Introduction: Navigating the Global Market for sueded microfiber fabric

In the dynamic landscape of fabric sourcing, navigating the global market for sueded microfiber fabric can present significant challenges for B2B buyers. With its combination of durability, aesthetic appeal, and ease of maintenance, sueded microfiber is increasingly sought after for applications ranging from upholstery to fashion. However, understanding the nuances of this material—such as its varying types, quality standards, and cost implications—can be daunting, especially for international buyers in regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany.

This comprehensive guide serves as a vital resource for B2B buyers, illuminating the multifaceted world of sueded microfiber fabric. It delves into the various types available on the market, their diverse applications, and the crucial factors to consider when vetting suppliers. Additionally, it offers insights into pricing structures, helping buyers make informed purchasing decisions that align with their business needs.

By equipping buyers with actionable insights and strategies, this guide empowers them to confidently navigate their sourcing challenges, ensuring they select the right materials that meet both quality and budgetary requirements. Whether you are looking to enhance your product offerings or streamline your procurement process, understanding the intricacies of sueded microfiber fabric will position your business for success in today’s competitive marketplace.

Table Of Contents

- Top 7 Sueded Microfiber Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for sueded microfiber fabric

- Understanding sueded microfiber fabric Types and Variations

- Key Industrial Applications of sueded microfiber fabric

- 3 Common User Pain Points for ‘sueded microfiber fabric’ & Their Solutions

- Strategic Material Selection Guide for sueded microfiber fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for sueded microfiber fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘sueded microfiber fabric’

- Comprehensive Cost and Pricing Analysis for sueded microfiber fabric Sourcing

- Alternatives Analysis: Comparing sueded microfiber fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for sueded microfiber fabric

- Navigating Market Dynamics and Sourcing Trends in the sueded microfiber fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sueded microfiber fabric

- Strategic Sourcing Conclusion and Outlook for sueded microfiber fabric

- Important Disclaimer & Terms of Use

Understanding sueded microfiber fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microfiber Suede | Soft texture; resembles real suede; dense fiber structure | Upholstery, clothing, accessories | Pros: Durable, stain-resistant; Cons: Can be less breathable than natural fabrics. |

| Heavy-Duty Microsuede | Thicker weave; high abrasion resistance; vegan-friendly | Commercial upholstery, automotive seats | Pros: Long-lasting, ideal for high-traffic areas; Cons: May be pricier than standard options. |

| Water-Resistant Microsuede | Treated for water resistance; smooth finish | Outdoor furniture, activewear | Pros: Easy to clean, suitable for various environments; Cons: Limited color options. |

| Vintage Microsuede | Distressed look; soft hand feel; medium-weight | Home décor, cushions, tablecloths | Pros: Unique aesthetic; Cons: May require special care. |

| Ultrasuede | High-performance microfiber; luxurious feel; eco-friendly | Luxury upholstery, fashion accessories | Pros: Exceptional durability and stain resistance; Cons: Higher cost compared to other microsuedes. |

What Are the Characteristics of Microfiber Suede Fabric?

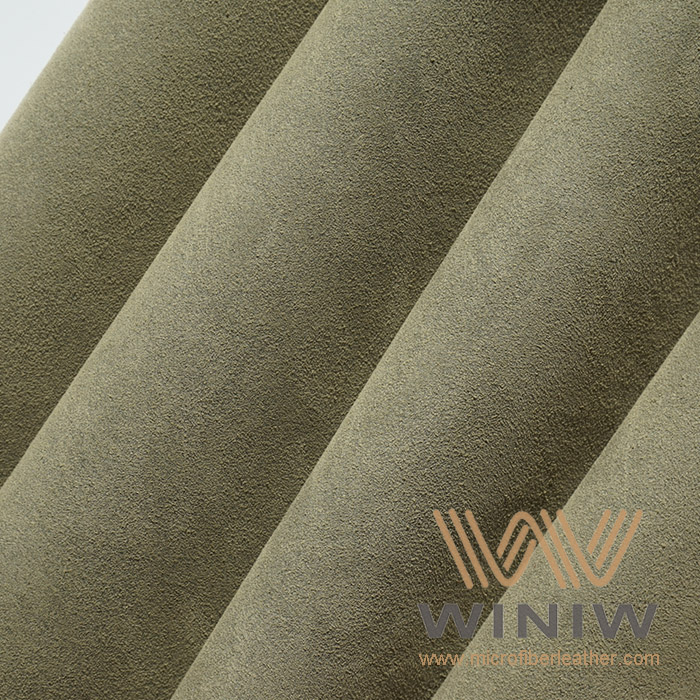

Microfiber suede, often referred to simply as microsuede, is a synthetic fabric crafted from ultra-fine polyester or nylon fibers. Its soft texture closely mimics that of genuine suede while providing enhanced durability and ease of maintenance. This fabric is particularly suitable for upholstery projects, clothing, and accessories, making it a versatile choice for B2B buyers. When sourcing microfiber suede, consider factors such as fiber density and weight, as these can affect the fabric’s durability and performance in various applications.

How Does Heavy-Duty Microsuede Differ from Regular Microsuede?

Heavy-duty microsuede features a thicker weave that offers increased abrasion resistance, making it ideal for commercial upholstery and automotive applications. This fabric is vegan-friendly, providing a sustainable alternative to traditional suede. B2B buyers should prioritize heavy-duty options for high-traffic areas or environments where spills are common. While it may come at a higher price point, its longevity often justifies the investment, especially in demanding settings.

Illustrative image related to sueded microfiber fabric

What Advantages Does Water-Resistant Microsuede Offer?

Water-resistant microsuede is specially treated to repel moisture, making it an excellent choice for outdoor furniture and activewear. This variation maintains the soft feel of traditional microsuede while providing added functionality. When purchasing, B2B buyers should assess the level of water resistance and ease of cleaning, as these factors are crucial for maintaining the fabric’s appearance and longevity in challenging environments. However, color options may be limited compared to standard microsuede.

What Is Unique About Vintage Microsuede?

Vintage microsuede is characterized by its distinct distressed look, offering a unique aesthetic appeal for home décor projects. Its medium weight and soft hand make it suitable for cushions, tablecloths, and other decorative items. Buyers interested in vintage microsuede should consider the care requirements, as this fabric may need special treatment to preserve its appearance. The stylish design can enhance the value of finished products, appealing to consumers looking for something unique.

Why Choose Ultrasuede for High-End Applications?

Ultrasuede is a high-performance microfiber that combines luxury with exceptional durability. This eco-friendly fabric is often used in luxury upholstery and fashion accessories due to its soft feel and high resistance to stains and wear. B2B buyers should consider Ultrasuede for projects that demand both aesthetic appeal and practicality. While it typically comes at a premium price, its long-term performance and low maintenance requirements can provide significant value over time.

Illustrative image related to sueded microfiber fabric

Key Industrial Applications of sueded microfiber fabric

| Industry/Sector | Specific Application of Sueded Microfiber Fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas, chairs, and headboards | Durable, stain-resistant, and low maintenance fabric | Ensure high abrasion resistance and color fastness |

| Automotive | Interior car upholstery and trim | Enhances aesthetic appeal while being easy to clean | Compliance with automotive standards and fire resistance |

| Fashion & Apparel | Jackets, skirts, and accessories | Offers luxurious look at a competitive price point | Consider fabric weight and stretchability for garment design |

| Home Textiles | Decorative pillows, cushions, and bedding | Soft texture adds comfort while being easy to maintain | Availability in various colors and patterns for customization |

| Hospitality | Upholstery for hotel furniture and decor | Combines elegance with durability for high-traffic areas | Sourcing from suppliers with proven quality and stain resistance |

How is Sueded Microfiber Fabric Utilized in Furniture Manufacturing?

In the furniture manufacturing sector, sueded microfiber fabric is extensively used for upholstery on sofas, chairs, and headboards. Its soft and luxurious feel mimics real suede while offering superior durability and stain resistance. This fabric is particularly advantageous in high-traffic environments, such as homes with children or pets, where maintenance is a concern. International buyers, especially from regions like Africa and South America, should prioritize suppliers that offer high abrasion resistance and color fastness to ensure longevity and aesthetic appeal.

What Role Does Sueded Microfiber Fabric Play in the Automotive Industry?

The automotive industry employs sueded microfiber fabric for interior car upholstery and trim, providing a stylish yet practical solution. This fabric enhances the vehicle’s aesthetic while being easy to clean, which is crucial for maintaining a pristine interior. For B2B buyers in the automotive sector, especially in the Middle East and Europe, it is essential to source materials that comply with automotive safety standards, including fire resistance and durability, to meet consumer expectations and regulatory requirements.

How is Sueded Microfiber Fabric Transforming Fashion & Apparel?

In the fashion and apparel industry, sueded microfiber fabric is favored for making jackets, skirts, and accessories due to its luxurious appearance at a more affordable price than genuine suede. This fabric provides designers with the flexibility to create stylish pieces without compromising on comfort or usability. For international fashion buyers, particularly from Germany and other European countries, it is vital to consider fabric weight and stretchability to ensure the garments meet market demands and consumer preferences.

Illustrative image related to sueded microfiber fabric

What are the Benefits of Using Sueded Microfiber Fabric in Home Textiles?

Sueded microfiber fabric is widely used in home textiles for decorative pillows, cushions, and bedding, where its soft texture adds comfort and elegance. The ease of maintenance makes it a practical choice for homeowners and designers alike. For B2B buyers in regions like Africa and South America, sourcing fabric in various colors and patterns is key to catering to diverse consumer tastes, ensuring that products stand out in a competitive market.

How is Sueded Microfiber Fabric Enhancing Hospitality Spaces?

In the hospitality sector, sueded microfiber fabric is used for upholstering hotel furniture and decor, combining elegance with durability to withstand high-traffic use. This fabric’s stain-resistant properties are particularly beneficial in environments where spills are common. Buyers in the hospitality industry should focus on sourcing from suppliers known for quality and resilience, ensuring that the fabric can endure rigorous cleaning and maintain its aesthetic appeal over time.

3 Common User Pain Points for ‘sueded microfiber fabric’ & Their Solutions

Scenario 1: Difficulty in Maintaining Color Consistency Across Batches

The Problem: B2B buyers often face challenges in maintaining consistent color quality when ordering ‘sueded microfiber fabric’ for large-scale upholstery projects. Due to variations in dye lots during production, a buyer may receive batches that do not match in shade, leading to aesthetic discrepancies that can be costly in terms of time and resources. This issue is particularly pronounced when sourcing from different suppliers or when reordering fabric after some time has passed, as even slight color variations can result in a mismatched final product.

The Solution: To ensure color consistency, buyers should establish a strong relationship with a single supplier who can guarantee dye lot control and transparency. Request fabric swatches before placing bulk orders, and use these swatches as a reference for future orders. Additionally, consider implementing a system where samples are labeled with dye lot numbers, allowing for easier tracking and consistency checks. When placing orders, specify that the fabric should come from the same dye lot to reduce the risk of color mismatches. Lastly, maintain open communication with the supplier regarding any upcoming projects and their specific color requirements, enabling them to prepare accordingly.

Scenario 2: Concerns About Durability and Wear Resistance in High-Traffic Areas

The Problem: Many B2B buyers are tasked with sourcing upholstery materials that will withstand heavy use in commercial settings, such as hotels or offices. The concern with ‘sueded microfiber fabric’ often revolves around its durability and ability to resist wear and tear over time. Buyers worry that lower-quality microfiber fabrics may not hold up against the rigors of daily use, leading to premature replacement and increased costs.

Illustrative image related to sueded microfiber fabric

The Solution: When selecting ‘sueded microfiber fabric’, buyers should prioritize materials with high abrasion resistance ratings, typically measured by the Wyzenbeek test. Look for fabrics rated for over 30,000 double rubs, which indicates they can withstand significant wear. Additionally, inquire about the fabric’s cleaning and maintenance properties; stain-resistant treatments can enhance longevity. Before making a purchase, request samples to test in the intended environment, evaluating their performance under actual conditions. Collaborating with suppliers who offer warranties or guarantees on their products can also provide peace of mind regarding durability.

Scenario 3: Navigating the Complexities of Fabric Specifications and Compliance

The Problem: B2B buyers often encounter challenges related to understanding and meeting the specific fabric specifications required for different applications. This is especially true when dealing with ‘sueded microfiber fabric’, where various attributes such as weight, texture, and fire resistance can impact compliance with industry standards. Buyers may feel overwhelmed by the technical jargon and the necessity to ensure that the fabric meets all necessary regulations.

The Solution: To navigate this complexity, buyers should invest time in understanding the essential specifications for their intended use. Familiarize yourself with industry standards and regulations relevant to your market—whether it’s fire safety codes for hospitality or durability standards for commercial use. Engage directly with fabric manufacturers or suppliers who can provide detailed specifications and guidance. Request comprehensive product data sheets and ask for assistance in interpreting them. Establishing a checklist of required attributes for the project can streamline the selection process. Additionally, consider collaborating with an experienced fabric consultant or interior designer who can help ensure that the chosen materials comply with all necessary specifications and enhance the overall design.

Strategic Material Selection Guide for sueded microfiber fabric

What Are the Key Materials Used in Sueded Microfiber Fabric?

Sueded microfiber fabric is primarily made from synthetic fibers, predominantly polyester and nylon. These materials are engineered to mimic the look and feel of genuine suede while offering enhanced durability and ease of maintenance. Below, we analyze several common materials used in the production of sueded microfiber fabric, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polyester in Sueded Microfiber Fabric?

Polyester is one of the most common materials used in sueded microfiber fabric. It is known for its excellent strength and resistance to shrinking and stretching. Polyester fibers can withstand a wide range of temperatures, making them suitable for various climates, from the humid conditions of Africa to the colder climates in Europe.

Illustrative image related to sueded microfiber fabric

Pros: Polyester is durable, lightweight, and resistant to wrinkles and mildew. It is also relatively inexpensive compared to other fibers, making it a cost-effective choice for manufacturers.

Cons: While polyester is robust, it can be less breathable than natural fibers, which may affect comfort in warmer environments. Additionally, it may not be as environmentally friendly due to its synthetic nature.

Impact on Application: Polyester’s durability makes it ideal for high-traffic upholstery applications, such as furniture and automotive interiors. Its stain-resistant properties also make it suitable for households with pets or children.

Illustrative image related to sueded microfiber fabric

How Does Nylon Contribute to the Performance of Sueded Microfiber Fabric?

Nylon is another key material in sueded microfiber fabric, known for its exceptional strength and elasticity. It is often blended with polyester to enhance the fabric’s overall performance.

Pros: Nylon offers high abrasion resistance, making it suitable for applications that require durability. It is also lightweight and has a natural sheen, contributing to the luxurious appearance of the fabric.

Cons: Nylon can be more expensive than polyester and may require more complex manufacturing processes. Additionally, it is prone to static buildup, which can be a concern in certain applications.

Impact on Application: The combination of nylon and polyester in sueded microfiber fabric results in a soft, luxurious feel that is perfect for upscale furniture and fashion applications. It is also suitable for outdoor use when treated for UV resistance.

Illustrative image related to sueded microfiber fabric

What Role Does the Fabric Weave Play in Sueded Microfiber Fabric?

The weave of the fabric significantly influences its texture and performance. Sueded microfiber typically features a dense, plush weave that mimics the soft feel of genuine suede.

Pros: A tight weave enhances durability and resistance to wear, making the fabric suitable for upholstery and other high-use applications. The plush texture also adds an aesthetic appeal.

Cons: Tighter weaves can increase manufacturing complexity and cost. Additionally, they may limit breathability, which can be a disadvantage in warmer climates.

Illustrative image related to sueded microfiber fabric

Impact on Application: The plush texture created by the weave makes it ideal for decorative pillows and cushions, where comfort and aesthetics are paramount. It can also be used in fashion applications, such as jackets and accessories.

What Are the Considerations for International B2B Buyers of Sueded Microfiber Fabric?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards, such as ASTM, DIN, or JIS, when sourcing sueded microfiber fabric. Additionally, preferences for eco-friendly materials are growing, and buyers may want to inquire about the sustainability of the materials used. Factors such as shipping costs and tariffs should also be taken into account, as these can significantly impact the overall cost of procurement.

Summary Table of Material Properties

| Material | Typical Use Case for Sueded Microfiber Fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Upholstery, automotive interiors, home decor | Durable, stain-resistant, cost-effective | Less breathable, less eco-friendly | Low |

| Nylon | Fashion, upscale upholstery, outdoor applications | High abrasion resistance, luxurious feel | More expensive, prone to static | Medium |

| Fabric Weave | Decorative pillows, cushions, fashion items | Soft texture, aesthetic appeal | Increased manufacturing complexity | Medium |

This guide provides a comprehensive overview of the materials used in sueded microfiber fabric, helping international B2B buyers make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for sueded microfiber fabric

What Are the Key Stages in the Manufacturing Process of Sueded Microfiber Fabric?

The manufacturing of sueded microfiber fabric involves several critical stages, each designed to ensure the final product meets the expected quality and performance standards. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the production of sueded microfiber fabric is the preparation of raw materials, primarily ultra-fine polyester or nylon fibers. These fibers are selected for their softness and durability. The material is then subjected to a dyeing process where color is infused into the fibers, ensuring uniformity. This step is crucial as it affects the aesthetic appeal and colorfastness of the final product.

Forming

Once the fibers are prepared, they undergo a weaving or knitting process to form the fabric. In the case of microfiber, the fibers are densely woven to create a soft texture that mimics the feel of genuine suede. Techniques such as warp knitting or circular knitting are often employed to enhance the fabric’s strength and flexibility. This stage is vital for ensuring that the fabric maintains its shape and durability through various applications.

Assembly

In this stage, the fabric may be cut and sewn into specific products, such as upholstery, clothing, or decorative items. The assembly process may involve additional treatments, like applying water-repellent coatings or enhancing the fabric’s stain resistance. Quality checks are often integrated during this phase to ensure that the cut pieces conform to the desired specifications.

Finishing

The final stage involves a series of finishing processes, including brushing, heat-setting, and applying any additional coatings. Brushing the fabric helps create the soft, suede-like texture that is characteristic of microsuede. Heat-setting ensures that the fabric retains its shape and structural integrity. This stage also may include final quality assessments to verify that the product meets all design and performance criteria.

How Is Quality Assurance Implemented in Sueded Microfiber Fabric Production?

Quality assurance (QA) is a critical component of the manufacturing process for sueded microfiber fabric. Adhering to international and industry-specific standards ensures that the fabric produced is of high quality and safe for consumers.

International Standards for Quality Assurance

One of the most recognized international quality management systems is ISO 9001. Compliance with ISO 9001 ensures that manufacturers have established processes for consistent quality, from raw material sourcing to final product delivery. Additionally, certifications such as CE mark for safety and environmental compliance are crucial for products marketed in Europe.

Industry-Specific Standards

For specialized applications, suppliers may need to comply with industry-specific standards like the American Petroleum Institute (API) for products used in oil and gas applications or various textile-specific standards that assess performance attributes like durability and safety.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is vital at several checkpoints throughout the manufacturing process. These checkpoints ensure that any deviations from quality standards are identified and rectified promptly.

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting the raw materials upon arrival at the manufacturing facility. Quality inspectors evaluate the fibers for defects, color consistency, and compliance with specified standards. This is crucial, as the quality of raw materials directly influences the final product.

In-Process Quality Control (IPQC)

During the forming and assembly phases, IPQC procedures are implemented to monitor the production process. This may include real-time inspections of fabric texture, strength tests, and color matching. Regular checks ensure that any inconsistencies are addressed immediately, minimizing waste and rework.

Illustrative image related to sueded microfiber fabric

Final Quality Control (FQC)

At the end of the manufacturing process, FQC involves comprehensive testing of the finished fabric. Tests may include abrasion resistance, colorfastness, and overall durability assessments. This stage is essential for verifying that the product meets the agreed specifications before it is shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is vital for ensuring product reliability.

Conducting Audits

Buyers should consider conducting on-site audits of potential suppliers. These audits can provide insights into the manufacturing processes, quality control measures, and overall operational efficiency. A thorough audit can reveal whether the supplier adheres to international and industry-specific standards.

Requesting Quality Control Reports

Buyers can request QC reports from suppliers, which should detail the results of IQC, IPQC, and FQC tests. These documents can offer assurance regarding the quality of the fabric and the supplier’s commitment to maintaining high standards.

Illustrative image related to sueded microfiber fabric

Engaging Third-Party Inspectors

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can perform random checks and testing to ensure that the products meet the required specifications before shipment.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances that can impact their purchasing decisions. Understanding these factors can enhance the buyer-supplier relationship and reduce risks.

Cultural and Regulatory Differences

Buyers should be aware of cultural differences that may affect communication and expectations regarding quality. Additionally, regulatory requirements vary by region; for example, products sold in the European Union must comply with stringent safety and environmental regulations, which may not be as rigorous in other regions.

Supply Chain Considerations

Buyers should consider the entire supply chain when assessing quality control. Issues such as transportation conditions, storage facilities, and handling practices can all impact the quality of the final product. Ensuring that suppliers maintain quality throughout the supply chain is essential.

Illustrative image related to sueded microfiber fabric

Long-Term Relationships with Suppliers

Building long-term relationships with suppliers can enhance trust and transparency regarding quality control practices. Regular communication, feedback, and collaborative problem-solving can improve product quality and ensure that both parties are aligned on expectations.

By understanding the manufacturing processes and quality assurance practices involved in sueded microfiber fabric production, B2B buyers can make informed decisions, ensuring that they select suppliers who deliver high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sueded microfiber fabric’

In the competitive landscape of sourcing sueded microfiber fabric, international B2B buyers must navigate a myriad of options and suppliers. This practical sourcing guide provides a step-by-step checklist to ensure that you procure high-quality materials that meet your specific needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining your requirements for the sueded microfiber fabric. This includes determining the fabric’s weight, texture, color, and intended application (e.g., upholstery, clothing, or accessories). Having precise specifications helps you communicate effectively with suppliers and ensures that the fabric meets your performance and aesthetic needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in sueded microfiber fabric. Look for manufacturers with a solid reputation and positive reviews from other B2B buyers. Utilize online platforms, trade directories, and industry-specific forums to gather information about their reliability and product offerings.

Illustrative image related to sueded microfiber fabric

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold relevant certifications that ensure quality and compliance with industry standards. Certifications such as ISO 9001 for quality management and OEKO-TEX for safety can indicate a supplier’s commitment to excellence. This step mitigates risks associated with substandard materials and unethical practices.

Step 4: Request Samples

Always request fabric samples from shortlisted suppliers before placing a bulk order. This allows you to assess the fabric’s quality, texture, and color accuracy firsthand. Pay attention to details such as weight, softness, and durability, as these factors are crucial for the fabric’s intended use.

Step 5: Inquire About Customization Options

Check if the supplier offers customization options that align with your project needs. This could include specific colors, patterns, or finishes that may not be available in their standard inventory. Customization can enhance the uniqueness of your final product and give you a competitive edge in your market.

Step 6: Assess Pricing and Payment Terms

Compare pricing among different suppliers, but do not base your decision solely on cost. Evaluate the total value offered, including fabric quality and supplier reliability. Additionally, clarify payment terms, including deposits, payment methods, and any potential discounts for bulk orders, to ensure a smooth transaction process.

Step 7: Establish Clear Communication Channels

Ensure that you have established clear communication channels with your chosen supplier. Discuss timelines, delivery schedules, and potential challenges upfront. A supplier who is responsive and transparent can significantly enhance your sourcing experience and help you manage any issues that may arise during the procurement process.

Illustrative image related to sueded microfiber fabric

By following this checklist, B2B buyers can make informed decisions when sourcing sueded microfiber fabric, ensuring that they receive high-quality materials that meet their specific requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for sueded microfiber fabric Sourcing

What Are the Key Cost Components in Sourcing Sueded Microfiber Fabric?

When sourcing sueded microfiber fabric, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, primarily polyester or nylon fibers, constitutes a significant portion of the total expense. Prices can vary based on fiber quality and market fluctuations.

-

Labor: Labor costs are incurred during the manufacturing process, including cutting, sewing, and finishing. In regions with higher wage standards, such as Europe, labor costs will be higher compared to regions like Africa or South America.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce these costs, impacting the final price.

-

Tooling: Investment in specialized machinery or tools required for production can affect pricing. Custom tooling may be necessary for unique fabric patterns or specifications.

-

Quality Control (QC): Ensuring high standards through quality checks incurs additional costs but is crucial for maintaining fabric integrity. Certifications such as ISO can influence QC expenses.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, vary significantly based on the origin and destination of the fabric. Buyers should factor in logistics, especially when sourcing from international suppliers.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary widely based on supplier reputation and market demand.

How Do Volume and Customization Influence Pricing of Sueded Microfiber Fabric?

Volume and Minimum Order Quantities (MOQs) play a critical role in pricing. Suppliers often provide discounts for bulk orders, making it economically viable for buyers to purchase larger quantities. On the other hand, smaller orders may incur higher per-yard costs due to fixed costs associated with production.

Customization options, such as specific colors, patterns, or finishes, can also affect pricing. Custom orders may require additional setup and processing time, leading to higher costs. Buyers should evaluate whether the added value of customization justifies the expense.

Illustrative image related to sueded microfiber fabric

What Are the Influencing Factors on Pricing for International B2B Buyers?

Several factors can influence the pricing of sueded microfiber fabric for international buyers:

-

Quality and Certifications: Fabrics that meet higher quality standards or possess certifications can command higher prices. Buyers should assess the importance of quality certifications based on their end-use requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to attract business.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms dictate who is responsible for shipping costs, insurance, and customs duties, directly affecting the overall cost.

What Are the Best Negotiation Strategies for Cost-Efficiency?

To achieve cost-efficiency when sourcing sueded microfiber fabric, buyers should consider the following negotiation strategies:

-

Leverage Volume Discounts: When possible, consolidate orders to meet or exceed MOQs for better pricing. This approach can lead to significant savings.

-

Request Samples: Before placing a large order, request samples to assess quality. This step helps avoid potential costs associated with poor-quality materials.

-

Explore Multiple Suppliers: Engage with various suppliers to compare prices and terms. This competitive approach can provide leverage during negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the fabric, including maintenance and durability. A higher upfront cost may yield savings over time if the fabric proves more durable and easier to maintain.

What Should Buyers Keep in Mind About Pricing Nuances in Different Regions?

B2B buyers from different regions, such as Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances. Currency fluctuations, local tariffs, and transportation costs can vary significantly across regions. Additionally, cultural factors and local market conditions may influence supplier pricing strategies.

Disclaimer on Indicative Prices

Prices for sueded microfiber fabric can vary widely based on the factors discussed above. Buyers are encouraged to conduct thorough market research and obtain quotes from multiple suppliers to ensure they receive competitive pricing.

Alternatives Analysis: Comparing sueded microfiber fabric With Other Solutions

Introduction to Alternatives in Fabric Solutions

When selecting upholstery fabrics for B2B applications, businesses often face the challenge of choosing between various materials that meet their performance, aesthetic, and budgetary requirements. Sueded microfiber fabric has gained popularity due to its unique combination of luxury and practicality. However, other alternatives also exist, each offering distinct advantages and disadvantages. This analysis compares sueded microfiber fabric with two viable alternatives: genuine suede and synthetic leather, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Sueded Microfiber Fabric | Genuine Suede | Synthetic Leather |

|---|---|---|---|

| Performance | Durable, stain-resistant, soft feel | Soft, luxurious but less durable | Highly durable, water-resistant |

| Cost | Affordable, typically lower price | Expensive, premium pricing | Mid-range pricing |

| Ease of Implementation | Readily available, easy to work with | Requires special care and handling | Easy to cut and sew |

| Maintenance | Easy to clean, machine washable | Requires regular conditioning | Easy to wipe clean |

| Best Use Case | High-traffic areas, furniture, apparel | Luxury furniture, fashion items | Automotive upholstery, casual furniture |

Detailed Breakdown of Alternatives

Genuine Suede

Genuine suede is a natural leather product made from the underside of animal hides. Its softness and luxurious appearance make it a favored choice for high-end furniture and fashion. However, genuine suede is considerably more expensive than sueded microfiber and requires meticulous care to maintain its appearance. Stains can be challenging to remove, and it is less resistant to wear and tear, making it less suitable for high-traffic environments. While it offers unparalleled aesthetic appeal, the maintenance demands and cost can be prohibitive for many businesses.

Illustrative image related to sueded microfiber fabric

Synthetic Leather

Synthetic leather, often referred to as faux leather or vegan leather, is made from various materials, typically polyurethane or PVC. It presents a highly durable option that is water-resistant and easy to clean, making it ideal for environments like automotive upholstery or casual furniture. The cost of synthetic leather falls within the mid-range, making it more accessible than genuine suede but potentially more expensive than sueded microfiber. While it lacks the soft texture of suede, it compensates with its durability and ease of maintenance, positioning it as a practical choice for businesses prioritizing longevity.

Conclusion: Choosing the Right Fabric Solution

Selecting the appropriate fabric for upholstery or apparel hinges on the specific needs and constraints of the project. Sueded microfiber fabric stands out for its affordability, ease of care, and versatility, making it ideal for high-traffic areas or environments with pets and children. In contrast, genuine suede offers unmatched luxury at a higher cost and maintenance requirement, while synthetic leather provides durability and ease of cleaning but sacrifices some of the plush aesthetics. B2B buyers should assess their budget, target application, and maintenance capabilities to determine which fabric solution aligns best with their project goals.

Essential Technical Properties and Trade Terminology for sueded microfiber fabric

What Are the Key Technical Properties of Sueded Microfiber Fabric?

When sourcing sueded microfiber fabric for various applications, understanding its technical properties is crucial for B2B buyers. Here are some essential specifications to consider:

-

Material Composition

Sueded microfiber fabric is primarily made from ultra-fine polyester or nylon fibers. This synthetic composition allows the fabric to mimic the luxurious feel of genuine suede while offering enhanced durability. For B2B buyers, this means selecting materials that provide a balance between aesthetics and functionality, particularly in high-traffic environments. -

Weight and Thickness

The weight of sueded microfiber fabric is typically measured in grams per square meter (g/m²). For instance, a heavier fabric (around 250 g/m²) is often more durable and suitable for upholstery applications that experience significant wear. Understanding weight is vital for buyers to ensure the fabric meets the demands of its intended use, such as furniture or clothing. -

Abrasion Resistance

Abrasion resistance is commonly tested using the Wyzenbeek method, which measures how many double rubs the fabric can withstand before showing signs of wear. A higher rating (e.g., 50,000 double rubs) indicates superior durability, making it ideal for upholstery in commercial settings or households with pets. For B2B buyers, this property assures long-lasting quality and reduces the need for frequent replacements. -

Cleaning and Maintenance Codes

Cleaning codes provide guidelines on how to maintain the fabric effectively. For example, a “W” cleaning code indicates the fabric can be cleaned with water-based solutions, making it user-friendly for end customers. B2B buyers should prioritize fabrics with easy care instructions to enhance customer satisfaction and reduce maintenance costs. -

Color Fastness

Color fastness refers to the fabric’s resistance to fading or running when exposed to light or washing. Fabrics with high color fastness ratings ensure that the aesthetic appeal remains intact over time, which is particularly important in decorative applications. Buyers should consider this property to ensure the longevity of their products. -

Environmental Considerations

Many sueded microfiber fabrics are produced as vegan alternatives, which appeals to environmentally conscious consumers. Understanding the environmental impact of the fabric, including its recyclability and the sustainability of its production, is increasingly important for buyers looking to align with eco-friendly practices.

What Are Common Trade Terms Related to Sueded Microfiber Fabric?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in the B2B sector. Here are some key trade terms to know:

Illustrative image related to sueded microfiber fabric

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand. Understanding OEM relationships can help buyers identify potential suppliers for custom fabric solutions. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of fabric that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to plan their budgets and inventory effectively, especially when sourcing fabric for large projects. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from multiple suppliers for specific products or services. Utilizing RFQs can help buyers secure competitive pricing and favorable terms in their procurement processes. -

Incoterms (International Commercial Terms)

These are a set of globally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping costs, risks, and delivery obligations, ensuring smooth international trade. -

DWR (Durable Water Repellent)

This term indicates that the fabric has been treated to resist water penetration, making it suitable for applications where moisture exposure is a concern. Buyers should consider DWR-treated fabrics for products intended for outdoor use or in environments prone to spills. -

Sample Swatch

A sample swatch is a small piece of fabric provided to buyers for evaluation before making a larger purchase. Requesting swatches allows buyers to assess the fabric’s texture, color, and quality, ensuring it meets their project specifications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing sueded microfiber fabric, ultimately leading to successful procurement and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the sueded microfiber fabric Sector

What Are the Current Market Dynamics and Key Trends in the Sueded Microfiber Fabric Sector?

The global market for sueded microfiber fabric is experiencing robust growth, driven by rising consumer demand for sustainable, durable, and versatile materials. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that can offer high-quality microfiber options for various applications, including upholstery, fashion, and automotive industries. The growing trend towards eco-friendly alternatives to traditional materials has led to innovations in production processes, allowing for the creation of synthetic fabrics that closely mimic the luxurious feel of genuine suede while providing enhanced durability and ease of maintenance.

Emerging technologies in textile manufacturing, such as digital printing and automated cutting, are also reshaping the sourcing landscape. These advancements enable suppliers to offer a wider range of colors and patterns, catering to the diverse preferences of international buyers. Additionally, the rise of e-commerce platforms has facilitated easier access to global suppliers, allowing B2B buyers to compare options and source materials more efficiently. As a result, the sueded microfiber fabric sector is poised for continued expansion, particularly as buyers prioritize suppliers who can meet their demands for quality and sustainability.

How Is Sustainability and Ethical Sourcing Influencing the Sueded Microfiber Fabric Market?

Sustainability is becoming a pivotal consideration for B2B buyers in the sueded microfiber fabric sector. The environmental impact of textile production, including water usage, chemical runoff, and waste generation, has prompted a shift towards ethical sourcing practices. Buyers are increasingly looking for suppliers who can provide transparency in their supply chains and demonstrate a commitment to sustainable practices.

Illustrative image related to sueded microfiber fabric

Certifications such as Global Recycled Standard (GRS) and OEKO-TEX® Standard 100 are becoming essential for establishing credibility in the market. These certifications ensure that the materials used in the production of microfiber fabrics are sourced responsibly, with minimal environmental impact. Additionally, the use of recycled polyester in the production of sueded microfiber fabric is gaining traction, as it not only reduces waste but also appeals to eco-conscious consumers.

For B2B buyers, partnering with manufacturers who prioritize sustainability can enhance their brand reputation and appeal to a growing segment of environmentally aware consumers. This trend is particularly pronounced in regions like Europe, where regulatory frameworks increasingly mandate sustainable practices across industries.

What Is the Historical Context of Sueded Microfiber Fabric Development?

Sueded microfiber fabric has evolved significantly since its introduction in the late 20th century. Originally developed as a synthetic alternative to traditional suede, its unique properties—such as softness, durability, and ease of care—quickly gained popularity in various sectors, including upholstery and fashion. The fabric is typically made from ultra-fine polyester or nylon fibers, which are woven densely to create a plush texture.

Over the years, advancements in textile technology have led to improvements in the manufacturing processes, allowing for the production of high-quality microfiber fabrics at a lower cost. As environmental awareness increased, the focus shifted towards sustainable practices, paving the way for innovations such as the use of recycled materials. Today, sueded microfiber fabric stands as a testament to the blend of luxury and practicality, catering to the evolving needs of B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of sueded microfiber fabric

-

How do I ensure the quality of sueded microfiber fabric before purchase?

To ensure quality, request samples from potential suppliers. Examine the fabric’s texture, weight, and color consistency. Look for certifications indicating compliance with international standards, such as OEKO-TEX or ISO. Conduct a quality assurance check by assessing the fabric’s durability, stain resistance, and washability. Establish clear communication with suppliers about your quality expectations and ask for references from other clients to gauge their reliability. -

What are the best applications for sueded microfiber fabric in my industry?

Sueded microfiber fabric is highly versatile and can be used in various applications, including upholstery for furniture, automotive interiors, and fashion accessories. Its soft texture and durability make it ideal for high-traffic areas, while its stain-resistant properties suit environments where spills are common. Additionally, it can be used for decorative items like cushions and throws, offering a luxurious aesthetic at an affordable price. -

What should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, consider your cash flow needs and the supplier’s payment policies. Common terms include 30, 60, or 90 days after delivery, but you may also negotiate partial upfront payments for large orders. Ensure that the terms are documented in your purchase agreement and clarify conditions for late payments or discounts for early payments. Always assess the supplier’s financial stability to minimize risk. -

How can I customize sueded microfiber fabric for my specific needs?

Customization options may include selecting specific colors, patterns, or finishes. Many suppliers offer the ability to create bespoke designs based on your specifications, which can involve minimum order quantities (MOQs). Discuss your needs with the supplier to understand their capabilities and lead times. Be prepared to provide detailed design files and samples to ensure the final product meets your expectations. -

What are typical minimum order quantities (MOQs) for sueded microfiber fabric?

MOQs can vary widely depending on the supplier and the specific fabric type. Typically, you may encounter MOQs ranging from 50 to 500 yards. Smaller suppliers might accommodate lower quantities, but prices per yard could be higher. Always inquire about MOQs upfront and consider consolidating orders with other buyers to meet supplier requirements while optimizing costs. -

How do I vet suppliers of sueded microfiber fabric for international trade?

Start by researching potential suppliers through trade directories and industry networks. Check their online presence, customer reviews, and case studies. Request references from existing clients and verify their production capabilities. Additionally, assess their compliance with international trade regulations and quality certifications. If possible, conduct a site visit or arrange for third-party audits to evaluate their facilities. -

What logistics considerations should I keep in mind when importing sueded microfiber fabric?

Logistics involve understanding shipping options, customs regulations, and duties applicable to your region. Choose a reliable freight forwarder with experience in fabric imports. Consider the lead times for production and shipping to avoid delays in your supply chain. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices and certificates of origin. -

How can I manage quality assurance during the production of my order?

Establish a quality assurance plan that includes regular communication with your supplier throughout the production process. Schedule inspections at various stages, such as pre-production, during manufacturing, and before shipment. Utilize third-party inspection services if necessary, especially for large orders. Document all findings and maintain a clear line of communication to address any issues promptly.

Top 7 Sueded Microfiber Fabric Manufacturers & Suppliers List

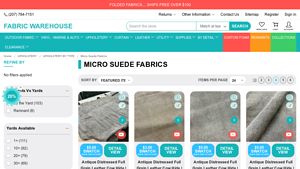

1. Fabric Warehouse – MicroSuede Upholstery Fabrics

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: MicroSuede Fabrics for Upholstery, available in various colors including Beige, Black, Blue, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver, Tan. Fabric weights include Extra Heavy Weight, Heavy Weight, Lightweight, Medium/Heavyweight, Medium Weight. Designs available in Printed and Woven, with patterns such as Abstract, Animal Print, Argyle, Geometric, Paisley, and Soli…

2. Top Fabric – Vintage Heavy Suede Upholstery Fabric

Domain: topfabric.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Vintage – Heavy Suede, Microsuede Upholstery Fabric”, “price”: “$18.99”, “original_price”: “$29.99”, “color_options”: [“Antique Rose”, “Black”, “Buck Skin”, “Camel”, “Canary”, “Caramel”, “Celery”, “Charcoal”, “Chinese Red”, “Chocolate”, “Cinnabar”, “Cloud”, “Copper”, “Cream”, “Denim Blue”, “Earth”, “Espresso”, “Fawn”, “Gold”, “Green Bay”, “Herb”, “Hunter Green”, “Jalapeno”, “Khak…

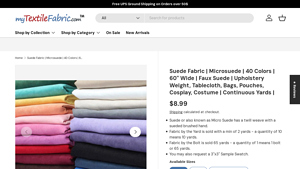

3. My Textile Fabric – Suede Fabric | Microsuede

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Suede Fabric | Microsuede”, “Colors Available”: 40, “Width”: “60 inches”, “Type”: “Faux Suede”, “Uses”: [“Upholstery”, “Tablecloth”, “Bags”, “Pouches”, “Cosplay”, “Costume”], “Price”: “$8.99 per yard”, “Minimum Order”: “2 yards”, “Bolt Size”: “65 yards”, “Sample Swatch Size”: “3×3 inches”, “Fabric Weight”: “Approximately 225 grams per square meter”, “Fabric Content”: “100% Polyes…

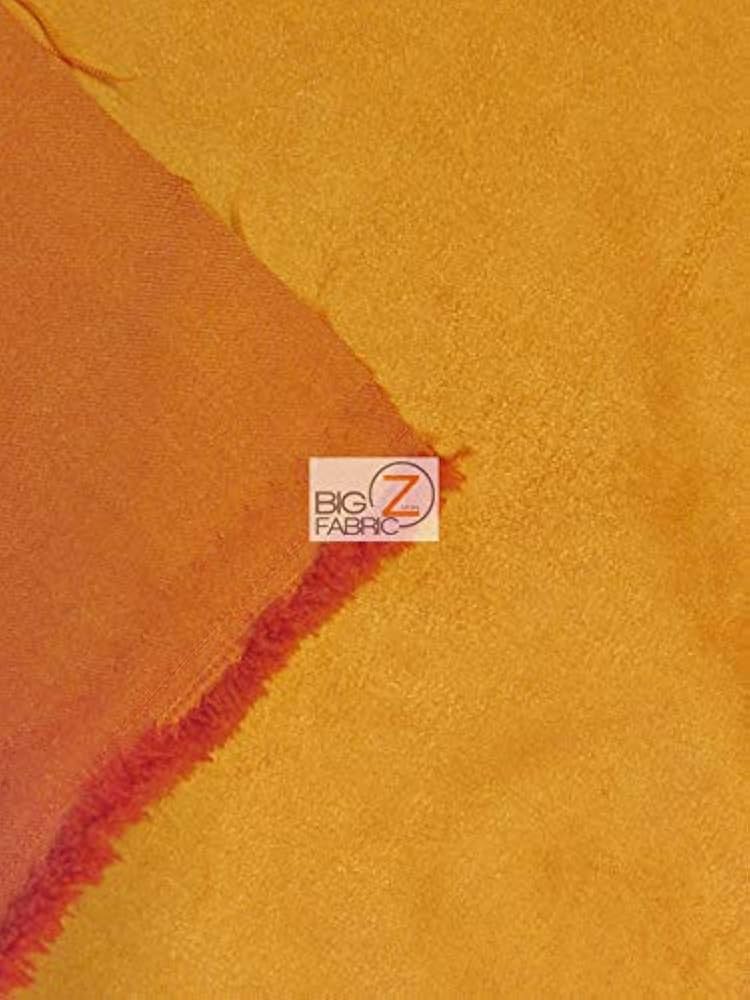

4. Big Z Fabric – Microfiber vs. Real Suede

Domain: blog.bigzfabric.com

Registered: 2010 (15 years)

Introduction: Microfiber Suede: Crafted from synthetic fibers like polyester or nylon; affordable; durable and resistant to wear and tear; easy to clean and maintain, often machine washable; better water resistance; hypoallergenic. Real Suede Fabric: Derived from the inner layer of animal hides (cows, sheep, goats); more expensive; luxurious appearance; durable but requires careful maintenance; sensitive to wat…

5. Seattle Fabrics – 60 Micro Suede Polyester DWR

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “60” Micro Suede Polyester DWR”, “Price”: “$10.95/linear yard”, “Part Number”: “FSILM”, “Material”: “100% polyester microfiber”, “Finish”: “Soft sanded finish”, “Water Resistance”: “Durable Water Resistant (DWR)”, “Fabric Width”: “58/59 inches”, “Construction”: “155 x 88 Yarns”, “Yarn Size”: “75D x 150D”, “Total Weight”: “3.99 ounces per square yard”, “Available Colors”: [“Burgund…

6. Kovi Fabrics – Microfiber Suede Upholstery Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: This company, Kovi Fabrics – Microfiber Suede Upholstery Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Fabric Wholesale Direct – Microsuede Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: Microsuede Fabric By The Yard | Free Shipping On Orders $99+

Strategic Sourcing Conclusion and Outlook for sueded microfiber fabric

As the demand for versatile and sustainable upholstery solutions continues to rise, sueded microfiber fabric stands out as a prime choice for international B2B buyers. Its combination of durability, easy maintenance, and luxurious feel makes it an attractive alternative to genuine suede, especially in regions where affordability and practicality are key considerations. Strategic sourcing of this fabric can lead to significant cost savings and enhanced product offerings, particularly for businesses in Africa, South America, the Middle East, and Europe.

Engaging with reliable suppliers who offer high-quality microsuede fabrics in a range of colors and textures is essential. This not only ensures that your projects meet customer expectations but also positions your brand as a leader in the sustainable fabric market. By leveraging the unique properties of sueded microfiber, businesses can cater to diverse applications—from upholstery to fashion—while appealing to eco-conscious consumers.

Looking ahead, the market for sueded microfiber fabric is poised for growth. Now is the time for international buyers to explore partnerships with manufacturers and distributors that prioritize innovation and sustainability. Invest in sueded microfiber today to elevate your product line and meet the evolving demands of the global marketplace.

Illustrative image related to sueded microfiber fabric

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.