Introduction: Navigating the Global Market for wholesale leather manufacturers

Navigating the global market for wholesale leather manufacturers presents a significant challenge for international B2B buyers, especially when sourcing high-quality materials that meet specific business needs. With the leather industry being diverse and complex, understanding the different types, applications, and sourcing options is crucial. This guide offers an in-depth exploration of the wholesale leather landscape, covering various leather types—ranging from premium Italian hides to exotic leathers—alongside their applications in apparel, accessories, and interiors.

Additionally, we delve into the vital aspects of supplier vetting, helping buyers identify reliable manufacturers that adhere to quality standards and ethical practices. Cost considerations are also examined, providing insights into pricing structures and volume discounts that can enhance your purchasing strategy.

By equipping buyers from regions like Africa, South America, the Middle East, and Europe—particularly in markets such as Saudi Arabia and Germany—with actionable insights, this guide aims to empower informed purchasing decisions. Whether you are a small artisan or a large-scale manufacturer, understanding the nuances of wholesale leather procurement will enable you to secure the best materials for your business, ensuring both quality and value in your supply chain.

Table Of Contents

- Top 9 Wholesale Leather Manufacturers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for wholesale leather manufacturers

- Understanding wholesale leather manufacturers Types and Variations

- Key Industrial Applications of wholesale leather manufacturers

- 3 Common User Pain Points for ‘wholesale leather manufacturers’ & Their Solutions

- Strategic Material Selection Guide for wholesale leather manufacturers

- In-depth Look: Manufacturing Processes and Quality Assurance for wholesale leather manufacturers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘wholesale leather manufacturers’

- Comprehensive Cost and Pricing Analysis for wholesale leather manufacturers Sourcing

- Alternatives Analysis: Comparing wholesale leather manufacturers With Other Solutions

- Essential Technical Properties and Trade Terminology for wholesale leather manufacturers

- Navigating Market Dynamics and Sourcing Trends in the wholesale leather manufacturers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of wholesale leather manufacturers

- Strategic Sourcing Conclusion and Outlook for wholesale leather manufacturers

- Important Disclaimer & Terms of Use

Understanding wholesale leather manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Italian Leather Manufacturers | Renowned for high-quality craftsmanship and aesthetics | Luxury fashion, upholstery, accessories | Pros: Superior quality, diverse styles. Cons: Higher cost, longer lead times. |

| Exotic Leather Suppliers | Specialize in rare materials (e.g., crocodile, ostrich) | High-end fashion, bespoke items, décor | Pros: Unique offerings, high market value. Cons: Limited availability, ethical concerns. |

| Bulk Leather Distributors | Focus on large quantities and competitive pricing | Mass production, industrial applications | Pros: Cost-effective, variety of hides. Cons: Quality can vary, less customization. |

| Tannery Direct Suppliers | Manufacturers that process leather from raw hides | Custom manufacturing, artisanal products | Pros: Fresh materials, customizable options. Cons: Requires more oversight, potential for variability. |

| Specialty Leather Providers | Offer niche products (e.g., suede, nubuck) | Specific applications, fashion, crafts | Pros: Tailored solutions, expertise in niche markets. Cons: May not meet bulk needs, higher prices. |

What Are the Characteristics of Italian Leather Manufacturers?

Italian leather manufacturers are celebrated for their exceptional craftsmanship, utilizing traditional tanning methods to produce high-quality hides. This type of leather is often associated with luxury brands and is used extensively in fashion, upholstery, and high-end accessories. When considering B2B purchases, buyers should evaluate the reputation of the manufacturer, the specific types of leather offered, and the lead times for orders, as these factors significantly influence product quality and availability.

How Do Exotic Leather Suppliers Stand Out?

Exotic leather suppliers specialize in unique materials such as crocodile, ostrich, and python, which are highly sought after in the luxury market. These suppliers cater to high-end fashion brands and bespoke item producers. B2B buyers must be mindful of ethical sourcing practices and legal regulations concerning exotic leathers. The rarity and high market value of these materials can justify their premium pricing, making them an attractive option for businesses looking to differentiate their product offerings.

What Advantages Do Bulk Leather Distributors Offer?

Bulk leather distributors focus on providing large quantities of leather at competitive prices, making them ideal for mass production and industrial applications. They typically offer a wide range of hides and finishes, allowing businesses to source materials for various products. However, buyers should be cautious about the quality of leather, as it can vary significantly between batches. Establishing a reliable relationship with a distributor can ensure consistent quality and pricing.

Illustrative image related to wholesale leather manufacturers

What Are the Benefits of Working with Tannery Direct Suppliers?

Tannery direct suppliers process raw hides into finished leather, offering a direct link between the source and the buyer. This type of supplier is suitable for custom manufacturing and artisanal products, as they can provide fresh materials tailored to specific requirements. B2B buyers should consider the level of customization available and the supplier’s ability to meet quality standards. While working directly with a tannery may require more oversight, it often results in superior products.

How Can Specialty Leather Providers Serve Niche Markets?

Specialty leather providers focus on niche products such as suede, nubuck, or performance leathers designed for specific applications. These suppliers often have deep expertise in their materials, making them valuable partners for businesses seeking tailored solutions. However, buyers should be aware that specialty leathers may not be suitable for bulk orders and can come at a higher price point. Understanding the specific needs of their target market will help buyers choose the right specialty provider.

Key Industrial Applications of wholesale leather manufacturers

| Industry/Sector | Specific Application of wholesale leather manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel | Supply of premium leather for high-end fashion garments | Enhances product quality and brand reputation | Look for suppliers with a history of craftsmanship and quality standards. |

| Footwear | Provision of durable leather for shoes and boots | Increases longevity and customer satisfaction | Prioritize sourcing from manufacturers who offer various finishes and weights. |

| Upholstery | Leather for furniture and interior design | Adds luxury appeal and durability to products | Ensure suppliers can provide large quantities and custom colors. |

| Automotive | Leather for car interiors and upholstery | Elevates the perceived value of vehicles | Seek manufacturers with experience in automotive-grade materials and compliance with industry standards. |

| Accessories | Leather for bags, belts, and wallets | Diversifies product offerings and attracts a broader customer base | Consider suppliers that provide a range of textures and colors to meet market trends. |

How Do Wholesale Leather Manufacturers Support the Apparel Industry?

Wholesale leather manufacturers play a vital role in the apparel industry by supplying high-quality leather suitable for premium fashion garments. The use of top-grade leather enhances the overall aesthetic and durability of clothing items, making them more appealing to consumers. International buyers, particularly from regions like Europe and the Middle East, should focus on sourcing from manufacturers with a proven track record in craftsmanship and quality assurance to ensure that their products meet market demands.

What Benefits Do Wholesale Leather Manufacturers Provide for Footwear?

In the footwear sector, wholesale leather manufacturers supply durable materials essential for crafting shoes and boots that withstand daily wear and tear. The longevity of leather not only satisfies consumer expectations for quality but also contributes to customer loyalty and satisfaction. Buyers should prioritize manufacturers that offer various finishes, weights, and treatments to cater to diverse styles and functionalities required in the footwear market.

Illustrative image related to wholesale leather manufacturers

How Is Leather Used in Upholstery Applications?

The upholstery industry benefits significantly from wholesale leather manufacturers, who provide luxurious leather for furniture and interior design projects. Leather adds an element of sophistication and durability to products, appealing to consumers looking for quality home furnishings. B2B buyers should ensure that suppliers can meet large quantity demands and offer customization options in terms of color and texture to align with current design trends.

Why Is Leather Critical in the Automotive Sector?

In the automotive industry, wholesale leather manufacturers supply materials for car interiors, enhancing the overall luxury and comfort of vehicles. High-quality leather can significantly elevate the perceived value of cars, making them more attractive to consumers. Buyers should seek manufacturers with expertise in automotive-grade leather that complies with industry standards and regulations to ensure product safety and durability.

How Do Accessories Benefit from Wholesale Leather Sourcing?

Wholesale leather manufacturers also cater to the accessories market by providing leather for bags, belts, and wallets. The versatility of leather allows businesses to diversify their product offerings, appealing to a broader customer base. When sourcing, buyers should consider suppliers that offer a wide range of textures and colors to stay aligned with market trends and consumer preferences.

3 Common User Pain Points for ‘wholesale leather manufacturers’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Leather Sourcing

The Problem: B2B buyers often face significant challenges in ensuring the quality of leather products when sourcing from wholesale manufacturers. Variability in quality can lead to inconsistent product offerings, affecting everything from customer satisfaction to brand reputation. For instance, a buyer may receive a shipment of leather that does not meet the specified standards, resulting in wasted resources and the need for costly returns or replacements.

The Solution: To overcome these quality assurance challenges, buyers should implement a robust supplier evaluation process before making a purchase. This involves requesting samples of leather hides to assess texture, finish, and durability firsthand. Additionally, establishing clear specifications regarding leather type, tanning processes, and treatment can help manufacturers understand expectations. Buyers should also consider partnering with manufacturers who provide transparency in their sourcing and production processes, including certifications that verify quality standards. Finally, regular audits and visits to manufacturing facilities can enhance trust and ensure compliance with agreed-upon quality metrics.

Illustrative image related to wholesale leather manufacturers

Scenario 2: Managing Inventory and Supply Chain Disruptions

The Problem: International buyers often struggle with inventory management due to unpredictable supply chain disruptions. Factors such as geopolitical tensions, transportation delays, or natural disasters can lead to sudden shortages or overstock situations, complicating planning and forecasting efforts. This unpredictability can result in missed sales opportunities or excess inventory that ties up capital.

The Solution: To manage these inventory challenges effectively, buyers should develop a diversified sourcing strategy. This includes identifying multiple wholesale leather manufacturers across different regions to reduce reliance on a single supplier. Implementing a just-in-time (JIT) inventory system can also help by allowing companies to order smaller quantities more frequently, thus reducing the risks associated with overstock. Furthermore, leveraging technology such as inventory management software can provide real-time insights into stock levels and trends, enabling better decision-making. Building strong relationships with suppliers can also facilitate better communication, allowing buyers to receive timely updates on potential disruptions.

Scenario 3: Understanding and Navigating Pricing Structures

The Problem: Pricing transparency is a common pain point for B2B buyers in the leather industry. Wholesale leather manufacturers often have complex pricing structures that can vary based on factors such as material quality, order quantity, and shipping costs. This lack of clarity can lead to budgeting difficulties and unexpected expenses, making it challenging for businesses to maintain profitability.

The Solution: To navigate pricing structures effectively, buyers should engage in open discussions with manufacturers about their pricing models. Requesting detailed breakdowns of costs associated with leather products can help buyers understand where their money is going. Additionally, buyers should explore bulk purchasing options, as many manufacturers offer discounts for larger orders. Establishing long-term relationships with suppliers can also lead to more favorable pricing agreements over time. Finally, buyers should consider using a price comparison tool to evaluate offers from different manufacturers, ensuring they secure the best deal without sacrificing quality. By taking these steps, businesses can better manage their budgets and enhance their overall profitability in the competitive leather market.

Strategic Material Selection Guide for wholesale leather manufacturers

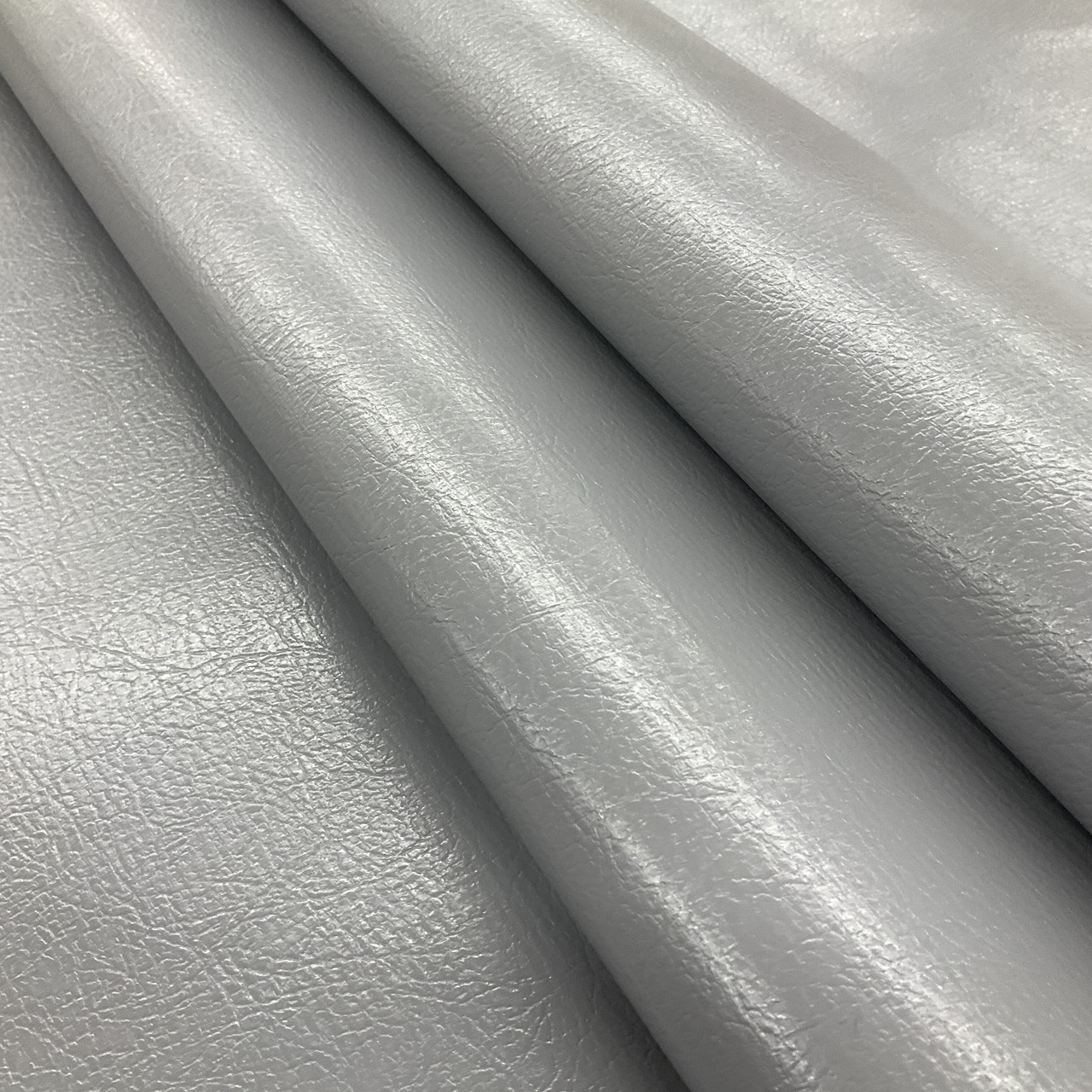

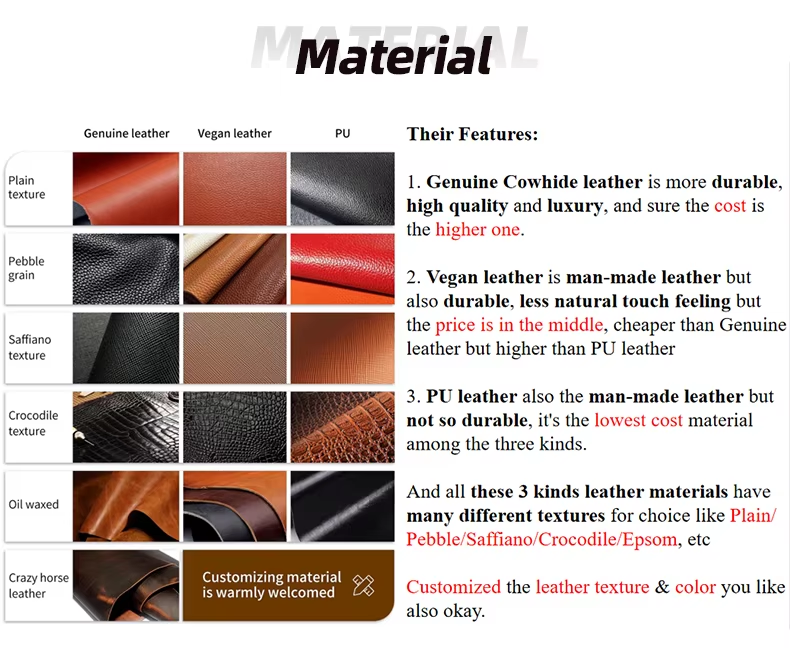

When selecting materials for wholesale leather manufacturing, it is essential to understand the properties, advantages, and limitations of various leather types. This guide analyzes four common materials used in the industry: Full Grain Leather, Top Grain Leather, Suede, and Exotic Leathers. Each material has unique characteristics that can significantly impact product performance and suitability for different applications.

What are the Key Properties of Full Grain Leather for Wholesale Leather Manufacturers?

Full Grain Leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. Its key properties include exceptional durability and breathability, making it suitable for high-end products such as luxury handbags and footwear. Full Grain Leather can withstand temperature fluctuations and is resistant to wear and tear, which is crucial for products intended for long-term use.

Pros & Cons: The primary advantage of Full Grain Leather is its longevity and aesthetic appeal. However, it comes at a higher cost, which may not be suitable for all markets. Additionally, the manufacturing process can be complex, requiring skilled labor to ensure quality.

Impact on Application: Full Grain Leather is ideal for high-end fashion items and upholstery, as it ages beautifully, developing a patina over time. International buyers should consider compliance with quality standards such as ASTM D-2047 for slip resistance, especially for footwear.

Illustrative image related to wholesale leather manufacturers

How Does Top Grain Leather Compare for Wholesale Leather Manufacturers?

Top Grain Leather is the second-highest quality leather, made by sanding down the surface of Full Grain Leather to remove imperfections. This process makes it more uniform in appearance while still offering good durability and flexibility.

Pros & Cons: The main advantage of Top Grain Leather is its balance of quality and cost, making it a popular choice for a wide range of products, from wallets to jackets. However, it is less durable than Full Grain Leather and may not develop the same character over time.

Impact on Application: Top Grain Leather is suitable for products requiring a refined look without the premium price tag. Buyers in regions with stringent quality standards, such as Germany, should ensure that the leather meets local regulations for manufacturing.

What are the Benefits and Limitations of Suede in Wholesale Leather Manufacturing?

Suede is made from the inner layer of animal hides, resulting in a soft, velvety texture. Its key properties include excellent flexibility and a unique aesthetic appeal, making it popular for fashion items and accessories.

Pros & Cons: Suede is lightweight and comfortable, which is beneficial for garments and linings. However, it is less durable than other leather types and can be more susceptible to stains and moisture damage, requiring special care.

Illustrative image related to wholesale leather manufacturers

Impact on Application: Suede is often used in fashion-forward applications, but buyers should be aware of its limitations in environments with high humidity or exposure to water. Compliance with care and maintenance standards is essential, especially for international buyers.

Why Consider Exotic Leathers for Wholesale Leather Manufacturing?

Exotic Leathers, such as crocodile or ostrich, offer unique textures and patterns that can elevate product appeal. These materials are often used in luxury items and high-end fashion.

Pros & Cons: The primary advantage of Exotic Leathers is their exclusivity and aesthetic appeal, which can command higher prices. However, they are often more expensive and may face stricter regulations regarding sourcing and trade.

Impact on Application: Exotic Leathers are best suited for luxury markets, where unique design and quality are paramount. Buyers from regions like the Middle East, known for luxury consumption, should ensure compliance with international trade laws and ethical sourcing standards.

Illustrative image related to wholesale leather manufacturers

| Material | Typical Use Case for wholesale leather manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Luxury handbags, high-end footwear | Exceptional durability and breathability | Higher cost and complex manufacturing | High |

| Top Grain Leather | Wallets, jackets, and mid-range fashion items | Good balance of quality and cost | Less durable than Full Grain Leather | Medium |

| Suede | Fashion garments and accessories | Soft texture and lightweight | Less durable and susceptible to stains | Medium |

| Exotic Leathers | Luxury goods, high-end fashion | Unique aesthetics and exclusivity | High cost and strict sourcing regulations | High |

This strategic material selection guide provides a comprehensive overview of the key leather types relevant to wholesale manufacturers. Understanding these materials’ properties and implications can help international buyers make informed purchasing decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for wholesale leather manufacturers

What Are the Key Stages in the Manufacturing Process of Wholesale Leather?

The manufacturing process of wholesale leather involves several critical stages that ensure the final product meets the desired quality standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: How Are Raw Hides Processed?

The first step in leather manufacturing is material preparation, which begins with sourcing raw hides from reputable suppliers. This stage includes curing and tanning, which are essential for preserving the hides and preventing decay. Curing can involve salting or drying, while tanning methods may include chrome tanning, vegetable tanning, or a combination of both. Each method affects the leather’s properties, such as softness, durability, and color.

Illustrative image related to wholesale leather manufacturers

After tanning, the hides undergo processes like splitting, shaving, and retanning. Splitting divides the hide into different thicknesses, while shaving ensures uniformity. Retanning may be necessary to enhance the leather’s characteristics, depending on the desired end use.

How Is Leather Formed and Assembled?

Once the hides are prepared, they enter the forming stage. This involves cutting the leather into specific patterns based on the intended product—be it bags, shoes, or upholstery. Precision cutting techniques, such as die-cutting and laser cutting, are employed to maximize material usage and minimize waste.

The assembly phase follows forming, where different leather pieces are stitched or bonded together. High-quality manufacturers often use industrial sewing machines to ensure durability and consistency in the seams. For products requiring additional strength, techniques such as rivets or adhesives may be utilized.

What Finishing Techniques Are Commonly Used?

Finishing is the final stage of the manufacturing process, which enhances the leather’s appearance and performance. Various techniques, such as dyeing, embossing, and applying protective coatings, are employed. Dyeing can range from traditional methods using natural dyes to modern chemical processes that provide vibrant colors.

Embossing adds texture or patterns, which can be a distinguishing feature for luxury brands. Protective coatings, such as water-resistant finishes, are often applied to enhance durability and reduce maintenance requirements. Manufacturers may also apply conditioning agents to improve the leather’s feel and longevity.

Illustrative image related to wholesale leather manufacturers

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is critical in leather manufacturing, ensuring that products meet international standards and customer expectations. For B2B buyers, understanding these QA processes can help in assessing suppliers effectively.

What International Standards Are Relevant to Leather Manufacturing?

Wholesale leather manufacturers often adhere to international quality standards like ISO 9001, which focuses on quality management systems. Compliance with these standards indicates a commitment to continuous improvement and customer satisfaction.

Additionally, industry-specific certifications, such as CE marking for products sold in Europe or API standards for specific applications, may also be relevant. These certifications ensure that the leather products meet safety and performance requirements specific to their intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. Common checkpoints include:

Illustrative image related to wholesale leather manufacturers

-

Incoming Quality Control (IQC): This stage assesses raw materials for defects before they enter production. B2B buyers should inquire about suppliers’ processes for inspecting hides upon arrival.

-

In-Process Quality Control (IPQC): During production, manufacturers should conduct regular inspections to identify issues early. This may involve checking stitching quality, color consistency, and adherence to specifications.

-

Final Quality Control (FQC): Before products are shipped, a final inspection ensures they meet all quality standards. This may include checking for defects, ensuring proper labeling, and verifying packaging integrity.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

-

Conduct Audits: Regular audits of suppliers can help buyers assess compliance with quality standards and identify areas for improvement. These audits can be conducted by the buyer or through third-party services.

-

Request Quality Reports: Suppliers should provide documentation detailing their QC processes, including inspection results and any corrective actions taken. This transparency builds trust and confidence in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These services can conduct inspections at various stages of production, ensuring that the final products meet the buyer’s requirements.

What Nuances Should International B2B Buyers Consider?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must be aware of specific nuances when dealing with wholesale leather manufacturers.

Are There Specific Regulations for Importing Leather Products?

Different countries have varying regulations regarding the importation of leather goods. Buyers should familiarize themselves with these regulations to avoid potential legal issues. For instance, some countries may have strict requirements regarding animal welfare and environmental impact, which could affect the sourcing of raw materials.

How Do Cultural Preferences Impact Quality Standards?

Cultural preferences can influence quality standards and expectations. For instance, European buyers may prioritize sustainability and eco-friendly practices, while buyers from the Middle East may focus on specific aesthetic qualities. Understanding these preferences can help buyers communicate their needs effectively to suppliers.

Illustrative image related to wholesale leather manufacturers

What Are the Challenges in Sourcing Leather Globally?

Sourcing leather globally can present challenges, such as fluctuating raw material prices, supply chain disruptions, and varying quality standards. B2B buyers should develop strong relationships with suppliers and maintain open communication to navigate these challenges effectively.

By understanding the manufacturing processes and quality assurance measures in wholesale leather production, B2B buyers can make informed decisions that align with their business needs and standards. This knowledge not only helps in selecting reliable suppliers but also in ensuring that the final products meet both quality and regulatory expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wholesale leather manufacturers’

Introduction

In the competitive world of leather goods manufacturing, sourcing high-quality leather from reliable suppliers is crucial for success. This guide provides a practical checklist for B2B buyers looking to procure from wholesale leather manufacturers, ensuring you make informed decisions that align with your business needs.

Illustrative image related to wholesale leather manufacturers

Step 1: Define Your Technical Specifications

Clearly outline the specific types of leather you need, including qualities such as thickness, tanning process, and intended use. This step is vital as it sets the foundation for your sourcing strategy and helps potential suppliers understand your requirements. Consider the end application of the leather—whether for apparel, accessories, or furniture—to ensure compatibility.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable wholesale leather manufacturers. Utilize online platforms, trade shows, and industry directories to compile a list of potential suppliers. Look for reviews and ratings from other businesses to gauge the reliability and quality of the suppliers. This groundwork is essential to avoid costly mistakes later in the procurement process.

Step 3: Verify Supplier Certifications

Confirm that your selected suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 for quality management and environmental sustainability standards are indicators of a reliable manufacturer. This verification process not only ensures quality but also builds trust in your supplier relationship.

Step 4: Request Samples

Before making a bulk order, always request samples of the leather. Assess the quality, texture, and color consistency to ensure it meets your specifications. This step is critical as it allows you to evaluate the supplier’s product firsthand and make adjustments to your order if necessary.

Illustrative image related to wholesale leather manufacturers

Step 5: Evaluate Pricing Structures

Discuss pricing with potential suppliers and inquire about bulk order discounts. Understand their pricing models, including any minimum order quantities and payment terms. Having clarity on costs upfront will help you budget effectively and negotiate favorable terms.

Step 6: Review Shipping and Delivery Options

Inquire about the supplier’s shipping policies, including lead times and delivery methods. Ensure they can meet your timeline and that they have a reliable logistics process in place. Timely delivery is crucial for maintaining production schedules and meeting market demands.

Step 7: Establish Communication Protocols

Set clear communication channels with your chosen suppliers to facilitate ongoing dialogue. Establish regular check-ins and updates on order status, which can help preempt any potential issues. Effective communication is key to building strong, long-term relationships with your suppliers.

Illustrative image related to wholesale leather manufacturers

By following this checklist, B2B buyers can streamline their sourcing process, ensuring they select the right wholesale leather manufacturers to meet their business objectives.

Comprehensive Cost and Pricing Analysis for wholesale leather manufacturers Sourcing

When navigating the world of wholesale leather sourcing, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances negotiation strategies and overall cost-efficiency.

What are the Key Cost Components for Wholesale Leather Manufacturers?

The cost structure for wholesale leather manufacturers typically encompasses several critical components:

-

Materials: The choice of leather type significantly influences costs. Premium materials, such as Italian leather, command higher prices due to their quality and craftsmanship. Additionally, variations in thickness, tanning processes, and finishes can affect the base price.

-

Labor: Skilled labor is essential in the leather production process, particularly for high-quality products. Labor costs can vary based on geographical location, with countries known for their leather craftsmanship, like Italy and Brazil, often having higher wage standards.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs, contributing to competitive pricing.

-

Tooling: Investment in specialized tools and machinery is necessary for producing specific leather goods. This upfront cost is typically factored into the pricing, especially for customized orders.

-

Quality Control (QC): Ensuring the final product meets specified standards incurs additional costs. Rigorous QC processes are essential for maintaining brand reputation and customer satisfaction, particularly for high-end leather products.

-

Logistics: Shipping and handling costs can vary dramatically based on the supplier’s location and the buyer’s destination. Factors such as transportation mode, distance, and customs duties should be considered when calculating total costs.

-

Margin: Manufacturers typically apply a markup to cover all costs and generate profit. This margin can vary based on competition, market demand, and the unique value proposition of the leather being sold.

What Influences Pricing for Wholesale Leather Orders?

Several factors can affect the pricing of leather sourced from manufacturers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for lower per-unit pricing. Understanding the MOQ can help buyers optimize their purchasing strategy to achieve cost savings.

-

Specifications and Customization: Custom orders may incur additional costs for specific requests, such as unique colors or finishes. Buyers should assess whether the benefits of customization align with their budget.

-

Quality and Certifications: Leather with specific certifications (e.g., eco-friendly tanning processes) may carry a premium price. Buyers should evaluate the importance of these certifications in relation to their target market.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance practices.

-

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is crucial for determining who bears the costs and risks during transportation. This can significantly impact the total cost of ownership.

How Can Buyers Negotiate Better Prices for Wholesale Leather?

To maximize value and achieve cost-efficiency, buyers should consider the following tips:

-

Leverage Volume Discounts: When feasible, consolidate orders to meet or exceed MOQs, as this often unlocks bulk pricing.

-

Conduct Market Research: Familiarize yourself with market prices for various leather types and qualities. This knowledge will empower you during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also factors like logistics, potential waste, and quality-related costs over the product’s lifespan.

-

Foster Supplier Relationships: Building long-term partnerships with suppliers can lead to better pricing, terms, and priority during high-demand periods.

-

Be Flexible with Specifications: If possible, remain open to alternative materials or finishes that may reduce costs without compromising quality.

Conclusion

Sourcing leather wholesale requires a comprehensive understanding of the cost structure and pricing influencers. By strategically navigating these factors, buyers from Africa, South America, the Middle East, and Europe can optimize their purchasing decisions, ensuring they receive high-quality materials at competitive prices. Always remember that prices can vary widely based on the discussed components, so engaging in thorough research and negotiation will be key to securing the best deals.

Alternatives Analysis: Comparing wholesale leather manufacturers With Other Solutions

Understanding the Alternatives to Wholesale Leather Manufacturers

As international B2B buyers explore sourcing options for leather products, it’s essential to consider alternatives to traditional wholesale leather manufacturers. These alternatives can provide different advantages, catering to varying business needs such as cost efficiency, customization, and supply chain flexibility. This section will compare wholesale leather manufacturers with alternative solutions to help buyers make informed decisions.

Comparison Table

| Comparison Aspect | Wholesale Leather Manufacturers | Leather Importers | Synthetic Leather Producers |

|---|---|---|---|

| Performance | High-quality, durable leather | Varies by supplier; often good quality | Consistent quality; less durable over time |

| Cost | Moderate to high, depending on type and quantity | Can be lower, especially with bulk orders | Generally lower initial cost |

| Ease of Implementation | Requires establishing relationships and minimum orders | Easier access; often no minimum orders | Simple sourcing through various retailers |

| Maintenance | Requires care and conditioning | Similar to wholesale; depends on quality | Low maintenance; easy to clean |

| Best Use Case | High-end products needing durability and luxury | Budget-conscious projects needing flexibility | Mass production of cost-effective goods |

In-Depth Analysis of Alternatives

Leather Importers

Leather importers serve as intermediaries, sourcing leather from various manufacturers globally. This method can provide buyers with access to diverse leather types at competitive prices. The primary advantage is flexibility, as importers often have no strict minimum order requirements, allowing businesses to test different leather types without significant upfront investment. However, the quality can vary widely based on the source, which may result in inconsistent material performance.

Synthetic Leather Producers

Synthetic leather, made from plastic compounds, offers a cost-effective alternative to traditional leather. This option is particularly attractive for businesses focused on sustainability or those operating within budget constraints. Synthetic leather is easier to clean and maintain, making it suitable for industries such as fashion and automotive where durability is essential. However, it often lacks the luxurious feel and longevity associated with genuine leather, which may be a critical factor for high-end brands.

Making the Right Choice for Your Leather Needs

Choosing the right leather solution depends on various factors, including your target market, product requirements, and budget. For businesses prioritizing quality and durability, wholesale leather manufacturers remain a strong choice, particularly for luxury goods. Conversely, leather importers can be a viable option for those needing flexibility and a broader range of materials at competitive prices. Lastly, for brands aiming to minimize costs or enhance sustainability, synthetic leather may be the ideal solution. By carefully evaluating these alternatives, B2B buyers can align their sourcing strategies with their specific operational goals and market demands.

Essential Technical Properties and Trade Terminology for wholesale leather manufacturers

What Are the Key Technical Properties for Wholesale Leather Manufacturers?

Understanding the technical properties of leather is crucial for B2B buyers in making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the quality and classification of leather hides based on factors such as texture, imperfections, and thickness. Common grades include full-grain, top-grain, and corrected grain. Full-grain leather, for instance, is the highest quality, retaining the natural grain and durability, making it ideal for high-end products. Recognizing these grades helps buyers ensure they meet their quality standards and customer expectations.

2. Tolerance

Tolerance in leather manufacturing indicates the acceptable range of variation in thickness, weight, and size of the leather hides. A typical tolerance range might be ±0.5 mm for thickness. Understanding these tolerances is vital for manufacturers to ensure that the leather fits the specifications of their final products, which helps in maintaining consistency and quality control.

3. Tannage Type

The tanning process affects the leather’s durability, flexibility, and appearance. Common tanning methods include chrome tanning and vegetable tanning. Chrome-tanned leather is often more water-resistant and softer, while vegetable-tanned leather is known for its eco-friendliness and natural look. Buyers should consider the intended application of the leather when choosing the tanning method, as it directly impacts product performance and sustainability.

4. Weight

Leather weight, typically measured in ounces per square foot or millimeters, plays a significant role in determining the leather’s suitability for various applications. For example, lighter leathers (1-3 oz) are preferable for garments, while heavier leathers (4 oz and above) are used for upholstery and luggage. Buyers need to assess weight specifications to match their product requirements and ensure they select the right type of leather for their projects.

5. Grain Type

Grain type describes the surface texture of the leather, influencing its aesthetic appeal and tactile feel. Common grain types include smooth, pebbled, and suede. Different grain types offer varying levels of durability and wear resistance, making it essential for buyers to understand how these characteristics align with their product design and functionality.

What Are Common Trade Terms in the Wholesale Leather Industry?

Familiarity with industry jargon is critical for effective communication and negotiation. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the leather industry, OEM relationships enable businesses to have their designs manufactured without investing in production facilities. Understanding OEM agreements can help buyers leverage partnerships for custom products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For leather manufacturers, MOQs can vary significantly based on the type of leather and supplier. Knowing the MOQ is crucial for buyers to plan their inventory and budget effectively, ensuring they do not overcommit financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific goods or services. In leather manufacturing, an RFQ typically includes details such as leather type, grade, and quantity. Buyers should prepare comprehensive RFQs to receive accurate quotes, aiding in price comparison and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping goods. Terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify who pays for shipping, insurance, and risk during transportation. Understanding these terms is essential for buyers to negotiate better shipping agreements and manage logistics effectively.

5. Leather Grades

Leather grades categorize hides based on their quality and characteristics, such as full-grain, top-grain, and corrected grain. Familiarity with these grades helps buyers choose the right materials for their specific applications, ensuring they meet both quality and cost expectations.

Illustrative image related to wholesale leather manufacturers

By understanding these technical properties and industry terms, B2B buyers can navigate the wholesale leather market more effectively, making informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the wholesale leather manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Wholesale Leather Manufacturing Sector?

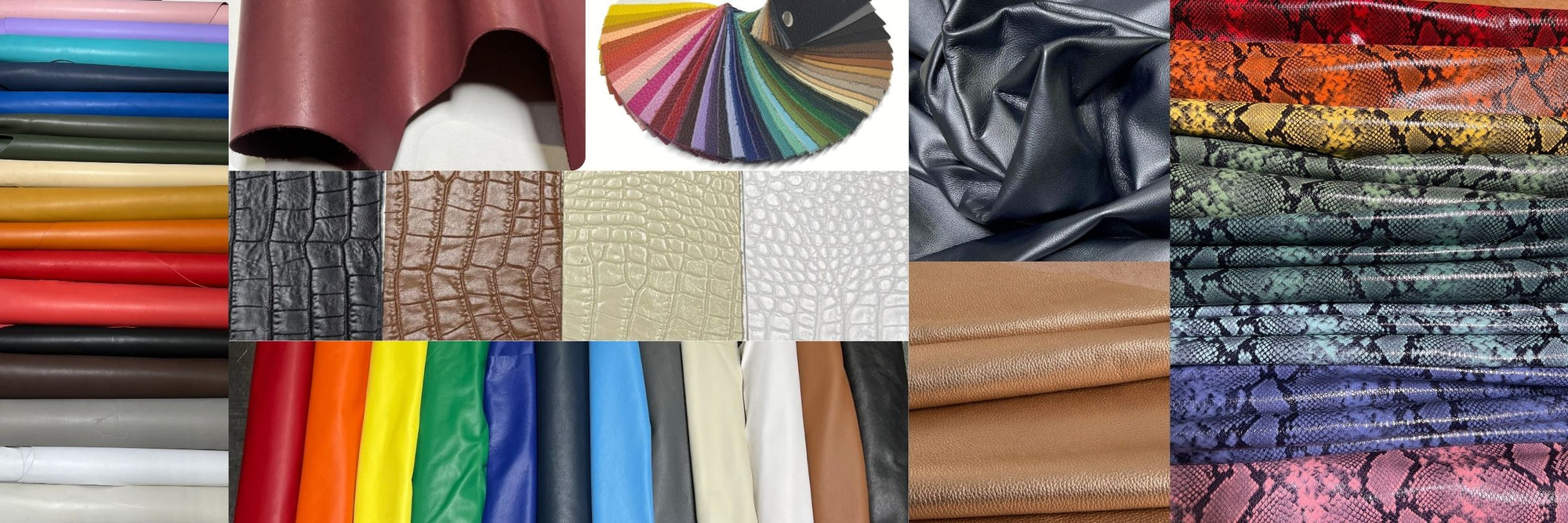

The wholesale leather manufacturing sector is currently experiencing a transformative phase influenced by several global drivers. The increasing demand for high-quality leather goods across various industries, including fashion, automotive, and furniture, is a significant market driver. With rising disposable incomes, particularly in emerging markets across Africa and South America, there is a growing appetite for premium leather products. Additionally, the Middle East and European markets, such as Saudi Arabia and Germany, continue to emphasize luxury and craftsmanship, further propelling demand.

Emerging B2B technologies are reshaping sourcing trends. Online platforms for bulk purchasing are gaining traction, allowing international buyers to access a broader range of products and suppliers quickly. Advanced analytics and AI-driven tools facilitate better supply chain management, enabling buyers to optimize inventory and reduce costs. Moreover, the rise of digital showrooms and virtual samples is enhancing product visualization, making it easier for buyers to make informed purchasing decisions.

Market dynamics are also influenced by geopolitical factors, trade agreements, and tariffs, which can affect pricing and availability. For instance, fluctuations in raw material costs and supply chain disruptions—exacerbated by global events—are key considerations for buyers. Understanding these dynamics is crucial for B2B buyers to navigate the complexities of sourcing leather effectively.

Illustrative image related to wholesale leather manufacturers

How Is Sustainability and Ethical Sourcing Impacting the Wholesale Leather Industry?

Sustainability and ethical sourcing are becoming paramount in the wholesale leather manufacturing sector. The environmental impact of leather production, particularly in terms of water consumption, waste generation, and chemical use, has led to increased scrutiny from consumers and regulatory bodies alike. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using vegetable-tanned leathers or implementing waste-reduction strategies.

Ethical supply chains are also gaining importance, with buyers seeking transparency in sourcing practices. This includes understanding the origins of raw materials and ensuring fair labor practices throughout the supply chain. Certifications such as the Leather Working Group (LWG) and ISO 14001 for environmental management systems are becoming essential for manufacturers looking to establish credibility in the market.

Moreover, the trend towards ‘green’ materials is on the rise, with suppliers exploring alternatives to traditional leather, such as mushroom leather or bio-based synthetics. These innovations not only address environmental concerns but also cater to a growing market segment that values sustainability. For international buyers, partnering with manufacturers that align with these values can enhance brand reputation and customer loyalty.

Illustrative image related to wholesale leather manufacturers

What Is the Evolution of the Wholesale Leather Manufacturing Sector?

The wholesale leather manufacturing sector has a rich history that reflects broader economic and cultural shifts. Initially rooted in traditional craftsmanship, the industry has evolved significantly over the decades. The advent of industrialization in the late 19th and early 20th centuries introduced mechanized processes, which increased production capacity and efficiency. This shift made leather more accessible, fueling the growth of various applications from fashion to automotive industries.

In recent years, globalization has further transformed the sector. The rise of international trade has enabled manufacturers to source raw materials from diverse regions, enhancing the variety and quality of leather available. Simultaneously, the digital revolution has introduced new business models, allowing for direct-to-consumer sales and online wholesale platforms, which are reshaping how buyers interact with suppliers.

Today, the sector stands at a crossroads, balancing traditional craftsmanship with modern demands for sustainability and ethical practices. This evolution underscores the importance for B2B buyers to stay informed about market trends and supplier capabilities to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of wholesale leather manufacturers

-

How do I choose the right wholesale leather manufacturer for my business?

Choosing the right wholesale leather manufacturer involves assessing several factors. Start by evaluating their product range, quality, and certifications (like ISO). Research their reputation through customer reviews and industry recommendations. Look for manufacturers that specialize in the type of leather you need, whether it’s for apparel, accessories, or upholstery. Additionally, consider their production capacity and ability to meet your volume requirements. Finally, communicate with potential suppliers to gauge their responsiveness and willingness to support your business needs. -

What is the typical minimum order quantity (MOQ) for wholesale leather?

Minimum order quantities for wholesale leather can vary widely depending on the manufacturer and the specific type of leather. Generally, MOQs range from 20 to 30 square meters or approximately 200 to 300 square feet. Some manufacturers may offer lower MOQs for certain products or sample orders, while others may require higher quantities for custom orders. Always confirm the MOQ with your chosen supplier before placing an order, as this can significantly impact your budget and inventory planning. -

What payment terms should I expect when sourcing wholesale leather?

Payment terms can vary among suppliers, but it’s common to encounter options such as advance payment, net 30, or net 60 days. Many manufacturers require a deposit (often 30-50%) upon order confirmation, with the balance due before shipping. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always discuss and agree on payment terms upfront to avoid misunderstandings that could delay your order. -

How can I ensure the quality of leather from a wholesale supplier?

To ensure quality, request samples of the leather before placing a bulk order. This allows you to assess the texture, finish, and durability. Additionally, inquire about the supplier’s quality assurance processes, including any certifications or testing they conduct. Establish clear quality standards in your purchase agreement, and consider conducting a factory audit if you’re sourcing from overseas. Regular communication with your supplier regarding quality expectations is also essential for long-term partnerships. -

What customization options are typically available from leather manufacturers?

Most wholesale leather manufacturers offer a range of customization options, including color, texture, thickness, and tanning methods. Some suppliers can accommodate specific requests for unique finishes or embossed patterns. When seeking customization, provide detailed specifications to your manufacturer, including samples if possible. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly to meet your production schedules. -

How do I handle logistics and shipping when sourcing leather internationally?

Logistics and shipping are critical components of international sourcing. Discuss shipping options with your supplier, including costs, delivery times, and methods (air freight vs. sea freight). Familiarize yourself with import regulations and duties in your country to avoid unexpected costs. Partnering with a reliable freight forwarder can help streamline the process and ensure compliance with all regulations. Also, consider insurance for your shipment to protect against loss or damage during transit. -

What are the best practices for vetting a wholesale leather supplier?

Vetting a wholesale leather supplier involves a thorough assessment of their credentials and capabilities. Start by checking their business registration and certifications. Look for industry affiliations and reviews from other buyers. Request references and follow up to gather feedback on their reliability and quality. Additionally, assess their communication responsiveness and willingness to accommodate your specific needs. A site visit or virtual tour of their facility can further enhance your confidence in their operations. -

How do I navigate international trade regulations when importing leather?

Navigating international trade regulations requires understanding both your home country’s and the supplier’s regulations. Research import duties, tariffs, and any specific certifications required for leather products in your region. Engage with customs brokers who can assist in paperwork and compliance. Stay informed about trade agreements that may affect tariffs. Ensure your supplier provides all necessary documentation, such as certificates of origin, to facilitate smooth customs clearance.

Top 9 Wholesale Leather Manufacturers Manufacturers & Suppliers List

1. Hide & Leather House – Leather Hides & Products

Domain: hidehouse.com

Registered: 1996 (29 years)

Introduction: The Hide & Leather House, Inc. offers a wide range of leather products including: 1. Leather Hides – Over 3,000 types in stock, including: – Bags & Personal Leather Gear – Belting & Strapping – Chap & Motorcycle Hides – Eco Friendly Tannage – Footwear & Shoe Hides – Garment Hides – Hair on Hides – Lining & Orthopedic Hides – Nonstock Leather Hides – Saddlery, Veg-Tan & Latigo Hides – Upholstery Hi…

2. United Leather – Cosmo Italian Pebble Cowhide

Domain: unitedleather.com

Registered: 2003 (22 years)

Introduction: Best Leather Hides Supplier | Shop Online | LA Headquarters. Product Categories: Cowhide, Lambskin, Novelty, Vegetable-Tanned, Suede & Nubuck, Shearling & Fur, Hair-On, Vegan. Price Ranges: Under $50, $50-$100, $100-$150, $150-$250, $250+. Featured Products: Cosmo Italian Pebble Cowhide – $160.00, Avalon Italian Pebble Cowhide – $160.00, DoubleFace Reversible Suede – $140.00, DoubleFace Smooth Rev…

3. Maverick Leather Company – Bulk Leather Solutions

Domain: maverickleathercompany.com

Registered: 2009 (16 years)

Introduction: Leather in Bulk & Wholesale Leather – Maverick Leather Company offers a variety of hides at competitive prices, ideal for businesses and high-volume leatherworkers. Key product details include:

1. **Leather Color Range**: Black, Brown, Burgundy, Blue, Gray, Green, Metallic, Natural, Orange, Pink, Purple, Red, Tan, White, Yellow.

2. **Leather Weight Options**: 1 oz / 0.4 mm, 2 oz / 0.8 mm, 3 oz /…

4. Buy Leather Online – Premium Italian Leather Hides

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Leather Wholesale: Buy premium Italian leather hides in bulk at unbeatable prices. Orders processed within 7 working days. Immediate discounts for bulk quantities (20-30m2). Custom productions available. Over 20,000 different kinds of leather. Features include various types (e.g., Aniline, Nappa, Suede), finishes, colors, thicknesses (1 oz to 14 oz), and firmness (soft, medium, hard). Sourced from…

5. Leather Unlimited – Wholesale Leather Supplier

Domain: leatherunltd.com

Registered: 2001 (24 years)

Introduction: This company, Leather Unlimited – Wholesale Leather Supplier, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Tandy Leather – Premium Leather Goods

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Premium Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Waterhouse Leather – Wholesale Leather Hides

Domain: waterhouseleather.com

Registered: 2006 (19 years)

Introduction: Wholesale Leather Skins and Leather Hides Supplier offers various categories of leather hides including: 1. New Leather – Recent offerings 2. Special & Closeout Leather – Lowest prices 3. Popular Leather – Most popular hides 4. Hides by Application: Upholstery, Belt & Strap, Handbag, Wallet, Patch & Badge, Journal & Book-covering, Holster, Knife Sheath, Laser Engraving, Carving & Tooling, Embossin…

8. RM Leather Supply – Premium Leather Products

Domain: rmleathersupply.com

Registered: 2014 (11 years)

Introduction: Free shipping on all orders in the USA; worldwide shipping with discounted rates; processing time of 2-4 business days; over 10,000 products available; free leather splitting service; various leather types including vegetable tanned, chrome tanned, and exotics; leather available by hide type (e.g., alligator, cowhide, calfskin); leather available by cut (e.g., bellies, butts, whole hides); product…

9. Hillside Leather – Wholesale Motorcycle Gear

Domain: hillsideusa.com

Registered: 2007 (18 years)

Introduction: Hillside Leather is a direct manufacturer of wholesale leather goods, offering a range of products including motorcycle jackets, vests, chaps, gloves, and armbands. They use high-grade leathers such as cowhide and horsehide, with features like polytwill shell lining, Thinsulate zip-out liners, and YKK zippers. Minimum order requirements are $500 for initial orders and $100 for re-orders, with a 15…

Strategic Sourcing Conclusion and Outlook for wholesale leather manufacturers

In the rapidly evolving landscape of wholesale leather manufacturing, strategic sourcing emerges as a cornerstone for international buyers aiming to enhance their supply chain efficiency and product quality. As markets in Africa, South America, the Middle East, and Europe continue to expand, understanding the nuances of sourcing leather—such as the significance of material provenance, supplier reliability, and pricing structures—becomes critical. By prioritizing partnerships with reputable manufacturers, buyers can secure premium materials that align with their brand ethos while also capitalizing on cost efficiencies through bulk purchasing.

Moreover, engaging with suppliers who offer customized solutions and diverse product ranges can empower businesses to meet specific market demands and consumer preferences. The future of the leather industry lies in sustainable practices and innovative designs, making it essential for buyers to stay ahead of trends and consumer expectations.

As you consider your next sourcing decisions, remember to leverage the wealth of options available to you. Connect with established suppliers and explore tailored solutions that can elevate your product offerings. The potential for growth is immense—take the first step today towards a more sustainable and profitable leather supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to wholesale leather manufacturers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.