Introduction: Navigating the Global Market for fire retardant furniture

In an increasingly safety-conscious global market, sourcing fire retardant furniture is a critical challenge for international B2B buyers. With diverse regulations and standards across regions, such as the stringent requirements of California’s Technical Bulletin 117, understanding the intricacies of flame retardant materials and their implications is essential. This comprehensive guide delves into the types of fire retardant furniture available, their applications across various sectors, and the importance of supplier vetting to ensure compliance with both local and international fire safety regulations.

Navigating the complexities of fire retardant furniture also involves a thorough examination of costs, sustainability practices, and the potential health impacts of flame retardants. For businesses operating in regions like Africa, South America, the Middle East, and Europe, making informed purchasing decisions is crucial. This guide empowers B2B buyers by providing actionable insights into sourcing safe and compliant furniture options that align with their specific needs and regulatory requirements.

By exploring the latest research and trends in fire safety, as well as practical strategies for evaluating suppliers, this guide equips businesses with the knowledge necessary to make confident and responsible purchasing decisions. Whether you’re looking to furnish a new office space or supply a hospitality project, understanding the global landscape of fire retardant furniture will enhance your procurement strategy and ensure the safety and satisfaction of your end users.

Table Of Contents

- Top 1 Fire Retardant Furniture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fire retardant furniture

- Understanding fire retardant furniture Types and Variations

- Key Industrial Applications of fire retardant furniture

- 3 Common User Pain Points for ‘fire retardant furniture’ & Their Solutions

- Strategic Material Selection Guide for fire retardant furniture

- In-depth Look: Manufacturing Processes and Quality Assurance for fire retardant furniture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fire retardant furniture’

- Comprehensive Cost and Pricing Analysis for fire retardant furniture Sourcing

- Alternatives Analysis: Comparing fire retardant furniture With Other Solutions

- Essential Technical Properties and Trade Terminology for fire retardant furniture

- Navigating Market Dynamics and Sourcing Trends in the fire retardant furniture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fire retardant furniture

- Strategic Sourcing Conclusion and Outlook for fire retardant furniture

- Important Disclaimer & Terms of Use

Understanding fire retardant furniture Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flame Retardant Upholstered | Contains treated fabrics or foams designed to resist ignition | Hotels, offices, and public spaces | Pros: Enhanced safety, compliance with regulations; Cons: Potential health concerns from chemicals. |

| Naturally Flame-Resistant | Made from materials like wool, cotton, or treated wood | Eco-friendly hotels, residential projects | Pros: Non-toxic, sustainable; Cons: Higher costs, may require special care. |

| Fire-Resistant Composite | Combines various materials to enhance fire resistance | Commercial buildings, furniture exports | Pros: Versatile, customizable; Cons: May require specific certifications. |

| Intumescent Coated Furniture | Features a special coating that expands under heat | Schools, hospitals, and public buildings | Pros: Excellent fire protection, low maintenance; Cons: Coating can wear off over time. |

| Fire-Resistant Metal Furniture | Constructed from metals with inherent fire-resistant properties | Industrial settings, outdoor use | Pros: Durable, low flammability; Cons: Heavier, may not be aesthetically pleasing. |

What are the Characteristics of Flame Retardant Upholstered Furniture?

Flame retardant upholstered furniture is typically made with treated fabrics and foams that are designed to resist ignition. This type of furniture is essential for environments where safety regulations are stringent, such as hotels and offices. When purchasing, B2B buyers should consider compliance with local fire safety standards, the potential for chemical exposure, and the lifecycle of the materials used.

How Do Naturally Flame-Resistant Materials Compare?

Naturally flame-resistant furniture is crafted from materials such as wool, cotton, or specially treated wood. This type is increasingly popular among eco-conscious buyers looking to minimize chemical use. While it offers a sustainable option, buyers need to weigh the higher costs and maintenance requirements against the benefits of a non-toxic product.

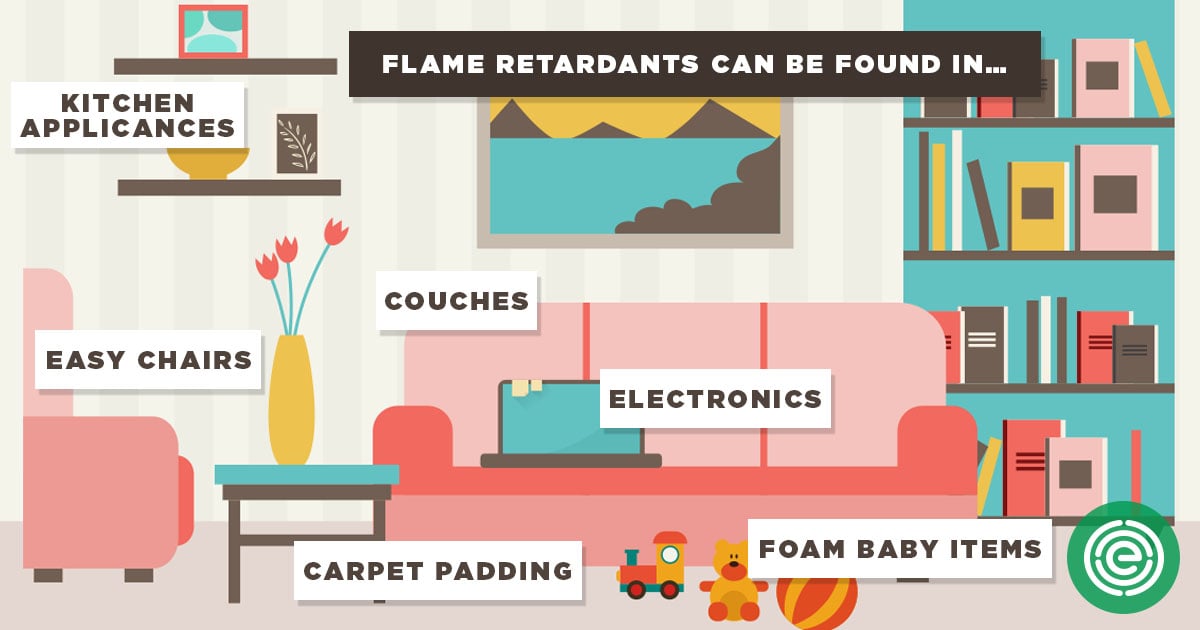

Illustrative image related to fire retardant furniture

What Makes Fire-Resistant Composite Furniture Unique?

Fire-resistant composite furniture combines various materials to enhance fire resistance and can be tailored to specific needs. It is commonly used in commercial applications and can be customized for aesthetic appeal. However, B2B buyers should ensure that the composites meet relevant safety certifications and are suitable for their intended application.

Why Choose Intumescent Coated Furniture?

Intumescent coated furniture features a special coating that expands when exposed to heat, providing an effective barrier against flames. This type is particularly suited for schools and hospitals where safety is paramount. Buyers should consider the durability of the coating and the potential need for periodic reapplication to maintain effectiveness.

What are the Benefits of Fire-Resistant Metal Furniture?

Fire-resistant metal furniture is constructed from metals that possess inherent fire-resistant properties. This type is ideal for industrial settings or outdoor use, where durability is crucial. While it offers low flammability and long-lasting performance, B2B buyers should take into account the weight and design aspects, which may not always align with aesthetic preferences.

Key Industrial Applications of fire retardant furniture

| Industry/Sector | Specific Application of Fire Retardant Furniture | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel guest room furnishings | Enhances guest safety and satisfaction, reducing liability risks | Compliance with local fire safety regulations, durability |

| Healthcare | Patient room and waiting area furniture | Protects vulnerable populations while ensuring comfort | Non-toxic materials, ease of cleaning, compliance standards |

| Education | Classroom and dormitory furnishings | Ensures a safe learning environment, fostering student well-being | Cost-effectiveness, aesthetic appeal, compliance |

| Commercial Offices | Office furniture for high-rise buildings | Minimizes fire hazards, protecting employees and assets | Design compatibility, ergonomic features, warranty terms |

| Public Spaces | Seating in theaters, airports, and public transport | Increases public safety and compliance with regulations | Customization options, ease of maintenance, bulk purchasing |

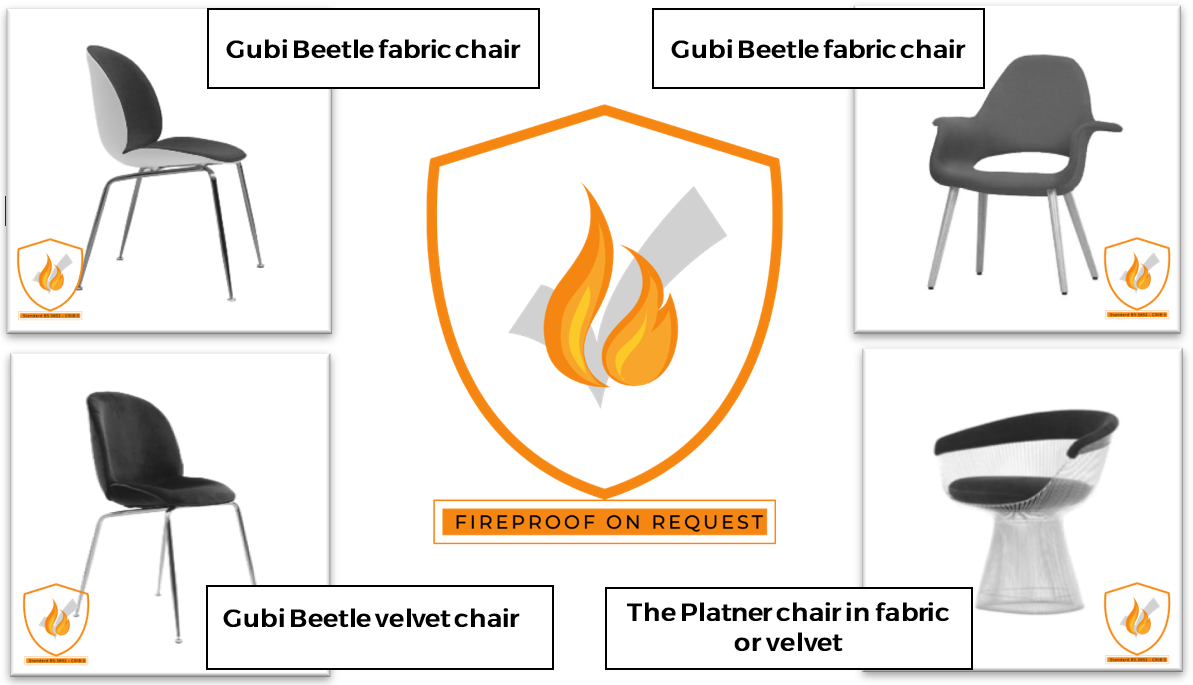

How is Fire Retardant Furniture Used in the Hospitality Industry?

In the hospitality sector, fire retardant furniture is crucial for guest room furnishings, including sofas, chairs, and beds. By integrating flame-resistant materials, hotels can significantly enhance guest safety and satisfaction while minimizing liability risks. International B2B buyers must consider compliance with local fire safety regulations and the durability of materials, as well as the aesthetic appeal to ensure a welcoming environment.

What Role Does Fire Retardant Furniture Play in Healthcare Settings?

Fire retardant furniture in healthcare facilities, such as patient rooms and waiting areas, is designed to protect vulnerable populations, including patients and elderly individuals. It helps mitigate fire risks while providing comfort and functionality. Buyers in this sector need to prioritize non-toxic materials that comply with health regulations, along with ease of cleaning to maintain hygiene standards.

Why is Fire Retardant Furniture Essential for Educational Institutions?

In educational settings, fire retardant furniture is vital for classrooms and dormitories, ensuring a safe learning environment for students. The use of flame-resistant materials helps to foster student well-being and can contribute to lower insurance premiums. For international buyers, cost-effectiveness, aesthetic appeal, and compliance with local safety standards are key considerations when sourcing these products.

How Can Fire Retardant Furniture Benefit Commercial Offices?

For commercial offices, especially in high-rise buildings, fire retardant furniture minimizes fire hazards, protecting employees and valuable assets. It plays a significant role in creating a safe workplace environment, which can enhance employee morale and productivity. When sourcing, businesses should focus on design compatibility, ergonomic features for employee comfort, and warranty terms to ensure long-term value.

In What Ways Does Fire Retardant Furniture Impact Public Spaces?

In public spaces such as theaters, airports, and public transport, fire retardant furniture is essential for seating arrangements. It not only increases public safety but also ensures compliance with stringent fire safety regulations. Buyers should consider customization options to meet specific design needs, ease of maintenance for high-traffic areas, and bulk purchasing discounts to optimize costs.

3 Common User Pain Points for ‘fire retardant furniture’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance Challenges with Fire Retardant Furniture

The Problem: B2B buyers, particularly those in the furniture manufacturing or retail sectors, face significant challenges in navigating complex and often changing regulations regarding fire safety standards. For instance, the adoption of California’s Technical Bulletin 117-2013 as a federal standard has raised concerns about the compliance of existing products. Manufacturers may struggle to determine whether their products meet these standards, leading to potential legal liabilities, recalls, or damage to their reputation. In regions with less stringent regulations, buyers might be unsure about the implications of sourcing fire retardant furniture that adheres to stricter standards.

The Solution: To overcome these regulatory compliance challenges, B2B buyers should prioritize sourcing fire retardant furniture from manufacturers who are transparent about their compliance with both local and international standards. This includes requiring detailed documentation proving that products meet the necessary fire safety certifications. Buyers should also stay informed about changing regulations by subscribing to industry newsletters, participating in relevant forums, or consulting with legal experts in product compliance. Engaging with manufacturers that offer continuous education on regulatory updates can further ensure that buyers are making informed decisions. Additionally, conducting regular audits of suppliers and their products can help maintain compliance and protect against potential liabilities.

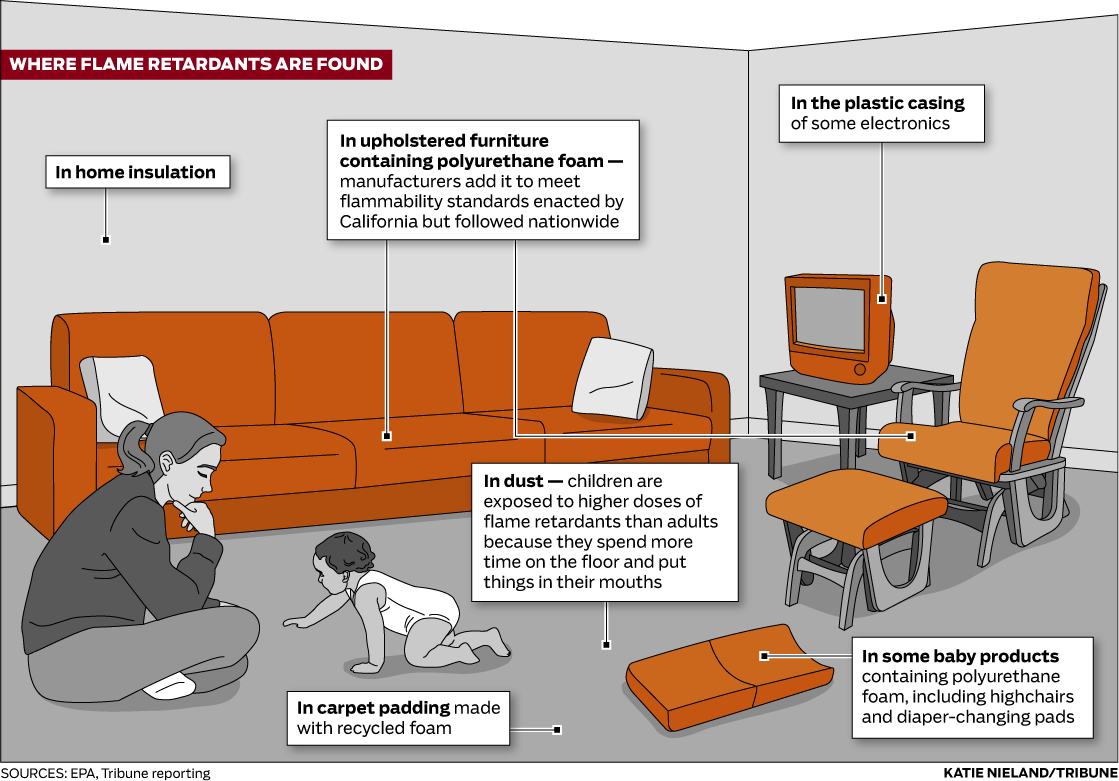

Scenario 2: Balancing Safety with Health Concerns in Fire Retardant Furniture

The Problem: Many B2B buyers grapple with the dual challenge of ensuring fire safety while also addressing health concerns associated with flame retardants. Studies have highlighted that certain chemicals used in flame retardants can migrate into indoor environments, posing health risks such as hormone disruption and impaired cognitive development in children. This creates a dilemma for buyers who want to provide safe products without compromising the health of their customers or employees.

The Solution: To effectively balance safety and health concerns, B2B buyers should prioritize sourcing fire retardant furniture that utilizes safer, eco-friendly alternatives to traditional flame retardants. Researching manufacturers who adhere to low-VOC (volatile organic compounds) standards and utilize natural fibers or non-toxic additives can provide a safer option. Furthermore, buyers should insist on transparency in product labeling, which includes detailed information about the materials used. This not only fosters trust with customers but also demonstrates a commitment to health-conscious practices. Collaborating with suppliers who offer certifications like GREENGUARD or OEKO-TEX can also help ensure that the furniture meets stringent health and safety standards.

Illustrative image related to fire retardant furniture

Scenario 3: Overcoming Misconceptions About Fire Retardant Furniture Efficacy

The Problem: A prevalent issue among B2B buyers is the misconception that all fire retardant furniture provides substantial fire safety benefits. Many buyers may believe that investing in flame-retardant products guarantees safety, leading to a false sense of security. This misunderstanding can lead to inadequate risk assessments in environments such as hotels, schools, or healthcare facilities, where fire safety is critical.

The Solution: B2B buyers need to educate themselves and their teams about the actual effectiveness of fire retardant furniture. This involves researching and understanding that not all flame retardants are equally effective, and that the presence of these chemicals does not necessarily equate to improved safety in real fire scenarios. Buyers should engage with fire safety experts or consultants to conduct thorough risk assessments tailored to their specific environments. Investing in training sessions for staff on fire safety standards and the limitations of flame retardant furniture can also empower them to make informed decisions. Additionally, buyers should consider integrating fire safety into their overall purchasing strategy by choosing suppliers who provide comprehensive fire safety solutions, including fire-resistant materials and training on best practices.

Strategic Material Selection Guide for fire retardant furniture

When selecting materials for fire retardant furniture, it is essential to consider their properties, advantages, and limitations from a B2B perspective. This analysis focuses on four common materials used in the production of fire retardant furniture: polyester, polyurethane foam, fiberglass, and treated wood. Each material offers unique characteristics that can influence performance, cost, and compliance with international standards.

Illustrative image related to fire retardant furniture

What are the Key Properties of Polyester in Fire Retardant Furniture?

Polyester is a synthetic fabric known for its durability and resistance to wrinkling and shrinking. In fire retardant applications, polyester can be treated with flame retardant chemicals to enhance its fire resistance. Its temperature rating typically hovers around 200°C (392°F), making it suitable for various environments.

Pros and Cons: Polyester is relatively low-cost and easy to manufacture, making it a popular choice for upholstered furniture. However, its susceptibility to melting under extreme heat can limit its effectiveness in high-temperature scenarios. Additionally, the chemical treatments used for fire retardancy can sometimes wear off over time, reducing the material’s effectiveness.

Impact on Application: Polyester’s compatibility with various upholstery designs makes it a versatile choice for residential and commercial furniture. However, international buyers should be aware of specific flame retardant regulations in their markets, such as California’s TB 117-2013 and equivalent standards in Europe.

Illustrative image related to fire retardant furniture

How Does Polyurethane Foam Perform in Fire Retardant Furniture?

Polyurethane foam is widely used for cushioning in furniture due to its comfort and adaptability. When treated with flame retardants, it can meet various fire safety standards. The material typically withstands temperatures up to 150°C (302°F).

Pros and Cons: The primary advantage of polyurethane foam is its excellent cushioning properties and lightweight nature, which enhances user comfort. However, it can be more expensive than other materials, and the manufacturing process can be complex, especially when incorporating flame retardant treatments. Moreover, some flame retardants used can pose health risks, which is a significant concern for buyers focused on sustainability.

Impact on Application: Polyurethane foam is suitable for both residential and commercial applications, but buyers must ensure compliance with local fire safety regulations. The foam’s compatibility with various upholstery fabrics makes it a popular choice, but it is crucial to verify the safety of the flame retardants used.

What Are the Advantages of Using Fiberglass in Fire Retardant Furniture?

Fiberglass is a composite material made from fine glass fibers and is known for its high strength-to-weight ratio and excellent fire resistance. It can withstand temperatures exceeding 500°C (932°F), making it one of the safest options for fire retardant furniture.

Pros and Cons: The key advantage of fiberglass is its inherent fire-resistant properties, which do not rely on chemical treatments. This makes it a safer choice for health-conscious consumers. However, fiberglass can be more expensive and challenging to work with during manufacturing, potentially increasing production costs.

Illustrative image related to fire retardant furniture

Impact on Application: Fiberglass is ideal for specialized applications, such as public seating in commercial spaces, where fire safety is paramount. International buyers should ensure that their suppliers comply with local and international standards, such as ASTM and DIN, to guarantee product safety.

How Does Treated Wood Compare in Fire Retardant Furniture Applications?

Treated wood involves the application of fire retardant chemicals to natural wood, enhancing its fire resistance. The temperature resistance can vary significantly based on the type of wood and the treatment used but generally ranges from 200°C (392°F) to 300°C (572°F).

Pros and Cons: The aesthetic appeal of wood and its structural integrity make it a popular choice for high-end furniture. However, the treatment process can be costly and may not be as durable as other materials, leading to potential re-treatment needs over time. Additionally, the effectiveness of flame retardant treatments can diminish with exposure to moisture.

Impact on Application: Treated wood is suitable for both residential and commercial applications, particularly in regions where traditional wooden furniture is preferred. Buyers must ensure compliance with local regulations regarding treated wood, especially in markets with stringent environmental standards.

Illustrative image related to fire retardant furniture

Summary Table of Material Selection for Fire Retardant Furniture

| Material | Typical Use Case for fire retardant furniture | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Upholstered furniture | Durable and cost-effective | Can melt under extreme heat | Low |

| Polyurethane Foam | Cushioned seating | Excellent comfort and adaptability | Higher cost and potential health risks | Medium |

| Fiberglass | Public seating and specialized applications | Inherent fire resistance | Expensive and complex to manufacture | High |

| Treated Wood | High-end residential and commercial furniture | Aesthetic appeal and structural integrity | Treatment durability concerns | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing fire retardant furniture materials.

In-depth Look: Manufacturing Processes and Quality Assurance for fire retardant furniture

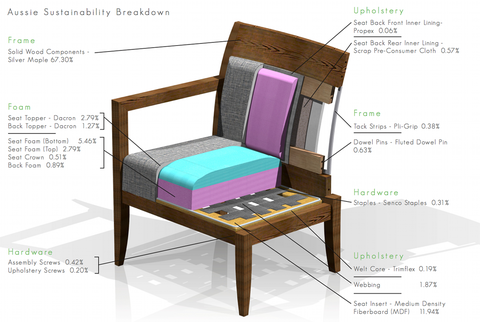

What Are the Main Stages in the Manufacturing Process of Fire Retardant Furniture?

Manufacturing fire retardant furniture involves several critical stages, each designed to ensure the final product meets safety standards while maintaining aesthetic and functional qualities. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase focuses on sourcing and preparing the raw materials. Manufacturers typically utilize flame-retardant-treated fabrics, foams, and wood. The selection of materials is crucial; for example, polyurethane foams may be treated with non-toxic flame retardants or sourced from suppliers that provide flame-retardant-free options.

-

Forming: In this stage, the prepared materials are shaped into the desired forms. Techniques such as cutting, molding, and stitching are employed to create furniture components like cushions, frames, and upholstery. Advanced technologies, including CNC machining for precision cutting and automated sewing machines, are often utilized to enhance efficiency and reduce waste.

-

Assembly: This stage involves the integration of all components into a finished product. Skilled labor is essential here, as the assembly process must maintain quality while ensuring that all parts fit together correctly. Furniture may be assembled using various techniques, including doweling, stapling, and gluing, with careful attention to the structural integrity of each piece.

-

Finishing: The final touches are applied during the finishing phase. This may involve applying protective coatings, treating surfaces to resist stains, and ensuring that all materials meet fire safety regulations. Quality control checks are integrated throughout this stage to ensure that the furniture not only looks appealing but also complies with safety standards.

How Do Quality Assurance Practices Ensure Safety in Fire Retardant Furniture Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of fire retardant furniture, ensuring that products meet international safety standards and customer expectations. Various international and industry-specific standards guide these practices.

-

International Standards: ISO 9001 is one of the most recognized quality management standards globally. Adhering to ISO 9001 helps manufacturers implement effective quality management systems, ensuring consistent quality and continuous improvement. This standard is particularly valuable for B2B buyers looking for reliable suppliers.

-

Industry-Specific Standards: For fire retardant furniture, compliance with standards such as the CE marking in Europe indicates that products meet safety, health, and environmental protection standards. Additionally, furniture sold in specific regions may need to comply with local regulations like California’s TB 117, which outlines flammability tests for upholstered furniture.

What Are the Key Quality Control Checkpoints in Fire Retardant Furniture Manufacturing?

Quality control (QC) is a multi-stage process that involves various checkpoints throughout the manufacturing cycle to ensure compliance with safety and quality standards.

-

Incoming Quality Control (IQC): This is the first checkpoint where raw materials are inspected upon arrival. Suppliers provide documentation proving that their materials meet specified flame retardant standards. This step is crucial, as the quality of the raw materials directly affects the safety and performance of the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to ensure that each stage adheres to predetermined quality standards. This includes checking the precision of cuts and the integrity of assembly techniques. IPQC helps identify issues early, minimizing waste and rework.

-

Final Quality Control (FQC): Once the furniture is assembled, a comprehensive inspection takes place before packaging. This includes checking the finished product for aesthetic defects, structural integrity, and compliance with fire safety standards. Documentation of these inspections is crucial for traceability and accountability.

Which Testing Methods Are Commonly Used to Ensure Fire Safety in Furniture?

To ensure that fire retardant furniture meets safety standards, various testing methods are employed:

-

Flammability Testing: This is the most critical testing method for fire retardant furniture. It assesses how materials react to ignition sources and how quickly they propagate flames. Common tests include the ASTM E1353 for upholstered furniture and the California Technical Bulletin 117.

-

Toxicity Testing: Understanding the potential release of harmful chemicals from flame retardants is essential. Manufacturers may conduct toxicity tests to evaluate the safety of materials used in their products, ensuring they do not pose health risks to consumers.

-

Durability Testing: Beyond fire safety, furniture must withstand daily use. Durability tests simulate wear and tear to ensure that materials remain intact over time, further contributing to safety by reducing the likelihood of materials breaking down and becoming flammable.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, ensuring that suppliers adhere to rigorous quality control processes is vital. Here are some strategies to verify these practices:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities helps assess their adherence to quality standards and manufacturing processes. This can include evaluating their quality management systems, production capabilities, and compliance with safety regulations.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes. These reports should outline results from various inspections and tests, demonstrating their commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can include both pre-shipment inspections and random checks during production to ensure consistency.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various certification requirements and quality control nuances:

-

Regional Compliance: Different regions may have varying regulations regarding fire safety standards. For instance, Europe may require CE marking, while North America may adhere to TB 117. Buyers should be familiar with the specific regulations applicable to their market.

-

Cultural and Logistical Considerations: Understanding local practices and logistical challenges can impact the effectiveness of quality control measures. Buyers should consider the geographical and cultural differences that may affect manufacturing and quality assurance in their sourcing decisions.

-

Documentation and Traceability: Maintaining clear documentation of all quality checks, certifications, and compliance reports is essential for international trade. This documentation not only facilitates smoother transactions but also provides buyers with the necessary assurance of product quality and safety.

By comprehensively understanding the manufacturing processes and quality assurance practices for fire retardant furniture, B2B buyers can make informed decisions and ensure that they are sourcing safe and reliable products for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fire retardant furniture’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure fire retardant furniture. In an increasingly safety-conscious market, understanding the complexities of fire safety standards, material specifications, and supplier reliability is crucial. This checklist will help streamline your sourcing process while ensuring compliance with relevant regulations and safety standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any procurement process. Identify the specific fire safety standards applicable in your region, such as California’s Technical Bulletin 117 or other international regulations. This will guide your selection of materials and design features, ensuring that the furniture meets necessary safety requirements.

Step 2: Conduct Market Research on Suppliers

Thoroughly research potential suppliers who specialize in fire retardant furniture. Look for manufacturers with a proven track record in your target markets, such as Africa, South America, the Middle East, and Europe. Focus on supplier certifications, previous projects, and customer feedback to gauge their reliability and expertise.

- Key Considerations:

- Industry reputation and longevity

- Specific experience with fire retardant materials

Step 3: Verify Supplier Certifications

Before finalizing any agreements, confirm that your potential suppliers possess the necessary certifications. Look for compliance with local and international fire safety standards, as well as any eco-labeling or sustainability certifications that may enhance your brand image. This step ensures that the products you source are both safe and reliable.

Step 4: Request Product Samples

Always request product samples before making a bulk purchase. Evaluating samples allows you to assess the quality, comfort, and aesthetic appeal of the furniture. Additionally, inquire about the fire retardant properties of the materials used and request documentation that verifies compliance with safety standards.

Illustrative image related to fire retardant furniture

Step 5: Evaluate Supply Chain Transparency

A transparent supply chain is vital for understanding the origins of the materials used in your fire retardant furniture. Inquire about the sourcing of raw materials, production processes, and any third-party testing that has been conducted. This not only supports compliance but also fosters trust in your supplier relationship.

Step 6: Assess After-Sales Support and Warranty Options

Investigate the after-sales support and warranty options offered by potential suppliers. A strong support system can be invaluable for addressing any issues post-purchase, ensuring customer satisfaction, and maintaining safety standards over time. Look for warranties that cover defects and ensure compliance with fire safety regulations.

Step 7: Negotiate Terms and Finalize Contracts

Once you have assessed potential suppliers and their products, enter negotiations with clarity on pricing, delivery timelines, and payment terms. Ensure that all fire safety specifications and compliance standards are clearly outlined in the contract. This protects your interests and ensures that both parties are aligned on expectations.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing fire retardant furniture, ensuring safety, compliance, and quality in their procurement process.

Comprehensive Cost and Pricing Analysis for fire retardant furniture Sourcing

What Are the Key Cost Components in Fire Retardant Furniture Manufacturing?

When sourcing fire retardant furniture, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to fire retardant furniture

-

Materials: This is often the largest portion of the total cost. High-quality flame-retardant fabrics, foams, and other materials that meet stringent safety standards can significantly impact pricing. The choice of materials also dictates compliance with regional regulations, such as those in California and the EU.

-

Labor: Skilled labor is required for manufacturing fire retardant furniture, particularly for assembly and quality control. Labor costs can vary widely depending on the location of the manufacturer. For instance, costs may be higher in Europe compared to South America or Africa.

-

Manufacturing Overhead: This includes utilities, rent, and other indirect costs of running a manufacturing facility. Efficient production processes can help reduce overhead costs, but this often requires significant investment in technology and training.

-

Tooling: Initial tooling costs for custom furniture designs can be substantial. These costs are amortized over the production run, so larger orders can reduce the per-unit cost significantly.

-

Quality Control (QC): Ensuring that products meet safety standards is essential, especially in markets with strict regulations. QC processes add to the overall cost but are necessary to avoid costly recalls and reputational damage.

-

Logistics: Shipping costs can vary based on the destination, mode of transport, and volume of goods. International shipping can add complexity and costs due to customs duties and import regulations.

-

Margin: Suppliers typically add a profit margin that can vary based on market conditions and competition. Understanding market pricing can help buyers negotiate better deals.

How Do Price Influencers Impact Fire Retardant Furniture Sourcing?

Several factors influence the pricing of fire retardant furniture, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing. Manufacturers may offer discounts for bulk purchases, so buyers should assess their inventory needs and consider larger orders if feasible.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly define their needs to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., compliance with TB 117-2013 or EU standards) can raise prices. Buyers should balance quality with budget constraints, considering the long-term benefits of investing in safer, more durable products.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their experience and the quality assurance processes they have in place.

-

Incoterms: The terms of sale can significantly impact the total cost of ownership. Understanding Incoterms (e.g., FOB, CIF) helps buyers anticipate shipping costs and responsibilities.

What Are Some Effective Tips for Negotiating Fire Retardant Furniture Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the following strategies can enhance negotiation outcomes:

-

Conduct Market Research: Understanding market trends and competitor pricing can provide leverage during negotiations. Familiarize yourself with the typical cost structures and pricing models used in the industry.

-

Evaluate Total Cost of Ownership (TCO): Don’t focus solely on the upfront price. Consider long-term factors such as durability, maintenance, and compliance costs. A higher initial investment in quality materials may lead to lower TCO.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and loyalty can often yield discounts and preferential treatment.

-

Be Open to Alternative Solutions: If pricing is a concern, consider discussing alternative materials or designs that can meet safety standards while reducing costs.

-

Understand Pricing Nuances: Different regions may have varying price sensitivities and expectations. Tailoring your approach based on cultural nuances can facilitate smoother negotiations.

Conclusion

While this analysis provides a framework for understanding the costs and pricing of fire retardant furniture, prices can vary widely based on numerous factors. Buyers should approach sourcing with comprehensive knowledge and strategic negotiation tactics to ensure they receive the best value for their investment.

Alternatives Analysis: Comparing fire retardant furniture With Other Solutions

Exploring Alternatives to Fire Retardant Furniture

As fire safety continues to be a crucial concern for businesses and consumers alike, the search for effective alternatives to traditional fire retardant furniture has intensified. This analysis compares fire retardant furniture with other viable solutions, providing B2B buyers with insights to make informed decisions tailored to their unique needs.

| Comparison Aspect | Fire Retardant Furniture | Natural Fiber Furniture | Flame Barrier Fabrics |

|---|---|---|---|

| Performance | Moderate fire resistance; often ineffective in real-world scenarios | Limited fire resistance; relies on design and materials | High fire resistance; effective against open flames |

| Cost | Generally higher due to chemical treatments | Often lower; varies by material quality | Moderate to high; varies by fabric type |

| Ease of Implementation | Standardized manufacturing; regulations influence design | Requires careful sourcing of materials | Requires specialized manufacturing and installation |

| Maintenance | Requires regular inspection for chemical degradation | Generally low; natural fibers may require special care | Low; durable fabrics can withstand cleaning |

| Best Use Case | Public spaces needing compliance with fire regulations | Residential or eco-conscious settings | Commercial settings or high-risk environments |

What Are the Advantages and Disadvantages of Natural Fiber Furniture?

Natural fiber furniture, made from materials like cotton, wool, or hemp, provides an eco-friendly alternative to traditional fire retardant options. While these materials are often less flame-resistant, their aesthetic appeal and sustainability can attract environmentally conscious buyers. However, the lack of inherent fire resistance means that additional precautions must be taken in high-risk environments, which could deter some businesses from opting for this alternative.

How Do Flame Barrier Fabrics Enhance Fire Safety?

Flame barrier fabrics are engineered materials designed to resist ignition and prevent the spread of flames. They are often used in commercial settings where stringent fire safety regulations apply. The primary advantage of these fabrics is their superior performance in fire resistance, providing a reliable solution for high-risk areas. However, the cost and complexity of sourcing and installing flame barrier fabrics may be a barrier for some buyers, particularly in budget-sensitive projects.

Making the Right Choice: How Should B2B Buyers Decide on Fire Safety Solutions?

When evaluating fire safety solutions, B2B buyers must consider a variety of factors, including the specific needs of their environment, regulatory requirements, and budget constraints. Fire retardant furniture may offer compliance with local regulations but often falls short in real-world effectiveness. Alternatives like natural fiber furniture can appeal to eco-conscious consumers, while flame barrier fabrics provide robust fire safety for high-risk applications. By thoroughly assessing these factors, buyers can select the most appropriate solution that aligns with their operational requirements and safety objectives.

Essential Technical Properties and Trade Terminology for fire retardant furniture

What Are the Key Technical Properties of Fire Retardant Furniture?

When sourcing fire retardant furniture, it is essential to understand specific technical properties that define the quality and safety of these products. Here are some critical specifications:

-

Flammability Rating

This rating indicates how well a material resists ignition and burning. Common standards include ASTM E84 (Surface Burning Characteristics of Building Materials) and TB 117-2013. For B2B buyers, understanding these ratings is crucial for compliance with local fire safety regulations and for ensuring the safety of end-users. -

Material Composition

The types of materials used in fire retardant furniture can vary significantly, including natural fibers, synthetic fabrics, and flame retardant-treated foams. Knowing the material composition helps buyers assess durability, comfort, and potential health impacts, especially concerning harmful chemicals that might be present. -

Durability and Lifecycle

This property refers to the expected lifespan of furniture under normal usage conditions. Buyers should consider factors like wear resistance, colorfastness, and the impact of fire retardant treatments on the material’s longevity. A longer lifecycle can reduce total cost of ownership, making it a vital consideration for commercial buyers. -

Moisture Resistance

The ability of furniture materials to resist moisture can significantly affect their performance and safety. Moisture can degrade flame retardant properties over time. Understanding this property is essential for environments with high humidity or where spills are common, such as restaurants or hotels. -

Toxicological Safety

Evaluating the potential health risks associated with flame retardant chemicals is crucial. Buyers should look for products that comply with safety standards like the California Proposition 65, which mandates labeling for products containing harmful substances. This knowledge is vital for protecting both consumers and brand reputation. -

Environmental Impact

Sustainability is becoming increasingly important in furniture sourcing. Buyers should inquire about the environmental impact of the materials and manufacturing processes. Certifications such as GREENGUARD or FSC can indicate lower emissions and responsible sourcing, appealing to eco-conscious businesses.

What Are Common Trade Terms in Fire Retardant Furniture Procurement?

Understanding industry jargon is essential for effective communication and negotiation in the fire retardant furniture market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces products that are then marketed by another company. In the context of fire retardant furniture, working with OEMs can ensure high-quality manufacturing standards and compliance with safety regulations. -

MOQ (Minimum Order Quantity)

This term specifies the smallest order size a supplier is willing to accept. Understanding the MOQ helps buyers manage inventory effectively and negotiate better pricing, especially when dealing with large-scale projects or commercial contracts. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests price quotes from suppliers for specific products. When sourcing fire retardant furniture, an RFQ can help buyers compare prices and terms from multiple vendors, ensuring they get the best value. -

Incoterms (International Commercial Terms)

These are standardized shipping terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms is crucial for international B2B transactions, as they clarify costs, risks, and logistics involved in shipping fire retardant furniture. -

Lead Time

Lead time refers to the time it takes from placing an order to delivery. Understanding lead times is essential for project planning and inventory management, especially in industries where timely delivery of fire retardant furniture can impact safety and compliance. -

Certification Standards

These are official approvals indicating that a product meets specific safety and performance criteria. Certifications relevant to fire retardant furniture include TB 117-2013 and various international fire safety standards. Buyers should prioritize certified products to ensure compliance and enhance customer trust.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with safety regulations, customer expectations, and their operational needs.

Navigating Market Dynamics and Sourcing Trends in the fire retardant furniture Sector

What Are the Global Drivers Shaping the Fire Retardant Furniture Market?

The fire retardant furniture market is experiencing significant transformation driven by regulatory changes, consumer awareness, and evolving safety standards. The push for enhanced fire safety regulations in regions such as North America and Europe is influencing global sourcing dynamics. For instance, the revisions to California’s Technical Bulletin 117-2013 represent a trend towards more stringent safety standards that do not mandate the use of harmful flame retardants. International B2B buyers are increasingly seeking suppliers who comply with these updated regulations, ensuring that their products not only meet safety requirements but also appeal to environmentally conscious consumers.

Moreover, the rise of e-commerce has facilitated easier access to global suppliers, enabling buyers from Africa, South America, and the Middle East to explore diverse sourcing options. Technological advancements in materials science are also emerging, with innovations in non-toxic flame retardant alternatives gaining traction. This shift is particularly relevant for markets such as Vietnam and Brazil, where demand for safer, high-quality furniture is on the rise. As a result, B2B buyers must stay informed about both local and international market trends to optimize their sourcing strategies.

How Are Sustainability and Ethical Sourcing Becoming Essential in Fire Retardant Furniture?

Sustainability and ethical sourcing have become vital components of the fire retardant furniture sector. The environmental impact of traditional flame retardants, which often migrate into indoor dust and pose health risks, is a growing concern among consumers and regulators alike. B2B buyers are increasingly prioritizing suppliers who use sustainable materials and adhere to ethical sourcing practices, as this aligns with broader global trends toward sustainability.

Illustrative image related to fire retardant furniture

Certifications such as GREENGUARD and OEKO-TEX are becoming benchmarks for environmentally friendly products, providing assurance to buyers about the safety and sustainability of materials used in furniture. As the market evolves, suppliers who can demonstrate their commitment to sustainability will have a competitive advantage. Additionally, there is a growing emphasis on the lifecycle of products, prompting buyers to consider the full environmental impact—from sourcing raw materials to end-of-life disposal. This shift not only enhances brand reputation but also meets the rising demand for responsible consumption among consumers in diverse markets.

How Has the Fire Retardant Furniture Sector Evolved Over Time?

The evolution of the fire retardant furniture sector has been marked by significant regulatory and technological changes. Initially driven by safety concerns, the introduction of flammability standards like California’s Technical Bulletin 117 in 1975 led to the widespread use of harmful flame retardant chemicals in furniture. However, studies revealing the ineffectiveness of these chemicals in real-world fire scenarios prompted a reevaluation of safety standards.

In recent years, the focus has shifted towards developing safer alternatives that do not compromise fire safety. The adoption of TB 117-2013 has further catalyzed this change, allowing manufacturers to explore non-toxic materials while still meeting safety requirements. This historical context is crucial for B2B buyers to understand the current landscape, as it informs sourcing decisions and highlights the importance of compliance with evolving regulations. As the market continues to adapt, staying abreast of these developments will enable buyers to make informed purchasing decisions that align with safety, sustainability, and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of fire retardant furniture

-

How do I ensure the fire safety compliance of furniture sourced internationally?

To ensure fire safety compliance for internationally sourced furniture, first familiarize yourself with the fire safety regulations applicable in your target market. For instance, California’s TB 117-2013 is a significant standard in the U.S. Ensure your suppliers can provide documentation that their products meet relevant standards. Additionally, request test certificates from accredited laboratories and verify their validity. Establish clear communication with suppliers regarding compliance requirements and consider conducting random inspections or audits to ensure ongoing adherence to safety standards. -

What are the key certifications to look for when sourcing fire retardant furniture?

When sourcing fire retardant furniture, look for certifications such as the California Technical Bulletin 117 (TB 117-2013) and European standards like EN 1021 for furniture flammability. Additionally, certifications from organizations like Underwriters Laboratories (UL) and the International Organization for Standardization (ISO) can indicate a commitment to safety and quality. These certifications not only ensure compliance with fire safety regulations but also enhance the credibility of your suppliers, making it easier to build trust with your customers. -

What customization options should I consider when purchasing fire retardant furniture?

When purchasing fire retardant furniture, consider customization options such as material selection, color, size, and design. Many manufacturers offer a range of flame-retardant fabrics and finishes that can align with your brand’s aesthetic and functional requirements. Discuss your specific needs with suppliers to explore available options, including bespoke designs tailored to your market. Customization can also extend to the incorporation of additional features, such as antimicrobial treatments or eco-friendly materials, which can enhance the value proposition of your offerings. -

What is the minimum order quantity (MOQ) for fire retardant furniture?

The minimum order quantity (MOQ) for fire retardant furniture varies by supplier and product type. Typically, MOQs can range from a few dozen to several hundred units, depending on the manufacturer’s production capabilities and the complexity of the design. When negotiating with suppliers, clarify the MOQ and explore the possibility of lower quantities for initial orders or samples. Consider consolidating orders with other buyers to meet MOQ requirements and reduce overall costs. -

What payment terms are commonly used in international transactions for fire retardant furniture?

Payment terms for international transactions often include options like advance payment, letters of credit, or payment upon delivery. Commonly, suppliers may require a deposit (20-30%) upfront, with the balance due before shipment or upon receipt of goods. It’s essential to establish clear payment terms that protect both parties and align with your cash flow management. Discuss potential payment methods that offer security and flexibility, such as escrow services or PayPal, which can mitigate risks associated with international trade. -

How can I vet suppliers for fire retardant furniture?

Vetting suppliers for fire retardant furniture involves assessing their credibility, quality, and compliance with safety standards. Start by researching the supplier’s background, including years in business, customer reviews, and industry reputation. Request references from previous clients and inquire about their experience with fire safety compliance. Additionally, consider visiting the supplier’s manufacturing facility if feasible, or conducting virtual audits to verify their production processes and quality assurance measures. -

What logistics considerations should I be aware of when importing fire retardant furniture?

When importing fire retardant furniture, consider logistics aspects such as shipping methods, customs regulations, and lead times. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with import duties and taxes in your country, as well as any specific regulations related to fire safety compliance. Collaborate with a reliable freight forwarder to navigate the complexities of international shipping and ensure timely delivery of your products. -

What quality assurance processes should be in place when sourcing fire retardant furniture?

Implementing robust quality assurance processes is crucial when sourcing fire retardant furniture. Establish quality checkpoints throughout the manufacturing process, from raw material inspection to final product testing. Request third-party testing reports to validate compliance with fire safety standards. Consider setting up a system for periodic audits of your suppliers to ensure they maintain quality and compliance over time. Additionally, maintain open communication with suppliers to address any quality concerns promptly, ensuring that the products meet your specifications and safety requirements.

Top 1 Fire Retardant Furniture Manufacturers & Suppliers List

1. Flame Retardant Facts – Essential Fire Protection Solutions

Domain: flameretardantfacts.com

Registered: 2013 (12 years)

Introduction: Flame retardants provide critical fire protection, reducing risks associated with combustible materials. They are used in various applications including furniture, electronics, and transportation. For furniture, safety standards like California Technical Bulletin 117-2013 (TB 117-2013) and Technical Bulletin 133 are key, although TB 117-2013 has been criticized for not effectively predicting real …

Strategic Sourcing Conclusion and Outlook for fire retardant furniture

How Can Strategic Sourcing Transform Your Approach to Fire Retardant Furniture?

In the evolving landscape of fire retardant furniture, strategic sourcing emerges as a pivotal tool for international B2B buyers. By understanding the intricacies of regulations and standards, such as California’s TB 117-2013, buyers can ensure compliance while also prioritizing health and environmental sustainability. The shift away from harmful flame retardants not only enhances safety but also aligns with consumer demand for eco-friendly products.

Illustrative image related to fire retardant furniture

As suppliers increasingly respond to regulatory changes and consumer preferences, the opportunity for buyers to leverage this shift is significant. Engaging with manufacturers who prioritize innovative, flame-retardant-free solutions can lead to improved product offerings and reduced liability risks. This proactive approach ensures that businesses remain competitive in a global market where safety and sustainability are paramount.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe must embrace these changes. By prioritizing strategic sourcing of fire retardant furniture, companies can secure safer, more compliant products that resonate with a growing base of conscientious consumers. Take the initiative today to redefine your sourcing strategy—partner with suppliers who align with your values and contribute to a safer, healthier environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.