Catalog

Material Insight: What Is Microfiber Fabric Made Of

Microfiber Synthetic Leather: Composition & Application Excellence

What is Microfiber Fabric Made Of?

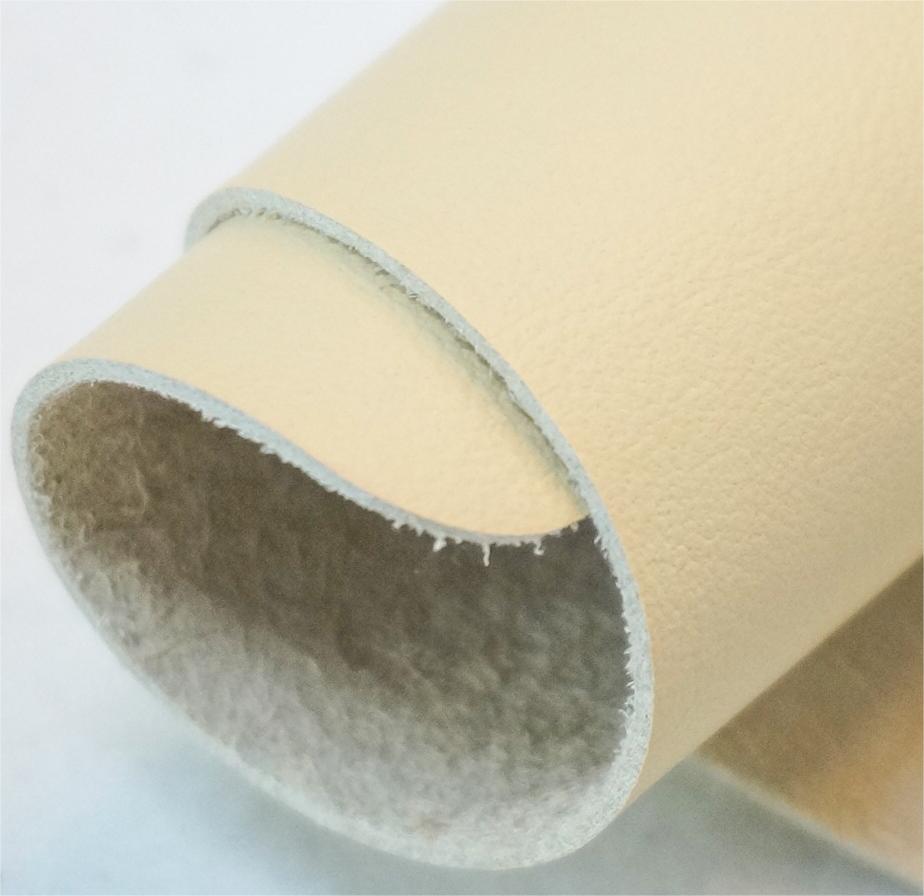

Microfiber synthetic leather is an engineered material composed of ultra-fine split fibers (typically polyester or nylon, measuring less than 1 denier per filament) bonded to a polyurethane (PU) resin base. Unlike traditional faux leather, it replicates the intricate three-dimensional structure of genuine leather through a non-woven fabric substrate. This substrate is created by entangling microfibers into a dense, porous network that is then impregnated, coated, and finished with specialized PU layers. Crucially, it contains zero animal byproducts, making it a 100% animal-free alternative with traceable, controlled inputs.

Why Microfiber Synthetic Leather is the Optimal Choice for Premium Applications

For demanding B2B sectors—automotive interiors, high-end furniture, and performance upholstery—microfiber synthetic leather outperforms conventional synthetic and natural leathers due to its engineered superiority:

- Unmatched Durability: Resists abrasion, tearing, and UV degradation 3–5x longer than standard PU leather, ensuring longevity in high-traffic environments.

- Eco-Efficiency: Uses 60% less water and generates 50% lower CO₂ emissions during production versus bovine leather, aligning with circular economy principles.

- Performance Precision: Offers superior breathability, stain resistance, and dimensional stability, even under extreme humidity or temperature fluctuations.

- Design Flexibility: Achieves consistent thickness, color fastness, and texture replication impossible with variable natural hides, reducing waste in manufacturing.

- End-of-Life Responsibility: Fully recyclable via closed-loop systems (unlike PVC-based alternatives), supporting brand sustainability certifications.

Introducing WINIW: Your Trusted Microfiber Innovation Partner

With over 20 years of specialized expertise in synthetic leather science, WINIW has pioneered next-generation microfiber solutions for global B2B leaders. We engineer materials at the molecular level—combining advanced polymer chemistry with sustainable manufacturing—to deliver products that exceed industry benchmarks for performance, ethics, and environmental stewardship. Our vertically integrated process, from fiber extrusion to finishing, ensures rigorous quality control and traceability. Today, WINIW serves 300+ clients across 50+ countries, turning material challenges into competitive advantages through relentless innovation. Partner with us to transform your sustainability goals into tangible market differentiation.

Technical Performance & Standards

B2B Product Guide: WINIW Microfiber Leather – The Sustainable Alternative to Genuine Leather

WINIW microfiber leather is a high-performance synthetic material engineered to serve as the premier alternative to real leather in a wide range of industrial and commercial applications. Designed with sustainability, durability, and compliance in mind, our microfiber fabric offers businesses a responsible and cost-effective solution without compromising on quality or aesthetics.

What Is Microfiber Fabric Made Of?

WINIW microfiber leather is composed of ultra-fine polyamide (nylon) and polyurethane (PU) fibers, intricately bonded through a non-woven process that mimics the structure of natural leather. The base layer replicates the dermal matrix of animal hide, while the surface is finished with advanced coatings to enhance texture, color fastness, and wear resistance. This composition delivers a material that is not only visually and tactilely similar to genuine leather but also surpasses it in several performance metrics.

Technical Advantages

- Superior Durability: WINIW microfiber exhibits higher tensile strength and abrasion resistance than most natural leathers, making it ideal for high-use applications such as automotive upholstery, furniture, and workwear.

- Consistent Quality: Unlike animal hides, which vary in grain and thickness, WINIW’s manufacturing process ensures uniform thickness, color, and texture across large production runs—critical for B2B consistency.

- Eco-Friendly Production: Our closed-loop manufacturing process minimizes water usage and chemical discharge. The absence of animal sourcing reduces carbon footprint and eliminates deforestation linked to cattle farming.

- Vegan & Cruelty-Free: WINIW microfiber is 100% animal-free, certified suitable for vegan product lines and aligned with global ethical sourcing standards.

- REACH Compliance: All WINIW microfiber products comply with EU REACH regulations (EC 1907/2006), ensuring no use of banned or hazardous substances such as phthalates, azo dyes, or heavy metals.

- ISO 9001 Certified Quality Management: WINIW’s production systems are certified under ISO 9001, guaranteeing consistent quality control, process efficiency, and continuous improvement across all operations.

- Enhanced Workability: The material is easier to cut, sew, and mold than real leather, reducing production waste and increasing yield in manufacturing environments.

Material Specifications

| Specification | WINIW Microfiber Leather |

|---|---|

| Base Fibers | Polyamide (Nylon 6) & Polyurethane (PU) |

| Weight Range | 200–400 g/m² |

| Thickness | 0.8–2.0 mm |

| Tensile Strength | ≥ 25 N/5mm (warp & weft) |

| Elongation at Break | ≤ 30% |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 4 (Grade) |

| Martindale Abrasion | ≥ 50,000 cycles |

| REACH Compliance | Fully compliant (SVHC-free) |

| ISO Certification | ISO 9001:2015 |

| Eco-Friendliness | OEKO-TEX® STANDARD 100 (Class II), RoHS compliant |

| Vegan Status | PETA-Approved Vegan |

| Customization Options | Thickness, texture, color, backings (cotton, knit, non-woven) |

Why Choose WINIW for Your B2B Needs?

- Sustainable Sourcing: Reduce environmental impact with a leather alternative that supports circular economy principles.

- Regulatory Ready: Meet global compliance requirements effortlessly with REACH, ISO, and vegan certifications pre-verified.

- Scalable Production: Available in wide-width rolls (up to 1.5 meters) for high-volume manufacturing with minimal seams.

- Brand Differentiation: Offer eco-conscious, cruelty-free products that align with modern consumer values and ESG goals.

WINIW microfiber leather is not merely a substitute—it is the next generation of performance materials, engineered for the future of responsible manufacturing.

Why Choose Synthetic over Real Leather

WINIW Microfiber vs. Real Leather: A B2B Material Comparison Guide

As a leading innovator in sustainable synthetic materials, WINIW provides this objective comparison to support informed sourcing decisions. Understanding core composition and performance metrics is critical for manufacturers prioritizing durability, cost-efficiency, and environmental stewardship.

Core Composition Breakdown

- Microfiber Fabric (WINIW Synthetic Leather)

- Made from ultra-fine split fibers (typically 0.3–1.0 denier), primarily polyester or nylon, bonded with high-performance polyurethane (PU) resins.

- WINIW’s premium variants utilize recycled PET content (up to 30%) and water-based PU, eliminating DMF and heavy metals.

-

Structurally engineered with a non-woven base for consistent thickness, tear resistance, and breathability.

-

Real Leather

- Derived from tanned animal hides (bovine, ovine, or exotic), processed through resource-intensive steps: liming, deliming, tanning (often chromium-based), dyeing, and finishing.

- Natural grain variation, scars, and thickness inconsistencies are inherent.

- Requires chemical-intensive tanning (15–20kg chemicals per hide) and significant water usage (up to 20,000L per kg of leather).

Performance & Sustainability Comparison

| Metric | WINIW Microfiber Synthetic Leather | Real Leather |

|---|---|---|

| Cost | 20–40% lower material cost; consistent yield reduces waste | Higher raw material cost; 20–30% waste due to hide defects |

| Durability | Superior abrasion resistance (50,000+ double-rubs); uniform strength; resistant to UV fading, stains, and moisture | Prone to cracking/drying; variable strength; vulnerable to moisture and stains; requires conditioning |

| Eco-Friendliness | WINIW: 60% lower carbon footprint; closed-loop water recycling; OEKO-TEX® certified; recyclable via specialized streams | High water/land use; toxic tannery effluent (Cr³⁺/Cr⁶⁺); methane emissions from livestock; limited end-of-life options |

Strategic Advantages for B2B Partners

- WINIW Microfiber

- Accelerates design-to-production cycles with consistent roll goods (no hide matching needed).

- Enables circular economy integration: WINIW’s RECYCLINE™ program supports take-back for mechanical recycling.

-

Meets stringent EU Ecolabel and REACH standards without compromising performance.

-

Real Leather

- Retains niche demand for luxury aesthetics in high-end automotive/furniture segments.

- Faces growing regulatory pressure (e.g., EU Chemicals Strategy for Sustainability targeting chromium tanning).

- Supply chain volatility due to livestock market fluctuations and ethical sourcing challenges.

WINIW’s engineered microfiber delivers parity in tactile quality while advancing measurable sustainability targets—critical for brands navigating ESG mandates and conscious consumer expectations. Partner with us to future-proof your material supply chain without sacrificing performance.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, operating from a state-of-the-art production facility spanning 100,000 square meters. Strategically located in China, our factory integrates advanced manufacturing capabilities with sustainable practices to deliver premium materials for global B2B clients.

Our large-scale manufacturing footprint enables high-volume production while maintaining exceptional consistency and on-time delivery. The facility is equipped with fully automated production lines, ensuring precision in coating, embossing, and finishing processes across a wide range of synthetic leather types, including PU, PVC, and eco-friendly alternatives.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 50 engineers and material scientists focused on innovation, durability, and sustainability. The team continuously develops new textures, functional properties (such as water resistance, abrasion resistance, and antimicrobial protection), and low-impact materials to meet evolving market demands.

- Strict quality control (QC) protocols implemented at every stage of production. Our QC system includes raw material inspection, in-line process monitoring, and final product testing in accordance with international standards such as ISO 9001, REACH, and RoHS.

- Comprehensive in-house testing laboratory capable of evaluating physical properties, color fastness, chemical compliance, and environmental resistance, ensuring every batch meets the highest performance benchmarks.

WINIW products are exported globally, with a strong presence in Europe and the USA. Our logistics network supports reliable, scalable distribution to meet the needs of large-scale partners in industries including automotive, furniture, fashion, and sports equipment.

Committed to sustainability, WINIW has implemented energy-efficient manufacturing processes and reduced solvent use through water-based and dry-process technologies. Our eco-conscious approach aligns with the environmental standards required by leading Western brands.

By combining scale, innovation, and quality, WINIW delivers synthetic leather solutions that meet the rigorous demands of international markets while supporting long-term business partnerships.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Performance for Commercial Applications

WINIW delivers next-generation microfiber leather engineered for demanding B2B sectors including automotive upholstery, high-end furniture, luggage, and technical apparel. Our eco-conscious manufacturing process produces ultra-durable, consistent materials that outperform traditional leathers and legacy synthetics while reducing environmental impact.

Core Composition & Technical Advantages

Microfiber leather is a precision-engineered composite. At WINIW, we utilize a proprietary blend where:

– 70% high-tenacity polyester microfiber non-woven base provides structural integrity and soft hand feel

– 30% advanced polyurethane (PU) resin forms a breathable, abrasion-resistant surface layer

– Zero PVC, phthalates, heavy metals, or DMF solvents – compliant with REACH, OEKO-TEX® STANDARD 100, and ISO 14001

Performance Comparison: WINIW vs. Industry Standards

| Property | WINIW Microfiber Leather | PVC Synthetic Leather | Genuine Leather |

|---|---|---|---|

| Tensile Strength (MPa) | 35-45 | 15-25 | 20-30 |

| Martindale Abrasion (cycles) | 100,000+ | 15,000-30,000 | 25,000-40,000 |

| Water Absorption (%) | <5 | 8-12 | 15-25 |

| VOC Emissions | Non-detectable | Moderate-High | Low-Moderate |

| Recycled Content | Up to 30% | 0% | 0% |

| Water Usage (vs. leather) | 90% reduction | N/A | Baseline |

Key Commercial Benefits

- Consistent Supply Chain: Eliminate natural hide variations with uniform roll goods (1.37m width, ±1mm thickness tolerance)

- Eco-Efficiency: 40% lower carbon footprint than bovine leather; OEKO-TEX® certified production

- Design Flexibility: 500+ color/matrix options with custom embossing; laser-cuttable with zero fraying

- Total Cost Savings: 50% longer lifespan than PVC synthetics; reduced waste during cutting

- Regulatory Ready: Meets FMVSS 302 (automotive), CA TB 117-2013 (furniture), and global RoHS standards

Curious about the science behind microfiber fabric composition?

Discover how WINIW’s molecular engineering achieves leather-like performance without ecological compromise. Our technical team provides detailed material breakdowns, lifecycle assessments, and compliance documentation.

→ Request Free Commercial Samples & Technical Dossier

Contact WINIW’s Material Science Division:

MKT88@MicrofiberLeather.com

Specify your application (e.g., automotive seating, contract furniture) for tailored material recommendations. Sample kits ship within 48 hours.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.