Catalog

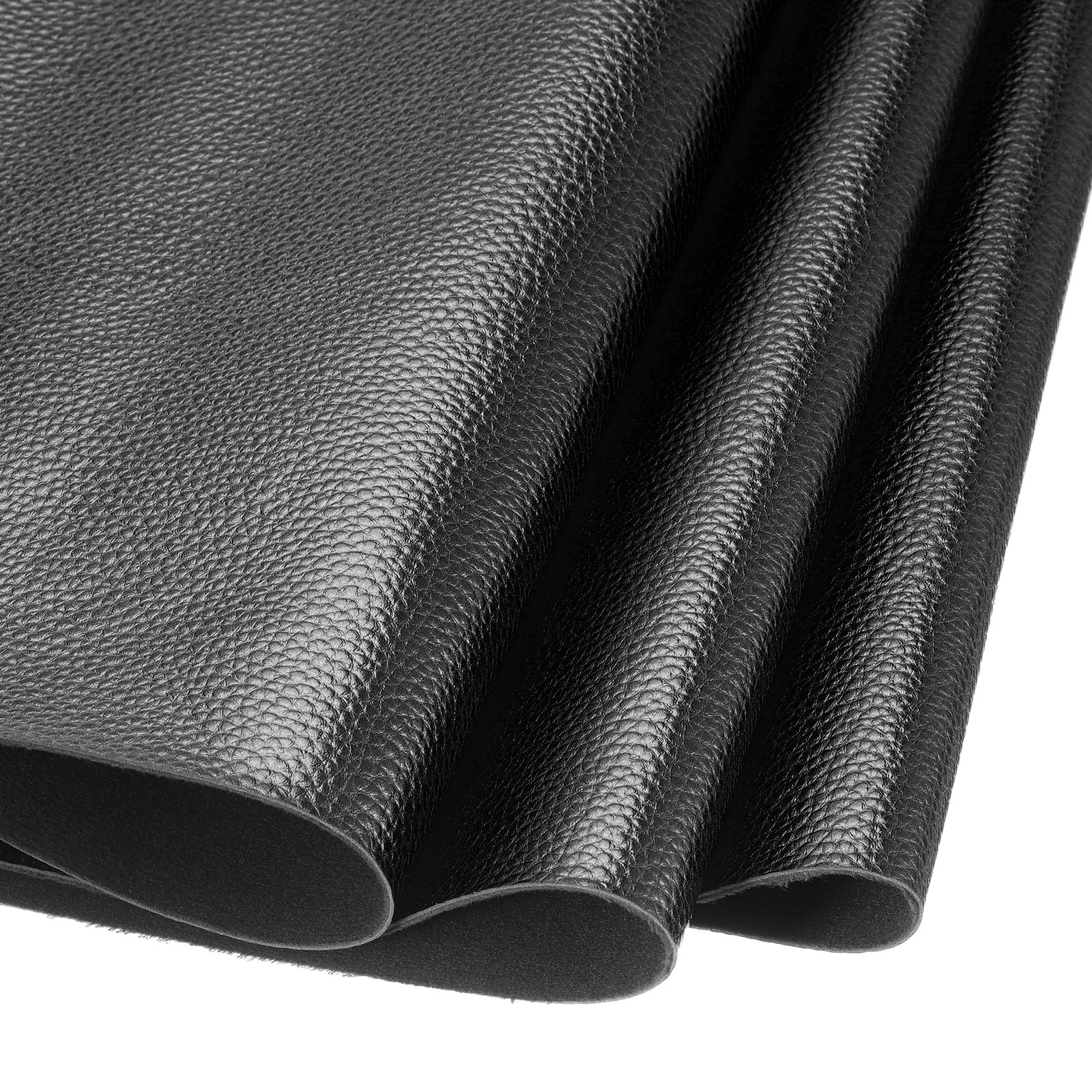

Material Insight: Waterproof Fake Leather

Waterproof Faux Leather: The Smart Choice for Modern Applications

In industries ranging from automotive and furniture to fashion and architecture, the demand for high-performance, sustainable materials continues to grow. Waterproof faux leather has emerged as a leading solution, combining durability, aesthetic versatility, and environmental responsibility. Unlike traditional leather, which is susceptible to water damage and requires extensive maintenance, waterproof faux leather delivers reliable performance in challenging environments—resisting moisture, stains, and wear without compromising on style.

Faux leather stands out as the best choice for waterproof applications due to its engineered composition. Made from high-quality polyurethane (PU) or polyvinyl chloride (PVC) on a durable backing, it is inherently more resistant to water absorption than natural leather. Advanced manufacturing techniques allow for precise control over texture, thickness, and performance characteristics, making it ideal for both indoor and outdoor use. Additionally, its production process supports eco-friendly practices by reducing reliance on animal products and minimizing environmental impact.

With over 20 years of experience in synthetic leather innovation, WINIW is a trusted name in the B2B materials industry. We specialize in high-performance faux leather solutions tailored to meet the exacting standards of global manufacturers. Our waterproof synthetic leathers are developed using cutting-edge technology, ensuring superior water resistance, breathability, and longevity. As a leader in sustainable material science, WINIW is committed to delivering products that combine functionality, aesthetics, and environmental responsibility—helping businesses future-proof their offerings in a competitive market.

Key advantages of choosing WINIW waterproof faux leather:

– Exceptional resistance to water, UV rays, and abrasion

– Consistent quality and batch-to-batch reliability

– Eco-conscious production with low-VOC emissions and recyclable materials

– Customizable textures, colors, and performance features

– Cost-effective alternative to treated natural leather without sacrificing premium appearance

Backed by decades of research and global partnerships, WINIW continues to set the standard for performance-driven synthetic leather solutions.

Technical Performance & Standards

WINIW Waterproof Synthetic Leather: Technical Product Guide for B2B Applications

WINIW’s advanced waterproof synthetic leather delivers engineered performance for demanding industrial and commercial applications. Designed for manufacturers prioritizing reliability, compliance, and operational efficiency, our material eliminates the cost volatility and ethical concerns of genuine leather while exceeding performance benchmarks in wet environments. Below are the core technical advantages driving ROI for forward-thinking partners.

Key Technical Advantages

- Cost-Effective Performance: Reduces material waste by 15–20% versus traditional coated textiles due to consistent thickness control and high yield rates. Eliminates pre-treatment costs required for natural leather waterproofing, lowering total production expenses by up to 25%.

- Extreme Durability: Features a proprietary dual-layer PU membrane technology with hydrolysis resistance (tested to 1,000+ hours per ISO 14184-1), ensuring structural integrity in high-humidity or submerged conditions. Resists abrasion (≥50,000 cycles Taber test), UV degradation (ISO 105-B02 Grade 7), and chemical exposure (pH 3–11).

- Full Customization Flexibility: Pantone®-matched color system with batch consistency (ΔE <0.8) across 1,200+ shades. Surface textures (suede, pebble, smooth) and thicknesses tailored to client specifications without MOQ constraints.

- REACH Compliance: Fully conforms to REACH Annex XVII (SVHC-free), with zero detectable levels of DMF, phthalates, or heavy metals (Cd, Pb, Hg, Cr⁶⁺). Certificates available per batch.

- ISO 9001:2015 Certified Production: Rigorous in-line quality control ensures <0.5% defect rate. Traceable lot numbering and real-time production monitoring guarantee batch uniformity for global supply chains.

Technical Specifications Overview

| Parameter | Specification | Test Standard |

|---|---|---|

| Thickness Range | 0.6 mm – 1.2 mm (customizable) | ISO 2418 |

| Waterproof Rating | >10,000 mm H₂O (hydrostatic head) | ISO 811 |

| Tensile Strength | ≥35 N/mm² (warp & weft) | ISO 1767 |

| Tear Strength | ≥8.0 N (Elmendorf) | ISO 9073-9 |

| Color Fastness (Rubbing) | ≥4–5 (dry/wet) | ISO 105-X12 |

| VOC Emissions | <50 mg/m³ (24h @ 23°C) | ISO 16000-9 |

| Temperature Resistance | -30°C to +80°C (continuous use) | ISO 188 |

| Recyclability | 92% material recovery rate (mechanical) | WINIW-certified process |

Why WINIW Outperforms Alternatives

Our closed-loop manufacturing process minimizes water/energy consumption by 40% versus industry averages, aligning with ESG mandates without sacrificing performance. Unlike PVC-based alternatives, WINIW’s PU formula ensures non-toxic decomposition and avoids chlorine-related emissions. The integrated waterproof barrier requires no additional lamination—reducing production steps while maintaining breathability (MVTR ≥500 g/m²/24h). This combination of operational efficiency, uncompromised compliance, and environmental responsibility makes WINIW the strategic choice for automotive interiors, medical upholstery, marine furniture, and outdoor equipment manufacturers.

Partner with WINIW to access scalable, audit-ready material solutions that protect your brand reputation and bottom line. Request technical datasheets or sample kits via WINIW’s B2B portal for project-specific validation.

Why Choose Synthetic over Real Leather

B2B Product Guide: Waterproof Fake Leather vs Real Leather

In the commercial and industrial sectors—particularly in furniture, automotive interiors, fashion accessories, and hospitality—material selection plays a critical role in product performance, sustainability, and cost-efficiency. Two of the most commonly compared materials are waterproof fake leather (synthetic leather) and real leather. Each offers distinct advantages and trade-offs depending on application requirements.

Waterproof fake leather, such as PU (polyurethane) or PVC-based synthetic leather, is engineered to mimic the look and feel of genuine leather while providing enhanced resistance to moisture, staining, and wear. Real leather, derived from animal hides, is valued for its natural aesthetics, breathability, and long-term aging characteristics. However, it requires more maintenance and is generally less resistant to water without treatment.

Below is a comparative analysis based on three key decision-making factors for B2B buyers: cost, durability, and eco-friendliness.

| Factor | Waterproof Fake Leather | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher upfront cost |

| Durability | High resistance to water, UV, and abrasion; may crack over time under extreme stress | Naturally durable; develops patina; susceptible to water damage if untreated |

| Eco-Friendliness | Can be engineered with recycled materials and low-VOC processes; fully synthetic composition limits biodegradability | Natural material; biodegradable but tanning process often involves high water use and toxic chemicals |

Key Considerations for B2B Buyers:

- Waterproof fake leather is ideal for high-moisture environments such as marine upholstery, healthcare seating, and outdoor furniture.

- Real leather is preferred in premium automotive interiors and luxury goods where natural texture and aging are valued.

- Maintenance costs for real leather are higher due to conditioning and protective treatments required.

- Synthetic leathers, especially those from sustainable manufacturers like WINIW, offer traceable supply chains, reduced carbon footprints, and compliance with environmental regulations such as REACH and RoHS.

- Innovations in bio-based PU and recycled polyester backings are closing the performance gap while improving sustainability metrics.

Ultimately, the choice between waterproof fake leather and real leather depends on balancing performance needs, sustainability goals, and budget constraints. For businesses prioritizing consistency, water resistance, and environmental responsibility, high-performance synthetic leathers present a compelling, future-ready alternative.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW operates one of Asia’s most advanced synthetic leather manufacturing facilities, delivering consistent quality and innovation for discerning global partners. Our vertically integrated production ecosystem, spanning 100,000 square meters, enables rigorous control from raw material sourcing to finished roll. This scale, combined with deep technical expertise, ensures we meet the exacting demands of international markets while advancing sustainable material science.

Core Manufacturing Strengths

– 100,000 sqm Integrated Facility: Fully controlled production environment housing extrusion, coating, finishing, and testing under one roof, minimizing supply chain variables and ensuring batch consistency.

– Dedicated R&D Team of 40+ Specialists: Continuously innovating in eco-performance materials, including water-based PU, recycled content formulations (up to 50% PCR), and bio-based alternatives, with 15+ patents filed in the last 5 years.

– Strict Multi-Stage Quality Control: Every meter undergoes 7-point inspection (color fastness, abrasion resistance, peel strength, VOC emissions, etc.) aligned with ISO 9001 protocols and region-specific standards (e.g., EU REACH, US CPSIA).

Global Compliance & Market Reach

Our commitment to quality and sustainability drives trusted partnerships across regulated markets. WINIW products consistently pass third-party certifications critical for international commerce:

| Certification Standard | Key Regions Served | Compliance Focus |

|---|---|---|

| OEKO-TEX® STANDARD 100 | Europe, USA, Japan | Harmful substance limits |

| ISO 14001 | Global | Environmental management |

| SCS Recycled Content | North America | Verified recycled material % |

| REACH Annex XVII | EU | Chemical safety |

WINIW exports to 30+ countries, with 65% of annual volume shipped to Tier-1 automotive, premium furniture, and sustainable fashion brands in Europe and North America. Our facility’s capacity for 15,000+ meters daily – without compromising traceability or eco-credentials – makes us a resilient partner for scaling sustainable material solutions worldwide. Partner with WINIW to transform performance and responsibility in your supply chain.

Contact Us for Samples

B2B Product Guide: Waterproof Fake Leather by WINIW

WINIW is a leading innovator in high-performance synthetic leather solutions, specializing in eco-friendly, durable, and versatile microfiber materials for global B2B markets. Our waterproof fake leather is engineered to meet the rigorous demands of industries ranging from automotive and furniture to fashion and outdoor equipment.

Designed with sustainability and functionality in mind, WINIW’s waterproof synthetic leather delivers superior water resistance, abrasion durability, and UV stability—without compromising on softness or aesthetic appeal. As a cruelty-free and environmentally responsible alternative to genuine leather, our products support eco-conscious manufacturing and branding initiatives.

Key Features of WINIW Waterproof Fake Leather:

- 100% waterproof with high hydrostatic pressure resistance (up to 3000mm+)

- Made from premium microfiber base with PU or eco-coating for enhanced durability

- Excellent resistance to abrasion, tearing, and color fading

- UV-stable—suitable for indoor and outdoor applications

- Breathable options available for enhanced comfort

- Available in a wide range of textures, including grain, nubuck, and custom embossing

- REACH and RoHS compliant; low in VOC emissions

- Recyclable and free from hazardous substances

Ideal Applications:

- Automotive interiors (seats, dashboards, door panels)

- Marine and outdoor furniture

- Upholstery for contract and residential furniture

- Luggage, bags, and accessories

- Protective covers and technical apparel

Technical Specifications (Standard Grade):

| Property | Specification |

|---|---|

| Thickness | 0.6 mm – 1.8 mm (customizable) |

| Width | 137 cm, 140 cm, 150 cm (roll width) |

| Weight | 280 – 450 g/m² |

| Water Resistance | >3000 mm H₂O |

| Color Fastness (ISO 105) | ≥ Grade 4 |

| Cold Crack Resistance | Passes -20°C test |

| Backing Material | Microfiber or knitted fabric |

WINIW’s commitment to innovation and sustainability ensures that our waterproof fake leather not only performs under pressure but also aligns with global environmental standards. We partner with manufacturers, designers, and brands seeking reliable, scalable, and green material solutions.

Request Free Samples Today

Experience the quality and performance of WINIW waterproof fake leather firsthand. Free samples are available for qualified B2B partners.

For inquiries, product specifications, or sample requests:

Contact: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.