Introduction: Navigating the Global Market for what is alcantara fabric

In the competitive landscape of textile sourcing, understanding the nuances of Alcantara fabric is crucial for international B2B buyers. This synthetic, suede-like material, known for its premium quality and versatility, has garnered attention across multiple industries, from automotive to fashion. However, sourcing Alcantara effectively can be challenging due to its proprietary nature and the variety of applications it supports. This guide aims to demystify Alcantara fabric, providing insights into its composition, types, and real-world applications, empowering buyers to make informed purchasing decisions.

Throughout this comprehensive guide, we will delve into the unique characteristics of Alcantara, including its durability, maintenance requirements, and advantages over traditional materials like leather. Additionally, we will explore the global market landscape, offering strategies for vetting suppliers, understanding pricing structures, and identifying the best applications for your specific needs. Whether you’re based in Africa, South America, the Middle East, or Europe—such as Saudi Arabia or Brazil—this guide equips you with the knowledge necessary to navigate the complexities of Alcantara sourcing. By the end, you will be well-prepared to leverage this exceptional material in your projects, ensuring both quality and value in your fabric selections.

Table Of Contents

- Top 5 What Is Alcantara Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is alcantara fabric

- Understanding what is alcantara fabric Types and Variations

- Key Industrial Applications of what is alcantara fabric

- 3 Common User Pain Points for ‘what is alcantara fabric’ & Their Solutions

- Strategic Material Selection Guide for what is alcantara fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for what is alcantara fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is alcantara fabric’

- Comprehensive Cost and Pricing Analysis for what is alcantara fabric Sourcing

- Alternatives Analysis: Comparing what is alcantara fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for what is alcantara fabric

- Navigating Market Dynamics and Sourcing Trends in the what is alcantara fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is alcantara fabric

- Strategic Sourcing Conclusion and Outlook for what is alcantara fabric

- Important Disclaimer & Terms of Use

Understanding what is alcantara fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Standard | Classic suede-like texture, available in various colors | Automotive interiors, upholstery | Pros: Premium feel, lightweight, and customizable. Cons: Requires regular maintenance. |

| Alcantara Sport | Enhanced grip, designed for high-performance applications | Racing seats, steering wheels | Pros: Superior grip in high-stress environments. Cons: Can become grimy with use. |

| Alcantara Eco | Made from recycled materials, eco-friendly options available | Sustainable fashion, automotive | Pros: Environmentally friendly, retains premium look. Cons: May have limited color options. |

| Alcantara Tech | Specialized for tech applications, often treated for durability | Electronics, furniture | Pros: Resistant to wear and tear, easy to clean. Cons: Higher cost than standard options. |

| Alcantara Luxury | Premium finish with a soft, plush feel | High-end vehicles, luxury goods | Pros: Exceptional aesthetic appeal, enhances brand image. Cons: Higher price point. |

What Are the Characteristics of Alcantara Standard Fabric?

Alcantara Standard is the quintessential version of this synthetic fabric, known for its soft, suede-like texture. It is often available in a broad spectrum of colors, making it versatile for various applications, especially in automotive interiors and upholstery. For B2B buyers, this type is ideal for projects where a premium aesthetic is desired but comes with the need for regular cleaning to maintain its appearance.

How Does Alcantara Sport Differ from Other Variants?

Alcantara Sport is engineered for high-performance environments, providing enhanced grip that is crucial for racing seats and steering wheels. This variant is particularly suited for automotive applications where driver control and comfort are paramount. Buyers should consider its tendency to accumulate dirt and oils, necessitating diligent maintenance to preserve its functionality and appearance.

What Are the Benefits of Choosing Alcantara Eco?

Alcantara Eco is a sustainable option made from recycled materials, catering to the growing demand for environmentally responsible products. This fabric retains the luxurious look and feel of traditional Alcantara while appealing to brands focused on sustainability. However, B2B purchasers should be aware of potentially limited color options, which may affect design choices.

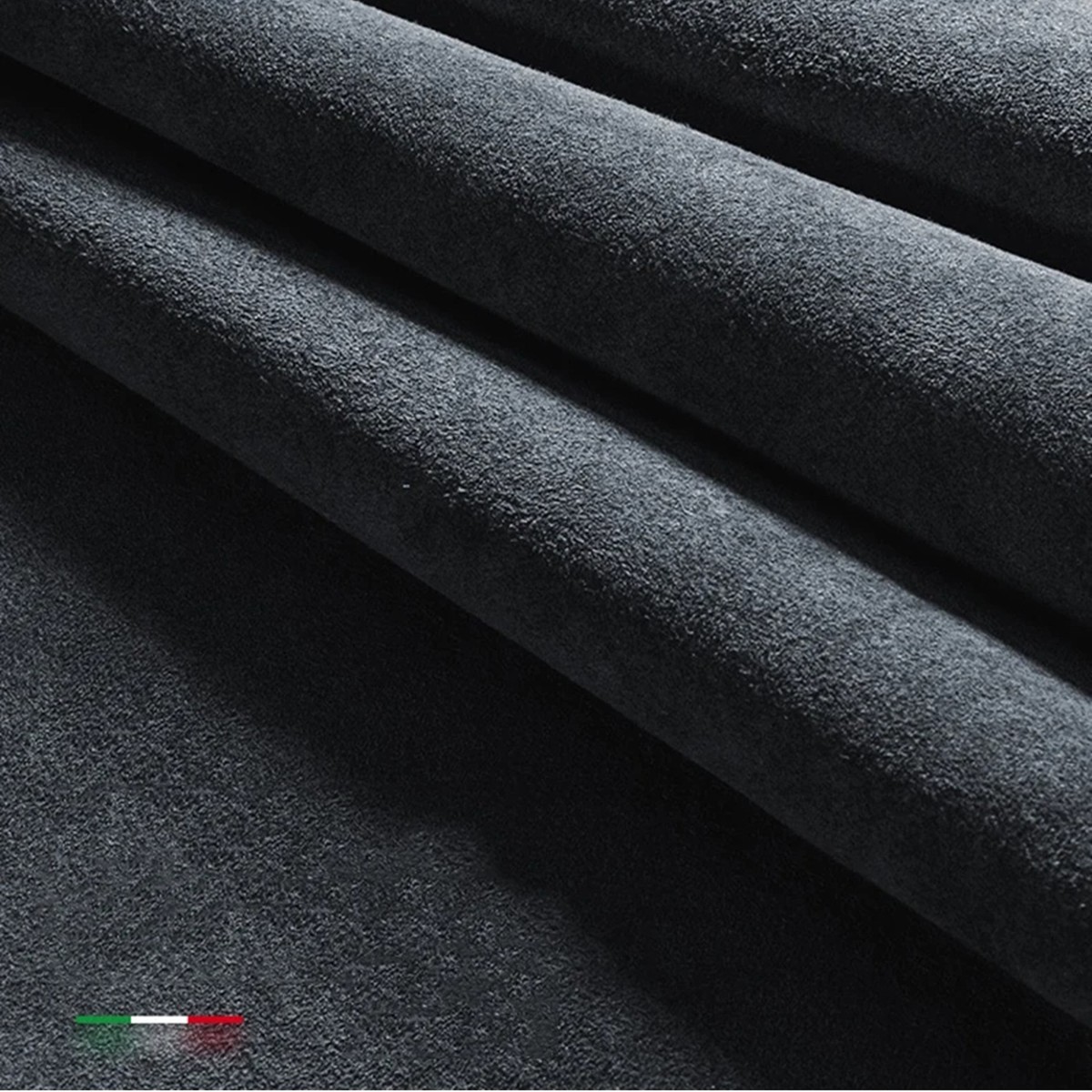

Illustrative image related to what is alcantara fabric

Why Is Alcantara Tech Important for Electronics and Furniture?

Alcantara Tech is specifically designed for durability in tech applications, featuring treatments that enhance its resistance to wear and tear. This makes it a suitable choice for electronics and furniture that require both aesthetic appeal and longevity. Buyers should weigh the higher cost against the long-term benefits of its durability and ease of cleaning.

What Makes Alcantara Luxury Stand Out?

Alcantara Luxury is the premium variant, offering an exceptionally soft and plush feel that elevates the aesthetic of high-end vehicles and luxury goods. This fabric is perfect for brands looking to convey exclusivity and sophistication. However, the higher price point may be a consideration for B2B buyers, especially when budgeting for large-scale projects.

Key Industrial Applications of what is alcantara fabric

| Industry/Sector | Specific Application of what is alcantara fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery for seats and dashboards | Provides a premium look and feel, enhances grip, and is lightweight | Ensure compliance with industry standards, evaluate durability and maintenance requirements |

| Fashion & Accessories | High-end apparel and accessories | Offers a luxurious aesthetic while being vegan-friendly | Assess fabric sourcing for ethical production and color fastness |

| Consumer Electronics | Laptop and device covers | Lightweight, stylish, and provides a non-slip surface | Consider compatibility with device specifications and durability against wear |

| Aviation | Cabin interiors and seating | Enhances passenger experience with comfort and aesthetics | Focus on fire-retardant properties and compliance with aviation regulations |

| Interior Design | Furniture upholstery and decorative elements | Adds a sophisticated touch to residential and commercial spaces | Evaluate fabric performance in different environments and ease of maintenance |

How is Alcantara Fabric Used in the Automotive Industry?

In the automotive sector, Alcantara fabric is predominantly utilized for interior upholstery, including seats, dashboards, and steering wheels. Its unique suede-like texture enhances grip, which is critical for performance vehicles where driver control is paramount. Additionally, Alcantara is lightweight, contributing to overall vehicle efficiency. International B2B buyers should consider sourcing Alcantara that meets stringent automotive standards for durability and maintenance, ensuring that the fabric can withstand wear and tear while maintaining its premium appearance.

What Role Does Alcantara Play in Fashion and Accessories?

Alcantara fabric is increasingly popular in high-end fashion and accessories, where it serves as a luxurious alternative to leather. Its vegan-friendly nature appeals to a growing consumer base prioritizing ethical fashion. The fabric’s soft texture and rich colors provide a premium aesthetic, making it ideal for designer handbags, shoes, and clothing. Buyers in this sector should focus on sourcing Alcantara that guarantees color fastness and quality, ensuring that the products remain appealing over time and align with sustainable practices.

Illustrative image related to what is alcantara fabric

How is Alcantara Fabric Beneficial for Consumer Electronics?

In the consumer electronics industry, Alcantara is used for laptop and device covers, providing a stylish and functional solution. The fabric’s lightweight nature and non-slip surface make it a practical choice for protecting devices while enhancing their aesthetic appeal. For international buyers, it’s essential to consider the compatibility of Alcantara with specific device models and its durability against everyday wear. Sourcing Alcantara that meets these criteria can significantly elevate product offerings in this competitive market.

Why is Alcantara Important in Aviation?

In the aviation industry, Alcantara is utilized in cabin interiors and seating, where it plays a crucial role in enhancing passenger comfort and overall aesthetics. The fabric not only looks sophisticated but also meets fire-retardant regulations, making it suitable for aircraft applications. Buyers in this sector must prioritize sourcing Alcantara that complies with aviation safety standards while also considering its maintenance and cleaning requirements to ensure long-term usability in high-traffic environments.

How Does Alcantara Enhance Interior Design Projects?

Alcantara fabric is a favored choice in interior design for upholstery and decorative elements, adding a touch of sophistication to both residential and commercial spaces. Its versatility allows it to be used in various applications, from furniture to wall coverings. For B2B buyers, it’s important to evaluate the fabric’s performance in different environments, especially in terms of durability and ease of maintenance. Sourcing high-quality Alcantara can significantly impact the aesthetic and functional outcomes of design projects, appealing to clients seeking luxury and style.

Illustrative image related to what is alcantara fabric

3 Common User Pain Points for ‘what is alcantara fabric’ & Their Solutions

Scenario 1: Difficulty in Understanding Alcantara Fabric Composition

The Problem: B2B buyers often struggle to grasp the unique composition of Alcantara fabric, which can hinder their ability to make informed purchasing decisions. This lack of understanding can lead to confusion when comparing Alcantara to other materials, such as leather or traditional fabrics. Buyers may also have concerns about the ethical implications of using synthetic materials versus natural ones, particularly in markets where sustainability is a key consideration.

The Solution: To overcome this challenge, buyers should prioritize sourcing information from reputable manufacturers and suppliers of Alcantara. Understanding that Alcantara is a blend of 68% polyester and 32% polyurethane is crucial. Buyers can request detailed technical data sheets from suppliers that outline the fabric’s properties, including its durability, maintenance requirements, and environmental impact. Additionally, engaging in discussions with suppliers about their production processes and sustainability certifications can provide valuable insights. By seeking this information, buyers can confidently position Alcantara against other materials, aligning their choices with market trends toward sustainability and quality.

Scenario 2: Maintenance and Longevity Concerns

The Problem: A common concern for B2B buyers is the maintenance and longevity of Alcantara fabric, especially when used in high-contact areas like car interiors. Many potential buyers worry that Alcantara will wear down quickly or require intensive maintenance, which could lead to additional costs and customer dissatisfaction. This concern is particularly acute in markets with extreme weather conditions, where materials may be subjected to more stress.

The Solution: Buyers should implement a proactive maintenance strategy to mitigate these concerns. This includes sourcing Alcantara that comes with manufacturer-recommended care instructions, ensuring that cleaning solutions and tools are specifically designed for use on Alcantara. Buyers can also invest in training for their staff on proper cleaning techniques, emphasizing the importance of regular maintenance to prevent dirt and oil accumulation. Additionally, establishing a warranty or service agreement with suppliers can provide further assurance regarding the fabric’s longevity and performance, helping to alleviate buyer apprehensions.

Illustrative image related to what is alcantara fabric

Scenario 3: Misalignment with Market Expectations

The Problem: B2B buyers may face challenges in aligning their product offerings with market expectations when using Alcantara fabric. In some regions, buyers might find that consumers have preconceived notions about the quality and performance of synthetic materials versus natural ones. This can lead to hesitance in adopting Alcantara for products that traditionally used leather or other textiles, impacting sales and market acceptance.

The Solution: To address this issue, buyers should conduct thorough market research to understand regional preferences and perceptions of Alcantara. Engaging with potential customers through surveys or focus groups can provide invaluable feedback on their perceptions of synthetic versus natural materials. Furthermore, buyers can collaborate with marketing teams to develop educational campaigns that highlight the benefits of Alcantara, such as its durability, ethical production, and aesthetic appeal. By effectively communicating the unique advantages of Alcantara and addressing consumer concerns, buyers can better position their products in the market, ultimately increasing acceptance and demand.

Strategic Material Selection Guide for what is alcantara fabric

What Are the Key Properties of Alcantara Fabric Compared to Other Materials?

Alcantara fabric is a synthetic material that has carved a niche in various industries, particularly in automotive and luxury goods. Understanding its properties in comparison to other materials is crucial for B2B buyers evaluating their options. Here, we analyze Alcantara alongside leather, vinyl, and microfiber, focusing on their key properties, pros and cons, and implications for international buyers.

How Does Alcantara Compare to Leather in Terms of Performance?

Key Properties: Alcantara is composed of 68% polyester and 32% polyurethane, making it lighter than leather while offering a soft, suede-like texture. Unlike leather, Alcantara is water-resistant but can absorb oils, which may affect its longevity.

Pros & Cons: Alcantara is easier to maintain than leather, as it can be cleaned with gentle solutions. However, it may wear more quickly in high-contact areas, leading to a loss of its plush texture. Leather, while more durable, requires extensive care and is often more expensive.

Impact on Application: Alcantara is suitable for high-end automotive interiors, providing a premium feel without the ethical concerns associated with animal products. Leather, while luxurious, may not appeal to vegan consumers.

Considerations for International Buyers: In regions like Europe, where sustainability is prioritized, Alcantara’s vegan-friendly nature is a significant advantage. Compliance with environmental regulations is also easier with Alcantara, as it does not involve animal byproducts.

What Are the Advantages of Using Vinyl Compared to Alcantara?

Key Properties: Vinyl is a synthetic material known for its durability and water resistance. It is often used in environments where moisture exposure is common, such as marine applications.

Illustrative image related to what is alcantara fabric

Pros & Cons: Vinyl is cost-effective and easy to clean, making it a popular choice for commercial applications. However, it lacks the luxurious feel of Alcantara and can become sticky in high temperatures. Alcantara offers a more premium aesthetic but at a higher price point.

Impact on Application: Alcantara is ideal for luxury vehicles and high-end consumer goods, while vinyl is often used in budget-friendly products. The choice between the two depends on the target market and brand positioning.

Considerations for International Buyers: Buyers in South America and Africa may prefer vinyl for its lower cost and durability in harsh climates. However, they should also consider the growing demand for premium materials in urban markets.

How Does Microfiber Fabric Stack Up Against Alcantara?

Key Properties: Microfiber is a synthetic blend, typically made from polyester and polyamide. It is known for its softness and high absorbency, making it suitable for cleaning and upholstery.

Pros & Cons: Microfiber is generally less expensive than Alcantara and offers good durability. However, it may not provide the same luxurious feel and aesthetic appeal that Alcantara does. Alcantara’s unique texture and brand recognition can justify its higher cost in premium markets.

Illustrative image related to what is alcantara fabric

Impact on Application: Microfiber is often used in budget-conscious applications, while Alcantara is favored in luxury segments. The choice will depend on the desired brand image and customer expectations.

Considerations for International Buyers: In regions like the Middle East, where luxury is highly valued, Alcantara may be preferred despite its higher cost. Buyers should assess the market demand for both materials to align their offerings accordingly.

Summary Table of Material Comparisons

| Material | Typical Use Case for what is alcantara fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara | Automotive interiors, luxury goods | Premium aesthetic, vegan-friendly | Can wear quickly, requires maintenance | High |

| Leather | High-end automotive, luxury fashion | Durable, classic appeal | Expensive, requires extensive care | High |

| Vinyl | Commercial upholstery, budget vehicles | Cost-effective, easy to clean | Lacks luxury feel, can be sticky | Low |

| Microfiber | Cleaning products, budget upholstery | Soft, durable, cost-effective | Less luxurious than Alcantara | Medium |

This analysis provides a comprehensive overview of Alcantara fabric in relation to other materials, enabling international B2B buyers to make informed decisions based on performance, cost, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for what is alcantara fabric

What Are the Key Stages in the Manufacturing Process of Alcantara Fabric?

The manufacturing process of Alcantara fabric is a complex and meticulous endeavor that involves several key stages: material preparation, forming, assembly, and finishing. Each of these stages employs specific techniques to ensure the fabric meets the high standards expected in various applications, particularly in automotive, fashion, and interior design industries.

Illustrative image related to what is alcantara fabric

How Is Material Prepared for Alcantara Fabric Production?

The foundation of Alcantara fabric lies in its unique composition, which consists of 68% polyester and 32% polyurethane. The first stage of manufacturing involves sourcing high-quality raw materials. These materials are subjected to a series of treatments to enhance their properties. For instance, the polyester fibers are extruded and combined with polyurethane to form a composite that provides the desired softness, durability, and visual appeal.

Once the raw materials are prepared, they are dyed using environmentally friendly dyes. This is crucial, as the dyeing process not only affects the aesthetic qualities of the fabric but also its resistance to fading and wear over time. The careful selection of dyes and additives ensures that the final product remains vibrant and retains its premium quality.

What Techniques Are Employed in the Forming and Assembly of Alcantara Fabric?

After material preparation, the next phase is the forming process. This involves the creation of the fabric substrate through advanced weaving techniques. The synthetic fibers are interwoven to produce a soft, suede-like texture, which is a hallmark of Alcantara. The unique structure of the fabric is designed to provide excellent grip and tactile comfort, making it a preferred choice for automotive interiors and luxury goods.

Illustrative image related to what is alcantara fabric

In the assembly stage, the Alcantara fabric is cut and shaped according to specific design requirements. This stage is critical for applications in automotive manufacturing, where precision and fit are paramount. The fabric can be customized in terms of thickness, pattern, and finish, allowing manufacturers to meet diverse client specifications.

What Quality Assurance Standards Are Essential for Alcantara Fabric?

Quality assurance is a pivotal aspect of the manufacturing process for Alcantara fabric, ensuring that the final product meets international standards and industry-specific regulations. The primary quality management standard that governs the manufacturing of Alcantara is ISO 9001, which outlines criteria for establishing and maintaining an effective quality management system.

How Do International and Industry-Specific Standards Apply to Alcantara Fabric?

In addition to ISO 9001, Alcantara fabric manufacturers may also adhere to various industry-specific certifications such as CE marking for compliance with European health, safety, and environmental protection standards. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is crucial to ensure that suppliers comply with these standards to minimize risks associated with product quality and safety.

What Are the Key Quality Control Checkpoints in Alcantara Fabric Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that the Alcantara fabric meets the required specifications. The main QC checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival at the manufacturing facility. Materials are checked for quality and compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor the quality of the fabric at various stages. This includes assessing the dyeing process, texture, and overall appearance of the fabric.

-

Final Quality Control (FQC): Once the fabric is completed, it undergoes a thorough inspection to ensure it meets all quality standards. This includes testing for durability, color fastness, and resistance to wear and tear.

What Common Testing Methods Are Used to Ensure Alcantara Fabric Quality?

B2B buyers should be familiar with common testing methods that manufacturers use to verify the quality of Alcantara fabric. These may include:

Illustrative image related to what is alcantara fabric

-

Abrasion Resistance Testing: This assesses the fabric’s durability and resistance to wear over time, which is particularly important for automotive applications.

-

Color Fastness Testing: This evaluates how well the fabric retains its color when exposed to light, washing, and rubbing.

-

Flame Retardancy Testing: Given the safety concerns in automotive and aerospace industries, testing for flame resistance is crucial to ensure compliance with safety regulations.

How Can B2B Buyers Verify the Quality Control Processes of Alcantara Fabric Suppliers?

To ensure they are sourcing high-quality Alcantara fabric, B2B buyers should take proactive steps to verify the quality control processes of their suppliers. This can be achieved through several methods:

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their manufacturing processes and quality control measures firsthand. This can include reviewing their compliance with ISO 9001 and other relevant standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the results of the various testing methods applied to the fabric. This documentation can provide insight into the consistency and reliability of the supplier’s products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. This is particularly useful for international buyers who may not be able to visit the manufacturing facility.

What QC Considerations Should International Buyers Keep in Mind?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, it is essential to understand the nuances of quality control in the context of Alcantara fabric. This includes being aware of local regulations and standards that may differ from international norms.

Additionally, buyers should consider the logistics of sourcing Alcantara fabric from different regions, as transportation and storage conditions can impact the quality of the fabric upon delivery. Establishing clear communication channels with suppliers and understanding their quality assurance practices can help mitigate potential risks and ensure a reliable supply of high-quality Alcantara fabric.

In summary, the manufacturing processes and quality assurance measures for Alcantara fabric are integral to its reputation as a premium material. By understanding these processes, B2B buyers can make informed decisions when sourcing this versatile fabric for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is alcantara fabric’

Introduction

This guide serves as a practical checklist for B2B buyers interested in sourcing Alcantara fabric. Understanding the unique characteristics and applications of this synthetic textile is crucial for making informed purchasing decisions that align with industry standards and customer expectations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before sourcing Alcantara fabric. Identify the desired qualities, such as weight, texture, and color options. Consider the specific applications, whether for automotive interiors, fashion, or upholstery, as these factors will influence the type of Alcantara you need.

- Texture and Finish: Decide if you require a matte or glossy finish based on your product’s aesthetic.

- Weight Considerations: Specify the weight of the fabric to ensure it meets durability and performance requirements.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in Alcantara fabric. Look for manufacturers with a proven track record in producing high-quality synthetic textiles.

- Supplier Reputation: Check reviews and testimonials from other B2B buyers to gauge the supplier’s reliability.

- Industry Experience: Prioritize suppliers with experience in your specific industry, as they are more likely to understand your needs.

Step 3: Evaluate Product Certifications

Before proceeding with any supplier, verify their product certifications. Alcantara fabric should meet specific industry standards, such as flame retardancy and environmental sustainability.

Illustrative image related to what is alcantara fabric

- Quality Assurance: Ensure that the fabric is certified by recognized standards organizations.

- Sustainability Practices: Look for certifications that confirm eco-friendly manufacturing processes, particularly if your brand emphasizes sustainability.

Step 4: Request Sample Swatches

Always request sample swatches before finalizing any orders. This step allows you to assess the fabric’s texture, color accuracy, and overall quality firsthand.

- Physical Evaluation: Examine the sample for any imperfections or inconsistencies.

- Compatibility Testing: Test how the fabric interacts with other materials you plan to use in your product.

Step 5: Inquire About Pricing and Minimum Order Quantities

Understanding pricing structures and minimum order quantities (MOQs) is vital for budgeting and planning. Ask suppliers for detailed pricing information, including bulk discounts and shipping costs.

- Negotiation Opportunities: Be open to negotiating terms, especially if you plan to establish a long-term relationship.

- Budget Alignment: Ensure that the pricing aligns with your overall project budget and financial constraints.

Step 6: Assess After-Sales Support and Services

Evaluate the after-sales support provided by the supplier. Good customer service can significantly enhance your purchasing experience and help resolve any issues that may arise post-purchase.

- Return Policies: Understand the supplier’s return and exchange policies in case the fabric does not meet your expectations.

- Technical Assistance: Check if they offer technical support for fabric care and maintenance, which can be beneficial for your end customers.

Step 7: Finalize the Purchase Agreement

Once you’ve completed the previous steps, draft a purchase agreement that outlines all terms, including pricing, delivery timelines, and quality expectations.

- Clear Communication: Ensure all parties understand the terms to prevent misunderstandings.

- Legal Compliance: Include clauses that comply with international trade regulations, especially if you are sourcing from overseas suppliers.

By following these steps, B2B buyers can effectively navigate the sourcing process for Alcantara fabric, ensuring they obtain high-quality materials that meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for what is alcantara fabric Sourcing

What Are the Key Cost Components for Sourcing Alcantara Fabric?

When considering the procurement of Alcantara fabric, understanding the cost structure is essential for effective budgeting and price negotiation. The primary cost components include:

-

Materials: Alcantara is composed of 68% polyester and 32% polyurethane. The raw material costs fluctuate based on global oil prices, as polyurethane is a petroleum-derived product. Additionally, the sourcing of high-quality polyester affects the overall material cost.

-

Labor: Labor costs are influenced by the manufacturing location. Countries with higher wage standards, such as Italy, where Alcantara is produced, will see elevated labor costs compared to regions with lower wages. Skilled labor is necessary for quality control and fabric finishing, contributing to the overall labor expenditure.

-

Manufacturing Overhead: This encompasses factory operation costs, utilities, and equipment maintenance. Efficient manufacturing processes can mitigate overhead costs, but investments in advanced machinery may be necessary to maintain quality standards.

-

Tooling: The creation of specialized machinery and molds for Alcantara production adds to the initial costs. Tooling is particularly significant for customized orders, where specific designs or patterns are required.

-

Quality Control (QC): Maintaining the high standards associated with Alcantara requires rigorous quality control processes. This may involve additional testing and inspection phases, further adding to costs.

-

Logistics: Transportation costs can vary significantly depending on the shipping method and distance to the buyer’s location. Import duties and tariffs may also impact the final cost, particularly for international buyers.

-

Margin: Suppliers will incorporate a profit margin based on their operational costs and market positioning. This margin can vary widely depending on the supplier’s reputation, service level, and market demand.

How Do Price Influencers Affect Alcantara Fabric Sourcing?

Several factors can influence the pricing of Alcantara fabric, especially for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Higher volume orders often lead to lower per-unit costs, while smaller orders may incur premium pricing.

-

Specifications and Customization: Custom designs or specific color requirements can increase production costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Certifications regarding environmental impact and product safety can influence costs. Suppliers with recognized quality certifications may charge higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may command higher prices, but they often provide better service and assurance.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms (e.g., FOB, CIF) can shift costs and responsibilities between the buyer and supplier, impacting the overall pricing structure.

What Are the Best Buyer Tips for Cost-Efficient Alcantara Fabric Sourcing?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the following tips can enhance sourcing efficiency:

-

Negotiate Effectively: Always engage in negotiations to achieve the best price. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance and cleaning of Alcantara. A lower initial cost may lead to higher long-term expenses if the fabric requires frequent replacement or intensive care.

-

Assess Regional Pricing Nuances: Prices can vary by region due to factors such as local demand, import tariffs, and currency fluctuations. Being aware of these nuances can help in making informed purchasing decisions.

-

Establish Long-term Relationships: Building strong relationships with suppliers can lead to better pricing and service. Long-term contracts often result in more favorable terms and conditions.

Disclaimer on Indicative Prices

It is important to note that prices for Alcantara fabric can vary widely based on the factors mentioned above. This analysis provides a framework for understanding potential costs but should not be viewed as definitive pricing. Buyers should conduct thorough market research and supplier evaluations to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing what is alcantara fabric With Other Solutions

When selecting materials for automotive interiors or high-end design applications, Alcantara fabric often comes to mind due to its unique qualities. However, it’s essential for B2B buyers to consider various alternatives that might better suit their specific needs. This analysis explores Alcantara fabric alongside two notable alternatives: UltraSuede and genuine leather.

Comparison Table

| Comparison Aspect | What Is Alcantara Fabric | UltraSuede | Genuine Leather |

|---|---|---|---|

| Performance | High grip, moisture resistant, softer feel | Comparable grip, soft texture | Durable, classic feel |

| Cost | £1,000 – £3,000 per vehicle | Typically lower than Alcantara | Higher, often £3,000+ |

| Ease of Implementation | Requires careful sewing and fitting | Easier to work with, less prone to wear | Traditional methods apply |

| Maintenance | Requires gentle cleaning; can stain | Easy to clean, resistant to stains | Needs regular conditioning |

| Best Use Case | Performance vehicles, luxury interiors | Fashion, home decor, automotive | Luxury vehicles, classic designs |

What Are the Advantages and Disadvantages of UltraSuede?

UltraSuede is a synthetic microfiber that serves as a direct competitor to Alcantara. It shares many of the same aesthetic qualities and is often easier to clean. UltraSuede is less prone to staining and does not absorb oils as readily, making it a practical choice for high-traffic applications. However, it may not offer the same level of grip as Alcantara, particularly in automotive settings where performance is critical. While generally less expensive than Alcantara, UltraSuede’s long-term durability can vary, which may affect its value proposition over time.

Illustrative image related to what is alcantara fabric

What Are the Pros and Cons of Genuine Leather?

Genuine leather stands out as a traditional material that offers unmatched durability and a classic aesthetic appeal. It typically provides a premium feel and can enhance the overall luxury perception of a vehicle or interior space. However, genuine leather comes with higher costs and requires regular maintenance to keep it looking its best. It is also less moisture-resistant compared to Alcantara and can become slippery when wet, which may be a disadvantage in performance settings. Additionally, the ethical considerations surrounding animal products may deter some buyers, particularly those looking for vegan options.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right material ultimately depends on the specific application and target market. Alcantara is ideal for those seeking a blend of performance, luxury, and modern aesthetics, especially in high-end automotive interiors. Conversely, if a buyer prioritizes ease of maintenance and cost-effectiveness, UltraSuede might be the better option. Genuine leather, while offering a timeless appeal, is best suited for luxury applications where the brand’s heritage plays a significant role. Buyers should assess their priorities—be it performance, cost, or maintenance—before making a decision, ensuring that the chosen material aligns with their overall business strategy and customer expectations.

Essential Technical Properties and Trade Terminology for what is alcantara fabric

What Are the Key Technical Properties of Alcantara Fabric?

Understanding the technical properties of Alcantara fabric is crucial for B2B buyers, especially those in industries such as automotive, fashion, and interior design. Here are some essential specifications:

Illustrative image related to what is alcantara fabric

-

Composition: Alcantara is primarily made from a blend of 68% polyester and 32% polyurethane. This synthetic composition provides durability and a suede-like texture, making it an attractive alternative to traditional materials like leather. For buyers, knowing the composition helps assess suitability for various applications, particularly in high-performance environments.

-

Weight: Alcantara typically weighs between 220 to 300 grams per square meter (gsm). This lightweight characteristic is beneficial for automotive applications, as it contributes to overall vehicle weight reduction, improving fuel efficiency and performance. B2B buyers should consider weight specifications when selecting materials for projects requiring strict weight limits.

-

Flame Retardancy: Alcantara can be treated to be flame retardant, making it a safer choice for automotive and aerospace applications. This property is critical for compliance with safety regulations in various industries. Buyers must ensure that the specific grade of Alcantara meets the necessary fire safety standards for their intended use.

-

Moisture Resistance: While Alcantara is not waterproof, it is water-resistant and does not easily stain from water. This feature is particularly advantageous in automotive interiors, where spills and moisture can occur. B2B buyers should evaluate the moisture resistance of Alcantara when considering it for environments that may be exposed to liquids.

-

Durability and Abrasion Resistance: Alcantara exhibits high durability and is more resistant to wear and tear than traditional leather or suede. It can withstand frequent handling without losing its texture or appearance, making it ideal for high-traffic areas in vehicles. Understanding durability metrics is vital for buyers looking for long-lasting material solutions.

-

Cleaning and Maintenance: Alcantara requires specific cleaning methods to maintain its appearance and feel. Buyers should be aware of recommended cleaning practices, as improper maintenance can lead to deterioration. This knowledge is essential for ensuring the longevity of the material in high-use applications.

What Are Common Trade Terms Related to Alcantara Fabric?

Familiarity with industry jargon can enhance communication and negotiation between B2B buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Alcantara, OEMs often utilize the material in vehicle interiors, and understanding this term is crucial for buyers seeking partnerships or materials for manufacturing.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. For Alcantara, MOQs can vary based on supplier agreements and material availability. Buyers should negotiate MOQs to align with their production needs while ensuring cost-effectiveness.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request pricing and terms for a specific quantity of goods. When sourcing Alcantara, a well-crafted RFQ can help buyers obtain competitive quotes, ensuring they make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce, used in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, costs, and risks associated with transporting Alcantara across borders.

-

Lead Time: This term refers to the time taken from placing an order to the delivery of the product. For Alcantara, understanding lead times is critical for production planning and inventory management. Buyers should factor in lead times when scheduling their projects to avoid delays.

-

Certification Standards: This refers to the various industry standards that Alcantara may meet, such as ISO certifications for quality and safety. Buyers should check for certification compliance to ensure that the materials they source meet industry regulations and expectations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Alcantara fabric, ensuring they select the right material for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the what is alcantara fabric Sector

What Are the Key Market Dynamics and Trends Influencing Alcantara Fabric Sourcing?

Alcantara fabric has emerged as a significant player in various industries, particularly in automotive, fashion, and home décor. The global market is currently driven by the rising demand for premium and innovative materials that offer both aesthetic appeal and functional benefits. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of this market is crucial.

One prominent trend is the shift towards lightweight materials that enhance performance without compromising on luxury. Alcantara, being both lightweight and durable, fits perfectly into this narrative, making it a preferred choice for high-performance vehicles and luxury interiors. Additionally, as automotive manufacturers focus on sustainability, there is a growing interest in materials that are not only appealing but also environmentally friendly. Buyers are increasingly looking for suppliers who can provide Alcantara that meets these sustainability criteria.

Emerging technologies in textile production, such as advanced weaving techniques and digital printing, are also reshaping how Alcantara is produced and sourced. These innovations allow for greater customization and efficiency, enabling manufacturers to respond quickly to market demands. Furthermore, the increasing penetration of e-commerce platforms is facilitating easier access to Alcantara suppliers, particularly for B2B buyers in emerging markets, allowing them to compare prices and quality more effectively.

How Is Sustainability and Ethical Sourcing Affecting Alcantara Fabric Procurement?

Sustainability is at the forefront of modern sourcing decisions, particularly for B2B buyers in the textile industry. Alcantara fabric stands out due to its synthetic composition, which is free from animal products, making it a vegan-friendly option. However, the environmental impact of its production processes must be carefully considered. Alcantara is made from a blend of polyester and polyurethane, and while these materials can be recycled, the sourcing of raw materials poses ecological challenges.

For B2B buyers, prioritizing ethical supply chains is essential. This includes sourcing Alcantara from manufacturers that adhere to strict environmental regulations and labor standards. Certifications such as Oeko-Tex and Global Recycle Standard can serve as indicators of a supplier’s commitment to sustainable practices. These certifications not only enhance brand reputation but also appeal to an increasingly eco-conscious consumer base.

Illustrative image related to what is alcantara fabric

Moreover, the push for ‘green’ materials is gaining traction. Buyers are encouraged to explore alternatives that utilize recycled materials or sustainable production methods. By doing so, they not only contribute to reducing the overall carbon footprint but also align with the values of a modern consumer base that is increasingly prioritizing sustainability in their purchasing decisions.

What Is the Historical Context Behind Alcantara Fabric Development?

Alcantara was developed in the 1970s by a Japanese chemist and has since been manufactured by the Italian company Alcantara S.p.A. This innovative fabric has evolved from a niche luxury material to a widely recognized textile used across various sectors. Initially, its use was predominantly in high-end automobiles, but its unique properties—lightweight, durable, and aesthetically appealing—have led to its adoption in fashion, interior design, and consumer electronics.

The evolution of Alcantara reflects broader trends in material science and consumer preferences, particularly the growing demand for sustainable and ethical products. As B2B buyers navigate the current landscape, understanding the historical significance of Alcantara can provide valuable context for sourcing decisions, helping them recognize its potential beyond mere aesthetic appeal.

Frequently Asked Questions (FAQs) for B2B Buyers of what is alcantara fabric

-

How do I clean and maintain Alcantara fabric?

Cleaning Alcantara fabric requires gentle care to preserve its appearance and texture. Use a soft, damp microfibre cloth to wipe away dirt and oils, as harsh chemicals can damage the fibers. For deeper cleaning, consider a specialized upholstery cleaner compatible with Alcantara. Regular maintenance, such as brushing the fabric with a soft brush, can help restore its nap and prevent flattening. Always refer to specific cleaning instructions provided by the manufacturer to ensure the longevity of the fabric. -

What are the key benefits of using Alcantara fabric for my products?

Alcantara fabric offers several advantages, including a premium aesthetic, durability, and excellent grip, making it ideal for automotive interiors, furniture, and fashion accessories. Its synthetic nature means it is vegan-friendly and does not involve animal byproducts, appealing to eco-conscious consumers. Additionally, Alcantara is lighter than leather, flame-retardant, and moisture-resistant, making it a versatile choice for various applications. These features can enhance your product offerings and attract a broader customer base. -

What is the typical minimum order quantity (MOQ) for Alcantara fabric?

The minimum order quantity for Alcantara fabric can vary significantly depending on the supplier and the specific type of fabric requested. Generally, MOQs can range from 50 to 500 meters for custom orders. It’s crucial to communicate your requirements with potential suppliers to negotiate MOQs that align with your production needs. Smaller businesses may benefit from suppliers who offer stock items with lower MOQs to reduce initial investment risks. -

How can I verify the quality of Alcantara fabric from suppliers?

To ensure the quality of Alcantara fabric, request samples from suppliers before placing a bulk order. Examine the fabric for texture, color consistency, and durability. Additionally, inquire about the supplier’s production processes, certifications, and quality assurance measures. It’s also beneficial to read reviews or obtain references from other businesses that have sourced from the supplier to gauge their reliability and product quality. -

What payment terms should I expect when sourcing Alcantara fabric?

Payment terms for Alcantara fabric can vary among suppliers, but common practices include a 30% deposit upon order confirmation, with the balance due before shipping. Some suppliers may offer net payment terms based on your credit history or relationship with them. Be sure to discuss payment options upfront to avoid any misunderstandings later. Consider establishing a letter of credit for larger transactions to enhance security and trust in international trade. -

How does Alcantara compare to other synthetic fabrics in terms of cost and durability?

Alcantara is generally priced similarly to high-quality synthetic fabrics and leather, making it a premium option for manufacturers. While it offers superior durability and a luxurious feel, it may require more maintenance than traditional fabrics. In comparison to other synthetics, Alcantara is more resistant to wear and tear, but it can absorb oils and dirt, which may necessitate regular cleaning. Evaluate your target market’s preferences and budget to determine if Alcantara aligns with your product strategy. -

What customization options are available for Alcantara fabric?

Customization options for Alcantara fabric often include a variety of colors, textures, and patterns. Suppliers may also offer the ability to print logos or designs directly onto the fabric, catering to specific branding needs. To explore customization possibilities, engage in discussions with your supplier early in the sourcing process. This ensures that you can obtain a product that meets your design specifications while still adhering to production timelines. -

What logistical considerations should I keep in mind when importing Alcantara fabric?

When importing Alcantara fabric, consider factors such as shipping methods, lead times, and customs regulations. Choose a reliable logistics partner experienced in handling textile imports to ensure timely delivery. Understand the import duties and tariffs applicable in your region, as these can impact overall costs. Additionally, account for potential delays in shipping due to customs inspections or documentation issues, and plan your inventory accordingly to avoid disruptions in your supply chain.

Top 5 What Is Alcantara Fabric Manufacturers & Suppliers List

1. Alcantara – Synthetic Textile for Car Interiors

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic textile made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is used in car interiors for upholstery on seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic, flame retardant properties, lightw…

2. Alcantara – Synthetic Suede Material

Domain: motortrend.com

Registered: 1998 (27 years)

Introduction: Alcantara is a synthetic suedelike material made of 68% polyester and 32% non-fibrous polyurethane, invented in the early 1970s by Miyoshi Okamoto. It is produced in Italy by Alcantara S.p.A. The fabric is commonly used in high-end automotive interiors and aftermarket parts, often as a substitute or complement to leather. Alcantara has a matte finish that reduces glare and provides a less slippery…

3. Alcantara – Unique Material

Domain: alcantara.com

Registered: 1996 (29 years)

Introduction: Alcantara is a 100% Italian brand known for its unique and exclusive material, which is versatile and suitable for various applications. Key features include:

– Elegant and soft to the touch

– Durable and easy to care for

– Can assume any aesthetic form

– Resistant to light and heat

– Breathable, warm in winter and cool in summer

– Low maintenance, can be washed and ironed

– Ideal for outdo…

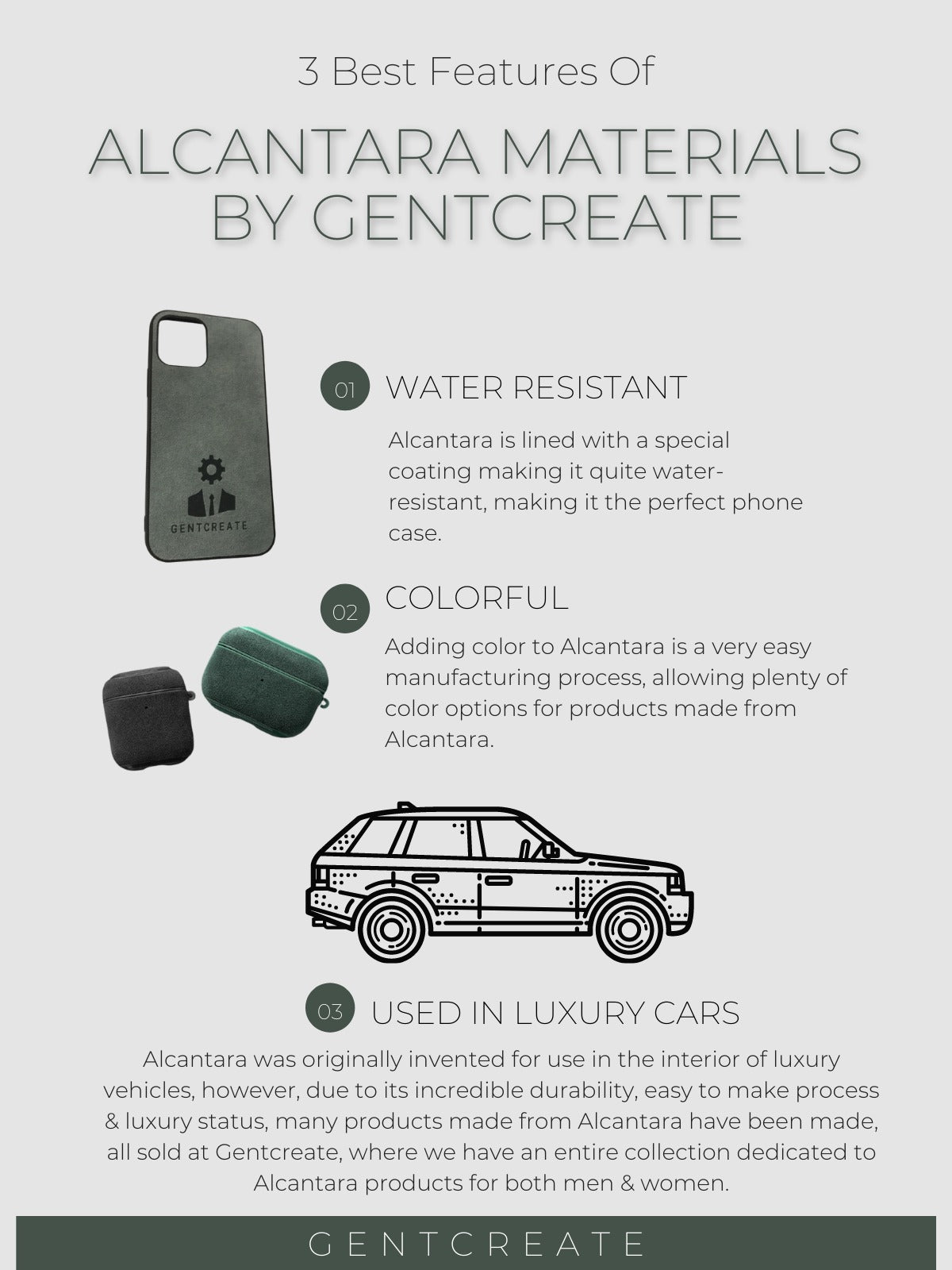

4. Gentcreate – Alcantara Material

Domain: gentcreate.com

Registered: 2020 (5 years)

Introduction: Alcantara is a synthetic material made primarily from a blend of 70% polyester and 30% polyurethane. It is resistant to fading, staining, scratching, and high temperatures. Alcantara has a leather-like texture but is not derived from animal skin, making it a vegan alternative to leather. It is used in various applications including fashion, clothing, footwear, accessories, furniture, and car inter…

5. Leather Repair Company – Suedes and Alcantara Guide

Domain: leatherrepaircompany.com

Registered: 2007 (18 years)

Introduction: Know Your Suedes and Alcantara Fabric Materials guide provides insights on distinguishing between suede, nubuck, and Alcantara fabrics. Key details include:

– Nubuck is top grain cattle leather sanded on the grain side for a velvet feel, showing grain structure.

– Suede is made from the lower quality split of the hide, lacking visible grain.

– Alcantara is a faux material with individual fibers…

Strategic Sourcing Conclusion and Outlook for what is alcantara fabric

Alcantara fabric has emerged as a versatile and premium material, particularly valued in automotive, fashion, and interior design sectors. Its unique blend of polyester and polyurethane not only offers a suede-like aesthetic but also enhances durability and grip, making it an attractive alternative to traditional leather and other fabrics. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the properties and applications of Alcantara is crucial for strategic sourcing decisions.

Illustrative image related to what is alcantara fabric

Investing in Alcantara can provide significant value, as it combines luxury with practicality, appealing to a broad customer base looking for high-quality materials. However, it’s essential to consider the maintenance requirements and potential wear over time, which may influence product offerings and customer satisfaction.

As the demand for sustainable and innovative materials continues to rise, integrating Alcantara into your supply chain can position your business advantageously in a competitive market. We encourage buyers to explore partnerships with reputable suppliers to harness the full potential of Alcantara fabric and meet the evolving needs of consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to what is alcantara fabric