Catalog

Material Insight: Lv Leather Fabric

B2B Product Guide: LV Leather Fabric

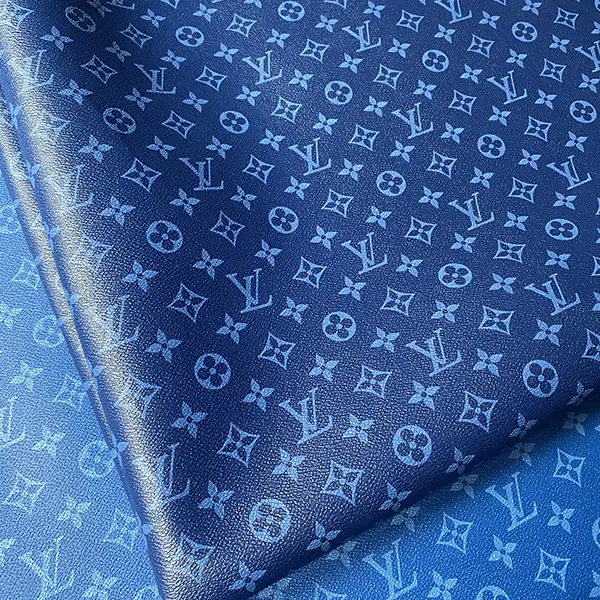

LV leather fabric is a high-performance synthetic leather engineered to meet the demanding requirements of luxury goods, automotive interiors, furniture, and fashion accessories. Designed to emulate the look, feel, and durability of premium genuine leather, LV leather fabric offers a consistent, cruelty-free, and sustainable alternative for forward-thinking manufacturers and designers. Its advanced composition ensures excellent abrasion resistance, color fastness, and dimensional stability, making it ideal for applications where aesthetics and performance are equally critical.

Why Faux Leather Is the Best Choice for This Application

- Faux leather provides a sustainable alternative to animal-derived materials, aligning with global environmental and ethical standards.

- It offers superior consistency in texture, thickness, and color compared to natural leather, reducing waste and improving production efficiency.

- LV leather fabric is highly customizable in terms of finish, embossing, and color, enabling brands to achieve unique design specifications at scale.

- With enhanced resistance to UV exposure, moisture, and wear, faux leather maintains its appearance and integrity over time—ideal for high-use environments.

- Lower production costs and reduced lead times make faux leather a cost-effective choice without compromising on luxury or quality.

About WINIW

WINIW is a leading innovator in synthetic leather solutions with over 20 years of industry expertise. Specializing in high-end microfiber and PU-based materials, WINIW serves global clients across automotive, furniture, apparel, and accessories markets. Our LV leather fabric is developed using eco-conscious processes, including water-based coatings and recyclable substrates, reflecting our commitment to sustainability and performance. With in-house R&D, strict quality control, and a focus on B2B partnerships, WINIW delivers reliable, scalable solutions that meet the evolving demands of modern manufacturing.

Technical Performance & Standards

WINIW LV Leather Fabric: Technical Product Guide for B2B Applications

WINIW Synthetic Leather delivers premium performance for demanding commercial and industrial sectors. Our LV Leather Fabric is engineered specifically for applications requiring superior aesthetics, resilience, and environmental responsibility without compromising on cost efficiency. Leveraging advanced water-based PU technology and rigorous process control, this material provides a sustainable alternative to genuine leather while exceeding key performance benchmarks for B2B procurement.

Core Technical Advantages

- Cost-Effectiveness Through Resource Optimization: LV Leather Fabric reduces total cost of ownership by 25-30% compared to premium genuine leather. This is achieved through precise resin formulation minimizing material waste, energy-efficient production cycles (30% lower energy consumption vs. industry average), and exceptional yield rates (>95% usable output per roll). Reduced maintenance costs over the product lifecycle further enhance ROI.

- Engineered Durability for High-Stress Environments: Built with a high-density, cross-linked polyurethane matrix and reinforced polyester backing, LV Leather Fabric delivers exceptional resistance to abrasion (50,000+ Martindale cycles), tearing (≥45 N), and flex cracking (>100,000 double folds). UV stabilizers ensure colorfastness (≥Grade 4 on ISO 105-B02) and surface integrity under prolonged exposure, critical for automotive interiors, public seating, and outdoor furniture.

- Precision Color Customization & Consistency: Our integrated digital pigment dispersion system allows for exact replication of Pantone® codes (within ΔE ≤ 0.8) across unlimited production runs. Unlike dyed genuine leather, colors are locked within the resin structure during coating, eliminating fading, bleeding, or batch variation. Clients receive consistent, brand-perfect finishes from prototype to full-scale manufacturing.

- Guaranteed REACH Compliance & Chemical Safety: LV Leather Fabric is rigorously tested and certified free of all SVHCs (Substances of Very High Concern) listed under EU REACH Regulation (EC 1907/2006). Full material disclosure (IMDS/SDS compliant) is provided, ensuring safety for end-users and simplifying supply chain compliance for global manufacturers, particularly in EU and North American markets.

- ISO 9001-Certified Quality Assurance: Every meter of LV Leather Fabric is produced under WINIW’s ISO 9001:2015 certified quality management system. This guarantees stringent process controls from raw material sourcing through final inspection, including 100% inline surface defect detection and batch traceability. Consistent thickness, bond strength, and physical properties are non-negotiable standards.

LV Leather Fabric Technical Specifications

| Parameter | Standard Specification | Test Method |

|---|---|---|

| Base Material | High-Tenacity Polyester Knit | ISO 1888 |

| Coating | Water-Based Polyurethane (PU) | – |

| Thickness | 0.8mm – 1.4mm (Customizable) | ISO 2424 |

| Weight | 380g/m² – 520g/m² | ISO 2280 |

| Tensile Strength | ≥ 280 N/5cm (Warp & Weft) | ISO 13934-1 |

| Tear Strength | ≥ 45 N | ISO 13937-2 |

| Martindale Abrasion | ≥ 50,000 cycles (No Rub-Through) | ISO 12947-2 |

| Colorfastness (Light) | ≥ Grade 7 (Blue Scale) | ISO 105-B02 |

| Colorfastness (Rub) | ≥ Grade 4 (Wet & Dry) | ISO 105-X12 |

| REACH Compliance | Full SVHC Free Declaration | EC 1907/2006 |

| Flammability | Meets FMVSS 302, CA TB 117 | ASTM D5116 |

| Recycled Content | Up to 30% (rPET backing) | GRS Certified |

WINIW LV Leather Fabric represents the convergence of economic efficiency, uncompromised performance, and verifiable sustainability. Designed for manufacturers prioritizing supply chain security, regulatory adherence, and long-term value, it provides a technically superior and ethically sound foundation for high-end commercial products. Partner with WINIW to integrate a material engineered for the future of responsible manufacturing.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs Real Leather – Performance and Sustainability Comparison

In today’s competitive market, material selection plays a crucial role in product development, especially in industries such as furniture, automotive interiors, fashion, and accessories. As sustainability and cost-efficiency become key decision drivers, many businesses are reevaluating traditional materials like real leather in favor of advanced synthetic alternatives. One such innovation is LV leather fabric—a high-performance synthetic leather engineered for durability, consistency, and environmental responsibility.

LV leather fabric, developed by WINIW, is a premium polyurethane (PU)-based synthetic leather designed to replicate the look, feel, and performance of real leather while addressing its inherent limitations. Unlike real leather, which relies on animal hides and resource-intensive processing, LV leather fabric is created through a controlled manufacturing process that ensures uniform quality, reduced environmental impact, and greater design flexibility.

Key advantages of LV leather fabric in B2B applications include:

– Consistent texture and thickness across batches, improving production efficiency

– Enhanced resistance to fading, cracking, and moisture

– Lower carbon footprint and reduced water usage during production

– Cruelty-free and compliant with global eco-standards (e.g., REACH, OEKO-TEX)

– Customizable finishes, colors, and textures for brand differentiation

Below is a comparative analysis of LV leather fabric and real leather across critical business and sustainability metrics:

| Metric | LV Leather Fabric | Real Leather |

|---|---|---|

| Cost | Lower upfront cost; no price volatility from raw material scarcity | Higher cost due to limited hide supply and labor-intensive processing |

| Durability | High resistance to abrasion, UV, and moisture; less prone to cracking | Prone to drying, cracking, and staining without regular maintenance |

| Eco-friendliness | Water-based production; recyclable components; zero animal sourcing | High water and energy consumption; chemical-intensive tanning (e.g., chromium); significant greenhouse gas emissions |

From a lifecycle perspective, LV leather fabric supports circular design principles by enabling longer product life with minimal maintenance and reduced environmental burden. For B2B clients aiming to meet ESG goals, reduce supply chain risks, and offer sustainable premium products, LV leather fabric presents a compelling alternative to traditional leather.

WINIW continues to lead in eco-conscious material innovation, offering scalable solutions that align performance with planetary responsibility.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a leading manufacturer of premium synthetic leather solutions, engineered to meet the rigorous demands of global brands and manufacturers. Our vertically integrated production ecosystem combines scale, innovation, and uncompromising quality control, ensuring reliable supply chains for partners across diverse industries—from automotive and furniture to fashion and technical textiles.

Core Manufacturing Strengths

- Integrated 100,000 sqm Production Facility: One of Asia’s largest dedicated synthetic leather campuses, featuring fully automated coating lines, precision embossing systems, and eco-conscious finishing units. This scale ensures consistent batch uniformity and agile capacity for large-volume global contracts.

- Dedicated R&D Team of 50+ Experts: Our innovation hub develops next-generation materials focused on performance, sustainability, and regulatory compliance. Capabilities include custom substrate engineering, bio-based PU formulations, and advanced texture replication for luxury applications.

- Closed-Loop Sustainability Systems: Water recycling (>85% reuse rate), solar energy integration, and solvent recovery units minimize environmental impact. All base materials are traceable to ISO 14001-certified suppliers.

Uncompromising Quality Assurance

WINIW’s QC protocols exceed international standards through:

– Multi-Stage Testing: Every batch undergoes 12+ physical performance tests (abrasion resistance, colorfastness, tensile strength) and 7 chemical screenings (heavy metals, phthalates, VOCs) per ASTM/ISO methods.

– Real-Time Process Monitoring: AI-driven sensors track coating thickness, color consistency, and surface defects during production, enabling immediate correction.

– Third-Party Validation: Annual audits by SGS, TÜV, and Bureau Veritas confirm adherence to ISO 9001 and ISO 14001 frameworks.

Global Compliance & Market Reach

Our materials are certified for seamless entry into regulated markets, with 70% of exports serving Europe and North America:

| Region | Key Certifications | Compliance Focus Areas |

|---|---|---|

| Europe | REACH, OEKO-TEX® Standard 100, EU Ecolabel | PFAS-free formulations, SVHC screening, circularity metrics |

| USA | CPSIA, CA Prop 65, FTC Leather Act | Formaldehyde limits, flame retardancy (FMVSS 302), traceability |

| Global | ISO 9001, ISO 14001, ZDHC MRSL Level 3 | Wastewater management, worker safety, chemical inventory control |

WINIW delivers more than material—we provide a partnership built on transparency, ethical manufacturing, and technical collaboration. Our facility’s scale and certification portfolio de-risk your supply chain while advancing your sustainability goals. Partner with us to access synthetic leather that meets tomorrow’s standards, today.

WINIW: Where Innovation Meets Responsibility.

Contact Us for Samples

WINIW LV Leather Fabric – Premium Microfiber Leather for Luxury Applications

WINIW’s LV Leather Fabric is a high-performance synthetic leather engineered for luxury goods, fashion accessories, automotive interiors, and high-end furniture. Designed to replicate the soft touch, durability, and aesthetic of premium natural leather, our LV series offers a sustainable, cruelty-free alternative without compromising on quality.

Crafted with advanced microfiber technology, LV Leather Fabric delivers exceptional tensile strength, abrasion resistance, and color fastness. It is ideal for B2B clients seeking consistent quality, eco-conscious materials, and scalable production solutions.

Key Features of LV Leather Fabric

- Ultra-soft hand feel with a natural leather-like grain

- High durability: Excellent tear and abrasion resistance

- Eco-friendly: PVC-free, phthalate-free, and REACH-compliant

- Breathable, lightweight structure for enhanced comfort

- UV and fade-resistant for long-term color retention

- Customizable thickness, texture, and color options

- Suitable for cutting, stitching, and embossing processes

Applications

- Handbags, wallets, and luxury fashion accessories

- Upholstery for automotive, aviation, and marine interiors

- Footwear and luggage manufacturing

- Furniture and decorative design elements

Technical Specifications

| Property | Standard Value |

|---|---|

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Width | 137 cm / 54 inches |

| Weight | 280 – 350 g/m² |

| Backing Fabric | Knitted or woven polyester |

| Abrasion Resistance | >20,000 cycles (Martindale) |

| Light Fastness | ≥ Grade 4 (ISO 105-B02) |

| Eco-Certifications | OEKO-TEX®, REACH, RoHS |

Why Choose WINIW LV Leather?

- Sustainable manufacturing with reduced environmental impact

- Consistent roll-to-roll quality for seamless production

- Global B2B supply with fast lead times and MOQ flexibility

- R&D support for custom development and branding

Free samples are available for qualified businesses to evaluate performance and quality firsthand.

Request Your Free Sample Today

For product inquiries, custom development, or sample requests, contact our materials team at MKT88@MicrofiberLeather.com. Discover how WINIW’s LV Leather Fabric can elevate your next luxury product line with sustainability and sophistication.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.