Introduction: Navigating the Global Market for fabric & leather

In today’s global market, sourcing high-quality fabric and leather can be a daunting challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The intricate landscape of suppliers, varying material qualities, and fluctuating costs can complicate the purchasing process. This guide aims to simplify your journey by providing a comprehensive overview of the fabric and leather market, covering types, applications, and essential strategies for vetting suppliers.

From luxurious leather upholstery to innovative fabric solutions for apparel, this guide will equip you with the knowledge needed to make informed decisions that align with your business goals. We delve into crucial aspects such as material properties, sustainable sourcing, and market trends, ensuring you understand the nuances of your options. With actionable insights and expert advice, you will be better prepared to navigate the complexities of international trade and secure the best materials for your projects.

Our focus on cost analysis and supplier evaluation will empower you to negotiate effectively and build strong partnerships. By leveraging this guide, international B2B buyers can enhance their procurement strategies, ensuring they not only meet but exceed their operational needs in a competitive market.

Table Of Contents

- Top 5 Fabric & Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric & leather

- Understanding fabric & leather Types and Variations

- Key Industrial Applications of fabric & leather

- 3 Common User Pain Points for ‘fabric & leather’ & Their Solutions

- Strategic Material Selection Guide for fabric & leather

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric & leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric & leather’

- Comprehensive Cost and Pricing Analysis for fabric & leather Sourcing

- Alternatives Analysis: Comparing fabric & leather With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric & leather

- Navigating Market Dynamics and Sourcing Trends in the fabric & leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric & leather

- Strategic Sourcing Conclusion and Outlook for fabric & leather

- Important Disclaimer & Terms of Use

Understanding fabric & leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather | Durable, pliable, and thermal-regulating; available in various textures and finishes | Apparel, upholstery, accessories, gear | Pros: High durability, luxury appeal. Cons: Higher cost, requires maintenance. |

| Cotton | Soft, breathable, and absorbent; available in various weaves and finishes | Apparel, home textiles, and upholstery | Pros: Versatile, easy to care for. Cons: Less durable than synthetics, may wrinkle. |

| Polyester | Strong, resistant to stretching and shrinking; often blended with other fibers | Activewear, home decor, and upholstery | Pros: Durable, quick-drying. Cons: Less breathable, can trap heat. |

| Canvas | Heavyweight and durable; often treated for water resistance | Outdoor gear, bags, and upholstery | Pros: Strong, weather-resistant. Cons: Can be heavy and less soft than other fabrics. |

| Faux Leather | Synthetic alternative to leather; mimics appearance and feel | Fashion items, furniture, and automotive | Pros: Animal-friendly, easier to clean. Cons: May lack durability compared to real leather. |

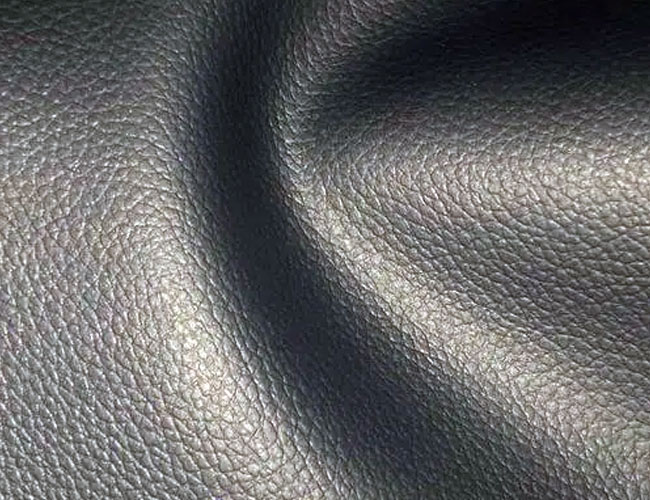

What Are the Key Characteristics of Leather in B2B Markets?

Leather is a luxurious and durable material derived from animal hides, offering a range of textures and finishes. It is prized for its ability to withstand wear and tear, making it ideal for high-quality apparel, upholstery, and accessories. B2B buyers should consider the source of the leather, as well as its tanning process, which can affect both the environmental impact and the product’s longevity. When purchasing, it is essential to assess the specific applications, such as whether the leather will be used for fashion items or heavy-duty upholstery, as this will influence the grade and treatment of the leather required.

How Does Cotton Stand Out Among Fabric Options?

Cotton is one of the most popular fabric choices due to its softness, breathability, and versatility. It is available in various weaves, making it suitable for a wide array of applications from apparel to home textiles. For B2B buyers, the key considerations include the fabric’s weight, weave type, and whether it has been treated for specific uses, such as water resistance or flame retardancy. While cotton is easy to care for and comfortable, it is important to note that it may not be as durable as synthetic options, which could affect its long-term viability in demanding applications.

What Advantages Does Polyester Offer for B2B Buyers?

Polyester is a synthetic fabric known for its strength and resistance to stretching and shrinking. It is often blended with other fibers to enhance its properties, making it a popular choice in activewear and home decor. B2B buyers should consider polyester’s quick-drying capabilities and resistance to wrinkles, which make it suitable for high-demand environments. However, its lower breathability compared to natural fibers can be a drawback, particularly in warm climates or for certain applications, such as summer apparel.

Why Is Canvas a Preferred Material for Outdoor Applications?

Canvas is a heavy-duty fabric that is renowned for its durability and strength, often treated for water resistance. This makes it an excellent choice for outdoor gear, bags, and upholstery. B2B buyers should evaluate the weight and treatment of the canvas to ensure it meets the specific needs of their projects. While canvas is robust and weather-resistant, its heavier weight may limit its use in applications requiring a softer, more flexible fabric.

What Makes Faux Leather an Attractive Alternative in the Market?

Faux leather, or synthetic leather, offers a stylish and animal-friendly alternative to traditional leather. It mimics the appearance and feel of real leather while being easier to clean and maintain. B2B buyers should consider the quality of the faux leather, as variations exist in durability and appearance. While it is often more affordable than genuine leather, potential downsides include a shorter lifespan and less breathability, which can impact its suitability for certain applications, such as high-end fashion items or upholstery.

Key Industrial Applications of fabric & leather

| Industry/Sector | Specific Application of fabric & leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end clothing and accessories | Enhances brand image and customer loyalty through quality | Sourcing sustainable materials; ensuring ethical practices |

| Automotive | Upholstery for car interiors | Increases vehicle resale value and customer satisfaction | Durability and color matching; compliance with safety standards |

| Furniture and Home Decor | Upholstery for sofas, chairs, and decorative items | Adds aesthetic appeal and durability to home furnishings | Style compatibility; fire retardant treatments |

| Sports Equipment | Manufacturing of sports gear (e.g., balls, bags) | Boosts performance and durability in competitive environments | Material weight and flexibility; adherence to sport-specific regulations |

| Footwear | Production of shoes and boots | Combines style with functionality for customer satisfaction | Sizing accuracy; comfort and breathability considerations |

How is Fabric & Leather Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, fabric and leather are essential for creating high-end clothing and accessories. These materials offer a luxurious touch that enhances brand image and fosters customer loyalty. International buyers should prioritize sourcing sustainable and ethically produced materials to meet the growing demand for environmentally friendly options. Additionally, understanding regional fashion trends is crucial, as preferences can vary significantly across markets in Africa, South America, the Middle East, and Europe.

What Role Does Fabric & Leather Play in the Automotive Sector?

In the automotive industry, fabric and leather are primarily used for upholstery in car interiors. High-quality leather enhances the aesthetic appeal of vehicles, increases resale value, and improves customer satisfaction. B2B buyers need to consider factors such as durability, color matching, and compliance with safety standards when sourcing these materials. Understanding regional preferences for vehicle interiors can also help suppliers tailor their offerings to specific markets, particularly in regions with distinct automotive cultures.

How Are Fabric & Leather Applied in Furniture and Home Decor?

Fabric and leather are widely utilized in the furniture and home decor industry, particularly for upholstery on sofas, chairs, and decorative items. These materials not only add aesthetic appeal but also contribute to the durability of home furnishings. Buyers should focus on sourcing materials that are compatible with various design styles and consider fire retardant treatments to meet safety regulations. Additionally, understanding local design trends can help suppliers cater to specific tastes in different regions.

What Is the Importance of Fabric & Leather in Sports Equipment Manufacturing?

In the sports equipment sector, fabric and leather play a critical role in the production of items such as balls and sports bags. The use of high-quality materials boosts performance and durability, essential for athletes in competitive environments. Buyers should pay attention to material weight and flexibility, ensuring that the sourced products meet sport-specific regulations. Furthermore, understanding the regional popularity of different sports can help suppliers align their offerings with market demands.

How Does Fabric & Leather Enhance Footwear Production?

Fabric and leather are integral to the footwear industry, where they are used to produce stylish and functional shoes and boots. These materials provide the necessary comfort and breathability that customers seek. When sourcing for this application, buyers must ensure sizing accuracy and consider the overall design to meet consumer preferences. With varying styles across different regions, suppliers should be attuned to local trends to effectively cater to diverse markets.

3 Common User Pain Points for ‘fabric & leather’ & Their Solutions

Scenario 1: Navigating Quality and Consistency in Leather Sourcing

The Problem:

B2B buyers often face significant challenges when sourcing leather due to the variability in quality and consistency. Factors such as sourcing location, tanning processes, and animal skin types can lead to discrepancies in color, texture, and durability. For buyers in regions like Africa or South America, where local suppliers may not adhere to international quality standards, this inconsistency can result in financial losses and reputational damage. Additionally, the lack of established quality control measures makes it difficult to ensure that the materials meet the necessary specifications for high-end applications.

The Solution:

To overcome these challenges, B2B buyers should establish stringent quality assurance protocols with their suppliers. This involves developing a clear specification document outlining the desired attributes of the leather, including thickness, grain structure, and color consistency. Buyers should conduct regular audits of suppliers and request sample batches before committing to larger orders. Furthermore, building relationships with trusted suppliers who understand the importance of quality can significantly mitigate risks. Utilizing technology, such as digital color matching and texture mapping tools, can also help ensure that the leather sourced meets the required standards.

Scenario 2: Addressing Environmental and Ethical Concerns in Fabric Production

The Problem:

With growing awareness of environmental sustainability and ethical production practices, B2B buyers are increasingly pressured to ensure that their fabric and leather sources adhere to eco-friendly and humane standards. In regions where labor laws may be lax, buyers face the risk of associating their brands with unethical practices, which can lead to public relations crises and consumer backlash. Additionally, sourcing sustainable materials often comes at a higher cost, creating a dilemma for buyers balancing budget constraints with ethical obligations.

The Solution:

B2B buyers can address these concerns by prioritizing suppliers who provide transparency in their sourcing and production processes. Look for certifications such as Global Organic Textile Standard (GOTS) for fabrics and Leather Working Group (LWG) for leather, which indicate compliance with environmental and ethical standards. Engaging in direct partnerships with manufacturers who practice sustainable methods can also yield long-term benefits. Buyers should consider investing in lifecycle assessments to understand the environmental impact of their materials. This proactive approach not only enhances brand reputation but can also open doors to new markets that prioritize sustainability.

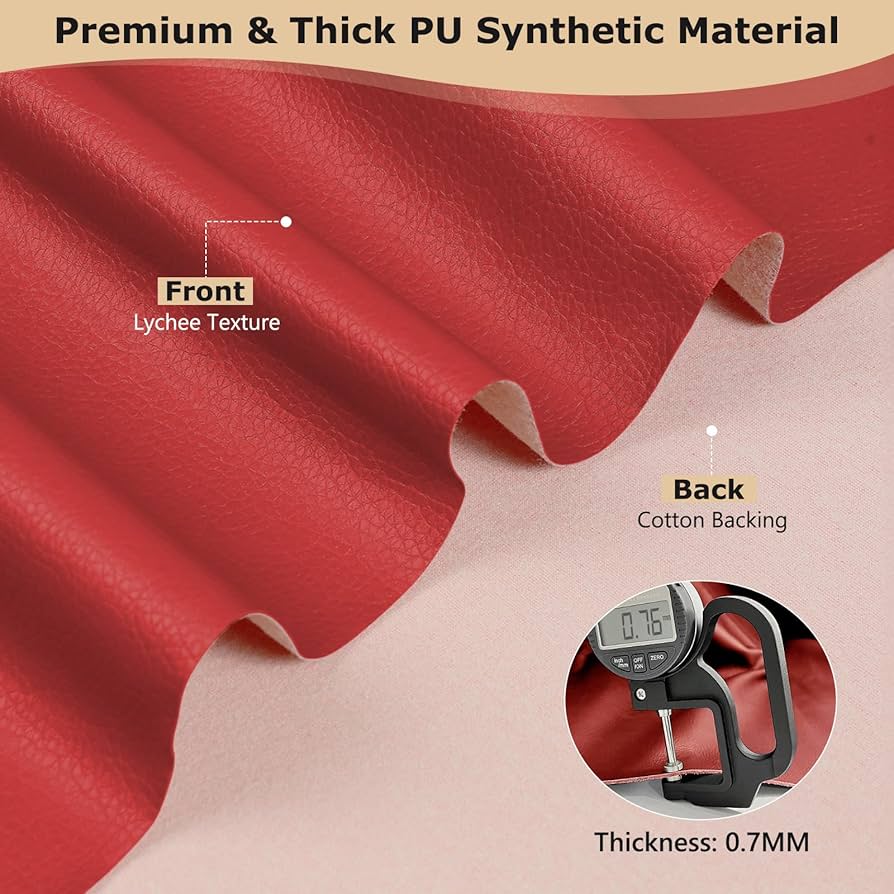

Illustrative image related to fabric & leather

Scenario 3: Managing Inventory and Supply Chain Disruptions

The Problem:

Supply chain disruptions are a common pain point for B2B buyers in the fabric and leather industry, exacerbated by factors such as geopolitical tensions, natural disasters, and global pandemics. These disruptions can lead to delays in production schedules, increased costs, and ultimately, a failure to meet customer demands. For international buyers, navigating the complexities of customs and import regulations can further complicate timely delivery.

The Solution:

To effectively manage these risks, B2B buyers should adopt a multi-sourcing strategy, identifying alternative suppliers across different regions to ensure continuity of supply. Establishing strong relationships with logistics providers can also facilitate smoother shipping processes and quicker responses to disruptions. Buyers should utilize inventory management software to track stock levels and forecast demand accurately, allowing for better planning. Additionally, investing in local suppliers can reduce reliance on international shipping and mitigate the risks associated with long supply chains. By enhancing flexibility and responsiveness within the supply chain, buyers can maintain operational efficiency even in unpredictable circumstances.

Strategic Material Selection Guide for fabric & leather

What Are the Key Properties of Cotton Fabric in B2B Applications?

Cotton fabric is a versatile material widely used in various industries, including apparel, home textiles, and upholstery. Its key properties include breathability, moisture absorption, and softness, making it comfortable for end-users. Cotton also has a moderate temperature rating, suitable for everyday wear, but it is less durable under high-pressure applications compared to synthetic alternatives.

Pros and Cons: Cotton is favored for its natural fibers, which are biodegradable and hypoallergenic. However, it can be prone to shrinking and wrinkling, which may affect the longevity of products. In terms of cost, cotton is generally affordable, but high-quality cotton can be more expensive, impacting budget considerations for manufacturers.

Impact on Application: Cotton fabric is compatible with various dyeing and printing techniques, allowing for customization in branding. However, it may not be suitable for outdoor applications due to its susceptibility to mold and mildew.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of the varying quality standards for cotton. Compliance with local regulations regarding pesticide use in cotton farming is also crucial. Familiarity with standards such as ASTM D5034 (breaking strength) can guide buyers in selecting suitable materials.

How Does Leather Fabric Compare in Terms of Performance and Suitability?

Leather fabric, derived from animal hides or synthetic materials, is known for its durability and luxurious appearance. It exhibits excellent thermal regulation and can be treated for water resistance, making it suitable for a range of applications from high-end apparel to automotive upholstery.

Pros and Cons: The primary advantage of leather is its durability and resistance to wear and tear, making it ideal for products that require longevity. However, it can be more expensive than other materials and may require specialized care. Manufacturing complexity can also be a factor, as leather processing involves tanning and finishing steps that can increase lead times.

Impact on Application: Leather is highly suitable for products that demand both aesthetic appeal and functionality, such as jackets, bags, and furniture. The material’s ability to withstand heavy use makes it a preferred choice in luxury markets.

Considerations for International Buyers: Compliance with environmental regulations concerning leather production is essential, especially in Europe where strict guidelines are enforced. Buyers should also consider sourcing leather that meets standards like ISO 14001 for environmental management.

What Are the Advantages of Polyester in Fabric Selection?

Polyester is a synthetic fabric known for its resilience and versatility. It has excellent resistance to shrinking, stretching, and wrinkling, making it a popular choice for various applications, including activewear and home furnishings.

Pros and Cons: The key advantage of polyester is its durability and low maintenance requirements. It is also cost-effective, making it suitable for high-volume production. However, polyester is less breathable than natural fibers, which can affect comfort in certain applications.

Impact on Application: Polyester’s compatibility with dyeing processes allows for vibrant colors and patterns, enhancing product appeal. However, its lower thermal regulation properties may limit its use in high-temperature environments.

Considerations for International Buyers: Buyers should ensure that polyester fabrics comply with international standards such as Oeko-Tex Standard 100, which verifies that textiles are free from harmful substances. This is particularly relevant for markets in Europe and the Middle East.

How Does Nylon Fabric Stand Up in Terms of Performance and Cost?

Nylon is another synthetic fabric known for its strength and elasticity. It exhibits high tensile strength, making it suitable for applications requiring durability, such as outdoor gear and industrial products.

Pros and Cons: Nylon’s key advantage is its resistance to abrasion and its lightweight nature, which is ideal for performance-oriented products. However, it can be more expensive than polyester and may require more complex manufacturing processes.

Impact on Application: Nylon is often used in applications where flexibility and strength are critical, such as in sportswear and protective gear. Its compatibility with various coatings can enhance its water and abrasion resistance.

Illustrative image related to fabric & leather

Considerations for International Buyers: Buyers should consider the environmental impact of nylon production and seek suppliers who adhere to sustainable practices. Compliance with standards such as ISO 9001 for quality management can also be beneficial.

Summary Table of Material Selection

| Material | Typical Use Case for fabric & leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Apparel, home textiles, upholstery | Breathable and comfortable | Prone to shrinking and wrinkling | Medium |

| Leather | High-end apparel, automotive upholstery | Durable and luxurious appearance | Expensive and requires specialized care | High |

| Polyester | Activewear, home furnishings | Durable and low maintenance | Less breathable than natural fibers | Low |

| Nylon | Outdoor gear, industrial products | High tensile strength and elasticity | More expensive than polyester | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for fabric & leather

What Are the Main Stages of Manufacturing Fabric and Leather?

The manufacturing processes for fabric and leather involve several stages that ensure the final product meets the desired quality and functionality. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

In the initial stage, raw materials are sourced and prepared. For fabric, this often involves selecting fibers such as cotton, polyester, or wool, which are then spun into yarn. In the case of leather, the process begins with the selection of animal hides or synthetic materials. The hides undergo tanning, where they are treated with chemicals to preserve and enhance their durability. Both processes require careful consideration of sustainability and sourcing practices, particularly for international buyers who may face different regulations and standards.

How Are Fabrics and Leathers Formed?

Once the materials are prepared, the forming stage begins. For fabrics, this typically involves weaving or knitting the yarn into a textile. Various techniques, such as jacquard weaving or circular knitting, can be employed to create different textures and patterns. In leather manufacturing, the hides are cut into desired shapes and sizes, often using precision cutting tools to ensure consistency and minimize waste.

What Does the Assembly Stage Entail?

The assembly stage involves stitching or bonding the formed materials together. For fabric products, this could mean sewing garments or upholstery. In leather products, assembly may involve stitching leather pieces to create items like bags or shoes. Quality craftsmanship is crucial in this stage, as it directly impacts the durability and aesthetics of the final product.

What Finishing Techniques Are Commonly Used?

Finishing is the final stage of manufacturing, where the products receive treatments that enhance their appearance and functionality. For fabric, this may involve dyeing, printing, or applying water-repellent coatings. Leather may undergo additional treatments, such as polishing or embossing, to achieve a specific look or texture. It’s essential for B2B buyers to inquire about the finishing techniques used, as these can significantly affect the product’s quality and performance.

What Quality Assurance Practices Should B2B Buyers Be Aware Of?

Quality assurance (QA) is vital in ensuring that the final products meet international standards and customer expectations. B2B buyers should be familiar with various quality control checkpoints and international standards that govern the fabric and leather industries.

Which International Standards Are Relevant?

International standards such as ISO 9001 provide a framework for quality management systems. This standard ensures that manufacturers consistently meet customer and regulatory requirements. For fabric and leather, additional certifications may include CE marking for safety compliance and API standards for performance in specific applications. Understanding these certifications helps buyers assess the reliability of their suppliers.

What Are the Key Quality Control Checkpoints?

Quality control typically involves several checkpoints throughout the manufacturing process. These include:

Illustrative image related to fabric & leather

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials before production begins. Ensuring that materials meet specified standards can prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor compliance with quality standards. This proactive approach allows for immediate corrections, minimizing waste and defects.

-

Final Quality Control (FQC): Once production is complete, the final products undergo thorough inspections. This includes checking for defects, assessing functionality, and ensuring that products meet customer specifications.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers, especially those sourcing from different regions. Here are some actionable steps:

What Audits and Reports Should Buyers Request?

Buyers should request quality audits and reports from their suppliers. These documents provide insights into the supplier’s quality management systems and their adherence to international standards. Regular audits, either conducted by the buyer or third-party organizations, can help ensure compliance and identify potential issues early.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further enhance quality assurance. These independent entities conduct thorough evaluations of the manufacturing processes and final products, offering unbiased assessments. B2B buyers can arrange for inspections at various stages of production to ensure that quality standards are consistently met.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential. Different regions may have varying requirements for product standards and certifications.

Illustrative image related to fabric & leather

How Do Regional Regulations Impact Quality Assurance?

In regions like Africa and South America, local regulations may influence the types of certifications required for fabric and leather products. Buyers should familiarize themselves with these regional standards to avoid compliance issues. Additionally, suppliers should be proactive in obtaining the necessary certifications to facilitate smoother transactions.

What Should Buyers Consider Regarding Sustainable Practices?

Sustainability is becoming increasingly important in the fabric and leather industries. Buyers should inquire about their suppliers’ sustainability practices, including the sourcing of materials, manufacturing processes, and waste management. Ensuring that suppliers adhere to sustainable practices can enhance the buyer’s brand reputation and appeal to environmentally conscious consumers.

Conclusion

In summary, understanding the manufacturing processes and quality assurance practices for fabric and leather is crucial for B2B buyers. By being informed about the stages of production, international standards, quality control checkpoints, and verification methods, buyers can make more informed decisions and establish reliable partnerships with suppliers. Prioritizing quality and sustainability will not only improve product offerings but also strengthen brand integrity in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric & leather’

To assist international B2B buyers in sourcing fabric and leather effectively, this guide provides a step-by-step checklist to streamline the procurement process. The goal is to ensure buyers are well-informed and can make decisions that align with their business needs while minimizing risk.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline your specific requirements for fabric and leather. Consider factors such as material type, weight, texture, and intended use (e.g., apparel, upholstery, or accessories).

– Be precise: Specify whether you need genuine leather, synthetic alternatives, or specific fabric blends.

– Quality standards: Identify any industry standards or certifications that the material must meet for your market.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in fabric and leather. Utilize trade directories, industry forums, and recommendations from peers to create a shortlist of potential partners.

– Supplier reviews: Look for feedback from other businesses to gauge reliability and quality.

– Market presence: Evaluate how long they have been in business and their reputation in the industry.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Sample requests: Ask for material samples to assess quality firsthand.

– Certifications: Verify whether they hold relevant certifications, such as ISO or environmental compliance, which can impact your product’s marketability.

Illustrative image related to fabric & leather

Step 4: Assess Pricing and Terms

Collect quotes from multiple suppliers and analyze their pricing structures. Be sure to compare not just the costs but also the payment terms and delivery schedules.

– Hidden costs: Inquire about shipping fees, taxes, and potential tariffs that could affect the total cost.

– Negotiation: Don’t hesitate to negotiate terms, especially for bulk orders, as many suppliers are open to adjustments.

Step 5: Understand the Supply Chain Logistics

Evaluate the logistics involved in sourcing your fabric and leather, including shipping times, customs clearance, and local regulations.

– Lead times: Clarify expected delivery dates to align with your production schedules.

– Local regulations: Familiarize yourself with import/export regulations that may affect your procurement.

Step 6: Establish Communication Protocols

Effective communication is key to a successful partnership. Set clear expectations regarding updates, order changes, and any issues that may arise during the procurement process.

– Regular updates: Agree on how often you will receive updates about your order status.

– Contact points: Designate specific contacts for both parties to streamline communication.

Step 7: Finalize Agreements and Place Orders

Once you’ve evaluated suppliers and terms, finalize agreements with clear terms of service, including warranties and return policies.

– Written contracts: Ensure all agreements are documented to protect both parties.

– Order confirmation: Confirm all details before placing your order to avoid misunderstandings.

By following these steps, B2B buyers can confidently navigate the sourcing process for fabric and leather, ensuring they select the right materials and suppliers for their business needs.

Illustrative image related to fabric & leather

Comprehensive Cost and Pricing Analysis for fabric & leather Sourcing

What Are the Key Cost Components in Fabric and Leather Sourcing?

When assessing the cost structure for sourcing fabric and leather, it’s crucial to understand the various components that contribute to the final price. The primary cost elements include:

-

Materials: The choice of raw materials significantly impacts costs. Leather sourced from high-quality hides or sustainable materials will generally have a higher price point. Similarly, specialty fabrics like silk or organic cotton can drive costs up compared to more common textiles.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Skilled labor is often required for high-quality leather goods, which can increase costs. In contrast, mass-produced fabric items may benefit from lower labor costs in countries with a lower cost of living.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help minimize overhead and thus reduce overall costs.

-

Tooling: Initial setup costs for manufacturing machinery and tools can be substantial, particularly for customized orders. This is especially relevant for leather goods that may require specialized tools for cutting and stitching.

-

Quality Control (QC): Ensuring the final product meets quality standards incurs costs. Rigorous QC processes can help avoid costly defects but may add to the overall price.

-

Logistics: Transportation and warehousing are essential components of the cost structure. International shipping fees can fluctuate based on fuel prices, distance, and shipping terms.

-

Margin: The profit margin added by the supplier will vary based on their market positioning and competitive landscape.

How Do Price Influencers Affect Fabric and Leather Costs?

Several factors can influence pricing in the fabric and leather market:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to reduced per-unit costs. Suppliers may offer discounts for bulk purchases, making it essential for buyers to consider their needs carefully.

-

Specifications and Customization: Customized products typically cost more due to additional design and production complexities. Buyers should weigh the benefits of customization against increased costs.

-

Material Quality and Certifications: Premium materials and certifications (like organic or eco-friendly labels) can elevate prices. Buyers should assess the value these attributes add to their products.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Different shipping terms can greatly affect pricing. Buyers should understand the responsibilities and costs associated with each Incoterm to make informed decisions.

What Are the Best Buyer Tips for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Wisely: Build relationships with suppliers and leverage your purchasing power to negotiate better terms. Understanding market conditions can provide leverage in discussions.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. TCO includes costs related to shipping, duties, storage, and potential waste. A lower upfront price may not be the best deal in the long run.

-

Pricing Nuances for International Markets: Be aware of fluctuations in currency and international trade agreements that can affect pricing. Staying informed about local market trends can provide insights into when to buy.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can prevent costly mistakes and ensure that the materials meet your specifications.

Conclusion: Why Understanding Pricing is Essential for B2B Buyers

Navigating the complexities of fabric and leather sourcing requires a deep understanding of cost components and pricing influencers. By being aware of these elements, B2B buyers can make more informed purchasing decisions that align with their business goals. Always remember that the prices provided by suppliers may vary, and it’s essential to confirm with them for the most accurate and up-to-date information.

Alternatives Analysis: Comparing fabric & leather With Other Solutions

Exploring Alternatives to Fabric & Leather: What Are Your Options?

In the realm of textiles and materials, fabric and leather have long been favored for their durability, versatility, and aesthetic appeal. However, various alternatives have emerged, each offering unique benefits and challenges. This analysis compares fabric and leather with two viable alternatives: synthetic textiles and eco-friendly materials, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Fabric & Leather | Synthetic Textiles | Eco-Friendly Materials |

|---|---|---|---|

| Performance | High durability; versatile use; thermal regulation | Good durability; often water-resistant | Variable performance; often biodegradable |

| Cost | Generally higher initial cost; long-term value | Lower initial cost; may require replacement | Variable costs; often premium pricing |

| Ease of Implementation | Requires skilled labor for production | Easier to produce and work with | May require special processing or treatment |

| Maintenance | Requires regular conditioning; long lifespan | Easy to clean; may degrade over time | Requires careful maintenance; variable lifespan |

| Best Use Case | Fashion, upholstery, automotive, accessories | Activewear, outdoor gear, fashion | Sustainable fashion, eco-friendly products, packaging |

What Are the Pros and Cons of Synthetic Textiles?

Synthetic textiles, such as polyester and nylon, are created from petroleum-based resources. They are widely used due to their affordability and ease of production.

Pros: These materials are often more water-resistant and easier to clean than traditional fabrics. They can be produced in various textures and colors, making them suitable for a wide range of applications, including activewear and outdoor gear.

Cons: Synthetic textiles can have a shorter lifespan compared to leather and may contribute to environmental pollution during production and disposal. They also lack the premium feel and breathability of natural materials.

How Do Eco-Friendly Materials Compare?

Eco-friendly materials, including organic cotton, bamboo, and recycled textiles, are designed to minimize environmental impact. They are often biodegradable and produced with sustainable practices.

Pros: These materials appeal to environmentally conscious consumers and businesses, providing a marketing edge. They can be soft, breathable, and comfortable, making them suitable for clothing and home goods.

Cons: The performance of eco-friendly materials can vary widely depending on the specific type and processing methods. They may also come with a higher price tag, which can be a consideration for budget-conscious buyers.

Choosing the Right Solution: What Should B2B Buyers Consider?

When selecting between fabric & leather and its alternatives, B2B buyers should assess their specific needs and target market. Consider factors such as the intended application, budget constraints, and sustainability goals. For businesses focused on high-end fashion or durable products, fabric and leather may be the best choice. Conversely, if cost and ease of production are priorities, synthetic textiles might be more appealing. Eco-friendly materials could be the ideal solution for companies aiming to enhance their sustainability credentials while appealing to a growing demographic of eco-conscious consumers. By aligning material choices with business objectives, buyers can make informed decisions that support both profitability and brand values.

Essential Technical Properties and Trade Terminology for fabric & leather

What Are the Key Technical Properties of Fabric & Leather That B2B Buyers Should Know?

When sourcing fabric and leather for various applications, understanding their technical properties is crucial for making informed decisions. Here are several key specifications that B2B buyers should be familiar with:

Illustrative image related to fabric & leather

-

Material Grade

Material grade refers to the quality and classification of the fabric or leather based on its composition and manufacturing process. Higher-grade materials typically offer better durability, appearance, and performance characteristics. For B2B buyers, selecting the right material grade ensures that the end product meets both aesthetic and functional requirements, reducing the likelihood of returns or customer dissatisfaction. -

Tolerance

Tolerance is the allowable variation in dimensions or properties of the fabric or leather. This specification is critical in ensuring that the materials fit perfectly in the final products, especially in industries like apparel and upholstery where precision is key. High tolerance levels can lead to increased production costs and waste, making it essential for B2B buyers to consider this factor when placing orders. -

Weight

The weight of fabric or leather, typically measured in grams per square meter (GSM), is an important property that affects the material’s usability and application. Lighter fabrics may be ideal for garments and linings, while heavier materials are suited for upholstery and outerwear. Understanding the weight helps buyers select the appropriate materials for their specific needs, ensuring that the final products are functional and comfortable. -

Water Resistance

This property indicates how well the fabric or leather can repel water. For applications that involve exposure to moisture, such as outdoor gear or upholstery in humid climates, water resistance is a critical specification. B2B buyers should evaluate water resistance levels to ensure product longevity and customer satisfaction, particularly in markets that experience varying weather conditions. -

Colorfastness

Colorfastness refers to the resistance of the fabric or leather to fading or running when exposed to light, washing, or abrasion. This property is crucial for maintaining the aesthetic appeal of products over time. Buyers need to assess colorfastness ratings to ensure that their products retain their vibrancy, especially in competitive markets where brand image is paramount.

What Common Trade Terms Should B2B Buyers Understand in the Fabric & Leather Industry?

Navigating the fabric and leather industry requires familiarity with specific trade terms. Here are several essential jargon terms that can impact purchasing decisions:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components or products that are sold under another company’s brand name. Understanding OEM relationships is vital for B2B buyers, as it can affect pricing, quality control, and supply chain management. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it can influence inventory management and cash flow. Knowing the MOQ helps businesses plan their orders strategically to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This term is essential for B2B transactions, as it allows buyers to compare offers and negotiate better deals based on detailed specifications. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and freight transactions. Familiarity with these terms helps B2B buyers understand their obligations regarding shipping costs, risk, and insurance, which is crucial for managing supply chain logistics effectively. -

Lead Time

Lead time refers to the time it takes from placing an order to the delivery of goods. Understanding lead times is essential for B2B buyers to manage production schedules and meet customer demands. Shorter lead times can enhance competitiveness and customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers in the fabric and leather industries can make more informed decisions, optimize their supply chains, and ultimately improve their product offerings.

Navigating Market Dynamics and Sourcing Trends in the fabric & leather Sector

What Are the Key Trends Shaping the Fabric & Leather Market for B2B Buyers?

The global fabric and leather market is currently experiencing a transformation driven by several key factors. The rise of e-commerce has significantly changed how international B2B buyers source materials, enabling them to access a wider range of suppliers beyond their local markets. In regions like Africa and South America, the demand for high-quality fabrics and leather goods is increasing, fueled by a burgeoning middle class and growing fashion industries. Furthermore, advancements in digital technologies, such as AI and blockchain, are reshaping the supply chain, enhancing transparency, and streamlining logistics.

Illustrative image related to fabric & leather

Another notable trend is the growing preference for customization. B2B buyers are increasingly looking for suppliers that offer bespoke solutions tailored to their specific needs, whether it’s unique fabric blends or personalized leather finishes. Additionally, sustainability is becoming a central theme; buyers are seeking eco-friendly materials and ethical manufacturing practices that align with their corporate social responsibility goals. As a result, suppliers are adapting by integrating sustainable practices and offering certifications that assure buyers of their environmental commitments.

How Is Sustainability Influencing Sourcing Decisions in the Fabric & Leather Sector?

Sustainability is no longer a niche concern; it has become a fundamental aspect of sourcing decisions in the fabric and leather industry. The environmental impact of conventional fabric production and leather tanning processes has raised significant concerns among international B2B buyers. The industry is being pushed towards adopting more sustainable practices, such as using organic materials, reducing water consumption, and employing eco-friendly dyes.

Ethical sourcing is equally important, as buyers increasingly favor suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction, providing buyers with the assurance that their materials are sourced responsibly. Moreover, the rise of alternative materials—such as vegan leather made from recycled plastics or plant-based sources—offers innovative options for businesses aiming to minimize their carbon footprint while still meeting consumer demand for quality and style.

Illustrative image related to fabric & leather

What Is the Historical Context of the Fabric & Leather Industry That Influences Today’s B2B Landscape?

The fabric and leather industry has a rich history that informs its current dynamics. Historically, leather production was a labor-intensive process, often associated with artisanal craftsmanship. Over the centuries, innovations such as chemical tanning and synthetic fabric development revolutionized the industry, making materials more accessible and affordable. However, these advancements also led to environmental challenges, prompting the current shift towards sustainable practices.

In recent decades, globalization has further transformed the landscape, enabling easier access to diverse materials and markets. Countries in Africa and South America have emerged as significant players, leveraging local resources to meet international demand. Understanding this historical context is essential for B2B buyers as they navigate sourcing decisions, ensuring they align with both market trends and ethical standards.

In summary, the fabric and leather sector is evolving rapidly, influenced by market dynamics, sustainability concerns, and a rich historical backdrop. B2B buyers must stay informed and adapt their sourcing strategies to remain competitive in this changing environment.

Illustrative image related to fabric & leather

Frequently Asked Questions (FAQs) for B2B Buyers of fabric & leather

-

How do I select the right fabric or leather supplier for my business needs?

To select the right supplier, consider factors such as their experience, reputation, and product range. Request samples to evaluate fabric quality, texture, and durability. Ensure the supplier has experience with international shipping, especially if you’re sourcing from regions like Africa, South America, or Europe. Look for certifications that indicate adherence to quality standards and environmental regulations. Conduct thorough background checks and read reviews from other buyers to assess reliability and customer service. -

What is the minimum order quantity (MOQ) for fabric and leather purchases?

MOQs can vary significantly depending on the supplier and the type of fabric or leather. Generally, fabric suppliers may require a minimum order of 10 to 50 yards, while leather suppliers might set MOQs at one hide or more. It’s essential to communicate your specific needs upfront and inquire about flexibility in order sizes, especially if you’re starting a new project or testing a market. Some suppliers may offer lower MOQs for first-time buyers or prototype orders. -

What payment terms should I expect when sourcing fabric and leather?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, partial deposits, or letters of credit, especially for international transactions. Negotiate terms that provide you with security while maintaining good relationships with suppliers. Be aware of currency fluctuations and additional costs, such as tariffs or taxes, when dealing with cross-border payments. Ensure clarity on payment methods accepted, including wire transfers, credit cards, or PayPal. -

How do I ensure quality assurance when sourcing fabric and leather?

Establish quality assurance protocols by requesting detailed specifications, including fabric composition, weight, and treatment processes. Conduct inspections at various stages, from production to delivery. Consider hiring third-party inspection services to verify quality before shipment, especially for large orders. Additionally, maintain open communication with your supplier to address any quality concerns promptly and ensure they understand your quality standards. -

What are the best practices for shipping and logistics when importing fabric and leather?

To optimize shipping and logistics, choose reliable freight forwarders experienced in handling textiles. Understand the shipping terms (FOB, CIF, etc.) and select the one that best suits your business needs. Ensure all documentation is in order, including invoices, packing lists, and customs declarations. Plan for potential delays by allowing extra time for customs clearance and be aware of any tariffs or duties applicable to your shipments. -

Can I customize fabric or leather for my specific requirements?

Yes, many suppliers offer customization options, including colors, patterns, and finishes. Discuss your specific requirements with the supplier and inquire about their capabilities for custom orders. Be prepared to provide detailed specifications and, if possible, samples of what you envision. Keep in mind that customization may require higher MOQs and longer lead times, so factor this into your planning. -

What types of fabrics and leathers are best suited for specific applications?

The choice of fabric or leather largely depends on the intended application. For apparel, consider breathable fabrics like cotton or blends that offer comfort and durability. For upholstery, opt for thicker, more durable materials like leather or heavy-duty canvas that can withstand wear and tear. If your products require water resistance, inquire about treated fabrics or synthetic alternatives. Always align your material choice with the functional and aesthetic needs of your end product. -

How do I handle disputes or issues with suppliers?

To effectively manage disputes, maintain clear and open communication with your supplier from the outset. Document all agreements and communications to provide a reference in case of misunderstandings. If issues arise, address them promptly and professionally, presenting your concerns with specific examples. If necessary, escalate the situation to higher management within the supplier’s organization. Consider mediation or arbitration as potential solutions for unresolved disputes, especially in international contexts where legal systems may differ.

Top 5 Fabric & Leather Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Premium Leather Fabrics

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Premium Leather Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Mood Fabrics – Genuine Leather by the Yard

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Buy Leather Fabric by the Yard | Genuine Leather Material

3. Nikwax – Fabric & Leather Proof

Domain: nikwax.com

Registered: 1999 (26 years)

Introduction: Product Name: Fabric & Leather Proof\nPrice: $12.55\nDescription: High performance waterproofer designed to revitalize breathability of all combination fabric and leather footwear. Easy to apply by hand, non-flammable, and PFAS-free.\nKey Features: \n- Easy to use sponge-on waterproofing for all fabric, leather, and combination footwear\n- Adds water repellency and revives breathability without so…

4. Diffen – Fabric vs. Leather Comparison

Domain: diffen.com

Registered: 2007 (18 years)

Introduction: Comparison of Fabric and Leather:

1. **Material**:

– Fabric: Cloth

– Leather: Animal hide treated with chemicals.

2. **Durability**:

– Fabric: Less durable

– Leather: Very durable (10-15 years if maintained well), used in rugged conditions, but will fade in sun and degrade with age.

3. **Cost**:

– Fabric: Less expensive

– Leather: Premium price luxury item; much more exp…

5. Sewport – Leather Fabric

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Leather Fabric, also known as Hide or Skin, is a natural fabric made from tanned animal skins. It is characterized by its low breathability, low moisture-wicking abilities, high heat retention, low stretchability, and low tendency to pill or bubble. The fabric is commonly used in jackets, coats, wallets, belts, bags, gloves, shoes, book bindings, upholstery, automobile seats, saddles, luggage, and…

Strategic Sourcing Conclusion and Outlook for fabric & leather

How Can Strategic Sourcing Enhance Your Fabric & Leather Procurement?

In today’s competitive landscape, strategic sourcing for fabric and leather is more crucial than ever. By leveraging supplier relationships, buyers can access high-quality materials that meet specific requirements while optimizing costs. Understanding the diverse applications of fabrics—from apparel to upholstery—enables businesses to make informed decisions that align with market demands.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize sourcing strategies that emphasize sustainability and innovation. This not only enhances brand reputation but also addresses the growing consumer demand for environmentally friendly products. Engaging with suppliers who offer eco-friendly alternatives can lead to a competitive edge in various markets.

As the fabric and leather industry evolves, it presents opportunities for growth and collaboration. Buyers are encouraged to explore new suppliers, technologies, and trends that can enhance product offerings and streamline operations. By investing in strategic sourcing, businesses can position themselves for future success and adaptability in a dynamic global market. Seize the moment—start refining your sourcing strategies today to ensure a sustainable and prosperous future in the fabric and leather sector.

Illustrative image related to fabric & leather

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.