Introduction: Navigating the Global Market for what is pu material

In the ever-evolving landscape of industrial materials, understanding what PU (polyurethane) material is and how it can meet your business needs is crucial for international B2B buyers. Sourcing high-quality PU materials can present challenges, particularly when navigating variations in quality, durability, and environmental impact. This comprehensive guide demystifies PU material, providing insights into its types, applications, and the critical factors to consider when selecting suppliers.

From furniture to automotive components and fashion accessories, PU material plays a pivotal role across diverse industries, making it essential for businesses in Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Vietnam, to make informed decisions. We delve into the nuances of PU material, including its composition, potential toxicity, and its environmental footprint, while also offering practical advice on supplier vetting and cost analysis.

By equipping yourself with the knowledge contained within this guide, you will be empowered to navigate the complexities of the global PU market effectively. This resource is designed to enhance your purchasing strategies, ensuring that you select the right materials that align with both your operational needs and sustainability goals. Whether you are looking to innovate your product line or optimize your supply chain, understanding PU material is a vital step toward achieving your business objectives.

Table Of Contents

- Top 6 What Is Pu Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is pu material

- Understanding what is pu material Types and Variations

- Key Industrial Applications of what is pu material

- 3 Common User Pain Points for ‘what is pu material’ & Their Solutions

- Strategic Material Selection Guide for what is pu material

- In-depth Look: Manufacturing Processes and Quality Assurance for what is pu material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is pu material’

- Comprehensive Cost and Pricing Analysis for what is pu material Sourcing

- Alternatives Analysis: Comparing what is pu material With Other Solutions

- Essential Technical Properties and Trade Terminology for what is pu material

- Navigating Market Dynamics and Sourcing Trends in the what is pu material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is pu material

- Strategic Sourcing Conclusion and Outlook for what is pu material

- Important Disclaimer & Terms of Use

Understanding what is pu material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather | Coated fabric with polyurethane; resembles real leather | Fashion, upholstery, accessories | Pros: Affordable, versatile, easy to clean. Cons: Limited durability, potential for peeling. |

| PU Foam | Soft, cushioning material; lightweight and flexible | Furniture padding, automotive interiors | Pros: Excellent shock absorption, lightweight. Cons: Can degrade over time, less eco-friendly. |

| PU Coated Fabrics | Textiles coated with polyurethane for water resistance | Outdoor gear, bags, and apparel | Pros: Water-resistant, durable. Cons: Can be less breathable, may retain heat. |

| Rigid PU | Hard, inflexible polyurethane; used for structural applications | Construction, automotive parts | Pros: Strong, durable, resistant to chemicals. Cons: Limited flexibility, heavier than other options. |

| Flexible PU | Soft, bendable polyurethane; good for molding and shaping | Toys, medical devices, and soft goods | Pros: Highly adaptable, good for various applications. Cons: Can be less durable than rigid variants. |

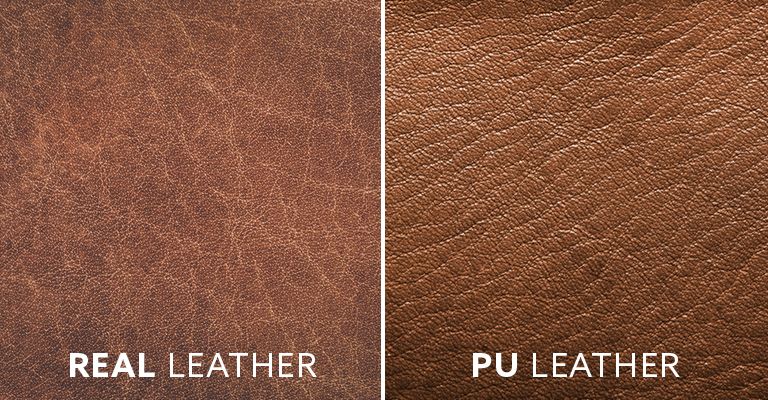

What are the Characteristics of PU Leather?

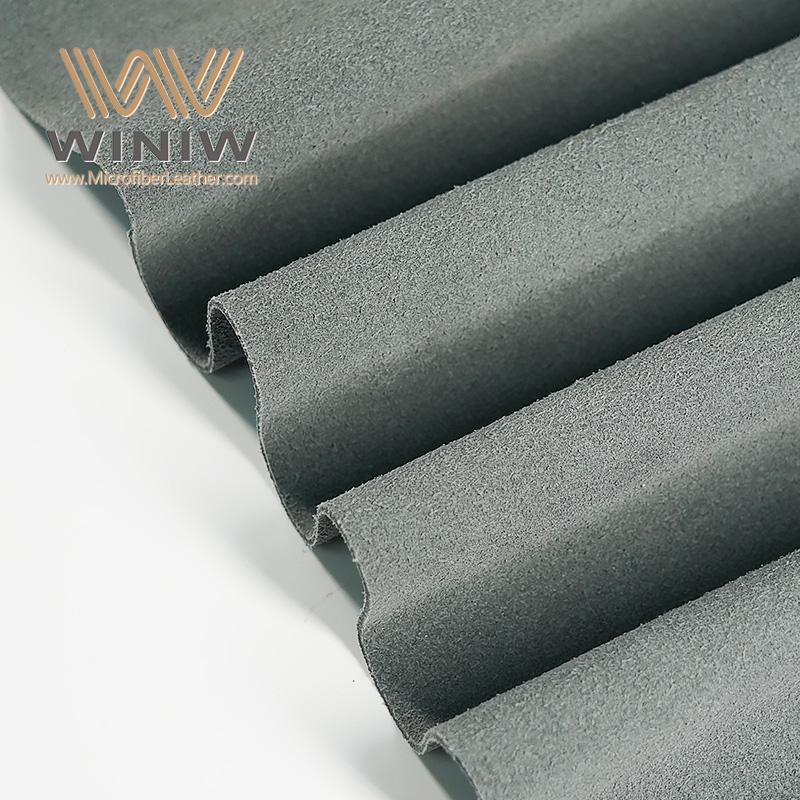

PU leather is a synthetic material designed to mimic the appearance of genuine leather. It is produced by applying a layer of polyurethane over a fabric backing, giving it a leather-like texture. B2B buyers in the fashion and upholstery industries often favor PU leather for its affordability and ease of maintenance. However, its durability is a concern, as it can crack and peel with regular use, leading to higher replacement costs over time. Buyers should weigh the initial cost savings against potential long-term expenses.

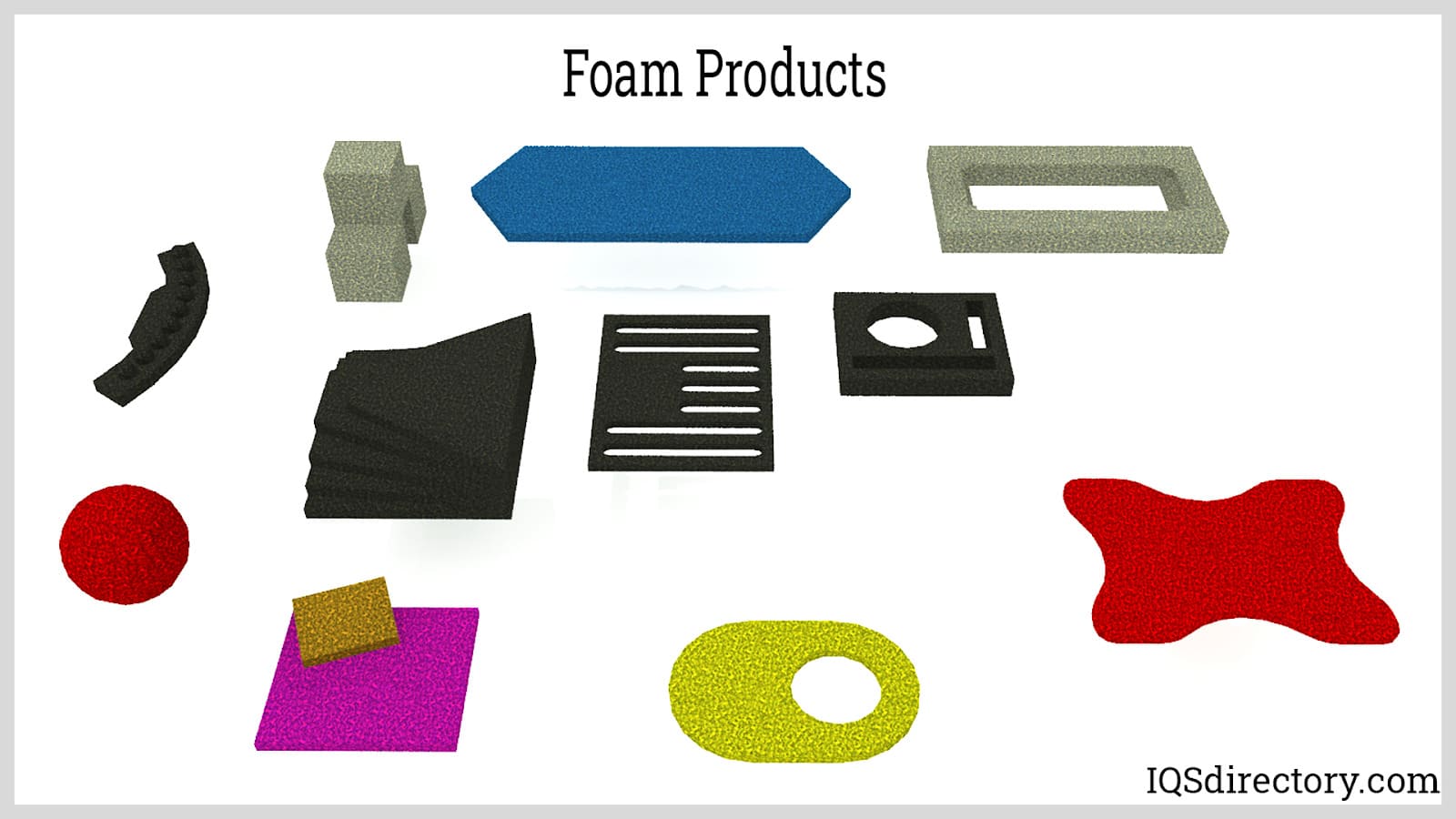

How Does PU Foam Benefit B2B Applications?

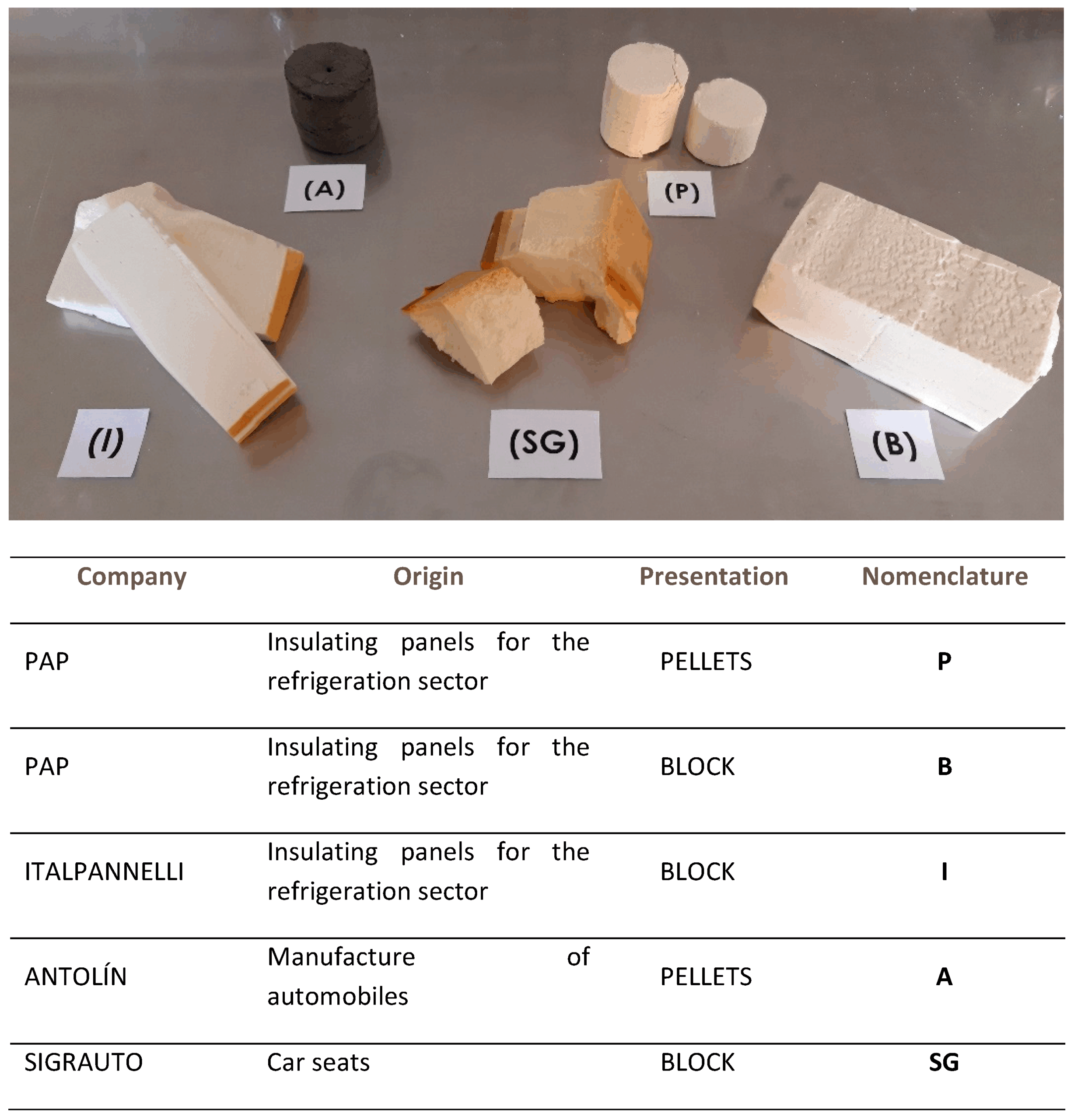

PU foam is characterized by its lightweight and cushioning properties, making it an ideal choice for furniture padding and automotive interiors. Its shock-absorbing capabilities provide comfort and protection, which are essential in industries like automotive and furniture manufacturing. While PU foam offers excellent performance, buyers should consider its longevity, as it can degrade over time, affecting the lifespan of products. Choosing high-density options can enhance durability, making it a more reliable investment.

What are the Advantages of PU Coated Fabrics?

PU coated fabrics are textiles treated with a layer of polyurethane to enhance water resistance and durability. These materials are commonly used in outdoor gear, bags, and apparel, appealing to B2B buyers looking for reliable, weather-resistant solutions. While they provide excellent protection against moisture, it’s important to note that such fabrics can be less breathable, which might not be suitable for all applications. Buyers should evaluate the intended use to ensure the selected fabric meets performance expectations.

Why Choose Rigid PU for Structural Applications?

Rigid PU is a hard, inflexible form of polyurethane that excels in structural applications. Its strength and chemical resistance make it suitable for construction materials and automotive components. B2B buyers in these sectors benefit from its durability and resistance to environmental factors. However, its lack of flexibility can be a drawback in applications requiring bending or shaping. Buyers should assess the specific requirements of their projects to determine if rigid PU is the right choice.

What Makes Flexible PU Ideal for Molding?

Flexible PU is a soft, bendable variant that allows for easy molding and shaping, making it suitable for products like toys and medical devices. Its adaptability is a significant advantage for manufacturers seeking to create intricate designs. However, while flexible PU offers versatility, it may not match the durability of its rigid counterparts. B2B buyers should consider the trade-offs between flexibility and longevity when selecting materials for their products.

Key Industrial Applications of what is pu material

| Industry/Sector | Specific Application of what is pu material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and interiors | Cost-effective, lightweight, and easy to clean | Ensure compliance with automotive standards and durability requirements. |

| Furniture Manufacturing | Upholstered furniture and soft goods | Aesthetic appeal and variety of textures/colors | Source from suppliers with eco-friendly practices and certifications. |

| Footwear | Shoe linings and outer materials | Flexibility, water resistance, and design versatility | Verify the material’s breathability and comfort for end-users. |

| Fashion and Accessories | Bags, wallets, and apparel | Affordable alternative to leather with trendy designs | Look for suppliers that provide customization options and ethical production. |

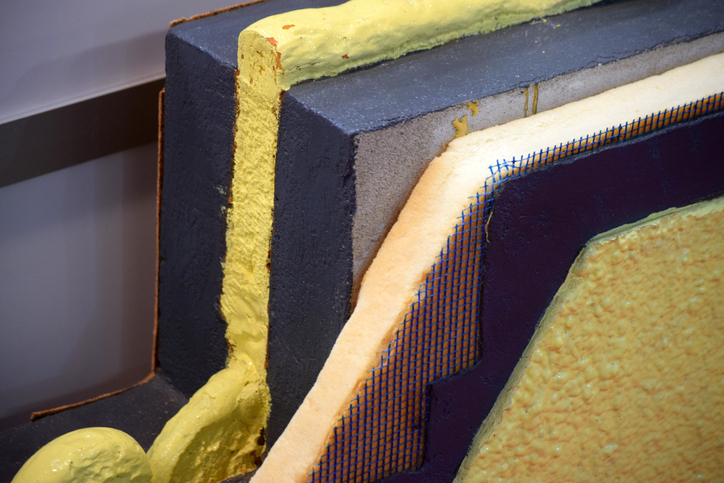

| Construction & Insulation | Insulating materials and coatings | Excellent thermal insulation properties | Assess fire resistance and long-term durability under environmental conditions. |

How is PU Material Used in the Automotive Industry?

In the automotive sector, PU material is widely utilized for upholstery in seats and interiors. Its lightweight nature contributes to overall vehicle efficiency, while its easy maintenance and resistance to stains enhance the longevity of vehicle interiors. For international buyers, particularly in regions like the Middle East and Africa, sourcing PU materials must involve ensuring compliance with automotive safety standards and durability requirements. Additionally, understanding the climatic conditions in which the vehicles will operate is crucial to selecting the right grade of PU.

Illustrative image related to what is pu material

What Role Does PU Material Play in Furniture Manufacturing?

PU material finds extensive use in the furniture industry, particularly in upholstered furniture and soft goods. Its aesthetic versatility allows manufacturers to offer a wide range of colors and textures, appealing to diverse consumer preferences. For B2B buyers in South America and Europe, it’s essential to source PU materials from suppliers who prioritize eco-friendly practices and certifications, as sustainability is becoming increasingly important in consumer purchasing decisions. Additionally, buyers should consider the durability and ease of maintenance of the material to meet customer expectations.

How is PU Material Applied in Footwear?

In the footwear industry, PU material is commonly used for shoe linings and outer materials due to its flexibility and water resistance. This makes it an ideal choice for various types of footwear, from casual to formal. International buyers, especially from Europe and Asia, need to ensure that the sourced PU material meets comfort and breathability standards, as these factors significantly influence consumer satisfaction. Furthermore, understanding local market trends can help buyers select the most appealing designs and finishes.

What Benefits Does PU Material Offer in Fashion and Accessories?

PU material is a popular choice in the fashion and accessories sector for items such as bags, wallets, and clothing. Its affordability compared to genuine leather allows brands to offer stylish products at competitive prices. For B2B buyers, particularly in emerging markets, sourcing PU material from suppliers that provide customization options and adhere to ethical production practices is crucial. This not only enhances brand reputation but also attracts consumers who value sustainability and ethical sourcing.

How is PU Material Utilized in Construction and Insulation?

In construction, PU material is utilized for insulation materials and coatings due to its excellent thermal insulation properties. This application is particularly beneficial in regions with extreme weather conditions, providing energy efficiency and comfort. Buyers in the construction sector should assess the fire resistance and long-term durability of PU materials, ensuring they meet local building codes and environmental conditions. Collaborating with suppliers who understand these specifications can lead to successful project outcomes.

3 Common User Pain Points for ‘what is pu material’ & Their Solutions

Scenario 1: Durability Concerns with PU Material in Industrial Applications

The Problem:

B2B buyers in industries such as automotive or furniture manufacturing often face significant challenges with the durability of PU materials. While PU is marketed as a cost-effective alternative to genuine leather, it is prone to cracking, peeling, and fading under heavy use. This can lead to higher replacement costs and customer dissatisfaction, especially when products fail to maintain their aesthetic appeal over time. Buyers may also struggle with warranties that do not cover material failures, further complicating their procurement decisions.

The Solution:

To mitigate durability issues, B2B buyers should prioritize sourcing PU materials that have been treated with advanced coatings for enhanced resistance to wear and tear. When specifying PU for their products, buyers should look for suppliers that offer detailed information about the material’s longevity, abrasion resistance, and any additional protective treatments applied during manufacturing. Establishing partnerships with reputable manufacturers who provide transparent testing data can significantly reduce the risk of premature material failure. Additionally, incorporating rigorous quality assurance processes in production will ensure that the final products meet durability expectations, ultimately enhancing customer satisfaction.

Scenario 2: Environmental Impact of PU Material Choices

The Problem:

As sustainability becomes a priority for consumers and businesses alike, B2B buyers are increasingly challenged by the environmental implications of using PU materials. Many PU products are derived from petroleum-based sources, contributing to a higher carbon footprint compared to natural alternatives. Buyers may find themselves facing criticism from stakeholders or customers concerned about eco-friendliness, making it imperative to choose materials that align with sustainability goals.

The Solution:

To address environmental concerns, B2B buyers should conduct thorough research into the lifecycle of the PU materials they intend to use. Engaging with suppliers who prioritize sustainable practices—such as using bio-based polyols or implementing eco-friendly production methods—can mitigate negative environmental impacts. Buyers can also explore certifications related to sustainability, such as the Global Organic Textile Standard (GOTS) or OEKO-TEX certification, which provide assurance that the materials meet stringent environmental criteria. By prioritizing suppliers that demonstrate a commitment to sustainability, buyers can enhance their brand reputation and appeal to environmentally conscious customers.

Illustrative image related to what is pu material

Scenario 3: Toxicity Concerns with PU Materials and Health Risks

The Problem:

Health and safety concerns are paramount for B2B buyers, especially in sectors such as textiles, upholstery, and automotive interiors. Some PU materials contain volatile organic compounds (VOCs) and other harmful chemicals that can pose health risks to both workers and end-users. Buyers may struggle to ensure compliance with health regulations while trying to balance cost and quality, leading to potential liabilities and reputational damage.

The Solution:

To navigate toxicity concerns effectively, B2B buyers should prioritize sourcing PU materials that are free from harmful substances and adhere to health and safety regulations. It is essential to request Material Safety Data Sheets (MSDS) from suppliers, which provide comprehensive information about the chemical composition of the materials. Buyers should also look for PU products that are labeled as “low-VOC” or “non-toxic,” ensuring a safer environment for production and usage. Additionally, collaborating with suppliers who are transparent about their manufacturing processes and who engage in regular testing can further minimize health risks, fostering a safer workplace and boosting consumer confidence in the products.

Strategic Material Selection Guide for what is pu material

What Are the Key Properties of PU Material?

PU material, primarily composed of polyurethane, is valued for its versatility and adaptability across various applications. Key properties include excellent flexibility, abrasion resistance, and the ability to mimic the aesthetic qualities of leather. PU materials can withstand a range of temperatures, typically performing well in environments from -30°C to 80°C, depending on the specific formulation. However, they may not be suitable for extreme pressure applications or environments with high chemical exposure without proper additives.

What Are the Pros and Cons of Using PU Material?

When evaluating PU material from a B2B perspective, several pros and cons emerge.

Pros:

– Cost-Effectiveness: PU is generally less expensive than genuine leather, making it an attractive option for companies looking to reduce production costs while maintaining a premium look.

– Durability: While PU leather is less durable than natural leather, it still offers a reasonable lifespan for many applications, particularly in low to moderate wear environments.

– Ease of Maintenance: PU materials are typically easier to clean and maintain than their natural counterparts, which can be a significant advantage for end-users.

Cons:

– Limited Lifespan: PU materials can degrade over time, particularly when exposed to harsh conditions, leading to cracking and peeling.

– Environmental Concerns: The production of PU involves petroleum-based chemicals, raising concerns about sustainability and environmental impact.

– Toxicity Issues: Some PU products may contain volatile organic compounds (VOCs) and other harmful substances, necessitating compliance with health and safety regulations.

How Does PU Material Impact Specific Applications?

The choice of PU material can significantly influence product performance in various applications. For instance, in the fashion industry, PU is often used for clothing, bags, and accessories due to its leather-like appearance and affordability. However, in industrial applications, the chemical resistance and temperature stability of PU must be carefully considered to ensure compatibility with specific media. For example, PU may not be suitable for environments involving strong solvents or extreme temperatures without additional protective treatments.

What Should International B2B Buyers Consider When Selecting PU Material?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider several factors when selecting PU materials. Compliance with local and international standards, such as ASTM, DIN, or JIS, is crucial to ensure product safety and quality. Additionally, understanding regional preferences for sustainability and environmental impact can influence purchasing decisions. For example, buyers in Europe may prioritize eco-friendly materials, while those in emerging markets may focus more on cost-effectiveness and durability.

Summary Table of PU Material Selection

| Material | Typical Use Case for what is pu material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PU Leather | Fashion accessories, upholstery | Affordable alternative to genuine leather | Limited durability, can crack and peel | Medium |

| PU Foam | Cushions, mattresses, insulation | Excellent flexibility and comfort | Can degrade under UV exposure | Low |

| PU Coatings | Protective coatings for fabrics | Enhances durability and water resistance | May contain VOCs, requiring safety compliance | Medium |

| PU Adhesives | Bonding materials in manufacturing | Strong bonding capabilities | Potential toxicity, requires careful handling | Medium |

This strategic material selection guide provides a comprehensive overview of PU materials, helping international B2B buyers make informed decisions based on their unique needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for what is pu material

What Are the Key Stages in the Manufacturing Process of PU Material?

The manufacturing process of PU (polyurethane) material involves several critical stages, each essential for ensuring the quality and functionality of the final product. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

What Is the Material Preparation Stage for PU Material?

The initial phase of PU material manufacturing begins with material preparation. This includes sourcing high-quality raw materials, primarily polyurethane resins, and additives. Manufacturers often choose between two main types of polyurethane: thermoplastic and thermosetting. Thermoplastic polyurethane is favored for its flexibility, while thermosetting polyurethane is known for its durability.

Additionally, the backing material, usually a textile like polyester or nylon, is prepared. This backing provides structural integrity and enhances the overall performance of the PU material. The selection of materials is crucial, as it directly influences the product’s durability, feel, and appearance.

How Is the Forming Process Conducted for PU Material?

Once the materials are prepared, the forming process begins. This stage involves coating the backing material with a layer of polyurethane. The coating can be applied through various techniques, such as:

- Spraying: A method where polyurethane is sprayed onto the substrate, allowing for a uniform application.

- Roll Coating: This technique involves passing the backing material through rollers that apply a consistent layer of polyurethane.

- Casting: In some cases, polyurethane is cast directly onto the backing material, allowing for thicker layers and more complex textures.

After the polyurethane is applied, it is embossed to create a texture that mimics the look and feel of genuine leather. This process is critical, as the texture significantly impacts the aesthetic appeal and marketability of the final product.

Illustrative image related to what is pu material

What Steps Are Involved in the Assembly of PU Products?

Following the forming process, the assembly stage takes place. This is where various components of the final product are combined. For example, in the production of handbags, this might involve sewing the PU material to other components like zippers and linings.

Quality control is paramount during assembly. Manufacturers often implement strict guidelines to ensure that each item meets specific design and functional criteria. This stage may also involve additional treatments, such as applying protective coatings to enhance water resistance and durability.

How Is the Finishing Process Executed for PU Material?

The finishing stage is the final step in the manufacturing process. Here, additional treatments may be applied to improve the product’s appearance and performance. Common finishing techniques include:

- UV Coating: This treatment enhances the resistance of the PU material to sunlight and environmental factors.

- Antimicrobial Treatments: These are applied to prevent the growth of bacteria and fungi on the surface of the material.

This stage also includes rigorous inspections to ensure that the finished product meets the desired specifications before it is packaged and shipped to customers.

What Are the Quality Control Standards for PU Material?

Quality assurance is a critical aspect of the manufacturing process, especially for B2B buyers who seek reliable and durable products. Several international standards govern the quality control processes for PU materials.

Which International Quality Standards Should Buyers Be Aware Of?

One of the most recognized international standards is ISO 9001, which outlines the requirements for a quality management system. Adhering to this standard demonstrates a manufacturer’s commitment to consistent quality and customer satisfaction.

Illustrative image related to what is pu material

In addition to ISO 9001, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for materials used in oil and gas applications are also important. These certifications ensure that the products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in PU Material Manufacturing?

To maintain high standards of quality, manufacturers implement various quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. Ensuring that only high-quality materials are used is vital for the overall quality of the PU products.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks are conducted to monitor the production process. This can include testing the consistency of the coating or the texture of the embossed material.

-

Final Quality Control (FQC): Once the products are finished, FQC inspections are carried out to assess the final output. This includes checking for defects, ensuring proper labeling, and confirming that products meet the necessary standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of potential suppliers is essential.

What Methods Can Buyers Use to Ensure Supplier Quality?

-

Supplier Audits: Conducting audits of manufacturing facilities helps buyers gain insight into the supplier’s quality management processes. This can include reviewing documentation related to quality control measures and observing the production environment.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide transparency regarding their quality control performance. These reports should outline the results of various tests and inspections conducted throughout the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can conduct inspections and provide unbiased reports on the quality of the products being manufactured.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific regional regulations and standards that may apply. For example, products sold in the European Union may need to comply with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations, which govern the use of chemicals in consumer goods.

Additionally, understanding the cultural and operational differences in manufacturing practices across regions can help buyers make informed decisions. This knowledge is crucial for establishing long-term relationships with reliable suppliers.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for PU material is vital for B2B buyers. By focusing on the stages of production, quality control standards, and verification methods, buyers can ensure they partner with manufacturers that meet their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is pu material’

In the competitive world of B2B procurement, understanding what PU material is and how to source it effectively is vital for making informed purchasing decisions. This guide provides a practical checklist for international buyers looking to procure PU material, ensuring a comprehensive understanding of its properties, applications, and supplier considerations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Specify the intended use of the PU material, whether for upholstery, fashion, or industrial applications. Consider factors such as thickness, finish, and any required certifications to ensure compatibility with your end product requirements.

Step 2: Research Material Properties and Standards

Understanding the properties of PU material is crucial for selecting the right type for your needs. Investigate its durability, flexibility, and resistance to moisture and stains. Familiarize yourself with relevant industry standards and regulations, especially concerning safety and environmental impact, to ensure compliance and quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their manufacturing capabilities and quality control processes to ensure they can meet your technical specifications consistently.

- Look for certifications: Verify if the supplier holds certifications for quality management (e.g., ISO 9001) and environmental standards (e.g., REACH).

- Assess production capacity: Ensure the supplier can meet your volume requirements, especially if you anticipate scaling up production.

Step 4: Request Samples for Evaluation

Obtaining samples allows you to assess the quality of the PU material firsthand. Evaluate the texture, durability, and overall finish to determine if it meets your specifications. This step is critical to avoid costly mistakes in the long run, as it helps ensure that the material performs as expected in its intended application.

Step 5: Inquire About Environmental Impact and Toxicity

As global awareness of sustainability increases, it’s essential to consider the environmental impact of the PU material you source. Inquire about the manufacturing processes used and the presence of any harmful substances, such as volatile organic compounds (VOCs). Prioritizing suppliers who use eco-friendly practices can enhance your brand’s reputation and contribute to sustainability goals.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a potential supplier, negotiate terms and conditions that align with your business objectives. Discuss pricing, payment terms, lead times, and delivery logistics to ensure clarity and prevent misunderstandings. A well-defined agreement helps build a strong supplier relationship and fosters mutual trust.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the performance of the PU material throughout its lifecycle. Regular inspections and testing can help catch any issues early, ensuring that the material consistently meets your standards and expectations. This proactive approach minimizes risks and enhances overall product quality.

By following this step-by-step guide, international B2B buyers can effectively navigate the complexities of sourcing PU material, ensuring they make informed decisions that align with their business needs and sustainability goals.

Illustrative image related to what is pu material

Comprehensive Cost and Pricing Analysis for what is pu material Sourcing

What Are the Key Cost Components in PU Material Sourcing?

When sourcing PU material, understanding the cost structure is essential for B2B buyers. The primary components of the cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The core of PU leather is polyurethane, which is derived from petroleum-based products. Variations in raw material prices can significantly influence overall costs. Additionally, the choice of backing material—often fabric—also affects pricing, especially if higher quality or specialty fabrics are used.

-

Labor: Labor costs can vary widely based on the location of production. Regions with lower labor costs may offer more competitive pricing, but this can impact quality and consistency. Skilled labor for quality finishing can add to costs, especially in regions known for craftsmanship.

-

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and equipment depreciation. Efficient manufacturing processes can minimize overhead, but investment in advanced technology may raise initial costs.

-

Tooling: Specialized molds and machinery for producing PU materials can be a significant upfront investment. However, these costs are amortized over production runs, making them less impactful on larger orders.

-

Quality Control (QC): Ensuring the durability and safety of PU materials requires stringent QC measures. This can include testing for toxic substances, durability, and compliance with international standards, which can add to the cost.

-

Logistics: Shipping and handling costs, including freight charges and customs duties, are vital considerations, particularly for international buyers. These costs can fluctuate based on geopolitical factors and global shipping rates.

-

Margin: Supplier profit margins vary based on competition, market demand, and perceived value. A transparent discussion about margins can facilitate better negotiations.

How Do Price Influencers Affect PU Material Costs?

Several factors can influence the pricing of PU materials, including volume or minimum order quantities (MOQ), specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should assess their demand forecasts to negotiate better pricing with suppliers.

-

Specifications and Customization: Customized PU materials that meet specific design or functional requirements often carry a premium. Buyers should clearly define their needs to avoid unexpected costs.

-

Materials Quality and Certifications: The inclusion of eco-friendly or certified materials can increase costs. However, these investments may provide long-term savings by enhancing brand reputation and meeting consumer demand for sustainable products.

-

Supplier Factors: Relationships with suppliers can impact pricing. Established partnerships may yield better terms and flexibility, while new suppliers may require more negotiation.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers in shipping, insurance, and tariffs, which can affect total costs.

What Are the Best Practices for Negotiating PU Material Prices?

When negotiating prices for PU materials, B2B buyers should consider several strategies to maximize cost-efficiency.

-

Total Cost of Ownership: Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, replacement, and disposal of PU materials. This comprehensive view can help justify higher upfront costs for better quality.

-

Volume Discounts: Engage suppliers about potential discounts for larger orders. Establishing a long-term purchasing agreement can also secure better rates.

-

Transparent Communication: Clearly communicate requirements and expectations to suppliers. This transparency can lead to more accurate quotes and minimize misunderstandings that could lead to additional costs.

-

Market Research: Understanding market trends and competitor pricing can empower buyers during negotiations. Staying informed about fluctuations in raw material prices can also provide leverage.

-

Cultural Sensitivity: For international buyers, being aware of cultural differences in negotiation styles can enhance communication and lead to more favorable outcomes.

Conclusion

Navigating the cost and pricing structure of PU material sourcing requires a strategic approach. By understanding the various cost components and price influencers, international B2B buyers can make informed decisions that align with their budget and quality requirements. Engaging in smart negotiation practices will further enhance value, ensuring a successful procurement process. Always consider that prices can vary widely based on location, supplier, and market conditions, so conducting thorough due diligence is crucial for optimal purchasing outcomes.

Alternatives Analysis: Comparing what is pu material With Other Solutions

Exploring Alternatives to PU Material: A Comparative Analysis

In the quest for sustainable and high-quality materials, businesses often seek alternatives to polyurethane (PU) material, particularly in industries such as fashion, automotive, and furniture. This analysis will compare PU material with two viable alternatives: genuine leather and recycled polyester, providing B2B buyers with essential insights to inform their purchasing decisions.

| Comparison Aspect | What Is PU Material | Genuine Leather | Recycled Polyester |

|---|---|---|---|

| Performance | Moderate durability; prone to cracking and peeling | High durability; develops a unique patina over time | Good durability; varies by quality |

| Cost | Generally low-cost | Higher initial investment | Mid-range cost |

| Ease of Implementation | Easy to produce and manipulate | Requires skilled craftsmanship | Simple to produce; widely available |

| Maintenance | Low maintenance; requires occasional cleaning | Requires conditioning and care | Low maintenance; easy to clean |

| Best Use Case | Cost-effective fashion items, furniture | Premium products, high-end fashion | Eco-friendly products, casual wear |

In-Depth Look at Alternatives

What Are the Advantages and Disadvantages of Genuine Leather?

Genuine leather is a time-honored alternative that offers superior durability and an aesthetic appeal that PU material cannot replicate. Its ability to age beautifully and develop a unique patina makes it a preferred choice for luxury items such as handbags and high-end furniture. However, the initial cost of genuine leather is significantly higher than that of PU material, which may deter cost-sensitive buyers. Additionally, genuine leather requires more maintenance and care to preserve its quality over time.

How Does Recycled Polyester Compare to PU Material?

Recycled polyester is an environmentally friendly alternative made from post-consumer plastic bottles. It offers a good balance of durability and cost, making it suitable for a wide range of applications, from casual wear to accessories. The production process is less harmful to the environment compared to PU material, which often involves toxic chemicals. However, the quality and longevity of recycled polyester can vary significantly based on manufacturing processes. While it is easier to clean and maintain than genuine leather, it does not possess the same premium feel or longevity.

Illustrative image related to what is pu material

Making the Right Choice for Your Business

When selecting the right material for your business needs, consider factors such as performance, cost, and the intended use of the final product. PU material may be ideal for budget-conscious projects where aesthetics are paramount but durability is less critical. Genuine leather stands out for high-end applications where quality and longevity are essential, while recycled polyester offers a sustainable solution for environmentally conscious brands seeking to reduce their carbon footprint.

Ultimately, understanding the specific requirements of your target market and aligning them with the characteristics of each material will empower B2B buyers to make informed decisions that enhance product value and brand reputation.

Essential Technical Properties and Trade Terminology for what is pu material

What Are the Key Technical Properties of PU Material for B2B Buyers?

Understanding the technical properties of polyurethane (PU) material is essential for businesses looking to source or utilize this versatile synthetic alternative to leather. Here are some critical specifications that decision-makers should consider:

1. Material Grade

Material grade refers to the classification of PU based on its composition and intended use. Common grades include PU foam, PU coating, and PU film, each designed for specific applications such as upholstery, automotive interiors, or footwear. For B2B buyers, selecting the appropriate material grade ensures that the product meets performance expectations and durability requirements for its intended use.

2. Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. For PU materials, tensile strength typically ranges from 10 to 20 MPa. This property is crucial for applications that require durability and resistance to wear and tear, making it a vital specification for buyers in industries such as automotive and furniture manufacturing.

Illustrative image related to what is pu material

3. Abrasion Resistance

Abrasion resistance indicates how well a material can withstand surface wear from friction or contact. PU materials often demonstrate high abrasion resistance, which is essential for products subjected to frequent use, such as bags, clothing, and upholstery. For B2B buyers, understanding abrasion resistance can help in assessing product longevity and reducing replacement costs.

4. Moisture Resistance

Moisture resistance refers to the ability of PU material to repel water and resist degradation due to moisture exposure. This property is particularly important in applications such as outdoor furniture or automotive interiors, where exposure to elements is common. Buyers should prioritize moisture resistance to enhance product durability and performance in varying environments.

5. Thermal Stability

Thermal stability denotes a material’s ability to maintain its physical and chemical properties under varying temperature conditions. PU materials typically exhibit good thermal stability, making them suitable for applications that may experience temperature fluctuations. For B2B buyers, this property is vital when sourcing materials for products used in diverse climates or heating applications.

Illustrative image related to what is pu material

6. UV Resistance

UV resistance is the capability of a material to resist degradation from ultraviolet (UV) radiation. PU materials can be treated to enhance their UV resistance, making them suitable for outdoor applications. Understanding UV resistance is essential for businesses sourcing materials for products intended for prolonged outdoor exposure, as it impacts the product’s lifespan and aesthetic appeal.

What Are Common Trade Terms Associated with PU Material?

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms related to PU material:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of PU materials, OEMs often produce components for automotive or electronic products, ensuring quality and compatibility with original specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and negotiate better pricing. Suppliers may impose MOQs based on production costs or material availability.

Illustrative image related to what is pu material

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products or services. B2B buyers often use RFQs to compare pricing and terms from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk transfer, and delivery points. For B2B buyers, understanding Incoterms is essential for managing logistics and ensuring compliance with international trade regulations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are received. This term is critical for B2B buyers to manage supply chain expectations and ensure timely product availability.

Illustrative image related to what is pu material

6. Compliance Standards

Compliance standards refer to the regulations and guidelines that products must meet to be deemed safe and effective. In the context of PU materials, compliance with environmental and health regulations is essential for B2B buyers to ensure product safety and marketability.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing PU materials, ultimately enhancing their product offerings and supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the what is pu material Sector

Market Overview & Key Trends in PU Material

The PU material sector has experienced significant growth driven by the increasing demand for sustainable and cost-effective alternatives to traditional materials. Global trends indicate a shift towards synthetic options that offer both aesthetic appeal and functional versatility. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, the adoption of PU materials can be linked to the rising consumer preference for eco-friendly products and the growing emphasis on ethical sourcing.

Emerging technologies are revolutionizing the sourcing landscape, with innovations in polymer chemistry leading to enhanced durability and performance of PU materials. Advanced manufacturing techniques such as 3D printing and automated production processes are streamlining supply chains, reducing lead times, and optimizing costs. Buyers should also be aware of the potential for customization that modern PU materials offer, allowing for tailored solutions that meet specific industry requirements.

Market dynamics are shifting as regulatory frameworks increasingly favor sustainable practices. For instance, the European Union’s stringent regulations on chemical safety have prompted suppliers to adopt safer production methods. B2B buyers in the Middle East and Africa can leverage these trends by prioritizing suppliers who comply with international standards, ensuring they are sourcing high-quality, safe PU materials that align with market expectations.

How Does Sustainability Impact the Sourcing of PU Material?

Sustainability is becoming a cornerstone of sourcing strategies within the PU material sector. The environmental impact of traditional PU production, particularly in terms of carbon emissions and chemical waste, has raised concerns among consumers and businesses alike. As a result, B2B buyers are increasingly seeking suppliers who prioritize ethical sourcing and environmentally friendly practices.

The importance of ethical supply chains cannot be overstated. Buyers should look for suppliers that have transparent operations and adhere to recognized sustainability certifications, such as Global Recycled Standard (GRS) and OEKO-TEX. These certifications ensure that the materials used in PU products are sourced responsibly, minimizing environmental harm and promoting social responsibility.

Moreover, the trend towards green materials is gaining traction. Innovations in bio-based polyurethanes, derived from renewable resources, are emerging as viable alternatives to conventional PU. These materials not only reduce reliance on fossil fuels but also mitigate the environmental footprint associated with traditional PU production. By prioritizing suppliers who invest in sustainable practices and materials, B2B buyers can enhance their brand reputation and meet the growing demand for eco-conscious products.

What is the Historical Context of PU Material Development?

The development of PU materials can be traced back to the mid-20th century, when advancements in polymer chemistry enabled the creation of synthetic alternatives to natural leather. Initially, PU was utilized for industrial applications; however, by the 1960s, manufacturers began experimenting with it as a coating for textiles to mimic the look and feel of leather. This marked the inception of PU leather, which gained popularity due to its affordability and versatility.

Over the decades, the production processes and formulations of PU materials have evolved significantly. Modern innovations focus on enhancing durability, reducing toxicity, and improving the environmental footprint of PU products. As a result, today’s B2B buyers are presented with a wide array of options that not only meet aesthetic and functional demands but also align with sustainability goals, making PU materials a compelling choice in various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of what is pu material

1. What is PU material and how is it made?

PU material, or polyurethane, is a synthetic material created through a chemical reaction between diisocyanates and polyols. This process involves coating a fabric backing with a layer of polyurethane, which can be embossed to mimic the texture of leather. PU is widely used in various applications, including upholstery, fashion, and automotive interiors, due to its affordability and versatility. However, it’s essential to consider its environmental impact and durability compared to natural materials.

2. How does PU material compare to genuine leather?

While PU material can imitate the look and feel of genuine leather, it has notable differences. Genuine leather is durable, ages gracefully, and can last for decades, whereas PU typically lasts only 1 to 2 years before showing signs of wear like cracking or peeling. Furthermore, genuine leather is biodegradable and has a lower environmental impact when sourced responsibly. When sourcing materials, consider the long-term value and sustainability of your choice.

3. What are the environmental concerns associated with PU material?

PU material production involves the use of chemicals that can release volatile organic compounds (VOCs), potentially harming both human health and the environment. The manufacturing process often contributes to air and water pollution, making it less eco-friendly compared to natural materials. B2B buyers should evaluate the sustainability practices of suppliers and consider alternatives that minimize environmental impact, such as vegetable-tanned leather or recycled materials.

4. What should I look for when vetting PU material suppliers?

When vetting suppliers for PU materials, prioritize those who provide transparency about their manufacturing processes, including the chemicals used and their environmental practices. Check for certifications that demonstrate compliance with safety and environmental standards. Additionally, request samples to assess the quality and durability of the PU material. Establishing strong communication channels with suppliers can also help ensure that your specific requirements are met consistently.

Illustrative image related to what is pu material

5. What customization options are available for PU material products?

Many suppliers offer customization options for PU material, including color selection, texture, and embossing patterns. Some may also provide tailored solutions based on your specific needs, such as specific dimensions for upholstery or unique designs for fashion items. Discuss your requirements with potential suppliers early in the negotiation process to ensure they can accommodate your requests and maintain quality standards.

6. What are typical minimum order quantities (MOQs) for PU material?

MOQs for PU material can vary widely depending on the supplier and the complexity of the product. Generally, MOQs can range from a few hundred to several thousand units. It’s crucial to clarify MOQs with potential suppliers to determine if they align with your purchasing capabilities. If you’re a smaller buyer, look for suppliers willing to negotiate or those who specialize in smaller batches.

7. What payment terms should I expect when sourcing PU material internationally?

Payment terms for international transactions can vary significantly among suppliers. Common arrangements include upfront payments, partial payments, or letters of credit. Always clarify payment terms before finalizing orders and consider the implications of currency fluctuations and transaction fees. Establishing a reliable payment method can help mitigate risks and ensure smoother transactions.

8. How can I ensure quality assurance (QA) for PU material products?

To ensure quality assurance for PU material products, request detailed specifications from your supplier, including material certifications and testing results. Implement a quality control process that includes pre-shipment inspections and random sampling of materials upon receipt. Establish clear communication regarding your quality standards and expectations with suppliers to minimize discrepancies and ensure product consistency.

Top 6 What Is Pu Material Manufacturers & Suppliers List

1. HowStuffWorks – PU Leather Insights

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is an artificial leather made from polyurethane, a type of plastic. It is 100% vegan and does not contain animal skin. There are two types of PU leather: full-synthetic (totally vegan) and semi-synthetic (which has a natural leather base). PU leather is water-resistant, easy to clean, and available in a wide variety of colors. However, it lacks the authentic appearance an…

2. Prestige Leather Care – PU Leather Solutions

Domain: prestigeleathercare.co.uk

Registered: 2015 (10 years)

Introduction: PU leather, or polyurethane leather, is an artificial type of leather made from thermoplastic polymers. It is known by various names including bicast leather, split leather, reconstituted leather, bonded leather, and corrected grain leather. PU leather can be cleaned with suitable leather cleaners and brushes. It is considered vegan only if it is 100% PU; otherwise, it may contain real leather. PU…

3. Carl Friedrik – PU Leather Essentials

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is made from polyurethane, a synthetic plastic. It is created by applying a PU resin coating to natural fabrics like nylon, cotton, or vinyl, mimicking the look and feel of animal leather. 100% PU leather is vegan-friendly, while PU applied to split leather is not. Benefits include being softer, lighter, and more UV resistant than animal l…

4. Senreve – PU Leather Fashion Accessories

Domain: senreve.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as polyurethane leather, is a synthetic material made from a base layer of fabric coated with a layer of polyurethane. It is designed to mimic the look and feel of genuine leather while being more affordable and easier to maintain. PU leather is often used in fashion and accessories, offering a cruelty-free alternative to animal leather. It is water-resistant, durable, and c…

5. Billy Tannery – PU Leather

Domain: billytannery.co.uk

Registered: 2016 (9 years)

Introduction: PU leather, or polyurethane leather, is a synthetic leather alternative designed to mimic the look and feel of real leather. It is made from a base layer of polyester or similar fabric, topped with a polyurethane coating, which gives it a smooth and shiny surface. PU leather is considered vegan and is used for products like furniture, shoes, bags, and wallets. It is generally cheaper than real lea…

6. Boulies – PU Leather Essentials

Domain: boulies.com

Registered: 2017 (8 years)

Introduction: PU leather (polyurethane leather) is a synthetic material that resembles real leather but is made without animal products. It consists of a fabric base (like polyester or cotton) coated with a thin layer of polyurethane. Key features include:

– Layered Structure: Fabric material with a polyurethane coating.

– Eco-Friendly Edge: Uses 70% less carbon emissions than real leather production.

– Ethi…

Strategic Sourcing Conclusion and Outlook for what is pu material

In conclusion, understanding PU material is essential for making informed sourcing decisions in today’s competitive marketplace. PU leather offers an appealing cost-effective alternative to genuine leather, yet it presents challenges regarding durability, environmental impact, and potential toxicity. B2B buyers should prioritize suppliers who demonstrate transparency in their sourcing practices and adhere to sustainable manufacturing processes, mitigating risks associated with inferior materials.

Strategic sourcing of PU materials necessitates a keen awareness of the long-term implications of material choices. By evaluating the lifecycle of PU products, businesses can enhance their brand reputation while catering to the growing consumer demand for eco-friendly options.

As the global market continues to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, the focus on sustainable materials will only intensify. International buyers are encouraged to engage with suppliers committed to ethical practices and innovative solutions. Embrace this opportunity to not only elevate your product offerings but also contribute positively to global sustainability efforts. The future of sourcing is here—make it count.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.