Introduction: Navigating the Global Market for pvc garments

In today’s fast-evolving fashion landscape, sourcing high-quality PVC garments presents a unique set of challenges for international B2B buyers, particularly those operating in diverse markets such as Nigeria, Saudi Arabia, and various regions across Africa, South America, and Europe. With the increasing demand for stylish yet durable apparel, understanding the nuances of PVC fabric—its types, applications, and manufacturing processes—becomes crucial. This guide serves as a comprehensive resource, addressing critical aspects such as supplier vetting, cost analysis, and market trends, ensuring that buyers can navigate the complexities of the global PVC garment market with confidence.

The versatility of PVC garments, ranging from fashionable clothing to protective gear, has made them essential across multiple industries. However, the key to successful procurement lies in discerning reliable suppliers and understanding pricing structures in different regions. This guide empowers B2B buyers by equipping them with actionable insights and strategies for making informed purchasing decisions. By exploring the characteristics of various PVC fabrics, potential applications, and supplier qualifications, buyers can effectively align their sourcing strategies with their business objectives. Whether you are looking to enhance your product offerings or seeking durable materials for specialized applications, this guide is designed to support your journey in the dynamic world of PVC garments.

Table Of Contents

- Top 4 Pvc Garments Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pvc garments

- Understanding pvc garments Types and Variations

- Key Industrial Applications of pvc garments

- 3 Common User Pain Points for ‘pvc garments’ & Their Solutions

- Strategic Material Selection Guide for pvc garments

- In-depth Look: Manufacturing Processes and Quality Assurance for pvc garments

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc garments’

- Comprehensive Cost and Pricing Analysis for pvc garments Sourcing

- Alternatives Analysis: Comparing pvc garments With Other Solutions

- Essential Technical Properties and Trade Terminology for pvc garments

- Navigating Market Dynamics and Sourcing Trends in the pvc garments Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pvc garments

- Strategic Sourcing Conclusion and Outlook for pvc garments

- Important Disclaimer & Terms of Use

Understanding pvc garments Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Coated Woven Fabric | Durable, weather-resistant, strong | Outdoor gear, tarpaulins, tents | Pros: High durability, excellent weather resistance. Cons: Heavier than non-woven options. |

| Transparent PVC Fabric | Clear, flexible, allows visibility | Raincoats, bags, protective covers | Pros: Aesthetic appeal, lightweight. Cons: Less durable than coated options. |

| Laminated PVC Fabric | Multiple layers for enhanced strength | Industrial applications, upholstery | Pros: Superior durability, waterproof. Cons: Can be rigid and less flexible. |

| Embossed PVC Fabric | Textured surfaces for decorative purposes | Fashion items, upholstery | Pros: Unique designs, maintains durability. Cons: Texture may affect cleaning. |

| Flame Retardant PVC Fabric | Treated for fire resistance | Protective clothing, public safety gear | Pros: Essential for safety compliance. Cons: May have higher production costs. |

What Are the Characteristics of PVC Coated Woven Fabric?

PVC coated woven fabric is renowned for its durability and strength, making it suitable for outdoor applications such as tarpaulins and tents. The woven base provides structural integrity, while the PVC layer enhances resistance to weather and wear. B2B buyers should consider this fabric for products requiring robust performance in harsh environments. Its heavier weight may be a drawback for some applications, but its long-lasting nature often outweighs this concern.

How Does Transparent PVC Fabric Stand Out?

Transparent PVC fabric is characterized by its clear, flexible nature, allowing visibility while providing protection. This type is commonly used in raincoats, bags, and protective covers where aesthetics and functionality are essential. B2B buyers in the fashion and accessory industries may find this material appealing for its lightweight properties. However, it is important to note that its durability may not match that of coated options, making it less suitable for heavy-duty applications.

What Are the Advantages of Laminated PVC Fabric?

Laminated PVC fabric consists of multiple layers bonded with PVC film, resulting in a sturdy textile ideal for industrial uses. Its combination of strength, waterproofing, and abrasion resistance makes it a favored choice for upholstery and heavy-duty applications. B2B buyers should consider the weight and rigidity of this fabric, as it may not be as flexible as other options. However, its superior durability makes it a reliable choice for long-term investments.

Why Choose Embossed PVC Fabric for Fashion?

Embossed PVC fabric features textured surfaces created by pressing patterns into the coated material, making it popular for decorative applications in fashion and upholstery. This type offers unique designs while maintaining the durability associated with PVC. B2B buyers should weigh the aesthetic appeal against potential challenges in cleaning, as the texture may trap dirt. This fabric is ideal for businesses looking to combine style with functionality.

What Makes Flame Retardant PVC Fabric Essential?

Flame retardant PVC fabric is treated to resist ignition and slow the spread of fire, making it crucial for protective clothing and safety gear in public spaces. B2B buyers in industries requiring compliance with safety standards should prioritize this material for its protective qualities. While it may come with higher production costs, the safety benefits and potential liability reduction make it a wise investment for businesses focused on workplace safety.

Key Industrial Applications of pvc garments

| Industry/Sector | Specific Application of PVC Garments | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Protective Clothing (e.g., gowns, aprons) | Ensures hygiene and safety in medical environments | Compliance with health regulations, durability, and ease of cleaning |

| Food Processing | Waterproof and Stain-resistant Gear | Protects workers from contaminants and moisture | FDA compliance, material safety, and availability of sizes |

| Fashion and Entertainment | Costumes and Fashion Apparel | Offers unique designs and durability for events | Trend alignment, customization options, and fabric quality |

| Outdoor and Sports Equipment | Weather-resistant Clothing | Provides protection against elements for outdoor activities | UV resistance, breathability, and weight considerations |

| Industrial and Manufacturing | Heavy-duty Workwear | Ensures worker safety and durability in harsh environments | Compliance with safety standards, material thickness, and abrasion resistance |

How Are PVC Garments Utilized in Healthcare Settings?

In the healthcare sector, PVC garments such as gowns and aprons are essential for maintaining hygiene and safety. These garments protect healthcare workers from exposure to bodily fluids and contaminants, significantly reducing the risk of infection. Buyers in this industry must ensure that the garments comply with health regulations and are made from durable materials that can withstand frequent cleaning and sterilization processes.

What Role Do PVC Garments Play in Food Processing?

In food processing, waterproof and stain-resistant PVC garments are critical for worker safety. They prevent moisture and contaminants from coming into contact with food products, thereby maintaining hygiene standards. B2B buyers in this sector should prioritize sourcing materials that comply with FDA regulations, ensuring that the garments are safe for food-related applications. Additionally, the garments should be available in various sizes to accommodate different body types.

How Are PVC Garments Used in Fashion and Entertainment?

The fashion and entertainment industries leverage PVC garments for creating striking costumes and apparel that stand out in events and performances. These garments offer unique design possibilities, combining aesthetics with durability. Buyers should focus on sourcing PVC fabrics that align with current fashion trends and provide customization options. The quality of the fabric is crucial, as it impacts both the visual appeal and the garment’s longevity.

Why Are PVC Garments Important for Outdoor and Sports Equipment?

For outdoor and sports applications, weather-resistant PVC garments play a vital role in protecting wearers from harsh environmental conditions. These garments are designed to be lightweight yet robust, ensuring comfort and safety during activities. Buyers in this market should consider factors such as UV resistance and breathability when sourcing PVC garments, as these features enhance performance and user experience.

How Do PVC Garments Contribute to Industrial and Manufacturing Safety?

In industrial and manufacturing settings, heavy-duty PVC workwear is essential for ensuring worker safety. These garments are designed to withstand tough conditions while providing protection from chemicals and abrasions. B2B buyers must ensure that the sourced garments comply with relevant safety standards, focusing on material thickness and abrasion resistance to ensure maximum protection for workers in demanding environments.

3 Common User Pain Points for ‘pvc garments’ & Their Solutions

Scenario 1: Sourcing Quality PVC Garments Amidst Quality Variations

The Problem: B2B buyers often face challenges when sourcing PVC garments due to the significant variations in quality. In many cases, suppliers may offer garments that appear similar but differ in durability, flexibility, and water resistance. This inconsistency can lead to customer dissatisfaction, increased returns, and ultimately harm the buyer’s reputation. Additionally, buyers in regions like Africa and South America may have limited access to reliable suppliers who can provide high-quality products that meet international standards.

The Solution: To effectively source high-quality PVC garments, buyers should prioritize working with reputable suppliers who have a proven track record. Conduct thorough research by looking for manufacturers with certifications such as ISO or those recognized by international textile standards. Consider requesting samples before placing bulk orders to assess the garment’s quality firsthand. It’s also advisable to establish clear specifications regarding the desired properties of the PVC garments, including thickness, coating type, and intended use. Engaging in regular communication with suppliers about quality expectations can help ensure that the garments meet the required standards consistently.

Scenario 2: Addressing Environmental Concerns Related to PVC Garments

The Problem: With increasing awareness of environmental issues, B2B buyers are often concerned about the sustainability of PVC garments. The production and disposal of PVC can have negative environmental impacts, leading to hesitation in placing orders. Buyers in the Middle East and Europe, in particular, are under pressure to adopt eco-friendly practices and seek out materials that align with sustainability goals. This creates a dilemma when choosing PVC garments, which are traditionally viewed as less environmentally friendly.

The Solution: To navigate these concerns, buyers should seek out suppliers that prioritize sustainable practices in their PVC production processes. This includes using recycled PVC, implementing environmentally friendly manufacturing techniques, and providing transparent information about the lifecycle of their products. Buyers can also explore alternative materials that mimic the properties of PVC but offer better environmental profiles, such as bio-based or biodegradable options. It is essential to communicate sustainability requirements clearly to suppliers and evaluate their commitment to eco-friendly practices through certifications or third-party audits.

Scenario 3: Ensuring Proper Care and Maintenance of PVC Garments

The Problem: Another common pain point for B2B buyers is the lack of clear guidance on the care and maintenance of PVC garments. Improper handling can lead to premature wear and damage, resulting in costly replacements and dissatisfied customers. This issue is particularly prevalent in sectors like fashion retail and event planning, where garments are frequently used and require regular maintenance.

The Solution: Buyers should request detailed care instructions from their suppliers upon purchasing PVC garments. This information should cover cleaning methods, storage recommendations, and tips for prolonging the life of the garments. Additionally, providing training for staff on how to properly care for PVC clothing can significantly reduce damage rates. As an added measure, buyers can invest in protective coatings or treatments that enhance the durability and water resistance of PVC garments, making them easier to maintain. Establishing a regular maintenance schedule can also help ensure that garments remain in optimal condition, ultimately saving costs and improving customer satisfaction.

Strategic Material Selection Guide for pvc garments

What Are the Key Materials Used in PVC Garments?

When selecting materials for PVC garments, it is crucial to understand the properties, advantages, and limitations of various fabric types. This analysis focuses on three common materials used in the production of PVC garments: PVC-coated polyester, PVC-coated cotton, and transparent PVC. Each material has unique characteristics that influence its application in the garment industry.

1. PVC-Coated Polyester

Key Properties: PVC-coated polyester combines the durability of polyester with the protective qualities of PVC. It offers excellent water resistance, UV stability, and abrasion resistance, making it suitable for outdoor garments and protective clothing.

Pros & Cons: The primary advantage of PVC-coated polyester is its high durability and resistance to environmental factors. It is lightweight and maintains its shape well. However, the manufacturing process can be complex and may involve higher costs compared to other materials. Additionally, polyester may not be as breathable, which could affect comfort in warmer climates.

Impact on Application: This material is ideal for garments requiring durability and protection from moisture, such as raincoats and outdoor jackets. Its compatibility with various weather conditions makes it a preferred choice for international markets, especially in regions with diverse climates.

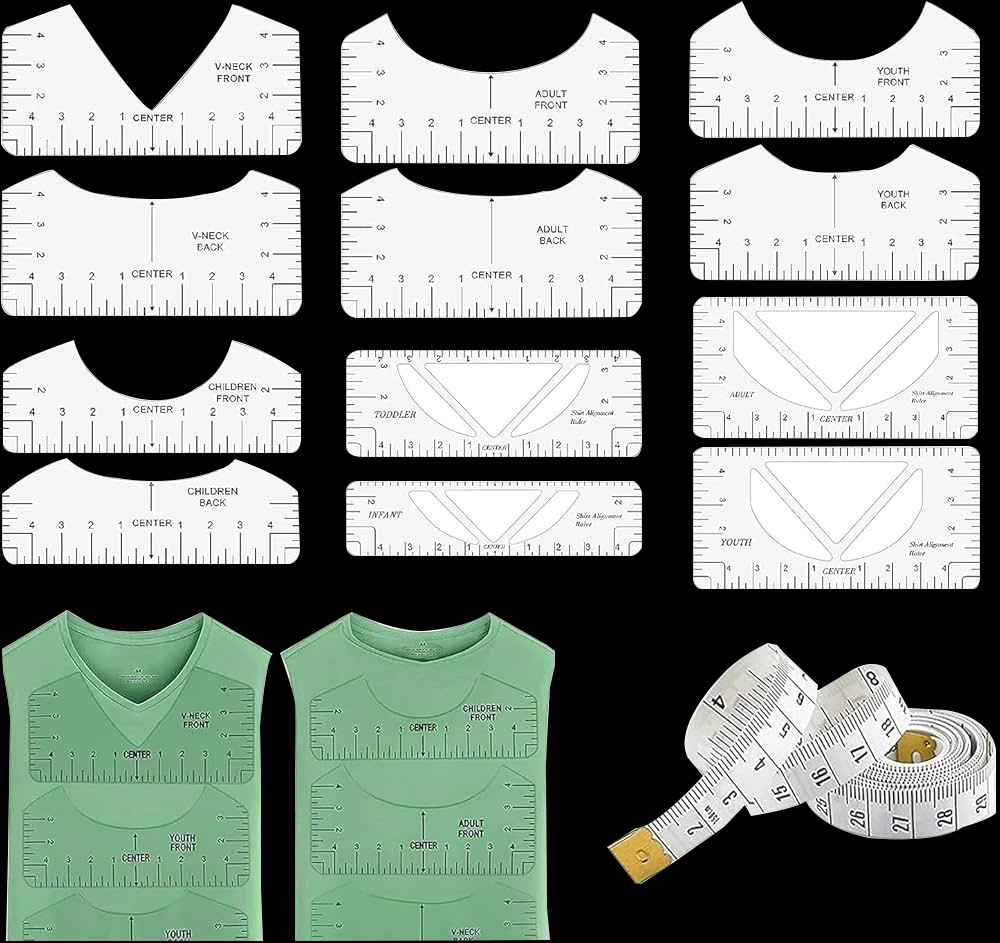

Illustrative image related to pvc garments

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local standards such as ASTM or DIN. Additionally, understanding the environmental regulations regarding synthetic materials is essential, as some regions may have restrictions on PVC use.

2. PVC-Coated Cotton

Key Properties: PVC-coated cotton offers a blend of natural fiber comfort with the protective qualities of PVC. This combination provides a softer feel while maintaining decent water resistance and durability.

Pros & Cons: The key advantage of PVC-coated cotton is its comfort and breathability, making it suitable for casual wear and lighter garments. However, it may not be as durable as polyester, especially in harsh conditions. The cost can also be higher due to the quality of cotton used.

Impact on Application: This material is particularly effective for fashion-oriented PVC garments where comfort is prioritized, such as stylish rain jackets or trendy outerwear. It is less suited for heavy-duty applications but works well in urban markets.

Considerations for International Buyers: Buyers should be aware of the sourcing of cotton and the potential for compliance with organic standards. Additionally, understanding the local market’s preference for natural fibers may influence purchasing decisions.

Illustrative image related to pvc garments

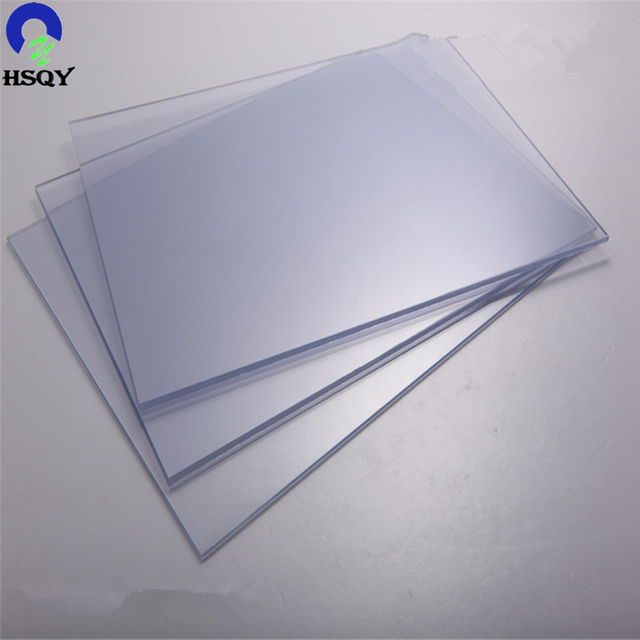

3. Transparent PVC

Key Properties: Transparent PVC is a flexible and versatile material that provides visibility while maintaining durability and water resistance. It is typically used in fashion applications where aesthetics are essential.

Pros & Cons: The primary advantage of transparent PVC is its unique visual appeal, allowing for creative designs in garments like raincoats and accessories. However, it may lack the breathability of other materials, which could limit comfort in prolonged wear. Additionally, its rigidity can restrict movement in fitted garments.

Impact on Application: Transparent PVC is ideal for fashion-forward applications, particularly in regions where unique styles are in demand. It is popular in urban fashion markets and can be used for statement pieces.

Considerations for International Buyers: Buyers should consider local fashion trends and the demand for unique materials. Compliance with safety standards is crucial, especially in regions with strict regulations regarding plastic materials.

Summary Table of Material Selection for PVC Garments

| Material | Typical Use Case for PVC Garments | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC-Coated Polyester | Raincoats, outdoor jackets | High durability and water resistance | Higher manufacturing complexity | Medium |

| PVC-Coated Cotton | Casual wear, stylish rain jackets | Comfort and breathability | Less durable in harsh conditions | High |

| Transparent PVC | Fashion garments, accessories | Unique visual appeal | Limited breathability and flexibility | Medium |

Understanding these materials’ properties and implications can empower B2B buyers to make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc garments

What Are the Main Stages of Manufacturing PVC Garments?

The manufacturing of PVC garments is a multi-stage process that ensures the final product meets the quality and durability standards expected by B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves selecting the appropriate PVC material. This typically includes a base textile such as polyester or nylon that is coated with polyvinyl chloride (PVC) resin. The selection of additives, such as plasticizers for flexibility and stabilizers for UV resistance, is crucial. This stage may also include color matching and sourcing of additional materials, such as zippers or buttons, which will be integrated into the final product.

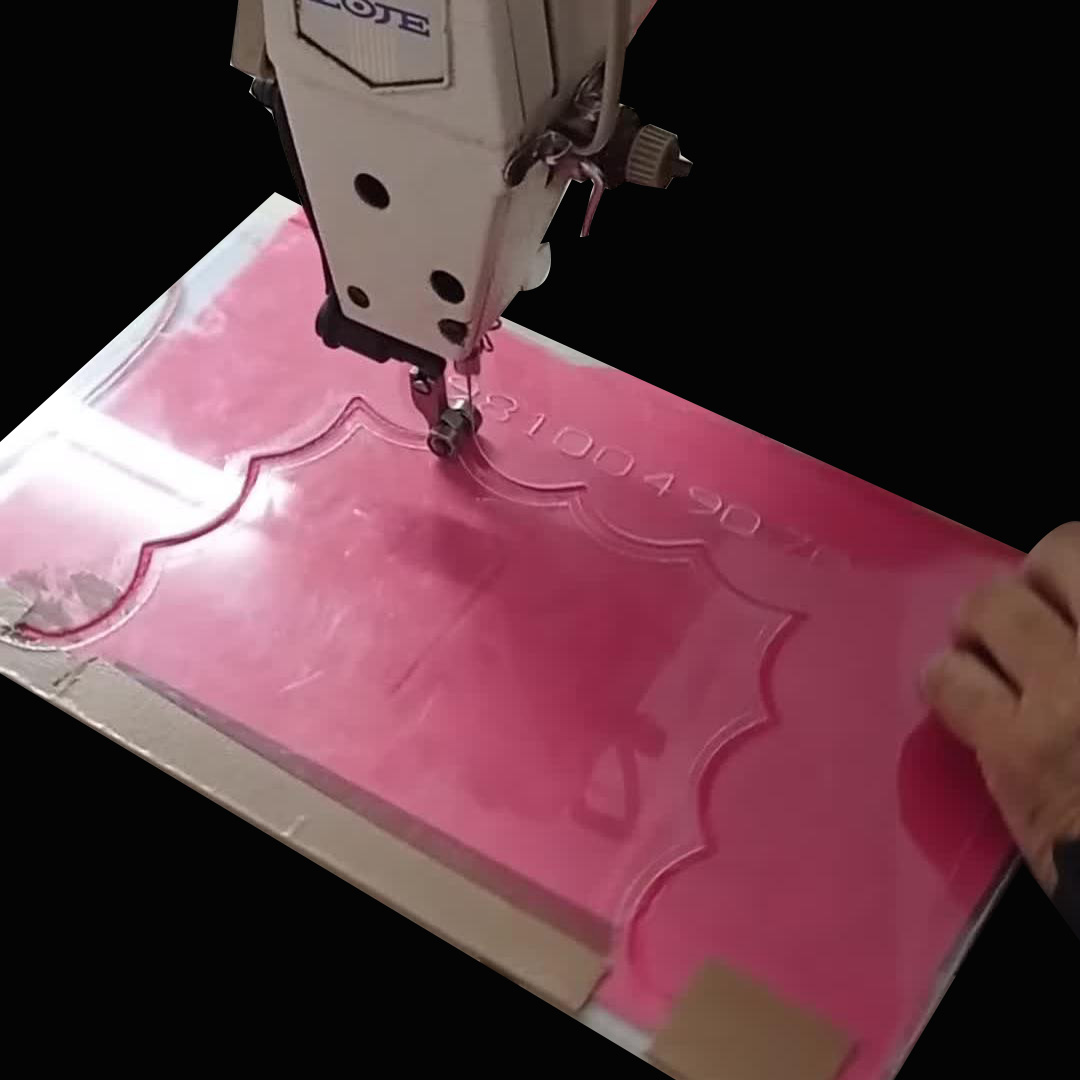

Illustrative image related to pvc garments

Forming Techniques

The forming stage employs various techniques to shape the PVC material into garments. Common methods include calendering, where the PVC is rolled into sheets, and coating, where the PVC is applied to the base textile. Heat-sealing and ultrasonic welding are also popular techniques for joining PVC pieces without the need for traditional stitching, providing a waterproof seam that enhances the garment’s durability.

Assembly Process

Once the components are formed, they are assembled according to the design specifications. This may involve cutting the fabric into pattern pieces, sewing, or welding the pieces together. Quality control is paramount during assembly; any defects at this stage can lead to significant issues later in the production cycle.

Finishing Touches

The finishing stage includes final inspections, trimming of excess materials, and applying any necessary treatments, such as anti-static or anti-bacterial coatings. This stage ensures that the garments not only look appealing but also meet specific functional requirements, such as waterproofing and breathability.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for PVC garments, ensuring that each product meets international standards and customer expectations. Key QA practices include adherence to international standards, implementation of various quality checkpoints, and consistent testing methods.

International Quality Standards

Manufacturers of PVC garments often adhere to international quality standards such as ISO 9001, which focuses on quality management systems, and CE marking for compliance with health, safety, and environmental protection standards. For specialized products, certifications from organizations like the American Petroleum Institute (API) may also be relevant, particularly for garments used in industrial applications.

Quality Checkpoints

Quality control is performed at several stages of the manufacturing process, including:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet predefined specifications. Any materials that do not meet standards are rejected.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to ensure that the processes are being followed correctly and that the products are being made to specification.

-

Final Quality Control (FQC): Before packaging, a final inspection is conducted to check for defects, ensure proper assembly, and verify that the finished products meet all quality standards.

What Testing Methods Are Commonly Used for PVC Garments?

Testing methods play a crucial role in verifying the quality and durability of PVC garments. Common tests include:

-

Physical Testing: Assessing tensile strength, tear resistance, and elongation to evaluate the material’s performance under stress.

-

Waterproof Testing: Conducting hydrostatic pressure tests to ensure garments maintain their waterproof properties, which is essential for protective clothing.

-

Chemical Resistance Testing: Evaluating how the PVC material reacts when exposed to various chemicals, ensuring safety and longevity.

-

Colorfastness Testing: Testing the fabric’s ability to retain color when exposed to light, washing, or perspiration, which is crucial for maintaining appearance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct thorough due diligence when selecting suppliers for PVC garments. Here are effective strategies for verifying supplier quality control:

Illustrative image related to pvc garments

-

Supplier Audits: Regular audits of the manufacturing facility can provide insight into the quality control processes in place. Audits can be conducted by the buyer or an independent third party to ensure objectivity.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of quality tests performed on their products, including results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These services can perform random checks at various stages of production.

-

Certifications Verification: Confirming the validity of international certifications and compliance with local regulations is crucial. Buyers should ask for copies of certifications and check their authenticity with the issuing bodies.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in PVC garment manufacturing is essential. Here are key considerations:

-

Regulatory Compliance: Different regions have varying regulations concerning materials and safety standards. It is vital for buyers to be aware of local requirements, such as REACH compliance in Europe, which governs the use of chemicals.

-

Cultural Differences: Understanding cultural attitudes towards quality and product expectations can impact business relationships. Buyers should engage with suppliers to establish clear communication regarding quality expectations.

-

Logistical Challenges: International shipping can introduce additional quality concerns, such as damage during transit. Buyers should discuss packaging and handling procedures with suppliers to mitigate these risks.

By comprehensively understanding the manufacturing processes and quality assurance practices for PVC garments, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc garments’

Introduction

Sourcing PVC garments requires a strategic approach to ensure quality, compliance, and alignment with market demands. This guide provides a practical checklist for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to streamline the procurement process and mitigate risks associated with sourcing this unique material.

1. Define Your Technical Specifications

Establishing clear technical specifications is essential for aligning your needs with supplier capabilities. Consider factors such as garment type (e.g., jackets, dresses), thickness of the PVC, flexibility, and intended use (fashion vs. protective wear). Clear specifications help in evaluating potential suppliers and prevent miscommunication down the line.

2. Research Market Trends and Consumer Preferences

Understanding current market trends and consumer preferences is vital for making informed purchasing decisions. Investigate popular styles, colors, and functionalities that resonate with your target audience in your region. This knowledge will guide your choices and enhance your competitive edge.

Illustrative image related to pvc garments

3. Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who specialize in PVC garments, as their expertise often translates into higher quality and better service.

- Check for Certifications: Ensure suppliers comply with relevant quality and safety standards, such as ISO certifications or compliance with local regulations.

- Assess Manufacturing Capabilities: Inquire about their production processes, capacity, and the materials they use to gauge their ability to meet your demands.

4. Request Samples for Quality Assessment

Always request samples before placing a bulk order. This step allows you to assess the quality, texture, and durability of the PVC garments. Pay close attention to details such as stitching, finishing, and the weight of the material.

- Test for Compliance: If applicable, test samples for water resistance and other relevant performance metrics to ensure they meet your specifications.

5. Negotiate Terms and Pricing

Engage in discussions about pricing, minimum order quantities, and payment terms. Make sure to clarify what is included in the price, such as shipping and handling fees. Effective negotiation can lead to better margins and more favorable terms.

Illustrative image related to pvc garments

- Consider Long-Term Partnerships: If you find a reliable supplier, discuss the potential for long-term collaboration, which can lead to better pricing and priority service.

6. Establish Quality Control Procedures

Implement quality control measures to ensure that the garments meet your standards upon delivery. This may involve setting up inspection protocols or arranging for third-party quality checks.

- Define Acceptance Criteria: Clearly outline what constitutes an acceptable product to avoid disputes and ensure consistency.

7. Plan for Logistics and Distribution

Finally, consider the logistics of transporting and distributing your PVC garments. Assess shipping options, customs regulations, and potential tariffs in your target markets. Efficient logistics planning is crucial for maintaining inventory levels and meeting customer demand.

By following this checklist, B2B buyers can navigate the complexities of sourcing PVC garments effectively, ensuring high-quality products that align with market needs.

Illustrative image related to pvc garments

Comprehensive Cost and Pricing Analysis for pvc garments Sourcing

What are the Key Cost Components in Sourcing PVC Garments?

When sourcing PVC garments, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The cost of PVC fabric is influenced by the type and quality of the base material used (e.g., polyester or cotton) and the additives that enhance its properties. Prices can vary significantly based on the specifications, such as thickness, finish (e.g., holographic, embossed), and whether the fabric is transparent or coated.

-

Labor: Labor costs depend on the location of manufacturing. Countries with lower labor costs, such as those in Southeast Asia, may offer more competitive pricing. However, labor quality and expertise, especially in specialized garment production, can also affect overall costs.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, and administrative costs. Efficient manufacturing processes can help minimize overhead, but buyers should be wary of low-cost options that may compromise quality.

-

Tooling: This refers to the costs associated with creating molds and patterns specific to the garment design. Custom designs often require higher initial investments in tooling, which can be amortized over larger production runs.

-

Quality Control (QC): Investing in quality control processes is essential to ensure product consistency and compliance with international standards. This can add to the cost but is crucial for maintaining brand reputation, especially in international markets.

-

Logistics: Transportation costs, including shipping and handling, play a significant role in the total cost. Buyers must consider the mode of transport, distance from the supplier, and any customs duties or taxes applicable in their region.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary widely depending on the supplier’s reputation, service level, and the complexity of the order.

How Do Price Influencers Affect the Sourcing of PVC Garments?

Several factors influence the pricing of PVC garments, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower unit prices due to economies of scale. Understanding a supplier’s MOQ can help negotiate better pricing structures.

-

Specifications and Customization: Custom designs or specific quality certifications (e.g., eco-friendly materials) may increase costs. Buyers should balance the need for customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., OEKO-TEX, REACH compliance) can significantly impact pricing. Buyers must assess the importance of these certifications in relation to their target market’s demands.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can all influence pricing. Established suppliers with a track record of quality may command higher prices, but they also reduce risk for buyers.

-

Incoterms: Understanding Incoterms is essential for buyers as they define responsibilities for shipping, insurance, and tariffs. Different terms can lead to varying total costs, affecting overall pricing strategies.

What Tips Can Help Buyers Negotiate Better Prices for PVC Garments?

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing, emphasizing long-term partnerships. Suppliers may be more flexible with pricing for committed buyers.

-

Assess Total Cost of Ownership (TCO): Look beyond initial costs to evaluate the total cost of ownership, including logistics, quality assurance, and potential returns. This perspective can provide a more comprehensive understanding of value.

-

Understand Pricing Nuances: International buyers, especially from regions like Africa, South America, and the Middle East, should be aware of currency fluctuations and economic conditions that might affect pricing. Building relationships with local suppliers can mitigate some of these risks.

-

Stay Informed on Market Trends: Being knowledgeable about market trends, including material prices and labor costs, can give buyers leverage during negotiations. Regularly reviewing industry reports can provide insights into potential cost changes.

-

Request Samples: Always request samples before finalizing orders. This ensures that the quality meets expectations and helps in negotiating based on the perceived value of the materials used.

Disclaimer on Indicative Prices

Prices for PVC garments can fluctuate based on various factors, including market demand, raw material costs, and international shipping rates. The indicative prices provided in industry listings should be used as a reference point, and buyers are encouraged to conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing pvc garments With Other Solutions

Introduction: Understanding Alternatives to PVC Garments

In the competitive landscape of garment production, B2B buyers often seek versatile, durable, and cost-effective solutions. PVC garments have established themselves as a popular choice due to their unique properties, but there are several alternatives worth considering. This analysis explores various options, focusing on their performance, cost, ease of implementation, maintenance, and best use cases, providing insights for informed decision-making.

Comparison Table

| Comparison Aspect | PVC Garments | TPU (Thermoplastic Polyurethane) Garments | Neoprene Garments |

|---|---|---|---|

| Performance | Highly durable, waterproof, and resistant to chemicals and UV | Flexible, abrasion-resistant, and breathable | Excellent insulation and water resistance |

| Cost | Moderate to high | Generally lower than PVC | Typically higher than PVC |

| Ease of Implementation | Requires specialized equipment for production | Easier to work with, compatible with existing machinery | Requires specific processes for cutting and bonding |

| Maintenance | Easy to clean but can be prone to scratching | Simple cleaning; resistant to stains | Requires careful cleaning to maintain insulation |

| Best Use Case | Fashion items, protective clothing | Sportswear, outdoor gear, and accessories | Wetsuits, athletic gear, and medical applications |

Detailed Breakdown of Alternatives

1. TPU (Thermoplastic Polyurethane) Garments

TPU offers a compelling alternative to PVC garments, particularly in applications requiring flexibility and breathability. Its abrasion resistance makes it suitable for sportswear and outdoor gear. While generally more affordable than PVC, TPU garments may lack some of the high-end aesthetics associated with PVC. Moreover, TPU is easier to process with standard machinery, making it a viable option for manufacturers looking to streamline production. However, buyers should consider its performance limitations in extreme weather conditions compared to PVC.

2. Neoprene Garments

Neoprene is known for its exceptional insulation properties, making it a preferred choice for wetsuits and other athletic gear. It provides a high level of water resistance and durability, but the production costs can be higher than PVC. Neoprene garments require specific cutting and bonding processes, which may complicate manufacturing for some businesses. While neoprene excels in thermal retention, it may not achieve the same level of style and fashion appeal as PVC. This makes it ideal for functional apparel rather than fashion-forward designs.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right garment solution, B2B buyers must weigh their specific needs against the characteristics of each material. PVC garments offer durability and style, making them suitable for fashion and protective clothing. However, alternatives like TPU and neoprene may provide better performance in specific applications, such as sportswear or thermal insulation. Assessing factors such as cost, ease of manufacturing, and intended use will guide buyers to make informed decisions that align with their business objectives and market demands. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to choose the most effective solution for their unique requirements.

Essential Technical Properties and Trade Terminology for pvc garments

What Are the Key Technical Properties of PVC Garments?

When sourcing PVC garments, understanding the material specifications is crucial for ensuring product quality and meeting customer expectations. Here are several essential technical properties to consider:

1. Material Grade

Material grade refers to the classification of PVC based on its chemical composition and performance characteristics. Higher-grade PVC offers enhanced durability, flexibility, and resistance to environmental factors like UV rays and chemicals. For B2B buyers, selecting the appropriate material grade is vital to ensure the longevity and functionality of garments, especially for demanding applications such as outdoor wear or industrial use.

2. Thickness

The thickness of PVC fabric is measured in millimeters (mm) and significantly influences its strength and flexibility. Thicker materials tend to be more durable but less flexible, which can affect the garment’s fit and comfort. Buyers should specify the desired thickness based on the intended use, whether for fashion items or protective clothing, as this can impact both production costs and consumer satisfaction.

3. Tolerance

Tolerance refers to the allowable variation in dimensions and properties of PVC garments during manufacturing. A tighter tolerance ensures consistency in product quality, which is crucial for maintaining brand reputation. For B2B transactions, understanding tolerance levels can help buyers avoid discrepancies in bulk orders, ensuring that every piece meets the required specifications.

4. Coating Type

PVC garments can feature various coatings, such as gloss, matte, or embossed finishes. Each coating type serves different aesthetic and functional purposes. For example, a glossy finish can enhance the visual appeal of fashion garments, while an embossed finish may provide additional grip or texture. Buyers should communicate their coating preferences clearly to manufacturers to achieve the desired product appearance and functionality.

5. Water Resistance

One of the primary advantages of PVC garments is their inherent water resistance, which is critical for outdoor apparel and protective clothing. This property is essential for buyers looking to enter markets where moisture protection is paramount. Understanding the degree of water resistance can help buyers match products to specific applications, such as raincoats or swimwear.

What Are Common Trade Terminology Used in PVC Garment Sourcing?

Navigating the world of PVC garments also involves understanding industry-specific jargon that can affect negotiations and transactions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products based on the specifications provided by another company, often the brand owner. In the PVC garment industry, working with an OEM allows brands to focus on design and marketing while relying on manufacturers for production. Understanding OEM partnerships can help buyers streamline their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of units a supplier is willing to produce or sell in a single order. Knowing the MOQ is crucial for buyers, as it impacts inventory management and cash flow. Buyers should negotiate MOQs to align with their sales forecasts and production capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Including detailed specifications for PVC garments in an RFQ ensures that suppliers provide accurate quotes. This process is essential for comparing costs and making informed purchasing decisions.

Illustrative image related to pvc garments

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for managing logistics and costs associated with shipping PVC garments. Common terms include FOB (Free on Board), which indicates when the responsibility for goods transfers from seller to buyer, and CIF (Cost, Insurance, Freight), which includes shipping and insurance costs in the price.

5. Lead Time

Lead time refers to the period from placing an order to its delivery. For PVC garments, understanding lead times is essential for inventory planning and meeting market demands. Buyers should communicate their timelines clearly to manufacturers to ensure timely production and delivery.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing PVC garments, ensuring they meet their business needs and customer expectations effectively.

Navigating Market Dynamics and Sourcing Trends in the pvc garments Sector

What Are the Key Market Dynamics Driving the PVC Garments Sector?

The PVC garments sector is experiencing robust growth driven by several global trends. The increasing demand for durable, water-resistant, and easy-to-clean apparel is a significant factor, particularly in regions with diverse weather conditions. For international B2B buyers from Africa, South America, the Middle East, and Europe, the versatility of PVC garments makes them appealing for various applications, from fashion to protective clothing. Emerging trends also include the rise of customization in PVC garments, supported by advancements in digital printing technology and e-commerce platforms, allowing businesses to tailor products to specific market needs.

Additionally, the shift towards online sourcing has accelerated, with buyers leveraging digital marketplaces to connect with manufacturers directly. This trend is particularly beneficial for B2B buyers in developing regions who may face challenges accessing traditional supply chains. The focus on innovative designs and collaborations with fashion influencers is also reshaping the PVC garment landscape, making it more attractive for younger demographics.

How Is Sustainability Influencing Sourcing Trends in the PVC Garments Sector?

Sustainability is becoming a pivotal concern in the PVC garments sector. As environmental awareness rises, B2B buyers are increasingly prioritizing ethical sourcing practices. The production of PVC, although versatile, raises environmental concerns due to its petroleum-based origins and potential chemical hazards. Consequently, buyers are seeking suppliers who adhere to sustainable practices, such as utilizing recycled materials or implementing eco-friendly production techniques.

Illustrative image related to pvc garments

Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are gaining importance in the procurement process, signaling a commitment to sustainability. Suppliers offering PVC garments with such certifications can enhance their marketability and appeal to ethically-conscious buyers. Additionally, innovations in biodegradable PVC alternatives are emerging, providing opportunities for businesses to align with green initiatives while meeting consumer demands for stylish yet sustainable apparel.

What Is the Historical Context of PVC in the Garments Industry?

The use of PVC in the garments industry has evolved significantly since its inception in the early 20th century. Initially utilized for construction and industrial applications, PVC began transitioning to textile use in the 1960s as manufacturers recognized its durability and waterproof characteristics. Over the decades, PVC garments have moved from functional protective wear to fashion statements, especially in niche markets such as cosplay and avant-garde fashion.

As fashion designers embraced PVC for its glossy finish and flexibility, the material gained popularity in various styles, from casual wear to high-fashion pieces. Today, the evolution of PVC garments reflects a blend of functionality and aesthetics, catering to diverse consumer needs while navigating the challenges of sustainability and ethical production. This historical context is vital for B2B buyers, as it highlights the material’s adaptability and potential for innovation in future applications.

Illustrative image related to pvc garments

Frequently Asked Questions (FAQs) for B2B Buyers of pvc garments

-

How do I ensure the quality of PVC garments from suppliers?

To ensure the quality of PVC garments, conduct thorough supplier vetting. Request samples to evaluate fabric durability, flexibility, and finish. Check for compliance with international quality standards and certifications. Additionally, consider suppliers who have established quality assurance processes, including regular inspections and testing. Building a relationship with suppliers for transparent communication can also help address any quality concerns proactively. -

What are the advantages of PVC garments in the fashion industry?

PVC garments offer several advantages, including durability, water resistance, and ease of maintenance. Their shiny, stylish appearance makes them popular in fashion-forward markets, appealing to consumers looking for unique designs. PVC is also versatile, used in various garment types from outerwear to accessories. Additionally, its ability to be easily cleaned and resistant to stains enhances its appeal for both consumers and manufacturers. -

What customization options are available for PVC garments?

Most suppliers offer customization options such as color, pattern, and size variations for PVC garments. You can request specific designs or branding elements like logos and labels. Some manufacturers may also provide custom fabric thickness or texture options. When discussing customization, ensure you clarify minimum order quantities (MOQs) and any additional costs associated with bespoke designs. -

What are the typical minimum order quantities (MOQs) for PVC garments?

MOQs for PVC garments can vary significantly based on the supplier and the complexity of the order. Generally, MOQs range from 100 to 1,000 units per style. It’s essential to communicate your requirements clearly to the supplier, as they may offer flexible options depending on your needs and their production capabilities. Discussing MOQs upfront can help avoid misunderstandings later in the procurement process. -

What payment terms should I expect when sourcing PVC garments internationally?

Payment terms can vary by supplier, but common practices include a deposit (usually 30-50%) upon order confirmation and the balance before shipment. Some suppliers may offer net terms based on your purchasing history. It’s crucial to establish clear payment terms in your contract to mitigate risks. Always consider using secure payment methods and letters of credit for larger transactions to protect your investment. -

How can I manage logistics for importing PVC garments?

Managing logistics for importing PVC garments involves selecting a reliable freight forwarder who understands international shipping regulations. Confirm that your supplier can provide necessary documentation such as invoices, packing lists, and certificates of origin. Be mindful of customs duties and taxes in your target market. Additionally, plan for potential delays by considering buffer time in your supply chain, especially during peak seasons. -

What should I know about international trade regulations for PVC garments?

International trade regulations for PVC garments can include tariffs, import restrictions, and compliance with safety standards. Research the specific regulations in your target market, as these can vary by country. Ensure that your supplier complies with labeling and safety standards to avoid customs issues. Engaging a customs broker can help navigate complex regulations and ensure your imports meet all legal requirements. -

What are the best practices for supplier communication during the sourcing process?

Effective communication with suppliers is vital for successful sourcing. Be clear and detailed about your requirements, expectations, and timelines. Utilize various communication channels, such as email, video calls, and messaging apps, to maintain regular contact. Establish a point of contact within the supplier’s organization to streamline communication. Additionally, documenting all agreements and updates can prevent misunderstandings and keep both parties aligned throughout the sourcing process.

Top 4 Pvc Garments Manufacturers & Suppliers List

1. Artifice Clothing – PVC Corseted Skirt

Domain: artificeclothing.com

Registered: 2005 (20 years)

Introduction: [{‘name’: ‘Fingerless PVC gloves (wrist length)’, ‘price’: 50.0}, {‘name’: ‘Buckle Garter Belt’, ‘price’: 70.0}, {‘name’: ‘PVC gloves with free height adjustments’, ‘price’: 55.0}, {‘name’: ‘PVC Corseted Skirt’, ‘price’: 140.0}, {‘name’: ‘PVC zipper miniskirt’, ‘price’: 27.5}, {‘name’: ‘PVC Miniskirt (free length adjustment)’, ‘price’: 20.0}, {‘name’: ‘PVC Plate D-ring Spiked Choker’, ‘price’: 45….

2. Corset Story – Elegant Corset Collection

Domain: corset-story.com

Registered: 2010 (15 years)

Introduction: Product Types: corset top, corset with shoulder straps, overbust corset top, underbust corset, waspie corset. Colors: Black, Brown, Gold, Purple, Red, Silver. Comfort Ratings: 6, 7, 8, 9. Corset Features: cord lacing, hip gores, ribbon lacing, shoulder straps, steel busk, swing hook, zip. Disguise Ratings: 1 to 10. Length Options: longline, petite, regular. Achievable Waist Reduction: 2″, 4″, 5″. …

3. Fabric Wholesale Direct – PVC Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – PVC Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Pinterest – PVC Clothing Inspiration

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: This company, Pinterest – PVC Clothing Inspiration, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pvc garments

In the dynamic world of PVC garments, strategic sourcing plays a pivotal role in ensuring quality, cost-effectiveness, and sustainability. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek reliable suppliers, understanding the nuances of PVC fabric—from its durability and versatility to its applications in fashion and protective clothing—becomes crucial. The ability to source high-quality PVC garments not only enhances product offerings but also aligns with market demands for innovative, stylish, and practical solutions.

Emphasizing partnerships with manufacturers who prioritize sustainable practices can significantly improve your supply chain resilience. By leveraging the strengths of various suppliers, you can create a diverse and robust portfolio that meets the unique preferences of your target markets.

Looking ahead, the demand for PVC garments is set to grow, fueled by trends in fashion and functionality. Now is the opportune moment for B2B buyers to engage with manufacturers and suppliers that align with their strategic objectives. By investing in strategic sourcing today, you position your business for success in tomorrow’s competitive landscape. Connect with industry leaders and explore the potential of PVC garments to elevate your product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.