Introduction: Navigating the Global Market for printed leatherette

In the competitive landscape of global commerce, sourcing high-quality printed leatherette can present significant challenges for B2B buyers. Whether you are seeking durable materials for fashion accessories, automotive interiors, or home furnishings, navigating the myriad of options available can be overwhelming. This guide is designed to demystify the complexities surrounding printed leatherette, offering insights into various types, applications, and key considerations for procurement.

From understanding the nuances of custom UV printing to exploring the latest trends in design and texture, this comprehensive resource equips international buyers—especially those from Africa, South America, the Middle East, and Europe, including markets like Nigeria and Germany—with the knowledge needed to make informed purchasing decisions.

Additionally, the guide delves into essential supplier vetting processes, cost factors, and the importance of adhering to intellectual property rights when customizing designs. By empowering buyers with actionable insights and practical strategies, this guide aims to streamline the sourcing process, ensuring that you can confidently select the best products to meet your business needs. Whether you are a seasoned buyer or entering the printed leatherette market for the first time, the information contained within this guide will serve as a valuable tool in your procurement arsenal.

Table Of Contents

- Top 5 Printed Leatherette Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for printed leatherette

- Understanding printed leatherette Types and Variations

- Key Industrial Applications of printed leatherette

- 3 Common User Pain Points for ‘printed leatherette’ & Their Solutions

- Strategic Material Selection Guide for printed leatherette

- In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette’

- Comprehensive Cost and Pricing Analysis for printed leatherette Sourcing

- Alternatives Analysis: Comparing printed leatherette With Other Solutions

- Essential Technical Properties and Trade Terminology for printed leatherette

- Navigating Market Dynamics and Sourcing Trends in the printed leatherette Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette

- Strategic Sourcing Conclusion and Outlook for printed leatherette

- Important Disclaimer & Terms of Use

Understanding printed leatherette Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| UV Printed Leatherette | High-resolution printing; vibrant colors; durable | Custom patches, promotional items, decor | Pros: Excellent color clarity, custom designs; Cons: Higher initial setup costs. |

| Custom Printed Leatherette | Personalized designs; various textures available | Fashion accessories, upholstery, bags | Pros: Unique branding opportunities; Cons: Design approval process can delay production. |

| Faux Leatherette with Adhesive | Self-adhesive backing; easy application | Craft projects, signage, home decor | Pros: Simplifies installation; Cons: Limited reusability once applied. |

| Litchi Leatherette | Textured finish resembling real leather | High-end products, luxury items | Pros: Aesthetic appeal; Cons: Can be more expensive than standard options. |

| Vegan Leatherette | Eco-friendly materials; cruelty-free | Sustainable products, fashion, and decor | Pros: Appeals to environmentally conscious buyers; Cons: May have a shorter lifespan than traditional leatherette. |

What Are the Key Characteristics of UV Printed Leatherette?

UV printed leatherette features high-resolution printing technology that delivers vibrant colors and exceptional detail. This type is particularly suitable for applications requiring durability, such as custom patches and promotional items. B2B buyers should consider the initial setup costs associated with custom designs, as well as the long-lasting quality that can enhance brand visibility.

How Does Custom Printed Leatherette Stand Out?

Custom printed leatherette allows businesses to personalize their products with unique designs and textures. This versatility makes it ideal for fashion accessories, upholstery, and bags, catering to diverse market needs. Buyers should be prepared for a design approval process that may extend lead times but ultimately results in tailored products that resonate with their brand identity.

Why Choose Faux Leatherette with Adhesive?

Faux leatherette with adhesive backing simplifies the application process, making it an excellent choice for craft projects, signage, and home decor. Its ease of use is a significant advantage for businesses looking for quick solutions. However, buyers should note that once applied, this material may not be reusable, which could affect long-term cost-effectiveness.

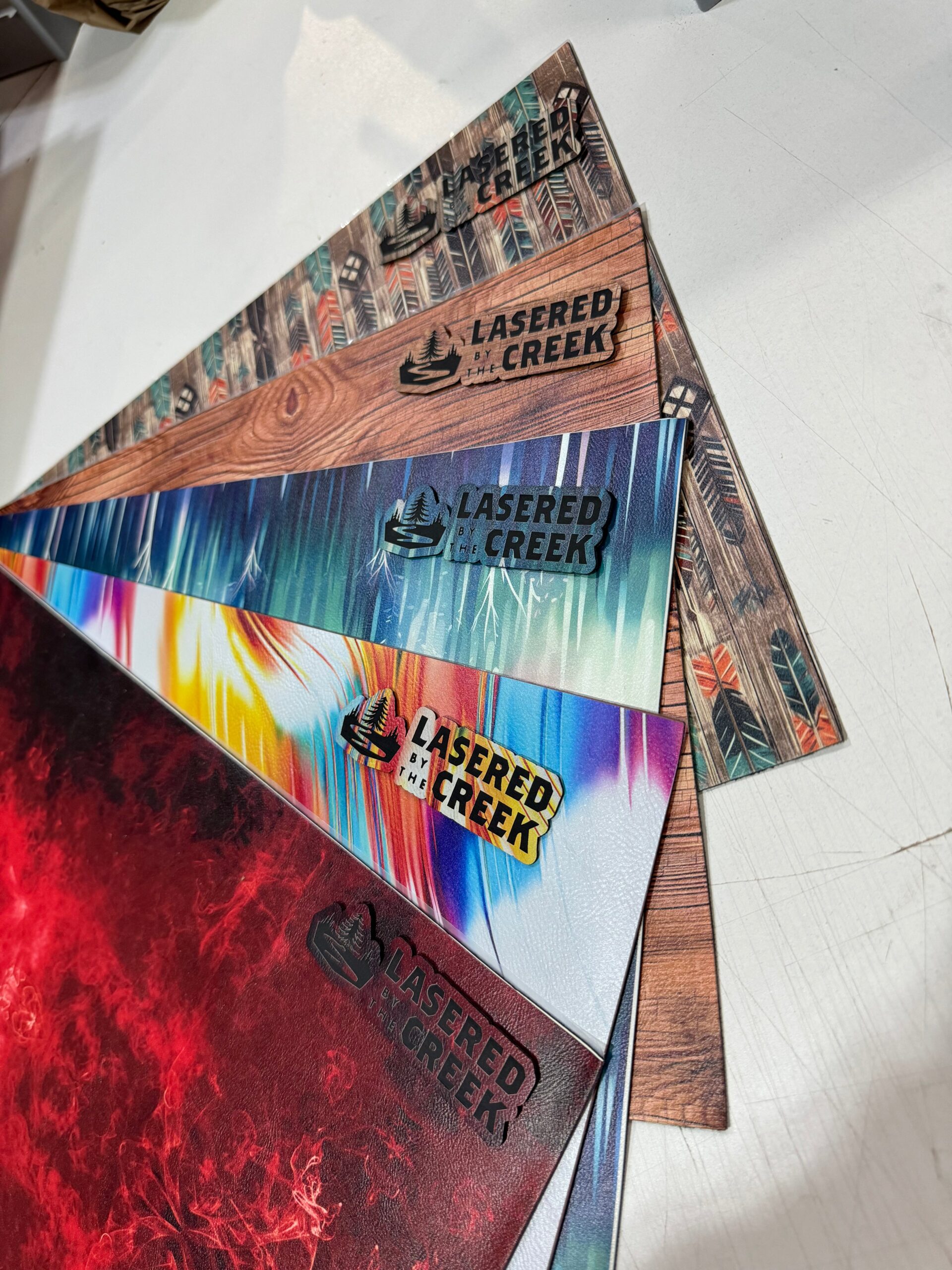

Illustrative image related to printed leatherette

What Are the Benefits of Litchi Leatherette?

Litchi leatherette mimics the texture of genuine leather, providing a luxurious look and feel. It is particularly suitable for high-end products and luxury items, appealing to markets that prioritize aesthetics. While this type offers a premium experience, it often comes at a higher price point, which buyers need to factor into their budget considerations.

How Does Vegan Leatherette Appeal to Modern Buyers?

Vegan leatherette is made from eco-friendly materials, aligning with the growing demand for sustainable products. This type is ideal for businesses targeting environmentally conscious consumers in sectors like fashion and decor. Although vegan leatherette may have a shorter lifespan compared to traditional options, its appeal lies in its ethical stance, making it a compelling choice for brands looking to enhance their corporate responsibility profile.

Key Industrial Applications of printed leatherette

| Industry/Sector | Specific Application of printed leatherette | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom handbags and wallets | Enhances brand visibility through unique designs | Quality of printing, durability, and material sourcing |

| Furniture & Interior Design | Upholstery for chairs and cushions | Provides a stylish, durable alternative to traditional leather | Colorfastness, texture variety, and ease of maintenance |

| Promotional Products | Customized patches for apparel | Boosts brand recognition and customer engagement | Customization options, minimum order quantities, and lead times |

| Home Décor | Decorative wall panels and art pieces | Adds a modern aesthetic while being cost-effective | Print quality, design flexibility, and material sustainability |

| Automotive | Interior trim and accessories | Offers a luxurious look with lower costs than genuine leather | Compliance with automotive standards and resistance to wear |

How is Printed Leatherette Used in Fashion and Accessories?

In the fashion industry, printed leatherette is widely utilized for custom handbags and wallets. Brands leverage vibrant, unique designs to enhance their visibility and appeal to consumers. The material provides a luxurious look while being cost-effective compared to genuine leather. Buyers must ensure that the printing quality is high and the material durable, particularly when sourcing from international suppliers in regions like Africa and Europe, where fashion trends can vary significantly.

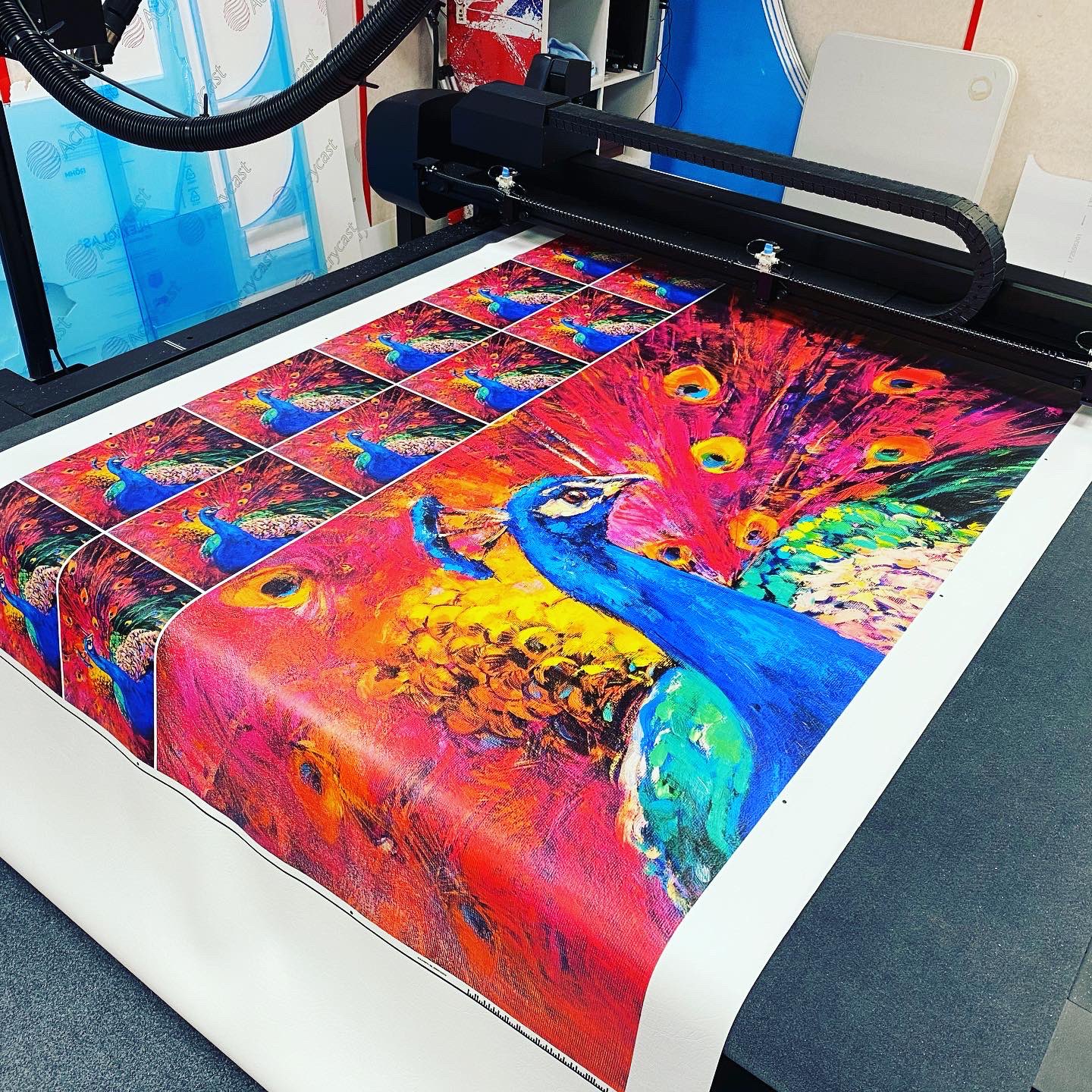

Illustrative image related to printed leatherette

What Role Does Printed Leatherette Play in Furniture and Interior Design?

In the furniture sector, printed leatherette is increasingly used for upholstery in chairs and cushions. It serves as a stylish and durable alternative to traditional leather, offering a broad range of colors and patterns that can match diverse interior designs. For B2B buyers, sourcing considerations include the material’s colorfastness and texture variety, as well as ease of maintenance, particularly in high-traffic areas like offices or public spaces.

How Can Printed Leatherette Enhance Promotional Products?

Printed leatherette is an excellent choice for customized patches used in promotional products, especially apparel. These patches can significantly boost brand recognition and customer engagement through eye-catching designs. When sourcing, businesses should consider customization options, minimum order quantities, and lead times to ensure timely delivery for marketing campaigns, especially in fast-paced markets in South America and the Middle East.

What Are the Benefits of Using Printed Leatherette in Home Décor?

In the realm of home décor, printed leatherette is frequently employed for decorative wall panels and art pieces. This material offers a modern aesthetic while remaining cost-effective compared to traditional artwork or materials. Buyers should focus on print quality and design flexibility, ensuring that the sourced products align with their brand’s style and sustainability goals, particularly in environmentally conscious markets in Europe.

How is Printed Leatherette Applied in the Automotive Industry?

Within the automotive sector, printed leatherette is used for interior trim and accessories, providing a luxurious appearance at a fraction of the cost of genuine leather. This application not only enhances the vehicle’s interior aesthetics but also addresses durability and maintenance concerns. Buyers must ensure that the printed leatherette complies with automotive standards and is resistant to wear and tear, particularly in regions with varying climate conditions like Africa and the Middle East.

Illustrative image related to printed leatherette

3 Common User Pain Points for ‘printed leatherette’ & Their Solutions

Scenario 1: Quality Control Challenges in Custom Orders

The Problem: B2B buyers often face significant challenges in ensuring that the printed leatherette meets their quality standards, especially when ordering custom designs. Variability in print quality, color accuracy, and material consistency can lead to dissatisfaction with the final product, resulting in costly returns and delays. This is particularly important for businesses in industries such as fashion and home décor, where the visual appeal and tactile quality of materials are paramount.

The Solution: To mitigate these risks, buyers should prioritize suppliers that offer a sample service before committing to bulk orders. Requesting a sample allows businesses to evaluate the print quality, color fidelity, and texture of the leatherette firsthand. Additionally, establishing clear communication regarding design specifications and expectations can help. When placing an order, provide detailed artwork files and specify printing techniques, such as UV printing for enhanced color vibrancy. It is also beneficial to inquire about the supplier’s quality control processes to ensure they adhere to consistent standards throughout production.

Scenario 2: Understanding Material Specifications and Applications

The Problem: Many B2B buyers are unsure about the specific types of printed leatherette available and their suitable applications, which can lead to poor purchasing decisions. For instance, selecting a material that is not durable enough for upholstery or failing to choose a water-resistant option for outdoor use can result in product failure and damage to brand reputation.

The Solution: Buyers should conduct thorough research on the different types of printed leatherette and their respective properties. Engaging with suppliers that provide comprehensive product specifications, including weight, thickness, and resistance to wear and tear, is crucial. Additionally, participating in product demonstrations or webinars hosted by manufacturers can provide deeper insights into the material’s capabilities. Buyers can also ask for case studies or examples of previous projects that utilized specific types of leatherette to better understand practical applications. By aligning the product choice with the intended use, businesses can ensure longevity and satisfaction in their end products.

Scenario 3: Navigating Intellectual Property Concerns

The Problem: When ordering custom-printed leatherette, B2B buyers often encounter challenges related to intellectual property rights, especially when using existing designs or logos. Misunderstandings about copyright can lead to legal issues, financial penalties, or the inability to use the desired designs in their products.

Illustrative image related to printed leatherette

The Solution: It is essential for buyers to have a clear understanding of the intellectual property rights associated with their designs. Before placing an order, businesses should verify that they own the rights to the artwork or have obtained proper permissions for use. This includes ensuring that any designs sourced from third-party creators comply with copyright laws. When working with suppliers, buyers should request documentation or contracts that clarify the ownership and usage rights of printed materials. Additionally, considering working with designers who specialize in creating original artwork can help avoid potential copyright issues. By taking these proactive steps, businesses can confidently proceed with their orders while safeguarding against legal complications.

Strategic Material Selection Guide for printed leatherette

What Are the Key Materials Used in Printed Leatherette?

When selecting materials for printed leatherette, it’s essential to understand the various substrates available in the market. Each material offers unique properties that can influence product performance, durability, and suitability for specific applications. Below, we analyze four common materials used in printed leatherette, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. PVC (Polyvinyl Chloride)

Key Properties: PVC is known for its excellent flexibility and durability. It can withstand a temperature range of -20°C to 70°C and has good resistance to moisture and UV light.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for various applications, including upholstery and accessories. However, it can be less environmentally friendly due to its production process and potential release of harmful substances.

Impact on Application: PVC is suitable for items that require vibrant prints and durability, such as bags and wallets. However, it may not be ideal for applications requiring high-temperature resistance.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations, as PVC may face restrictions in certain markets. Understanding ASTM standards for PVC can also help in assessing quality.

2. PU (Polyurethane)

Key Properties: PU offers superior abrasion resistance and flexibility compared to PVC, with a temperature tolerance of -30°C to 80°C. It is also known for its breathability.

Pros & Cons: PU is more environmentally friendly than PVC and provides a luxurious feel, making it suitable for high-end applications. However, it tends to be more expensive and may require more complex manufacturing processes.

Illustrative image related to printed leatherette

Impact on Application: PU is ideal for fashion items, automotive interiors, and high-quality upholstery. Its breathability makes it suitable for products that require comfort, such as clothing and footwear.

Considerations for International Buyers: Compliance with European Union regulations regarding chemical use in textiles is crucial for buyers in Europe. In regions like the Middle East, buyers should verify the material’s performance under extreme temperatures.

3. PET (Polyethylene Terephthalate)

Key Properties: PET is known for its excellent dimensional stability and resistance to chemicals. It can operate effectively in temperatures ranging from -40°C to 120°C.

Pros & Cons: PET is lightweight and recyclable, making it an environmentally friendly option. However, it may not have the same level of softness and flexibility as PU or PVC, which can limit its use in certain applications.

Impact on Application: PET is commonly used in applications requiring durability and resistance to wear, such as in furniture and packaging. Its chemical resistance makes it suitable for products exposed to various substances.

Illustrative image related to printed leatherette

Considerations for International Buyers: Buyers should be aware of recycling regulations in their regions, particularly in Europe, where sustainability is a significant focus. Understanding JIS standards can also aid in ensuring product quality.

4. Neoprene

Key Properties: Neoprene is a synthetic rubber that offers excellent elasticity and thermal insulation. It can withstand temperatures from -20°C to 100°C.

Pros & Cons: Neoprene is highly durable and provides good resistance to water and oils, making it suitable for various applications. However, it is generally more expensive and may not be as easy to print on as other materials.

Impact on Application: Neoprene is ideal for products requiring waterproofing, such as laptop sleeves and outdoor gear. Its insulation properties also make it suitable for thermal applications.

Considerations for International Buyers: Buyers should ensure that neoprene products comply with local health and safety regulations, particularly in the Middle East and Africa, where specific standards may apply.

Summary Table of Material Selection for Printed Leatherette

| Material | Typical Use Case for printed leatherette | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, bags, accessories | Cost-effective and durable | Less environmentally friendly | Low |

| PU | Fashion items, automotive interiors | Luxurious feel and eco-friendly | Higher cost and complex manufacturing | High |

| PET | Furniture, packaging | Lightweight and recyclable | Limited softness and flexibility | Medium |

| Neoprene | Waterproof products, thermal gear | Excellent durability and insulation | Higher cost and printing challenges | High |

This guide provides actionable insights for B2B buyers looking to make informed decisions regarding printed leatherette materials. Understanding the properties, advantages, and regional considerations will facilitate better procurement strategies and product development.

In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette

What Are the Main Stages in the Manufacturing Process of Printed Leatherette?

The manufacturing process for printed leatherette involves several critical stages, ensuring that the final product meets both aesthetic and functional requirements.

1. Material Preparation

The process begins with the selection of high-quality base materials, typically a synthetic substrate that mimics leather. Common materials include polyurethane (PU) or polyvinyl chloride (PVC). The chosen substrate is treated to enhance adhesion properties and durability. Prior to printing, the material is cut into manageable sheets, often sized according to the intended final product specifications.

Illustrative image related to printed leatherette

2. Forming and Printing

Once the material is prepped, the next step is forming, which includes any necessary shaping or texturing of the leatherette. This may involve processes like embossing or debossing to create a unique tactile finish. After forming, the UV printing process is employed, where designs are applied directly onto the leatherette using high-resolution UV printers. This method ensures vibrant colors and intricate details, making the product visually appealing.

3. Assembly

Post-printing, the printed leatherette can be cut and sewn into various products, such as bags, upholstery, or decorative items. This stage may involve the application of adhesives, stitching, or heat-sealing, depending on the design requirements. Customization at this stage is critical, as B2B buyers often seek unique patterns or branding elements.

4. Finishing Touches

The final stage involves finishing processes, such as applying a protective coating to enhance durability and resistance to wear. This may include laminating or treating the surface to improve water resistance. Quality inspection occurs at each stage to ensure the product meets specifications before packaging and shipping.

How Is Quality Assurance Implemented in Printed Leatherette Manufacturing?

Quality assurance (QA) in printed leatherette production is essential to maintain product integrity and customer satisfaction.

Relevant International Standards and Certifications

International standards, such as ISO 9001, outline a framework for quality management systems that manufacturers must adhere to. In addition, industry-specific certifications like CE marking for safety and compliance in the European market are crucial for B2B buyers. These standards ensure that the products meet regulatory requirements and industry benchmarks.

Illustrative image related to printed leatherette

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated into the manufacturing process through several checkpoints:

-

Incoming Quality Control (IQC): This phase involves the inspection of raw materials before they enter the production line. Suppliers must provide documentation verifying that materials meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to ensure that processes are being followed correctly, and that the product is being produced according to the specified design and quality standards.

-

Final Quality Control (FQC): Once production is complete, finished products undergo a comprehensive inspection. This includes visual checks for printing quality, dimensional accuracy, and structural integrity.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to verify the quality of printed leatherette:

-

Adhesion Testing: This assesses how well the printed design adheres to the substrate, ensuring it won’t peel or fade over time.

-

Color Fastness Testing: This evaluates the resistance of the printed colors to fading due to exposure to light, washing, or abrasion.

-

Durability Testing: Products are subjected to wear-and-tear simulations to assess their long-term performance and resilience.

-

Environmental Testing: This involves exposing the leatherette to different environmental conditions (e.g., humidity, temperature) to ensure it maintains its properties under various circumstances.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers.

Conducting Audits

One effective method is to conduct on-site audits of the manufacturing facilities. This allows buyers to directly assess the quality management systems in place and ensure compliance with international standards.

Requesting Quality Reports

Buyers should also request detailed quality reports that outline the QC processes, testing results, and any certifications the supplier holds. This documentation provides transparency and helps buyers make informed decisions.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes. These services can verify that the products meet specified standards before shipment, reducing the risk of quality issues upon delivery.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Regulatory Compliance: Buyers must be aware of local regulations regarding materials and safety standards. Compliance with these regulations is crucial to avoid legal issues and ensure product acceptance in the target market.

-

Cultural Considerations: Different regions may have varying expectations regarding product quality and aesthetics. Understanding these cultural nuances can help in selecting suppliers who align with market demands.

-

Supply Chain Transparency: Buyers should seek suppliers who are transparent about their sourcing and production processes. This transparency builds trust and ensures that suppliers are accountable for their quality standards.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing printed leatherette products. This strategic approach not only mitigates risks but also enhances the likelihood of successful partnerships in the competitive global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette’

To assist B2B buyers in procuring printed leatherette, this guide provides a structured checklist that outlines essential steps. Each step is designed to streamline the sourcing process, ensuring quality and compatibility with your specific needs.

Illustrative image related to printed leatherette

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as the desired thickness, texture, and color of the printed leatherette. Additionally, think about the intended application—whether it’s for fashion items, upholstery, or promotional materials—as this will influence your choices.

- Material Properties: Specify whether you need a vegan option, durability requirements, or water resistance.

- Printing Specifications: Outline the type of printing (e.g., UV printing, dye-sublimation) that will suit your design needs.

Step 2: Identify Reputable Suppliers

Finding trustworthy suppliers is critical to ensuring product quality and reliability. Research potential suppliers by reviewing their online presence, industry reputation, and customer reviews.

- Supplier Background: Look for companies with a proven track record in printed leatherette, especially those that cater to your target market.

- Certifications: Check for certifications that validate their manufacturing processes, such as ISO or environmental standards.

Step 3: Evaluate Sample Quality

Before placing a bulk order, request samples to assess the quality of the printed leatherette. This step allows you to examine the material’s texture, print clarity, and color vibrancy firsthand.

- Print Quality: Ensure the samples reflect the high standards you require for your products.

- Durability Tests: Evaluate how well the material holds up under stress, such as bending or exposure to moisture.

Step 4: Understand Pricing Structures

Navigating pricing can be complex, so it’s essential to comprehend the cost implications of your order. Gather detailed quotes from multiple suppliers, considering factors like minimum order quantities and potential discounts for bulk purchases.

Illustrative image related to printed leatherette

- Transparent Pricing: Ensure that the pricing includes all potential costs, such as shipping and setup fees.

- Negotiation Opportunities: Be open to discussing pricing adjustments based on order volume or long-term partnerships.

Step 5: Clarify Lead Times and Delivery Terms

Understanding lead times is crucial for planning your production schedule. Confirm the expected turnaround time for your order and any shipping terms.

- Production Time: Inquire about the time required for printing and preparation.

- Shipping Logistics: Discuss delivery methods and timelines to ensure timely receipt of your materials.

Step 6: Verify Intellectual Property Compliance

When sourcing custom printed leatherette, it’s vital to ensure that all designs comply with intellectual property laws. Confirm that you have the rights to any images or patterns used in your designs.

- Design Ownership: Ensure that you possess the necessary rights or licenses for the artwork you intend to print.

- Supplier Policies: Review suppliers’ policies regarding design submission and copyright to avoid potential legal issues.

Step 7: Establish a Quality Assurance Process

Implementing a quality assurance process helps maintain standards throughout the production cycle. Define criteria for inspecting the printed leatherette upon delivery.

Illustrative image related to printed leatherette

- Inspection Protocols: Develop a checklist for evaluating the received products based on your initial specifications.

- Feedback Mechanism: Establish a process for providing feedback to suppliers to facilitate continuous improvement.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing printed leatherette, ensuring they find a reliable supplier that meets their specific needs.

Comprehensive Cost and Pricing Analysis for printed leatherette Sourcing

What Are the Key Cost Components in Printed Leatherette Sourcing?

When analyzing the cost structure of printed leatherette, several key components come into play. The materials used for production significantly impact the overall cost. Leatherette, often made from polyvinyl chloride (PVC) or polyurethane (PU), varies in price based on quality and supplier relationships. Labor costs also contribute to the total, particularly if intricate designs or custom prints are involved, requiring skilled workers.

Manufacturing overhead encompasses utilities, equipment maintenance, and facility costs, which can vary by region and manufacturer. Additionally, tooling costs for custom molds or printing plates can add to initial expenses, especially for unique designs. Quality Control (QC) measures ensure the final product meets specified standards, and these processes can incur additional costs, particularly for international orders that may require stringent inspections.

How Do Price Influencers Affect B2B Buyers in Different Regions?

Several factors influence pricing in the printed leatherette market. Volume and Minimum Order Quantities (MOQs) play a crucial role; larger orders typically attract discounts, making it more cost-effective for buyers. The level of specification and customization also affects pricing; bespoke designs or high-quality finishes can lead to higher costs.

Illustrative image related to printed leatherette

Regional differences in material availability and supplier factors can further impact prices. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to varying labor costs and material sourcing. Additionally, Incoterms—which define the responsibilities of buyers and sellers regarding shipping and logistics—can influence overall pricing. Understanding these terms is essential for B2B buyers to avoid unexpected costs.

What Are Effective Buyer Tips for Negotiating Printed Leatherette Prices?

B2B buyers should employ strategic negotiation tactics to secure favorable pricing. One effective approach is to leverage Total Cost of Ownership (TCO) calculations, which consider not just the purchase price but also long-term costs such as shipping, storage, and potential waste. This comprehensive view can strengthen a buyer’s position during negotiations.

Buyers should also be aware of pricing nuances that vary by region. For example, buyers from Africa or the Middle East may face additional tariffs or shipping costs, making it vital to factor these into the overall budget. Establishing a strong relationship with suppliers can also lead to better pricing and terms. Regular communication and feedback can foster a partnership that benefits both parties.

Lastly, understanding the market trends and comparing prices among multiple suppliers can empower buyers. By being informed about the current landscape of printed leatherette sourcing, buyers can make decisions that align with their budget and quality requirements.

Illustrative image related to printed leatherette

Disclaimer on Pricing Information for B2B Buyers

It is essential to note that the prices for printed leatherette can vary significantly based on multiple factors, including order size, customization, and supplier specifics. The information provided here is indicative and should be used as a guideline for understanding potential costs in the market. Always seek direct quotes from suppliers to obtain accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing printed leatherette With Other Solutions

Introduction to Alternative Solutions for Printed Leatherette

In the competitive landscape of B2B materials, understanding the alternatives to printed leatherette is essential for making informed purchasing decisions. Printed leatherette, a versatile and visually appealing material, is widely used in various applications including fashion, upholstery, and promotional products. However, alternative solutions may offer different advantages based on performance, cost, and specific use cases. This analysis will compare printed leatherette with two viable alternatives: PVC vinyl and genuine leather.

Comparison Table

| Comparison Aspect | Printed Leatherette | PVC Vinyl | Genuine Leather |

|---|---|---|---|

| Performance | High durability and water resistance | Good durability but less breathable | Extremely durable and breathable |

| Cost | Mid-range pricing | Low-cost option | High-cost option |

| Ease of Implementation | Easy to print and sew | Easy to cut and apply | Requires skilled craftsmanship |

| Maintenance | Low maintenance | Low maintenance | Requires regular conditioning |

| Best Use Case | Fashion items, bags, upholstery | Promotional items, banners | Luxury goods, high-end fashion |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of PVC Vinyl?

PVC vinyl is a popular alternative to printed leatherette, particularly in applications where cost is a major consideration. Its affordability makes it an attractive option for businesses looking to produce promotional materials or temporary displays. PVC vinyl is easy to cut and apply, making it suitable for quick turnaround projects. However, it lacks the breathability and luxurious feel of leatherette, which may affect customer perception and satisfaction. Additionally, while PVC is durable, it may not offer the same level of water resistance as printed leatherette, limiting its use in certain environments.

How Does Genuine Leather Compare to Printed Leatherette?

Genuine leather is often viewed as the premium choice for high-end applications. Its durability and natural breathability make it ideal for luxury goods, such as high-fashion items and quality upholstery. The tactile quality of leather provides a unique experience for end users, enhancing brand prestige. However, the high cost of genuine leather can be a significant barrier for many businesses, especially those operating in price-sensitive markets. Moreover, genuine leather requires more intensive maintenance, including conditioning and careful cleaning, which can add to long-term costs.

Illustrative image related to printed leatherette

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the right material for your B2B projects, consider the specific requirements of your application, including budget constraints, desired performance characteristics, and the target market’s preferences. Printed leatherette offers a balanced solution with its durability, vibrant printing capabilities, and mid-range pricing, making it suitable for a variety of applications. However, if cost is your primary concern, PVC vinyl may be the way to go. Conversely, if you are aiming for a high-end market, genuine leather could justify its premium price through its unmatched quality and luxury appeal. Assessing these factors will enable you to make an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for printed leatherette

What Are the Essential Technical Properties of Printed Leatherette?

Printed leatherette, also known as faux leather, is a versatile material widely used in various applications, including upholstery, fashion, and promotional products. Understanding its technical properties is crucial for B2B buyers to ensure they make informed purchasing decisions.

-

Material Grade

The material grade of printed leatherette refers to the quality and composition of the synthetic material used. High-grade leatherette is typically made from polyurethane (PU) or polyvinyl chloride (PVC), offering superior durability, flexibility, and aesthetic appeal. For B2B buyers, choosing the right material grade can affect product longevity and customer satisfaction, particularly in high-use applications like furniture or bags. -

Thickness

The thickness of printed leatherette is measured in millimeters and can range from 0.5mm to 2.0mm or more. A thicker material may offer greater durability and wear resistance, while thinner options can provide flexibility and ease of handling. Understanding thickness is vital for buyers to match the product to its intended use, whether for soft furnishings or structured items. -

Print Quality

Print quality is determined by the printing technology used and the inks applied. High-quality UV printing or dye-sublimation techniques yield vibrant colors and intricate designs. For businesses, investing in high print quality can enhance brand visibility and product appeal, making it a significant consideration for promotional items or custom projects. -

Adhesive Properties

Many printed leatherette products come with adhesive backing, which can be heat-activated or pressure-sensitive. This property is essential for applications like patches or labels where a strong bond is required. Buyers should assess adhesive properties to ensure the end product meets application requirements, particularly in outdoor or high-stress environments. -

Fire Resistance

Fire resistance is a critical property for materials used in public spaces or products that may encounter heat. Some printed leatherette options are treated with fire-retardant chemicals, making them safer for specific applications. B2B buyers, especially in sectors like hospitality or transport, should prioritize fire-resistant materials to comply with safety regulations. -

Water Resistance

Water resistance refers to the material’s ability to repel moisture. High-quality printed leatherette can withstand spills and humidity, making it suitable for various environments. For businesses in regions with high humidity or for products exposed to liquid, selecting water-resistant leatherette is crucial to maintain product integrity.

What Are Common Trade Terms in the Printed Leatherette Industry?

Understanding trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms related to printed leatherette:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that may be marketed by another company. In the printed leatherette industry, this term is crucial for businesses looking to source custom designs or materials that will be branded under their name. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cost efficiency. Understanding MOQ helps buyers plan their purchases and avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This process is vital for B2B buyers to compare prices, negotiate terms, and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping costs, risk transfer, and delivery obligations, which is especially important when sourcing materials from different countries. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is crucial for B2B buyers to plan production schedules and manage inventory effectively. -

Customs Duties

Customs duties are taxes imposed on imported goods. B2B buyers should be aware of customs duties when sourcing printed leatherette from international suppliers, as these costs can significantly affect the overall price.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the printed leatherette market with greater confidence, making informed decisions that align with their business needs.

Illustrative image related to printed leatherette

Navigating Market Dynamics and Sourcing Trends in the printed leatherette Sector

What Are the Current Market Dynamics and Key Trends in the Printed Leatherette Sector?

The printed leatherette market is experiencing a significant transformation driven by a combination of technological advancements, consumer preferences, and global economic factors. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing a growing demand for customizability and unique designs in faux leather products. This trend is fueled by the rise of e-commerce platforms that facilitate personalized orders, allowing businesses to differentiate themselves in competitive markets. For instance, the ability to upload custom designs for printing on leatherette enables businesses to cater to niche markets and specific consumer tastes.

Moreover, the integration of sustainable practices is becoming a key consideration for buyers. As environmental consciousness rises, businesses are increasingly looking for suppliers that offer eco-friendly options, such as recycled materials and non-toxic inks. This shift is not only a response to consumer demand but also a proactive strategy to comply with stringent regulations in various countries regarding sustainability.

Another noteworthy trend is the adoption of advanced printing technologies, such as UV printing, which enhances the quality and durability of printed leatherette products. This technology allows for vivid colors and intricate designs, making it ideal for applications ranging from fashion accessories to home décor. As more companies invest in these technologies, the competition intensifies, pushing down prices and expanding access for B2B buyers.

Illustrative image related to printed leatherette

How Can Sustainability and Ethical Sourcing Impact the Printed Leatherette Sector?

Sustainability and ethical sourcing are becoming increasingly pivotal in the printed leatherette sector, aligning with a broader global movement towards responsible consumption. The environmental impact of traditional leather production has prompted many businesses to seek alternatives that minimize ecological footprints. Printed leatherette, often made from synthetic materials, can offer a more sustainable option when produced responsibly.

B2B buyers are encouraged to prioritize suppliers who implement ethical supply chain practices. This includes transparency in sourcing materials, adherence to labor laws, and certifications that affirm environmental responsibility. For example, certifications like OEKO-TEX® or GOTS (Global Organic Textile Standard) indicate that the materials used in printed leatherette are free from harmful substances and produced in an environmentally friendly manner.

Furthermore, integrating sustainable materials into product offerings can enhance brand reputation and appeal to environmentally conscious consumers. Businesses that can demonstrate a commitment to sustainability not only meet regulatory requirements but also attract a growing segment of the market that values ethical production. As the demand for green products increases, sourcing from suppliers with sustainable practices will become a vital strategy for B2B buyers in the printed leatherette sector.

What is the Historical Context of Printed Leatherette in the B2B Market?

The evolution of printed leatherette can be traced back to the rise of synthetic materials in the mid-20th century, when the demand for affordable and versatile alternatives to genuine leather surged. Initially developed for fashion and upholstery, printed leatherette quickly gained popularity due to its durability, ease of maintenance, and cost-effectiveness. Over the decades, advances in printing technologies and material science have expanded its applications beyond traditional uses, making it a favored choice in various industries, including automotive, furniture, and fashion.

Illustrative image related to printed leatherette

In recent years, the printed leatherette market has shifted towards customization and personalization, driven by consumer preferences for unique and tailored products. This trend has been further accelerated by digital printing technologies, enabling businesses to create intricate designs and patterns that cater to diverse market needs. As a result, printed leatherette has established itself as a key player in the B2B landscape, offering both aesthetic appeal and functional advantages to businesses across multiple sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette

-

How do I determine the best supplier for printed leatherette?

To find the best supplier for printed leatherette, consider factors such as their reputation, production capabilities, and quality assurance processes. Look for suppliers with a proven track record in your target market and positive customer reviews. Request samples to assess material quality and printing precision. Additionally, inquire about their ability to meet your specific customization needs and delivery timelines. Engaging in direct communication can also provide insights into their responsiveness and customer service. -

What are the typical minimum order quantities (MOQs) for printed leatherette?

Minimum order quantities (MOQs) for printed leatherette can vary significantly among suppliers, typically ranging from 50 to 500 yards or sheets, depending on the customization level and material type. Some suppliers may offer lower MOQs for standard designs, while custom prints often require higher volumes due to setup costs. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your business objectives while ensuring cost-effectiveness. -

What payment terms should I expect when sourcing printed leatherette?

Payment terms can differ based on the supplier and your negotiation. Common practices include a deposit of 30-50% upfront with the balance due upon completion or prior to shipping. Some suppliers might offer net 30 or net 60 terms for established clients. Ensure to clarify the payment methods accepted (e.g., bank transfer, credit card) and check if there are additional fees for international transactions, especially when dealing with suppliers outside your region. -

How can I ensure quality assurance when ordering printed leatherette?

To ensure quality assurance, establish clear specifications for your printed leatherette order, including color accuracy, material thickness, and print resolution. Request samples before placing large orders to evaluate the print quality and material durability. Additionally, ask suppliers about their quality control processes, including any certifications they hold. Regular communication throughout the production process can help address any concerns early and ensure the final product meets your expectations. -

What are the best uses for printed leatherette in various industries?

Printed leatherette is highly versatile and suitable for numerous applications across industries. In fashion, it’s used for bags, wallets, and accessories. The automotive industry utilizes it for interior upholstery, while home décor sectors favor it for cushions and wall coverings. Additionally, promotional products like custom patches and signage benefit from the durability and aesthetic appeal of printed leatherette. Understanding your target market’s needs can guide you in selecting the right applications. -

What customization options are available for printed leatherette?

Customization options for printed leatherette are extensive, allowing businesses to create unique products. Buyers can choose from various patterns, colors, and textures, and even submit their own designs for printing. Suppliers often offer different sizes, shapes, and finishes (e.g., matte or gloss) to enhance the final product. When discussing customization, be clear about your design requirements and any specific applications to ensure the supplier can meet your vision. -

How does international shipping work for printed leatherette orders?

International shipping for printed leatherette typically involves multiple logistics considerations, including customs clearance, shipping methods, and delivery times. Suppliers may offer various shipping options, such as air freight for quicker delivery or sea freight for cost-effectiveness. Ensure to clarify shipping costs and estimated delivery times upfront. It’s also vital to understand any import regulations or tariffs that may apply in your country to avoid unexpected delays or fees. -

What are the environmental considerations when sourcing printed leatherette?

When sourcing printed leatherette, consider the environmental impact of the materials used and the printing processes. Look for suppliers who utilize eco-friendly inks and sustainable practices in production. Certifications, such as OEKO-TEX or GOTS, can indicate compliance with environmental standards. Additionally, inquire about the recyclability of the printed leatherette products. Prioritizing sustainability not only supports environmental stewardship but can also enhance your brand’s reputation among environmentally conscious consumers.

Top 5 Printed Leatherette Manufacturers & Suppliers List

1. Contrado – Custom Printed Faux Leather Fabric

Domain: contrado.com

Registered: 2004 (21 years)

Introduction: Custom Printed Faux Leather Fabric

– Price: From $37.50

– Composition: 85% PVC, 15% Polyester

– Max Width: 1.39yd

– Weight: 20.65oz

– Certification: Greenguard Certified

– Features: Soft polyester back, PVC face, fire rated, suitable for upholstery, bags, and more.

– Design: Super bright white base for vibrant prints.

– Care Instructions: Surface wipe only, clean gently by hand with mild soapy dam…

2. Lone Star – Textured Printed Premium Leatherette™ Sheets

Domain: lonestaradhesive.com

Registered: 2023 (2 years)

Introduction: Textured Printed Premium Leatherette™ Sheets

3. Thunder Laser – UV Printed Premium Leatherette® Sheets

Domain: shop.thunderlaserusa.com

Registered: 2018 (7 years)

Introduction: {“product_name”:”UV Printed Premium Leatherette® Sheets”,”dimensions”:”12×24 inches”,”design”:”Weathered Wood”,”material”:”Leatherette”,”features”:”UV printed for durability, suitable for various applications, high-quality finish”}

4. Proof Engraving – UV Printed Leatherette Patches

Domain: proofengraving.com

Registered: 2021 (4 years)

Introduction: {“product_name”: “UV Printed Leatherette Patches”, “key_features”: {“vivid_uv_printing”: “Exceptional color clarity and detail with Mimaki UV printer.”, “premium_material”: “LoneStar Heritage Series Premium Bright White leatherette.”, “precision_cutting”: “Each patch is precisely laser-cut to specified design.”, “customizable_size_shape”: “Tailored to exact requirements; cut to specified shape and…

5. Oliver & May – Custom Printed Leatherette

Strategic Sourcing Conclusion and Outlook for printed leatherette

In navigating the dynamic landscape of printed leatherette, international B2B buyers can harness significant opportunities by implementing strategic sourcing practices. Key takeaways from this guide highlight the versatility and cost-effectiveness of printed leatherette across diverse applications, from fashion accessories to home décor. By focusing on quality materials and reliable suppliers, businesses can ensure they meet customer demands while maintaining competitive pricing.

Strategic sourcing not only enhances product offerings but also fosters sustainable partnerships. As markets in Africa, South America, the Middle East, and Europe continue to evolve, establishing connections with manufacturers who prioritize innovation and sustainability will be crucial. Buyers are encouraged to explore custom printing options, leveraging unique designs that resonate with local preferences.

Looking ahead, the printed leatherette market is poised for growth, driven by increasing consumer interest in personalized products and sustainable materials. As you consider your sourcing strategies, prioritize suppliers who offer flexibility, quality, and a commitment to ethical practices. Embrace the potential of printed leatherette to elevate your product lines and position your business for success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.