Introduction: Navigating the Global Market for leather tanning solution

Navigating the global market for leather tanning solutions can be a daunting task for international B2B buyers, especially with the diverse array of products and suppliers available. The challenge lies not only in identifying high-quality tanning agents but also in understanding their applications across various leather types—from buckskin to cowhide. This guide serves as a comprehensive resource, covering the essential aspects of leather tanning solutions, including different types of tanning methods, product applications, and supplier vetting processes.

By providing insights into cost structures and quality assessments, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Vietnam, to make informed purchasing decisions. With a focus on practical knowledge and actionable strategies, we aim to simplify the procurement process, ensuring that buyers can effectively source reliable tanning solutions that meet their specific needs. Whether you are a newcomer to the leather industry or an established player looking to refine your supply chain, this guide will equip you with the tools necessary to navigate the complexities of the leather tanning market confidently. Embrace the opportunity to enhance your product offerings with high-quality leather, crafted through advanced tanning techniques that meet global standards.

Table Of Contents

- Top 5 Leather Tanning Solution Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather tanning solution

- Understanding leather tanning solution Types and Variations

- Key Industrial Applications of leather tanning solution

- 3 Common User Pain Points for ‘leather tanning solution’ & Their Solutions

- Strategic Material Selection Guide for leather tanning solution

- In-depth Look: Manufacturing Processes and Quality Assurance for leather tanning solution

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather tanning solution’

- Comprehensive Cost and Pricing Analysis for leather tanning solution Sourcing

- Alternatives Analysis: Comparing leather tanning solution With Other Solutions

- Essential Technical Properties and Trade Terminology for leather tanning solution

- Navigating Market Dynamics and Sourcing Trends in the leather tanning solution Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather tanning solution

- Strategic Sourcing Conclusion and Outlook for leather tanning solution

- Important Disclaimer & Terms of Use

Understanding leather tanning solution Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable Tanning | Uses natural tannins from plant sources; eco-friendly | High-end leather goods, upholstery | Pros: Sustainable, rich patina; Cons: Longer process, less water-resistant. |

| Chrome Tanning | Utilizes chromium salts; faster process | Mass production, footwear, apparel | Pros: Quick drying, vibrant colors; Cons: Environmental concerns, less natural feel. |

| Synthetic Tanning | Employs chemical compounds for tanning | Specialty leather, fur dressing | Pros: Consistent quality, customizable; Cons: Can lack natural texture, potential chemical sensitivity. |

| Oil Tanning | Incorporates oils for a soft, flexible finish | Outdoor gear, leather clothing | Pros: Water-resistant, durable; Cons: Heavier feel, potential for oil transfer. |

| Alum Tanning | Uses aluminum salts; often for lighter leathers | Crafts, historical reproductions | Pros: Quick process, lightweight; Cons: Limited durability, less water resistance. |

What are the Characteristics of Vegetable Tanning Solutions?

Vegetable tanning is one of the oldest methods, relying on tannins derived from plant materials such as tree bark and leaves. This method is particularly favored for high-quality leather goods, including luxury handbags and furniture upholstery. B2B buyers should consider the environmental benefits of vegetable tanning, as it is a sustainable option. However, the process is time-consuming and may not produce water-resistant leather, which could be a drawback for certain applications.

How Does Chrome Tanning Differ from Other Methods?

Chrome tanning is characterized by its speed and efficiency, using chromium salts to produce leather in a fraction of the time required by traditional methods. This technique is widely employed in mass production, particularly for footwear and apparel. For B2B buyers, the vibrant colors and quick drying times are significant advantages. However, the environmental impact and potential health concerns associated with chromium use are critical factors to weigh when sourcing this type of leather.

Illustrative image related to leather tanning solution

What are the Applications of Synthetic Tanning Solutions?

Synthetic tanning involves the use of chemical compounds, offering a level of consistency and customization that traditional methods may not provide. This type of tanning is ideal for specialty leathers and fur dressing, catering to niche markets. B2B purchasers should assess the specific requirements of their projects, as synthetic tanned leather may lack the natural texture desired in some applications. Additionally, considerations around chemical sensitivity should be made when selecting materials.

Why Choose Oil Tanning Solutions for Leather Products?

Oil tanning utilizes oils to achieve a soft and flexible finish, making it particularly suitable for outdoor gear and leather clothing. This method enhances water resistance, which is a significant advantage for products exposed to harsh conditions. For B2B buyers, the durability and comfort of oil-tanned leather are appealing; however, the heavier feel and potential for oil transfer should be carefully evaluated, especially for items requiring a lighter touch.

What is the Role of Alum Tanning in the Leather Industry?

Alum tanning employs aluminum salts to produce lighter leathers quickly, making it a popular choice for crafts and historical reproductions. This method is beneficial for projects that require a rapid turnaround time. B2B buyers should note that while alum tanned leather is lightweight and easy to work with, it may not offer the same durability or water resistance as other tanning methods. Understanding these limitations is essential for ensuring the right material choice for specific applications.

Key Industrial Applications of leather tanning solution

| Industry/Sector | Specific Application of leather tanning solution | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Tanning of hides for leather garments and accessories | High-quality, durable leather that enhances product appeal | Sourcing sustainable and ethically sourced tanning solutions |

| Automotive | Production of leather interiors and upholstery | Improved aesthetics and longevity of vehicle interiors | Compliance with industry regulations and quality standards |

| Furniture Manufacturing | Upholstery for sofas, chairs, and other furniture | Enhanced comfort and durability, leading to customer satisfaction | Availability of various leather types and finishes |

| Sports Equipment | Tanning for leather sports goods (balls, gloves) | Increased performance and durability in sports equipment | Consistency in tanning processes and material availability |

| Craft and Hobby | Tanning for DIY leather projects and crafts | Versatile applications for artisans and hobbyists | Access to specialized tanning kits and user-friendly products |

How is Leather Tanning Solution Used in Fashion and Apparel?

In the fashion and apparel industry, leather tanning solutions are essential for transforming raw hides into high-quality leather suitable for garments and accessories. These solutions address common issues such as preserving the hide’s durability and enhancing its aesthetic appeal. International buyers, especially from Europe and South America, need to ensure that the tanning solutions they source meet sustainable practices and provide consistent quality. Additionally, understanding local regulations regarding leather sourcing is crucial for compliance.

What Role Does Leather Tanning Solution Play in Automotive Applications?

Automotive manufacturers utilize leather tanning solutions to create luxurious interiors and upholstery. The tanning process not only enhances the leather’s appearance but also increases its resistance to wear and tear, ensuring longevity. Buyers from the Middle East and Africa should prioritize sourcing products that comply with stringent automotive standards. They must also consider the environmental impact of the tanning agents used, as consumers increasingly demand eco-friendly options.

How is Leather Tanning Solution Beneficial for Furniture Manufacturing?

In furniture manufacturing, leather tanning solutions are pivotal for producing durable upholstery for sofas and chairs. The tanning process enhances the leather’s texture and resilience, which translates into higher customer satisfaction and reduced returns. B2B buyers in this sector should focus on sourcing a variety of leather types and finishes to cater to diverse customer preferences. Additionally, consistency in tanning quality is vital for maintaining brand reputation.

Why is Leather Tanning Solution Important for Sports Equipment?

Leather tanning solutions are used to produce high-quality leather for sports equipment, such as balls and gloves. These solutions ensure that the leather is not only durable but also performs well under various conditions. Buyers in this market, particularly from regions with a strong sporting culture, should look for tanning products that guarantee consistency and performance. They also need to evaluate suppliers based on their ability to meet high-volume demands.

How Does Leather Tanning Solution Support Craft and Hobby Industries?

For artisans and hobbyists, leather tanning solutions facilitate a wide range of DIY projects. These solutions simplify the tanning process, allowing users to achieve professional results at home. International buyers should seek out specialized tanning kits that are user-friendly and include comprehensive instructions. Additionally, sourcing from reputable suppliers ensures access to high-quality materials necessary for successful crafting endeavors.

3 Common User Pain Points for ‘leather tanning solution’ & Their Solutions

Scenario 1: Inconsistent Quality of Tanned Leather Products

The Problem: One of the most significant challenges B2B buyers face when sourcing leather tanning solutions is the inconsistency in the quality of the final product. This inconsistency can stem from using subpar tanning agents or improper methods that lead to leather that is either too stiff, too brittle, or lacks the desired finish. Buyers often find themselves in a situation where the leather they receive does not meet the quality standards required for their end products, which can damage their reputation and lead to financial losses.

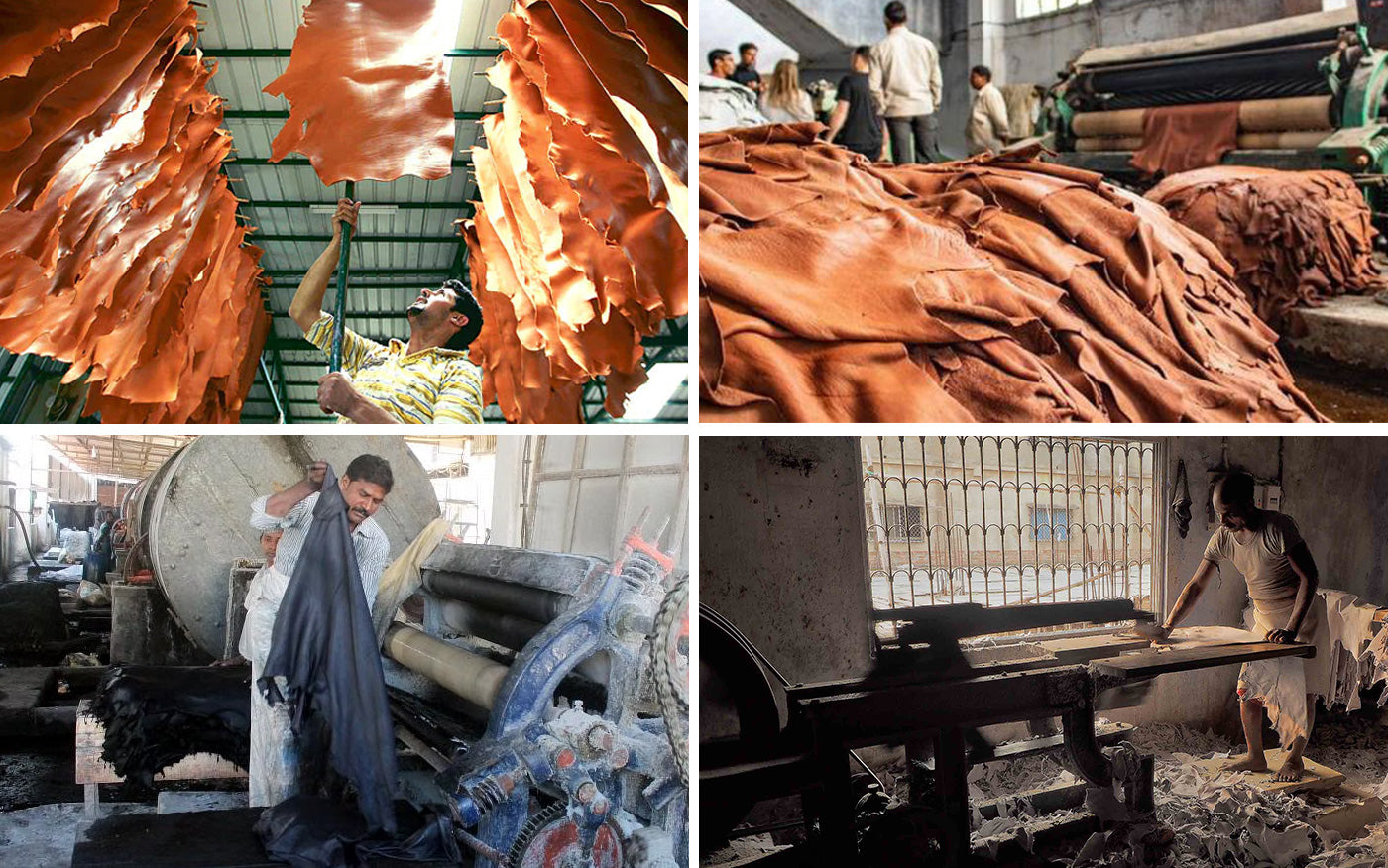

Illustrative image related to leather tanning solution

The Solution: To ensure consistency in the quality of tanned leather, buyers should opt for high-quality, industry-recognized tanning agents that have been tested and approved by professional tanneries. It is advisable to source tanning solutions from reputable suppliers who provide detailed specifications and performance data. Additionally, implementing standardized tanning processes across all batches can help maintain quality. Buyers should consider using all-in-one tanning kits that simplify the tanning process while ensuring uniform results. This can include products like Tan-a-Buckskin, which offers a complete set of tools and materials, ensuring that even those new to leather tanning can achieve professional-grade results.

Scenario 2: Environmental Regulations and Compliance Issues

The Problem: As global awareness of environmental issues increases, many B2B buyers are confronted with stringent regulations regarding the use of chemicals in the leather tanning process. This can be particularly challenging for businesses operating in regions with strict environmental laws, as non-compliance can lead to hefty fines and damage to brand reputation. Buyers are often left unsure of which tanning agents are eco-friendly and compliant with local regulations.

The Solution: To navigate these regulatory challenges, buyers should prioritize sourcing eco-friendly tanning solutions that comply with both local and international environmental standards. Engaging suppliers who provide transparency regarding the ingredients and processes involved in their tanning products is essential. For instance, opting for synthetic tanning agents that are biodegradable and free from harmful chemicals can mitigate compliance risks. Additionally, conducting regular audits of suppliers and their products can ensure ongoing adherence to environmental regulations. Collaborating with industry experts and organizations focused on sustainable practices can also provide valuable insights into compliant tanning solutions.

Scenario 3: Difficulty in Training Staff on Tanning Processes

The Problem: Another pain point for B2B buyers in the leather tanning industry is the challenge of effectively training staff to use tanning solutions and techniques. Many organizations struggle with high turnover rates or have staff with varying levels of expertise, which can result in inconsistent application of tanning methods. This inconsistency can lead to poor-quality leather and inefficiencies in production.

The Solution: To address the training challenges, businesses should invest in comprehensive training programs that incorporate hands-on experience with their chosen tanning solutions. Suppliers often provide instructional materials, including videos and manuals that outline best practices and techniques for using their products effectively. Buyers should take advantage of these resources and consider organizing workshops or training sessions led by industry professionals. Additionally, implementing a mentorship program where experienced staff can guide newcomers can foster a culture of learning and improve overall product quality. Utilizing all-inclusive tanning kits that come with user-friendly instructions can also simplify the learning curve for new employees, enabling them to achieve better results more quickly.

Strategic Material Selection Guide for leather tanning solution

What Are the Key Materials Used in Leather Tanning Solutions?

When selecting materials for leather tanning solutions, it’s essential to consider several factors, including performance properties, cost-effectiveness, and compliance with international standards. Here, we analyze four common materials used in leather tanning processes: aluminum sulfate, synthetic tanning agents, vegetable tannins, and chrome salts.

How Does Aluminum Sulfate Perform in Leather Tanning?

Aluminum sulfate is a widely used tanning agent, particularly in the pickling phase of leather production. It has a relatively low temperature rating and is effective in lowering the pH of hides, making them more receptive to tanning processes.

Illustrative image related to leather tanning solution

Pros: Aluminum sulfate is cost-effective and readily available, making it a popular choice for tanneries. It also enhances the leather’s durability and resistance to moisture.

Cons: However, it can lead to a stiffer leather product if not used correctly. Additionally, the environmental impact of aluminum sulfate is a concern, as it can contribute to water pollution if not managed properly.

Impact on Application: Its compatibility with various hides makes it suitable for a range of leather products, but tanneries must ensure compliance with environmental regulations to avoid penalties.

What Are the Advantages of Using Synthetic Tanning Agents?

Synthetic tanning agents, such as acrylics and polyurethanes, offer a modern alternative to traditional tanning methods. They provide excellent flexibility and can be tailored to specific performance requirements.

Pros: These agents often result in softer and more pliable leather, which is desirable for high-end products. They also tend to have a lower environmental impact compared to chrome-based agents.

Illustrative image related to leather tanning solution

Cons: On the downside, synthetic tanning agents can be more expensive and may require specialized equipment for application, increasing manufacturing complexity.

Impact on Application: Their versatility allows for use in various leather types, but international buyers must consider the specific regulations governing synthetic chemicals in their respective regions.

Why Are Vegetable Tannins Preferred in Sustainable Tanning?

Vegetable tannins, derived from plant sources, are favored for their eco-friendly properties. They are primarily used in the production of high-quality leather for luxury goods.

Pros: The use of vegetable tannins results in leather that is not only soft and supple but also biodegradable, appealing to environmentally conscious consumers. They also offer good UV resistance.

Cons: The tanning process with vegetable tannins is typically slower, which can lead to longer production times. Additionally, the cost of raw materials may be higher compared to synthetic alternatives.

Impact on Application: This method is particularly suitable for markets in Europe and North America, where there is a growing demand for sustainable products. However, compliance with organic certification standards may be necessary.

How Do Chrome Salts Compare in Leather Tanning Solutions?

Chrome salts are among the most widely used tanning agents globally due to their efficiency and the quality of leather produced. They allow for rapid tanning processes, which is advantageous for large-scale operations.

Pros: Chrome-tanned leather is known for its durability, water resistance, and ability to maintain color and shape over time, making it ideal for various applications, from footwear to upholstery.

Illustrative image related to leather tanning solution

Cons: The primary drawback is the environmental and health concerns associated with chromium, particularly hexavalent chromium, which is toxic. Many countries have strict regulations regarding its use.

Impact on Application: International buyers, especially in regions like Europe, must ensure compliance with REACH regulations and other environmental standards to avoid legal issues.

Summary Table of Material Selection for Leather Tanning Solutions

| Material | Typical Use Case for leather tanning solution | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Sulfate | Pickling and initial tanning phase | Cost-effective and widely available | Can produce stiffer leather if misused | Low |

| Synthetic Tanning Agents | High-end leather products | Softness and pliability | Higher cost and requires specialized equipment | High |

| Vegetable Tannins | Eco-friendly luxury leather | Biodegradable and UV resistant | Slower tanning process and higher raw material costs | Med |

| Chrome Salts | Mass production of durable leather | Fast tanning and excellent durability | Environmental and health concerns | Med |

This guide provides a comprehensive overview of the materials commonly used in leather tanning solutions, offering B2B buyers critical insights into their properties, advantages, and limitations. Understanding these factors can help businesses make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to leather tanning solution

In-depth Look: Manufacturing Processes and Quality Assurance for leather tanning solution

What Are the Main Stages of the Manufacturing Process for Leather Tanning Solutions?

The manufacturing process for leather tanning solutions involves several critical stages, each designed to ensure that the final product meets high-quality standards. These stages include material preparation, tanning, and finishing, and they often utilize advanced techniques to enhance the properties of the leather.

Material Preparation: How Are Raw Hides Processed?

The first step in the manufacturing process is the preparation of raw hides. This involves several sub-steps:

-

Fleshing and Salting: Raw hides are fleshed to remove excess fat and meat, followed by salting to prevent decomposition. This step is crucial for maintaining the integrity of the hide until the tanning process begins.

-

Soaking: After salting, hides are soaked in water to rehydrate them, which also helps in removing salt and other impurities.

-

Pickling: The hides are treated with a pickling solution, usually containing acids and salts, to prepare them for tanning. This step helps to adjust the pH levels and enhances the penetration of tanning agents.

What Techniques Are Used in the Tanning Process?

The tanning stage is where the transformation of raw hides into leather occurs. There are three primary methods of tanning:

Illustrative image related to leather tanning solution

-

Vegetable Tanning: This traditional method uses tannins extracted from plant materials. It is eco-friendly and produces leather that is soft and durable. However, it is a slower process and may not be suitable for all types of leather products.

-

Chrome Tanning: This modern method employs chromium salts and is favored for its efficiency and ability to produce a more uniform product. Chrome-tanned leather is often more resistant to water and wear, making it ideal for various applications.

-

Synthetic Tanning: This technique utilizes synthetic agents, offering a quick tanning process with consistent results. It is increasingly popular among manufacturers looking for specific leather qualities.

How Is Leather Finished After Tanning?

Once the tanning process is complete, the leather undergoes finishing to enhance its appearance and durability. This includes:

-

Dyeing: Hides are dyed using various methods to achieve the desired color. This step is critical for aesthetic appeal and may involve both natural and synthetic dyes.

-

Conditioning and Oiling: After dyeing, leather is often conditioned with oils to maintain its suppleness and flexibility. This step is essential for ensuring the leather’s longevity.

-

Finishing Treatments: Additional treatments may include water repellents, gloss finishes, and protective coatings to enhance the leather’s performance characteristics.

What Quality Control Measures Are Essential in Leather Tanning?

Quality assurance in leather tanning is paramount, especially for B2B buyers looking for reliable suppliers. The industry adheres to several international standards and practices to ensure product consistency and safety.

Which International Standards Should B2B Buyers Consider?

For leather tanning solutions, international standards such as ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems) are essential. These standards provide frameworks for quality assurance and environmental responsibility, which are increasingly important to global buyers.

In addition to ISO standards, certifications like CE (Conformité Européenne) ensure that products meet European health, safety, and environmental protection standards. Buyers should look for suppliers with these certifications, as they indicate a commitment to quality and regulatory compliance.

What Are the Key Quality Control Checkpoints?

Quality control in leather tanning typically involves several checkpoints throughout the manufacturing process:

Illustrative image related to leather tanning solution

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. It ensures that only high-quality hides are used, minimizing defects in the final product.

-

In-Process Quality Control (IPQC): During the tanning and finishing stages, IPQC involves continuous monitoring of processes to identify and rectify any issues in real-time. This ensures that the tanning agents and techniques are applied correctly.

-

Final Quality Control (FQC): The final inspection occurs before products are shipped. This includes visual inspections, testing for color consistency, durability, and other specific performance metrics relevant to the intended application.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence to verify the quality control measures of potential suppliers. Here are several effective strategies:

-

Supplier Audits: Regular audits of suppliers’ facilities can provide insights into their quality assurance practices. Buyers should consider engaging third-party auditors to ensure an unbiased evaluation.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the testing methods used and the results achieved. This transparency is crucial for building trust.

-

Third-Party Inspections: Utilizing independent inspection services can offer additional assurance. These services can conduct random checks and quality assessments at different stages of production, providing an extra layer of verification.

What Are the QC and Certification Nuances for International Buyers?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is critical. Different markets may have specific regulations and expectations regarding leather products.

-

Cultural and Regulatory Considerations: Buyers should be aware of local regulations regarding leather products, which may differ significantly from those in their home countries. For instance, environmental regulations may vary, impacting the choice of tanning methods.

-

Sustainability Practices: An increasing number of buyers are prioritizing sustainability. Suppliers who can demonstrate eco-friendly practices and sustainable sourcing of materials are likely to have a competitive edge.

By understanding the manufacturing processes and quality assurance measures in the leather tanning industry, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather tanning solution’

When sourcing leather tanning solutions, a structured approach is essential for ensuring quality and suitability for your business needs. This guide offers a practical checklist designed to help B2B buyers streamline the procurement process, ensuring that the tanning solutions selected meet industry standards and operational requirements.

Illustrative image related to leather tanning solution

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right tanning solutions. Consider factors such as the type of leather you intend to tan (e.g., buckskin, cowhide), the tanning method (vegetable, chrome, synthetic), and any specific qualities required, such as softness or durability. This clarity will guide your supplier selection and help avoid miscommunication down the line.

Step 2: Research Supplier Reputation

Conduct thorough research on potential suppliers to gauge their reliability and industry standing. Look for reviews, testimonials, and case studies from other businesses that have used their products. Engaging with industry forums can also provide insights into the supplier’s reputation and customer service track record.

Step 3: Evaluate Product Range and Quality

Assess the variety and quality of tanning solutions offered by each supplier. A robust product line can indicate a supplier’s expertise and ability to meet diverse needs. Request samples where possible to evaluate the quality of the tanning agents, oils, and any additional tools included in their kits. Pay attention to performance metrics such as tanning speed, leather quality, and ease of use.

Step 4: Verify Compliance with Industry Standards

Ensure that the tanning solutions comply with relevant industry regulations and standards, particularly if you are exporting or importing goods across borders. Look for certifications such as ISO or specific environmental compliance certifications that demonstrate adherence to safety and quality standards. This step is vital to mitigate legal risks and ensure product acceptability in your target markets.

Step 5: Assess Supply Chain Reliability

Understanding the supplier’s supply chain dynamics is critical for ensuring consistent product availability. Investigate their sourcing practices, production capacity, and logistics capabilities. Consider factors such as lead times, shipping options, and their ability to handle large orders, which can significantly impact your operations.

Step 6: Negotiate Terms and Pricing

Once you have identified potential suppliers, engage in discussions about pricing, payment terms, and delivery schedules. Be clear about your budget but also inquire about bulk discounts or loyalty programs that could benefit long-term partnerships. Transparent negotiations can foster goodwill and lead to better pricing structures over time.

Step 7: Establish a Trial Order

Before committing to a large purchase, consider placing a trial order. This allows you to assess the quality and performance of the tanning solution in real-world conditions. Monitor the results closely, gather feedback from your production team, and evaluate whether the product meets your specifications and expectations.

By following these steps, B2B buyers can make informed decisions when sourcing leather tanning solutions, ensuring that they choose products that align with their operational needs and market demands.

Illustrative image related to leather tanning solution

Comprehensive Cost and Pricing Analysis for leather tanning solution Sourcing

What Are the Key Cost Components in Leather Tanning Solutions?

In analyzing the cost structure of leather tanning solutions, several key components come into play. Materials are the most significant factor, encompassing tanning agents, oils, and other chemicals used in the tanning process. For example, products like the PRO-1 Brush On Tanning Oil or the Tan-a-Buckskin kits illustrate the range of materials required, with prices varying based on quality and effectiveness.

Labor costs are another critical element. Skilled labor is necessary for both the tanning process and quality control, impacting the overall cost. Manufacturing overhead includes expenses related to facility maintenance, utilities, and equipment depreciation, which can vary significantly depending on the location and scale of operations.

Tooling and equipment costs are also noteworthy. The initial investment in machinery for tanning and finishing leather can be substantial, affecting the pricing structure. Quality Control (QC) processes are essential to ensure that the final product meets industry standards, contributing to the cost through rigorous testing and compliance measures.

Logistics costs, including transportation and warehousing, can vary by region and are influenced by local infrastructure. Finally, the margin applied by suppliers can differ based on their market position and competitive strategy, further impacting the final pricing of tanning solutions.

Illustrative image related to leather tanning solution

How Do Price Influencers Affect Leather Tanning Solutions?

Several factors influence the pricing of leather tanning solutions, particularly for international B2B buyers. Volume and Minimum Order Quantity (MOQ) are critical; larger orders typically result in lower per-unit costs due to economies of scale. Customization in specifications can also lead to increased costs, as tailored solutions often require additional resources and time.

The quality of materials plays a significant role; higher-quality tanning agents and oils tend to be more expensive but can result in superior end products. Certifications related to environmental standards or quality assurance can also affect pricing, as suppliers may charge more for compliant products.

Supplier factors such as reputation, reliability, and service levels impact pricing as well. Buyers should consider the total cost of ownership, which includes not only the initial purchase price but also factors such as durability, maintenance, and potential rework costs.

Incoterms dictate the responsibilities of buyers and sellers during shipping, impacting overall costs. Understanding these terms is crucial for B2B buyers, especially when sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

What Are the Best Negotiation Tips for B2B Buyers in the Leather Tanning Market?

For buyers looking to optimize costs, effective negotiation strategies are essential. Start by gathering comprehensive market intelligence on current pricing trends and competitor offerings. This knowledge can empower buyers during negotiations, allowing them to advocate for better terms based on market data.

Illustrative image related to leather tanning solution

Consider leveraging bulk purchasing to negotiate lower prices, especially when dealing with suppliers who offer discounts for larger orders. Additionally, establishing a long-term relationship with suppliers can create opportunities for better pricing and favorable terms over time.

Understanding the Total Cost of Ownership is critical. Buyers should analyze not just the upfront costs but also the long-term implications of their purchases. Factors like product lifespan, maintenance requirements, and resale value should be factored into negotiations.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers should be acutely aware of pricing nuances influenced by regional factors. Currency fluctuations can affect costs significantly, making it essential to lock in prices when possible. Additionally, import tariffs and taxes can dramatically impact the final cost of products sourced from abroad.

Buyers from regions like Africa or South America may encounter different logistical challenges compared to those in Europe or the Middle East, which can affect delivery timelines and costs. Understanding local regulations regarding imports can help avoid unforeseen expenses.

In conclusion, while indicative prices can serve as a guide, it is vital for buyers to conduct thorough due diligence to ensure they secure the best value for their investment in leather tanning solutions.

Alternatives Analysis: Comparing leather tanning solution With Other Solutions

Exploring Alternatives to Leather Tanning Solutions

When considering leather tanning solutions, it’s essential to evaluate alternatives that can achieve similar results. This analysis will compare traditional leather tanning solutions with two notable alternatives: synthetic tanning agents and natural tanning methods. Each option has unique benefits and limitations that can influence a buyer’s decision based on their specific needs.

| Comparison Aspect | Leather Tanning Solution | Synthetic Tanning Agents | Natural Tanning Methods |

|---|---|---|---|

| Performance | High-quality, durable leather with excellent flexibility and strength | Consistent results; often yields softer leather; water-resistant | Produces unique textures and colors; environmentally friendly |

| Cost | Moderate to high (varies by kit and material) | Generally lower initial cost; may require more products | Variable; may involve higher labor and time costs |

| Ease of Implementation | User-friendly kits available for beginners and professionals | Requires knowledge of chemical handling; can be complex | Labor-intensive; requires significant time and expertise |

| Maintenance | Minimal; periodic conditioning recommended | Moderate; may need additional products for finishing | High; requires careful monitoring of conditions and materials |

| Best Use Case | Ideal for crafting, garments, and high-quality leather goods | Suitable for mass production and consistent quality | Best for artisanal, unique leather items and sustainable practices |

What Are the Benefits and Drawbacks of Synthetic Tanning Agents?

Synthetic tanning agents, such as those offered by PRO-1 Performance Chemicals, provide a modern solution that can yield softer, more flexible leather. These agents often deliver consistent results across large batches, making them suitable for manufacturers looking to optimize efficiency. However, they require knowledge of chemical handling and precise application methods, which can complicate the process for less experienced users. Additionally, while they may have a lower upfront cost, buyers should consider the potential for needing various finishing products, which can add to overall expenses.

How Do Natural Tanning Methods Compare?

Natural tanning methods, often involving plant-based materials or oils, produce leather with unique textures and colors. They appeal to environmentally conscious businesses looking to minimize their ecological footprint. However, this method is labor-intensive and time-consuming, requiring significant expertise to achieve desirable results. Buyers should weigh the benefits of sustainable practices against the higher labor costs and longer production times. Natural tanning may be ideal for niche markets focused on artisanal products but may not be feasible for high-volume production.

Illustrative image related to leather tanning solution

Conclusion: How Can B2B Buyers Make Informed Decisions?

Choosing the right leather tanning solution requires careful consideration of specific business needs, including production scale, target market, and budget constraints. For businesses focused on high-quality, consistent leather, traditional tanning solutions or synthetic agents may be the best fit. Conversely, those prioritizing sustainability and unique craftsmanship might lean towards natural tanning methods. Ultimately, understanding the trade-offs between performance, cost, and ease of implementation will empower B2B buyers to select the most suitable tanning solution for their operations.

Essential Technical Properties and Trade Terminology for leather tanning solution

What Are the Key Technical Properties of Leather Tanning Solutions?

When sourcing leather tanning solutions, understanding the technical properties is crucial for making informed decisions. Here are several critical specifications that B2B buyers should consider:

-

Material Grade

Material grade refers to the quality classification of the tanning agents used in the process. High-grade materials ensure superior performance, resulting in leather that is not only durable but also has enhanced aesthetic qualities. In B2B transactions, the material grade can significantly affect pricing, so buyers must ensure that they are receiving products that meet their specific requirements without compromising quality. -

Tanning Efficiency

This specification indicates how effectively a tanning agent can convert raw hides into usable leather. Efficiency is often measured in terms of time and chemical consumption. Higher efficiency translates to reduced operational costs and faster turnaround times, which is essential for manufacturers looking to optimize their production processes. -

pH Level

The pH level of tanning solutions is vital for achieving the desired leather characteristics. Most tanning processes require a specific pH range to ensure proper tanning and preservation of the hide. Buyers should request pH test results from suppliers to guarantee that the tanning solutions will perform as expected during their production processes. -

Flexibility and Softness

These properties determine the tactile and functional characteristics of the finished leather. A tanning solution that produces soft and flexible leather is essential for applications requiring comfort and ease of use, such as in garments and upholstery. Understanding how different solutions affect flexibility can help manufacturers choose the right product for their specific applications. -

Water Resistance

Water resistance is an essential property for leather used in various applications, especially in outdoor products. Tanning solutions that enhance water resistance can significantly extend the life of leather products. Buyers should inquire about the water-resistant capabilities of tanning agents to meet market demands for durability and longevity. -

Environmental Compliance

With increasing regulations on chemical usage, B2B buyers must ensure that the tanning solutions they procure comply with environmental standards. Understanding the environmental impact of tanning agents can safeguard businesses against potential legal issues and enhance their brand reputation among environmentally conscious consumers.

What Are Common Trade Terms in the Leather Tanning Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key trade terms:

-

OEM (Original Equipment Manufacturer)

In the leather tanning industry, an OEM refers to a company that produces tanning agents or machinery that are marketed by another company under its own brand. Understanding OEM relationships can help buyers identify reliable suppliers and manufacturers of quality products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs to suit their production needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. This process is essential for comparing pricing and terms across multiple suppliers, allowing businesses to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of international rules that define the responsibilities of sellers and buyers in global transactions. Understanding these terms can help businesses navigate shipping and delivery logistics, ensuring clarity on costs and responsibilities associated with the transport of tanning solutions. -

Lead Time

Lead time refers to the time taken from placing an order until the product is received. In the leather tanning industry, understanding lead times is critical for planning production schedules and meeting customer demand. -

Batch Processing

This term refers to the method of producing leather in large quantities at once. Batch processing can affect the consistency and quality of the final product, making it essential for buyers to understand the production methods of their suppliers to ensure uniformity in their leather products.

By grasping these technical properties and trade terms, B2B buyers can navigate the leather tanning landscape more effectively, ensuring they make informed and strategic purchasing decisions.

Illustrative image related to leather tanning solution

Navigating Market Dynamics and Sourcing Trends in the leather tanning solution Sector

What Are the Key Trends Shaping the Leather Tanning Solutions Market?

The global leather tanning solutions market is experiencing significant growth, driven by rising demand for leather products across various sectors, including fashion, automotive, and furniture. Emerging economies in Africa and South America are becoming key players in the leather industry, spurred by increased consumer spending and a growing middle class. In Europe, particularly in countries like Germany, there is a heightened focus on quality leather goods, creating opportunities for suppliers of premium tanning solutions.

Recent technological advancements are reshaping the sourcing landscape. Automation and digitization are streamlining production processes, enhancing efficiency, and reducing lead times. B2B buyers are increasingly adopting e-commerce platforms for sourcing, enabling them to compare products, prices, and suppliers more effectively. Additionally, the rise of data analytics is allowing companies to forecast demand better and optimize inventory management.

In terms of market dynamics, the competitive landscape is intensifying, with both established players and new entrants vying for market share. International buyers must stay informed about the latest innovations in tanning agents and technologies, as these can significantly impact product quality and cost-effectiveness. Moreover, the integration of sustainable practices is becoming a differentiator in the market, influencing purchasing decisions among environmentally conscious consumers and businesses.

How Is Sustainability Influencing B2B Purchasing Decisions in Leather Tanning?

Sustainability is becoming a cornerstone of purchasing decisions in the leather tanning sector. The environmental impact of traditional tanning processes, particularly those involving toxic chemicals, has prompted buyers to seek more eco-friendly alternatives. There is an increasing demand for ‘green’ certifications and materials, such as vegetable-tanned leather and chromium-free tanning agents. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, which can enhance their brand reputation and meet regulatory requirements.

Ethical sourcing is equally crucial, especially for international buyers from regions where labor practices may come under scrutiny. Transparency in the supply chain is essential; buyers are looking for partners who can provide clear information on sourcing practices and labor conditions. Companies that adopt ethical sourcing and sustainability initiatives not only mitigate risks but also tap into a growing market of environmentally conscious consumers.

The trend towards sustainability is also influencing product development, with suppliers innovating to create biodegradable tanning solutions and minimizing waste in their processes. As sustainability becomes a key competitive differentiator, B2B buyers must evaluate potential partners based on their environmental practices and commitment to ethical sourcing.

Illustrative image related to leather tanning solution

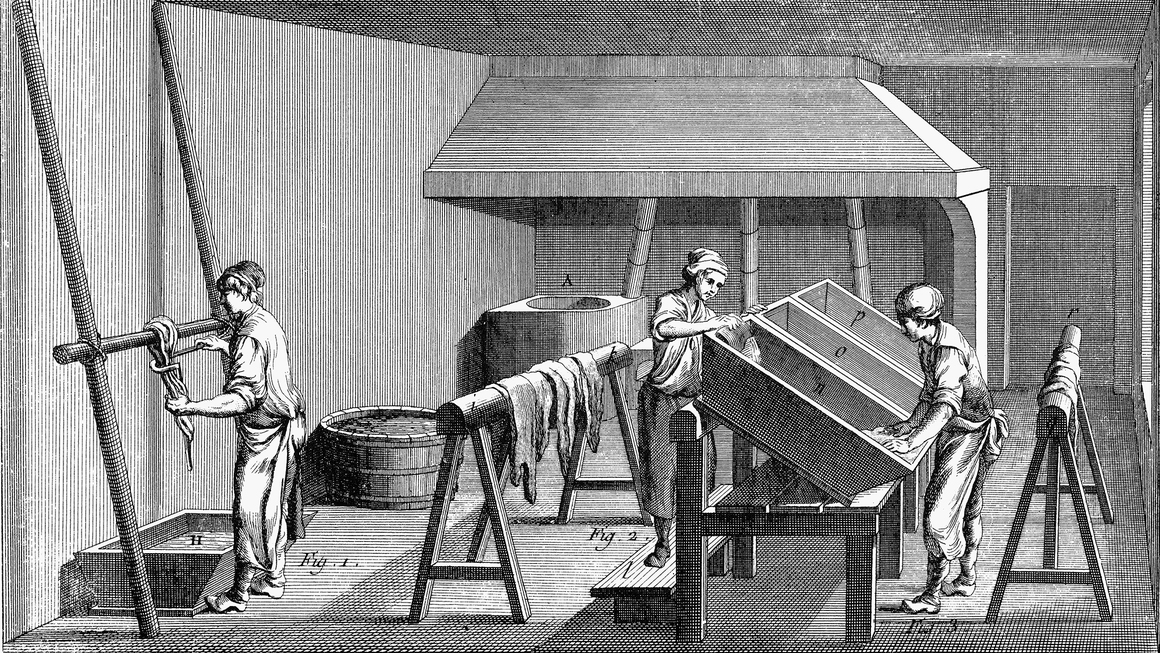

What Is the Historical Context of Leather Tanning Solutions in B2B Markets?

The evolution of leather tanning solutions dates back thousands of years, initially utilizing natural materials such as tannins from tree bark. The Industrial Revolution marked a significant turning point, introducing synthetic tanning agents and mechanized processes that increased efficiency and reduced costs. As the leather industry expanded, so did the complexity of tanning methods, with chrome tanning becoming the dominant technique due to its speed and effectiveness.

However, growing environmental concerns have led to a resurgence of interest in traditional methods, such as vegetable tanning, as well as the development of innovative, eco-friendly alternatives. This historical context is essential for B2B buyers to understand the trajectory of the industry and the ongoing shift towards sustainability and ethical practices that is reshaping the market today. By recognizing these trends, international buyers can make informed decisions that align with their values and business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of leather tanning solution

-

How do I solve issues with leather quality during tanning?

To resolve quality issues during the tanning process, ensure you are using high-grade tanning agents that are suitable for your specific type of leather. Conduct a thorough pre-tanning assessment, including pH testing of the hides and ensuring proper pickling. Follow manufacturer guidelines closely for application rates and techniques. Additionally, invest in quality control measures, such as sampling and testing the leather at various stages to catch any issues early. -

What is the best tanning solution for buckskin leather?

For buckskin leather, a comprehensive tanning kit like Tan-a-Buckskin is highly recommended. This kit includes all necessary tools and agents for a professional-grade tan. The included Pickle Tan A-21 and buckskin oil ensure a soft, supple finish, perfect for crafting garments and accessories. Always check that the tanning solution is compatible with the specific animal hide you are working with to achieve optimal results. -

How can I vet suppliers of leather tanning solutions?

When vetting suppliers, prioritize those with a solid track record in the industry. Request references or case studies from previous clients, and verify their certifications and compliance with international quality standards. Conduct site visits if possible, or use video conferencing to assess their facilities. Additionally, inquire about their product range and the sourcing of their materials to ensure they align with your quality requirements. -

What are the typical minimum order quantities (MOQ) for tanning solutions?

Minimum order quantities can vary significantly based on the supplier and the type of tanning solution. Generally, MOQs for tanning agents may range from 5 to 100 gallons, depending on the product line and supplier capabilities. For bulk purchases, negotiate with suppliers to potentially lower MOQs, especially if you are committing to a long-term partnership. -

What payment terms are standard for international B2B transactions in the tanning industry?

Standard payment terms often include a 30% deposit upon order confirmation and the remaining balance before shipment. However, terms can vary based on the supplier’s policies and your negotiation. Some suppliers might offer letters of credit or other financing options for larger orders. Always clarify payment methods, currency, and any potential fees associated with international transactions to avoid surprises. -

How do I ensure quality assurance (QA) in leather tanning?

Implement a comprehensive QA process that includes regular inspections at each stage of the tanning process. Establish clear quality benchmarks based on international standards and the specific requirements for your end products. Use third-party testing for critical parameters, such as pH levels, dye consistency, and strength. Regular training for your staff on QA protocols can also enhance product quality and consistency. -

What logistics considerations should I be aware of when importing tanning solutions?

When importing tanning solutions, consider shipping methods, customs regulations, and potential tariffs. Work with logistics providers experienced in handling chemical products to ensure compliance with safety regulations. Additionally, factor in lead times for production and delivery, and consider using incoterms that clearly define the responsibilities of each party regarding shipping, insurance, and costs. -

Can tanning solutions be customized for specific leather types or processes?

Many suppliers offer customization options for their tanning solutions based on the specific requirements of your leather type or production process. Discuss your needs with potential suppliers and inquire about their ability to formulate products tailored to your specifications. Customization can include adjustments in pH levels, tanning agents, or packaging sizes to better fit your operational needs.

Top 5 Leather Tanning Solution Manufacturers & Suppliers List

1. Advanced Tanning Solutions – Tan-a-Buckskin Deluxe Tanning Kit

Domain: advancedtanningsolutions.com

Registered: 2015 (10 years)

Introduction: Tan-a-Buckskin is an all-inclusive deluxe tanning kit designed for tanning buckskin, hair-off leather from deer, elk, bison, or cow hides. Regular price is $149.95. The kit includes a fleshing/shaving tool, hide hair removal, pickle, Tan A-21, buckskin oil, softening stone, water repellent, dust mask, and non-latex disposable gloves. It can tan approximately 5-6 medium size deer buckskin or 2-3 la…

2. FNT Post – Trapper’s Hide Tanning Formula

Domain: fntpost.com

Registered: 2006 (19 years)

Introduction: [{‘name’: “Trapper’s Hide Tanning Formula”, ‘price’: ‘$8.95’, ‘description’: ‘Allows easy home tanning of all fur skins and deer hides. Produces a soft, supple Indian-style tan in 5-7 days. Comes in an 8 oz. bottle. Tans all fur skins and deer hides. One bottle tans two medium sized fur skins or one deer hide. Elk, moose, caribou and bear require 3 to 6 bottles.’}, {‘name’: “Rittel’s EZ-100 Tannin…

3. Pro1 Performance Chemicals – Leather Tanning Concentrate

Domain: pro1performancechemicals.com

Registered: 2011 (14 years)

Introduction: This company, Pro1 Performance Chemicals – Leather Tanning Concentrate, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – Non-Toxic Tanning Methods

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Non-toxic tanning methods include buckskin tanning, which uses potassium hydroxide derived from wood ash and animal brains or eggs. Chrome tanning is identified as a toxic process, often resulting in blue or green leather, and is associated with cheaper leather due to its fast and inexpensive nature. Environmental impact is more related to wastewater treatment than the chemicals used in tanning.

5. Facebook – Leather Tanning Techniques

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Leather Tanning Techniques, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather tanning solution

In the competitive landscape of leather tanning solutions, strategic sourcing emerges as a critical factor for international B2B buyers. By prioritizing high-quality tanning agents and kits, such as those that offer comprehensive solutions for various leather types, businesses can enhance their product offerings while ensuring compliance with evolving environmental standards. Buyers from regions like Africa, South America, the Middle East, and Europe must consider suppliers that not only deliver reliable products but also provide technical support and insights into best practices.

Investing in advanced tanning methods and sustainable practices will not only improve leather quality but also resonate with a growing consumer demand for environmentally friendly products. As the global market continues to evolve, leveraging relationships with reputable suppliers will empower businesses to remain agile and responsive to market changes.

Looking ahead, now is the time for B2B buyers to reassess their sourcing strategies and establish partnerships that align with their long-term growth objectives. By embracing innovation and sustainability in leather tanning, businesses can position themselves as leaders in a dynamic industry. Engage with suppliers that share your vision, and together, let’s shape the future of leather craftsmanship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather tanning solution

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.