Introduction: Navigating the Global Market for how to make a leather purse

The global market for leather goods is thriving, with the demand for high-quality leather purses rising steadily across diverse regions, including Africa, South America, the Middle East, and Europe. However, navigating the complexities of sourcing materials, selecting reliable suppliers, and understanding production techniques can pose significant challenges for B2B buyers. This comprehensive guide on how to make a leather purse is designed to address these challenges head-on, equipping you with actionable insights and strategies to make informed purchasing decisions.

Within this guide, you will explore a wide array of leather purse types—from elegant clutches to rugged totes—each with unique applications that cater to various consumer preferences. We delve into critical topics such as supplier vetting processes, cost considerations, and essential techniques for crafting durable and stylish leather products. By highlighting best practices and industry standards, this guide empowers international buyers to confidently source leather goods that not only meet quality expectations but also resonate with local markets.

Whether you are a retailer in Nigeria looking to expand your product line or a fashion distributor in Germany seeking to capitalize on the latest trends, this resource will serve as a vital tool in your strategic planning. Embrace the opportunity to enhance your offerings while ensuring compliance with international standards, ultimately leading to greater customer satisfaction and business growth.

Table Of Contents

- Top 5 How To Make A Leather Purse Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather purse

- Understanding how to make a leather purse Types and Variations

- Key Industrial Applications of how to make a leather purse

- 3 Common User Pain Points for ‘how to make a leather purse’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather purse

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather purse

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather purse’

- Comprehensive Cost and Pricing Analysis for how to make a leather purse Sourcing

- Alternatives Analysis: Comparing how to make a leather purse With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather purse

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather purse Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather purse

- Strategic Sourcing Conclusion and Outlook for how to make a leather purse

- Important Disclaimer & Terms of Use

Understanding how to make a leather purse Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tote Bag | Spacious, open design; often has short and long straps | Retail, fashion accessories, corporate giveaways | Pros: Versatile; Cons: Less secure than zippered bags |

| Clutch | Compact, handheld design; often embellished or stylish | Evening events, fashion boutiques | Pros: Stylish; Cons: Limited storage capacity |

| Saddlebag | Crossbody style; typically features a flap closure | Casual wear, outdoor activities | Pros: Functional; Cons: May not suit formal occasions |

| Pouch | Small, simple design; often used for organization | Travel accessories, promotional items | Pros: Lightweight; Cons: Limited use case |

| Briefcase | Structured design; typically includes compartments | Professional settings, business travel | Pros: Organized; Cons: Bulky for casual use |

What Are the Key Characteristics of a Tote Bag?

Tote bags are characterized by their large, open design, which allows for easy access to contents. They often come with both short handles and longer straps, making them versatile for various uses. For B2B buyers, totes are ideal for retail and corporate giveaways, as they can be customized with branding. While they provide ample space for items, their lack of secure closures may be a drawback for some buyers concerned about theft.

How Does a Clutch Stand Out in the Market?

Clutches are small, handheld bags that are often used for formal occasions. They can be embellished with various designs, making them attractive for fashion boutiques. B2B buyers should consider the target demographic when purchasing clutches, as they are primarily suited for evening events. The compact nature of clutches limits storage capacity, which may not be ideal for all consumers, but their stylish appeal can drive sales in niche markets.

What Makes a Saddlebag a Popular Choice?

Saddlebags are designed for crossbody wear and typically feature a flap closure, giving them a casual yet functional look. They are popular in outdoor and casual settings, making them ideal for buyers focused on lifestyle brands. The practicality of saddlebags makes them suitable for everyday use, but they may not fit well in formal contexts. B2B purchasers should evaluate their target market’s lifestyle to ensure the saddlebag aligns with consumer needs.

Why Consider a Pouch for Your Product Line?

Pouches are simple, small bags often utilized for organization and storage. They are lightweight and can be used for travel accessories or as promotional items. For B2B buyers, pouches are versatile and can be easily branded, making them a popular choice for giveaways. However, their limited capacity and functionality may restrict their appeal in certain markets, making it essential to identify the right use cases for effective sales strategies.

How Does a Briefcase Meet Business Needs?

Briefcases are structured bags designed for professionals, typically featuring multiple compartments for organization. They are ideal for business travel and professional settings, making them a staple for B2B buyers in corporate environments. While briefcases provide excellent organization, their bulkiness may deter casual users. Buyers should consider the balance between functionality and style when selecting briefcases for their product offerings, ensuring they meet the demands of modern professionals.

Key Industrial Applications of how to make a leather purse

| Industry/Sector | Specific Application of how to make a leather purse | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom leather purse production for retail brands | High-quality, unique products that enhance brand identity | Sourcing premium leather, skilled artisans, and sustainable practices |

| Craft & DIY Supplies | DIY leather purse kits for hobbyists | Expanding product lines to meet growing DIY trends | Cost-effective materials, detailed instructional content, and packaging |

| Corporate Gifting | Personalized leather purses for corporate gifts | Strengthening client relationships through unique, branded gifts | Customization options, bulk ordering capabilities, and international shipping |

| E-commerce & Online Retail | Online sales of handmade leather purses | Tapping into global markets with trending products | Reliable logistics, payment gateways, and customer service support |

| Sustainable Fashion | Eco-friendly leather purses for conscious consumers | Meeting the demand for sustainable products and enhancing brand reputation | Sourcing ethically produced leather and sustainable materials |

How is Custom Leather Purse Production Beneficial for Fashion Brands?

In the fashion and accessories sector, custom leather purse production allows brands to offer high-quality, unique products that resonate with consumers. This personalization enhances brand identity and fosters customer loyalty. International B2B buyers must consider sourcing premium leather and collaborating with skilled artisans to ensure the final products meet market expectations. Additionally, sustainable practices are increasingly important, as consumers prioritize eco-friendly brands.

Why are DIY Leather Purse Kits Important for Craft & DIY Suppliers?

DIY leather purse kits present a lucrative opportunity for craft and DIY suppliers. By providing comprehensive kits that include all necessary materials and instructions, businesses can tap into the growing trend of home crafting. This application not only expands product lines but also caters to a diverse customer base. Buyers should focus on sourcing cost-effective materials and creating detailed instructional content that appeals to both beginners and experienced crafters.

How Can Corporate Gifting Leverage Personalized Leather Purses?

In the realm of corporate gifting, personalized leather purses serve as exceptional gifts that strengthen client relationships. They offer a unique way to showcase a company’s brand while providing recipients with a functional item. For international buyers, it’s essential to ensure customization options and bulk ordering capabilities are available, along with efficient international shipping to reach global clients seamlessly.

What Are the Advantages of Selling Handmade Leather Purses Online?

E-commerce platforms provide a significant avenue for selling handmade leather purses, allowing businesses to reach global markets. This application is particularly advantageous as it aligns with consumer trends favoring unique, artisanal products. Buyers should focus on establishing reliable logistics and payment gateways to facilitate smooth transactions while ensuring robust customer service support to enhance the shopping experience.

How Does Sustainable Fashion Influence Leather Purse Production?

Sustainable fashion has become a driving force in consumer purchasing decisions, making eco-friendly leather purses a vital application for brands. By sourcing ethically produced leather and sustainable materials, businesses can meet the demand for environmentally conscious products, thereby enhancing their reputation. International B2B buyers must consider the sustainability credentials of their suppliers to align with consumer expectations and regulatory requirements in various regions.

Illustrative image related to how to make a leather purse

3 Common User Pain Points for ‘how to make a leather purse’ & Their Solutions

Scenario 1: Navigating Material Quality for Leather Purse Production

The Problem: One of the foremost challenges faced by B2B buyers in the leather goods industry is sourcing high-quality leather. Buyers from various regions, particularly in Africa and South America, often encounter difficulties in ensuring the leather meets their quality standards. This concern is exacerbated by the varying grades of leather available, which can significantly impact the final product’s durability, aesthetics, and overall marketability. Compromising on material quality can lead to increased returns and dissatisfied customers, which can damage a brand’s reputation.

The Solution: To address this issue, it’s essential for buyers to establish strong relationships with reputable suppliers who can provide detailed information about the leather’s origin, tanning process, and grade. Conducting thorough research and visiting tanneries, if possible, can yield valuable insights into the quality of materials. Additionally, implementing a sample-testing phase before committing to large orders can mitigate risks. Buyers should also consider investing in leather certification programs that ensure the material is sourced ethically and sustainably, which can enhance brand image and appeal to environmentally conscious consumers.

Scenario 2: Overcoming Complexity in Leather Purse Assembly

The Problem: Another significant pain point for B2B buyers is the complexity involved in the assembly of leather purses. Many buyers lack the technical know-how or workforce skilled in leather craftsmanship, which can lead to errors in production, delays, and increased costs. The fear of producing subpar products due to assembly mistakes can be daunting, especially for companies aiming to penetrate high-end markets where quality is paramount.

The Solution: To streamline the assembly process, companies should consider investing in comprehensive training programs for their workforce. Collaborating with experienced leather artisans to conduct workshops can build essential skills among employees. Additionally, opting for DIY leather purse kits that come with pre-cut materials and clear instructional videos can significantly reduce complexity. These kits not only simplify the production process but also allow businesses to maintain high-quality standards without requiring extensive expertise. Moreover, leveraging technology such as augmented reality (AR) for virtual assembly guidance can enhance learning and efficiency.

Scenario 3: Dealing with Customization Requests from Clients

The Problem: As consumer preferences evolve, B2B buyers increasingly face the challenge of fulfilling customization requests for leather purses. Buyers must strike a balance between meeting client demands for unique designs and maintaining production efficiency. Failure to effectively manage customization can lead to bottlenecks in the supply chain, wasted resources, and ultimately, lost sales opportunities.

The Solution: To effectively manage customization requests, companies should adopt a modular design approach for leather purses. This method allows for a base model that can be easily customized with various colors, patterns, and accessories without requiring an entirely new production process. Additionally, implementing a digital platform for clients to visualize their customizations can streamline the ordering process. Buyers should also encourage open communication with clients to understand their specific needs, which can lead to collaborative design efforts. By establishing a clear framework for customization, businesses can enhance customer satisfaction while optimizing production workflows.

Strategic Material Selection Guide for how to make a leather purse

What Are the Key Materials for Making a Leather Purse?

When selecting materials for crafting leather purses, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: full-grain leather, top-grain leather, suede, and synthetic leather. Each material has unique characteristics that can influence the final product’s performance and marketability.

How Does Full-Grain Leather Perform in Purse Manufacturing?

Full-grain leather is the highest quality leather available, made from the top layer of the hide, retaining the natural grain. Its key properties include exceptional durability, breathability, and the ability to develop a rich patina over time. This material can withstand various environmental conditions, making it suitable for long-lasting products.

Pros: Full-grain leather offers unmatched durability and aesthetic appeal, making it ideal for high-end leather purses. Its natural characteristics mean that it ages beautifully, enhancing its value over time.

Illustrative image related to how to make a leather purse

Cons: The primary drawback is its cost, as full-grain leather is often more expensive than other types. Additionally, it requires more care and maintenance to prevent damage from moisture and scratches.

Impact on Application: Full-grain leather is compatible with luxury markets, appealing to consumers looking for quality and longevity in their purchases.

Considerations for International Buyers: Buyers should be aware of compliance with international leather standards, such as the ISO 17075 for leather testing. Additionally, understanding local preferences for leather quality can help in targeting specific markets, such as the luxury segment in Germany.

What Are the Advantages of Top-Grain Leather?

Top-grain leather is the second-highest quality leather, made from the upper layer of the hide but sanded and treated to remove imperfections. This material is slightly less durable than full-grain leather but offers a more uniform appearance.

Pros: Top-grain leather is more affordable than full-grain leather while still providing a premium look and feel. It is also easier to maintain due to its treated surface, making it a popular choice for everyday purses.

Cons: While it is durable, top-grain leather does not develop the same rich patina as full-grain leather, which may affect its long-term appeal.

Impact on Application: This material is suitable for mid-range products, appealing to consumers who desire quality without the high price tag.

Illustrative image related to how to make a leather purse

Considerations for International Buyers: Compliance with standards such as ASTM D7255 for leather testing is crucial. Buyers should also consider regional preferences for leather finishes, particularly in markets like South America, where vibrant colors may be favored.

How Does Suede Compare to Other Leather Types?

Suede is made from the inner layer of the hide, giving it a soft, velvety texture. Its key properties include flexibility and a unique aesthetic, although it is less durable than full-grain or top-grain leather.

Pros: Suede offers a luxurious feel and is often used in fashion-forward designs, making it appealing to trendy markets. It is lightweight and can be dyed in various colors.

Cons: Suede is more susceptible to stains and water damage, which can limit its usability in certain environments. It also requires special care for cleaning and maintenance.

Impact on Application: Suede is ideal for fashion-centric purses but may not be suitable for all markets, particularly in regions with high humidity or rain, such as parts of Africa.

Considerations for International Buyers: Buyers should be aware of the need for specialized cleaning products and maintenance guidelines. Additionally, understanding local climate conditions can impact the decision to use suede in specific markets.

Illustrative image related to how to make a leather purse

What Role Does Synthetic Leather Play in Purse Manufacturing?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is designed to mimic the appearance and feel of genuine leather. Its key properties include water resistance and ease of cleaning.

Pros: Synthetic leather is typically more affordable than genuine leather and can be produced in a wide range of colors and textures. It is also vegan-friendly, appealing to environmentally conscious consumers.

Cons: While it is durable, synthetic leather may not offer the same longevity or aesthetic appeal as natural leather. Over time, it can wear and lose its visual appeal.

Impact on Application: This material is suitable for budget-friendly products and can cater to a broader audience, particularly in emerging markets.

Illustrative image related to how to make a leather purse

Considerations for International Buyers: Buyers should ensure compliance with environmental regulations regarding synthetic materials, such as REACH in Europe. Understanding consumer preferences for sustainable products can also enhance marketability.

Summary Table of Material Selection for Leather Purses

| Material | Typical Use Case for how to make a leather purse | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end luxury purses | Exceptional durability and patina | High cost and maintenance required | High |

| Top-Grain Leather | Mid-range quality purses | Affordable with premium appearance | Less durability than full-grain | Med |

| Suede | Fashion-forward purses | Luxurious feel and lightweight | Susceptible to stains and damage | Med |

| Synthetic Leather | Budget-friendly purses | Affordable and vegan-friendly | Less durability and longevity | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather purse

What Are the Main Stages in the Manufacturing Process for Leather Purses?

The manufacturing process of leather purses involves several critical stages that ensure both the aesthetic appeal and functionality of the final product. These stages include material preparation, forming, assembly, and finishing. Each stage employs specific techniques tailored to the unique characteristics of leather.

How Is Material Prepared for Leather Purse Production?

Material preparation begins with sourcing high-quality leather, which is typically derived from cowhide, lambskin, or exotic leathers. Suppliers must ensure the leather is tanned properly to enhance durability and resistance to wear. Tanning processes can vary, with vegetable tanning being preferred for its eco-friendliness, while chrome tanning is favored for its efficiency and color retention.

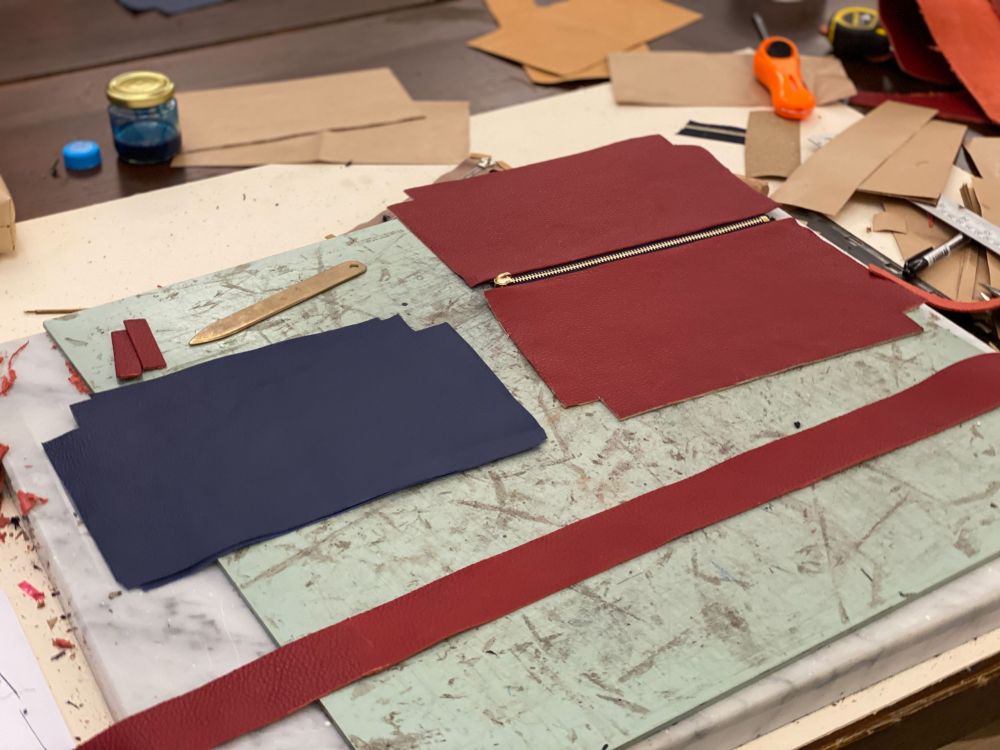

Illustrative image related to how to make a leather purse

Once sourced, the leather is cut into required shapes, often utilizing advanced cutting machines or hand tools for more intricate designs. It’s essential that the leather pieces are inspected for defects at this stage, ensuring only the best materials proceed to the next phase.

What Techniques Are Used for Forming Leather Purses?

Forming is where the leather begins to take its final shape. Techniques such as die cutting and laser cutting are common, allowing for precise and complex designs. After cutting, the leather pieces may undergo processes like embossing or debossing, which add texture and branding elements.

Heat and moisture may be applied to soften the leather, making it easier to mold into the desired shapes. This is particularly important for structured bags that require a defined silhouette. Furthermore, edge finishing techniques, such as burnishing, are employed to give the edges a polished look and prevent fraying.

How Is the Assembly Process Conducted for Leather Purses?

The assembly stage involves stitching the various leather components together. Hand-stitching is often preferred for high-quality leather purses due to its strength and aesthetic appeal, with the saddle stitch being a popular choice. This method involves using two needles on either end of a single thread, creating a robust seam that can withstand stress.

Illustrative image related to how to make a leather purse

During assembly, additional components such as zippers, buckles, and decorative elements are integrated. It is crucial to maintain alignment and symmetry throughout this process to ensure the finished purse is visually appealing and functional.

What Finishing Techniques Enhance the Quality of Leather Purses?

Finishing techniques include dyeing, conditioning, and applying protective coatings. Dyeing adds color and can enhance the leather’s natural grain, while conditioning treatments ensure the leather remains supple and resistant to cracking. Finally, a protective finish may be applied to guard against water and stains, ensuring longevity.

Quality assurance is critical during this stage to ensure that all finishes are uniform and meet the desired specifications. Any imperfections must be addressed before the product is packaged for distribution.

How Is Quality Assurance Implemented in Leather Purse Manufacturing?

Quality assurance (QA) in leather purse manufacturing is a multi-step process that adheres to both international standards and industry-specific requirements. Implementing a robust QA system ensures that products meet customer expectations and regulatory compliance.

Which International Standards Guide Quality Assurance in Leather Manufacturing?

Adhering to international standards such as ISO 9001 is vital for manufacturers looking to establish credibility in the B2B market. ISO 9001 outlines the requirements for a quality management system (QMS), focusing on continuous improvement and customer satisfaction. In addition to ISO, manufacturers may also comply with CE marking standards, particularly when exporting to Europe, which indicates conformity with health, safety, and environmental protection standards.

What Are Key Quality Control Checkpoints During Leather Purse Production?

Quality control (QC) checkpoints are integral at various stages of production:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified quality criteria. Any defective materials are rejected to prevent downstream issues.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor compliance with production standards. This includes checking stitching consistency, alignment, and the quality of finishes.

-

Final Quality Control (FQC): This stage involves a comprehensive inspection of the finished product before packaging. It assesses overall construction, appearance, and functionality, ensuring that the purse meets all quality standards.

What Common Testing Methods Are Used to Ensure Leather Quality?

Common testing methods include tensile strength tests to evaluate the leather’s durability, water resistance tests to assess protective finishes, and colorfastness tests to ensure dyes do not bleed or fade. Manufacturers may also conduct visual inspections for aesthetic defects, such as scratches or inconsistent stitching.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should implement several strategies to verify supplier QC practices:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This includes evaluating their compliance with international standards and internal QA protocols.

-

Requesting Quality Reports: Buyers should ask for documentation of quality control tests and inspections, which can demonstrate the supplier’s commitment to maintaining high standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can conduct inspections at various stages of production, ensuring compliance with agreed-upon specifications.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various QC and certification nuances when sourcing leather purses. Different regions may have specific regulatory requirements, such as customs documentation and certifications for imported goods.

Illustrative image related to how to make a leather purse

In Africa, for instance, buyers might face challenges related to import tariffs and customs inspections, which can delay delivery times. Conversely, buyers in Europe may prioritize suppliers with CE certifications due to stringent product safety regulations.

Understanding these regional differences and maintaining open communication with suppliers can mitigate risks and ensure a smooth procurement process.

Conclusion

The manufacturing processes and quality assurance practices for leather purses are complex and multifaceted. For B2B buyers, particularly those in emerging markets, understanding these processes is crucial for making informed purchasing decisions. By focusing on quality control checkpoints, international standards, and supplier verification strategies, businesses can ensure they procure high-quality leather products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather purse’

This guide serves as a practical checklist for B2B buyers interested in procuring materials and resources to create leather purses. By following these steps, businesses can streamline their sourcing process, ensuring they acquire quality materials and reliable suppliers while navigating international markets effectively.

Step 1: Identify Your Design Requirements

Before sourcing materials, clearly define the design and style of the leather purse you want to create. Consider factors such as size, color, and functionality. Understanding your design requirements will guide your material selection and help communicate effectively with suppliers.

Illustrative image related to how to make a leather purse

- Consider target market preferences: Research trends in your target regions (e.g., Africa, Europe) to align your product with local tastes.

- Assess potential variations: Decide whether you want to offer multiple styles or a single signature piece to simplify your sourcing.

Step 2: Source High-Quality Leather Materials

Quality leather is vital for durability and aesthetic appeal. Look for reputable suppliers who offer a variety of leather types, such as full-grain, top-grain, or suede, depending on your product specifications.

- Request samples: Always ask for leather samples to assess texture, weight, and color fidelity before making bulk orders.

- Check sustainability practices: Ensure the leather is sourced ethically, as consumers increasingly prefer environmentally friendly products.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your quality and quantity demands. Reliable suppliers will have a strong track record and positive reviews from other businesses in your industry.

- Request certifications: Look for ISO certifications or other quality assurance documents to verify their production standards.

- Ask for client references: Speaking with other buyers who have sourced from the supplier can provide insights into their reliability and service quality.

Step 4: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms upfront to avoid surprises later. Transparency in pricing can help you budget effectively and ensure you maintain healthy profit margins.

- Negotiate bulk discounts: If you plan to place large orders, inquire about discounts for bulk purchases.

- Clarify payment options: Confirm acceptable payment methods and any terms for deposits or payment upon delivery.

Step 5: Assess Shipping and Delivery Capabilities

International shipping can be complex, so ensure your supplier can handle logistics efficiently. Confirm their ability to ship to your target regions without excessive delays or additional customs fees.

Illustrative image related to how to make a leather purse

- Inquire about lead times: Understand how long it will take for materials to arrive, factoring in production time.

- Check customs handling: Suppliers with experience in international shipping can help navigate customs requirements specific to your destination countries.

Step 6: Request Prototypes for Quality Assurance

Before committing to large orders, request prototypes or small batches of the leather purses. This step allows you to evaluate the final product and make any necessary adjustments.

- Test functionality and aesthetics: Ensure the prototype meets your design specifications and quality standards.

- Gather feedback: Share prototypes with potential customers or industry peers to gather constructive feedback before full-scale production.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing materials for leather purses, ensuring a successful and streamlined procurement process.

Comprehensive Cost and Pricing Analysis for how to make a leather purse Sourcing

What Are the Key Cost Components in Leather Purse Production?

When analyzing the cost structure for producing leather purses, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary expense in leather purse production is the cost of high-quality leather. Prices can vary significantly based on the type (e.g., cowhide, exotic leathers like crocodile), thickness, and finish. Additional materials, such as threads, zippers, and metal hardware, also contribute to the total material costs.

-

Labor: Labor costs encompass the wages for skilled artisans who cut, sew, and finish the purses. In regions like Africa and South America, labor costs may be lower than in Europe, but the skill level required for quality leatherwork can necessitate higher wages for experienced workers.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and maintenance of equipment. Overhead costs can vary by location and may influence the final pricing structure.

-

Tooling: For custom designs, tooling costs can be significant. This includes the expense of dies, molds, and specialized equipment required to create unique purse designs.

-

Quality Control: Ensuring the final product meets quality standards is crucial. QC processes can involve additional labor and testing, contributing to overall production costs.

-

Logistics: Shipping costs, import duties, and handling fees must be factored into the pricing, especially for international transactions. The complexity of logistics can differ based on the buyer’s location and the supplier’s shipping capabilities.

-

Margin: Finally, the profit margin is added to cover business operating expenses and desired profit. Margins can vary depending on market positioning and competitive landscape.

How Do Price Influencers Affect Leather Purse Sourcing?

Several factors can influence the pricing of leather purses, particularly for B2B buyers.

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate better deals.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Quality and Certifications: High-quality materials and certifications (e.g., eco-friendly production) can drive up costs but may be necessary for certain markets. Buyers should assess the importance of these factors based on their target audience.

-

Supplier Factors: Supplier reliability, experience, and reputation can impact pricing. Established suppliers may charge more for their expertise and quality assurance.

-

Incoterms: The agreed-upon Incoterms can significantly affect the total cost of ownership. Buyers should be aware of whether prices include shipping, insurance, and duties to avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Purse Sourcing?

To maximize cost-efficiency in sourcing leather purses, buyers should consider the following strategies:

Illustrative image related to how to make a leather purse

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Total Cost of Ownership: Evaluate not just the purchase price but also the costs associated with shipping, customs, and handling. Understanding the total cost can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: International buyers should be mindful of currency fluctuations, import tariffs, and regional pricing trends. For instance, buyers in Germany may face different logistics costs compared to those in Nigeria due to local regulations and transport infrastructure.

-

Research and Networking: Building relationships with suppliers and attending trade shows can provide insights into market trends and pricing strategies. Networking can also lead to better deals and more favorable terms.

In conclusion, understanding the cost components and price influencers in leather purse production is crucial for B2B buyers. By applying these insights and strategies, businesses can optimize their sourcing processes and achieve better pricing outcomes.

Alternatives Analysis: Comparing how to make a leather purse With Other Solutions

Introduction to Alternatives for Making Leather Purses

When considering how to make a leather purse, it’s essential to evaluate various alternatives that can achieve similar outcomes. This analysis will help B2B buyers identify the best method suited to their production capabilities, target market, and budget constraints. The following comparison examines traditional leather crafting against alternative solutions such as synthetic material production and mass-manufactured leather goods.

Comparison Table

| Comparison Aspect | How To Make A Leather Purse | Alternative 1: Synthetic Leather Production | Alternative 2: Mass-Manufactured Leather Goods |

|---|---|---|---|

| Performance | High quality, unique designs | Variable quality, often less durable | Consistent quality, often lower than handmade |

| Cost | Moderate to high, depending on materials | Generally lower due to cheaper materials | Low cost per unit due to economies of scale |

| Ease of Implementation | Requires skilled craftsmanship | Easy to produce in bulk | Simple process, often automated |

| Maintenance | Requires care and occasional repairs | Generally easy to maintain | Minimal maintenance needed, often machine washable |

| Best Use Case | Custom, artisanal markets | Fast fashion, budget-conscious consumers | Retail chains looking for uniformity |

Detailed Breakdown of Alternatives

Alternative 1: Synthetic Leather Production

Synthetic leather, often made from PVC or polyurethane, offers a cost-effective and versatile option for creating purses. While the production process is less labor-intensive than traditional leather crafting, the quality can vary significantly. Synthetic leather is lighter and often waterproof, making it appealing for trendy, budget-conscious consumers. However, it may not provide the same durability or aesthetic appeal as genuine leather, which could impact brand perception in markets where quality is paramount.

Alternative 2: Mass-Manufactured Leather Goods

Mass-manufactured leather goods are produced on a large scale, leveraging automated processes to reduce costs significantly. This method allows for a consistent product that can be delivered quickly to retailers. However, the downsides include a lack of customization and uniqueness, which can alienate consumers seeking artisanal or bespoke products. Additionally, mass production often leads to lower quality materials, which may not withstand the test of time as well as handmade leather purses.

Illustrative image related to how to make a leather purse

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right method for producing leather purses hinges on understanding their target market and production capabilities. If aiming for a high-end, customized product, investing in traditional leather crafting may yield the best return despite higher costs and labor intensity. Conversely, if the focus is on rapid production and affordability, synthetic leather or mass-manufactured options may be more appropriate. Understanding these alternatives will enable buyers to align their product offerings with market demands while optimizing their operational efficiencies.

Essential Technical Properties and Trade Terminology for how to make a leather purse

What Are the Key Technical Properties for Making a Leather Purse?

When entering the leather goods market, understanding the technical specifications of materials and construction is vital. Here are some essential properties to consider:

1. Material Grade

The grade of leather is a critical specification that defines the quality and durability of the purse. Common grades include full-grain, top-grain, corrected grain, and bonded leather. Full-grain leather, for instance, retains the natural surface, offering superior strength and aging characteristics. Buyers should prioritize high-grade materials to ensure longevity and appeal, particularly in competitive markets where craftsmanship is valued.

2. Tolerance Levels

Tolerance refers to the allowable variation in dimensions during the manufacturing process. For leather purses, maintaining precise tolerances is crucial for ensuring that components fit together seamlessly. Inconsistent tolerances can lead to defects, impacting the product’s aesthetic and functional quality. B2B buyers must communicate their tolerance requirements clearly to avoid costly rework and ensure product consistency.

Illustrative image related to how to make a leather purse

3. Stitching Density

Stitching density, or the number of stitches per inch, affects the purse’s durability and appearance. A higher stitch density typically indicates a stronger seam, which is essential for items subjected to frequent use. B2B buyers should specify their desired stitching density based on intended use—higher for utility bags and lower for fashion items—helping manufacturers align with customer expectations.

4. Finish and Treatment

The finish applied to leather not only enhances its visual appeal but also provides protective qualities. Common treatments include oiling, waxing, or applying water-resistant coatings. Understanding the desired finish is essential for B2B buyers, as it affects the product’s marketability and performance in various environments, particularly in regions with varying climates.

5. Weight and Thickness

Leather weight (measured in ounces) and thickness (often in millimeters) are crucial factors that influence the purse’s look and feel. Heavier, thicker leather typically offers more structure and durability, while lighter leather provides flexibility and comfort. B2B buyers should consider their target market’s preferences when specifying weight and thickness, as these factors can significantly impact consumer satisfaction.

Illustrative image related to how to make a leather purse

What Are Common Trade Terms in the Leather Purse Industry?

Understanding industry jargon is essential for effective communication and negotiation in the leather goods market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods based on the designs and specifications provided by another company. In the leather purse industry, this is crucial for businesses looking to have their designs manufactured without investing in production facilities. Establishing an OEM relationship can lead to cost savings and efficiency.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers, as understanding MOQs helps in planning inventory and production schedules. Negotiating favorable MOQs can lead to better cash flow management and inventory control.

Illustrative image related to how to make a leather purse

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific goods or services. In the context of leather purses, an RFQ can include specifications such as material grade, design, and order quantity. This process is essential for comparing suppliers and securing competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is crucial for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and customs duties. Proper understanding can prevent misunderstandings and disputes during the purchasing process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the leather purse industry, lead time can vary based on production schedules and material availability. B2B buyers must account for lead time when planning product launches or inventory replenishment to ensure timely delivery and customer satisfaction.

By understanding these technical properties and trade terms, international B2B buyers can navigate the complexities of the leather purse market with confidence, ensuring they make informed decisions that align with their business goals.

Illustrative image related to how to make a leather purse

Navigating Market Dynamics and Sourcing Trends in the how to make a leather purse Sector

What Are the Key Market Dynamics and Trends Influencing Leather Purse Production?

The leather purse sector is experiencing significant growth driven by a combination of fashion trends, technological advancements, and consumer preferences. Globally, the increasing demand for handmade and artisanal products is reshaping the market, particularly among B2B buyers in regions such as Africa, South America, the Middle East, and Europe. Countries like Nigeria and Germany are witnessing a shift towards locally sourced, high-quality leather goods, with buyers seeking unique designs that cater to a growing demographic of eco-conscious consumers.

Emerging B2B technologies, including e-commerce platforms and digital design tools, are streamlining the sourcing process. Buyers can now access a wider range of suppliers, enabling them to compare materials, designs, and pricing with ease. Additionally, advancements in supply chain management are allowing for more efficient inventory control and product tracking, which is essential for managing the complexities of international trade.

Another notable trend is the rise of customization. B2B buyers are increasingly looking for suppliers who can offer personalized options, whether through bespoke designs or customizable features. This trend aligns with the broader consumer preference for unique, individualized products that reflect personal style.

How Is Sustainability and Ethical Sourcing Shaping the Leather Purse Industry?

Sustainability is becoming a central tenet of the leather purse market. B2B buyers are increasingly aware of the environmental impact of leather production, which can include deforestation, water pollution, and greenhouse gas emissions. As a result, ethical sourcing has gained prominence, with businesses seeking suppliers who adhere to sustainable practices.

Illustrative image related to how to make a leather purse

The importance of transparency in the supply chain cannot be overstated. Buyers are demanding information about the origins of the leather, the methods used in tanning, and the treatment of animals. Suppliers who can demonstrate compliance with ethical standards and sustainability certifications, such as the Leather Working Group (LWG) or Global Organic Textile Standard (GOTS), will have a competitive edge.

Furthermore, there is a growing market for alternative materials that are eco-friendly, such as plant-based leathers or recycled materials. This shift not only appeals to environmentally conscious consumers but also opens new avenues for innovation in design and production methods. B2B buyers who prioritize sustainable sourcing will likely enhance their brand reputation and align with the values of their target markets.

What Is the Historical Context of Leather Purse Production Relevant to Today’s Market?

The art of leatherworking dates back thousands of years, evolving from basic utility items to intricate fashion statements. Historically, leather goods were crafted by skilled artisans who utilized traditional techniques passed down through generations. This craftsmanship remains highly valued today, particularly in markets that appreciate handmade products.

Illustrative image related to how to make a leather purse

In the modern context, the leather purse industry has adapted to globalization and technological advancements. The introduction of mass production techniques in the 20th century made leather goods more accessible, but it also led to concerns over quality and sustainability. Today, the industry is witnessing a resurgence in artisanal methods, with a focus on quality, sustainability, and ethical practices. This evolution reflects a broader consumer shift towards valuing craftsmanship and the stories behind products, making it a vital consideration for B2B buyers in the leather purse market.

By understanding these market dynamics, trends, and historical contexts, B2B buyers can make informed decisions that align with their business goals and meet the demands of a conscientious consumer base.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather purse

-

How do I choose the right leather supplier for making purses?

Selecting the right leather supplier involves assessing their reputation, product quality, and reliability. Look for suppliers who have been in the industry for a while and have positive reviews from other B2B buyers. Request samples to evaluate the leather’s texture, durability, and finish. Additionally, check for certifications related to leather sourcing and ethical practices, which can be crucial for marketability in various regions. Establishing a good communication channel is also vital to ensure clarity in your orders and expectations. -

What is the best leather type for making durable purses?

Full-grain leather is often regarded as the best choice for making durable purses due to its strength, natural beauty, and ability to develop a unique patina over time. Other options include top-grain leather, which is slightly more affordable and still offers good durability, and genuine leather, which is a cost-effective alternative but may not last as long. Consider the intended use and target market preferences when selecting the leather type to ensure your product meets customer expectations. -

What are common minimum order quantities (MOQs) for leather purses?

Minimum order quantities can vary widely among suppliers, typically ranging from 50 to 500 units for custom leather purses. Smaller manufacturers may offer lower MOQs, allowing for flexibility, while larger suppliers might require higher quantities to justify production costs. When negotiating, clarify whether the MOQ includes different styles or colors, as this can influence your product range and inventory management. Always discuss potential for scaling orders as your business grows. -

How can I ensure quality assurance (QA) in leather purse production?

To ensure quality assurance in leather purse production, implement a robust QA process that includes inspecting raw materials upon receipt and conducting regular quality checks during the manufacturing process. Establish clear quality standards and specifications in your contract with the supplier. Consider visiting the production facility if possible, or hire a third-party inspection service to verify that the final products meet your quality expectations before shipment. -

What payment terms should I expect when sourcing leather purses internationally?

Payment terms can vary based on the supplier’s policies and your negotiation power. Common terms include a deposit (usually 30-50%) upfront, with the balance paid upon completion or before shipment. Some suppliers may offer letters of credit or escrow services for larger orders to ensure both parties are protected. Be sure to discuss and agree on payment methods, such as bank transfers or online payment platforms, and consider currency fluctuations when negotiating prices. -

What logistics considerations should I keep in mind when importing leather purses?

When importing leather purses, consider shipping methods, customs regulations, and potential tariffs in your target market. Choose between air freight for faster delivery or sea freight for cost-effectiveness, weighing the urgency against budget constraints. Familiarize yourself with customs documentation required for leather goods, including certificates of origin and compliance with local regulations. Working with a logistics partner experienced in international trade can streamline the process and minimize delays. -

How can I customize leather purses for different markets?

Customization can be achieved through design alterations, material selection, and branding elements. Research market trends and preferences in your target regions to identify popular styles, colors, and features. Collaborate with your supplier to explore options for personalized branding, such as embossing or stitching logos. Additionally, consider offering variations in size and functionality to cater to specific consumer needs in different markets, enhancing your product’s appeal. -

What are the benefits of using leather purse kits for beginners?

Leather purse kits are an excellent option for beginners, as they provide all necessary materials and pre-cut pieces, simplifying the crafting process. These kits often include detailed instructions or video tutorials, making it easy to follow along without prior experience. Using a kit allows new artisans to gain hands-on experience with leatherworking techniques while minimizing waste and errors. This can also serve as a low-risk entry point into the leather goods market for businesses looking to diversify their offerings.

Top 5 How To Make A Leather Purse Manufacturers & Suppliers List

1. Weaver Leather Supply – Handmade Leather Bags

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: DIY Handmade Leather Bag Projects including various types of bags such as Turquoise Crocodile Leather Purse, Leather Briefcase, Leather Drawstring Pouch, Firewood Tote, Leather Purse with Inlay, Leather Tote Bag, Leather Hip Pouch, Leather Knee Pouch, Leather Saddlebag, and Leather Sporran. The site also offers educational resources on how to line a leather bag and various belt pouch chapters.

2. Babylon Leather – DIY Purse Kit

Domain: thethingswellmake.com

Registered: 2013 (12 years)

Introduction: DIY leather purse kit from Babylon Leather, suitable for beginners. Includes various strips and larger pieces of leather, metal rings, plastic cording, tapestry needles, strong waxed white thread, snips for cutting thread, and binder clips. Pre-cut stitching holes for easy assembly. Video tutorials provided for step-by-step guidance. Uses saddle stitch for sewing. Requires a lighter to finish thre…

3. Pinterest – Premium Leather Tote Bag

Domain: ca.pinterest.com

Registered: 2009 (16 years)

Introduction: Making a Tote Bag out of Premium English Tan Leather

4. Instructables – Simple Leather Purse

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Simple Leather Purse

– Dimensions: Approximately 9″ x 9″ x 3″

– Materials Required:

1) Leather (vegetable tanned leather, large scrap) – $20

2) Lacing (35 yard roll, only 3 yards needed) – $35

3) Lacing needle (Perma Lok 1/8″ needle) – $5-$10

4) Razor (for cutting lacing)

5) Laser cutter (optional, for cutting leather)

– Pattern Files Available:

1) .dwg file (full scale)

2) .dxf file…

5. YouTalent – Leather Bag Crafting Essentials

Domain: blog.youtalent.com

Registered: 2006 (19 years)

Introduction: To craft your own leather bag, you need to select the right type of leather, such as chrome-tanned calfskin, vegetable-tanned leather, or cowhide suede. Essential tools include a cutting mat, rotary cutter, scratch awl, leather sewing kit, mallet, high-quality iron stamps, and contact adhesive. Design your bag by sketching and creating a paper pattern. Prepare the leather by cleaning, cutting accu…

Strategic Sourcing Conclusion and Outlook for how to make a leather purse

What Are the Key Takeaways for Strategic Sourcing in Leather Purse Production?

In conclusion, the strategic sourcing of materials and kits for leather purse production is critical for ensuring quality and efficiency in the manufacturing process. By leveraging high-quality leather suppliers and comprehensive DIY kits, businesses can cater to a growing market of consumers interested in both handcrafted and luxury items. The integration of user-friendly instructional materials, such as video tutorials, enhances the learning curve for new artisans and can significantly improve customer satisfaction.

How Can International Buyers Benefit from Quality Leather Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the opportunity to source premium leather and purse-making kits is substantial. Establishing relationships with reputable suppliers can lead to competitive pricing, reduced lead times, and access to innovative designs that resonate with diverse markets.

What Is the Future Outlook for Leather Purse Production?

As consumer preferences shift towards sustainable and artisanal products, the demand for quality leather goods will continue to rise. By prioritizing strategic sourcing and maintaining a focus on craftsmanship, your business can position itself at the forefront of this evolving market. Engage with suppliers, explore new designs, and invest in training to ensure your leather purse offerings stand out. The future is bright for those ready to innovate and adapt in this vibrant industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.