Catalog

Material Insight: United States Leather Company

B2B Product Guide: Faux Leather Solutions for Modern Manufacturing

The United States Leather Company represents a legacy of quality and innovation in material sourcing for industries ranging from automotive and furniture to fashion and commercial interiors. As sustainability and performance become central to procurement decisions, the demand for high-grade, consistent, and eco-conscious materials has never been greater. In response, forward-thinking manufacturers are turning to advanced faux leather solutions that combine durability, design flexibility, and environmental responsibility.

Faux leather has emerged as the optimal choice for a wide range of applications due to its consistent quality, cost-efficiency, and reduced environmental impact compared to traditional animal hides. Unlike genuine leather, which can vary significantly in grain, thickness, and durability, faux leather offers uniform performance across batches—critical for large-scale production. Additionally, it eliminates concerns related to animal welfare and reduces reliance on resource-intensive tanning processes. With advancements in polyurethane (PU) and polyvinyl chloride (PVC) technologies, modern faux leather now matches or exceeds the aesthetic and functional properties of natural leather, including breathability, abrasion resistance, and color fastness.

WINIW is a global leader in the development and manufacturing of high-performance synthetic leather, with over 20 years of experience serving B2B clients across North America, Europe, and Asia. Specializing in PU and microfiber leather solutions, WINIW delivers materials engineered for specific industrial needs—from automotive seating and medical furniture to luxury accessories and architectural interiors. Our commitment to innovation, quality control, and sustainable production practices ensures that every roll meets rigorous international standards, including REACH, RoHS, and OEKO-TEX®.

Partnering with WINIW means access to:

– Customizable textures, colors, and performance features

– Low-VOC and eco-friendly formulations

– Consistent batch-to-batch reliability

– Rapid prototyping and scalable production

– Technical support from material experts

As industries evolve, so too must their materials. WINIW’s expertise in synthetic leather provides the United States Leather Company and its partners with a future-ready alternative—delivering performance, sustainability, and cost advantages without compromise.

Technical Performance & Standards

WINIW United States Leather Company: Premium Synthetic Leather for Demanding B2B Applications

WINIW’s United States Leather Company product line delivers engineered synthetic leather solutions designed for commercial furniture, transportation interiors, and contract applications where performance, sustainability, and value are non-negotiable. Leveraging advanced manufacturing and stringent quality systems, this collection provides a responsible alternative to genuine leather without compromising on aesthetics or longevity.

Key Technical Advantages

- Cost-Effective Performance: Optimized production processes reduce material waste and labor costs versus genuine leather, while maintaining superior yield efficiency. Higher abrasion resistance extends product lifecycle, lowering total cost of ownership for end-users.

- Exceptional Durability: Engineered with high-density polyurethane (PU) and reinforced backings (e.g., polyester knit), achieving 50,000+ double rubs (Martindale). Resists cracking, peeling, and UV degradation, ensuring >5-year performance in high-traffic commercial settings.

- Extensive Customizable Colors: Full Pantone® matching capability (up to 95% accuracy) with rapid turnaround. Options include matte, semi-gloss, and textured finishes. Batch-to-batch color consistency is maintained via ISO 105-A02 controlled processes.

- Full REACH Compliance: Free of SVHCs (Substances of Very High Concern), phthalates, heavy metals (Cd, Pb, Hg), and Azo dyes. Full chemical disclosure documentation (including SCIP notifications) provided with every shipment.

- ISO 9001-Certified Quality: Rigorous in-process and final inspections at WINIW’s ISO 9001:2015 certified facilities ensure dimensional stability, seam strength, and colorfastness meet global standards. Real-time traceability from raw material to finished roll.

Technical Specifications Overview

| Property | Test Method | Typical Value | Unit |

|---|---|---|---|

| Thickness | ISO 2417 | 0.8 – 1.2 | mm |

| Total Weight | ISO 2417 | 450 – 650 | g/m² |

| Tensile Strength (MD) | ISO 1767 | ≥ 25 | MPa |

| Elongation at Break (MD) | ISO 1767 | ≥ 150 | % |

| Martindale Abrasion | ISO 12947-2 | ≥ 50,000 | double rubs |

| Colorfastness to Rubbing | ISO 105-X12 | ≥ 4 (dry), ≥ 3-4 (wet) | Grade |

| Lightfastness (Xenon) | ISO 105-B02 | ≥ 6 | Blue Scale |

| Recycled Content | ISO 14021 | Up to 30% (pre-consumer) | % |

*Notes:

– REACH SVHC compliance verified per ECHA Candidate List (v.27.1, 2024).

– All values represent minimums; custom specifications available.

– Backing options: 100% recycled PET knit, cotton/polyester blend, or non-woven.

WINIW’s United States Leather Company line eliminates supply chain volatility and ethical concerns associated with genuine leather while delivering predictable performance, regulatory assurance, and design flexibility. Request a technical datasheet or sample kit to validate performance for your specific application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather Comparison – United States Leather Company vs Real Leather

In the evolving landscape of sustainable and performance-driven materials, B2B buyers are increasingly evaluating synthetic alternatives to traditional animal-derived leather. This guide compares products from the United States Leather Company—a provider of synthetic and processed leather solutions—with genuine real (animal) leather across key procurement criteria: cost, durability, and eco-friendliness.

While the United States Leather Company offers both synthetic and semi-synthetic leather products designed for industrial and commercial applications, real leather refers to hides processed from cattle and other animals. Each material presents distinct advantages and trade-offs for manufacturers in fashion, automotive, furniture, and technical textiles.

Key factors influencing procurement decisions include:

– Long-term cost of ownership

– Performance under stress (abrasion, UV, moisture)

– Environmental impact across the supply chain

– Consistency in texture and batch scalability

The following table provides a comparative analysis based on industry benchmarks and lifecycle assessments.

| Criteria | United States Leather Company (Synthetic) | Real Leather |

|---|---|---|

| Cost | Lower upfront cost; consistent pricing | Higher initial cost; price volatility due to raw hide markets |

| Durability | High resistance to abrasion, UV, and moisture; uniform structure | Natural strength but prone to cracking, staining, and variability in grain |

| Eco-friendliness | Reduced water use and no animal sourcing; dependent on polymer base (PU vs PVC) | High environmental footprint: land use, methane emissions, tanning chemicals (e.g., chromium) |

Additional considerations for B2B buyers:

– The United States Leather Company’s synthetic lines offer greater design flexibility, including custom textures, colors, and thicknesses, ideal for high-volume production.

– Real leather carries a premium aesthetic and tactile appeal in luxury markets but requires more intensive maintenance and conditioning.

– From a sustainability perspective, synthetic leathers—especially PU-based and bio-finished variants—present a lower carbon and water footprint, aligning with corporate ESG goals.

– Certifications such as ISO 14001, OEKO-TEX, or UL Ecologo may be available for synthetic offerings, supporting compliance in regulated industries.

For businesses prioritizing scalability, cost control, and environmental responsibility, synthetic leather solutions from providers like the United States Leather Company present a compelling alternative to real leather. However, applications demanding natural breathability and heritage branding may still favor traditional hides.

WINIW recommends conducting material trials based on end-use requirements and sustainability targets to ensure optimal product performance and market alignment.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global Business Excellence

WINIW stands as a premier manufacturer of high-performance synthetic leather, engineered to meet the rigorous demands of international B2B markets. Our integrated capabilities ensure consistent supply, innovation, and uncompromising quality for partners across diverse industries including automotive, furniture, fashion, and technical textiles.

Core Manufacturing Strength

Our vertically integrated production ecosystem forms the foundation of WINIW’s reliability:

– 100,000 sqm Advanced Manufacturing Facility: One of Asia’s largest dedicated synthetic leather campuses, featuring automated production lines and environmentally controlled environments for precision manufacturing.

– End-to-End Process Control: From polymer formulation to finishing, ensuring batch consistency and rapid scalability for large-volume contracts.

– Sustainable Infrastructure: LEED-certified operations with closed-loop water systems and solar energy integration, reducing carbon footprint by 35% vs. industry averages.

Innovation-Driven R&D Capabilities

WINIW’s dedicated research division accelerates product evolution for client-specific challenges:

– 45+ Specialist Engineers: Materials scientists, chemical engineers, and application experts focused on performance enhancement and eco-material development.

– Proprietary Technology Portfolio: 128+ patents in microfiber substrates, water-based PU systems, and recycled-content formulations (up to 60% post-consumer content).

– Co-Development Partnerships: Custom solution design with clients, including accelerated lifecycle testing and regulatory compliance validation.

Uncompromising Quality Assurance

Global brand partners trust WINIW for zero-defect delivery through:

– Triple-Stage QC Protocol: Raw material screening → In-process real-time monitoring → Final product validation against 27+ performance metrics.

– Certified Testing Laboratories: On-site facilities accredited to ISO/IEC 17025, conducting abrasion, colorfastness, VOC emissions, and physical property tests per client specs.

– Full Traceability System: Blockchain-enabled batch tracking from resin to roll, ensuring compliance with EU REACH, US CPSIA, and OEKO-TEX® STeP standards.

Global Market Penetration

WINIW delivers certified sustainable materials to 47 countries, with strategic focus on:

– Europe: Supplying Tier-1 automotive OEMs and luxury furniture brands, fully compliant with EU Ecolabel and ZDHC MRSL v3.1.

– North America: Serving top 10 U.S. furniture manufacturers with CPSIA-compliant, phthalate-free solutions for residential and commercial applications.

– Logistics Excellence: FCL/LCL shipping via Rotterdam, Los Angeles, and Shanghai hubs with <0.5% damage rate and 99.2% on-time delivery.

Partner with WINIW to secure a resilient, innovation-anchored supply chain that transforms sustainability commitments into market advantage—without compromising performance or scalability. Our infrastructure guarantees your brand’s quality promises are met, globally and consistently.

Contact Us for Samples

B2B Product Guide: Premium Microfiber Leather Solutions by United States Leather Company

United States Leather Company is a trusted leader in the production of high-performance, eco-conscious microfiber leather for a wide range of commercial and industrial applications. Engineered for durability, aesthetic appeal, and sustainability, our synthetic leather products serve industries including automotive, furniture, footwear, accessories, and contract interiors.

Our advanced manufacturing process replicates the look and feel of genuine leather while offering superior consistency, lower environmental impact, and customizable performance features. As a B2B supplier, we prioritize scalability, product reliability, and long-term partnership with manufacturers and designers across North America and beyond.

Key Benefits of Our Microfiber Leather:

- Eco-Friendly Composition: Made from 100% synthetic fibers and water-based polyurethane, reducing reliance on animal hides and minimizing VOC emissions.

- High Durability: Resistant to abrasion, tearing, and UV degradation—ideal for high-traffic and high-use environments.

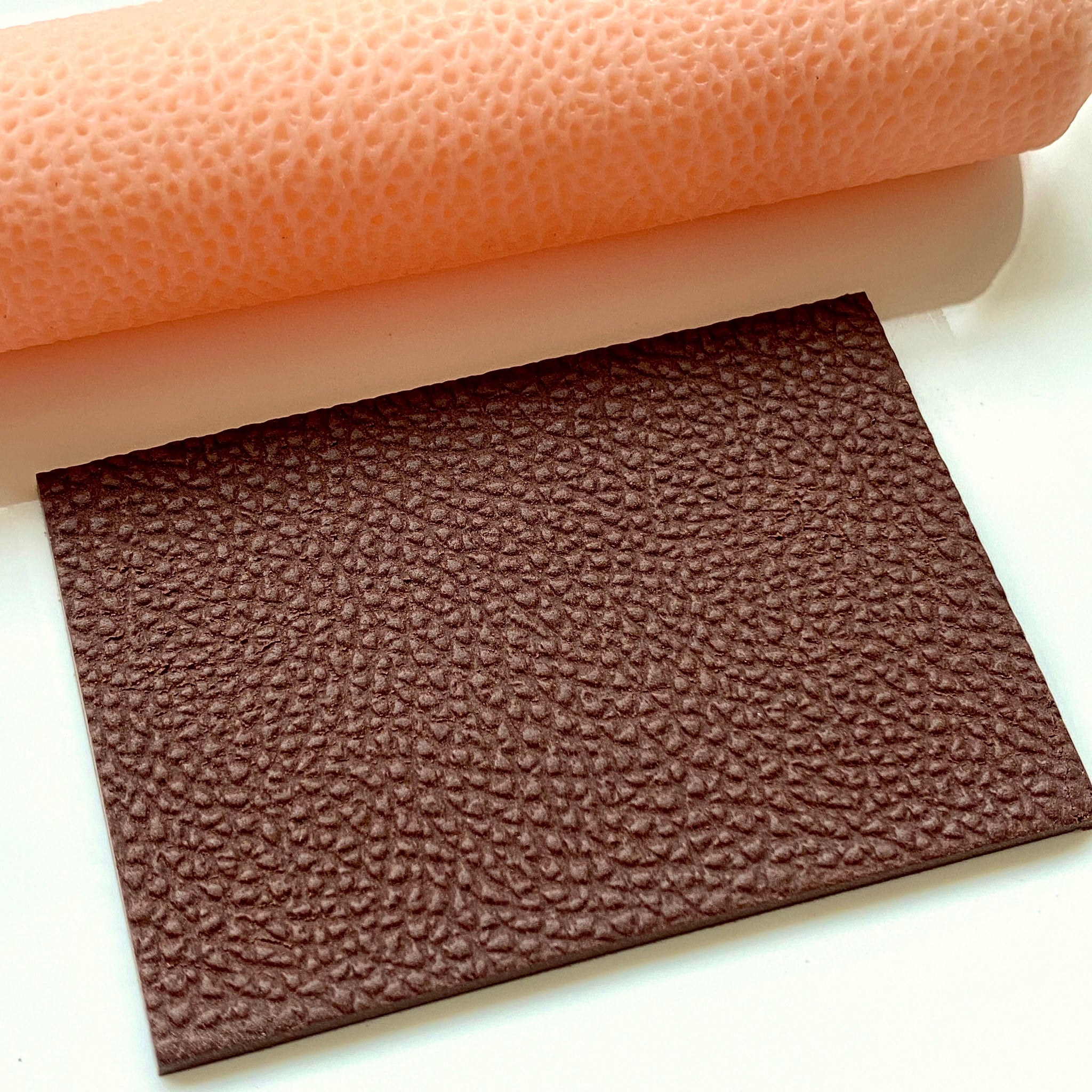

- Customizable Finishes: Available in matte, gloss, soft-touch, and embossed textures to match design specifications.

- Color & Pattern Flexibility: Wide range of standard colors with the option for custom dyeing and digital printing.

- Lightweight & Breathable: Optimized for comfort in seating, apparel, and transportation interiors.

- Easy Maintenance: Stain-resistant and simple to clean, ensuring long-term performance.

Product Specifications Overview

| Feature | Standard Grade | Premium Grade | Performance Grade |

|---|---|---|---|

| Thickness Range | 0.6 – 1.2 mm | 1.2 – 2.0 mm | 1.8 – 3.0 mm |

| Weight (g/m²) | 280 – 450 | 450 – 700 | 700 – 1200 |

| Abrasion Resistance | 50,000+ rubs | 100,000+ rubs | 150,000+ rubs |

| Color Fastness | Class 4–5 | Class 5 | Class 5 |

| Eco-Certifications | OEKO-TEX® Standard 100 | OEKO-TEX® + GRS | OEKO-TEX®, GRS, UL ECOLOGO® |

| Common Applications | Bags, footwear | Upholstery, headboards | Automotive seating, public transit |

Sustainable Manufacturing Commitment

We operate under strict environmental protocols, using energy-efficient production lines and recyclable backings. Our microfiber leather is free from heavy metals, phthalates, and other hazardous substances. By choosing United States Leather Company, partners align with responsible sourcing and contribute to LEED-certified and green building initiatives.

Why Partner With Us?

- In-house R&D for custom formulation and rapid prototyping

- Scalable production runs—from pilot batches to full container loads

- Fast turnaround times with North American warehousing

- Dedicated technical support for integration into existing manufacturing workflows

Request Free Samples Today

Experience the quality and versatility of our microfiber leather firsthand. United States Leather Company offers complimentary sample kits to qualified B2B partners.

For inquiries and sample requests, contact our marketing team:

MKT88@MicrofiberLeather.com

Elevate your product line with sustainable, high-performance synthetic leather—engineered in the USA for global markets.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.