Introduction: Navigating the Global Market for leather working supplies

Navigating the global market for leather working supplies can be a daunting task, especially for international B2B buyers seeking to source quality materials and tools that meet their specific needs. The challenge often lies in identifying reliable suppliers, understanding the diverse range of products, and navigating various pricing structures. This comprehensive guide aims to address these challenges by providing valuable insights into the types of leather working supplies available, their applications in various industries, and the essential criteria for vetting suppliers.

From tools and machinery to leather types and finishing products, this guide covers every aspect of leather working supplies. Buyers will gain a clear understanding of how to evaluate product quality, compare costs, and identify reputable suppliers across key regions, including Africa, South America, the Middle East, and Europe—particularly in countries like Germany and Saudi Arabia. By empowering buyers with the knowledge to make informed purchasing decisions, this guide not only enhances procurement efficiency but also fosters long-term business relationships.

As you delve into the subsequent sections, expect to find actionable strategies and expert recommendations that will streamline your sourcing process, ensuring that you acquire the best leather working supplies tailored to your unique business requirements.

Table Of Contents

- Top 8 Leather Working Supplies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather working supplies

- Understanding leather working supplies Types and Variations

- Key Industrial Applications of leather working supplies

- 3 Common User Pain Points for ‘leather working supplies’ & Their Solutions

- Strategic Material Selection Guide for leather working supplies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather working supplies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather working supplies’

- Comprehensive Cost and Pricing Analysis for leather working supplies Sourcing

- Alternatives Analysis: Comparing leather working supplies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather working supplies

- Navigating Market Dynamics and Sourcing Trends in the leather working supplies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather working supplies

- Strategic Sourcing Conclusion and Outlook for leather working supplies

- Important Disclaimer & Terms of Use

Understanding leather working supplies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Tools | Includes cutting, stitching, and finishing tools | Handbag, wallet, and accessory making | Pros: High precision; varied applications. Cons: Requires skill; initial investment. |

| Leather Hardware | Fasteners like buckles, snaps, and rivets | Apparel and bag manufacturing | Pros: Enhances product durability; wide selection. Cons: Quality varies; may require bulk purchasing. |

| Leather Materials | Types include vegetable-tanned, chrome-tanned, and suede | Upholstery, fashion, and crafts | Pros: Diverse textures; suitable for various projects. Cons: Price fluctuations; sourcing challenges. |

| Leather Finishing Products | Dyes, conditioners, and sealants | Customization and protection | Pros: Improves aesthetics; extends leather life. Cons: Requires application knowledge; potential for inconsistency. |

| Leather Crafting Kits | Pre-packaged supplies for specific projects | Educational and DIY markets | Pros: Convenient; often includes instructions. Cons: Limited to specific projects; may not suit advanced users. |

What Are the Key Characteristics of Leather Tools for B2B Buyers?

Leather tools are essential for precision crafting, encompassing items like cutting knives, stitching awls, and mallets. These tools are designed for durability and efficiency, catering to various applications from handbag creation to custom leather goods. B2B buyers should consider the quality of materials, ergonomics for prolonged use, and compatibility with existing processes when selecting tools. Investing in high-quality tools can significantly enhance production speed and craftsmanship quality, making them a crucial consideration for manufacturers.

How Do Leather Hardware Options Impact B2B Operations?

Leather hardware includes essential fasteners such as buckles, snaps, and rivets, which are vital for creating functional and durable leather products. B2B buyers must evaluate the hardware’s material quality, load capacity, and finish, as these factors directly influence the final product’s durability and aesthetic appeal. While sourcing hardware, businesses should also consider bulk purchasing options to reduce costs and ensure consistent supply, which is crucial for maintaining production schedules.

What Should B2B Buyers Know About Leather Materials?

Leather materials vary widely, including vegetable-tanned, chrome-tanned, and suede, each offering unique characteristics suitable for different applications. B2B buyers should assess the leather’s thickness, texture, and treatment method to ensure it meets the specific requirements of their projects, whether for upholstery or fashion items. Additionally, understanding market trends and price fluctuations is vital for effective budgeting and sourcing, as the quality and availability of leather can significantly impact production costs.

Illustrative image related to leather working supplies

Why Are Leather Finishing Products Important for B2B Buyers?

Finishing products like dyes, conditioners, and sealants play a crucial role in enhancing leather’s appearance and longevity. B2B buyers should consider the compatibility of these products with their leather types and the application methods required for optimal results. While these products can elevate the final product quality, buyers must also be aware of the knowledge and skill needed for effective application, as improper use can lead to subpar results.

How Can Leather Crafting Kits Benefit B2B Buyers?

Leather crafting kits provide a convenient solution for businesses looking to engage in educational or DIY projects, offering pre-packaged supplies tailored to specific items. These kits often include all necessary materials and instructions, making them suitable for workshops and beginner classes. However, B2B buyers should note that these kits may limit creativity and customization for advanced users, making them best suited for entry-level applications or promotional events rather than high-volume production.

Key Industrial Applications of leather working supplies

| Industry/Sector | Specific Application of leather working supplies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Handbag and accessory manufacturing | High-quality leather enhances product appeal and marketability. | Sourcing from reputable suppliers ensures consistent quality. |

| Automotive | Upholstery for vehicles | Durable leather provides luxury and comfort in vehicle interiors. | Consider sourcing leather that meets industry standards for safety. |

| Footwear | Production of leather shoes | Premium leather increases product lifespan and customer satisfaction. | Ensure compliance with sustainability and ethical sourcing practices. |

| Furniture and Interior Design | Leather furniture and decor items | Adds aesthetic value and durability to home and office environments. | Look for suppliers offering a variety of finishes and textures. |

| Sporting Goods | Leather goods for sports equipment (e.g., gloves, bags) | Enhances performance and comfort for athletes. | Focus on durability and performance specifications in sourcing. |

How Are Leather Working Supplies Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, leather working supplies are essential for creating handbags, wallets, and other accessories. High-quality leather not only elevates the aesthetic appeal of these products but also contributes to their durability. Buyers in this industry must prioritize sourcing from reputable suppliers to ensure consistent quality and availability of materials. This is particularly important for international buyers from regions like Europe and South America, where fashion standards are high, and competition is fierce.

What Role Do Leather Working Supplies Play in Automotive Upholstery?

Automotive manufacturers utilize leather working supplies extensively for vehicle upholstery, including seats and interiors. The use of premium leather enhances the luxury feel of vehicles while providing long-lasting durability and comfort. Buyers must consider sourcing leather that meets specific industry standards for safety and performance, especially in regions like the Middle East and Europe where consumer expectations are elevated. Additionally, the availability of different finishes can allow for customization, appealing to diverse market segments.

How Is Leather Used in Footwear Production?

In the footwear industry, leather working supplies are critical for producing high-quality shoes and boots. The use of premium leather not only extends the lifespan of footwear but also significantly enhances customer satisfaction due to comfort and style. Buyers should ensure that their suppliers adhere to sustainability practices, as ethical sourcing is increasingly important to consumers, particularly in Europe and North America. Furthermore, buyers should evaluate suppliers based on their ability to provide a range of leather types and finishes to meet various design requirements.

Why Is Leather Important in Furniture and Interior Design?

Leather working supplies are fundamental in the production of leather furniture and decorative items. The aesthetic appeal of leather adds significant value to both residential and commercial interiors, while its durability ensures long-term use. For international buyers, especially those in Africa and the Middle East, sourcing considerations should include the variety of textures and colors available to match diverse design preferences. Additionally, buyers should seek suppliers who can provide custom solutions to meet specific project needs.

Illustrative image related to leather working supplies

How Are Leather Working Supplies Used in Sporting Goods?

Leather working supplies are vital in the sporting goods sector for creating items such as gloves, bags, and protective gear. The durability and comfort provided by leather enhance performance for athletes, making it a preferred material for high-quality sports equipment. Buyers should focus on sourcing leather that meets rigorous performance specifications to ensure safety and reliability. In regions like South America, where sports culture is vibrant, the demand for premium leather goods is significant, making quality sourcing essential for competitive advantage.

3 Common User Pain Points for ‘leather working supplies’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Diverse Applications

The Problem: Many B2B buyers, especially those operating in regions with limited access to specialty supplies, struggle to find high-quality leather that meets their specific needs. This challenge is particularly pronounced for businesses that require various leather types for different applications, such as upholstery, bags, or crafts. The inconsistencies in quality can lead to product failures, wasted resources, and ultimately dissatisfied customers. This issue is compounded by the lack of reliable suppliers who can provide consistent product specifications and support.

The Solution: To effectively source quality leather, buyers should establish relationships with multiple suppliers who specialize in different leather types. Conducting thorough research and requesting samples before making bulk purchases can help ensure that the leather meets quality standards. Additionally, buyers should specify their requirements clearly, including leather type, thickness, grain, and finish. Engaging in regular communication with suppliers can also facilitate better understanding and alignment on quality expectations. Utilizing online platforms that aggregate reviews and ratings of suppliers can guide buyers in making informed decisions.

Scenario 2: Understanding Leather Tooling Techniques for Optimal Results

The Problem: B2B buyers, especially those new to leatherworking, often find themselves overwhelmed by the various tooling techniques and tools available. Misunderstandings about how to properly use these tools can lead to subpar product outcomes, which in turn affects overall business reputation. For instance, failing to select the right type of mallet or incorrectly using a stitching tool can result in damaged leather, increased waste, and lost time.

The Solution: Investing in training sessions and workshops can significantly enhance the skills of the workforce. Buyers should look for suppliers that offer educational resources, such as online tutorials or in-person classes, to help their teams understand the nuances of leather tooling. Additionally, when purchasing tools, buyers should seek out comprehensive guides that explain the purpose and proper usage of each tool. Creating a reference library that includes videos and manuals can serve as an ongoing training resource. By fostering a culture of continuous learning, companies can improve craftsmanship and reduce errors in production.

Scenario 3: Managing Inventory Levels of Leather Working Supplies

The Problem: Maintaining optimal inventory levels of leather working supplies is a common challenge for B2B buyers. Overstocking can tie up capital and storage space, while understocking can lead to production delays and missed opportunities. This issue is exacerbated by fluctuating demand and supply chain disruptions, particularly in regions where logistics may be less reliable.

The Solution: Implementing a just-in-time (JIT) inventory management system can help businesses balance their supply levels effectively. This approach involves analyzing historical sales data to forecast demand and align orders accordingly. Buyers should collaborate closely with suppliers to establish flexible ordering options, allowing them to adjust quantities based on real-time needs. Utilizing inventory management software can also streamline the tracking process, providing insights into stock levels, turnover rates, and reordering points. Additionally, forming strategic partnerships with suppliers can ensure quicker turnaround times, allowing businesses to respond to market demands without overcommitting resources.

Strategic Material Selection Guide for leather working supplies

What Are the Key Properties of Common Materials Used in Leather Working Supplies?

When selecting materials for leather working supplies, it is crucial to understand the properties that influence product performance. Below, we analyze four common materials used in the leather crafting industry, focusing on their suitability for various applications, pros and cons, and considerations for international B2B buyers.

Illustrative image related to leather working supplies

1. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is known for its natural tannins derived from plant sources. It is biodegradable, breathable, and develops a rich patina over time. This type of leather can withstand moderate temperature and pressure, making it suitable for various applications.

Pros & Cons: The primary advantage of vegetable-tanned leather is its durability and ability to age beautifully, which is appealing for high-end products like handbags and wallets. However, it can be more expensive than chrome-tanned leather and may require more complex manufacturing processes, including longer curing times.

Impact on Application: This material is particularly compatible with dyeing and tooling, allowing for intricate designs. It is favored for products that require a natural finish but may not be suitable for items exposed to excessive moisture.

Considerations for International Buyers: Compliance with environmental regulations is essential, especially in regions like Europe where sustainability is prioritized. Buyers should also ensure that the leather meets standards such as ASTM D-2000 for rubber materials, which can be relevant for leather accessories.

2. Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is produced using chromium salts, resulting in a supple and flexible material. It has excellent resistance to water and heat, making it suitable for various leather goods.

Illustrative image related to leather working supplies

Pros & Cons: The key advantage of chrome-tanned leather is its affordability and quick production time, allowing for mass manufacturing. However, it is less environmentally friendly due to the chemicals used in the tanning process, and it may not develop the same character as vegetable-tanned leather over time.

Impact on Application: This leather type is ideal for products requiring durability and water resistance, such as shoes and outdoor gear. However, its chemical properties may limit its compatibility with certain dyes and finishes.

Considerations for International Buyers: Buyers in regions with strict environmental regulations, such as Germany, should verify that chrome-tanned leather meets local standards for chemical safety and waste management.

3. Suede

Key Properties: Suede is made from the underside of animal hides, providing a soft and textured finish. It is less durable than full-grain leather but offers a unique aesthetic appeal.

Illustrative image related to leather working supplies

Pros & Cons: The softness of suede makes it ideal for fashion items and upholstery. However, it is more susceptible to stains and damage from water, which can limit its use in certain applications.

Impact on Application: Suede is commonly used in garments, accessories, and soft furnishings. Its unique texture lends a luxurious feel, but its care requirements must be communicated clearly to end-users.

Considerations for International Buyers: Buyers should be aware of the care and maintenance needs of suede, especially in humid climates found in parts of Africa and South America. Compliance with animal welfare standards is also critical in markets with stringent regulations.

4. Synthetic Leather

Key Properties: Synthetic leather, or faux leather, is made from polyurethane (PU) or polyvinyl chloride (PVC). It mimics the appearance of genuine leather while being more resistant to stains and moisture.

Pros & Cons: The primary advantage of synthetic leather is its cost-effectiveness and ease of maintenance. However, it may lack the durability and breathability of natural leather, which can impact the longevity of products made from it.

Impact on Application: Synthetic leather is widely used in fashion, automotive upholstery, and furniture. Its versatility allows for a variety of designs, but buyers should consider its environmental impact, particularly in regions focused on sustainability.

Considerations for International Buyers: Buyers should check for compliance with international standards for synthetic materials, such as ISO 14001 for environmental management. Preferences for eco-friendly options are growing, especially in Europe and North America.

Summary Table of Material Selection

| Material | Typical Use Case for leather working supplies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Handbags, wallets, belts | Durability and beautiful aging | Higher cost and longer manufacturing | High |

| Chrome-Tanned Leather | Shoes, outdoor gear | Affordability and quick production | Less environmentally friendly | Medium |

| Suede | Garments, accessories | Soft texture and aesthetic appeal | Susceptible to stains and damage | Medium |

| Synthetic Leather | Fashion, upholstery | Cost-effective and easy maintenance | Lacks durability compared to natural leather | Low |

This guide provides essential insights for international B2B buyers, helping them make informed decisions on material selection for leather working supplies. Understanding the properties, advantages, and limitations of each material is crucial for ensuring product quality and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leather working supplies

What Are the Main Stages of Manufacturing Leather Working Supplies?

Manufacturing leather working supplies involves several critical stages that ensure the products meet the necessary quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Working Supplies?

The initial stage of manufacturing begins with the selection and preparation of raw materials. Leather is sourced from various suppliers, often categorized by type—such as vegetable-tanned, chrome-tanned, or synthetic options. The quality of the leather greatly influences the final product, so it is essential to choose materials that meet specific durability and aesthetic requirements.

Once selected, the leather undergoes a preparation process that may include cleaning, cutting, and conditioning. This process is crucial as it sets the foundation for the subsequent stages. For instance, cutting involves precise measurements to ensure uniformity, while conditioning treatments can enhance the leather’s flexibility and appearance.

What Techniques Are Used in the Forming Stage?

After the materials are prepared, the forming stage begins. This stage typically employs various techniques depending on the type of leather working supplies being manufactured. Common methods include:

-

Die Cutting: This technique uses metal dies to cut leather into specific shapes and sizes. It is particularly effective for producing high volumes of uniform pieces, such as straps or panels.

-

Stitching: Hand stitching or machine stitching is employed to assemble different leather components. Quality stitching is vital for the durability and aesthetic appeal of the final product.

-

Molding: For certain products, such as bags or wallets, molding techniques can be utilized to create specific shapes. This process may involve heat and pressure to ensure the leather retains its shape.

How Does Assembly Take Place in Leather Supply Manufacturing?

Assembly is the next critical stage in the manufacturing process, where prepared and formed leather components are brought together. This stage may involve:

-

Joining Components: This can be achieved through stitching, riveting, or using adhesives, depending on the design and intended use of the product.

-

Adding Hardware: Many leather products require additional hardware, such as buckles, snaps, or zippers. The integration of these components must be done with precision to ensure functionality and aesthetics.

-

Quality Checks During Assembly: It is essential to conduct in-process quality checks to identify any defects early. This can help prevent further costs associated with rework or waste.

What Finishing Techniques Enhance the Quality of Leather Working Supplies?

Finishing is the final stage in the manufacturing process, and it significantly impacts the product’s final appearance and performance. Common finishing techniques include:

Illustrative image related to leather working supplies

-

Dyeing: This process enhances the color of the leather, allowing for a wide range of aesthetic options. Quality dyes are essential to ensure colorfastness and prevent fading.

-

Conditioning and Protecting: Applying conditioners or protective coatings can improve the leather’s resistance to wear and environmental factors. This step is crucial for ensuring the longevity of the product.

-

Final Inspection: Before products are packaged, a final inspection is carried out to check for any defects in craftsmanship or material quality.

What Quality Assurance Practices Are Essential for Leather Working Supplies?

Quality assurance (QA) is vital in the leather manufacturing process to ensure that products meet international standards and customer expectations. Various quality assurance practices are implemented throughout the manufacturing process.

Which International Standards Are Relevant for Leather Working Supplies?

Adhering to recognized international standards is critical for ensuring product quality and safety. Key standards include:

-

ISO 9001: This standard outlines the criteria for a quality management system (QMS). Companies that comply with ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, certain leather products may require CE marking, indicating compliance with health, safety, and environmental protection standards.

-

API Standards: For leather products used in specific industries, such as automotive or aerospace, compliance with American Petroleum Institute (API) standards may be necessary.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to monitor and maintain product quality. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC monitors processes and outputs to catch defects early. This can involve random sampling and testing of products during assembly.

-

Final Quality Control (FQC): The final inspection stage ensures that finished products meet all quality standards before they are shipped. This may include visual inspections, functional testing, and documentation reviews.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must ensure that their suppliers adhere to rigorous quality control processes. Here are several methods to verify supplier QC:

Illustrative image related to leather working supplies

What Audits and Reports Should B2B Buyers Request?

Buyers should request regular audits and quality reports from their suppliers. These documents should detail compliance with international standards and internal quality metrics. A reputable supplier should be transparent about their quality assurance practices and willing to share audit results.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an independent assessment of the supplier’s quality processes. These inspections can occur at various stages of production, offering buyers confidence in the quality of the products they are purchasing.

What Nuances Should International Buyers Consider in Quality Control?

International buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Understanding regional regulations and standards is crucial, as they can vary significantly. Additionally, language barriers may affect communication regarding quality expectations, making it essential for buyers to establish clear and concise requirements.

Illustrative image related to leather working supplies

In summary, a thorough understanding of the manufacturing processes and quality assurance measures is vital for B2B buyers in the leather working supplies industry. By focusing on these elements, buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather working supplies’

In the competitive landscape of leather working supplies, B2B buyers must navigate a complex procurement process to ensure they source high-quality materials and tools. This practical sourcing guide provides a comprehensive checklist to help you make informed purchasing decisions, ultimately leading to successful leathercraft projects.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your leather working supplies. This includes determining the types of leather (e.g., full-grain, top-grain, or suede), tools, and hardware needed for your projects. Clear specifications help in identifying suitable suppliers who can meet your needs without compromising on quality.

- Material Type: Decide on the leather grade and finish that align with your product offerings.

- Tool Requirements: List the essential tools such as mallets, needles, and stitching supplies.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the leather working industry. Utilize online platforms, trade shows, and industry publications to compile a list of potential vendors.

Illustrative image related to leather working supplies

- Supplier Reputation: Look for reviews and testimonials from other businesses to gauge reliability.

- Product Range: Ensure suppliers offer a comprehensive selection of products that meet your technical specifications.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with international standards. Certifications can indicate a supplier’s commitment to quality and ethical practices.

- Quality Assurance: Check for ISO certifications or industry-specific quality standards.

- Sustainability Practices: Inquire about sourcing practices, especially if you prioritize environmentally friendly materials.

Step 4: Request Samples

Request samples of leather and tools from shortlisted suppliers. Testing these samples allows you to assess the quality and suitability for your specific applications.

- Quality Assessment: Evaluate the texture, durability, and appearance of the leather.

- Tool Functionality: Test the tools for ease of use and effectiveness in your leatherworking processes.

Step 5: Negotiate Terms and Pricing

Once you have selected a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Establishing favorable terms can significantly affect your overall project costs and timelines.

- Volume Discounts: Ask about pricing tiers based on order quantities.

- Payment Flexibility: Consider payment terms that align with your cash flow needs.

Step 6: Establish a Communication Plan

Effective communication is crucial for a successful supplier relationship. Set up a clear communication plan to ensure timely updates and address any concerns that may arise during the procurement process.

Illustrative image related to leather working supplies

- Regular Check-Ins: Schedule periodic meetings to discuss order status and any potential issues.

- Feedback Mechanism: Create a channel for providing feedback on product quality and service.

Step 7: Monitor Supplier Performance

After procurement, continuously monitor your supplier’s performance. Regular assessments help ensure that they consistently meet your quality standards and delivery timelines.

- Quality Control: Implement checks to verify that received products match your specifications.

- Supplier Evaluation: Periodically review the supplier relationship and make adjustments as necessary based on performance.

By following this checklist, B2B buyers can streamline their sourcing process for leather working supplies, ensuring that they partner with reliable suppliers who meet their specific needs.

Comprehensive Cost and Pricing Analysis for leather working supplies Sourcing

What Are the Key Cost Components in Leather Working Supplies Sourcing?

When sourcing leather working supplies, understanding the cost structure is essential for effective budgeting and negotiation. The primary components of cost include:

-

Materials: The type of leather, tools, and accessories significantly influence costs. High-quality leather, such as vegetable-tanned or full-grain varieties, typically incurs a higher price due to the sourcing and processing methods involved.

-

Labor: Labor costs can vary based on the complexity of the leather products being crafted. Skilled artisans may demand higher wages, especially in regions where craftsmanship is valued.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and indirect labor. Overhead is typically a percentage of direct costs and can be higher in regions with stringent labor laws or high operational costs.

-

Tooling: Investment in specialized tools can be significant, particularly for custom designs. These costs should be amortized over the expected production volume.

-

Quality Control (QC): Ensuring that products meet quality standards requires investment in QC processes, which can add to the overall cost. This is particularly crucial for international buyers who may face strict import regulations.

-

Logistics: Transportation costs can vary widely based on distance, mode of transport, and the shipping terms (Incoterms). These costs are vital in calculating the total landed cost of the supplies.

-

Margin: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can vary based on market conditions and competition.

How Do Price Influencers Affect Leather Working Supplies Sourcing?

Several factors can influence the pricing of leather working supplies:

-

Volume/MOQ: Bulk orders often lead to lower per-unit prices. Understanding the minimum order quantities (MOQ) can help buyers negotiate better rates.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materials: The choice of materials directly impacts pricing. Sustainable or ethically sourced materials may command a premium, but they can also enhance brand value.

-

Quality and Certifications: Products that come with quality certifications (e.g., ISO, organic certification) may be priced higher but can also offer assurance of quality and compliance with international standards.

-

Supplier Factors: The reputation, reliability, and location of suppliers can affect pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The choice of Incoterms can significantly impact costs. For example, FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) can lead to differences in how costs are allocated between buyers and sellers.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Working Supplies Sourcing?

International B2B buyers should consider several strategies to optimize their sourcing costs:

-

Negotiation: Engage in open discussions with suppliers about pricing. Understanding the cost structure allows for more effective negotiations on pricing and payment terms.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the initial purchase price. This includes costs related to quality assurance, logistics, and potential returns.

-

Pricing Nuances for Different Regions: Be aware of regional price variations. For example, suppliers in Europe may have different pricing strategies compared to those in Africa or South America due to local economic conditions and supply chain dynamics.

-

Supplier Diversification: Avoid relying on a single supplier. Diversifying suppliers can lead to better pricing and terms, as well as reduced risk.

-

Market Research: Conduct thorough market research to understand average pricing and prevailing trends. This knowledge can empower buyers during negotiations and sourcing decisions.

Final Thoughts

While this analysis provides a framework for understanding costs and pricing in leather working supplies, it’s important to note that prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Therefore, buyers should always seek updated quotations and perform due diligence to ensure a competitive edge in their sourcing endeavors.

Alternatives Analysis: Comparing leather working supplies With Other Solutions

Understanding Alternatives in Leather Working Supplies

In the world of leather crafting, businesses often seek the most effective tools and materials to enhance their production capabilities. While leather working supplies are essential for creating high-quality leather products, several alternative solutions exist that may serve similar purposes. This analysis will compare traditional leather working supplies with two alternatives: synthetic leather materials and automated leather cutting machines. Each option has its distinct advantages and drawbacks, making it crucial for B2B buyers to evaluate their specific needs before making a decision.

Comparison Table

| Comparison Aspect | Leather Working Supplies | Synthetic Leather Materials | Automated Leather Cutting Machines |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Good durability; less authentic | High precision and speed |

| Cost | Generally higher upfront costs | Typically lower costs | High initial investment |

| Ease of Implementation | Requires skill and experience | Easy to work with, less training needed | Requires technical knowledge |

| Maintenance | Regular upkeep needed | Minimal maintenance | Requires regular calibration |

| Best Use Case | High-end, artisanal products | Mass production of items | Large-scale, complex designs |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Synthetic Leather Materials?

Synthetic leather, commonly known as faux leather, is a cost-effective alternative to genuine leather. It is made from materials such as polyurethane or polyvinyl chloride (PVC), offering a similar appearance and feel without the high price tag. The primary advantage of synthetic leather is its affordability and ease of use, making it ideal for mass production. However, it may lack the durability and aesthetic appeal of real leather, which can be a significant drawback for businesses focused on high-end products. Additionally, the environmental impact of synthetic materials is a growing concern, which could influence purchasing decisions.

How Do Automated Leather Cutting Machines Compare?

Automated leather cutting machines represent a technological advancement in leather crafting. These machines utilize computer-aided design (CAD) and laser cutting technology to produce precise cuts, significantly reducing material waste and production time. The main advantage of automated machines is their ability to handle large-scale production with consistent quality, making them suitable for businesses looking to scale operations. However, the initial investment is high, and technical expertise is required to operate and maintain these machines effectively. This solution may not be practical for smaller businesses or those focusing on bespoke items.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right solution for leather working, B2B buyers should consider several factors, including production volume, budget constraints, and the desired quality of finished products. For companies focusing on artisanal, high-quality leather goods, traditional leather working supplies may be the best choice despite the higher costs. Conversely, businesses looking to mass-produce items at a lower cost may find synthetic leather materials more suitable. Finally, organizations aiming for efficiency and scalability may benefit from investing in automated leather cutting machines, provided they have the necessary technical skills and financial resources. By carefully evaluating these alternatives, buyers can make informed decisions that align with their business goals and market demands.

Essential Technical Properties and Trade Terminology for leather working supplies

What Are the Key Technical Properties of Leather Working Supplies?

When sourcing leather working supplies, understanding specific technical properties is crucial for ensuring product quality and suitability for various applications. Here are some of the essential specifications that B2B buyers should consider:

-

Material Grade

Material grade refers to the quality classification of leather based on its origin and processing. For example, full-grain leather, which retains the natural grain and is the highest quality, is often preferred for luxury goods. Understanding material grades helps buyers select the right leather for their projects, ensuring durability and aesthetic appeal. -

Thickness (Oz)

The thickness of leather is typically measured in ounces (oz), where one ounce equals approximately 1/64 of an inch. Thicker leather (e.g., 8-10 oz) is ideal for heavy-duty applications like belts and bags, while thinner leather (e.g., 2-4 oz) is suited for lighter goods such as wallets or linings. Knowing the thickness required for specific projects helps buyers avoid issues with material performance. -

Finish Type

The finish of leather affects its appearance, texture, and durability. Common types include aniline, semi-aniline, and pigmented finishes. Each finish has unique characteristics; for instance, aniline leather is soft and retains natural markings, while pigmented leather is more resistant to wear and stains. Understanding these finishes allows buyers to align their product offerings with market demands. -

Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress a material can withstand before failure. This property is crucial for leather used in items that will undergo stress, such as straps and belts. A higher tensile strength indicates better durability, making it a critical factor for manufacturers aiming for longevity in their products. -

Moisture Resistance

This property indicates the leather’s ability to resist water absorption. Certain applications may require leather that can withstand exposure to moisture, such as outdoor gear. Buyers should evaluate moisture resistance to ensure the longevity and usability of their products, particularly in varying climates. -

Flexibility

Flexibility refers to how easily leather can bend and conform without breaking. This property is especially important in applications requiring intricate designs or movement, such as footwear or fashion accessories. Flexible leather enhances user comfort and product functionality, making it an essential consideration for buyers.

What Are Common Trade Terms in the Leather Industry?

Understanding industry jargon is vital for effective communication and negotiation in the leather supply chain. Here are several common terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or products that are used in another company’s end product. In the leather industry, this could involve a manufacturer creating custom leather goods based on a client’s specifications. Familiarity with OEM processes can help buyers streamline sourcing and ensure product alignment with their brand. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory effectively and avoid over-purchasing. It also aids in cost management, as larger orders often lead to reduced per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. This process is crucial for comparing offers and ensuring competitive pricing. Understanding how to effectively craft and respond to RFQs can enhance procurement efficiency. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping and logistics. They clarify who is responsible for shipping costs, insurance, and tariffs. Familiarity with Incoterms helps buyers negotiate better shipping agreements and avoid unexpected costs. -

Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead time is vital for buyers to plan inventory and production schedules effectively. Shorter lead times can improve responsiveness to market demands, while longer lead times may necessitate more careful inventory management.

By comprehensively understanding these technical properties and industry terms, B2B buyers can make informed decisions that enhance their procurement strategies and product offerings in the leather working supplies market.

Navigating Market Dynamics and Sourcing Trends in the leather working supplies Sector

What Are the Key Market Dynamics and Trends Influencing Leather Working Supplies?

The leather working supplies market is undergoing significant transformation, driven by global trends and regional dynamics that shape sourcing strategies for B2B buyers. Key drivers include the rising demand for high-quality leather products across diverse industries such as fashion, automotive, and furniture. Moreover, the advent of e-commerce has revolutionized how buyers access leather working supplies, enabling them to source globally while comparing prices and product quality with ease.

Emerging technologies like 3D printing and digital pattern-making are also influencing the sector. These innovations allow for customized leather products, providing manufacturers with a competitive edge. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can offer both traditional craftsmanship and modern technological solutions. Additionally, the trend towards direct sourcing—where buyers connect with manufacturers—facilitates better pricing and fosters long-term partnerships.

Illustrative image related to leather working supplies

As the market evolves, understanding local regulations, tariffs, and trade agreements becomes crucial for international buyers. For instance, the European Union has stringent regulations regarding leather sourcing, which may affect supply chain decisions. Buyers must remain vigilant to ensure compliance while maximizing their sourcing efficiency.

How Does Sustainability and Ethical Sourcing Impact Leather Working Supplies?

Sustainability is becoming a central theme in the leather working supplies sector, driven by growing consumer awareness and regulatory pressures. The environmental impact of leather production, particularly in terms of water usage and chemical waste, has prompted international buyers to seek more sustainable options. As a result, suppliers are increasingly adopting eco-friendly practices, such as vegetable tanning and sourcing hides from certified sustainable farms.

Ethical sourcing is equally important, as buyers prioritize transparency in their supply chains. Brands that can demonstrate their commitment to ethical labor practices and environmental stewardship are more likely to gain the trust of B2B buyers. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for suppliers looking to appeal to eco-conscious businesses.

Buyers should also consider the lifecycle of leather products, from sourcing to disposal. Sustainable practices, such as recycling and upcycling leather, are gaining traction, providing opportunities for businesses to differentiate themselves in a competitive market. By prioritizing sustainability and ethical sourcing, international buyers can not only enhance their brand reputation but also contribute positively to the global leather industry.

What Is the Historical Context of Leather Working Supplies?

The leather working supplies industry has a rich history that reflects the evolution of craftsmanship and industrialization. Initially, leather was processed using traditional methods passed down through generations. These artisanal techniques were integral to creating high-quality products, often tailored to local markets.

Illustrative image related to leather working supplies

The Industrial Revolution marked a significant turning point, introducing mechanization and mass production. This shift allowed for greater accessibility to leather goods, but it also raised concerns about quality and sustainability. In recent decades, as consumer preferences evolved, there has been a resurgence of interest in traditional craftsmanship, alongside a demand for sustainable practices.

Today, the leather working supplies market is a blend of heritage and innovation, where international buyers seek a balance between quality, sustainability, and technological advancement. Understanding this historical context can provide valuable insights for B2B buyers looking to navigate the complexities of sourcing in today’s dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of leather working supplies

1. How do I choose the right leather working supplies for my business needs?

Selecting the right leather working supplies begins with assessing your specific project requirements. Consider the type of leather you will be working with, such as vegetable-tanned or chrome-tanned leather, as different projects necessitate different materials. Additionally, evaluate the tools and hardware you’ll need, from cutting and stitching tools to rivets and buckles. It’s also beneficial to reach out to suppliers for samples or advice tailored to your project, ensuring compatibility with your craftsmanship and business goals.

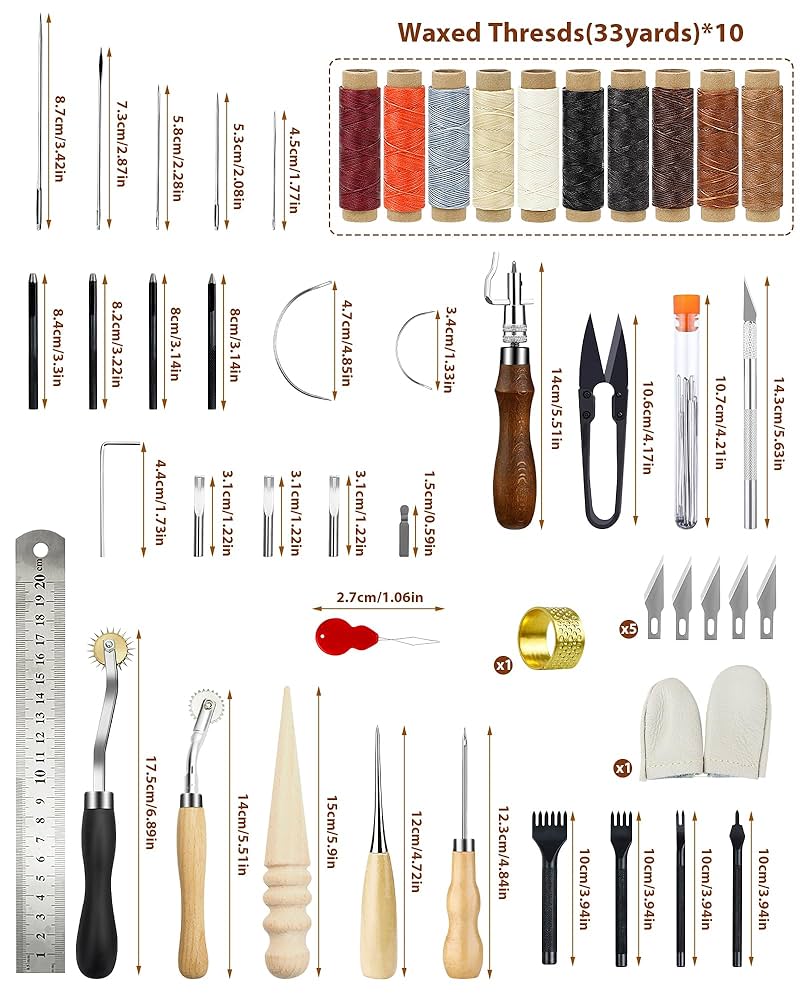

2. What types of leather working tools are essential for a beginner?

For beginners, essential leather working tools include a cutting mat, rotary cutter or knife, stitching awl, needles, thread, and a mallet. Additionally, consider investing in edge tools, such as an edge beveler and burnishing tools, for a polished finish. As your skills develop, you may wish to explore more specialized tools like leather punches and embossing stamps. Starting with a basic toolkit allows you to grow your craft while keeping initial costs manageable.

Illustrative image related to leather working supplies

3. How can I verify the reliability of a leather working supply supplier?

To verify a supplier’s reliability, conduct thorough research, including checking their business credentials, customer reviews, and product quality. Request references from other businesses in your industry and evaluate their communication responsiveness. Additionally, consider their experience in international trade, particularly if you’re sourcing from different regions. A reliable supplier should also provide clear information about their quality assurance processes and return policies.

4. What are typical minimum order quantities (MOQs) for leather working supplies?

Minimum order quantities (MOQs) can vary widely based on the supplier and the type of leather working supplies being ordered. Generally, MOQs for tools and hardware may range from 50 to 500 units, while leather hides might have higher MOQs depending on the quality and type. It’s advisable to discuss your specific needs with suppliers, as some may offer flexibility for first-time buyers or smaller businesses.

5. What payment terms should I expect when ordering leather working supplies internationally?

Payment terms for international orders often include options like advance payment, letters of credit, or payment on delivery. Common practices include a 30% deposit upfront with the balance due before shipment. Be sure to clarify these terms with your supplier in advance, and understand any currency exchange implications. Additionally, consider utilizing secure payment platforms that offer buyer protection for added security.

6. How do I handle customs and logistics for international shipments of leather working supplies?

Managing customs and logistics requires a clear understanding of both your home country’s and the supplier’s regulations. Ensure that all paperwork, including invoices and certificates of origin, is accurately completed to avoid delays. Partnering with a freight forwarder can simplify this process, as they can navigate customs requirements and ensure compliance. Additionally, stay informed about tariffs and duties that may apply to leather imports to budget accordingly.

7. What quality assurance practices should I implement when sourcing leather working supplies?

Implementing quality assurance practices starts with establishing clear specifications for the materials and tools you require. Conduct initial quality checks upon receipt of goods, such as inspecting for defects or inconsistencies. Regular communication with your supplier is crucial, so consider scheduling audits or requesting samples before larger orders. Building a relationship based on trust and transparency will enhance the overall quality of your supply chain.

8. Can I customize leather working supplies to fit my brand needs?

Yes, many suppliers offer customization options for leather working supplies, including branded tools or unique hardware designs. Customization can enhance your brand identity and cater to specific market demands. Discuss your requirements with potential suppliers, as they may have minimum order quantities for custom items. Additionally, inquire about lead times and any extra costs associated with customization to plan your budget effectively.

Illustrative image related to leather working supplies

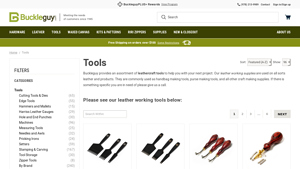

Top 8 Leather Working Supplies Manufacturers & Suppliers List

1. RM Leather Supply – Premium Leather Products

Domain: rmleathersupply.com

Registered: 2014 (11 years)

Introduction: Free shipping on all orders in the USA; worldwide shipping with discounted rates; processing time of 2-4 business days; over 10,000 products available; free leather splitting service; various leather types including vegetable tanned, chrome tanned, and exotics; leather cuts available such as bellies, butts, double shoulder, side, tails, and whole hides; leather sourced from various tanneries inclu…

2. Buckleguy – BG Awl Needles

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: Buckleguy offers a variety of leather working tools and supplies, including cutting tools, edge tools, hammers, mallets, hole and end punches, measuring tools, needles, awls, pricking irons, setters, and stamping tools. Key products include: 1. BG Awl Needles (Multiple Shapes) – $10.62 – $14.13 2. BG Leather Bone Folder/Edge Slicker (Multi-Function) – $28.94 3. BG Stitching Punch Replacement (1pc)…

3. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies, including various types of leather such as ChahinLeather®, Hermann Oak® Veg Tan, and Water Buffalo Leather. They provide leather cuts like double shoulders, backs, bends, panels, and whole hides. The textures available include top grain, pebbled, smooth, pull-up, and waxy. Tools for leathercrafting include cu…

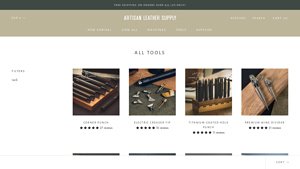

4. Artisan Leather Supply – Corner Punch

Domain: artisanleathersupply.com

Registered: 2020 (5 years)

Introduction: [{‘name’: ‘Corner Punch’, ‘reviews’: ’27 reviews’, ‘price’: ‘From $14’}, {‘name’: ‘Electric Creaser Tip’, ‘reviews’: ’10 reviews’, ‘price’: ‘From $17’}, {‘name’: ‘Titanium-Coated Hole Punch’, ‘reviews’: ’11 reviews’, ‘price’: ‘From $5.50’}, {‘name’: ‘Premium Wing Divider’, ‘reviews’: ’31 reviews’, ‘price’: ‘From $32’}, {‘name’: ‘Locking Pins (pack of 5)’, ‘reviews’: ’13 reviews’, ‘price’: ‘From $5…

5. Tandy Leather – Free Delivery on Orders Over $149.90

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Free Delivery on Orders Over $149.90, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Reddit – Essential Leather Crafting Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Sharp Blade: Box knives are suitable for cutting leather. 2. Self-Healing Cutting Board: Essential for cutting on. 3. Rubber or Rawhide Mallet: Used to hit punches. 4. Punches and Stamps: Necessary tools for crafting. 5. Punch Pad: Protects punches from damage. 6. Leather Needles and Thread: Required for stitching. 7. 6″ Stainless Steel Ruler: For measuring. 8. Wood Edge Burnisher: For finishin…

7. Makers Leather Supply – 3/32 Plastic Piping Core

Domain: makersleathersupply.com

Registered: 2012 (13 years)

Introduction: [{‘name’: ‘3/32 Plastic Piping Core by the Yard’, ‘regular_price’: ‘$1.00’, ‘sale_price’: ‘$1.00’}, {‘name’: ‘Cross Body 1.5 inch Buckle’, ‘regular_price’: ‘$8.95’, ‘sale_price’: ‘$8.95’}, {‘name’: ‘Dye Bottle Caps-5 Pack’, ‘regular_price’: ‘$4.95’, ‘sale_price’: ‘$4.95’}, {‘name’: ‘El Matador 1.75″ Belt Liners’, ‘regular_price’: ‘$14.95’, ‘sale_price’: ‘$14.95’}, {‘name’: ‘GUNSLINGER DEAL! 5-Pack…

8. Fine Leatherworking – Leather Craft Supplies

Domain: fineleatherworking.com

Registered: 2012 (13 years)

Introduction: Fine Leatherworking offers a variety of leather craft supplies including threads (Linen, Polycotton, Polyester), tools (Doldokki, Leather Electric Creaser, Vergez Blanchard, Saddle Maker Tools, Sewing Clams and Jigs), and different types of leather (Fjord Shrunken Calf, Shell Cordovan, Alpine Full Grain Calf, Krispel Box Calf, Chevre Chagrin, Chevre Crispe, Chromexcel Fjord Calf, Accessory Grade E…

Strategic Sourcing Conclusion and Outlook for leather working supplies

In the competitive landscape of leather working supplies, strategic sourcing emerges as a pivotal strategy for B2B buyers seeking quality and value. By identifying reliable suppliers and understanding market dynamics, businesses can ensure a steady flow of essential materials and tools, from specialized leather to high-quality crafting instruments. Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize building strong supplier relationships to navigate the complexities of international trade and logistics.

Furthermore, embracing innovation in sourcing practices, such as bulk purchasing and exploring diverse product lines, can lead to significant cost savings and enhanced product offerings. The growing trend of sustainable leather sourcing also presents an opportunity for businesses to align with eco-conscious consumers, thus enhancing brand reputation and market appeal.

As the demand for leather goods continues to rise, now is the time for international buyers to take proactive steps in their sourcing strategies. By leveraging these insights and fostering strong partnerships, you can position your business for success in the dynamic leather market. Engage with suppliers today to secure the resources you need to thrive in this evolving industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather working supplies

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.