Introduction: Navigating the Global Market for material suede

Navigating the intricacies of the global market for material suede can be a daunting task for B2B buyers, particularly when sourcing high-quality materials that meet both aesthetic and functional requirements. With its unique properties, suede is sought after for various applications, from luxury apparel to automotive interiors. However, buyers often face challenges related to supplier reliability, material authenticity, and cost-effectiveness. This comprehensive guide aims to equip international B2B buyers—especially those from Africa, South America, the Middle East, and Europe, including markets like Brazil and Germany—with the insights needed to make informed purchasing decisions.

Within these pages, we delve into the diverse types of suede available, explore its wide-ranging applications, and provide actionable strategies for vetting suppliers effectively. Additionally, we address cost considerations, helping you understand pricing structures and the factors influencing them. By focusing on the nuances of sourcing suede, this guide empowers businesses to navigate the complexities of the global market, ensuring that your procurement decisions align with both your brand’s quality standards and budgetary constraints. Armed with this knowledge, you can confidently engage with suppliers and select the right suede materials that enhance your product offerings and elevate your business.

Table Of Contents

- Top 6 Material Suede Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for material suede

- Understanding material suede Types and Variations

- Key Industrial Applications of material suede

- 3 Common User Pain Points for ‘material suede’ & Their Solutions

- Strategic Material Selection Guide for material suede

- In-depth Look: Manufacturing Processes and Quality Assurance for material suede

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘material suede’

- Comprehensive Cost and Pricing Analysis for material suede Sourcing

- Alternatives Analysis: Comparing material suede With Other Solutions

- Essential Technical Properties and Trade Terminology for material suede

- Navigating Market Dynamics and Sourcing Trends in the material suede Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of material suede

- Strategic Sourcing Conclusion and Outlook for material suede

- Important Disclaimer & Terms of Use

Understanding material suede Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lamb Suede | Soft, lightweight, and luxurious feel | High-end apparel, bags, and shoes | Pros: Soft texture, premium appeal. Cons: Less durable, requires careful cleaning. |

| Cowhide Suede | Thicker and more durable than lamb suede | Outerwear, upholstery, and automotive seats | Pros: Greater durability, versatile. Cons: Heavier, less soft compared to lamb suede. |

| Synthetic Suede | Made from polyester or nylon, mimics natural suede | Budget-friendly apparel and accessories | Pros: Cost-effective, easier to clean. Cons: Less breathable, may lack premium feel. |

| Deerskin Suede | Unique texture and softness, often used in gloves | Specialty apparel and accessories | Pros: Durable, comfortable. Cons: Higher cost, less available. |

| Microfiber Suede | Ultra-soft, water-resistant synthetic alternative | Fashion items, upholstery, and accessories | Pros: Water-resistant, easy maintenance. Cons: May not have the same luxury appeal. |

What Are the Characteristics of Lamb Suede and Its Suitability for B2B Buyers?

Lamb suede is revered for its luxurious softness and lightweight nature, making it a popular choice for high-end apparel, handbags, and footwear. Its delicate texture provides a premium feel, appealing to fashion designers and retailers targeting upscale markets. However, buyers should consider that lamb suede is less durable than other options and requires professional cleaning to maintain its appearance, which could lead to higher long-term maintenance costs.

How Does Cowhide Suede Compare in Terms of Durability and Applications?

Cowhide suede is thicker and more robust compared to lamb suede, making it suitable for outerwear, upholstery, and automotive seat covers. Its durability allows it to withstand more wear and tear, appealing to manufacturers needing long-lasting materials. While it offers versatility and resilience, buyers should note that its heavier weight and less luxurious feel compared to lamb suede may not be ideal for all high-end applications.

Why Should B2B Buyers Consider Synthetic Suede as a Cost-Effective Alternative?

Synthetic suede, crafted from polyester or nylon, provides a budget-friendly alternative that mimics the appearance of genuine suede. It is commonly used in budget-conscious apparel and accessories, appealing to manufacturers seeking to minimize production costs. While it is easier to clean and maintain, B2B buyers should be aware that synthetic options may lack the breathability and luxury feel of natural suede, potentially affecting consumer perception.

What Makes Deerskin Suede Unique and Valuable for Specialized Applications?

Deerskin suede stands out due to its unique texture and exceptional softness, making it ideal for specialty apparel and accessories, such as gloves and high-end garments. Its durability and comfort are significant advantages for B2B buyers looking for quality materials. However, the higher cost and limited availability may restrict its use, making it a niche option for luxury brands and specialized markets.

How Does Microfiber Suede Enhance Functionality and Maintenance in B2B Applications?

Microfiber suede is an ultra-soft, water-resistant synthetic alternative that excels in various applications, including fashion items and upholstery. Its easy maintenance and resistance to stains make it an attractive choice for manufacturers focused on practicality. While it may not carry the same luxury appeal as natural suede, its functionality and affordability make it a popular choice for a wide range of consumer products.

Key Industrial Applications of material suede

| Industry/Sector | Specific Application of material suede | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end clothing and accessories | Enhances luxury appeal and comfort for premium products | Quality of suede, color options, and supplier reputation |

| Automotive | Upholstery for luxury vehicles | Offers a premium feel and aesthetic in high-end interiors | Durability, maintenance requirements, and colorfastness |

| Footwear | Dress shoes and casual footwear | Provides a soft, stylish alternative to traditional leathers | Availability of various textures and finishes |

| Home Décor | Upholstery for furniture and decorative items | Adds elegance and warmth to interior spaces | Fabric weight, color choices, and treatment against stains |

| Sporting Goods | Specialty gloves for sports and outdoor activities | Combines comfort with grip for improved performance | Breathability, flexibility, and moisture resistance |

How is Material Suede Used in the Fashion and Apparel Industry?

In the fashion industry, material suede is primarily utilized for high-end clothing and accessories, such as jackets, handbags, and belts. Its soft texture and luxurious appearance appeal to consumers seeking premium products. Buyers in this sector must prioritize sourcing high-quality suede that meets specific color and texture requirements to ensure brand consistency. Additionally, they should consider the environmental impact of sourcing practices, particularly when dealing with international suppliers from regions like Africa and South America.

What Role Does Material Suede Play in the Automotive Sector?

In the automotive industry, suede is favored for upholstery in luxury vehicles, providing a sophisticated touch to interiors. Its soft feel enhances the overall aesthetic, appealing to consumers who value comfort and style. Businesses must focus on sourcing suede that is durable and stain-resistant, as automotive applications require materials that can withstand everyday wear and tear. Buyers should also inquire about the supplier’s ability to provide consistent color matching for custom interiors, especially in regions like Europe and the Middle East.

Why is Material Suede Popular in Footwear?

Material suede is a popular choice for dress shoes and casual footwear due to its stylish appearance and comfort. It offers a unique texture that differentiates products in a competitive market. B2B buyers need to consider the availability of various suede types, including synthetic alternatives, which may offer greater durability and ease of care. Sourcing partners should also provide clear information on maintenance requirements, as suede can be prone to staining and requires specific cleaning methods to maintain its look.

How is Material Suede Used in Home Décor?

In home décor, material suede is employed for upholstery on furniture and decorative items, adding an elegant touch to interiors. Its rich texture and wide range of colors make it a preferred choice for designers looking to create inviting spaces. Buyers should focus on fabric weight and treatment options to ensure the suede is suitable for high-traffic areas. Additionally, sourcing considerations should include the environmental credentials of suppliers, particularly in markets sensitive to sustainability issues, such as Europe.

What are the Applications of Material Suede in Sporting Goods?

In the sporting goods sector, material suede is used in specialty gloves designed for various sports and outdoor activities. Its soft texture enhances grip and comfort, providing athletes with a performance edge. Buyers in this industry need to prioritize materials that offer breathability and flexibility while being resistant to moisture. When sourcing suede for sporting applications, it’s crucial to work with suppliers who understand the specific requirements of performance gear, ensuring that the products meet international standards for quality and durability.

3 Common User Pain Points for ‘material suede’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Suede for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality suede materials that meet specific application requirements. With a plethora of suppliers and varying grades of suede, differentiating between genuine, high-end suede and lower-quality alternatives can be challenging. This not only affects the final product quality but also impacts brand reputation, especially in industries like fashion and upholstery where material quality is paramount.

The Solution: To effectively source quality suede, buyers should prioritize suppliers that offer transparent information regarding the sourcing and processing of their materials. Request samples to evaluate texture, durability, and colorfastness before making a bulk purchase. Establishing relationships with suppliers who specialize in suede, such as those offering Italian or premium suede, can ensure consistent quality. Additionally, utilizing certifications or standards (like ISO) can help verify the supplier’s commitment to quality. Engaging in direct conversations with suppliers about their tanning processes and dyeing methods can further assure buyers that they are procuring the best materials for their specific needs.

Scenario 2: Maintaining Suede Products in Challenging Climates

The Problem: Suede’s inherent properties make it less durable in harsh environmental conditions. B2B buyers in regions with high humidity or frequent rainfall face the challenge of maintaining the integrity of suede products. For example, retailers selling suede footwear or apparel may find that their products quickly deteriorate, leading to customer dissatisfaction and increased return rates.

The Solution: Buyers should consider investing in protective treatments specifically designed for suede. These treatments create a barrier against moisture and stains, significantly extending the life of suede products. Furthermore, educating customers on proper care techniques is essential. Providing care kits or informative guides that include cleaning and maintenance instructions can help end users preserve their suede items. For businesses operating in challenging climates, opting for synthetic suede alternatives that mimic the appearance of genuine suede while offering better resistance to water and stains may also be a viable solution.

Scenario 3: The Challenge of Cleaning and Maintaining Suede Materials

The Problem: Cleaning suede presents a unique set of challenges due to its delicate nature. B2B buyers often encounter complaints from customers about the difficulty of removing stains or restoring the appearance of suede items. This issue is particularly pressing for businesses in the fashion and automotive industries, where suede is commonly used in apparel and car interiors.

The Solution: Implementing a robust care strategy is critical for maintaining suede products. Buyers should partner with professional cleaning services that specialize in suede to offer as an added value to their customers. Additionally, providing clients with detailed care instructions, including the use of specialized suede brushes and cleaning solutions, can empower them to maintain their products effectively. Companies can also consider offering a warranty or service plan that includes periodic professional cleaning, enhancing customer trust and satisfaction. Furthermore, exploring the latest advancements in cleaning technology, such as environmentally friendly cleaning solutions, can provide innovative options for maintaining suede without compromising its quality.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their product offerings, improve customer satisfaction, and ultimately drive sales in a competitive marketplace.

Strategic Material Selection Guide for material suede

What Are the Key Properties of Natural Suede?

Natural suede is derived from the underside of animal hides, primarily lamb, goat, or calf. Its key properties include a soft texture and a matte finish, making it a luxurious option for various applications such as clothing, accessories, and upholstery. However, natural suede has low moisture resistance and is prone to staining, which limits its use in outdoor or high-moisture environments. Its breathability is low, but it retains heat well, making it suitable for cooler climates.

What Are the Advantages and Disadvantages of Synthetic Suede?

Synthetic suede, often made from polyester or nylon, offers a range of advantages over natural suede. It is generally more durable, water-resistant, and stain-resistant, making it suitable for a wider range of applications, including automotive interiors and outdoor wear. Additionally, synthetic suede is easier to clean and maintain, which can be a significant selling point for B2B buyers in sectors requiring high durability. However, it may lack the luxurious feel and aesthetic appeal of natural suede, and the manufacturing complexity can vary depending on the production process.

How Do Different Types of Suede Impact Application Suitability?

The choice between natural and synthetic suede significantly impacts application suitability. Natural suede is ideal for high-end fashion items and luxury goods, where aesthetics and tactile quality are paramount. Conversely, synthetic suede is more appropriate for mass-market products, such as affordable footwear and outerwear, where durability and ease of care are prioritized. B2B buyers should consider the specific end-use of their products when selecting the type of suede, as this will influence customer satisfaction and product longevity.

What Should International B2B Buyers Consider When Sourcing Suede?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance and regulatory standards associated with suede materials. For instance, they may need to adhere to ASTM standards in the U.S. or DIN standards in Germany. Additionally, cultural preferences can influence the choice of suede type; for example, buyers in Brazil may favor synthetic options due to their practicality in humid climates, while European markets may still value the luxury of natural suede. Understanding these regional preferences and regulations is crucial for successful procurement and market entry.

Summary Table of Material Suede Options

| Material | Typical Use Case for material suede | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Suede | High-end fashion apparel | Luxurious feel and aesthetic appeal | Low moisture resistance, prone to stains | High |

| Synthetic Suede | Automotive interiors, outdoor wear | Durable, water-resistant, easy to clean | May lack luxury feel | Medium |

| Ultrasuede | Apparel linings, bags | Soft texture, environmentally friendly | Higher cost than traditional synthetics | High |

| Microfiber Suede | Casual footwear, home textiles | Excellent durability and stain resistance | Less breathable compared to natural suede | Medium |

This strategic material selection guide provides actionable insights for B2B buyers navigating the complexities of suede materials, ensuring informed decisions that align with their specific market needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for material suede

What Are the Key Stages in the Manufacturing Process of Material Suede?

The manufacturing process of suede is intricate, involving several critical stages to transform raw animal hides into the soft, luxurious fabric that is highly valued in the fashion and upholstery industries. Understanding these stages is essential for B2B buyers to ensure they source high-quality materials.

1. Material Preparation: How Is Suede Fabric Initially Processed?

The journey of suede begins with the procurement of animal hides, most commonly lamb, goat, or calf skin. Once the hides are acquired, they undergo a rigorous cleaning process to remove any residual hair and impurities. The hides are then dried, often through air drying or salting, to prepare them for the tanning process.

Illustrative image related to material suede

Following drying, a lime treatment is applied to eliminate hair follicles, leading to a clean surface ready for tanning. Tanning agents, primarily tannins, are then introduced to convert the raw hide into leather. This step is crucial as it preserves the material and imparts the necessary characteristics for subsequent processing.

2. Forming: What Techniques Are Used to Create the Soft Texture of Suede?

Once tanned, the leather is split to achieve the desired thickness. This splitting process is essential for producing the characteristic napped finish of suede. The outer layer of the hide is often discarded, leaving the softer inner layer.

To enhance the texture, manufacturers employ techniques such as buffing and sanding. These processes create the soft, velvety surface that defines suede. Additionally, some producers may apply surface treatments to further enhance durability and texture.

3. Assembly: How Is Suede Fabric Prepared for Final Products?

After the suede has been formed, it is typically dyed to achieve the desired color. The dyeing process can involve both natural and synthetic dyes, with the unique texture of suede allowing for excellent color adhesion.

Once dyed, the suede may undergo a final treatment to apply a waterproofing finish, although this is less common due to the fabric’s inherent permeability. At this stage, the material can be cut into various patterns and shapes, ready for assembly into end products such as jackets, shoes, or accessories.

4. Finishing: What Final Touches Are Added to Suede Fabric?

The finishing stage involves additional processes to enhance the appearance and usability of the suede. This may include applying protective coatings or additional buffing to ensure a consistent texture and appearance.

Quality control checks are often integrated into the finishing process to ensure that the suede meets specified quality standards before being packaged and shipped.

What Quality Assurance Measures Should B2B Buyers Expect from Suede Manufacturers?

Quality assurance is paramount in the suede manufacturing process, especially for B2B buyers who require consistency and reliability in their materials.

1. Which International Standards Are Relevant to Suede Production?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems and continuous improvement. Compliance with these standards ensures that manufacturers maintain consistent quality throughout their production processes.

Illustrative image related to material suede

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold within the European market are critical. These certifications verify that products meet European health, safety, and environmental protection standards.

2. What Are the Key Quality Control Checkpoints in Suede Manufacturing?

Quality control in suede manufacturing typically involves multiple checkpoints, including:

- Incoming Quality Control (IQC): This initial check evaluates the quality of raw materials upon arrival to ensure they meet the manufacturer’s standards.

- In-Process Quality Control (IPQC): During the manufacturing stages, ongoing checks are performed to identify any deviations from quality standards.

- Final Quality Control (FQC): Before products are packaged, a final inspection ensures that they meet all specifications, both in terms of appearance and functionality.

Common testing methods include visual inspections, physical property tests (such as thickness and softness), and durability assessments to ensure the suede can withstand normal usage conditions.

3. How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control measures of their suede suppliers. This can be achieved through:

- Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards and practices.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s QC processes and any issues that may have arisen during production.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in suede manufacturing is essential.

1. Are There Specific Regional Standards for Suede?

Different regions may have specific requirements or standards that manufacturers must comply with. For example, European buyers may prioritize compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations to ensure that the materials used are safe for consumers.

2. How Do Cultural Differences Impact Quality Expectations?

Cultural differences can also influence quality expectations. Buyers from different regions may have varying standards for what constitutes acceptable quality, making it crucial for suppliers to communicate openly about their manufacturing processes and quality assurance measures.

3. What Role Does Supply Chain Transparency Play?

In today’s global market, supply chain transparency is increasingly important. Buyers should seek suppliers who are willing to share detailed information about their sourcing, production, and quality control practices. This transparency fosters trust and ensures that both parties are aligned in their quality expectations.

Illustrative image related to material suede

Conclusion

Understanding the manufacturing processes and quality assurance measures for material suede is vital for B2B buyers. By familiarizing themselves with the stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions that ensure the quality and reliability of the suede products they source. As the global market continues to evolve, maintaining a focus on quality will be essential for successful partnerships and sustainable business growth.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘material suede’

Introduction

This sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure material suede. As a luxury fabric used in various applications from apparel to accessories, understanding the nuances of sourcing suede is essential for ensuring quality, cost-effectiveness, and supplier reliability. This guide will walk you through crucial steps to streamline your procurement process.

Step 1: Define Your Technical Specifications

Establish clear requirements for the suede you intend to purchase. Consider factors such as the type of animal hide (e.g., lamb, calf, goat), thickness, color, and finish. Detailing these specifications helps suppliers provide accurate samples and pricing, ensuring that you receive a product that meets your quality standards.

- Identify end-use applications: Suede for shoes will differ in durability requirements compared to that for jackets or handbags.

- Consider environmental factors: If the suede will be exposed to moisture, confirm if suppliers offer treated options.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suede suppliers. Look for manufacturers with a proven track record in the suede market, particularly those who can meet your specifications. Use industry directories, trade shows, and online platforms to compile a list of candidates.

- Check for reviews and testimonials: Analyze feedback from other B2B buyers to gauge supplier reliability.

- Prioritize local suppliers: If possible, source from suppliers within your region to reduce shipping costs and lead times.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a personal interaction can reveal a lot about their business practices.

Illustrative image related to material suede

- Inquire about production capabilities: Ensure they can scale up production if your demand increases.

- Ask about quality control measures: Understand their processes to ensure that the suede meets your standards consistently.

Step 4: Request Samples for Quality Assessment

Always request samples before placing a bulk order. This step allows you to evaluate the suede’s texture, color, and overall quality firsthand. It is essential for verifying that the material meets your technical specifications and expectations.

- Test for durability and feel: Assess how the suede responds to wear and tear, especially if used for garments.

- Consider dye lots: Ensure that color consistency aligns with your requirements across different batches.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your suppliers comply with industry standards and regulations. Certifications related to environmental sustainability, labor practices, and quality assurance can indicate a supplier’s commitment to ethical sourcing and production.

- Look for ISO certifications: These demonstrate a supplier’s adherence to international quality management standards.

- Confirm compliance with regional regulations: Especially important if you’re sourcing from countries with different labor laws.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, enter negotiations with clear objectives. Discuss pricing, payment terms, delivery schedules, and minimum order quantities to ensure transparency and mutual benefit.

- Consider long-term partnerships: Establishing a good relationship can lead to better pricing and priority service in the future.

- Be clear on return policies: Understand the process for returns or exchanges in case the delivered suede does not meet your expectations.

Step 7: Monitor Production and Delivery

Stay engaged during the production and delivery phases. Regular communication with your supplier can help address any issues early and keep your project on schedule.

- Set up progress updates: Regular check-ins can help you gauge if the supplier is on track with your order.

- Plan for logistics: Coordinate shipping arrangements well in advance to avoid delays in receiving your materials.

By following this checklist, B2B buyers can enhance their sourcing strategy for material suede, ensuring they receive high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for material suede Sourcing

What are the Key Cost Components in Material Suede Sourcing?

When sourcing material suede, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The cost of suede itself can vary significantly based on the type of animal hide used, with lambskin generally being more expensive than goat or calfskin. Prices for suede can range from approximately $29.99 to $39.99 per yard, depending on the quality and source.

-

Labor: The complexity of the tanning and finishing processes influences labor costs. Skilled artisans are often required for high-quality suede production, particularly when it comes to the finishing touches that make the fabric soft and appealing.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, maintenance, and equipment depreciation. Overhead can significantly impact the final price of suede, especially in regions with higher operational costs.

-

Tooling: Investment in specialized equipment for cutting, stitching, and finishing suede can be substantial. This is particularly important for custom orders, where unique specifications may require additional tools or machinery.

-

Quality Control (QC): Ensuring that suede meets quality standards involves rigorous inspection processes, which add to overall costs. This is crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the origin of the suede, distance to the buyer, and the chosen shipping method. International buyers should consider import duties and tariffs, which can influence overall expenses.

-

Margin: Suppliers typically include a markup to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and the supplier’s positioning.

How Do Price Influencers Affect Material Suede Sourcing?

Several factors can influence the pricing of suede, making it essential for buyers to understand these nuances:

Illustrative image related to material suede

-

Volume/MOQ: Suppliers often provide better pricing for bulk orders. Minimum order quantities (MOQs) can impact the cost significantly; larger orders can lead to cost savings per unit.

-

Specifications and Customization: Custom dyeing, finishing, or specific textures can increase costs. Buyers should be clear about their requirements upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality suede, particularly those with certifications for sustainability or ethical sourcing, will generally come at a premium. Buyers should evaluate the value of these certifications against their budget.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers with a history of high-quality products may charge more, but can also reduce risks associated with defects and delays.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can influence costs and risks associated with shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and insurance, impacting the overall price structure.

What Tips Can Help Buyers Negotiate Better Suede Prices?

International B2B buyers from regions like Africa, South America, the Middle East, and Europe should consider the following strategies to enhance cost efficiency:

-

Conduct Thorough Market Research: Understand market prices, competitor offerings, and supplier capabilities to negotiate effectively. This knowledge can empower buyers during discussions.

-

Leverage Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but the long-term costs associated with maintenance, durability, and performance. This approach can justify spending more upfront for higher-quality suede.

-

Build Strong Relationships with Suppliers: Establishing a rapport can lead to better pricing and terms. Long-term partnerships may offer discounts and favorable terms for repeat orders.

-

Be Open to Alternatives: While genuine suede is desirable, synthetic alternatives may offer cost savings and durability. Be willing to explore various options that meet your specifications.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns and allow for more strategic purchasing decisions. Discussing staggered payments or discounts for early payment can be beneficial.

Understanding these cost components and pricing influencers equips B2B buyers with the insights needed to make informed decisions when sourcing material suede. Always remember that prices can vary, and it’s prudent to obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing material suede With Other Solutions

In the quest for high-quality materials for apparel and accessories, businesses often seek alternatives to traditional options like material suede. Understanding these alternatives is crucial for B2B buyers looking to optimize their product offerings while balancing performance, cost, and user experience. This analysis compares material suede with two viable alternatives: synthetic suede and genuine leather, providing insights into their respective strengths and weaknesses.

Illustrative image related to material suede

| Comparison Aspect | Material Suede | Synthetic Suede | Genuine Leather |

|---|---|---|---|

| Performance | Soft, luxurious feel; less durable and water-resistant | Durable, stain-resistant; mimics suede texture | Highly durable, water-resistant; ages well |

| Cost | Moderate ($29.99 – $39.99 per yard) | Generally lower cost; varies by brand | Higher cost; premium pricing based on quality |

| Ease of Implementation | Requires professional cleaning; sensitive to water | Easy to clean; often machine washable | Needs conditioning and maintenance; more resilient |

| Maintenance | High maintenance; prone to staining | Low maintenance; resistant to dirt and stains | Moderate; requires regular conditioning |

| Best Use Case | Fashion apparel, luxury handbags, and footwear | Casual wear, everyday accessories, and upholstery | High-end products, durable goods, and outdoor applications |

What Are the Advantages and Disadvantages of Synthetic Suede?

Synthetic suede, also known as microfiber suede, offers a practical alternative to material suede. One of its main advantages is durability; it is resistant to stains and can often be cleaned easily, making it suitable for everyday use. Additionally, synthetic suede is typically more affordable than genuine suede, which is attractive for businesses aiming to cut costs. However, some purists argue that synthetic suede lacks the luxurious feel and aesthetic appeal of natural materials. Additionally, while it is designed to mimic suede, it may not provide the same breathability or comfort.

How Does Genuine Leather Compare to Material Suede?

Genuine leather is renowned for its durability and timeless appeal, making it a strong contender against material suede. Its performance in high-stress applications, such as outdoor gear and footwear, is superior due to its resistance to wear and water. However, genuine leather comes with a higher price tag, which may not be feasible for all businesses, especially those targeting budget-conscious consumers. Furthermore, maintaining genuine leather requires regular conditioning to prevent drying and cracking, which can increase the total cost of ownership over time.

Conclusion: Which Material Should B2B Buyers Choose for Their Needs?

When selecting the right material, B2B buyers must consider their target market, application, and budget. Material suede offers a luxurious option for high-end fashion, but its maintenance needs and susceptibility to the elements may limit its use. Synthetic suede provides a cost-effective and durable alternative, ideal for casual and everyday products. Conversely, genuine leather is perfect for businesses prioritizing longevity and premium offerings but may not fit every budget. Ultimately, the choice will depend on the specific requirements of the end product and the brand’s positioning in the marketplace.

Illustrative image related to material suede

Essential Technical Properties and Trade Terminology for material suede

What Are the Key Technical Properties of Material Suede for B2B Buyers?

When considering suede for procurement or manufacturing, understanding its technical properties is crucial. Here are some essential specifications that influence purchasing decisions and product performance.

1. Material Grade

Material grade refers to the quality of the suede, which is often determined by the source animal skin and the tanning process used. Higher-grade suede typically comes from lamb or calf skins, offering superior softness and durability. For B2B buyers, selecting the right grade is vital to meet consumer expectations for luxury products, impacting brand reputation and customer satisfaction.

2. Thickness

The thickness of suede can vary, typically ranging from 0.6 mm to 1.2 mm. Thicker suede is more durable and resistant to wear, making it suitable for high-traffic items like shoes and bags. Conversely, thinner suede is often used in garments where a lightweight feel is desired. Buyers must assess the thickness based on the intended application to ensure product longevity and performance.

3. Tolerance

Tolerance in suede refers to the acceptable variations in dimensions and qualities (such as color and texture) during production. This is particularly important for manufacturers who require precise specifications for cutting and sewing. A tight tolerance ensures uniformity across batches, which is essential for maintaining quality in mass production.

4. Colorfastness

Colorfastness indicates how well the dye adheres to the suede and its resistance to fading or bleeding when exposed to moisture or light. For B2B buyers, particularly in fashion and upholstery, high colorfastness ratings are crucial to ensure that products retain their aesthetic appeal over time, reducing the risk of returns and customer dissatisfaction.

5. Water Resistance

While suede is naturally porous, treatments can enhance its water resistance. This property is vital for products exposed to varying environmental conditions. Buyers must evaluate the level of water resistance required for their applications, as this can influence maintenance needs and product lifespan.

What Are Common Trade Terminology and Jargon Related to Suede?

Understanding trade terminology is essential for effective communication and negotiation in the suede supply chain. Here are some key terms that B2B buyers should be familiar with:

Illustrative image related to material suede

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are sold under another company’s brand name. In the context of suede, manufacturers may create suede goods for brands that focus on design and marketing. Understanding OEM relationships can help buyers navigate sourcing and branding strategies effectively.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of product that a supplier is willing to sell. For suede, MOQs can vary based on the manufacturer and the type of suede. Buyers should consider MOQs in their purchasing strategy to avoid excess inventory while ensuring they meet production needs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products, such as suede. This process allows buyers to compare offers and negotiate better deals. Crafting a clear RFQ can lead to more competitive pricing and better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers, particularly when sourcing suede globally, as they can significantly impact costs and logistics.

5. Tanning Process

The tanning process is the method used to convert animal hides into leather. In suede production, this process is critical for determining the final quality of the material. Understanding the different tanning methods can help buyers choose suppliers that align with their quality and sustainability goals.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing suede, ensuring that they meet both market demands and operational requirements effectively.

Navigating Market Dynamics and Sourcing Trends in the material suede Sector

What Are the Current Market Dynamics and Key Trends in the Material Suede Sector?

The global suede market is experiencing a transformation driven by several factors, including changing consumer preferences, technological advancements, and evolving trade dynamics. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly looking for high-quality suede products that cater to luxury markets. The demand for premium suede, often sourced from Italy and Spain, is on the rise, with buyers seeking unique colors and finishes that enhance the aesthetic appeal of fashion items.

Emerging technologies are reshaping the sourcing landscape, with digital platforms facilitating direct connections between manufacturers and buyers. This trend is particularly beneficial for B2B buyers in emerging markets, enabling them to access a wider range of products and suppliers. Additionally, advancements in synthetic suede alternatives are gaining traction, offering cost-effective solutions without compromising on quality. These innovations are particularly relevant in markets where price sensitivity is high.

Illustrative image related to material suede

Furthermore, economic factors such as fluctuations in currency exchange rates and trade policies are influencing sourcing decisions. Buyers must remain agile and informed about geopolitical developments that could impact supply chains. Collaborations between suppliers and fashion brands are also becoming more common, fostering innovation in design and production processes that cater to specific market needs.

How Is Sustainability and Ethical Sourcing Reshaping the Material Suede Industry?

Sustainability has emerged as a critical concern in the material suede sector, prompting buyers to prioritize ethical sourcing and environmentally friendly practices. The environmental impact of traditional suede production, particularly in terms of water usage and chemical runoff, has led to increased scrutiny from consumers and regulators alike. As a result, B2B buyers are increasingly seeking suppliers that adhere to sustainable practices, including the use of eco-friendly tanning processes and responsible animal husbandry.

The importance of ethical supply chains cannot be overstated. Brands that transparently communicate their sourcing practices are more likely to gain consumer trust and loyalty. B2B buyers should look for certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG), which signify compliance with sustainability standards. These certifications not only enhance a brand’s reputation but also align with the growing consumer demand for ethically produced goods.

Moreover, the rise of synthetic suede alternatives presents a viable option for brands looking to reduce their environmental footprint. While these materials may not fully replicate the luxurious feel of genuine suede, they offer durability and ease of maintenance, making them attractive for both manufacturers and consumers.

What Is the Historical Context of Suede Production Relevant to Today’s B2B Landscape?

The history of suede can be traced back to Sweden, where artisans first developed the technique of using the underside of animal hides to create soft, luxurious leather. Initially popularized for glove production, the versatility of suede has led to its adoption in various applications, including clothing, footwear, and accessories. As global trade routes expanded, suede gained prominence in luxury markets across Europe and beyond.

In recent decades, the suede market has evolved significantly, driven by technological advancements in tanning and dyeing processes. This evolution has enabled manufacturers to produce a wider range of colors and textures, appealing to diverse consumer preferences. The growing popularity of ethical and sustainable practices has also influenced suede production, as modern buyers seek products that align with their values.

Understanding the historical context of suede production helps B2B buyers appreciate the craftsmanship and innovation involved in creating this sought-after material. By recognizing the evolution of suede, buyers can make informed sourcing decisions that balance quality, sustainability, and market demand.

Frequently Asked Questions (FAQs) for B2B Buyers of material suede

-

How do I source high-quality suede for my business needs?

To source high-quality suede, start by identifying reputable suppliers known for their craftsmanship and ethical practices. Look for suppliers that offer detailed product specifications, including the type of animal hide used and the tanning process. Request samples to evaluate the texture, durability, and color. Additionally, check for certifications that guarantee the quality of the suede. Engaging with trade shows and online marketplaces can also help you discover potential suppliers and verify their credibility through reviews and ratings. -

What is the best suede for fashion accessories?

The best suede for fashion accessories typically comes from lambskin, known for its softness and luxurious feel. Italian suede is often regarded as superior due to its premium aniline dyes and thorough finishing processes that enhance its texture and appearance. When selecting suede for accessories like handbags or shoes, consider the weight and thickness, as lighter suede provides more flexibility while maintaining elegance. Ensure that the suede is treated for stain resistance, especially for items that will see frequent use. -

What should I consider when vetting suede suppliers?

When vetting suede suppliers, assess their production capabilities, quality control processes, and compliance with international regulations. Look for suppliers with a proven track record of delivering consistent quality and meeting deadlines. Request references from other B2B clients to gauge their reliability. It’s also important to check for certifications related to environmental and ethical sourcing practices, as this can impact your brand’s reputation in the market. -

What are the minimum order quantities (MOQs) for suede materials?

Minimum order quantities for suede can vary significantly depending on the supplier and the type of suede requested. Generally, MOQs can range from 10 to 100 yards for bulk orders. Smaller suppliers may offer more flexibility with lower MOQs, while larger manufacturers may require higher quantities for cost-effectiveness. Always confirm MOQs before placing an order to ensure they align with your production needs and budget constraints. -

What are the common payment terms for suede suppliers?

Payment terms can vary widely among suede suppliers, with common practices including upfront deposits (typically 30-50%) followed by the balance upon shipment or delivery. Some suppliers may offer net payment terms, allowing for payment within 30, 60, or 90 days post-delivery. It’s crucial to discuss and agree upon payment terms before finalizing any order to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance (QA) for my suede orders?

To ensure quality assurance for suede orders, implement a robust QA process that includes pre-production samples and inspections during manufacturing. Set clear specifications regarding color, texture, and finish, and communicate these to your supplier. Additionally, consider hiring third-party inspection services to verify that the suede meets your standards before shipment. Establishing a quality agreement with your supplier can also help maintain consistency and accountability throughout the production process. -

What logistics considerations should I keep in mind when importing suede?

When importing suede, consider shipping methods, customs regulations, and potential tariffs that may apply based on the origin and destination countries. It’s advisable to partner with a logistics provider experienced in handling textile imports to navigate these complexities. Ensure that your supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin. Additionally, plan for lead times and potential delays in customs to avoid disruptions in your supply chain. -

What are the best practices for storing suede materials?

To maintain the quality of suede materials, store them in a cool, dry place away from direct sunlight, as UV rays can cause fading. Use breathable fabric bags for storage to prevent dust accumulation while allowing air circulation. Avoid plastic covers, as they can trap moisture and lead to mildew. Regularly check stored suede for any signs of damage or discoloration and handle it with clean hands to prevent oils from your skin from transferring onto the fabric.

Top 6 Material Suede Manufacturers & Suppliers List

1. The Fabric Outlet – Faux Leather Suede Fabric

Domain: thefabricoutlet.com

Registered: 2000 (25 years)

Introduction: Suede Fabric by the Yard | The Fabric Outlet

– Type: Faux leather suede fabric

– Characteristics: Sleek, smooth, easy to care for, durable

– Usage: Suitable for furniture, offers a rustic or contemporary touch

– Material: Polyester suede

– Pricing:

– Doro Suede: Regular price from $39.99 / yard

– Vista: Regular price $39.99 / yard

– GEO – Herringbone Suede: Regular price $39.99 / yard

– B…

2. Leather Hide Store – Premium Suede Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Suede leather offered in a variety of colors and sizes. Tanned with premium aniline dyes that penetrate the entire leather. Each piece is finished through a fine sanding process for an even surface and velvety touch. Suede is single-sided, with only the top side fully buffed and polished. Key colors available include: Fuchsia, Pink, Vineyard Brown, Dark Taupe, Bordo, Cinnamon, Midnight Marble, Pur…

3. Sewport – Suede Fabric

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: {“Fabric Name”:”Suede Fabric”,”Also Known As”:”Fuzzy leather, napped leather, Ultrasuede”,”Fabric Composition”:”The underside of animal skins or a similar synthetic material”,”Fabric Breathability”:”Low”,”Moisture-wicking Abilities”:”Low”,”Heat Retention Abilities”:”High”,”Stretchability”:”Low”,”Prone to Pilling/Bubbling”:”Low”,”Country of Origin”:”Sweden”,”Biggest Exporting/Producing Country”:”Ch…

4. CNC Fabrics – Faux Suede Fabric

Domain: cncfabrics.com

Registered: 2011 (14 years)

Introduction: Faux Suede fabric, high quality, smooth fuzzy finish, heavyweight, suitable for apparel (pants, skirts, jackets, gloves, handbags) and upholstery (chair and couch coverings, pillows). Available in various colors and prints, including Black, Charcoal, Cinnabar Red, Godiva Brown, Indigo Blue, and more. Prices range from $3.95 to $15.95. Free samples available upon request.

5. MasterClass – Suede Leather

Domain: masterclass.com

Registered: 1995 (30 years)

Introduction: Suede is a type of leather made from the underside of animal skin, primarily lamb, goat, or calf. It has a soft, napped finish and is known for its luxurious feel. Suede is different from nubuck, which is made from the outer layer of the hide and has a more durable surface. Suede is more susceptible to stains and water damage compared to nubuck. It is commonly used in clothing, shoes, and accessor…

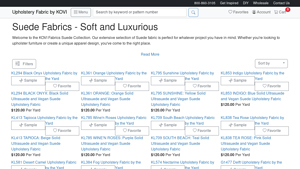

6. KOVI Fabrics – Suede Collection

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Suede Fabrics – Soft and Luxurious Collection from KOVI Fabrics. Available in various colors including black, brown, orange, yellow, blue, beige, purple, teal, pink, gray, and green. Each fabric is priced at $120.00 per yard, except for select microfiber and suede options priced at $24.99 per yard. Fabrics are suitable for upholstery and apparel projects, offering a soft, supple texture ideal for …

Strategic Sourcing Conclusion and Outlook for material suede

In navigating the evolving landscape of suede sourcing, international B2B buyers must prioritize strategic partnerships and a deep understanding of material provenance. Suede, while celebrated for its luxurious texture and aesthetic appeal, requires careful consideration regarding its applications and maintenance. Buyers should leverage insights into the production processes and regional sourcing advantages, particularly from leading manufacturers in China and Italy, to ensure quality and sustainability in their supply chains.

Illustrative image related to material suede

Strategic sourcing not only enhances product offerings but also fortifies competitive advantage in diverse markets across Africa, South America, the Middle East, and Europe. By focusing on ethical sourcing practices and exploring innovative synthetic alternatives, businesses can meet consumer demands for quality while addressing environmental concerns.

Looking ahead, it is crucial for buyers to stay informed about market trends and advancements in suede technologies. Engaging with suppliers who demonstrate a commitment to sustainability and quality will be essential in positioning your brand as a leader in this luxurious segment. Embrace the opportunity to refine your sourcing strategies and elevate your product lines with premium suede materials that resonate with discerning consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to material suede

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.