Introduction: Navigating the Global Market for belt thickness

In the dynamic landscape of global commerce, sourcing the right belt thickness can pose significant challenges for B2B buyers. Whether you’re focused on procurement for industrial applications, fashion retail, or fitness equipment, understanding the nuances of belt thickness is crucial. This guide is designed to help you navigate the complexities associated with various belt types, their applications, supplier vetting processes, and cost implications.

The comprehensive scope of this guide encompasses an in-depth analysis of the different styles and thicknesses of belts, such as power belts, training belts, and specialized lifting belts, each catering to unique needs and preferences. By exploring the functional benefits and limitations of each option, you will be equipped to make informed purchasing decisions that align with your business objectives.

Moreover, this guide specifically addresses the needs of international B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Brazil. With actionable insights and practical recommendations, you will gain the knowledge necessary to select the most suitable belt thickness for your specific application, ensuring both quality and value in your procurement process. Empower your business with the right information to thrive in the global market for belt thickness.

Table Of Contents

- Top 7 Belt Thickness Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for belt thickness

- Understanding belt thickness Types and Variations

- Key Industrial Applications of belt thickness

- 3 Common User Pain Points for ‘belt thickness’ & Their Solutions

- Strategic Material Selection Guide for belt thickness

- In-depth Look: Manufacturing Processes and Quality Assurance for belt thickness

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt thickness’

- Comprehensive Cost and Pricing Analysis for belt thickness Sourcing

- Alternatives Analysis: Comparing belt thickness With Other Solutions

- Essential Technical Properties and Trade Terminology for belt thickness

- Navigating Market Dynamics and Sourcing Trends in the belt thickness Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of belt thickness

- Strategic Sourcing Conclusion and Outlook for belt thickness

- Important Disclaimer & Terms of Use

Understanding belt thickness Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6.5mm Belt | Thin, pliable, and lightweight | General training, casual use | Pros: Comfortable, flexible; Cons: Limited support |

| 10mm Belt | Balanced thickness offering good support and comfort | Powerlifting, bodybuilding | Pros: Versatile, well-reviewed; Cons: May feel bulky for some users |

| 13mm Belt | Maximum thickness for high support and rigidity | Competitive powerlifting | Pros: Excellent support; Cons: Can be uncomfortable for prolonged use |

| Training Belt | Tapers in width, typically 4″ to 6″ back, 2.5″ front | Olympic training, bodybuilding | Pros: Good for dynamic movements; Cons: Less support than thicker belts |

| Lever Belt | Features a quick-release lever mechanism | Professional athletes, heavy lifters | Pros: Easy to adjust; Cons: May require more maintenance |

What are the Characteristics of a 6.5mm Belt and Its Suitability for B2B Buyers?

The 6.5mm belt is designed for those seeking a lightweight and flexible option. Its thinness makes it ideal for general training and casual use, appealing to businesses that cater to fitness enthusiasts or recreational athletes. When purchasing, buyers should consider the comfort level required for their clientele, as this belt offers limited support compared to thicker options.

Why is the 10mm Belt a Popular Choice Among B2B Buyers?

The 10mm belt strikes an optimal balance between support and comfort, making it a popular choice for powerlifting and bodybuilding. Its versatility allows it to cater to a wide range of athletes, from beginners to advanced lifters. B2B buyers should consider customer feedback and reviews when selecting this option, as its popularity often translates to higher satisfaction rates among users.

Illustrative image related to belt thickness

What Makes the 13mm Belt Suitable for Competitive Powerlifters?

The 13mm belt is engineered for maximum support, making it suitable for competitive powerlifters who require a sturdy belt during heavy lifts. While its thickness provides unparalleled stability, it may not be the best choice for all users due to potential discomfort during extended wear. Businesses should evaluate their target market’s needs, as this belt is best suited for serious athletes rather than casual gym-goers.

How Does the Training Belt Cater to Dynamic Movements in B2B Markets?

Training belts typically feature a tapered design that allows for greater mobility, making them ideal for Olympic training and bodybuilding. This type of belt is favored in environments where dynamic movements are frequent, such as in CrossFit gyms. B2B buyers should assess the specific training styles of their customers to ensure that the training belt meets their needs effectively.

What are the Benefits of Lever Belts for Professional Athletes?

Lever belts are distinguished by their quick-release mechanism, which allows for easy adjustments and removal. This feature is particularly beneficial for professional athletes and heavy lifters who need to maximize efficiency during workouts. B2B buyers should consider the maintenance needs of lever belts, as their mechanisms may require more attention compared to traditional prong belts, impacting overall customer satisfaction.

Illustrative image related to belt thickness

Key Industrial Applications of belt thickness

| Industry/Sector | Specific Application of belt thickness | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Ensures efficient material handling and minimizes downtime. | Material durability, thickness specifications, and load capacity. |

| Construction | Safety Harnesses and Belts | Enhances worker safety by providing proper support. | Compliance with safety standards and comfort for extended use. |

| Agriculture | Agricultural Equipment Belts | Increases operational efficiency and reduces maintenance costs. | Weather resistance, thickness for load-bearing capacity. |

| Sports and Fitness | Weightlifting and Training Belts | Optimizes performance and supports injury prevention. | Personalization options, thickness for comfort and support. |

| Automotive | Timing and Drive Belts | Improves engine performance and longevity of parts. | Compatibility with vehicle models, thickness for durability. |

How is belt thickness utilized in manufacturing conveyor systems?

In the manufacturing sector, belt thickness is crucial for conveyor systems that transport materials across various production stages. Thicker belts can withstand heavier loads, reducing the frequency of replacements and maintenance. For international B2B buyers, especially in regions like Africa and South America, sourcing durable belts that meet specific thickness requirements can lead to significant cost savings and operational efficiency. Buyers should consider the load capacity and material properties to ensure they select the right belt for their operational needs.

What role does belt thickness play in construction safety harnesses?

In the construction industry, the thickness of safety harness belts is vital for providing adequate support and security for workers at heights. Thicker belts offer better weight distribution and can withstand more stress, enhancing worker safety. For buyers from the Middle East and Europe, it’s essential to ensure that the belts comply with local safety regulations and standards. Comfort and adjustability are also important factors, as these harnesses are often worn for extended periods during work.

Why is belt thickness important in agricultural equipment?

In agriculture, the thickness of belts used in machinery such as tractors and harvesters directly impacts their efficiency and durability. Thicker belts can handle greater tension and stress, leading to reduced downtime and maintenance costs. For B2B buyers in regions like Brazil, where agricultural demands are high, sourcing belts that can endure harsh weather conditions and heavy loads is crucial. Buyers should focus on the material properties and thickness to ensure optimal performance in their specific agricultural applications.

How does belt thickness enhance performance in sports and fitness?

In the sports and fitness industry, particularly for weightlifting, belt thickness is essential for providing the necessary support to athletes during heavy lifts. Thicker belts can offer greater stability and reduce the risk of injury, making them a preferred choice for competitive lifters. Buyers from Europe and the Middle East should look for customizable options that cater to personal preferences in thickness and comfort. The right thickness can significantly influence performance and safety, making it a critical consideration for fitness professionals and enthusiasts alike.

What benefits does proper belt thickness bring to automotive applications?

In the automotive sector, the thickness of timing and drive belts is critical for ensuring optimal engine performance and longevity. Thicker belts can withstand higher stress and temperature variations, which is vital for maintaining engine integrity. For international buyers in regions like Saudi Arabia, understanding the compatibility of belt thickness with various vehicle models is essential. Sourcing high-quality belts that meet OEM specifications can enhance vehicle reliability and performance, making it a key consideration for automotive suppliers and manufacturers.

3 Common User Pain Points for ‘belt thickness’ & Their Solutions

Scenario 1: Struggling to Find the Right Belt Thickness for Different Applications

The Problem: Many B2B buyers face the challenge of selecting the appropriate belt thickness for varying applications, such as weightlifting, manufacturing, or general use. Each application demands different support levels, which can lead to confusion. For instance, a buyer might purchase a belt that is too thick for casual training, resulting in discomfort, while another might choose a belt that is too thin for heavy lifting, compromising safety and effectiveness.

The Solution: To effectively address this issue, buyers should first conduct a comprehensive assessment of their specific needs based on the intended application. For example, a 10mm belt often strikes a balance between comfort and support for general training, making it a versatile choice for various users. In contrast, for powerlifting, a 13mm belt may be more appropriate, as it offers maximum rigidity and support. Buyers should also consult with suppliers to understand the properties of different materials and thicknesses, ensuring they select a belt that meets the specific requirements of their application. Additionally, buyers can benefit from testing various belt thicknesses in real-world scenarios to find the best fit for their operations.

Scenario 2: Misalignment Between Belt Thickness and User Comfort

The Problem: A significant pain point for B2B buyers is the misalignment between the belt thickness chosen and the comfort levels experienced by users. For instance, purchasing a thick belt without considering the user’s body type and preferences can lead to dissatisfaction. This issue is particularly pronounced in industries like fitness, where user experience directly impacts performance and retention.

The Solution: To mitigate this issue, buyers should prioritize user feedback in their selection process. Conducting surveys or focus groups with end-users can provide valuable insights into comfort preferences related to belt thickness. Furthermore, offering a range of thickness options—from 6.5mm for those who prioritize comfort to 13mm for competitive lifters—can cater to diverse user needs. Suppliers should be encouraged to provide trial periods or flexible return policies, allowing buyers to test the belts in actual use cases before committing to bulk orders. This approach not only enhances user satisfaction but also reduces the risk of returns and dissatisfaction.

Scenario 3: Overlooking Local Regulations and Standards on Belt Thickness

The Problem: B2B buyers, especially in international markets, often overlook local regulations and standards concerning belt thickness. Different regions may have specific requirements based on safety, industry norms, or competitive standards. For example, in certain countries, lifting belts must adhere to specific thickness regulations to be deemed compliant for competitive use, which can create barriers for buyers importing products that do not meet these criteria.

The Solution: Buyers should conduct thorough research on local regulations and industry standards before sourcing belts. This involves engaging with local industry associations or regulatory bodies to understand compliance requirements. Additionally, establishing strong relationships with manufacturers that are familiar with these standards can simplify the sourcing process. Buyers should also consider customizing their orders to meet regional specifications, which may include adjusting belt thickness or material. By proactively addressing these regulatory challenges, B2B buyers can ensure that their products not only comply with local laws but also enhance their marketability and customer satisfaction.

Strategic Material Selection Guide for belt thickness

What Are the Key Properties of Common Materials Used for Belt Thickness?

When selecting materials for belt thickness, it is crucial to consider various factors such as durability, cost, and application suitability. Below, we analyze four common materials used in belt manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Leather Perform as a Material for Belt Thickness?

Leather is a traditional choice for belts, renowned for its strength, flexibility, and aesthetic appeal. It typically offers good temperature resistance and can withstand moderate pressure. However, leather’s performance can be affected by moisture, leading to potential degradation if not properly treated.

Pros: Leather belts are durable and can last for years with proper care. They provide excellent comfort and conform to the wearer’s body over time, enhancing usability.

Cons: The cost of high-quality leather can be significant, and manufacturing complexity increases with the need for tanning and treatment processes. Additionally, leather may not be suitable for environments with high humidity or exposure to chemicals.

For international buyers, compliance with animal welfare standards and sourcing from sustainable suppliers may be essential considerations, especially in regions like Europe where regulations are stringent.

What Are the Benefits of Synthetic Materials for Belt Thickness?

Synthetic materials such as nylon and polyester are increasingly popular for belt manufacturing due to their high strength-to-weight ratio and resistance to abrasion and chemicals. These materials can withstand extreme temperatures and pressures, making them suitable for various applications.

Pros: Synthetic belts are often more affordable than leather and can be produced in a wide range of colors and designs. They are also easier to clean and maintain, which is beneficial for industries requiring hygiene.

Cons: While synthetic materials offer durability, they may lack the aesthetic appeal of leather. Additionally, their environmental impact is a concern, as they are derived from petroleum-based products.

International buyers should consider the environmental regulations in their respective regions, particularly in Europe, where there is a growing demand for eco-friendly materials.

Illustrative image related to belt thickness

How Do Rubber and Elastomeric Materials Compare for Belt Thickness?

Rubber and elastomeric materials are excellent choices for belts used in heavy-duty applications. They provide exceptional flexibility, shock absorption, and resistance to wear and tear. These materials can handle high temperatures and pressures, making them ideal for industrial settings.

Pros: Rubber belts are highly durable and can withstand harsh conditions, making them suitable for various applications, including automotive and machinery.

Cons: The manufacturing process for rubber can be complex and costly, particularly when producing specialized compounds. Additionally, rubber may degrade over time when exposed to UV light or ozone.

B2B buyers should be aware of the specific standards related to rubber products in their regions, such as ASTM or DIN, to ensure compliance with safety regulations.

What Role Does Metal Play in Belt Thickness Applications?

Metal belts, often made from stainless steel or other alloys, are used in specialized applications requiring high strength and resistance to corrosion. They can handle extreme pressures and temperatures and are often used in industrial and manufacturing settings.

Pros: Metal belts are incredibly durable and resistant to chemical corrosion, making them suitable for harsh environments. They also offer excellent load-bearing capabilities.

Cons: The cost of metal belts can be high, and they may require specialized manufacturing processes. Additionally, they can be heavier and less flexible than other materials, which may limit their application in certain contexts.

International buyers must consider the material certifications and compliance with industry standards, particularly in regions like the Middle East and Europe, where regulatory requirements can be stringent.

Summary Table of Material Selection for Belt Thickness

| Material | Typical Use Case for belt thickness | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Fashion belts, casual wear | Durable and comfortable | Sensitive to moisture | Medium |

| Synthetic | Sports and casual belts | Affordable and easy to maintain | Lacks aesthetic appeal | Low |

| Rubber | Industrial applications | High durability and shock absorption | Can degrade with UV exposure | Medium |

| Metal | Heavy-duty industrial use | Exceptional strength and corrosion resistance | High cost and less flexibility | High |

This comprehensive analysis aims to guide international B2B buyers in selecting the most suitable material for their belt thickness needs, considering performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for belt thickness

What Are the Main Stages in the Manufacturing Process of Belts?

The manufacturing process for belts, particularly concerning thickness, involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets the desired specifications for thickness, durability, and quality.

Material Preparation: How Are Raw Materials Selected and Processed?

Material preparation begins with sourcing high-quality raw materials, typically leather, synthetic fabrics, or a combination of both. The choice of material significantly affects the thickness and overall performance of the belt. For instance, premium leather belts may require specific tanning processes to enhance their durability and flexibility.

Once the materials are sourced, they undergo cutting and shaping to create the desired thickness. For leather belts, manufacturers may use single or multiple layers of leather, as well as suede or other materials to achieve the target thickness. Accurate measurements are crucial at this stage to ensure consistency across production batches.

How Is the Belt Formed During Production?

The forming stage involves shaping the prepared materials into the belt’s final design. This can include processes such as die-cutting, molding, or stitching, depending on the belt style. For instance, a powerlifting belt may require specific contours to provide maximum support, while a training belt could be designed with a taper for added flexibility.

Manufacturers often employ automated machinery for precision cutting and stitching, ensuring uniform thickness across each belt produced. Advanced technologies, such as laser cutting, may also be used to enhance accuracy and reduce waste.

What Steps Are Involved in the Assembly of Belts?

During the assembly stage, the various components of the belt are put together. This includes attaching buckles, levers, or other fastening mechanisms. For thicker belts, the assembly may require additional reinforcement to ensure that the components can withstand the stresses of use.

Quality control measures are often implemented at this stage to check for any inconsistencies in thickness or assembly. Each belt is inspected to ensure that it meets the design specifications before moving on to the finishing stage.

What Finishing Techniques Are Used to Enhance Belt Quality?

The finishing stage includes processes like polishing, dyeing, and applying protective coatings. These steps not only enhance the belt’s aesthetic appeal but also improve its durability and resistance to wear and tear. For instance, a suede finish may be applied to a leather belt to provide a better grip, while synthetic belts may undergo treatments to make them water-resistant.

Illustrative image related to belt thickness

Finishing techniques can also include embossing or printing logos and designs, allowing for customization that appeals to specific markets. This stage is crucial for ensuring that the belt not only looks good but also performs well under various conditions.

How Is Quality Assurance Implemented in Belt Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for international B2B buyers who demand high standards. Various international and industry-specific standards guide QA processes, ensuring that products meet safety and performance criteria.

What International Standards Are Relevant for Belt Quality Assurance?

The ISO 9001 standard is widely recognized and establishes criteria for a quality management system. Manufacturers aiming for ISO certification must demonstrate their ability to consistently provide products that meet customer requirements and regulatory standards. Compliance with this standard can enhance a manufacturer’s credibility and appeal to international buyers.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for belts used in oil and gas applications may be relevant. These certifications indicate that products comply with safety and performance standards specific to their intended use.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential for maintaining product integrity throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): This stage includes monitoring production processes to identify and rectify any issues in real-time, ensuring that thickness and other specifications are maintained.

- Final Quality Control (FQC): The final inspection occurs before products are packaged and shipped. At this stage, belts are tested for durability, thickness, and overall quality.

What Testing Methods Are Commonly Used for Belt Quality Assurance?

Testing methods can vary based on the belt’s intended use, but common approaches include tensile strength tests, thickness measurements, and wear resistance evaluations. For example, a weightlifting belt may undergo stress tests to ensure it can withstand significant loads without compromising integrity.

Manufacturers may also employ third-party testing labs to verify compliance with international standards, providing an additional layer of assurance for B2B buyers.

Illustrative image related to belt thickness

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. There are several methods to ensure that suppliers maintain high standards:

What Are the Best Practices for Conducting Supplier Audits?

Conducting thorough audits is one of the most effective ways to verify a supplier’s quality control processes. Buyers should consider visiting the manufacturing facility to observe operations firsthand. During the audit, buyers can review documentation related to quality control procedures, including inspection reports, certifications, and compliance with international standards.

How Can Buyers Request Quality Reports and Documentation?

Buyers should request detailed quality reports and documentation from suppliers. This can include certificates of compliance with ISO standards, test results from third-party labs, and records of previous inspections. Having access to these documents allows buyers to assess the supplier’s commitment to quality assurance.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Third-party inspections are a valuable tool for buyers looking to ensure product quality. Engaging an independent inspection service can provide an unbiased assessment of the manufacturing process and product quality. This adds a level of transparency and trust that is particularly important in international transactions.

Conclusion: What Should B2B Buyers Consider for Quality Assurance in Belt Manufacturing?

In summary, understanding the manufacturing processes and quality assurance practices for belt thickness is crucial for B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, and verification methods, buyers can make informed decisions when selecting suppliers. This not only helps in ensuring product quality but also fosters long-term partnerships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt thickness’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure belts with specific thicknesses. Understanding belt thickness is crucial for ensuring that the products meet the performance requirements of your applications, whether in weightlifting, industrial use, or fashion. By following this checklist, you can make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications that your belts must meet. This includes not only the desired thickness but also materials, width, and design features. By having a well-defined set of specifications, you can streamline your search and ensure compatibility with your intended use.

Step 2: Understand the Functionality of Different Thicknesses

Different thicknesses serve various purposes and applications. For instance, a 10mm belt may provide a balance of support and comfort, making it suitable for general training, while a 13mm belt offers maximum support for competitive powerlifting. Consider the functional requirements of your end-users to select the appropriate thickness.

- Key Considerations:

- Weight Capacity: Thicker belts typically handle more weight but may be less comfortable.

- User Comfort: Evaluate the comfort levels associated with different thicknesses, especially for prolonged use.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications. Request detailed company profiles, product samples, and case studies showcasing their experience in your industry. It’s also beneficial to seek references from other buyers in similar markets to gauge reliability and quality.

- Questions to Ask:

- What thickness options do you offer?

- Can you provide samples of your belts for testing?

Step 4: Request Material Certifications

Ensure that the materials used in the belts meet industry standards and safety regulations. Request certifications for leather quality, durability, and environmental compliance. This step is vital for mitigating risks associated with product failures or regulatory issues.

- Specific Certifications to Consider:

- ISO certifications for manufacturing processes

- Environmental certifications for sustainable materials

Step 5: Negotiate Pricing and Terms

Once you have shortlisted suppliers, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Ensure that the pricing structure reflects the quality and thickness of the belts offered. Clear agreements on delivery timelines and potential discounts for bulk orders can also enhance your purchasing strategy.

Step 6: Conduct Quality Assurance Checks

Before finalizing your order, establish a quality assurance process to verify that the belts meet your specifications. This may include inspecting samples for thickness, material integrity, and overall craftsmanship. Implementing a robust quality check can prevent costly returns and ensure customer satisfaction.

Illustrative image related to belt thickness

Step 7: Plan for After-Sales Support

Consider the after-sales support offered by suppliers, which can be essential for maintenance and addressing any product issues. A reliable supplier should be willing to provide support services and respond to inquiries about product care or replacements. This commitment can significantly enhance your long-term partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing belts with the right thickness, ensuring their procurement process is efficient, effective, and aligned with their business goals.

Comprehensive Cost and Pricing Analysis for belt thickness Sourcing

What Are the Key Cost Components in Sourcing Belt Thickness?

When evaluating the cost structure for sourcing belts of varying thickness, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of leather or synthetic materials significantly influences the cost. For instance, premium leather belts will incur higher material costs compared to synthetic alternatives. Thickness also plays a role; thicker belts require more material, thus increasing costs.

-

Labor: Labor costs vary based on geographic location and manufacturing complexity. Regions with lower labor costs may offer competitive pricing but could compromise on quality. Skilled labor is essential for producing high-quality belts, especially when intricate designs or customizations are involved.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Overhead can vary significantly by region, impacting the final price of the belts.

-

Tooling: Custom tooling for belt production can be a substantial upfront investment. The cost is typically amortized over the production run, meaning larger orders can dilute the tooling cost per unit.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the belts meet specified standards. While this can increase production costs, it ultimately reduces returns and enhances customer satisfaction.

-

Logistics: Transportation costs are a crucial factor, particularly for international shipments. These can fluctuate based on distance, mode of transport, and current fuel prices. Efficient logistics management can mitigate costs.

-

Margin: Finally, suppliers will add a margin to cover their operational costs and profit. The margin can vary based on market demand and competition.

How Do Price Influencers Affect Belt Thickness Sourcing?

Several factors can influence pricing in the sourcing of belt thickness:

-

Volume/MOQ: Minimum Order Quantity (MOQ) requirements can significantly impact pricing. Larger orders often lead to discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom features such as embroidery, special finishes, or specific thicknesses can drive up costs. Buyers should balance customization desires with budget constraints.

-

Materials and Quality Certifications: The quality of materials and the presence of certifications (such as ISO or environmental standards) can also influence price. Higher quality typically equates to higher costs but can lead to better durability and customer satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their expertise and quality assurance.

-

Incoterms: Understanding Incoterms is critical for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly influencing the overall cost.

What Tips Can Buyers Utilize for Cost-Efficient Sourcing?

To ensure cost-effective sourcing of belt thickness, buyers should consider the following strategies:

-

Negotiation: Leverage negotiation tactics to achieve better pricing. Understanding the supplier’s cost structure can provide insights that facilitate negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate the complete cost associated with the belt, including purchase price, maintenance, and potential returns due to quality issues. A lower initial cost may not always yield the best TCO.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and regional market conditions that can affect pricing.

-

Build Relationships with Suppliers: Long-term relationships with suppliers can lead to better pricing and terms. Suppliers are more likely to offer discounts or favorable terms to repeat customers.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices and assess the competitiveness of suppliers. This can aid in making informed purchasing decisions.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, material availability, and specific buyer-supplier agreements. Always consult with multiple suppliers for accurate pricing tailored to your needs.

Alternatives Analysis: Comparing belt thickness With Other Solutions

Exploring Alternatives to Belt Thickness: A Comparative Analysis

In today’s diverse industrial landscape, businesses often seek alternatives to established solutions. For companies considering the implementation of belt thickness in their operations—whether for manufacturing, transportation, or weightlifting—it’s essential to evaluate other viable options. This section provides a comparative analysis of belt thickness against two alternative solutions: straps and rigid supports.

Comparison Table

| Comparison Aspect | Belt Thickness | Straps | Rigid Supports |

|---|---|---|---|

| Performance | Offers varying support based on thickness; ideal for weightlifting and securing items. | Flexible and adjustable; suitable for lighter loads. | Provides maximum support and stability; excellent for heavy-duty applications. |

| Cost | Moderate to high depending on material and thickness. | Generally low-cost and widely available. | Higher initial investment, but durable in the long run. |

| Ease of Implementation | Requires specific sizing and may need adjustments based on user. | Easy to use and can be quickly adjusted. | Installation may require tools and expertise. |

| Maintenance | Moderate; needs regular inspection for wear and tear. | Low; minimal upkeep required. | Low; typically requires occasional checks for structural integrity. |

| Best Use Case | Best for weightlifting, heavy-duty transport, and industrial applications. | Ideal for lighter loads, securing items in place temporarily. | Best for structural support in construction and heavy machinery. |

Understanding the Alternatives: Straps and Rigid Supports

Straps: Straps are versatile solutions used across various industries. They are typically made from durable synthetic materials, providing flexibility and ease of use. Straps excel in situations where quick adjustments are necessary, such as securing cargo during transport or when lightweight support is sufficient. However, their performance can be limited under heavy loads, making them less suitable for demanding applications. Their low cost and minimal maintenance requirements make them an attractive option for businesses looking to optimize expenses.

Illustrative image related to belt thickness

Rigid Supports: Rigid supports, such as beams or braces, offer robust structural integrity for heavy-duty applications. These solutions are essential in construction and manufacturing settings where maximum support is critical. While they provide superior stability compared to belts or straps, their installation can be more complex and may require professional expertise. Additionally, the initial investment is often higher, although the long-term durability can justify the cost. Businesses that prioritize safety and structural reliability will find rigid supports to be an invaluable asset.

Making the Right Choice for Your Business Needs

When considering the right solution for your operational needs, it’s crucial to analyze the specific requirements of your application. If your primary focus is on flexibility and ease of use, straps may serve you well. However, for tasks that demand high levels of support and security, particularly in weightlifting or heavy industrial settings, investing in the appropriate belt thickness is advisable. Rigid supports should be considered for projects where maximum stability is essential.

Ultimately, the decision should be guided by the balance of performance, cost, and the specific use case. By assessing these factors, B2B buyers can make informed choices that align with their operational goals, ensuring both safety and efficiency in their processes.

Essential Technical Properties and Trade Terminology for belt thickness

What Are the Key Technical Properties of Belt Thickness?

When evaluating belt thickness, several critical specifications must be considered to ensure optimal performance and suitability for specific applications. Understanding these properties is essential for B2B buyers, particularly those involved in manufacturing, distribution, and retail.

1. Material Grade

The grade of material used in belt production is paramount. Common materials include leather, synthetic fabrics, and rubber. Each material grade impacts durability, flexibility, and weight-bearing capacity. High-grade leather, for example, offers superior support and longevity, making it ideal for heavy-duty applications. B2B buyers should assess material grades to ensure the belt meets industry standards and end-user expectations.

Illustrative image related to belt thickness

2. Thickness Tolerance

Thickness tolerance refers to the acceptable variation in the belt’s thickness. For instance, a belt marketed as 10mm thick may have a tolerance of ±0.5mm. This specification is crucial because deviations can affect performance—thinner belts may not provide adequate support, while thicker belts could hinder flexibility. Buyers must ensure that suppliers can consistently meet these tolerances to maintain product quality.

3. Belt Width

Belt width is another essential property, influencing both comfort and functionality. Wider belts, typically ranging from 2 to 4 inches, offer better support for heavy lifting, while narrower belts allow for greater mobility. B2B buyers should consider the intended use of the belt when selecting the appropriate width, as this will directly affect user experience and safety.

4. Load Capacity

The load capacity of a belt indicates the maximum weight it can safely support without compromising structural integrity. This property is critical for industries like construction or fitness, where belts are subjected to significant loads. Buyers should verify load capacity ratings with suppliers to ensure compliance with safety regulations and performance requirements.

5. Finish Type

The finish type of a belt can affect its aesthetics and functionality. Options may include untreated leather, treated leather with oils, or synthetic finishes. Each finish type has implications for durability, maintenance, and appearance. Buyers should consider the environment in which the belt will be used to select the most suitable finish.

What Are Common Trade Terms Related to Belt Thickness?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B sector. Here are some common terms related to belt thickness that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another brand’s name. In the context of belts, an OEM may produce belts for various brands, ensuring adherence to specific quality and design standards. Knowing the OEM can help buyers assess the reliability and reputation of the product.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers as it impacts inventory management and cash flow. Understanding MOQ can help businesses plan their purchasing strategies and avoid overcommitting to unnecessary stock.

3. RFQ (Request for Quotation)

An RFQ is a formal process through which buyers solicit price quotes from suppliers for specific products, including belts. This document typically outlines the required specifications, including thickness, material, and quantity. A well-prepared RFQ can lead to competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, ensuring both parties understand their obligations. Familiarity with relevant Incoterms can help B2B buyers navigate international trade more effectively.

By grasping these essential properties and trade terminologies related to belt thickness, B2B buyers can make informed decisions, ensuring the products they select meet both performance and compliance standards. This knowledge ultimately contributes to the efficiency and success of their operations.

Navigating Market Dynamics and Sourcing Trends in the belt thickness Sector

What are the Current Market Dynamics and Key Trends Influencing the Belt Thickness Sector?

The global market for belt thickness, particularly in the B2B sector, is driven by a combination of fashion trends, fitness culture, and industrial applications. As international buyers from regions such as Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Brazil) engage in sourcing, several key trends have emerged. Firstly, the increasing popularity of fitness and weightlifting has led to a surge in demand for specialized belts, such as powerlifting and training belts. These products often emphasize varying thicknesses, with 10mm belts gaining traction due to their optimal balance of support and comfort.

Furthermore, advancements in technology are influencing sourcing strategies. Digital platforms for procurement are becoming integral for buyers to access a wider range of suppliers, compare prices, and evaluate product specifications. Innovations in material science, such as the use of synthetic leathers and innovative fabrics, are also reshaping the market, allowing manufacturers to offer belts that are both durable and lightweight. Additionally, regional trade agreements and logistics improvements are facilitating smoother cross-border transactions, enabling B2B buyers to tap into global supply chains more efficiently.

How is Sustainability and Ethical Sourcing Impacting the Belt Thickness Market?

Sustainability and ethical sourcing have become paramount in the belt thickness sector, reflecting the growing awareness of environmental impact among consumers and businesses alike. B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to environmentally friendly practices, including the use of sustainable materials and ethical labor practices. For instance, belts made from recycled materials or organic cotton are gaining popularity, appealing to both environmentally conscious buyers and end consumers.

Moreover, certifications such as Global Organic Textile Standard (GOTS) or Fair Trade can enhance a supplier’s credibility and appeal in competitive markets. These certifications assure buyers that the products meet stringent environmental and social standards. Suppliers who invest in sustainable practices often find themselves at an advantage, as they not only meet regulatory requirements but also cater to a market segment willing to pay a premium for responsibly sourced products. This trend is particularly relevant for B2B buyers in emerging markets, where consumer demand for sustainability is rapidly evolving.

Illustrative image related to belt thickness

What is the Historical Context of Belt Thickness in B2B Sourcing?

The evolution of belt thickness in the B2B context can be traced back to the early 20th century when belts were primarily utilitarian, serving functional purposes in various industries. As fashion began to evolve in the mid-20th century, the focus shifted towards aesthetics, leading to the introduction of belts as fashion accessories. The late 20th century witnessed the rise of fitness culture, significantly impacting the demand for specialized weightlifting belts.

Today, the market is characterized by a diverse range of products catering to both functional and aesthetic preferences. The introduction of different thicknesses—ranging from 6.5mm for flexibility to 13mm for maximum support—reflects a deeper understanding of consumer needs and preferences. This historical trajectory has laid the groundwork for the current market dynamics, where B2B buyers seek not only functional products but also those that align with broader lifestyle trends and sustainability goals. As the sector continues to evolve, the interplay of tradition and innovation will remain crucial in shaping sourcing strategies for international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of belt thickness

-

1. How do I choose the right belt thickness for my business needs?

Selecting the appropriate belt thickness depends on the intended use and user preference. For applications requiring maximum support, such as powerlifting, a thicker belt (around 13mm) is ideal. Conversely, for general training or casual use, a 10mm or 6.5mm belt may provide sufficient support while ensuring comfort. It’s essential to consider the specific activities your clients will engage in and any regional preferences that may affect demand. -

2. What are the most common thickness options available for belts?

The most prevalent thickness options for belts are 6.5mm, 10mm, and 13mm. The 10mm thickness is often regarded as a versatile choice, providing a balance of support and comfort suitable for various activities. The 6.5mm option is more pliable and comfortable, ideal for less intense use. The 13mm belts offer maximum rigidity and support, primarily appealing to competitive lifters or those requiring extra stability during heavy lifts. -

3. How do I verify the quality of belts from potential suppliers?

When vetting suppliers, request samples to assess the material quality, thickness, and craftsmanship. Look for certifications or compliance with industry standards, especially if sourcing internationally. Additionally, review customer testimonials and previous client portfolios to gauge reliability and performance. Engage in direct communication with suppliers to clarify their production processes and quality assurance measures. -

4. What are the minimum order quantities (MOQs) for custom belt thicknesses?

MOQs can vary significantly by supplier and the complexity of customization. Typically, for customized belts, MOQs can range from 50 to 200 units. Discuss specific requirements with potential suppliers to negotiate terms that suit your business needs. Factors such as material availability and production capacity will influence MOQs, so it’s beneficial to clarify these details upfront. -

5. What payment terms should I expect when sourcing belts internationally?

International suppliers may offer various payment terms, typically ranging from 30% upfront and 70% upon shipment to full payment in advance. Be sure to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Understanding the currency exchange rates and potential fees involved is also crucial for budgeting accurately. -

6. How can I ensure timely logistics and delivery of my belt orders?

To ensure timely delivery, establish clear communication with your supplier regarding production timelines and shipping schedules. Utilize freight forwarders experienced in international logistics to navigate customs and shipping complexities. Consider setting up a tracking system to monitor shipments in real-time, allowing for proactive responses to any delays. -

7. What customization options should I consider for belt thickness?

Customization options may include varying thicknesses, materials, colors, and design features such as embroidery or unique buckles. Discussing your specific branding needs and market preferences with suppliers can yield tailored solutions that enhance product appeal. Understanding consumer trends in your target markets can also guide your customization choices for better alignment with customer expectations. -

8. How do I handle quality assurance for bulk orders of belts?

Implementing a robust quality assurance (QA) process is vital. This includes defining quality standards before production begins and conducting inspections at various stages of manufacturing. Consider arranging for third-party inspections to ensure compliance with your specifications. Establish a clear return policy with suppliers for any defective products to safeguard your business interests and maintain customer satisfaction.

Top 7 Belt Thickness Manufacturers & Suppliers List

1. Art of Manliness – Belts

Domain: artofmanliness.com

Registered: 2007 (18 years)

Introduction: Belts are worn for both function and style, impacting the overall impression of an outfit. They consist of two main parts: the buckle and the strap, with additional components like a keeper loop and end tip. Belts should be worn with pants that have belt loops, especially with formal outfits. There are two main categories of belts: formal and casual. Formal belts typically have a frame-style buckl…

2. Pioneer Fit – Weightlifting Belts

Domain: pioneerfit.com

Registered: 2019 (6 years)

Introduction: Pioneer Fit offers a variety of weightlifting belts including: Lever Lifting Belts, Powerlifting Belts, Cut Weight Lifting Belts, Hybrid Weightlifting Belts, Deadlift Belts, Bench Belts, Dip Belts, Training Belts, Special Design Belts, and Nylon Belts. They also provide Custom Lifting Belts, Custom Lever Lifting Belts, and Custom Powerlifting Belts with customizable levers. Additionally, they have…

3. Obscure Belts – High Quality Full-Grain Leather Belts

Domain: obscurebelts.com

Registered: 2005 (20 years)

Introduction: High quality leather belts are made using full grain leather from a double butt cut hide in 8.5 – 9.5 ounce thickness. Different grades of leather include top-grain, full-grain, corrected grain, split grain, genuine, and bonded. Full-grain leather is the best for belts due to its durability, style, and unique character. Corrected grain leather is the second highest quality, while split grain leath…

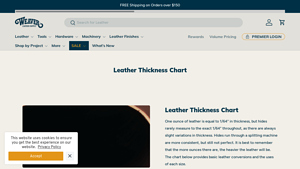

4. Weaver Leather – Thickness & Ounces Chart

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather Thicknesses & Ounces Chart – One ounce of leather is equal to 1/64″ in thickness. Hides run through a splitting machine are more consistent, but still not perfect. The chart provides basic leather conversions and the uses of each size. More ounces indicate heavier leather.

5. Groove Life – Adjustable Belts

Domain: groovelife.com

Registered: 2007 (18 years)

Introduction: {“belt_sizes”: {“XS”: {“total_length”: “34 inches”, “fits_waist_size”: “23 – 27 inches”}, “S”: {“total_length”: “39 inches”, “fits_waist_size”: “28 – 32 inches”}, “M”: {“total_length”: “44 inches”, “fits_waist_size”: “33 – 36 inches”}, “L”: {“total_length”: “49 inches”, “fits_waist_size”: “37 – 40 inches”}, “XL”: {“total_length”: “56 inches”, “fits_waist_size”: “41 – 50 inches”}, “XXL”: {“total_le…

6. Dalgado – Handcrafted Belts

Domain: dalgado.de

Introduction: Handcrafted in Europe, 2 year warranty, 30 Day Returns, Free International Shipping for orders starting from 250€, belt sizes typically have 5 holes, recommended to add 3 inches to pants waist size for sizing, widths: 4cm/1.6in for jeans, 3.5cm/1.4in for multipurpose, 3.2cm/1.3in and 3cm/1.2in for classic, 2.5cm/1in for casual, 4 edge styles: plain straight, raised without stitching, straight with…

7. Elliot Rhodes – Belt Width Guide

Domain: elliotrhodes.com

Registered: 2003 (22 years)

Introduction: Belt Width Guide: 40mm (standard) for men and women – versatile for casual wear, ideal for denim, suitable for dresses and skirts. 35mm (standard) for men – smart/casual, works with suits and formal trousers. 35mm (for women) – less common, suitable for suede belts or performance collection. 30mm (narrow) for men – recommended for smaller waist sizes, formal occasions, skinny trousers. 30mm (for w…

Strategic Sourcing Conclusion and Outlook for belt thickness

In the evolving landscape of belt thickness, strategic sourcing emerges as a critical component for international buyers. By understanding the nuances of different belt thicknesses—ranging from the versatile 10mm to the robust 13mm—buyers can tailor their procurement strategies to meet specific operational needs. The right belt not only enhances performance in various applications but also contributes to overall cost efficiency and supplier reliability.

As markets in Africa, South America, the Middle East, and Europe continue to grow, leveraging strategic sourcing can provide a competitive edge. Buyers should prioritize partnerships with manufacturers that offer customization options, ensuring that products align with regional preferences and compliance standards. Moreover, investing in quality belts can reduce replacement frequency, ultimately benefiting the bottom line.

Looking ahead, the demand for specialized belts is poised to rise as industries evolve and consumer preferences shift. International buyers are encouraged to stay informed about emerging trends in belt thickness and to engage proactively with suppliers to secure the best options for their unique requirements. Embrace strategic sourcing today to drive operational excellence and foster long-term success in your business endeavors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.