Introduction: Navigating the Global Market for artificial leather sheet

In the rapidly evolving global market for artificial leather sheets, international B2B buyers face the crucial challenge of sourcing high-quality materials that meet diverse application needs while remaining cost-effective. As industries increasingly shift towards sustainable and ethical alternatives, understanding the nuances of artificial leather becomes essential. This guide delves into the multifaceted world of artificial leather sheets, covering various types such as polyurethane (PU) and polyvinyl chloride (PVC), along with their unique properties and applications across sectors including fashion, upholstery, and automotive.

Navigating the complexities of supplier vetting, pricing structures, and market trends can be daunting, especially for buyers from regions like Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia. This comprehensive resource aims to empower decision-makers by providing actionable insights and strategies for informed purchasing decisions. From recognizing quality indicators to understanding the environmental implications of artificial leather production, this guide equips B2B buyers with the knowledge needed to make choices that align with their business goals and sustainability commitments.

By addressing these critical aspects, this guide not only enhances your understanding of artificial leather sheets but also positions you to capitalize on market opportunities and foster successful supplier relationships in a competitive landscape.

Table Of Contents

- Top 8 Artificial Leather Sheet Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for artificial leather sheet

- Understanding artificial leather sheet Types and Variations

- Key Industrial Applications of artificial leather sheet

- 3 Common User Pain Points for ‘artificial leather sheet’ & Their Solutions

- Strategic Material Selection Guide for artificial leather sheet

- In-depth Look: Manufacturing Processes and Quality Assurance for artificial leather sheet

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘artificial leather sheet’

- Comprehensive Cost and Pricing Analysis for artificial leather sheet Sourcing

- Alternatives Analysis: Comparing artificial leather sheet With Other Solutions

- Essential Technical Properties and Trade Terminology for artificial leather sheet

- Navigating Market Dynamics and Sourcing Trends in the artificial leather sheet Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of artificial leather sheet

- Strategic Sourcing Conclusion and Outlook for artificial leather sheet

- Important Disclaimer & Terms of Use

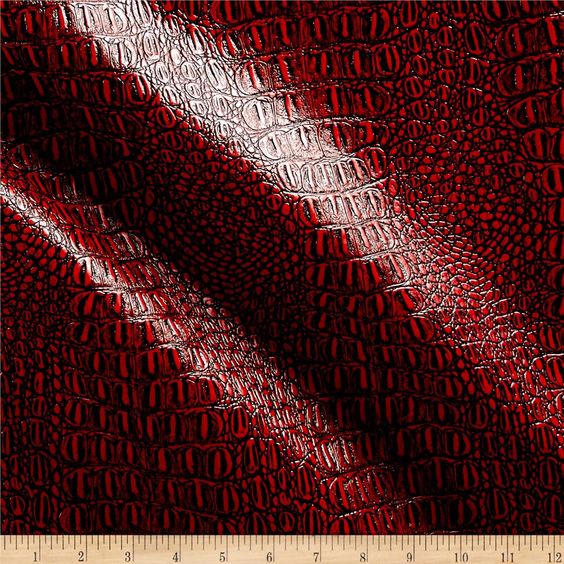

Understanding artificial leather sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather | Made from a polyurethane coating; soft, supple texture; resembles genuine leather closely | Upholstery for furniture, automotive interiors, fashion | Pros: Affordable, easy to clean, durable. Cons: Can be less breathable than genuine leather. |

| PVC Leather | Composed of polyvinyl chloride; typically more rigid; waterproof and stain-resistant | Outdoor furniture, marine applications, commercial settings | Pros: Cost-effective, highly durable. Cons: Can feel less luxurious; less flexible than PU leather. |

| Vegan Leather | Made from plant-based materials; eco-friendly alternative; various textures available | Fashion accessories, upholstery, eco-conscious products | Pros: Sustainable, animal-friendly. Cons: May not have the same durability as synthetic options. |

| Microfiber Leather | Ultra-fine synthetic fibers; soft and lightweight; high abrasion resistance | High-end upholstery, automotive interiors, bags | Pros: Breathable, resistant to stains. Cons: Higher cost compared to other synthetic options. |

| Faux Suede | Soft, suede-like texture; available in various colors; mimics the look of real suede | Apparel, upholstery, and accessories | Pros: Soft feel, versatile applications. Cons: May require special cleaning to maintain appearance. |

What are the Characteristics and Suitability of PU Leather for B2B Buyers?

PU leather, or polyurethane leather, is a popular choice in the B2B sector due to its close resemblance to genuine leather. Its soft and supple texture makes it ideal for upholstery in furniture and automotive interiors. Buyers should consider its affordability, ease of cleaning, and durability as significant advantages. However, it is essential to note that PU leather may not be as breathable as genuine leather, which could impact comfort in certain applications.

Illustrative image related to artificial leather sheet

How Does PVC Leather Compare for Commercial Use?

PVC leather, made from polyvinyl chloride, is recognized for its waterproof and stain-resistant properties, making it suitable for outdoor furniture and marine applications. Its rigid nature provides durability, especially in commercial settings. While it is a cost-effective option, buyers should be aware that PVC leather may not offer the same luxurious feel as PU leather, which could influence customer perception in high-end markets.

Why Consider Vegan Leather as a Sustainable Option?

Vegan leather, derived from plant-based materials, appeals to businesses focused on sustainability and eco-friendliness. Its various textures allow for creative applications in fashion accessories and upholstery. While vegan leather is an ethical choice, buyers should weigh its durability against synthetic options. Its environmental benefits can enhance brand image, especially among eco-conscious consumers.

What are the Advantages of Microfiber Leather in High-End Applications?

Microfiber leather is crafted from ultra-fine synthetic fibers, providing a soft and lightweight material with high abrasion resistance. This type of artificial leather is favored in high-end upholstery and automotive interiors due to its luxurious feel and breathability. Although it may come at a higher price point, its stain resistance and durability make it a worthwhile investment for businesses targeting premium markets.

How Does Faux Suede Serve Versatile Needs in the Market?

Faux suede offers a soft, suede-like texture that mimics real suede, making it a versatile option for apparel, upholstery, and accessories. Its availability in various colors allows businesses to cater to diverse consumer preferences. However, buyers should consider that faux suede may require special cleaning to maintain its appearance, which could influence its practicality in certain applications.

Key Industrial Applications of artificial leather sheet

| Industry/Sector | Specific Application of artificial leather sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for Residential and Commercial Use | Cost-effective, durable, and easy to clean | Quality certifications, color and texture options |

| Automotive | Interior Upholstery and Seat Covers | Lightweight, water-resistant, and customizable | Compliance with automotive standards and regulations |

| Fashion and Accessories | Handbags, Wallets, and Footwear | Trendy, versatile designs at a lower price point | Sourcing materials with specific textures and finishes |

| Marine and Outdoor Furniture | Cushions and Upholstery for Boats and Patios | Weather-resistant and easy maintenance | UV and mildew resistance, durability in harsh conditions |

| Health Care | Upholstery for Medical Furniture | Hygienic, easy to disinfect, and durable | Compliance with health regulations and certifications |

How is Artificial Leather Sheet Used in Furniture Manufacturing?

In the furniture manufacturing sector, artificial leather sheets are widely used for upholstery in both residential and commercial settings. The material provides a luxurious appearance at a fraction of the cost of genuine leather, making it an attractive option for cost-sensitive projects. International buyers should consider sourcing materials that meet quality certifications to ensure durability and aesthetics. Additionally, the availability of various colors and textures allows manufacturers to cater to diverse design preferences, enhancing product appeal.

What Role Does Artificial Leather Play in Automotive Applications?

Artificial leather sheets are extensively utilized in automotive interior applications, including seat covers, dashboards, and door panels. The lightweight nature of synthetic leather combined with its water-resistant properties makes it an ideal choice for vehicle interiors. Buyers in this sector, particularly from regions with stringent automotive regulations, should prioritize sourcing materials that comply with safety and environmental standards. Customizability in design and texture also allows automotive manufacturers to create unique branding opportunities.

How is Artificial Leather Employed in Fashion and Accessories?

In the fashion industry, artificial leather sheets are increasingly popular for crafting handbags, wallets, and footwear. The versatility of this material allows designers to experiment with various styles and colors without the high costs associated with genuine leather. For B2B buyers, it’s essential to source high-quality faux leather that mimics the texture and appearance of real leather. This not only ensures customer satisfaction but also helps in maintaining a competitive edge in the fast-paced fashion market.

What are the Benefits of Using Artificial Leather in Marine and Outdoor Furniture?

Artificial leather is commonly used for cushions and upholstery in marine and outdoor furniture due to its weather-resistant properties. This material can withstand exposure to water, UV rays, and mildew, making it ideal for outdoor settings. Buyers should focus on sourcing sheets that offer enhanced durability and ease of maintenance to ensure long-lasting performance. The ability to clean artificial leather easily is a significant advantage, especially for outdoor applications where cleanliness and upkeep are essential.

Illustrative image related to artificial leather sheet

How is Artificial Leather Utilized in the Health Care Sector?

In the health care industry, artificial leather sheets are used for upholstery on medical furniture, such as examination tables and chairs. The material’s easy-to-clean nature and resistance to stains make it a hygienic choice for medical environments. International buyers must ensure that the materials sourced comply with health regulations and certifications to guarantee safety and reliability. Durability is also crucial, as medical furniture is subject to frequent use and requires materials that can withstand wear and tear.

3 Common User Pain Points for ‘artificial leather sheet’ & Their Solutions

Scenario 1: Sourcing Quality Artificial Leather Sheets for Diverse Applications

The Problem: Many B2B buyers face the challenge of sourcing artificial leather sheets that meet specific quality and durability standards, especially when catering to diverse applications like automotive upholstery, furniture, or fashion accessories. Often, suppliers may not provide detailed information about the material specifications, leading to uncertainty about whether the product can withstand wear and tear or meet regulatory requirements in different regions, particularly in markets like Europe or the Middle East.

The Solution: To address this issue, B2B buyers should prioritize sourcing from reputable suppliers who offer comprehensive product information, including material composition, durability tests, and compliance with relevant industry standards. It is advisable to request samples before making bulk purchases to evaluate the texture, flexibility, and overall quality of the artificial leather sheets. Additionally, utilizing platforms that specialize in artificial leather, where suppliers are vetted and rated, can help buyers make informed decisions. Establishing direct communication with manufacturers can also clarify specifications and ensure that the product aligns with the intended application, whether for high-traffic commercial use or luxury fashion items.

Scenario 2: Ensuring Consistency in Color and Texture Across Orders

The Problem: Another common pain point for international B2B buyers is the inconsistency in color and texture of artificial leather sheets across different orders. This inconsistency can lead to significant issues in manufacturing processes, especially for businesses that require uniformity for branding purposes. For instance, a furniture manufacturer may find that the shade of faux leather received in a new shipment does not match previous orders, jeopardizing their production schedules and customer satisfaction.

Illustrative image related to artificial leather sheet

The Solution: To mitigate this issue, buyers should establish a strong relationship with their suppliers, emphasizing the importance of consistent quality and color matching. When placing orders, it is beneficial to specify the exact color codes and request a color swatch for approval before full production. Implementing a standard operating procedure for order verification can help ensure that each batch meets predetermined specifications. Buyers can also consider collaborating with suppliers who provide color matching services or digital color previews, allowing for adjustments before production begins. Regular quality checks upon receipt of goods can further protect against discrepancies.

Scenario 3: Addressing Environmental Concerns and Sustainability

The Problem: With increasing awareness of environmental issues, B2B buyers are often concerned about the sustainability of artificial leather sheets. Buyers may struggle to find products that are not only cost-effective but also eco-friendly and ethically produced. This challenge is particularly relevant for companies in Europe and North America, where consumers are demanding more transparency regarding the sourcing and production methods of materials used in their products.

The Solution: To navigate these concerns, buyers should prioritize sourcing artificial leather sheets made from sustainable materials, such as recycled plastics or plant-based alternatives. Conducting thorough research into suppliers’ manufacturing processes and certifications can provide insights into their commitment to sustainability. Buyers can also engage with suppliers who transparently disclose their environmental impact and offer certifications such as OEKO-TEX or GRS (Global Recycle Standard). By aligning with suppliers who share a commitment to eco-friendly practices, B2B buyers can enhance their brand’s reputation while meeting customer expectations for sustainability. Implementing a clear sustainability policy within the procurement process can guide decisions and foster long-term partnerships with environmentally responsible suppliers.

Strategic Material Selection Guide for artificial leather sheet

What Are the Key Materials Used in Artificial Leather Sheets?

When selecting artificial leather sheets for various applications, understanding the properties and performance characteristics of the materials used is crucial. This guide analyzes four common materials—Polyurethane (PU) Leather, Polyvinyl Chloride (PVC) Leather, Microfiber Leather, and Eco-Leather—highlighting their advantages, disadvantages, and implications for international B2B buyers.

How Does Polyurethane (PU) Leather Perform?

Polyurethane leather, often referred to as PU leather, is a popular choice due to its soft texture and leather-like appearance. It is produced by coating a fabric backing with a flexible polymer, resulting in a material that is both durable and visually appealing. PU leather is highly resistant to water, stains, and mildew, making it suitable for a wide range of applications, including upholstery and fashion accessories.

Illustrative image related to artificial leather sheet

Pros: PU leather is cost-effective, typically priced at 75% less than genuine leather. It is easy to clean and maintain, with many products featuring stain-resistant finishes. Additionally, it is available in various colors and textures, providing flexibility in design.

Cons: While PU leather is durable, it may not withstand extreme temperatures as well as other materials. Over time, it can show signs of wear, particularly in high-friction areas.

Impact on Application: PU leather is compatible with various media, including upholstery for furniture and automotive applications. However, it is essential to consider the environmental regulations in different regions, as some countries may have specific requirements for synthetic materials.

What About Polyvinyl Chloride (PVC) Leather?

PVC leather is another widely used artificial leather material, known for its robust properties. It is created by applying a layer of PVC to a fabric backing, resulting in a product that is both waterproof and resistant to UV light.

Pros: PVC leather is highly durable and can withstand harsh conditions, making it suitable for outdoor applications. It is also less expensive than PU leather, appealing to budget-conscious buyers.

Cons: PVC leather is less breathable than PU leather, which can lead to discomfort in certain applications, such as clothing. Additionally, it may not have the same aesthetic appeal as PU leather.

Impact on Application: PVC leather is commonly used in commercial settings, such as restaurants and healthcare facilities, where durability and ease of cleaning are paramount. International buyers should be aware of compliance with standards such as ASTM and DIN, particularly in Europe and the Middle East.

How Does Microfiber Leather Compare?

Microfiber leather is a synthetic material made from ultra-fine fibers, offering a soft texture and high durability. It is often used in high-end products due to its luxurious feel and appearance.

Pros: Microfiber leather is highly resistant to stains and water, making it easy to maintain. It is also lightweight and breathable, providing comfort in applications like clothing and upholstery.

Illustrative image related to artificial leather sheet

Cons: The manufacturing process for microfiber leather can be more complex, potentially leading to higher costs. It may also require special care to maintain its appearance.

Impact on Application: Microfiber leather is ideal for fashion and luxury items, but international buyers should consider the environmental impact of production. Compliance with sustainability standards is increasingly important in markets like Europe and North America.

What Is Eco-Leather and Its Significance?

Eco-leather refers to leather-like materials made from sustainable sources, often incorporating recycled materials or natural fibers. This material appeals to environmentally conscious consumers and businesses.

Pros: Eco-leather is biodegradable and often free from harmful chemicals, making it a safer choice for both users and the environment. It can also offer a unique aesthetic due to its natural fibers.

Cons: The cost of eco-leather can be higher than traditional synthetic options, which may deter some buyers. Additionally, its durability may vary depending on the manufacturing process.

Impact on Application: Eco-leather is suitable for a variety of applications, including fashion and home décor, particularly in regions where sustainability is a key purchasing factor. Buyers in Europe and North America may find eco-leather aligns with their corporate social responsibility goals.

Summary Table of Artificial Leather Materials

| Material | Typical Use Case for Artificial Leather Sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Upholstery, fashion accessories | Soft texture, easy to clean | May wear over time | Medium |

| Polyvinyl Chloride (PVC) | Commercial upholstery, outdoor applications | Highly durable, waterproof | Less breathable | Low |

| Microfiber Leather | High-end fashion, upholstery | Luxurious feel, stain-resistant | Higher manufacturing complexity | High |

| Eco-Leather | Sustainable fashion, home décor | Biodegradable, environmentally friendly | Higher cost, variable durability | Medium to High |

This strategic material selection guide provides B2B buyers with essential insights into the various artificial leather materials available, enabling informed decisions that align with their specific application needs and regional compliance requirements.

Illustrative image related to artificial leather sheet

In-depth Look: Manufacturing Processes and Quality Assurance for artificial leather sheet

What Are the Main Stages of Manufacturing Artificial Leather Sheets?

The manufacturing process of artificial leather sheets involves several critical stages, each designed to ensure the final product meets quality standards while maximizing efficiency and cost-effectiveness. Here’s an overview of the main stages:

-

Material Preparation: The process begins with sourcing raw materials, predominantly polyurethane (PU) or polyvinyl chloride (PVC). These materials are selected based on the desired properties of the final product, such as durability, flexibility, and texture. The raw materials are then processed into a workable form, which may involve mixing chemicals to achieve specific performance characteristics.

-

Forming: This stage involves applying the prepared materials onto a backing fabric, typically made of polyester or cotton. The coating is achieved through techniques like calendaring or coating, where the polymer is spread evenly over the substrate. The thickness and texture can be adjusted by controlling the application process, allowing for a wide variety of finishes, from smooth to embossed textures that mimic real leather.

-

Assembly: After the artificial leather is formed, it is cut into sheets or rolls based on customer specifications. This stage may also include additional processes, such as laminating or bonding, where multiple layers are adhered together to enhance durability or aesthetic appeal. Assembly can be done manually or through automated systems, depending on the scale of production.

-

Finishing: The finishing stage enhances the visual and functional properties of the artificial leather. This may involve applying surface treatments for color, gloss, or texture, as well as protective coatings that improve stain resistance and durability. The finished product is then inspected for consistency and quality before being prepared for shipment.

Which Key Techniques Are Used in the Production of Artificial Leather Sheets?

A variety of techniques are employed in the production of artificial leather sheets, each contributing to the unique characteristics of the final product. Some of the most notable techniques include:

-

Coating and Lamination: These processes are fundamental in creating the leather-like finish and ensuring the material’s durability. Coating involves applying a liquid polymer to the fabric, while lamination adds an additional layer for enhanced protection.

-

Embossing: This technique is used to create patterns or textures that mimic genuine leather. By pressing a patterned plate onto the surface of the material, manufacturers can achieve a variety of finishes, adding aesthetic value to the sheets.

-

Coloring: Advanced dyeing techniques allow manufacturers to produce artificial leather in a wide range of colors. This flexibility is especially appealing to B2B buyers looking for specific branding or design requirements.

What Quality Assurance Practices Are Essential for Artificial Leather Sheets?

Quality assurance (QA) is paramount in the artificial leather industry to ensure that products meet international standards and customer expectations. Here are some critical aspects of QA:

-

International Standards: Adhering to international quality standards such as ISO 9001 is crucial for manufacturers. This standard outlines requirements for a quality management system, emphasizing customer satisfaction and continuous improvement. Compliance with CE marking is also essential for products sold in Europe, ensuring they meet safety and environmental protection requirements.

-

Industry-Specific Standards: In addition to general standards, manufacturers may need to comply with specific certifications such as API (American Petroleum Institute) for applications in the automotive and marine industries, where performance under stress and exposure to elements is critical.

-

Quality Control Checkpoints: Implementing a systematic approach to quality control involves several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor production processes and identify defects early.

– Final Quality Control (FQC): The finished product undergoes thorough testing for consistency, appearance, and performance before shipment.

What Common Testing Methods Are Used for Quality Assurance?

Quality assurance in artificial leather production involves various testing methods to assess the material’s properties:

Illustrative image related to artificial leather sheet

-

Physical Tests: These tests measure durability, tensile strength, and flexibility, ensuring that the artificial leather can withstand regular use without degrading.

-

Chemical Resistance Tests: The material is exposed to various substances, such as oils and solvents, to evaluate its resistance to stains and degradation.

-

Environmental Tests: These tests assess how well the material performs under extreme conditions, including UV exposure and temperature fluctuations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure product reliability. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. An on-site visit can help buyers assess compliance with international standards and industry-specific regulations.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes and results from recent tests. This transparency is crucial for building trust.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the supplier’s quality control measures and product quality. This step is particularly important for buyers from regions with strict import regulations, such as Europe and the Middle East.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulations regarding materials and manufacturing processes. Understanding these requirements can help buyers avoid compliance issues.

-

Cultural Considerations: Different cultures may have varying expectations regarding quality and service. Being mindful of these differences can aid in building strong supplier relationships.

-

Sustainability Concerns: As global demand for sustainable products rises, buyers should consider suppliers who prioritize eco-friendly materials and practices. Certifications such as OEKO-TEX can indicate a commitment to sustainability.

By understanding the manufacturing processes and quality assurance practices involved in producing artificial leather sheets, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘artificial leather sheet’

In today’s competitive market, sourcing artificial leather sheets requires a strategic approach to ensure quality, cost-effectiveness, and supplier reliability. This guide provides a comprehensive checklist to assist international B2B buyers in navigating the procurement process.

Illustrative image related to artificial leather sheet

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the artificial leather sheets you intend to purchase. Consider factors such as thickness, texture, color, and durability. Establishing these specifications is crucial to ensure that the materials meet your end-use applications, whether for upholstery, fashion, or automotive purposes.

Step 2: Research Market Trends and Pricing

Investigate current market trends and pricing for artificial leather sheets. Understanding the price range will help you identify a fair cost and spot any potential red flags when evaluating suppliers. Pay attention to regional differences in pricing, especially if sourcing from international markets like Africa or Europe.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from previous clients, especially those in similar industries or regions. This evaluation not only helps in assessing reliability but also provides insights into the supplier’s production capabilities and quality assurance processes.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you consider comply with relevant industry standards and certifications. Look for certifications such as ISO, REACH, or RoHS, which indicate adherence to quality and safety regulations. This step is crucial for maintaining product integrity and ensuring that the materials are safe for end-users.

Illustrative image related to artificial leather sheet

Step 5: Request Samples for Quality Assessment

Always request samples of the artificial leather sheets before finalizing your order. Assessing the quality firsthand allows you to evaluate texture, flexibility, and overall appearance. This step can help prevent costly mistakes and ensure that the materials meet your specifications.

Step 6: Understand Payment Terms and Shipping Logistics

Clarify payment terms and shipping logistics with your chosen supplier. Consider factors such as payment methods, lead times, and shipping costs, which can significantly impact your overall budget. Understanding these details upfront can prevent misunderstandings and facilitate a smoother procurement process.

Step 7: Establish Communication Channels

Maintain open lines of communication with your supplier throughout the sourcing process. Establishing clear communication channels can help address any issues or changes in specifications promptly. Regular updates and responsiveness can enhance your relationship with the supplier and ensure timely delivery of materials.

Illustrative image related to artificial leather sheet

By following this checklist, B2B buyers can navigate the complexities of sourcing artificial leather sheets more effectively, ensuring that they obtain high-quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for artificial leather sheet Sourcing

What Are the Key Cost Components in Artificial Leather Sheet Sourcing?

When sourcing artificial leather sheets, it is crucial to understand the various cost components that contribute to the overall price. The primary cost elements include:

-

Materials: The base material, often polyurethane (PU) or polyvinyl chloride (PVC), significantly influences the cost. PU leather typically commands a higher price due to its quality and feel, while PVC is more economical but may compromise on durability and aesthetics.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. This varies by region, with countries in Africa and South America generally experiencing lower labor costs compared to Europe.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead, impacting the final pricing.

-

Tooling: Initial investment in tooling, such as molds and cutting equipment, is essential for producing various designs and specifications. Custom tooling can increase upfront costs but may lead to lower per-unit costs in larger production runs.

-

Quality Control (QC): Ensuring product consistency and quality involves additional costs. Implementing stringent QC measures can enhance product value but may also raise the price.

-

Logistics: Shipping and transportation costs are significant, especially for international buyers. Factors such as distance, mode of transport, and shipping agreements can greatly influence overall costs.

-

Margin: Suppliers typically add a markup to cover their costs and desired profit margin, which varies based on market conditions and competition.

What Influences Pricing in the Artificial Leather Market?

Several factors can influence the pricing of artificial leather sheets:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding your volume needs can lead to significant cost savings.

-

Specifications and Customization: Custom designs or specific textures may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., eco-friendly, hypoallergenic) can justify a higher price point. Buyers should assess whether these certifications align with their product requirements.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their quality assurance and service levels.

-

Incoterms: Understanding the terms of sale (e.g., FOB, CIF) can impact total costs. Incoterms dictate who bears the risk and cost at various stages of shipping, influencing the final price.

How Can Buyers Negotiate for Better Prices?

International B2B buyers should consider several strategies to enhance cost-efficiency in their sourcing efforts:

-

Leverage Volume Discounts: Engage in discussions about bulk purchasing. Establishing long-term relationships with suppliers can also open avenues for better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase costs, consider factors such as durability, maintenance, and lifecycle costs. A higher upfront investment in quality materials may result in lower long-term costs.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing trends, especially when sourcing from different continents. For instance, the price of artificial leather sheets may vary significantly between suppliers in Europe and those in Africa or South America.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure the product meets your standards.

Conclusion: What to Keep in Mind When Sourcing Artificial Leather Sheets?

When sourcing artificial leather sheets, understanding the comprehensive cost structure, price influencers, and effective negotiation strategies is vital for international buyers. Each component—from materials to logistics—plays a significant role in determining the final cost. By applying these insights, buyers can make informed decisions that optimize their sourcing strategy while ensuring they achieve the best possible price. Keep in mind that prices may fluctuate based on market conditions, so always request current quotes and be prepared to negotiate.

Alternatives Analysis: Comparing artificial leather sheet With Other Solutions

In the realm of materials used for upholstery and fashion, the demand for versatile and cost-effective solutions has led to the emergence of various alternatives to traditional leather. Among these, artificial leather sheets have gained popularity due to their aesthetic appeal and practicality. However, buyers should consider other viable alternatives that may fit their specific needs better. This analysis presents a comparative overview of artificial leather sheets against two alternatives: genuine leather and polyurethane (PU) leather.

| Comparison Aspect | Artificial Leather Sheet | Genuine Leather | PU Leather |

|---|---|---|---|

| Performance | Durable, water-resistant | Highly durable, breathable | Durable, soft, easy to clean |

| Cost | 75% less than leather | High cost per hide | Moderate, but cheaper than genuine leather |

| Ease of Implementation | Easy to cut and sew | Requires skilled labor | Easy to work with |

| Maintenance | Low; wipe clean | Requires conditioning | Low; wipe clean |

| Best Use Case | Fashion accessories, upholstery | High-end furniture, luxury goods | Everyday furniture, automotive |

What Are the Pros and Cons of Genuine Leather as an Alternative?

Genuine leather is revered for its luxurious feel and durability. Its breathability makes it suitable for high-end applications such as luxury furniture and fashion items. However, the high cost and ethical concerns regarding animal welfare may deter some buyers. Additionally, genuine leather requires regular maintenance to prevent cracking and drying out, which can increase long-term costs.

Illustrative image related to artificial leather sheet

How Does PU Leather Compare to Artificial Leather Sheets?

PU leather, a type of synthetic leather, offers a soft texture and a similar aesthetic to genuine leather while being more affordable. Its manufacturing process allows for a wide range of colors and designs, making it a flexible option for various applications, including upholstery and fashion accessories. However, PU leather may not be as durable as artificial leather sheets in extreme conditions and can be less environmentally friendly, depending on the specific production methods used.

In What Scenarios Should Buyers Choose Artificial Leather Sheets?

Artificial leather sheets are an excellent choice for businesses looking for a cost-effective solution without compromising on appearance. They are particularly suited for fashion accessories, craft projects, and upholstery for commercial environments where durability and ease of maintenance are priorities. Their low cost and availability in various textures and colors make them highly attractive for bulk purchases.

Conclusion: How to Choose the Right Material for Your Needs?

When selecting between artificial leather sheets, genuine leather, and PU leather, B2B buyers should carefully evaluate their specific requirements, including budget constraints, application needs, and maintenance capabilities. While artificial leather sheets offer a budget-friendly and versatile solution, genuine leather may be ideal for high-end applications where quality is paramount. PU leather presents a middle ground, offering a balance of affordability and aesthetic appeal. Ultimately, the right choice will depend on the intended use, desired durability, and financial considerations of the buyer’s project.

Essential Technical Properties and Trade Terminology for artificial leather sheet

What Are the Key Technical Properties of Artificial Leather Sheets?

When considering artificial leather sheets for B2B applications, understanding their technical properties is essential. Here are several critical specifications that buyers should evaluate:

Illustrative image related to artificial leather sheet

-

Material Composition

– Artificial leather is typically made from polyurethane (PU) or polyvinyl chloride (PVC). PU leather is favored for its softness and flexibility, making it a popular choice for upholstery, while PVC is more durable and cost-effective. Understanding the material composition helps buyers assess the suitability of the product for specific applications, whether for fashion, upholstery, or automotive use. -

Thickness

– The thickness of artificial leather sheets generally ranges from 0.5 mm to 3 mm. Thicker materials provide enhanced durability and wear resistance, making them ideal for high-traffic areas. Conversely, thinner sheets are more suitable for applications requiring flexibility, such as fashion accessories. Buyers should align thickness with the intended use to ensure longevity and performance. -

Abrasion Resistance

– This property indicates how well the material can withstand wear and tear from friction. Measured using the Martindale test, higher abrasion resistance ratings (measured in cycles) signify a more durable product. For B2B buyers, choosing materials with adequate abrasion resistance is crucial, especially for applications like furniture upholstery that experience frequent contact. -

Water Resistance

– Most artificial leather sheets are designed to be water-resistant, which is a significant advantage over genuine leather. This property is particularly important for applications in environments where spills are common, such as restaurants or automotive interiors. A water-resistant material reduces maintenance costs and extends the lifespan of the product. -

UV Resistance

– UV resistance refers to the material’s ability to withstand fading and degradation from sunlight exposure. This property is vital for outdoor applications or in environments with high sun exposure. B2B buyers should ensure that the artificial leather selected has adequate UV resistance to maintain aesthetic appeal and functionality over time. -

Fire Retardancy

– In certain industries, fire retardant properties are essential, especially for upholstery in commercial settings. Fire retardancy ratings indicate how well the material can resist ignition and limit flame spread. Buyers in sectors like hospitality or transportation should prioritize materials that comply with fire safety regulations.

What Are Common Trade Terms Related to Artificial Leather Sheets?

Understanding trade terminology is crucial for effective communication and negotiation in the B2B space. Here are some common terms relevant to artificial leather sheets:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that manufacture products that are then sold under another company’s brand. In the context of artificial leather, buyers may work with OEMs to produce custom designs tailored to specific market needs. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of product that a supplier is willing to sell. For artificial leather sheets, understanding MOQ is critical for buyers to manage inventory costs and ensure they can meet their production requirements without excess. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for price quotes for specific products or services. For B2B buyers, issuing an RFQ for artificial leather sheets helps in comparing prices and negotiating better terms with suppliers. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand shipping costs and liability during transit. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the goods. For artificial leather sheets, knowing the lead time is essential for planning production schedules and ensuring timely delivery to customers. -

Certification Standards

– Certifications such as OEKO-TEX or REACH indicate compliance with safety and environmental standards. These certifications can enhance product credibility and appeal to eco-conscious buyers in the B2B market.

By grasping these technical properties and trade terms, international buyers can make informed decisions when sourcing artificial leather sheets, ensuring they meet their specific needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the artificial leather sheet Sector

What Are the Current Market Dynamics and Key Trends in the Artificial Leather Sheet Sector?

The artificial leather sheet market is experiencing a transformative phase driven by various global factors. Increased demand for sustainable and animal-friendly materials is reshaping the landscape, particularly as consumers and businesses alike prioritize ethical sourcing. This shift is pronounced in regions such as Europe, where strict regulations regarding animal products and environmental impact are influencing purchasing decisions. Additionally, markets in Africa and South America are witnessing a surge in demand due to the rise of local manufacturing and the growing popularity of faux leather in fashion, upholstery, and automotive industries.

Emerging technologies are also playing a crucial role in the sourcing and production of artificial leather sheets. Innovations in material science, such as the development of bio-based and recycled materials, are enhancing the performance characteristics of faux leather, making it more competitive against genuine leather. B2B buyers are increasingly leveraging digital platforms for sourcing, with online marketplaces providing broader access to suppliers and allowing for price comparisons, which can lead to more cost-effective purchasing decisions. Furthermore, the introduction of advanced manufacturing techniques like 3D printing is enabling custom designs, thus catering to niche markets and specific buyer requirements.

How Is Sustainability Shaping Ethical Sourcing in the Artificial Leather Sheet Market?

Sustainability has become a cornerstone of B2B procurement strategies, especially in the artificial leather sheet sector. The environmental impact of traditional leather production is significant, involving high water usage and chemical treatments that can harm ecosystems. In contrast, synthetic alternatives, particularly those made from polyurethane (PU) or recycled materials, offer a more sustainable option, significantly reducing water and energy consumption. B2B buyers are now prioritizing suppliers who demonstrate commitment to sustainable practices, such as using eco-friendly dyes and processes that minimize waste.

Ethical sourcing is equally crucial, as businesses face increasing pressure from consumers and regulatory bodies to ensure their supply chains are free from exploitation and environmental degradation. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® provide buyers with assurance regarding the sustainability and safety of the materials they are sourcing. By choosing suppliers with these certifications, B2B buyers can enhance their brand reputation and align their operations with global sustainability goals.

What Is the Historical Context of Artificial Leather Sheets in B2B Sourcing?

The evolution of artificial leather sheets can be traced back to the early 20th century when synthetic alternatives to genuine leather began to emerge. Initially developed for military and industrial applications, these materials gained traction in consumer markets during the mid-1900s as technological advancements improved their quality and affordability. The introduction of polyurethane in the 1960s marked a significant milestone, as this material closely mimicked the feel and appearance of real leather while offering enhanced durability and ease of maintenance.

In recent decades, the rise of ethical consumerism and environmental awareness has further propelled the artificial leather market. As businesses increasingly seek to reduce their carbon footprints and appeal to conscientious consumers, the demand for high-quality, sustainable faux leather continues to grow. This historical context underscores the ongoing shift toward innovative materials and ethical sourcing practices, making it a pivotal period for B2B buyers in the artificial leather sheet sector.

Frequently Asked Questions (FAQs) for B2B Buyers of artificial leather sheet

-

How do I select the right artificial leather sheet for my business needs?

Choosing the right artificial leather sheet involves assessing your specific application requirements. Consider the texture, durability, and color that align with your intended use, whether it’s for upholstery, fashion, or accessories. Evaluate the types available, such as PU or PVC, based on their properties like flexibility, water resistance, and ease of cleaning. Additionally, review supplier catalogs for product samples to ensure the material meets your quality standards. -

What are the advantages of using artificial leather sheets over genuine leather?

Artificial leather sheets offer significant cost savings, often being up to 75% less expensive than genuine leather. They are easier to clean and maintain, as they resist stains and do not absorb moisture, preventing issues like warping or cracking. Furthermore, they are available in a wide variety of colors and textures, providing greater design flexibility. Being animal-friendly, they also appeal to environmentally conscious consumers. -

What is the minimum order quantity (MOQ) for artificial leather sheets?

Minimum order quantities for artificial leather sheets can vary significantly by supplier, typically ranging from 50 to 500 yards or sheets, depending on the material and customization options. It’s essential to communicate your needs clearly with potential suppliers to negotiate terms that align with your production scale. Always inquire about discounts for larger orders, which can further reduce your costs. -

How can I vet potential suppliers of artificial leather sheets?

To vet suppliers, start by reviewing their reputation in the market through customer testimonials and case studies. Request samples to assess the quality of their products. Additionally, check for certifications related to material safety and environmental standards. Engaging in direct communication can help gauge their responsiveness and willingness to accommodate your specific needs, which is crucial for a reliable partnership. -

What payment terms should I expect when sourcing artificial leather sheets internationally?

Payment terms for international transactions can vary, but common practices include upfront deposits (often 30-50%) with the balance due before shipment. Some suppliers may offer letters of credit or payment through escrow services for larger orders. It’s important to clarify payment methods and terms before finalizing orders to avoid misunderstandings. Always ensure that your payment terms are secure and aligned with your cash flow needs. -

What are the logistics considerations when importing artificial leather sheets?

When importing artificial leather sheets, consider shipping methods, customs duties, and lead times. Evaluate whether air freight or sea freight is more cost-effective based on your timeline. Ensure compliance with import regulations in your country, including any tariffs on synthetic materials. Collaborating with a freight forwarder can simplify the logistics process, ensuring timely delivery and handling of customs paperwork. -

How do I ensure quality assurance for artificial leather sheets?

Quality assurance can be maintained by establishing clear specifications and standards with your supplier prior to production. Conduct regular inspections during manufacturing or request third-party quality checks. It’s also beneficial to set up a return policy for defective goods and to communicate expectations regarding material performance, such as colorfastness and durability. Creating a strong partnership with your supplier can facilitate better quality control. -

Can I customize artificial leather sheets for my business?

Yes, many suppliers offer customization options for artificial leather sheets, including color, texture, and thickness. Discuss your specific design requirements with potential suppliers to explore available options. Customization may affect the MOQ and lead times, so be sure to clarify these aspects. Collaborating closely with your supplier during the design phase can ensure that the final product meets your brand’s standards and expectations.

Top 8 Artificial Leather Sheet Manufacturers & Suppliers List

1. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes a variety of vegan materials that serve as alternatives to leather or cork fabric. The faux leather is soft, pliable, and available in eight different textures: Weave, Pebble, Legacy, Shimmer, Crocodile, Alligator, Ostrich, and Rugged. Select Faux Leathers are also available in Lite Legacy, an ultra-thin material. The fabrics are sold by quarter ya…

2. Frog Jelly Leather – Faux Leather Sheets & Synthetics

Domain: frogjellyleather.com

Registered: 2016 (9 years)

Introduction: Faux Leather Sheets & Synthetics include various products such as:

– Faux Leather Scrap Strips – 4oz for $4.99, made from printed marine grade upholstery vinyl, suitable for earrings and keychains.

– Faux Leather Remnants – Printed Marine Vinyl starting from $4.99, UV resistant, great for bags and jewelry.

– Holiday Printed Faux Leather Scrap Pack from $4.99, UV resistant, suitable for various cra…

3. Fashion Fabric LA – Premium Faux Leather Vinyl

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Introduction: This company, Fashion Fabric LA – Premium Faux Leather Vinyl, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Hair Bow Center – Faux Leather Sheets

Domain: hairbowcenter.com

Registered: 2008 (17 years)

Introduction: Faux Leather Sheets available for DIY hair-bows, earrings, and jewelry. Prices range from $1.95 to $2.00 per sheet. Options include Shimmer Faux Leather Felt Sheets in various colors (Dusty Blue, Mineral Ice, Gray Iridescent, Champagne) priced at $1.95 each, and High Gloss Vinyl Textured Faux Leather Sheets in multiple colors (Orange, Peach, Watermelon, Royal Blue, Yellow, Red, Blush Pink, Maroon,…

5. Decorative Fabrics Direct – PU Leather & Faux Leather

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric, Free Shipping Coupon Code: SHIPFREE for Most $199 Orders, Available in various colors including Black, Gray, Blue, Turquoise, Aqua, Brown, Beige, Green, Orange, Coral, Purple, Red, Pink, White, Yellow, Gold. Suitable for Furniture, Automotive, Marine use. Brands include Naugahyde, Omnova Boltaflex, Nassimi, Spradling. Types include Vinyl (PVC), …

6. PIP Supply – Custom Printed Faux Leather Sheets

Domain: pipsupply.com

Registered: 2018 (7 years)

Introduction: Custom Printed Faux Leather Sheets, Faux Leather Rolls, Faux Leather for Cricut, Sizzix, Silhouette, Vegan Leather, Free Domestic Shipping for orders $75 and up, Current Processing Time 4-8 Business Days.

7. Fabric Wholesale Direct – Faux Leather Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Hobby Lobby – Imitation Leather Felt Sheet

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Imitation Leather Felt Sheet’, ‘sku’: ‘2106656’, ‘original_price’: ‘$1.49’, ‘color’: ‘Black’, ‘length’: ’12 inches’, ‘width’: ‘9 inches’, ‘description’: ‘Work unique patterns and textures into your crafts using this Imitation Leather Felt Sheet! This printed fabric sheet has a faux leather surface with a solid color. The surface of the sheet is slightly glossy, while the back is soft. Cu…

Strategic Sourcing Conclusion and Outlook for artificial leather sheet

In conclusion, strategic sourcing of artificial leather sheets presents a compelling opportunity for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The advantages of faux leather, such as its cost-effectiveness—up to 75% less than genuine leather—combined with its durability and ease of maintenance, make it an attractive alternative for various applications, from upholstery to fashion accessories. Buyers should prioritize suppliers who offer a wide range of textures and colors, ensuring that they can meet the specific needs of their clientele.

As global trends shift towards sustainable and animal-friendly materials, the demand for high-quality artificial leather is expected to rise. Engaging in strategic partnerships with reputable manufacturers can provide access to innovative products and competitive pricing. Now is the time for international buyers to leverage the advantages of faux leather in their sourcing strategies.

Explore reliable suppliers and seize the opportunity to enhance your product offerings with artificial leather sheets that align with market demands and consumer preferences. The future of sourcing in this sector is bright—capitalize on it today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.