long-lasting products.

Impact on Application: This material is often used for low-cost items like notebooks, portfolios, and decorative accessories. However, its limited durability can affect its suitability for functional products.

Considerations for International Buyers: Buyers should be aware of varying quality standards for bonded leather across regions, particularly in Europe, where consumer protection regulations may apply.

Summary Table of Material Selection for Custom Leather Workers

| Material | Typical Use Case for custom leather worker near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end bags, shoes, furniture | Exceptional durability and breathability | High cost and complex manufacturing | High |

| Top-Grain Leather | Wallets, belts, bags | Good balance of quality and affordability | Less durable than full-grain | Medium |

| Suede | Fashion items, jackets, shoes | Soft texture and aesthetic appeal | Less durable and requires special care | Medium |

| Bonded Leather | Notebooks, portfolios, decorative accessories | Cost-effective and visually appealing | Inferior durability and prone to wear | Low |

This guide provides essential insights for B2B buyers in selecting the right materials for their custom leather products, ensuring they make informed decisions that align with their market needs and compliance requirements.

Illustrative image related to custom leather worker near me

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather worker near me

What Are the Main Stages of the Manufacturing Process for Custom Leather Goods?

The manufacturing process for custom leather goods typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the final product meets the desired quality and specifications.

How Is Material Prepared in Leather Manufacturing?

Material preparation is the first step in the leather manufacturing process. This involves sourcing high-quality leather hides, which are often selected based on their texture, grain, and thickness. Once the hides are sourced, they undergo a tanning process to preserve the leather and enhance its durability. Tanning can be done using various methods, including vegetable tanning and chrome tanning, each imparting different properties to the leather.

After tanning, the leather is conditioned and dyed, if necessary. Conditioning involves applying oils or waxes to maintain suppleness and prevent cracking. Dyeing can either be done in the tanning stage or as a separate process, allowing for custom colors that meet client specifications.

Illustrative image related to custom leather worker near me

What Techniques Are Used for Forming Leather Products?

Forming is the next stage, where the prepared leather is cut into patterns. This is typically done using precision cutting tools or dies to ensure accuracy. Advanced manufacturers may use laser cutting technology for intricate designs, which minimizes waste and enhances design capabilities.

Once the leather is cut, it may undergo additional treatments such as embossing or debossing, where patterns or logos are pressed into the leather. This not only adds a unique aesthetic but also serves as a branding opportunity for B2B buyers looking to enhance their product offerings.

How Does Assembly Take Place in Custom Leather Goods Production?

The assembly stage involves stitching or bonding the cut leather pieces together. This can be achieved through hand-stitching or machine stitching, depending on the complexity and volume of production. High-quality assembly ensures that seams are strong and durable, which is crucial for the longevity of leather products.

For custom projects, manufacturers often collaborate closely with clients during this stage to ensure that design specifications are met. This may include discussions about thread color, stitch patterns, and additional features such as pockets or linings.

What Finishing Techniques Are Commonly Applied to Leather Goods?

Finishing is the final stage of the manufacturing process, where products are polished, conditioned, and inspected. This may involve applying protective coatings to enhance water resistance or adding final touches such as hardware attachments or labels.

Finishing also includes quality checks to ensure that each product meets the required standards before it is packaged and shipped. This is particularly important for B2B buyers who require consistency and reliability in their orders.

Illustrative image related to custom leather worker near me

What Are the Key Quality Assurance Practices in Leather Manufacturing?

Quality assurance (QA) is a critical aspect of leather manufacturing, ensuring that products not only meet aesthetic standards but also functional and durability requirements.

Which International Standards Are Relevant for Leather Goods Quality Assurance?

International standards such as ISO 9001 for quality management systems are commonly adopted in the leather industry. This standard provides a framework for consistent quality in production processes and customer satisfaction. Additionally, specific certifications like CE marking indicate compliance with European safety and health regulations, which may be a requirement for buyers in markets such as Germany.

Industry-specific standards, such as those set by the American Leather Chemists Association (ALCA), focus on environmental and safety practices in the leather tanning process. B2B buyers should inquire about these certifications when evaluating potential suppliers.

What Are the Common Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to identify and rectify issues early. These checkpoints typically include:

Illustrative image related to custom leather worker near me

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined standards.

- In-Process Quality Control (IPQC): Conducted during the production stages, IPQC checks for adherence to specifications in cutting, stitching, and assembly.

- Final Quality Control (FQC): This stage involves a thorough inspection of the finished products, focusing on defects, functionality, and overall quality.

B2B buyers should ensure that their suppliers have robust QC protocols in place, as this significantly impacts product reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can employ several strategies to verify the quality control practices of their suppliers:

-

Audits: Conducting regular audits of the manufacturing facilities can provide insights into the processes and adherence to quality standards. This can be done by the buyer or through third-party auditing firms.

-

Quality Reports: Requesting detailed quality reports from suppliers can help assess their QC performance over time. These reports should include metrics related to defect rates, returns, and compliance with industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the products before shipment. This is particularly beneficial for international buyers who may face challenges in conducting on-site inspections.

What Are the Quality Assurance Nuances for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality assurance in leather manufacturing is essential. Different regions may have varying expectations regarding quality standards, certifications, and compliance.

Buyers should consider factors such as local regulations, cultural expectations, and market trends when assessing potential suppliers. Additionally, establishing clear communication channels with suppliers can help mitigate misunderstandings related to quality expectations.

By focusing on these manufacturing and quality assurance aspects, B2B buyers can make informed decisions when sourcing custom leather products, ensuring that they receive high-quality goods that meet their specific needs.

Illustrative image related to custom leather worker near me

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather worker near me’

In the evolving landscape of custom leather goods, sourcing the right leather worker is crucial for B2B buyers looking to meet specific needs. This guide will help you navigate the selection process effectively, ensuring that you partner with a skilled and reliable leather craftsman.

Step 1: Define Your Project Requirements

Before you begin searching for a custom leather worker, clearly outline your project specifications. Consider factors such as the type of leather goods you need (e.g., bags, belts, or shoes), desired materials, and design complexity. Defining these parameters will streamline your search and help potential suppliers provide accurate quotes.

Step 2: Research Local and International Options

Utilize online platforms and industry directories to identify custom leather workers both locally and internationally. Look for reviews and ratings on platforms like Yelp or Google, which can provide insights into their craftsmanship and customer service. Pay attention to their experience with international shipping if you plan to source from abroad.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have demonstrated experience with your specific type of leather goods, ensuring they can meet your quality and design requirements.

Step 4: Verify Certifications and Standards

Ensure that the leather workers you are considering adhere to industry standards and certifications. This might include environmental certifications for leather sourcing or quality management certifications such as ISO. These credentials not only reflect the quality of their work but also their commitment to sustainable practices.

Step 5: Assess Communication and Responsiveness

Effective communication is key in any B2B relationship. Gauge how quickly and thoroughly potential suppliers respond to your inquiries. A responsive supplier is likely to be more attentive to your needs throughout the production process, which can prevent misunderstandings and delays.

Step 6: Request Samples and Prototypes

Before finalizing your order, ask for samples or prototypes of their work. This will allow you to assess the quality of craftsmanship and materials firsthand. Pay attention to details such as stitching, finishing, and overall design, as these elements are critical to the success of your custom leather products.

Step 7: Discuss Terms and Conditions

Finally, ensure that you have a clear understanding of the terms and conditions of your partnership. Discuss pricing, payment terms, lead times, and warranty policies. A transparent agreement will help mitigate risks and foster a smoother working relationship.

By following these steps, B2B buyers can confidently source a custom leather worker that meets their unique needs, ensuring high-quality products and a successful partnership.

Comprehensive Cost and Pricing Analysis for custom leather worker near me Sourcing

What Are the Key Cost Components for Custom Leather Work?

When sourcing custom leather goods, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of leather directly impact pricing. For instance, full-grain leather is generally more expensive due to its durability and aesthetic appeal compared to corrected grain leather. Additionally, sourcing premium materials such as exotic skins can significantly increase costs.

-

Labor: Skilled artisans are essential for high-quality leather work. Labor costs can vary based on the complexity of the designs and the level of craftsmanship required. Regions with lower wage standards may offer more competitive pricing, but this could affect quality.

-

Manufacturing Overhead: This encompasses the operational costs of running a leather workshop, including rent, utilities, and administrative expenses. Efficient operations can help keep these costs down.

-

Tooling: Customization often requires specialized tools and machinery. The initial investment in tooling can be substantial, influencing the overall cost structure, especially for small-scale orders.

-

Quality Control (QC): Implementing rigorous quality checks is vital to ensure that the final products meet specified standards. The costs associated with QC processes can vary based on the supplier’s practices.

-

Logistics: Shipping costs are a critical factor, especially for international transactions. Factors such as shipping method, distance, and customs duties can add to the overall expense.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. Understanding the expected profit margins within the leather industry can help buyers gauge whether a quote is fair.

How Do Price Influencers Affect Custom Leather Goods?

Several factors can influence the pricing of custom leather products:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can be beneficial for both the buyer and the supplier.

-

Specifications and Customization: Highly customized products with unique designs or specifications can significantly increase costs. Buyers should be prepared to discuss their needs in detail to obtain accurate quotes.

-

Material Quality and Certifications: The presence of certifications (e.g., eco-friendly or cruelty-free) can affect pricing. Buyers should consider whether these certifications are a priority when evaluating costs.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Well-established suppliers may charge a premium for their expertise, while newer entrants might offer lower prices to gain market traction.

-

Incoterms: Understanding shipping terms is crucial for international transactions. Incoterms define the responsibilities of buyers and sellers in terms of shipping costs, insurance, and risk, impacting overall pricing.

What Are Effective Buyer Tips for Sourcing Custom Leather Goods?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage in negotiations with suppliers to secure better prices. Highlighting potential long-term partnerships may incentivize suppliers to offer discounts.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and potential repairs. This perspective can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and their impact on pricing. Additionally, consider the implications of tariffs and duties when importing goods.

-

Research and Comparison: Conduct thorough research on various suppliers to compare pricing and quality. Utilizing platforms that aggregate supplier information can save time and effort.

-

Sample Orders: Before committing to large orders, request samples to assess quality and craftsmanship. This step can prevent costly mistakes later on.

Disclaimer

Prices mentioned in this analysis are indicative and can vary significantly based on numerous factors, including market conditions, supplier negotiations, and specific buyer requirements. Always request detailed quotes from suppliers to obtain accurate pricing tailored to your needs.

Alternatives Analysis: Comparing custom leather worker near me With Other Solutions

Exploring Alternative Solutions to Custom Leather Workers

When considering options for custom leather products, it’s essential to evaluate various solutions that can meet business needs effectively. While local custom leather workers offer personalized services, alternatives such as mass-produced leather goods, DIY leather crafting kits, and online custom leather services can provide different benefits and drawbacks. Below, we will compare these options to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Custom Leather Worker Near Me | Mass-Produced Leather Goods | DIY Leather Crafting Kits |

|---|---|---|---|

| Performance | High quality, tailored products | Standardized quality, limited customization | Variable quality, skill-dependent |

| Cost | Higher due to craftsmanship | Generally lower prices | Moderate, depending on materials |

| Ease of Implementation | Requires direct interaction | Easy, available in stores | Requires skill and tools |

| Maintenance | High durability with proper care | Varies based on quality | Dependent on user skill and care |

| Best Use Case | Unique, custom requirements | Bulk orders or common styles | Hobbyists or small batch production |

Detailed Breakdown of Alternatives

Mass-Produced Leather Goods

Mass-produced leather products are widely available and often come at a lower price point than custom solutions. They are produced in bulk, which means businesses can quickly acquire items without the wait associated with custom orders. However, the downside is that these goods lack personalization and may not meet specific quality expectations. For businesses looking for uniformity in bulk purchases, this option may be viable, but it sacrifices the unique touch that custom leather workers provide.

DIY Leather Crafting Kits

DIY kits allow businesses to engage in the creative process of leather crafting. These kits come with all necessary materials and instructions, making them suitable for those interested in hands-on projects. While this option can be cost-effective and rewarding, the quality of the final product largely depends on the skill level of the user. Additionally, the time investment may not be suitable for businesses needing quick solutions. DIY crafting is ideal for small-scale operations or businesses wanting to offer unique, handmade items but may not be practical for larger enterprises.

Conclusion: Choosing the Right Leather Solution for Your Business Needs

When selecting the best leather solution, B2B buyers should consider their specific needs, including quality, budget, and time constraints. Custom leather workers near you provide high-quality, tailored products that reflect unique brand identities, making them ideal for businesses requiring specialized items. On the other hand, mass-produced options can fulfill bulk needs with minimal customization at a lower cost, while DIY kits offer a creative outlet for those willing to invest time and effort. Evaluating these factors will help businesses make an informed choice that aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather worker near me

What Are the Key Technical Properties Relevant to Custom Leather Work?

When engaging with a custom leather worker, understanding the technical properties of leather and associated products is vital for making informed decisions. Here are some critical specifications that B2B buyers should be familiar with:

Illustrative image related to custom leather worker near me

-

Material Grade

Material grade refers to the quality of leather used in production. It is typically categorized into full-grain, top-grain, genuine, and bonded leather. Full-grain leather, for example, is the highest quality, retaining the natural grain and durability, making it ideal for luxury goods. Understanding the material grade is essential for buyers to ensure they are receiving products that meet their quality expectations and market demands. -

Thickness (Gauge)

The thickness of leather is measured in ounces or millimeters. Different applications require specific thicknesses; for instance, wallets may need thinner leather, while belts may require thicker material for durability. Knowledge of thickness allows buyers to specify requirements accurately, ensuring the final product aligns with intended use. -

Finish and Treatment

Leather finishes can include aniline, semi-aniline, or pigmented treatments. Each finish offers different aesthetic qualities and durability levels. Aniline leather, for example, retains the natural look but is more susceptible to stains. Buyers should specify their preferences for finish to achieve the desired appearance and longevity in their products. -

Color Fastness

This property indicates how well the color of leather holds up against various environmental factors, such as light, water, and abrasion. Color fastness is particularly important for products intended for outdoor use or those exposed to high wear. Ensuring high color fastness can prevent premature fading and maintain the product’s aesthetic appeal over time. -

Tensile Strength

Tensile strength measures the leather’s resistance to being pulled apart. It is crucial for items like belts and bags that undergo significant stress. Understanding tensile strength helps buyers assess the durability and longevity of the leather goods they are sourcing. -

Environmental Compliance

As sustainability becomes increasingly important, knowledge of the environmental standards adhered to during the tanning and production processes is essential. Buyers should inquire about eco-friendly practices and certifications, ensuring that their suppliers align with their corporate social responsibility goals.

What Are Common Trade Terms in the Custom Leather Industry?

Familiarity with industry jargon can enhance communication and negotiations with custom leather workers. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

In the leather industry, OEM refers to companies that produce leather goods based on the designs and specifications of another brand. This term is significant for B2B buyers looking to create branded products without investing in production facilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to gauge whether a supplier can meet their production needs while managing costs effectively. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. For custom leather goods, an RFQ helps buyers clarify their requirements, such as material specifications and order volumes, ensuring competitive pricing. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and costs associated with leather goods procurement. -

Lead Time

Lead time refers to the time taken from placing an order until the goods are delivered. In the custom leather industry, lead times can vary based on complexity and order size. Knowing lead times aids buyers in planning inventory and ensuring timely product availability. -

Custom Design Specifications

This term refers to the unique requirements set by a buyer for their custom leather products. Detailing custom design specifications ensures that the final products align with brand identity and functional needs.

By understanding these technical properties and trade terms, B2B buyers can navigate the landscape of custom leather goods more effectively, ensuring they make informed and strategic purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the custom leather worker near me Sector

What Are the Current Trends Influencing the Custom Leather Worker Market?

The custom leather market is witnessing substantial transformation driven by evolving consumer preferences and technological advancements. Global demand for bespoke leather goods is on the rise, particularly in regions such as Africa, South America, the Middle East, and Europe. This growth is propelled by an increasing inclination towards personalized products, where buyers seek unique, handcrafted items that reflect their individual style and values. The trend is particularly prominent among B2B buyers, who are increasingly sourcing custom leather products for branding and corporate gifting.

Emerging technologies such as digital fabrication and 3D printing are reshaping traditional leatherworking processes, allowing for more intricate designs and efficient production methods. Additionally, platforms enabling direct communication between buyers and artisans are gaining traction, facilitating quicker turnaround times and more tailored services. As a result, international buyers are encouraged to explore local artisans and manufacturers, enhancing their supply chain agility and responsiveness.

Furthermore, the rise of e-commerce has expanded market access for custom leather workers, enabling them to reach global clientele more effectively. This shift is particularly relevant for buyers from regions with burgeoning middle classes, where demand for luxury and custom goods is increasing. As such, B2B buyers should keep a keen eye on these market dynamics to capitalize on emerging opportunities.

Illustrative image related to custom leather worker near me

How Is Sustainability Reshaping the Sourcing Strategies of Custom Leather Workers?

Sustainability has become a cornerstone of sourcing strategies in the custom leather industry. The environmental impact of leather production has drawn scrutiny, prompting buyers to prioritize ethical sourcing and sustainable practices. B2B buyers are increasingly looking for suppliers who can demonstrate a commitment to environmentally friendly processes, such as using vegetable-tanned leather or recycled materials, which significantly reduce ecological footprints.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers that adhere to fair labor practices and provide transparency regarding their sourcing methods. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential criteria for B2B buyers when selecting suppliers. These certifications not only ensure compliance with environmental standards but also bolster brand reputation, aligning with the growing consumer demand for responsible sourcing.

As businesses aim to minimize waste, many custom leather workers are adopting circular economy principles, which include recycling leather scraps and repurposing old goods. This approach not only addresses sustainability concerns but also appeals to a market increasingly focused on eco-consciousness. By aligning sourcing strategies with sustainable practices, B2B buyers can enhance their brand value and meet the expectations of a discerning consumer base.

What Is the Historical Context of Custom Leather Goods in B2B Transactions?

The custom leather industry has a rich history that dates back centuries, evolving from artisanal craftsmanship to a more sophisticated market driven by global trade. Historically, leather goods were handmade by skilled artisans, with each piece reflecting the unique techniques and traditions of its maker. This artisanal approach laid the foundation for the bespoke leather market we see today.

In recent decades, the industry has shifted towards mass production, largely driven by technological advancements and globalization. However, the resurgence of interest in handmade, personalized products has rekindled appreciation for traditional leatherworking techniques. This evolution has not only created a niche market for custom leather goods but has also opened up opportunities for B2B transactions that prioritize quality and craftsmanship over mass-produced items.

Illustrative image related to custom leather worker near me

As international buyers seek to differentiate their offerings, understanding the historical context of leather craftsmanship can provide valuable insights into sourcing decisions. By connecting with local artisans and embracing traditional methods, B2B buyers can enhance their product lines and cater to a growing demand for authenticity in their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather worker near me

1. How do I find a reliable custom leather worker near me?

To locate a dependable custom leather worker, consider leveraging online directories and local business listings. Look for reviews and testimonials to gauge the quality of their craftsmanship. Additionally, visiting their physical location can provide insight into their materials and production methods. Networking within industry-specific forums or trade shows can also yield recommendations from other B2B buyers who have had positive experiences with local artisans.

2. What factors should I consider when vetting a custom leather supplier?

When vetting a custom leather supplier, evaluate their experience and expertise in the specific type of leather goods you need. Request samples of their work to assess quality, craftsmanship, and material sourcing. It’s also crucial to inquire about their production capacity, turnaround times, and adherence to international quality standards. Establishing clear communication about your expectations and their ability to meet them is essential for a successful partnership.

3. What customization options are typically available for leather goods?

Most custom leather workers offer a variety of customization options, including size, color, texture, and design features like embossing or engraving. You can often request specific hardware, stitching styles, and finishes to align with your brand’s identity. Discussing your needs upfront with the supplier will help them provide tailored solutions that meet your specifications and enhance your product offerings.

Illustrative image related to custom leather worker near me

4. What is the typical minimum order quantity (MOQ) for custom leather goods?

The MOQ for custom leather goods can vary significantly between suppliers, often depending on the complexity of the design and materials used. Generally, smaller artisans may have lower MOQs, sometimes starting at 10-50 units, while larger manufacturers may require orders in the hundreds. Be sure to clarify MOQs before proceeding, as this can impact your purchasing decisions and inventory management.

5. What payment terms should I expect when working with a custom leather supplier?

Payment terms can vary widely among custom leather suppliers. Common practices include a deposit upfront (often 30-50% of the total order value) and the remainder upon completion or delivery. Some suppliers may offer credit terms for established businesses, while others may require full payment in advance for first-time orders. Always negotiate clear payment terms that suit your cash flow and ensure they are documented in the contract.

6. How can I ensure quality assurance in my leather goods?

To ensure quality assurance, establish clear specifications and standards upfront with your supplier. Request samples before mass production to evaluate material quality and craftsmanship. Many suppliers offer quality checks at different production stages; inquire about their quality control processes. Additionally, consider third-party inspections for larger orders to validate compliance with your quality expectations.

7. What are the logistics considerations when importing custom leather products?

When importing custom leather products, consider factors such as shipping methods, customs duties, and import regulations specific to your country. Collaborate with your supplier to determine the best shipping options that balance cost and delivery time. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate smooth customs clearance and avoid delays.

Illustrative image related to custom leather worker near me

8. How do cultural differences affect the sourcing of custom leather goods internationally?

Cultural differences can significantly impact the sourcing of custom leather goods, affecting negotiation styles, communication, and business practices. Understanding cultural norms and expectations in your supplier’s country can foster stronger relationships and smoother transactions. For instance, some cultures value direct communication, while others may prefer a more relational approach. Conducting research and being culturally sensitive can enhance your partnership and lead to better outcomes.

Top 5 Custom Leather Worker Near Me Manufacturers & Suppliers List

1. CandB Leather – Custom Handcrafted Leather Goods

Domain: candbleather.com

Registered: 2021 (4 years)

Introduction: Custom leather work handcrafted with quality. Handmade leather items made in traditional ways of Western American Saddle Makers. Specializes in personalized items including custom notebooks, designer handbags, money clips with geometric designs, floral pendant, Celtic Trinity Knot notebooks, and floral clutch wallets.

2. Reddit – Custom Leather Work Gloves

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: custom leather gloves for a particular work purpose

3. Yelp – Leather Craft Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Leather Craft services in Denver, CO include: custom leather belts, leather gloves, leather shoes, leather handbags, leather wallets, leather supply, purse repair, cobbler and shoe repair, leather jacket repair, leather engraving, leather restoration, custom made shoes, leather alterations, handmade shoes, leather dye, leather embroidery, and cowboy boots. Notable businesses include JT Leather Cra…

4. Amish Leatherworks – Handmade Leather Goods

Domain: amishleatherworks.com

Registered: 2017 (8 years)

Introduction: [{“name”:”Leather Guitar Strap”,”color”:”Brown”,”style”:”Handmade Classic Style”,”features”:”Personalized Engraved, Full Grain Leather, Made in USA”},{“name”:”Deluxe Flask with Buffalo Leather”,”features”:”Made in USA”},{“name”:”Leather Utility Bag”,”features”:”Secure Wrist Strap, Solid Brass Zipper, Handmade Storage Pouch, Full Grain Buffalo Leather, Personalized, Made in USA”,”price”:”$84.99″},{…

5. Tandy Leather – Save 15% Off Everything

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: SAVE 15% OFF EVERYTHING* THIS WEEKEND ONLY!

Strategic Sourcing Conclusion and Outlook for custom leather worker near me

In the dynamic realm of custom leather goods, strategic sourcing plays a pivotal role for international B2B buyers seeking quality and craftsmanship. By prioritizing local artisans, such as custom leather workers, businesses can not only reduce lead times but also foster relationships that enhance product authenticity and customization. Buyers from regions like Africa, South America, the Middle East, and Europe, particularly Germany and Saudi Arabia, stand to benefit significantly from sourcing partnerships that emphasize quality, sustainability, and bespoke services.

The diverse offerings from local leather craftsmen—ranging from bespoke handbags to footwear repairs—provide an invaluable resource for companies looking to differentiate themselves in a competitive market. Moreover, engaging with these artisans allows for greater flexibility in order volume and design specifications, ensuring that businesses can meet evolving consumer demands effectively.

As the global market continues to evolve, now is the time for B2B buyers to explore strategic partnerships with local leather workers. By leveraging their expertise and craftsmanship, companies can enhance their product lines and build a reputation for quality that resonates with discerning customers. Embrace this opportunity to elevate your brand and connect with skilled artisans who can help you transform your vision into reality.

Illustrative image related to custom leather worker near me

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.